Silicon paper unreeling frame utilizing limit switches

A technology of limit switch and silicone oil paper, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of reducing product quality, low production efficiency, and affecting the efficiency of unwinding, so as to improve production efficiency, The effect of reducing production costs and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

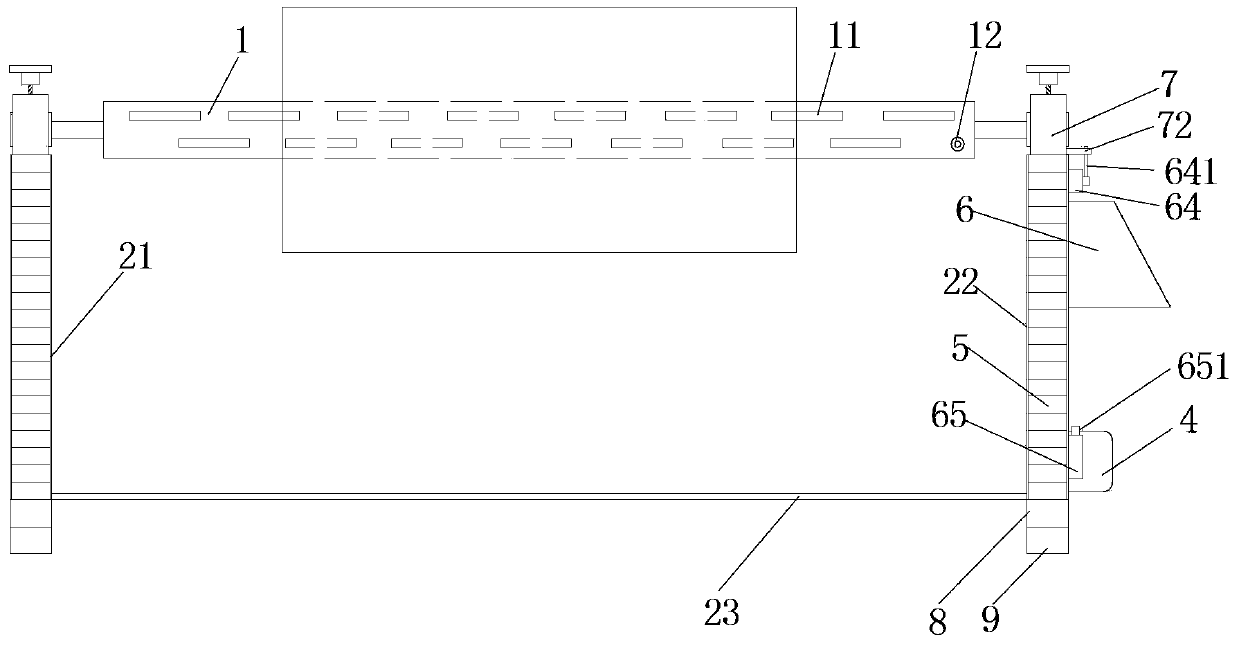

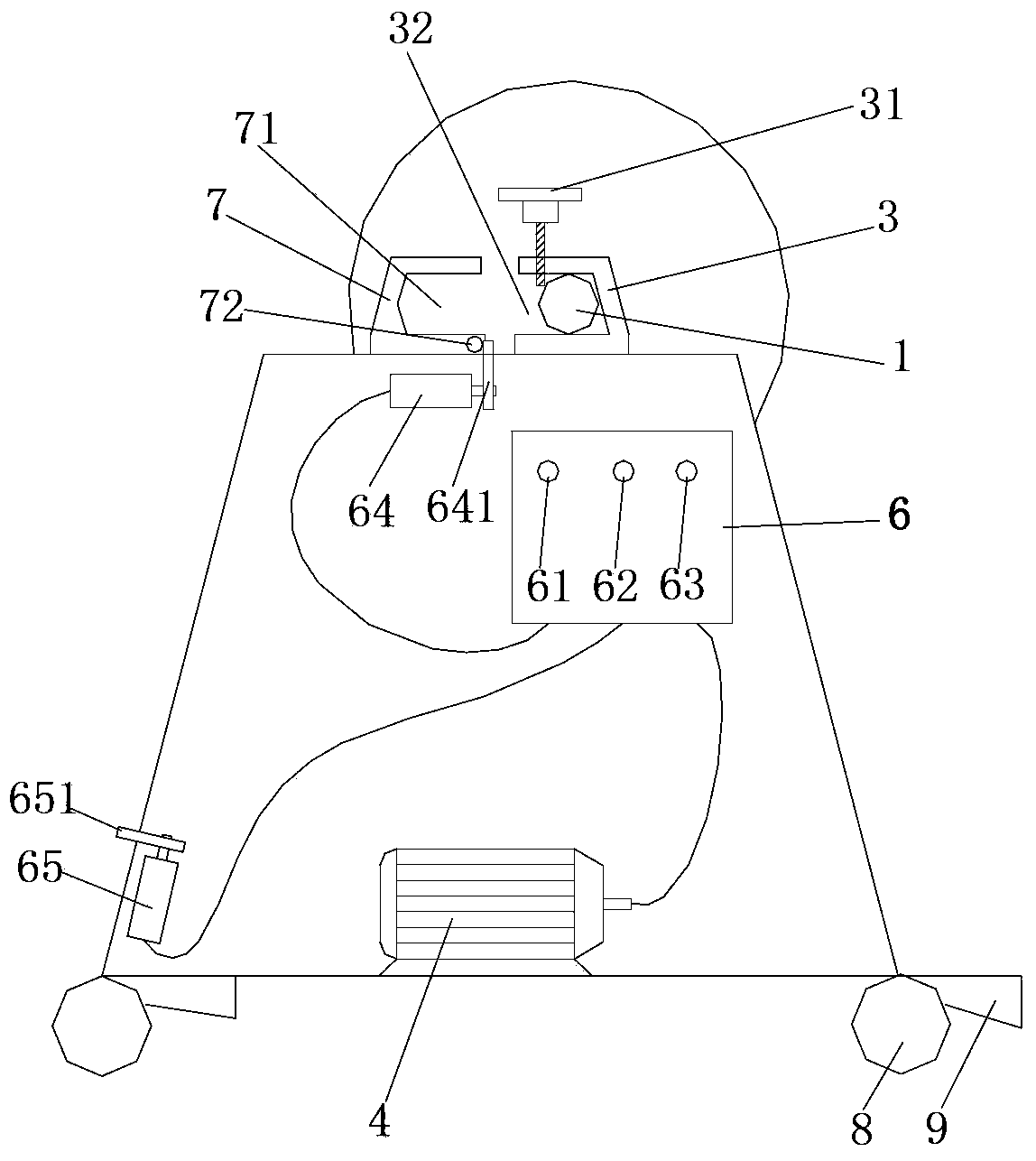

[0018] refer to figure 1 and figure 2 , a silicone oil paper unwinding frame using a limit switch in the present invention, including a winding roller 1, a first support frame 21, a second support frame 22, a motor 4, between the first support frame 21 and the second support frame 22 Connected by connecting rods 23, a fixing device 3 is installed above the first support frame 21, a conveyor chain 5 is set on the first support frame 21, a fixing device 3 is installed above the second support frame 22, The second support frame 22 is sleeved with a conveyor chain 5, and one side of the second support frame 22 is equipped with a lift control part 6, a first limit switch 64, a second limit switch 65 and a motor 4, and the lift control part 6 is connected to the first limit switch 64 through wires, the lifting control part 6 is connected to the second limit switch 65 through wires, the lifting control part 6 is connected to the motor 4 through wires, and the lifting control part 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com