Unwinding cloth hopper

A technology of unwinding and side support, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of large cloth damage, high friction, low unwinding efficiency, etc., and achieves improved unwinding efficiency, The effect of friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

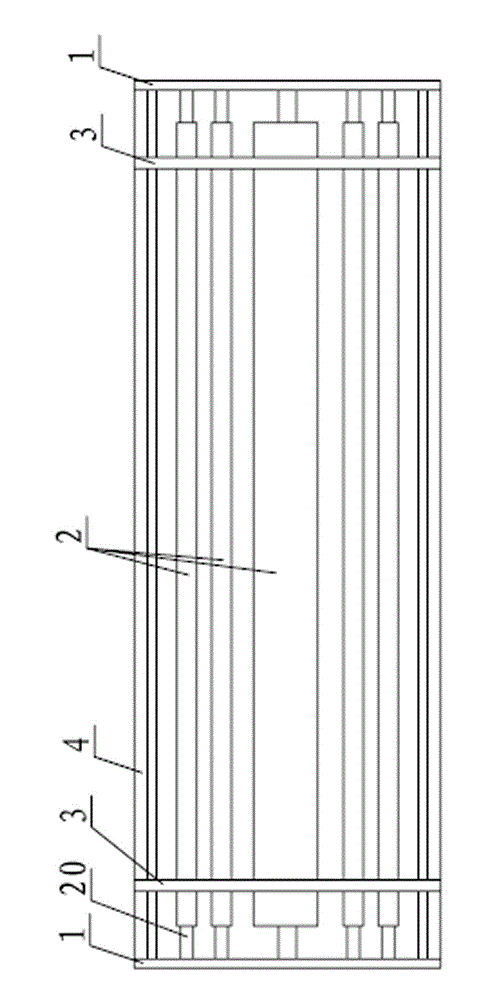

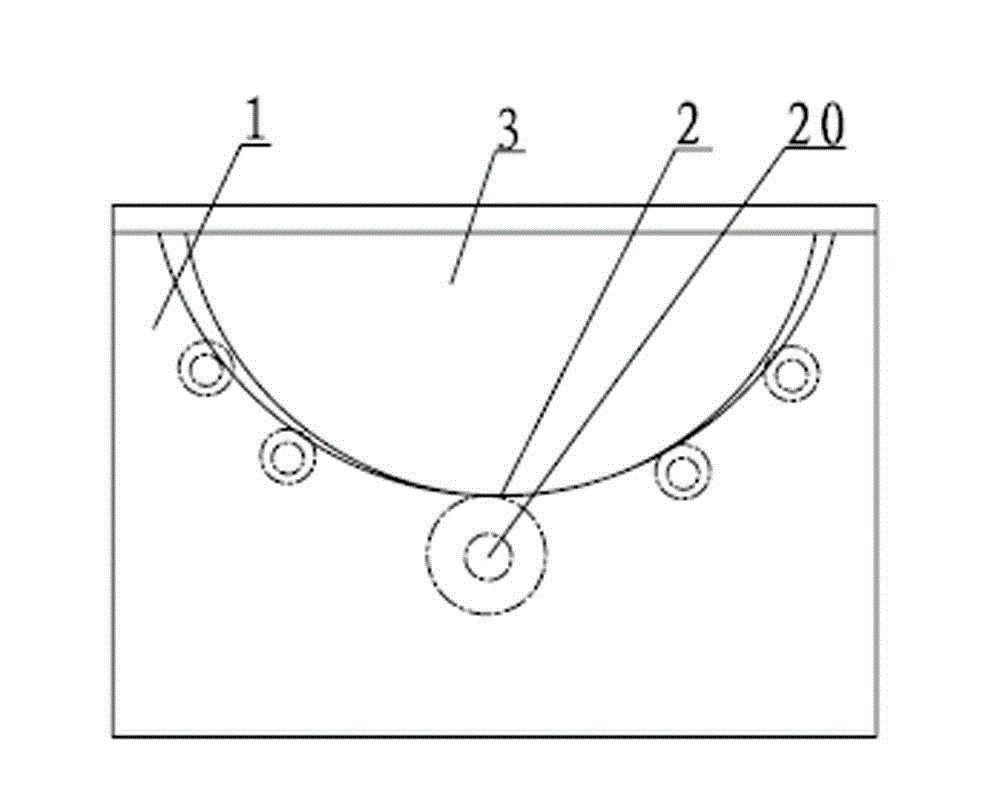

[0013] Such as figure 1 with figure 2 As shown, the unwinding cloth bucket according to this embodiment includes side brackets 1 on both sides, connecting rods 4 connected between the side brackets 1 on both sides, and multiple rods horizontally arranged between the side brackets 1 on both sides. The rollers 2 and the baffles 3 that are movably arranged on the connecting rod 4 and located above the plurality of rollers 2 . The diameters of the plurality of rollers 2 can be the same or different, and the plurality of rollers 2 are parallel to each other, and an arc-shaped surface is formed between the upper surfaces for placing the packaged fabrics, and the plurality of rollers 2 are rotatably arranged through the rotating shaft 20 On the side support 1 , the direction of the axis of the rotating shaft 20 coincides with the axis of the roller 2 .

[0014] When unwinding, put the roll fabric to be unrolled on multiple rollers 2, adjust the position of the baffles 3 on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com