Batch uncoiling device of coiled cloth

A cloth and batch technology, applied in the field of batch unwinding devices, can solve the problems of low unwinding efficiency, waste of manpower, etc., and achieve the effects of simple structure, strong practicability and high unwinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

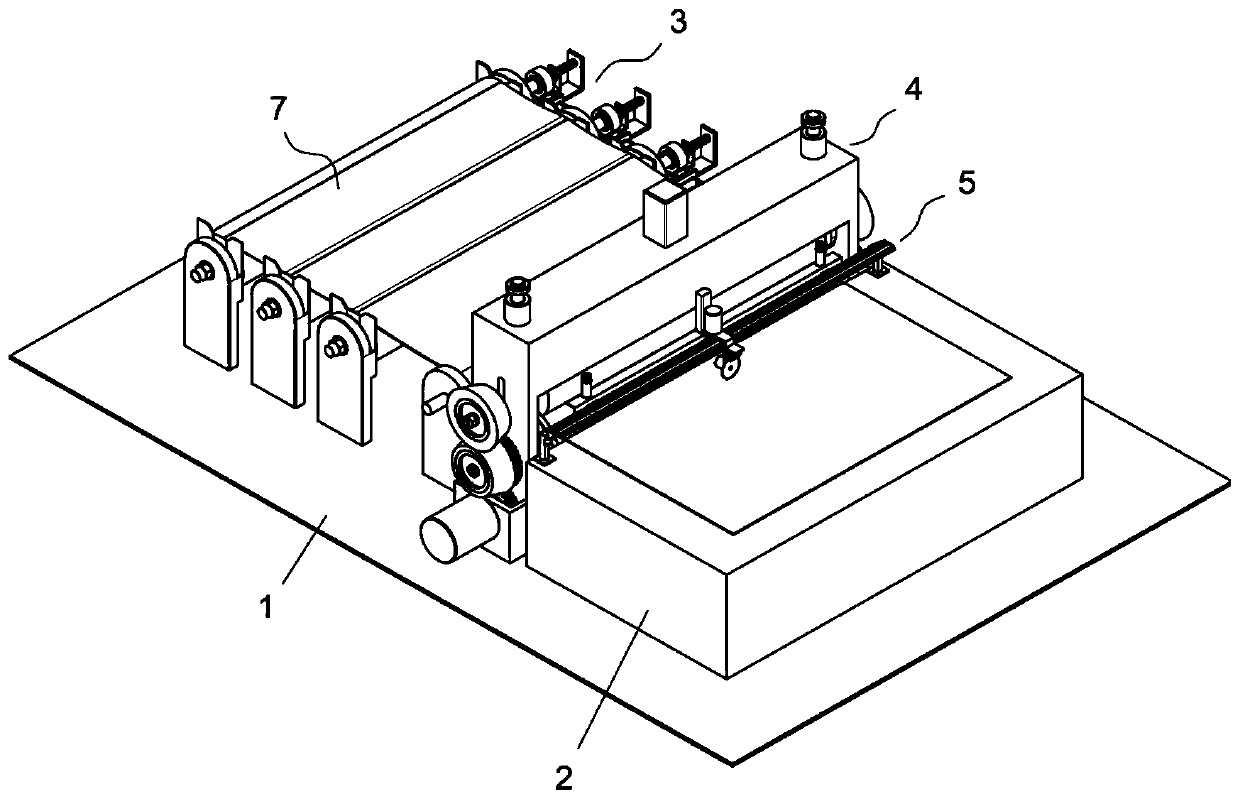

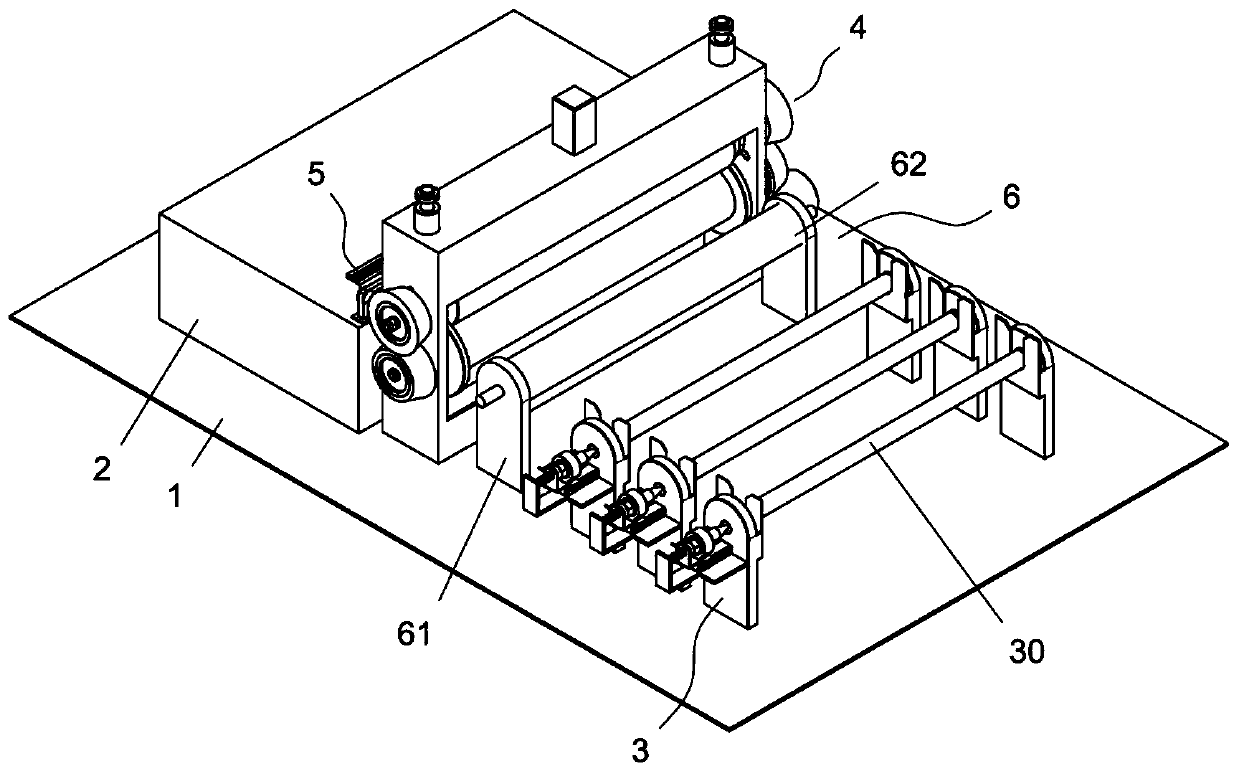

[0019] Such as Figure 1-6 As shown, a batch unrolling device for rolled cloth includes a cloth roll support unit 3 with a fixed seat placed on the working bottom surface 1, a rolling conveying unit 4 and a roll arrangement platform 2, a cloth roll support unit 3, The rolling conveying unit 4 and the roll arrangement table 2 are arranged in sequence from front to back, and the fixed frame on the roll arrangement table 2 is equipped with a level detection unit 5;

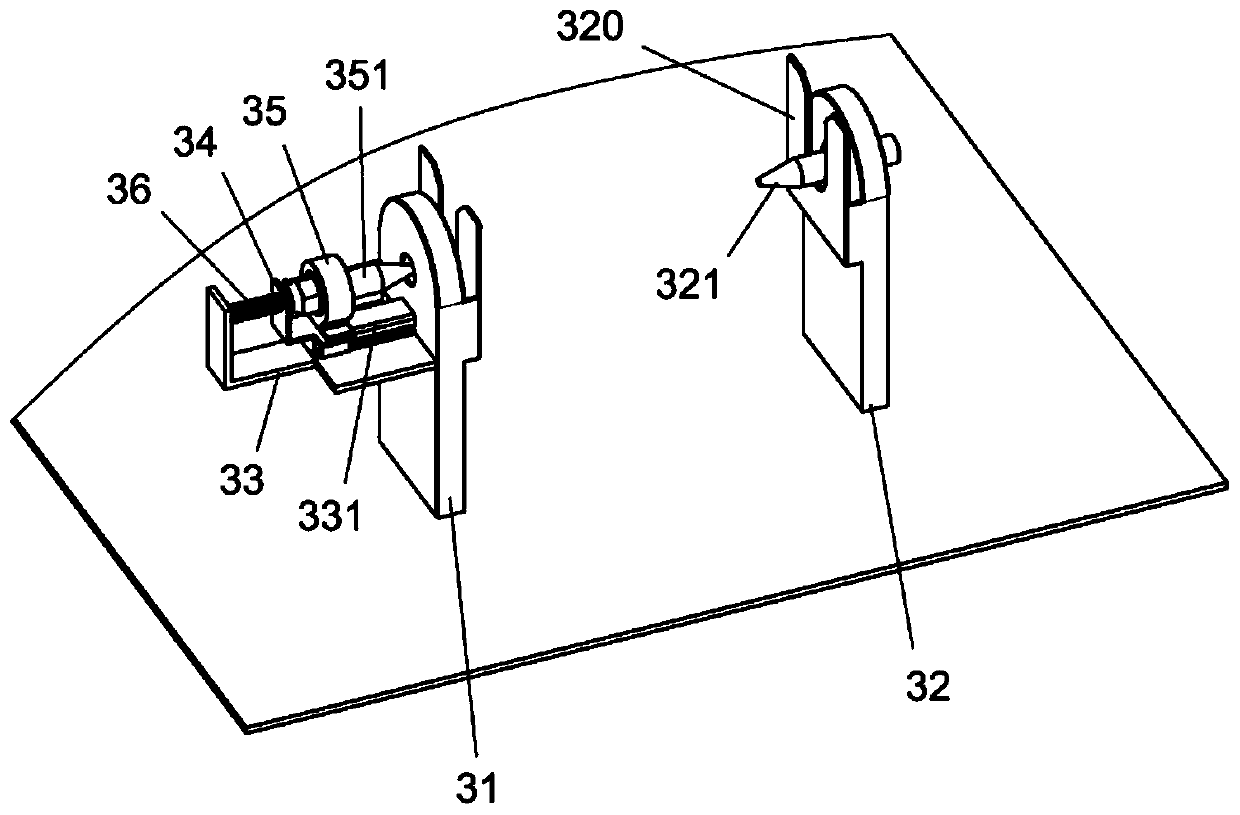

[0020] Cloth roll support unit 3 quantity is several groups, and it comprises the first shelf plate 31 and the second shelf plate 32 that are oppositely arranged, and the outer side of the first shelf plate 31 is fixed with the first L-shaped supporting plate 33, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com