Winder with spring-fixed creel spindles

A spring-fixed and creel technology, which is applied to spinning machines, open-end spinning machines, and continuously wound spinning machines, etc. Problems such as low wire unwinding efficiency, to achieve the effect of reducing the breakage rate, reducing the tension and increasing the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

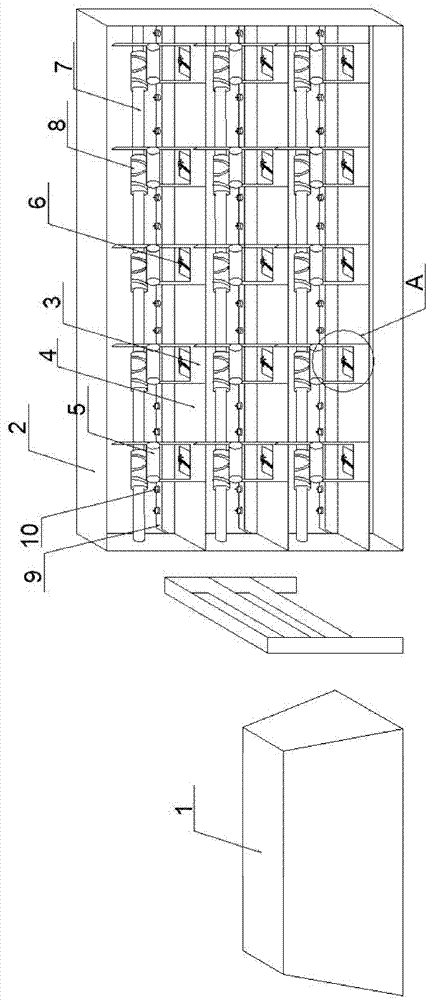

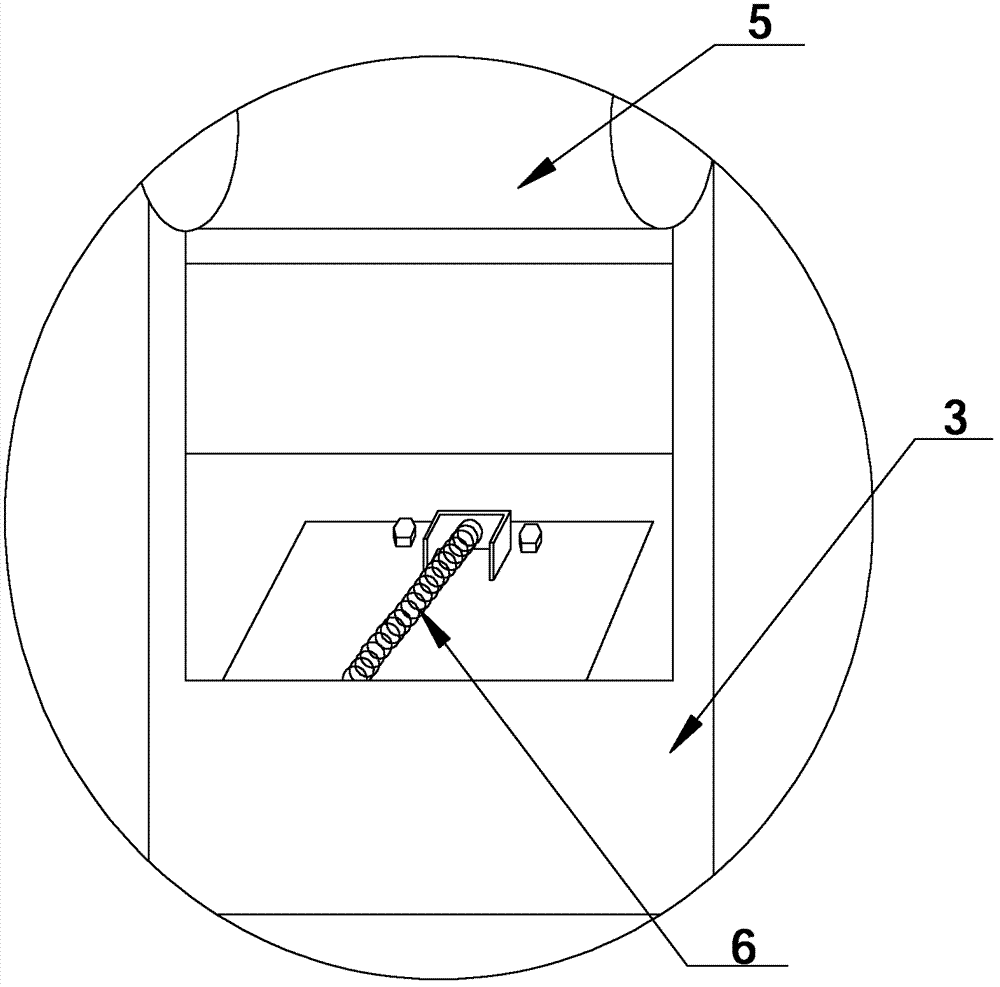

[0013] Such as Figure 1~2 The spring-fixed bobbin-making machine of the creel spindle shown includes a servo motor 1, a creel 2, and an air spinning creel spindle 3 on the creel 2. The creel 2 has at least three beams 4, and the air spinning creel spindle 3 The yarn bobbins 5 synchronously controlled by the servo motor 1 are placed on the upper part, and the bottom of the air spinning frame spindle 3 is provided with a spring 6 which is connected to the beam 4 of the creel 2 .

[0014] The yarn creel 2 is also provided with a guide roller shaft 7, and the position corresponding to the yarn bobbin 5 is provided with a guide roller 8 to help the yarn bobbin 5 to wind the yarn.

[0015] In order to reduce the tension, the creel 2 is also provided with a cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com