Driving device of hank yarn shed frame

A driving device and skein technology, which is applied in the field of spinning machinery components and driving devices of skein scaffolding, can solve problems such as broken or loose threads, reduced speed, too large or too small, etc., to reduce broken threads or The effect of loose thread and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

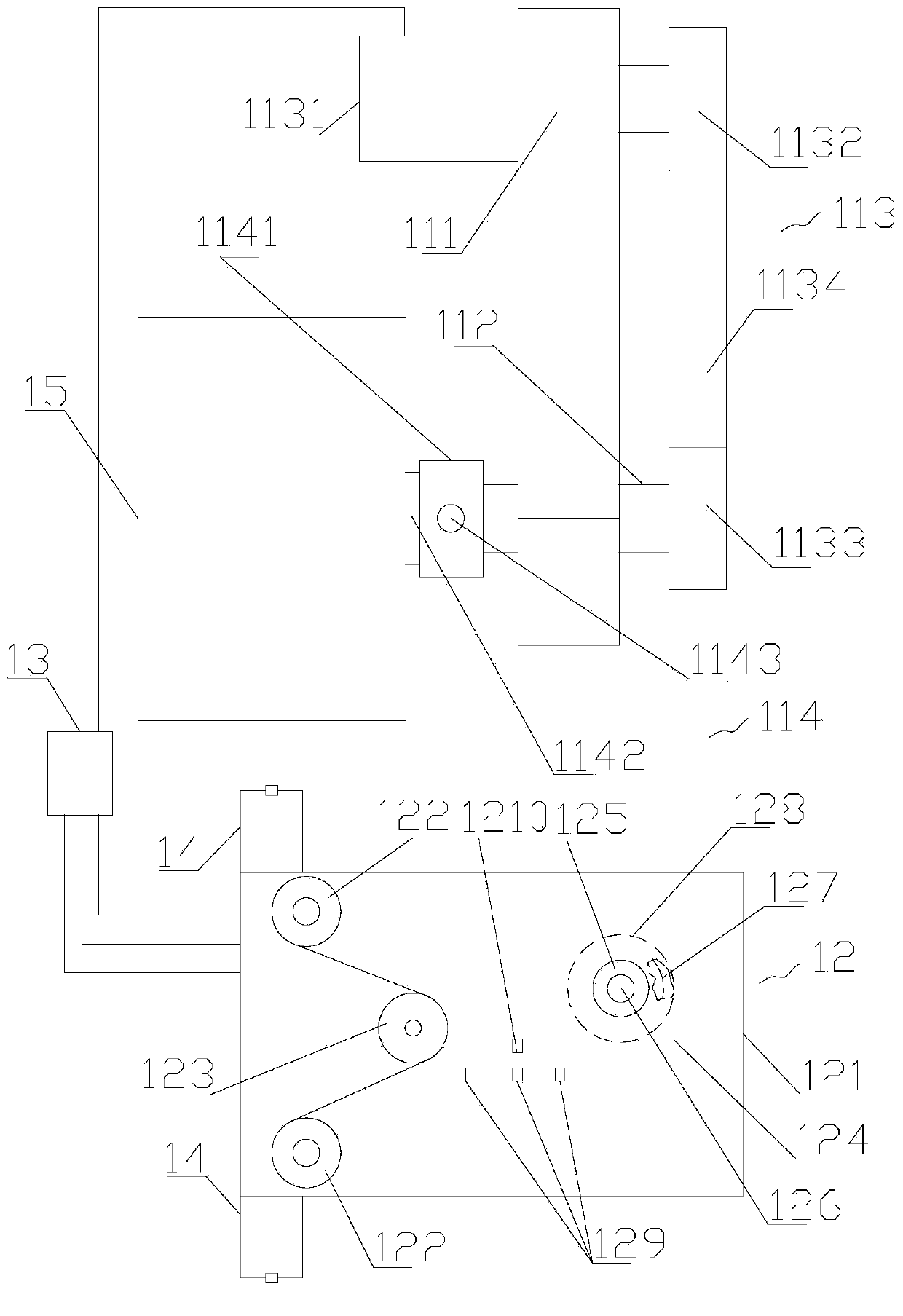

[0017] refer to figure 1 , a driving device for a skein scaffold in the present invention, comprising a driving mechanism 11, a tension monitoring mechanism 12 and a controller 13 located below the driving mechanism 11, the driving mechanism 11 and the tension monitoring mechanism 12 are connected to the controller 13, The tension monitoring mechanism 12 includes a mounting seat 121, two fixed guide wheels 122, a moving guide wheel 123, a sliding rack 124, a driving gear 125, a driving shaft 126, a constant force spring 127, a housing 128, and three inductors. 129 and the induced body 1210, two fixed guide wheels 122 and a slidably mounted sliding rack 124 are provided on the outside of the mounting seat 121, and the front end of the sliding rack 124 is provided with two fixed guide wheels 122 At the rear of the middle, the outer side of the mounting seat 121 is provided with an inductor 129 located below the sliding rack 124. The three inductors 129 are arranged in sequence f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com