a textile equipment

A textile equipment and equipment technology, applied in the field of textile equipment, can solve the problems of low machine utilization rate, single production variety, inconvenient operation, etc., and achieve the effects of simple operation, improved production efficiency, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

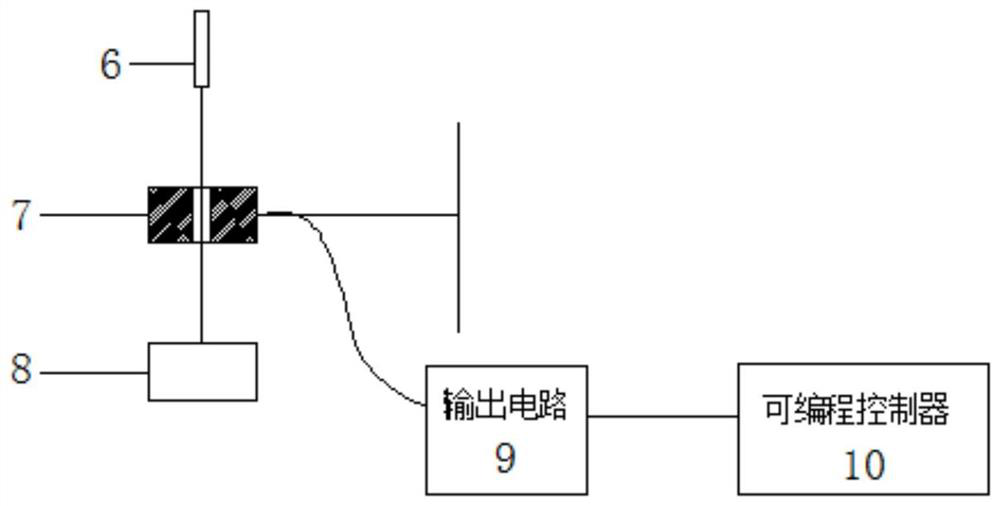

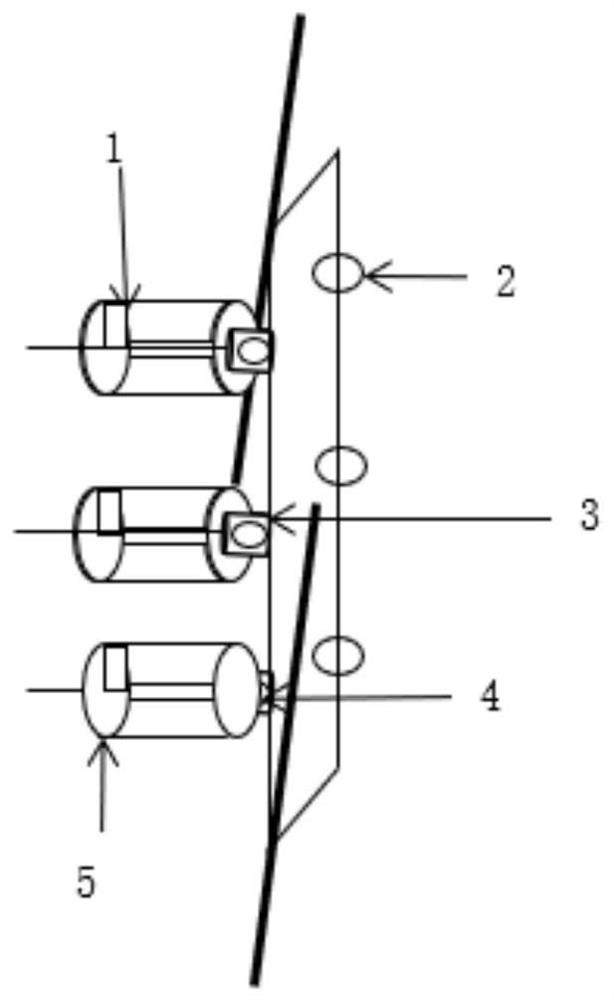

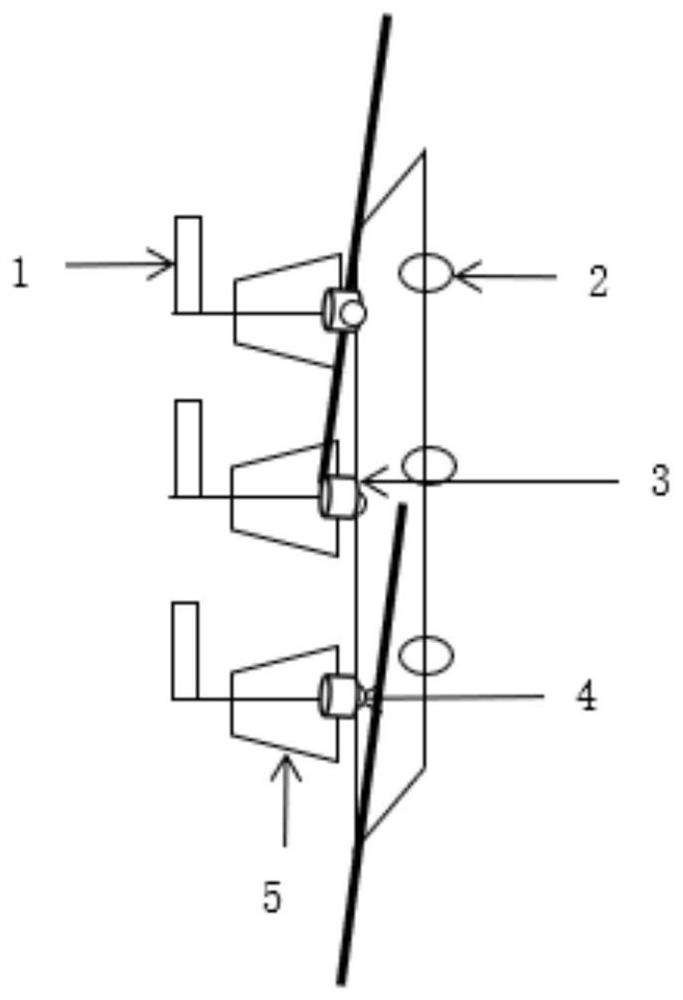

[0032] The embodiment of the present invention provides a kind of textile equipment, and described textile equipment comprises:

[0033] slideway; slider 8, the slider 8 is arranged on the slideway; heald guide rod, the heald guide rod is arranged on the slider 8; heald 6, the heddle is arranged on the on the guide rod, and the heddle 6 moves on the slideway under the action of the heddle guide rod and the slider 8; the output circuit 9 is arranged on the heald 6. On the movement path, a programmable controller 10, the programmable controller 10 is connected to the output circuit 9, and the programmable controller 10 controls the conduction and disconnection of the contacts of the output circuit 9 , to realize the movement of the heald 6 .

[0034]Specifically, the slider 8 is arranged on the slideway, the heddle guide rod is arranged on the slider 8, the heald 6 is arranged on the guide rod, and the heddle 6 moves on the slideway under the action of the described heald guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com