Cloth inspecting method

A cloth and gray cloth inspection technology, applied in the field of cloth inspection, can solve problems such as low work efficiency, low degree of automation, and wrinkles, and achieve the effects of saving equipment investment, improving stability, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

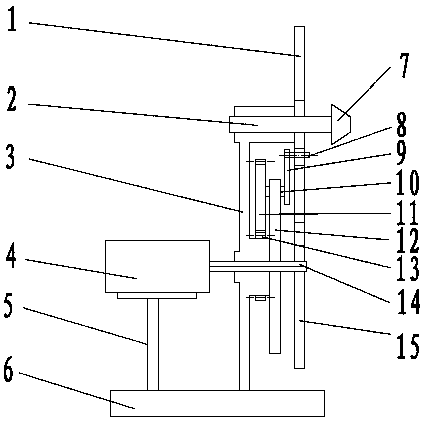

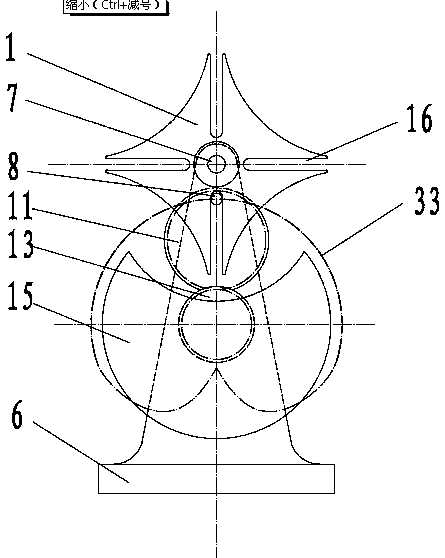

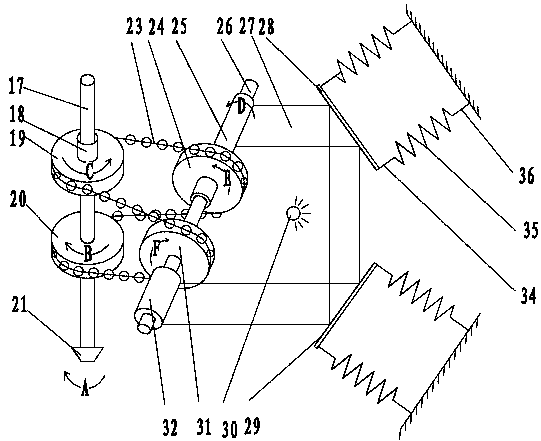

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] A cloth inspection method, which is realized by a cloth inspection machine, such as Figure 1-3 As shown, the cloth inspection machine includes a driving device, a transmission device, a winding device, an unwinding device and a cloth inspection device, wherein the driving device is used to provide intermittent driving force, and the transmission device is used to drive the driving device simultaneously It is connected with the winding device and the unwinding device. That is, the intermittent driving force provided by the driving device realizes the pause in the gray cloth conveying process, so as to facilitate the staff to inspect the gray cloth, and uses a single driving source to drive two winding devices and unwinding devices with opposite rotation directions at the same time, which can ensure the unwinding speed The same as the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com