Yarn positioning electrostatic treatment device

An electrostatic processing and finishing device technology, applied in the field of garment production, can solve the problems affecting the yarn weight difference coefficient test of 100 meters, yarn and yarn entanglement, etc. The effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

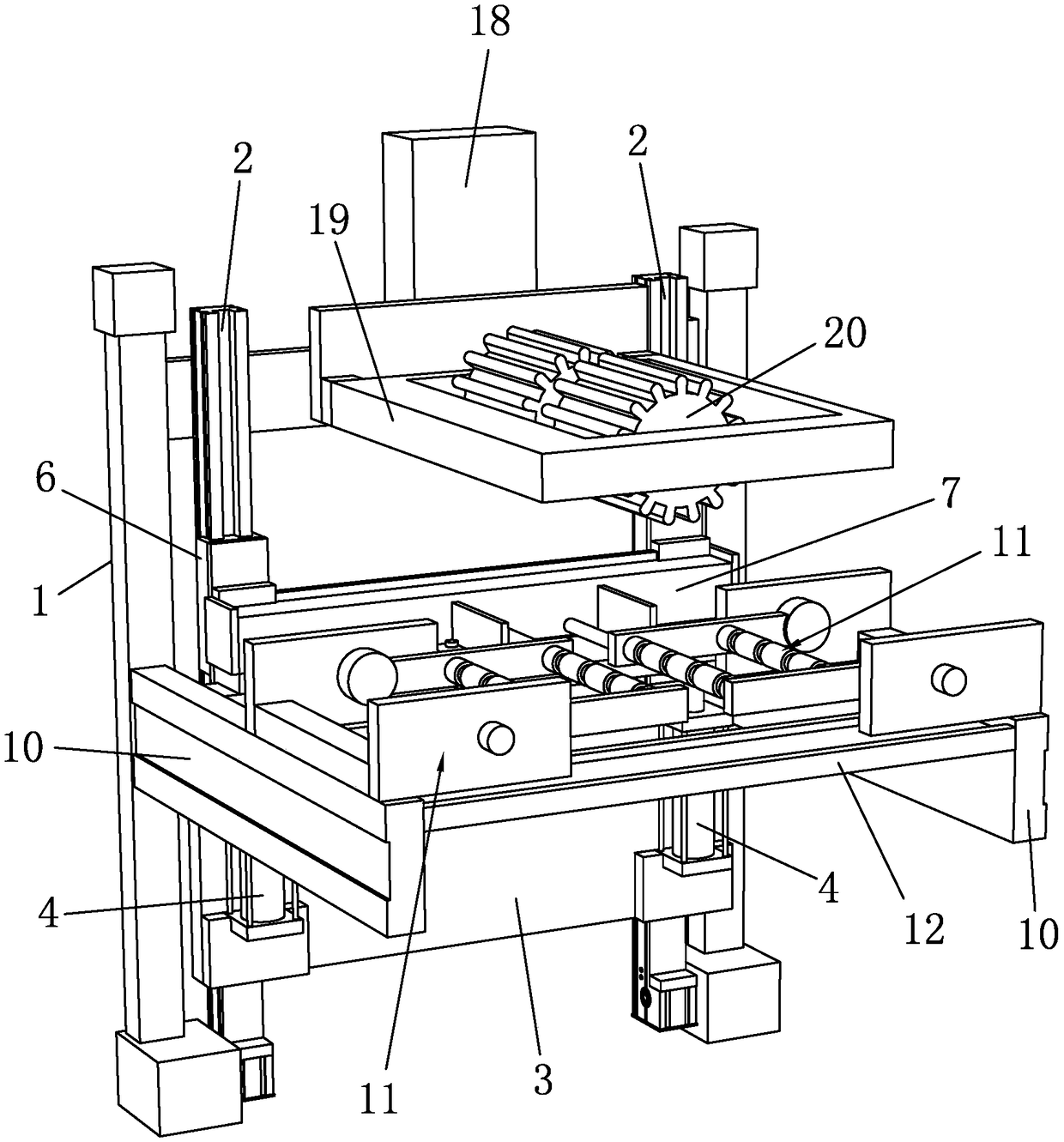

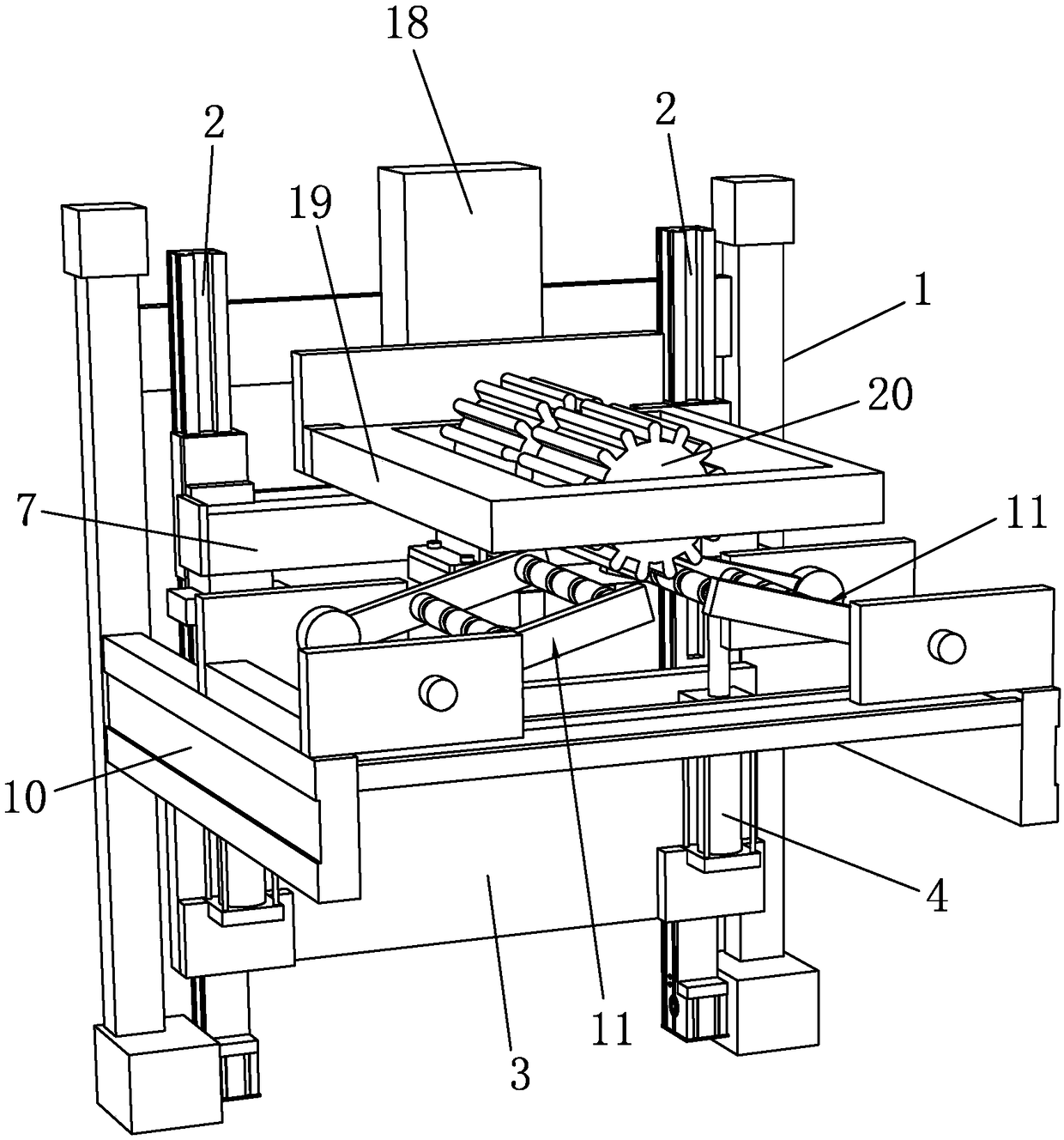

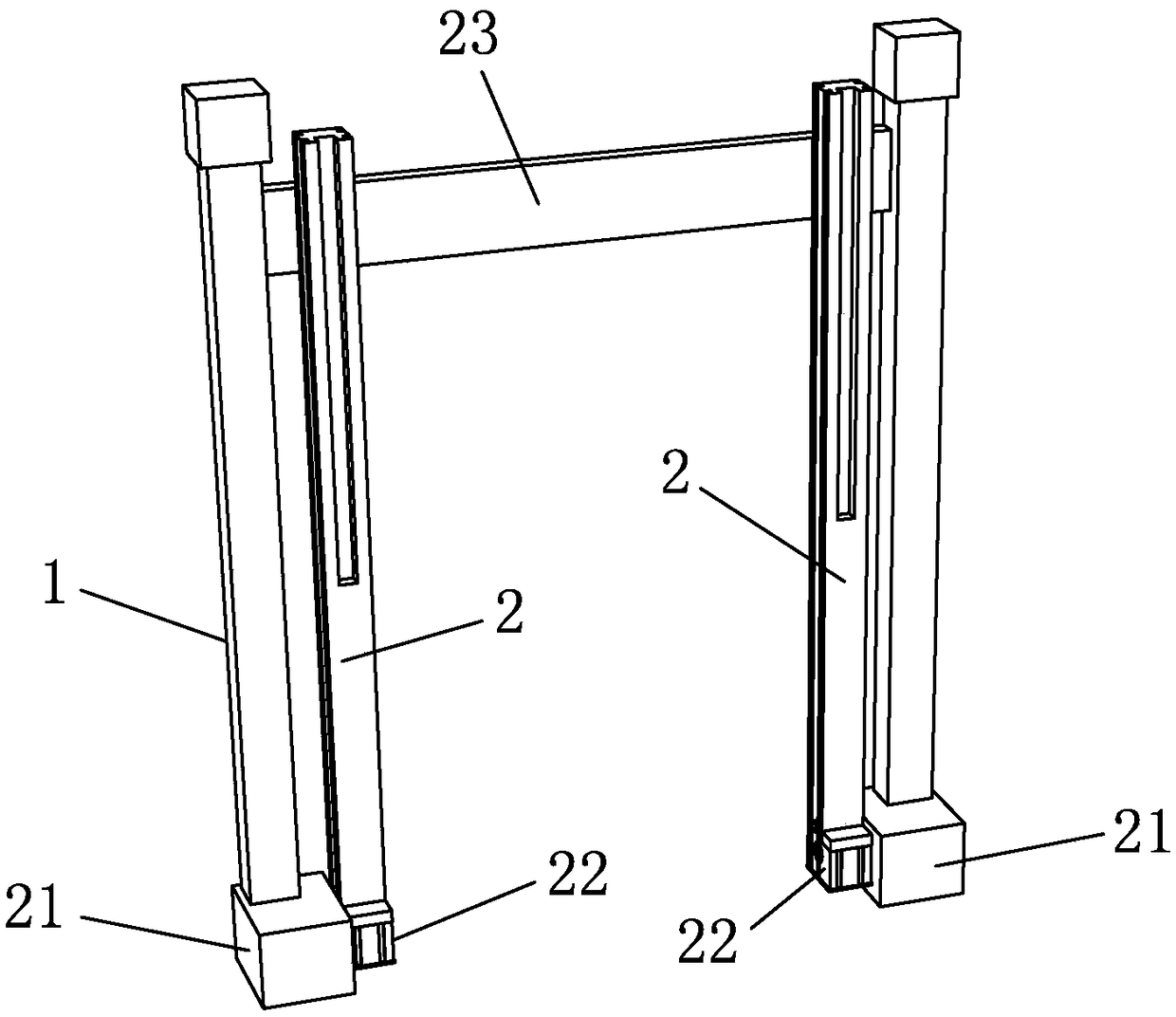

[0028] Such as Figure 1 to Figure 7As shown, it is a yarn positioning electrostatic treatment device of the present invention, including a frame 1 and an automatic control system. The frame 1 is provided with two linear guide rails 2, and the end of the frame 1 is provided with a locking block 21. The end of 2 is provided with fixed head 22, is provided with locking screw between fixed head 22 and locking block 21, and frame 1 is provided with connecting plate 23, and linear guide rail 2 and connecting plate 23 are welded and fixed. When installing the linear guide rail 2, first fix the lower part of the linear guide rail 2, initially position the linear guide rail 2, and then weld the connecting plate 23 on the frame 1 according to the length of the linear guide rail 2, and use the connecting plate 23 to weld the linear guide rail 2 Fixed to improve the installation efficiency of the linear guide rail 2. The linear guide rail 2 is provided with a mounting plate 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com