Method for feeding in and starting a thread and false twist texturing device

A false twist deformation and yarn technology, which is applied in the field of yarn insertion and start-up and false twist deformation devices, can solve the problems of labor-intensive, complicated start-up, time-consuming, etc., and achieve the effect of avoiding yarn breakage and preventing yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

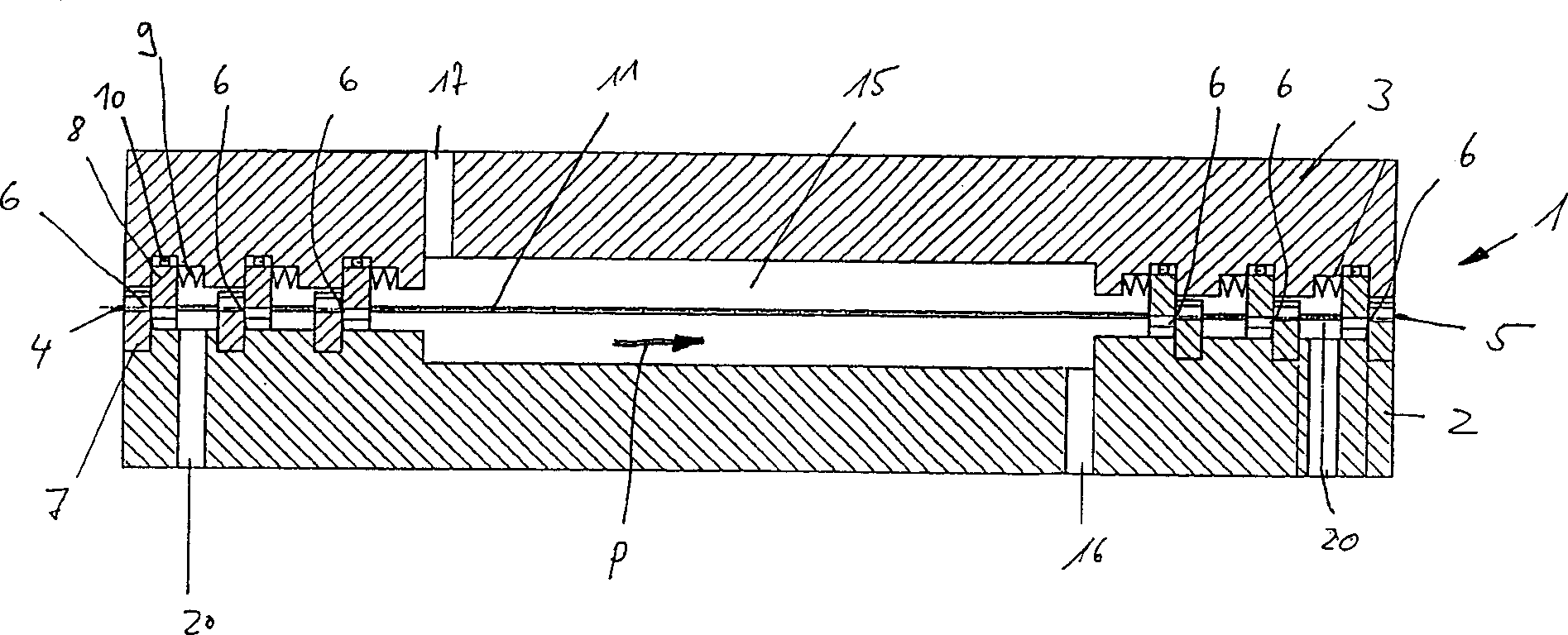

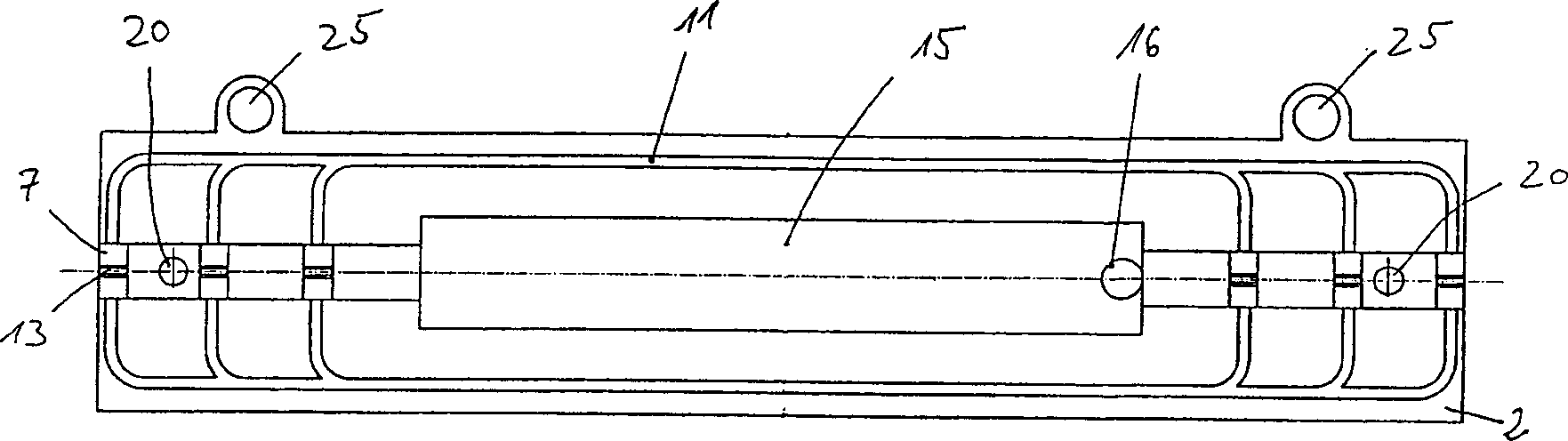

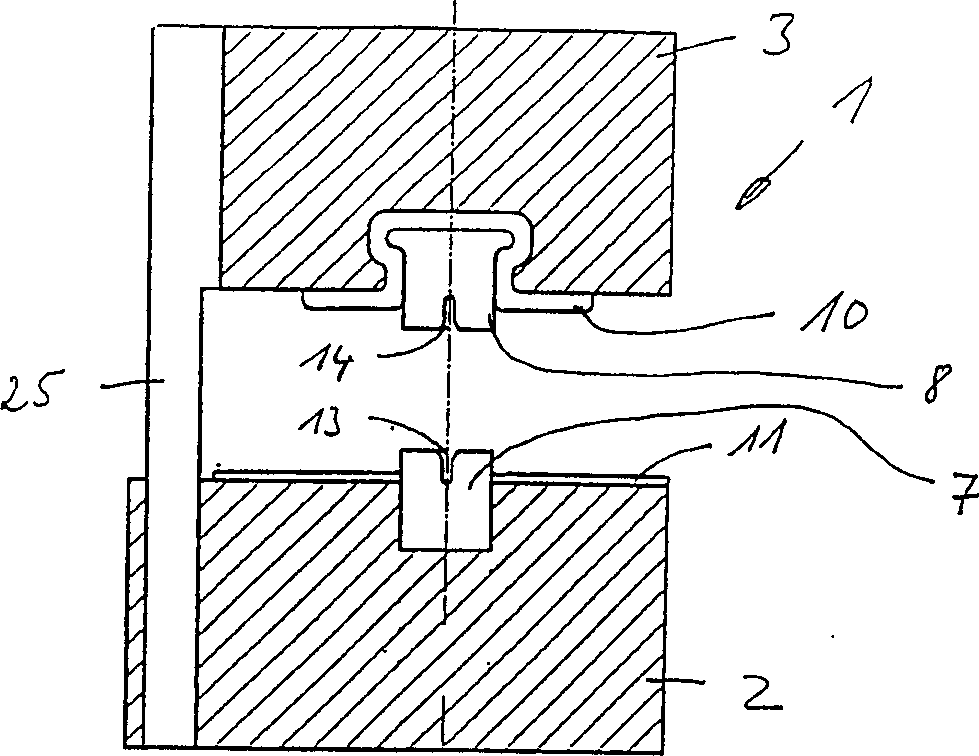

[0040] figure 1 It is a cross-sectional view of the heat exchanger 1. The heat exchanger 1 has a lower part 2 and an upper part 3, which can be separated from each other. A yarn inlet 4 and a yarn outlet 5 are provided between the lower part 2 and the upper part 3. In addition, there are a plurality of yarn channels 6 between the lower part 2 and the upper part 3, and each yarn channel always has two sectors. The components 7 and 8 are composed of the fan-shaped member 7 fixedly arranged in the lower part 2 of the heat exchanger, and the fan-shaped member 8 is movably arranged in the upper part 3 along the axis of the yarn passage 6. At the same time, the fan-shaped member 8 is supported by a spring 9 squeezes a surface of the upper part 3, that is, a surface of the fan-shaped member 7, so that the two are sealed to each other. The two fan-shaped members 7, 8 together form the yarn channel 6, the diameter of which is usually a few tenths of a millimeter. A sealing device / ring 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com