Single-yarn control device of computer type Jacquard warp-knitting machine

A control device and computer-based technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as gaps, mesh openings, and blurred patterns of leaky patterns, so as to achieve convenient use and prevent breakage. yarn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

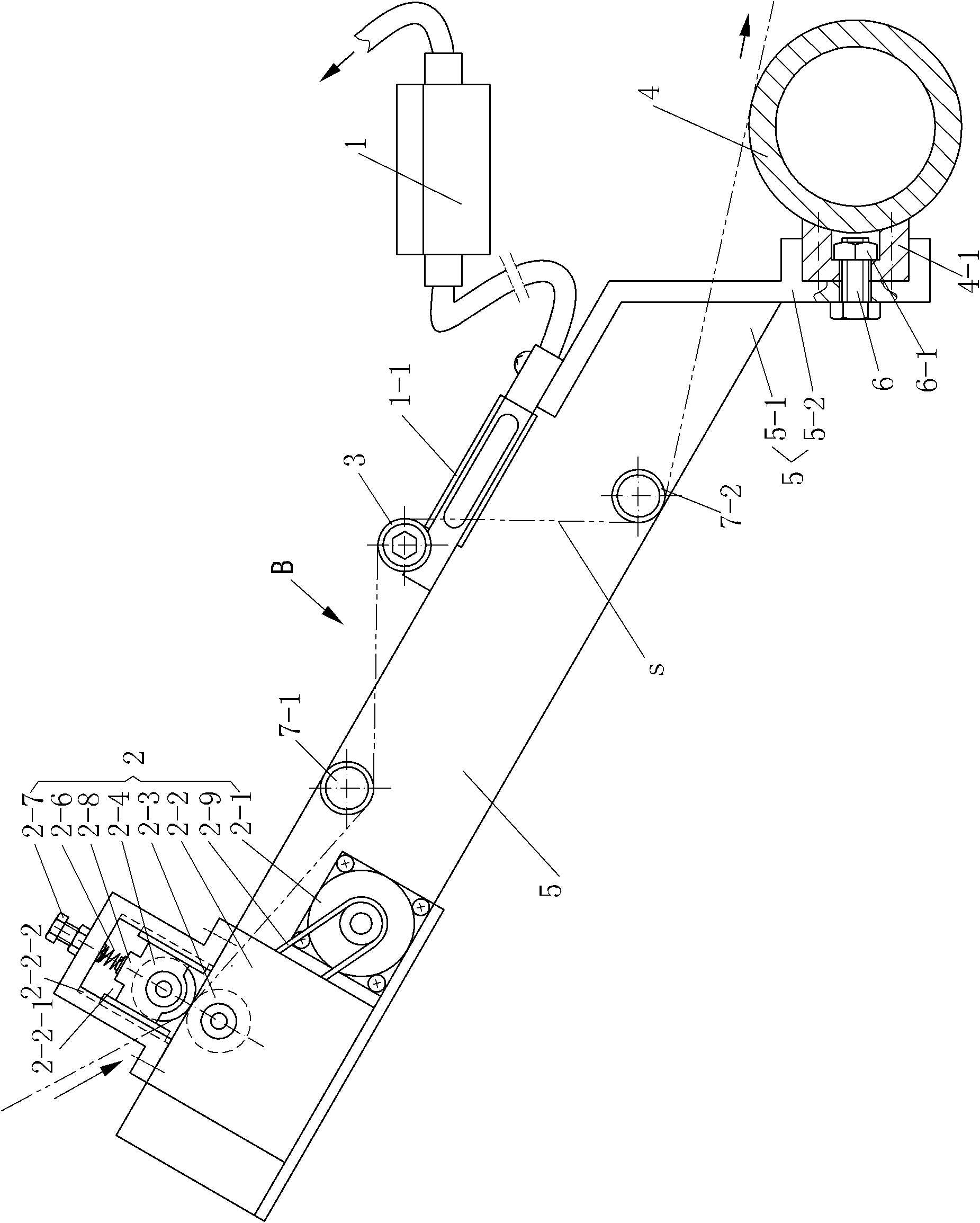

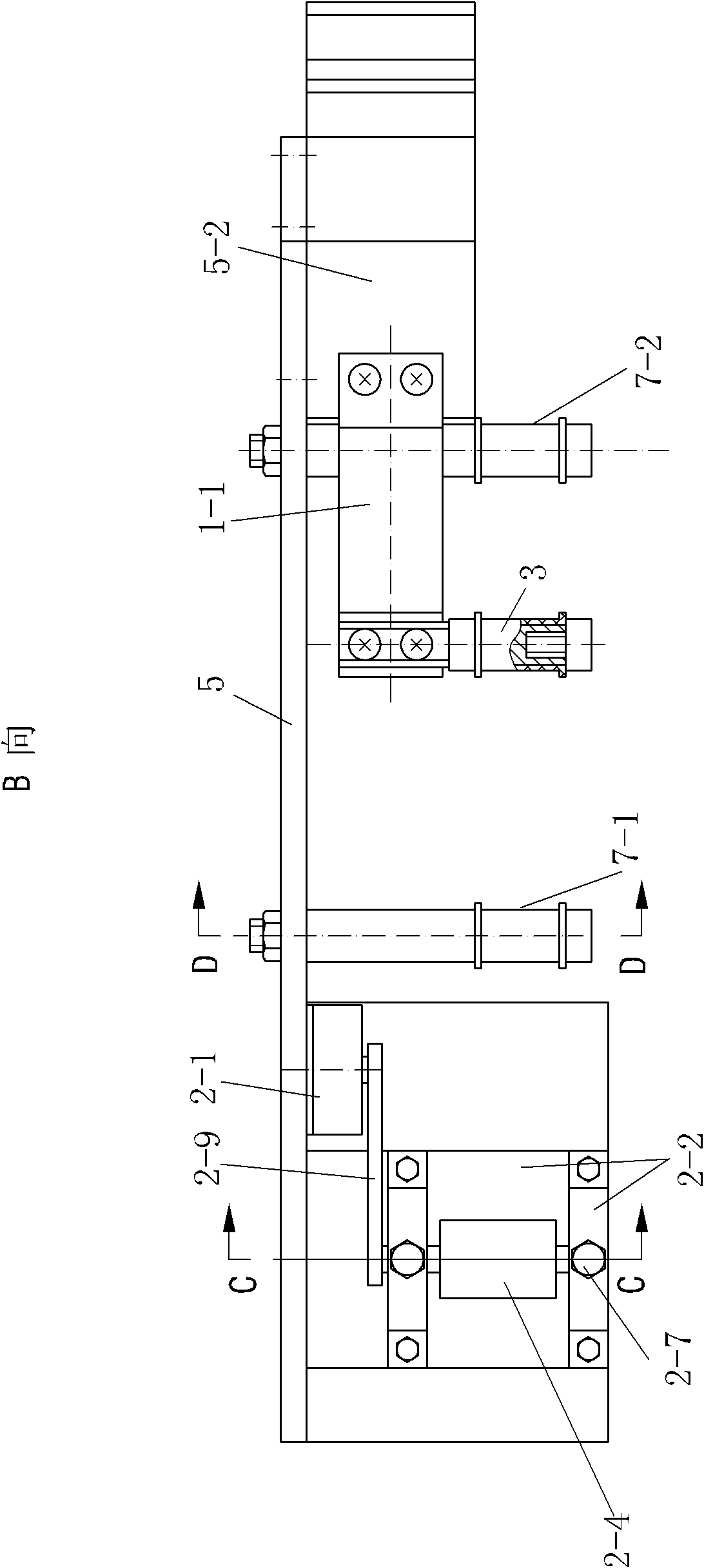

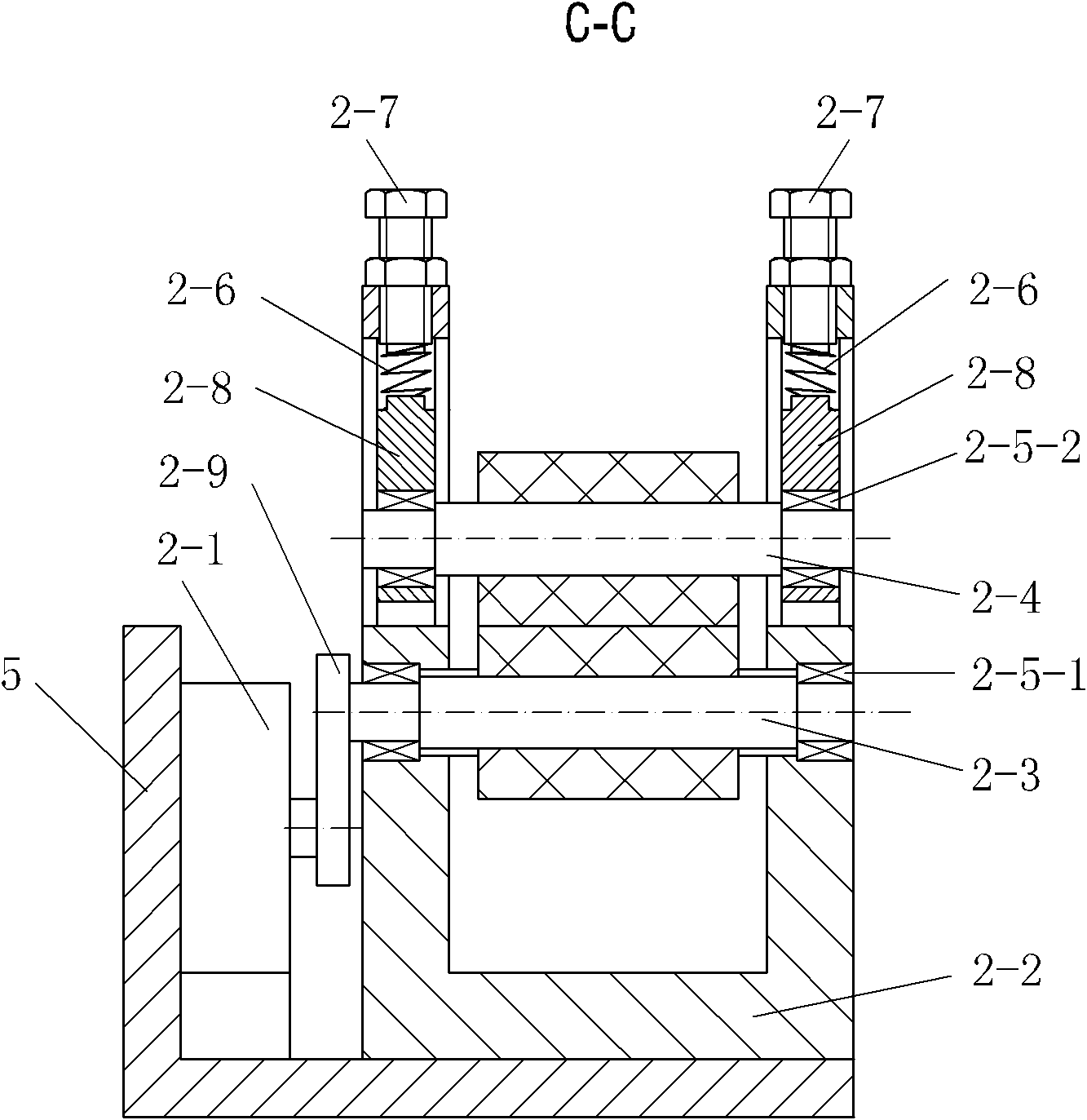

[0028] Example 1 see Figure 1 to Figure 6 , The present embodiment includes a weight transmitter 1, an adjuster 2 and a slide seat 5, and in addition, also involves the upper yarn guide bar 4 of the warp knitting machine.

[0029] A strip slide rail 4-1 is fixed on the upper yarn guide rod 4 . The sliding seat 5 is formed by connecting the main part 5-1 and the connecting part 5-2, and the connecting part 5-2 is provided with two convex strips 5-2-1 (see Figure 5 ), the chute 5-2-2 that cooperates with the slide rail 4-1 of the upper yarn guide rod 4 is formed between the two convex strips 5-2-1, and the groove bottom wall of the chute 5-2-2 is provided with Screw holes 5-2-3. On the slide rail 4-1 of upper yarn guide bar 4, be provided with step bar groove 4-1-1 (see Figure 6 ), a locking screw 6 passes through the screw hole 5-2-3 on the sliding seat 5, the bar groove 4-1-1 of the slide rail 4-1, and the wide groove in the stepped bar groove 4-1-1 Nut 6-1 connection (...

Embodiment 2

[0035] Example 2 see Figure 8 and Figure 9 , the upper end of the sliding seat 5 is connected with a bobbin holder 13 . The rest is the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com