Synthetic leather embossing equipment

A synthetic leather and embossing technology, applied in textiles and papermaking, etc., can solve problems such as uneven embossing effect, affecting embossing effect, and inaccurate control of synthetic leather preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

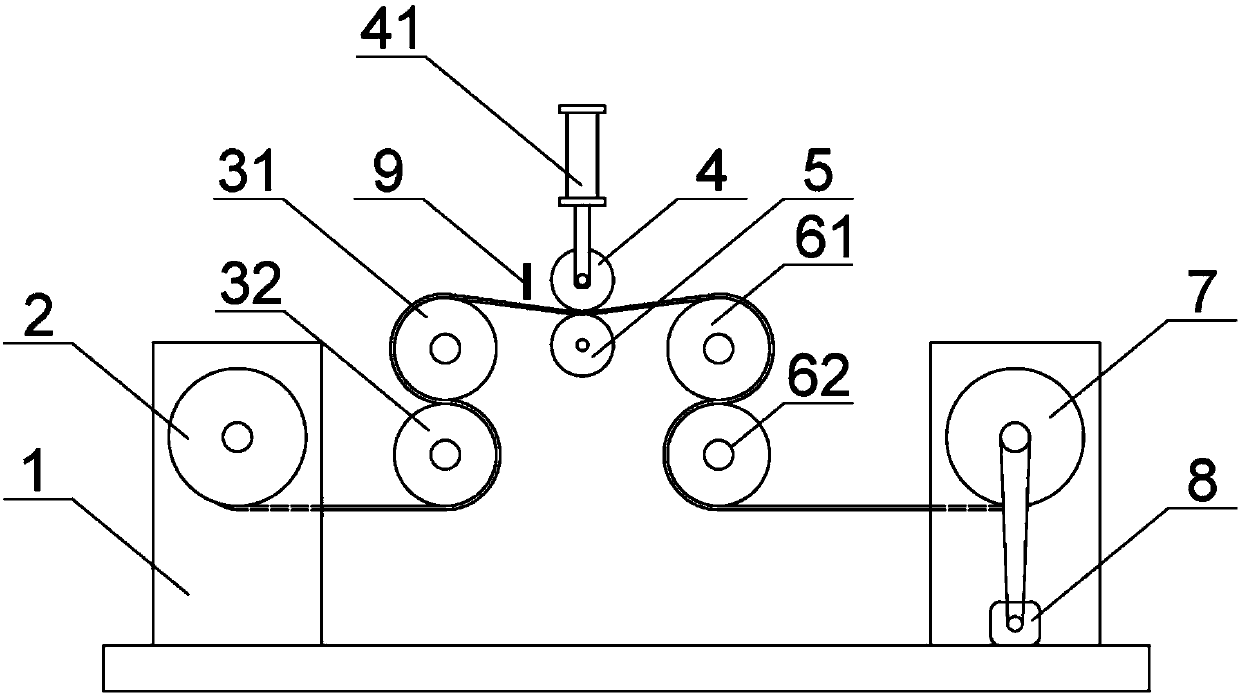

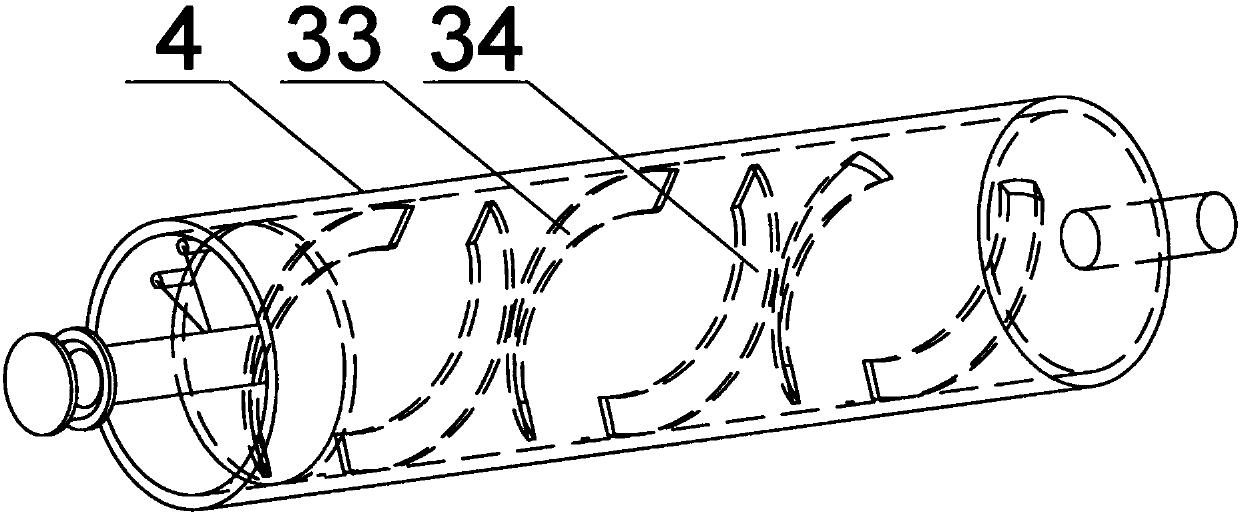

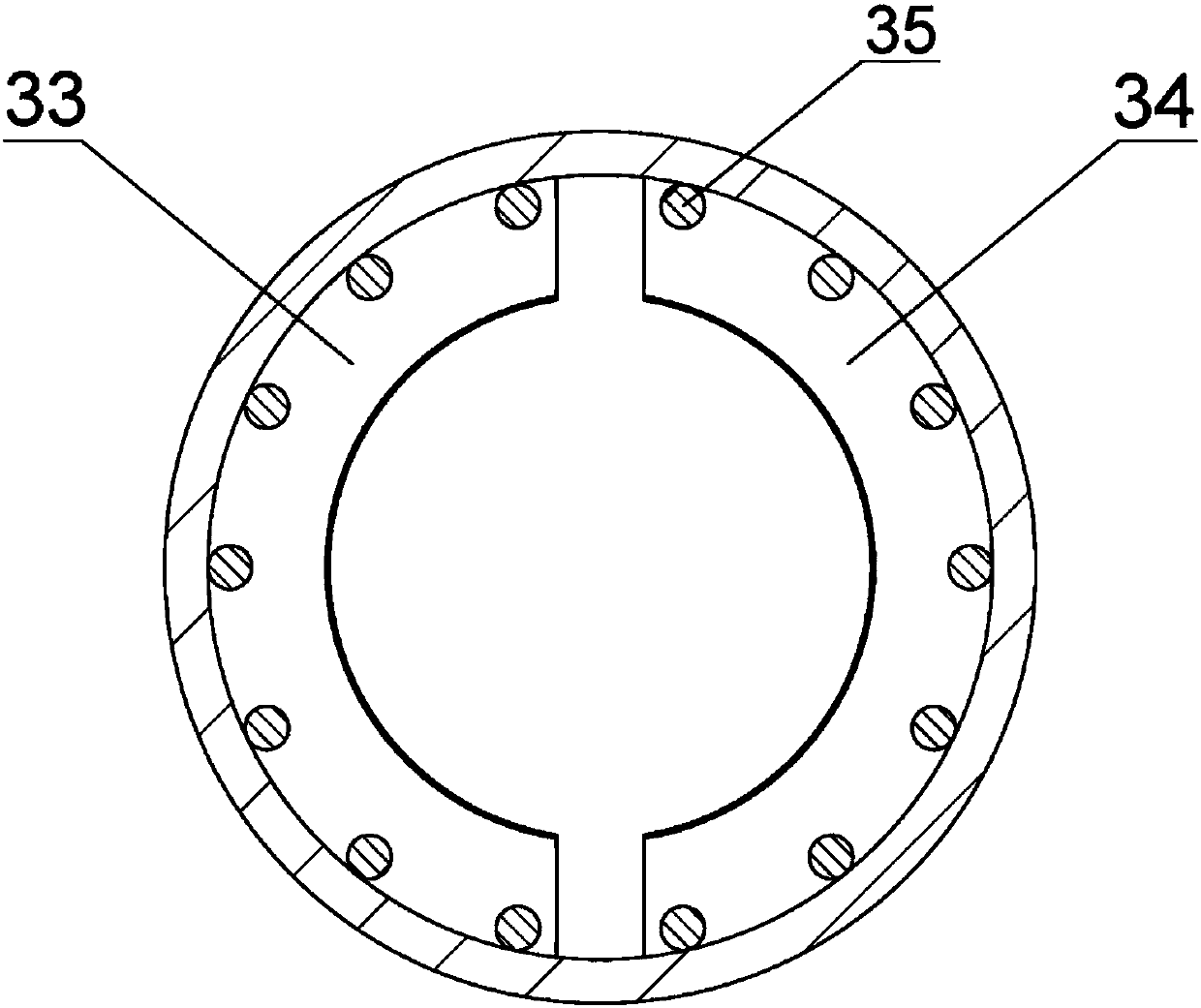

[0015] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a synthetic leather embossing device proposed by the present invention, figure 2 It is a structural schematic diagram of an embossing roller of a synthetic leather embossing equipment proposed by the present invention, image 3 It is a radial sectional view of an embossing roller of a synthetic leather embossing equipment proposed by the present invention.

[0016] refer to figure 1 , a kind of synthetic leather embossing equipment that the present invention proposes, comprises frame 1, feeding roller 2, heating roller, embossing roller 4, back pressure roller 5, cooling roller, receiving roller 7 and control system; Feeding roller 2, The heating roll, embossing roll 4, back pressure roll 5, cooling roll and receiving roll 7 are sequentially installed on the frame 1 from left to right, the embossing roll 4 and the back pressure roll 5 are set up and down opposite each other and between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com