Patents

Literature

167results about How to "Improve embossing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

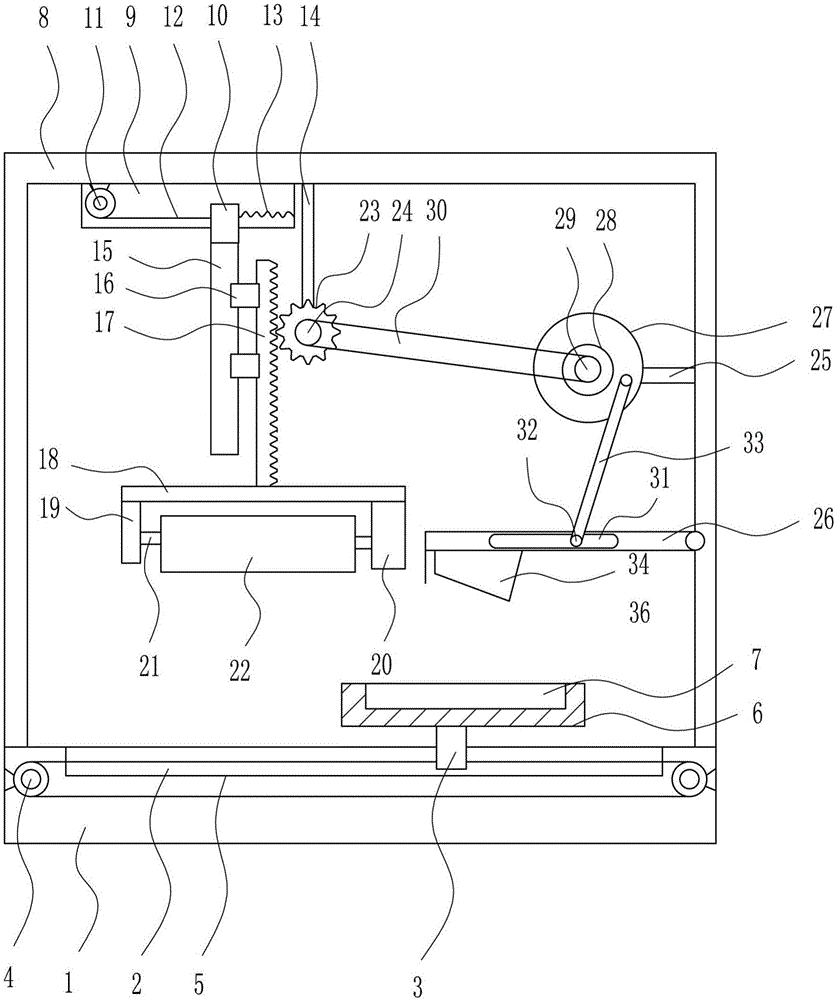

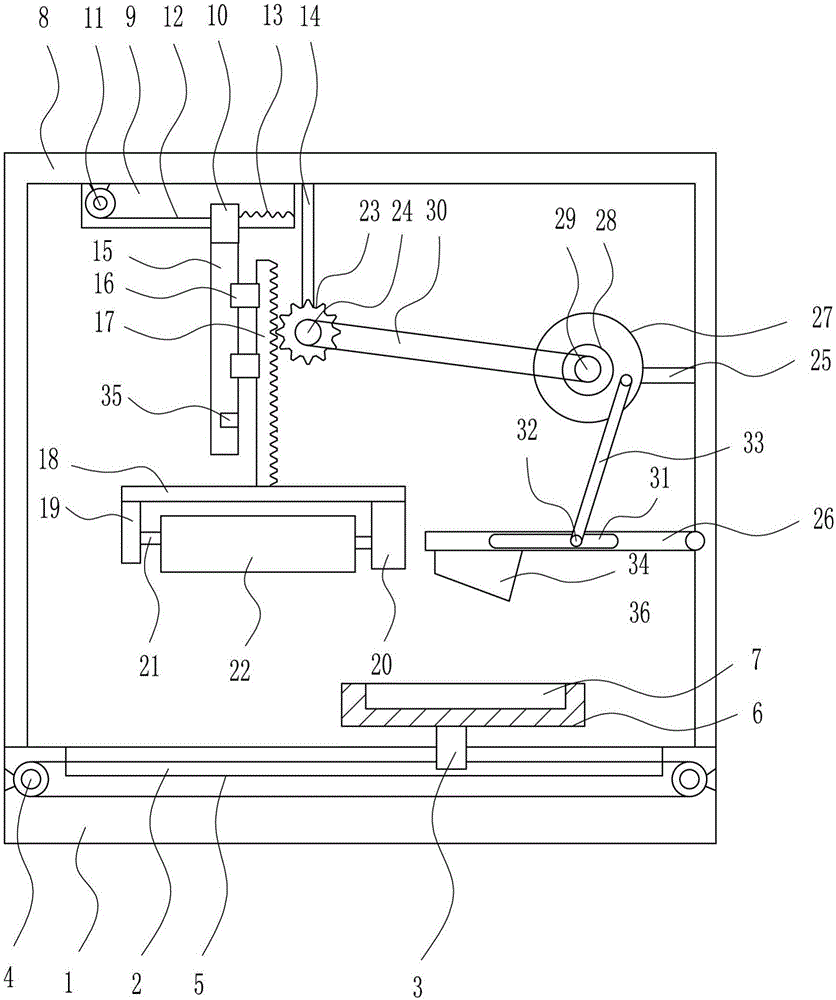

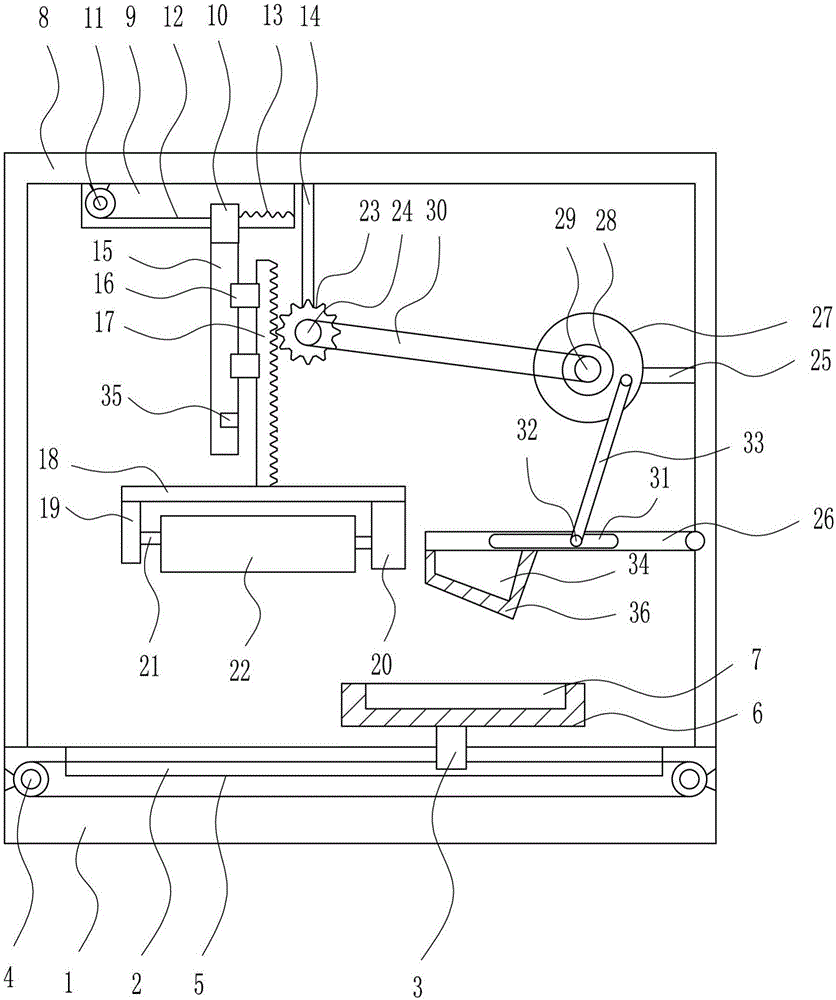

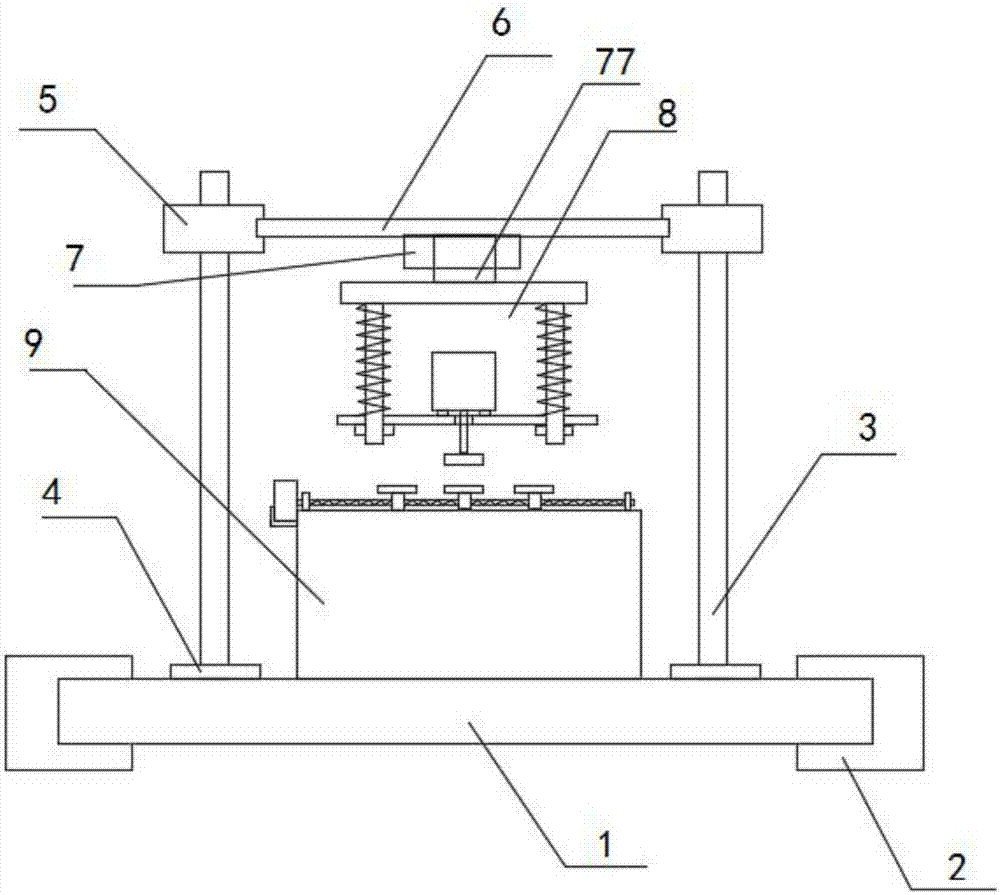

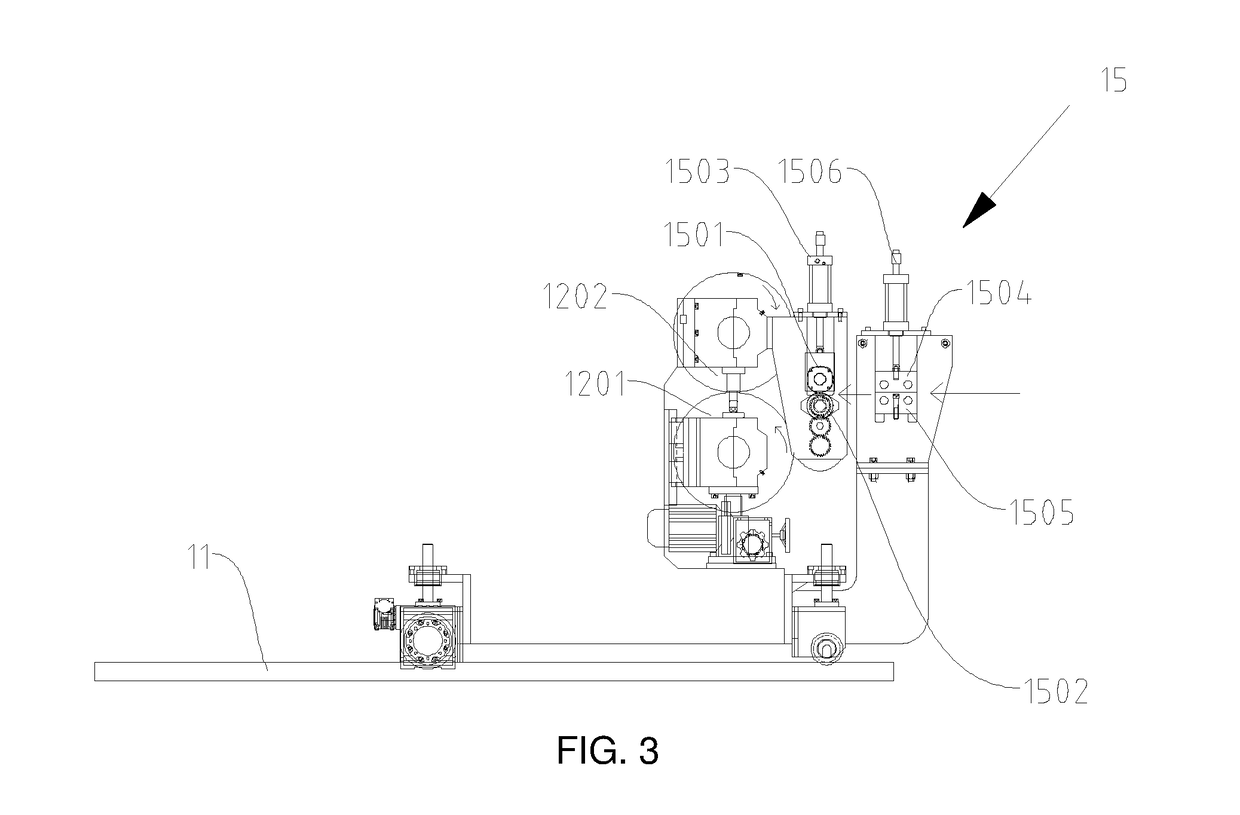

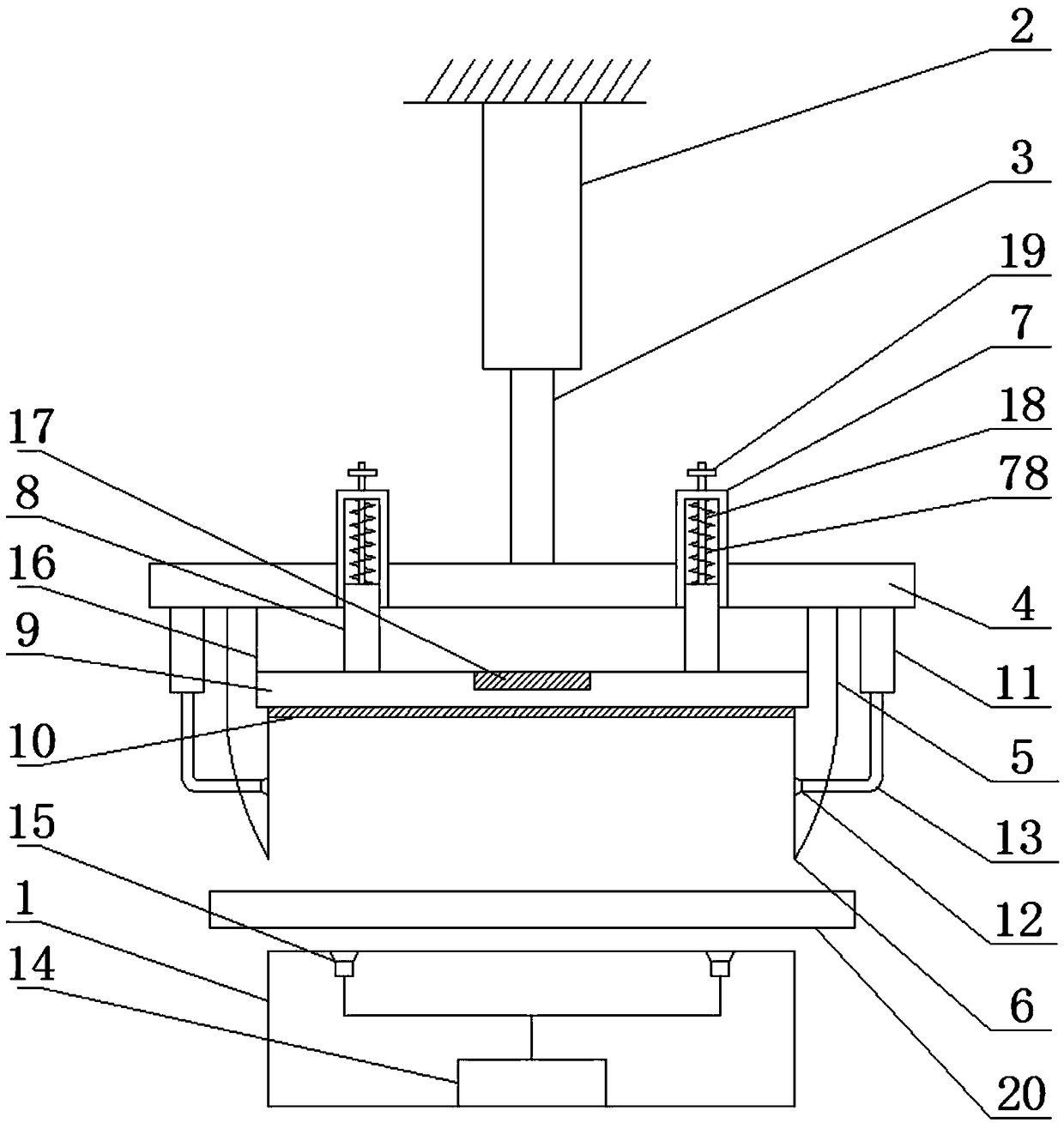

Sole embossing device used for shoe production

InactiveCN106108254AGood embossing effectImprove work efficiencyShoemaking devicesDrive wheelEngineering

The invention relates to a sole embossing device, and especially relates to a sole embossing device used for shoe production. A to-be-solved technical problem is to provide a sole embossing device used for shoe production, and the device is good in embossing effect, high in working efficiency, and simple in operation. In order to solve the above technical problem, the sole embossing device used for shoe production comprises a base, a first sliding rail, a first sliding block, a first electric reel, a first bracing wire, a placing board, an N-type rack, a spring, a first strut, a rack, a fixing plate, a bearing pedestal, a first motor, a rotating rod, a drum, a gear, a driven wheel, an oscillating rod, a disk, a second motor, a driving wheel, a flat belt, a roller, a connecting rod, and a pressing block. The top of the base is provided with the first sliding rail. The device achieves good embossing effect, high working efficiency, and simple operation. The device continuously makes the pressing block beat a sole, to emboss a sole.

Owner:张浩杰

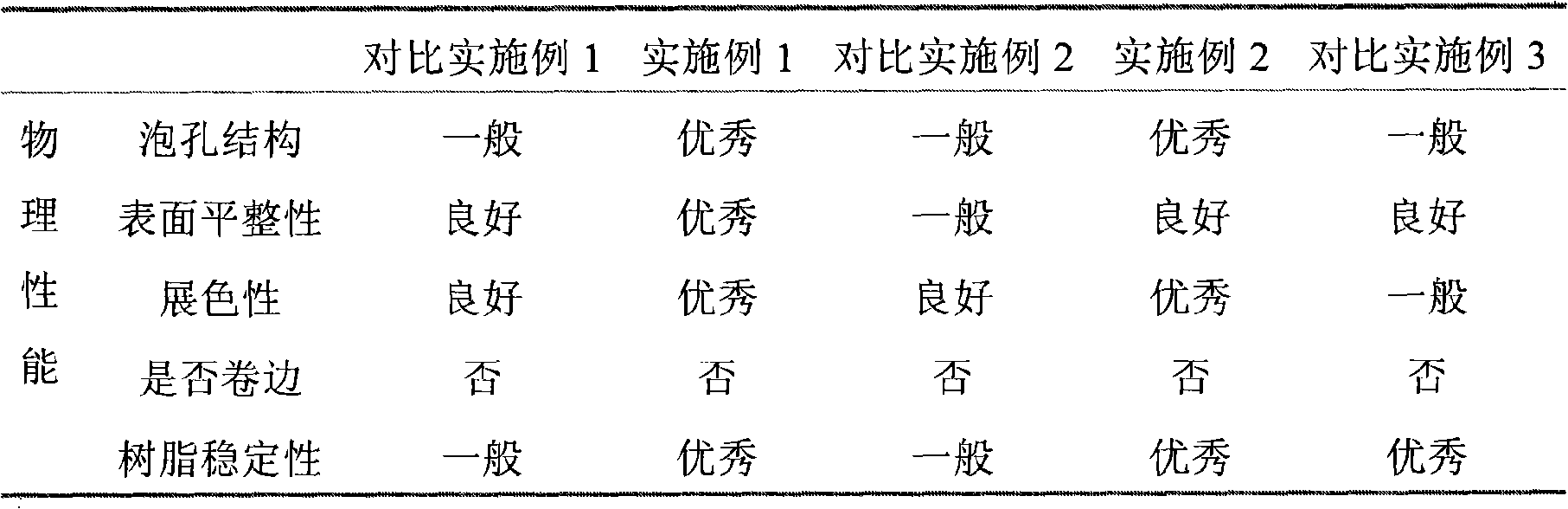

Wear-resistant leather and preparation method thereof

InactiveCN106702753AImprove embossing effectImprove wear resistanceTextiles and paperWater basedWear resistant

The invention discloses wear-resistant leather and a preparation method thereof. The wear-resistant leather comprises a base fabric, an adhesive layer, a foaming layer, a surface layer and a surface treatment layer, wherein the surface layer comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride paste resin powder having a polymerization degree of 1600-2000, 60-80 parts of a plasticizer, 1-3 parts of a heat stabilizer and 3-5 parts of color paste; the surface treatment layer comprises the following raw materials in parts by weight: 80-90 parts of water-based polycarbon type PU resin, 15-20 parts of aliphatic polyurethane, 4-6 parts of an aziridine crosslinking agent, 3-5 parts of an isocyanate-based crosslinking agent, 15-20 parts of water-based silicone hand feeling agent, 6-8 parts of an acrylic thickening agent and 2-3 parts of a pH adjusting agent. The wear resistance and the mechanical fatigue resistance of the wear-resistant leather provided by the invention are improved by mainly improving the surface layer, the surface treatment layer, the foaming layer and the preparation method of the original polyvinyl chloride artificial leather.

Owner:广西鑫深科技有限公司

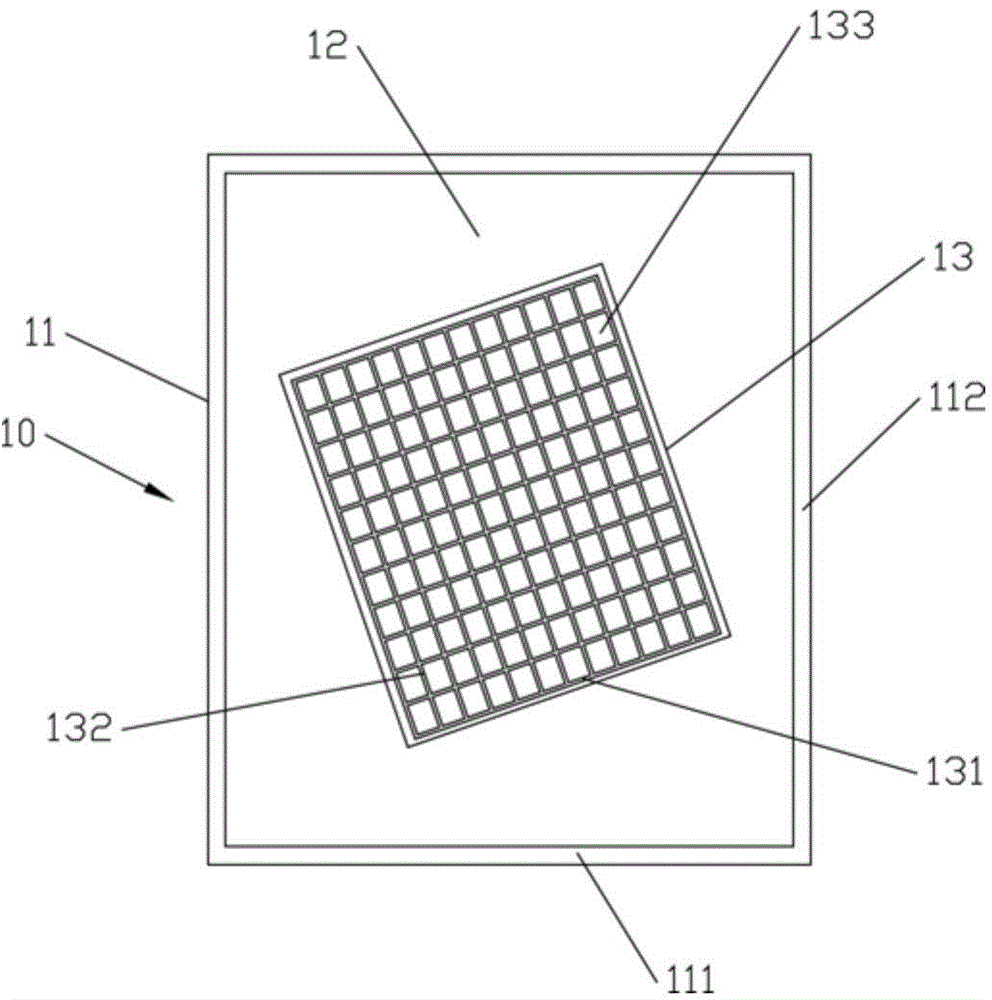

Screen printing method, screen structure and pressing marker

InactiveCN104608513AReduce defective rateAvoid different stressScreen printersOther printing apparatusScreen printingEngineering

The invention relates to the technical field of screen printing and discloses a screen printing method. The screen printing method includes: providing a screen, wherein the screen comprises a screen frame and screen cloth stretching tight on the screen frame, the screen cloth is provided with a pressing figure mold forming a plurality of grids by cross arrangement of a plurality of parallel warps and a plurality of parallel wefts, and the warps and the wefts are mutually vertical; providing a substrate, attaching the screen to the upper surface of the substrate, applying coating materials on the position corresponding to the pressing figure mold of the screen cloth, and using a scraper to press down to abut against the screen cloth prior to moving the scraper so as to enable the coating materials to be distributed according to the pressing figure mold, wherein the latitude line of the scraper and the pressing figure mold forms a first included angle, the longitude line of the scraper and the pressing figure mold forms a second included angle, and neither the first included angle or the second included angle is zero degree; removing the screen to form printing patterns on the substrate. The invention further provides a screen structure and a pressing marker, and reject ratio of screen printing can be reduced.

Owner:BOE TECH GRP CO LTD +1

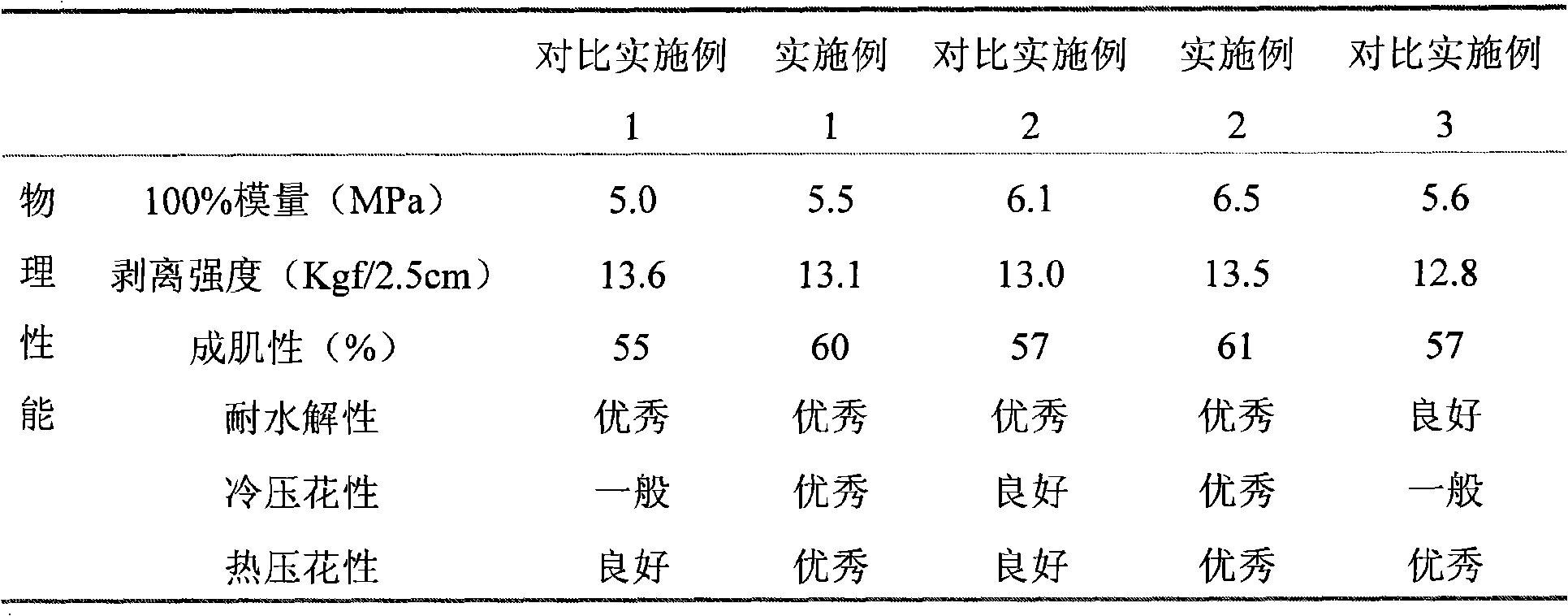

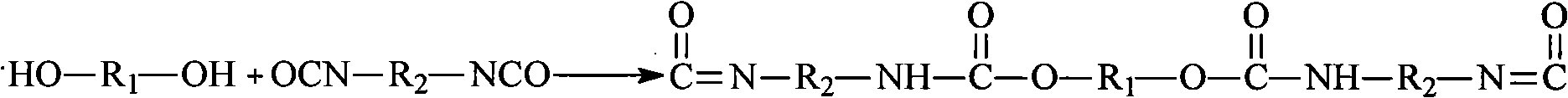

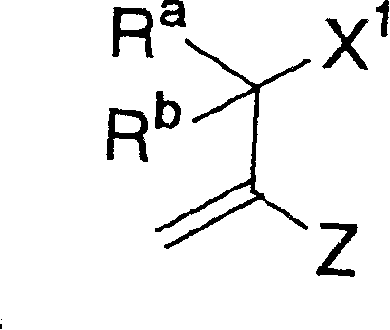

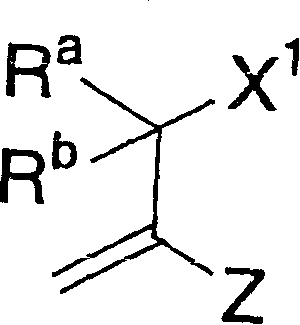

High-performance anti-hydrolysis and high-density resin material for coining polyurethane leather and preparing method thereof

The invention discloses a high-performance anti-hydrolysis and high-density resin material for coining polyurethane leather and a preparing method thereof. The resin material is made by mixing polyurethane resin A component and polyurethane resin B component, wherein the A component is prepared by the two-step polymerization reaction or the three-steep polymerization reaction of isocyanate, polyester polyol, polyether glycol I and alcohol chain extender; and the B component is prepared by the one-step polymerization reaction of isocyanate, polyester polyol, polyether glycol II and alcohol chain extender, with the addition of a proper amount of cell regulator and catalytic agent. The A component and the B component are added into a reaction vessel according to certain mass ratio, the temperature range is controlled, and then the high-performance anti-hydrolysis and high-density resin material for coining polyurethane leather is obtained after uniform stirring. The resin material has the advantages that the coining performance of the common anti-hydrolysis and high-density resin for polyurethane leather is improved under the condition of low cost; and the important performances such as the coining performance, the thickness conservation rate and the like of the material are improved under the condition that the hydrolytic resistance and the stripping strength are not reduced, and the application fields of the material are greatly expanded. The prepared material can be widely applied to the manufacturing industries, such as the clothing leather, the luggage leather, the instep leather and the like. On the other hand, by adopting the double-component system, later process can be performed under lower temperature, and the double-component system is in favor of energy conservation and consumption reduction.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Anti-static two-sided gold-stamped, printed and embossed PVC (polyvinyl chloride) sheet and preparation method thereof

InactiveCN104558963AImprove embossing effectImprove antistatic performancePlasticizerPolyvinyl chloride

The invention relates to the technical field of sheets, in particular to an anti-static two-sided gold-stamped, printed and embossed PVC (polyvinyl chloride) sheet and a preparation method thereof. The sheet comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 32-52 parts of a plasticizer, 6-10 parts of a lubricant, 1-4 parts of a heat stabilizer, 0.03-0.07 parts of a slipping agent, 0.03-0.07 parts of pigment powder and 0.1-0.5 parts of calcium powder, wherein the calcium powder is a mixture of nano calcium carbonate and heavy calcium carbonate in the weight ratio of 1:(1.5-2.5), the particle size of the nano calcium carbonate is in a range of 120-150 nm, and the particle size of the heavy calcium carbonate is in a range of 1-10 [mu]m. The raw materials are adopted, and the weight ratio of the raw materials is strictly controlled, so that the sheet is good in anti-static effect, heat-resistant, cold-resistant, acid-resistant, alkali-resistant, heavy-load-resistant, anti-aging, smooth in surface, free of cracks and bubbles, uniform in color, strong in stereoscopic impression, soft in texture, comfortable, healthy and environment-friendly.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Ultra-soft wet process embossing-type polyurethane resin and preparation method and application thereof

ActiveCN102010496AWork around limitationsSolve the costTextiles and paperPolyesterN dimethylformamide

The invention discloses ultra-soft wet process embossing-type polyurethane resin and a preparation method and application thereof, in particular to the ultra-soft wet process embossing-type polyurethane resin which adapts to the direct hot pressing and cold pressing process. The ultra-soft wet process embossing-type polyurethane resin is prepared from isocyanate, a polyester polyol mixture, a mixed chain extender prepared by matching a chain extender with a pendant group with an ethylene glycol chain extender and N, N-dimethylformamide as an organic solvent. A block structure containing ethylene glycol chain extension makes the polyurethane resin structure have the characteristics of high stripping strength and good embossing property by combining with the side chain action after the chain extender with the pendant group fully reacts, and therefore, a wet process base manufactured by the invention can adapt to direct embossing on the base, and the embossed grains are full and clear; and the base has soft and elastic hand feeling and approaches the true skin feeling. The invention solves the problems of grain restriction, complicated process flow, higher manufacturing cost and the like of the traditional process.

Owner:SHANGHAI HUIDE TECH CO LTD

Concave-convex three-dimensional knurled knitted fabric

The invention discloses concave-convex three-dimensional knurled knitted fabric. The concave-convex three-dimensional knurled knitted fabric is formed by interweaving surface yarns and bottom yarns, wherein the surface yarns are made of polyester fibers, and the bottom yarns comprise 25%-35% of polyester fibers and 65%-75% of acrylic fibers. The post finishing technique of the fabric comprises the knurling technique. The knurling technique particularly comprises the steps that the fabric is fixed between an upper mold and a lower mold of an embossing machine, the upper mold and the lower mold are heated to 165 DEG C to 175 DEG C, the upper mold and the lower mold are squeezed, pressurizing and cooling are conducted after knurling, and the fabric is taken out after being cooled to indoor temperature. In this way, the concave-convex three-dimensional knurled knitted fabric has the advantages that the handfeeling and the knurling effect of the knurled fabric can be improved, the three-dimensional impression of knurled patterns of the fabric is improved, the shape maintenance performance is high, the technology is simple, operation is easy, and cost is low.

Owner:CHANGSHU OXIYI TEXTILE CO LTD

Processing technique for obtaining embossment type wood grain surface of aluminum profile

ActiveCN105034673AImprove color retention and weather resistanceImprove realismNatural patternsDecorative surface effectsWeather resistanceMetallurgy

The invention discloses a processing technique for obtaining an embossment type wood grain surface of an aluminum profile. The processing technique includes the following steps of pre-processing, wood grain ground color powder spraying, solidifying, transfer powder spraying, secondary solidifying, wooden transfer film packaging, laminating in a vacuumizing mode and heat transfer printing solidifying. A wood grain ground color coating is sprayed by more than 60 [u]m, so that wood grains on a transfer film better permeate into the wood grain ground color coating in heat transfer printing solidifying. The color keeping performance and weather resistance of the coating are improved, and the fidelity of wood grain texture is improved. Moreover, a wood grain mold is used for spraying, a concave-convex stereoscopic impression is strong, a good embossment effect is achieved, a realistic log feeling is better achieved, the problems that the wood grains on the surface of the aluminum profile have no stereoscopic impression or have a poor stereoscopic impression, and the fidelity is insufficient are solved, and the quality and aesthetic feeling of decorative building materials are improved.

Owner:浙江富丽华铝业有限公司

Printing and forming process of environment-friendly APET plastic products

InactiveCN106827598AStable printingBeautiful printPattern printingFlat articlesScreen printingPlastic film

The invention relates to a processing process of APET plastic products, in particular to a printing and forming process of environment-friendly APET plastic products. The printing process comprises the following steps:1) making an APET plastic plate; 2) embossing a leading wire on the APET plastic plate and laminating a film on the APET plastic plate; 3) cutting the APET plastic plate; 4) carrying out silk-screen printing; 5) coating the APET plastic plate with a protective film layer; 6) pressing sides; 7) carrying out die-cutting forming; and 8) carrying out high-frequency splicing. According to the process, the APET plastic is used as an original material of the plastic products so that the environment can be protected, the resources can be recycled, and the processing cost can be reduced; the reasonable printing process is adopted so that the pattern printing and the pattern die-cutting forming of the APET plastic sheet material can be smoothly completed in shortest time and in most convenient operation steps; and the most suitable forming process is adopted, so that the APET sheet material can be stereoscopically formed smoothly, and the APET plastic products which are attractive in printing, stable in quality and energy-saving can be obtained.

Owner:东莞市巨泓彩色印刷有限公司

Laser printing film and fabrication technology thereof

ActiveCN103707593AHeat resistantCorrosiveSynthetic resin layered productsLaminationPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to the technical field of laser printing films, and particularly relates to a laser printing film and a fabrication technology thereof. The laser printing film sequentially comprises a polyethylene terephthalate (PET) base film, a coating layer, a laser layer and an aluminium layer, and also comprises an acrylic resin layer which is coated on the other surface of the PET base film. The fabrication technology of the laser printing film comprises the following steps: 1, dissolving nitrocotton into ethyl acetate to obtain nitrocotton liquid; 2, coating one surface of the PET base film with the nitrocotton liquid, and baking to obtain the coating layer; 3, heating the coating layer until the coating layer becomes soft, and then coining laser grains on the coating layer, so as to obtain the laser layer; 4, plating the aluminium layer on the surface of the laser layer by using a vacuum aluminum plating machine; and 5, coating the acrylic resin on the other surface of the PET base film, and baking to obtain the acrylic resin layer, so as to obtain the laser printing film. The laser printing film is good in combination degree with UV (Ultraviolet) ink, so that the paint of the laser printing film does not peel off in the use procedure.

Owner:桂林澳群核径迹有限责任公司

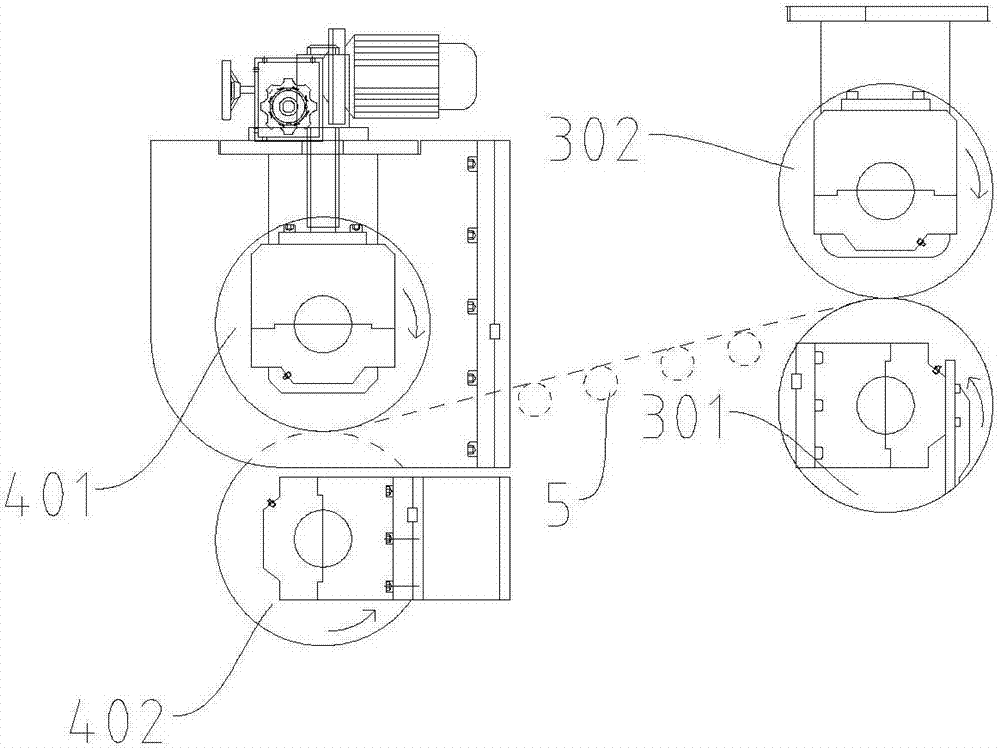

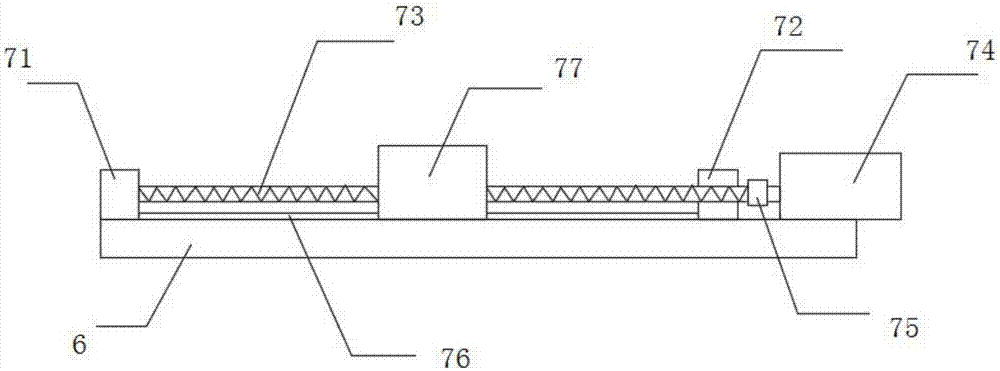

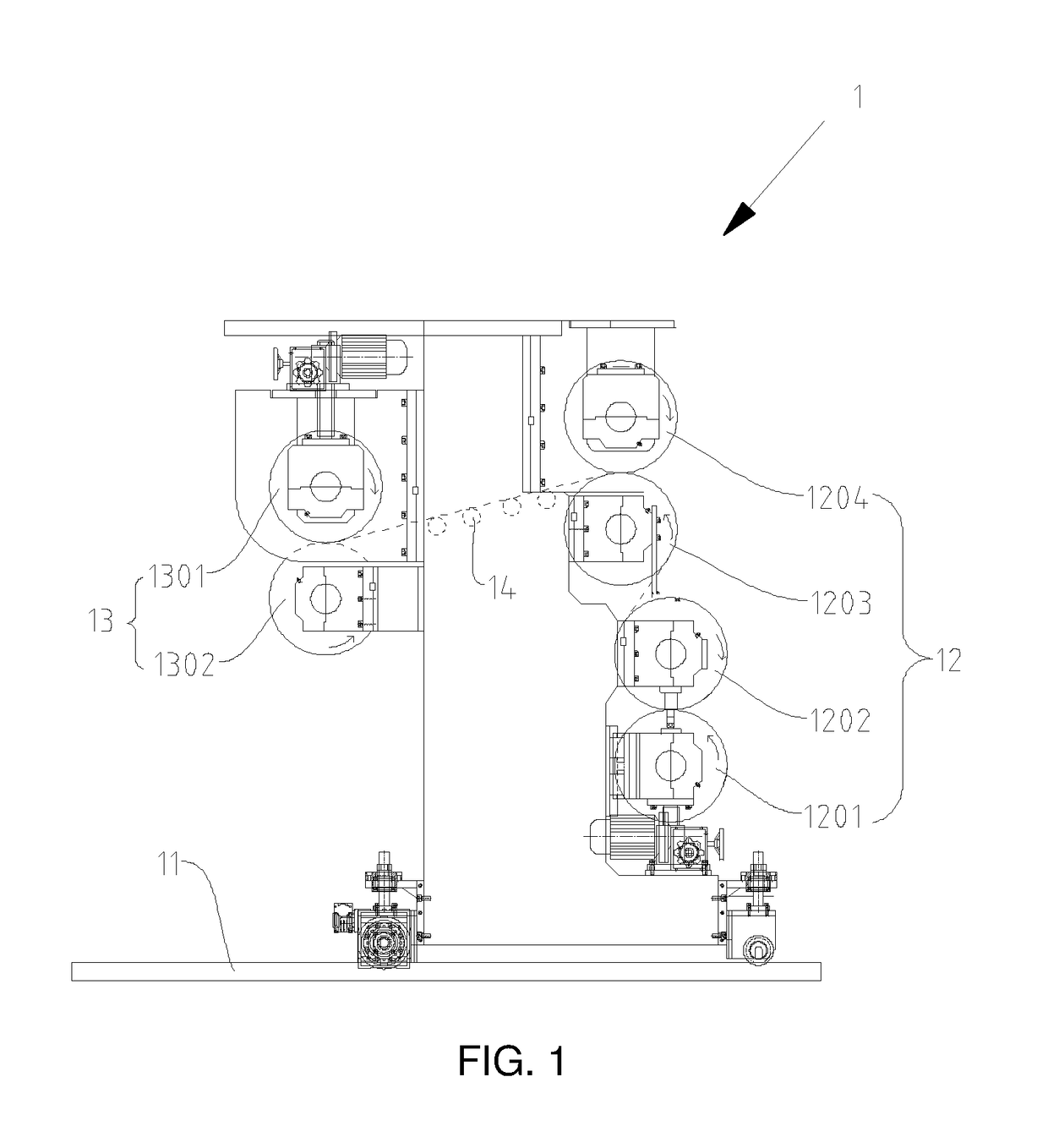

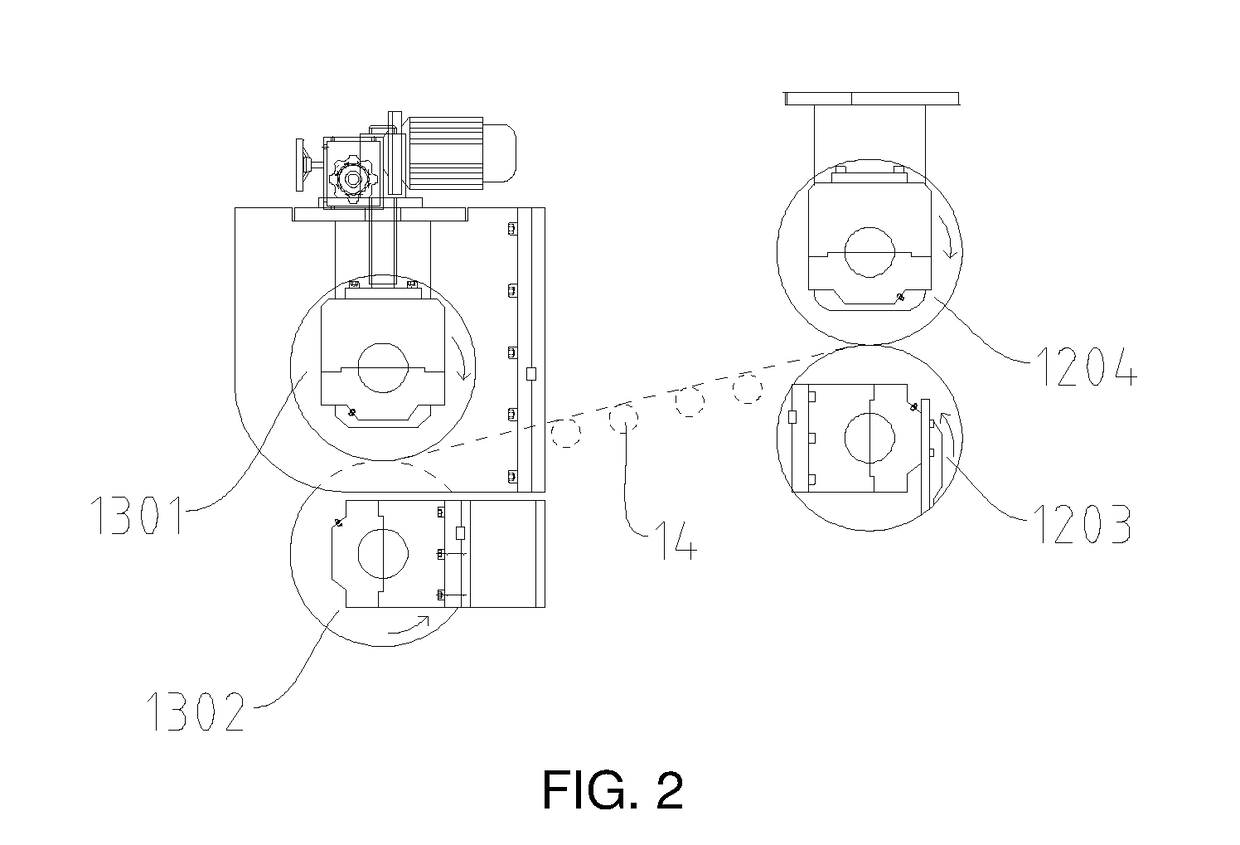

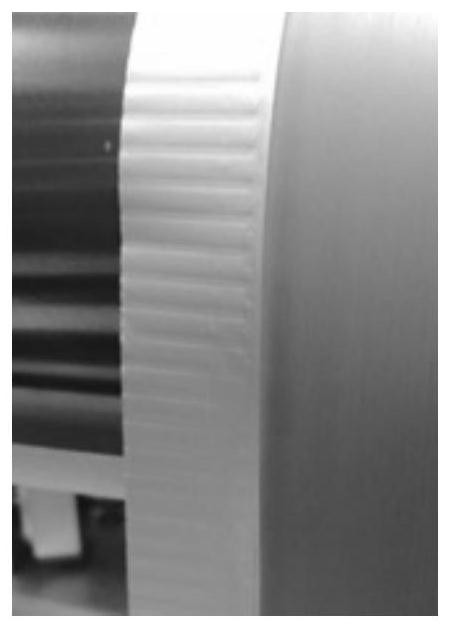

Calendar, foamed floor production line and one-time forming production process

InactiveCN107186937AReduce the temperatureGuarantee the quality of follow-up processingProduction linePulp and paper industry

A calender, comprising a machine base and a set of calender rolls arranged on the base, characterized in that: the set of calender rolls includes a main set of calender rolls and a set of embossing rolls for embossing the material to be processed, the main set of calender rolls Calendering rollers and embossing rollers are spaced at a certain distance so that the material can be cooled before passing from one roller group to another. The calender mirror can achieve better embossing embossing effect. The calender is used in the production of foamed floor, which can realize the integrated production of foamed floor.

Owner:QINGDAO SANYI PLASTIC MACHINERY

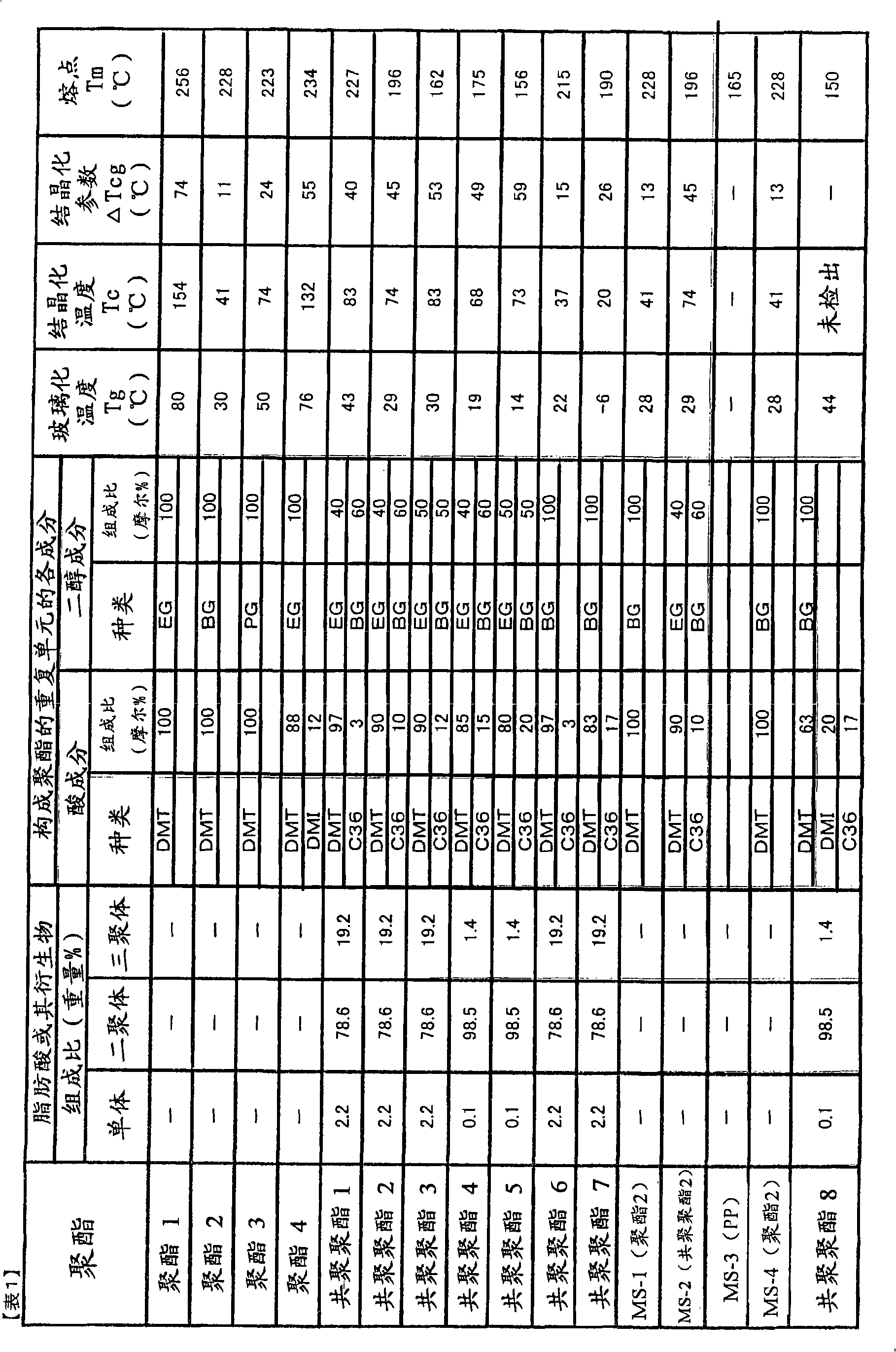

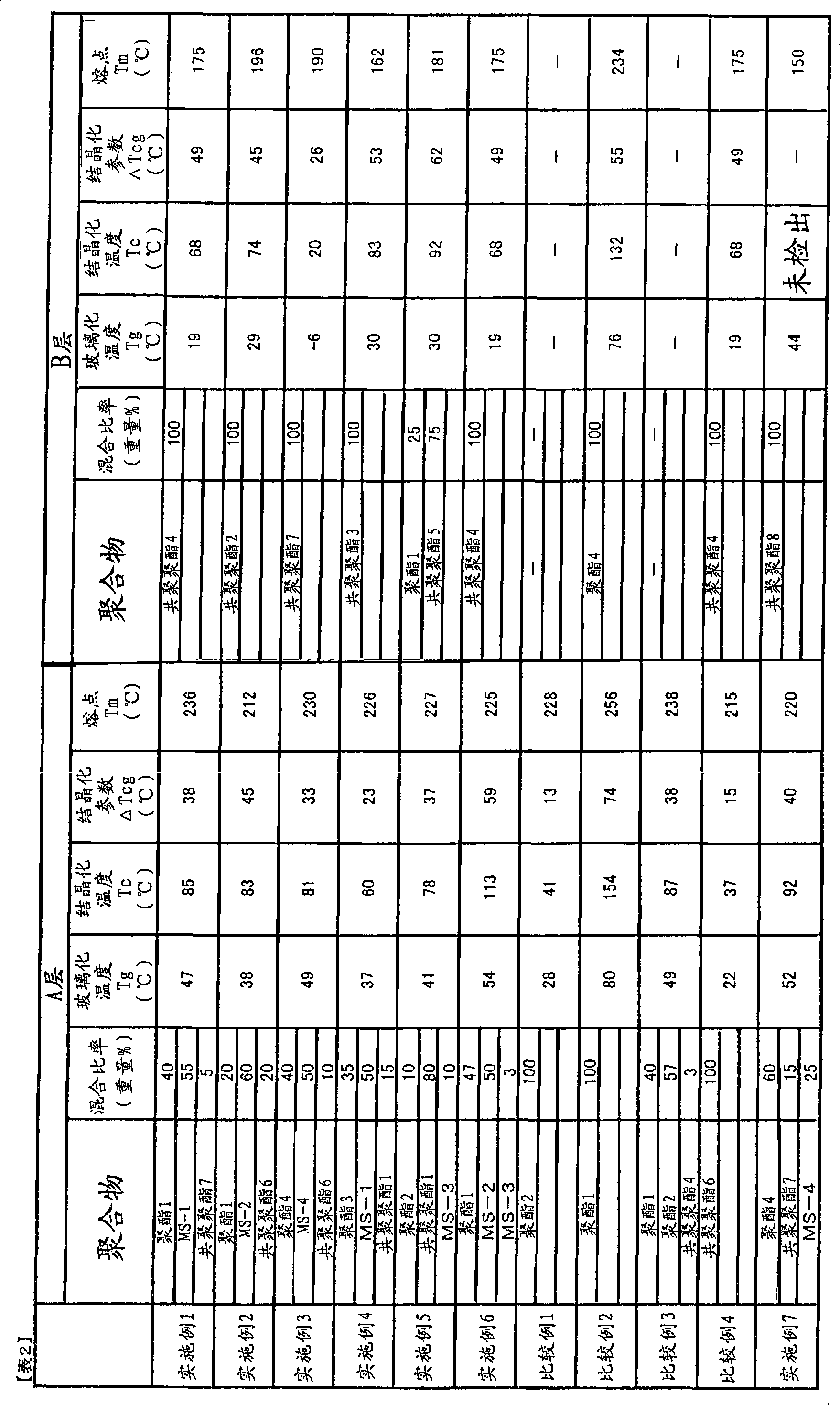

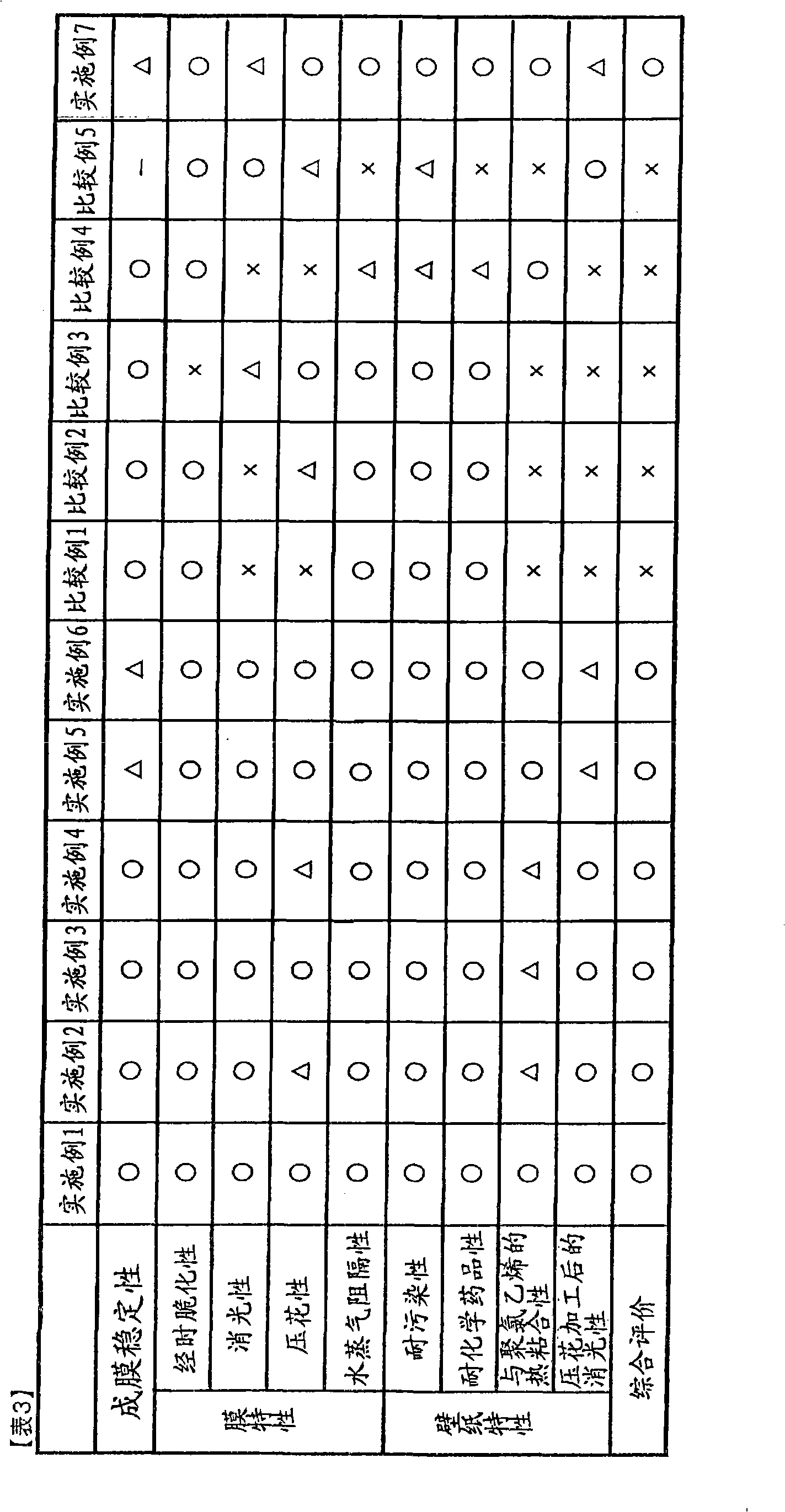

Matte multilayer polyester film

InactiveCN101296797AGood mattingImprove embossing effectSynthetic resin layered productsFloor coveringsPolyesterWater vapor

Disclosed is a matte multilayer polyester film excellent in contamination resistance, chemical resistance, formability, heat bondability, delustering properties, embossing properties, water vapor barrier properties and the like, which is particularly suitable for wallpapers. Specifically disclosed is a matte multilayer polyester film having at least a two-layer structure of A / B. The polyester of layer A is composed of a composition containing 60-95% by weight of a polyester (a) and 5-40% by weight of an incompatible resin (b), while having a glass transition temperature TgA of 30-70 DEG C. The polyester of layer B is mainly composed of a copolymerized polyester having a melting point TmB of 120-210 DEG C. The degree of surface glossiness of the layer A is less than 50%.

Owner:TORAY IND INC

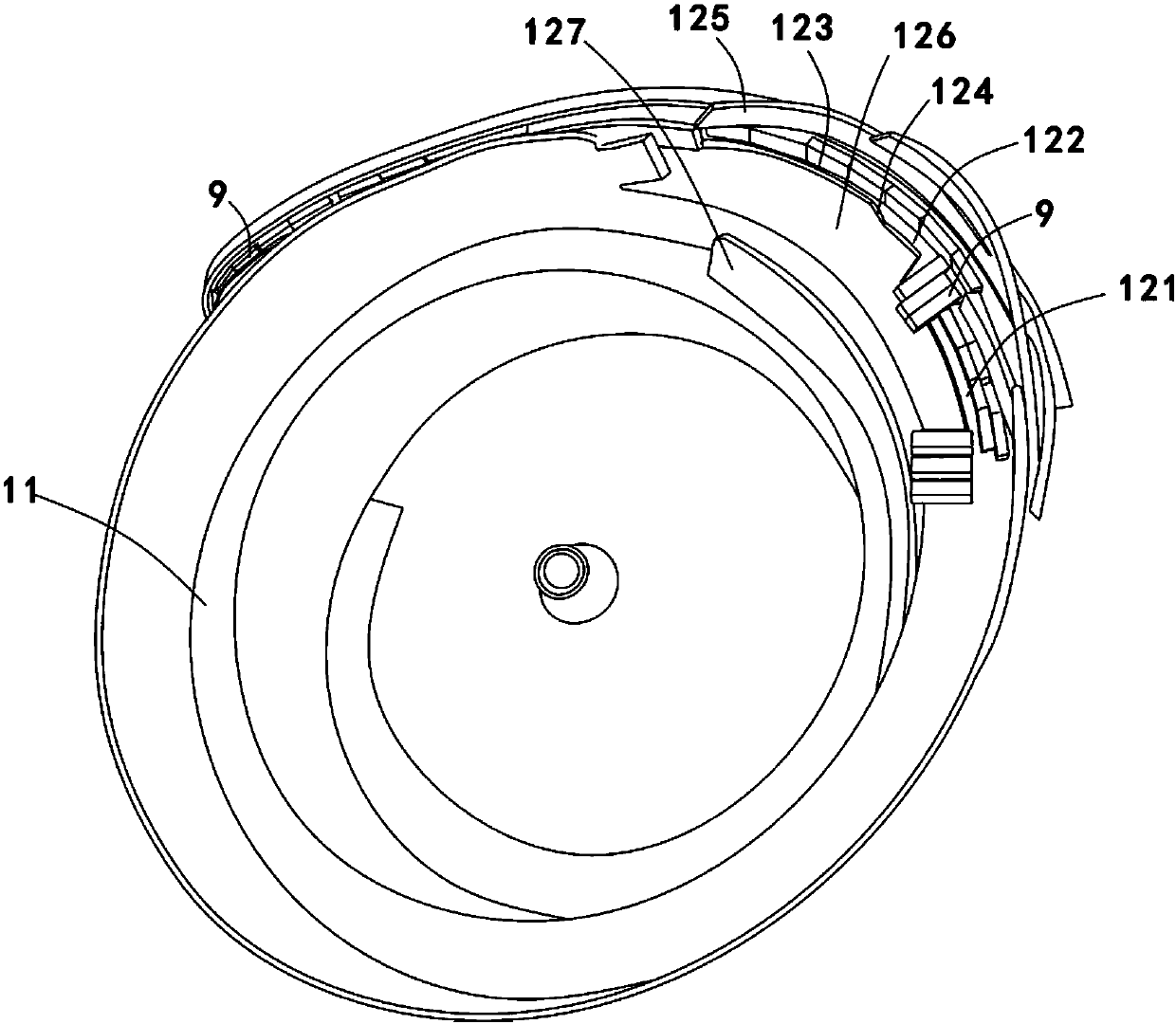

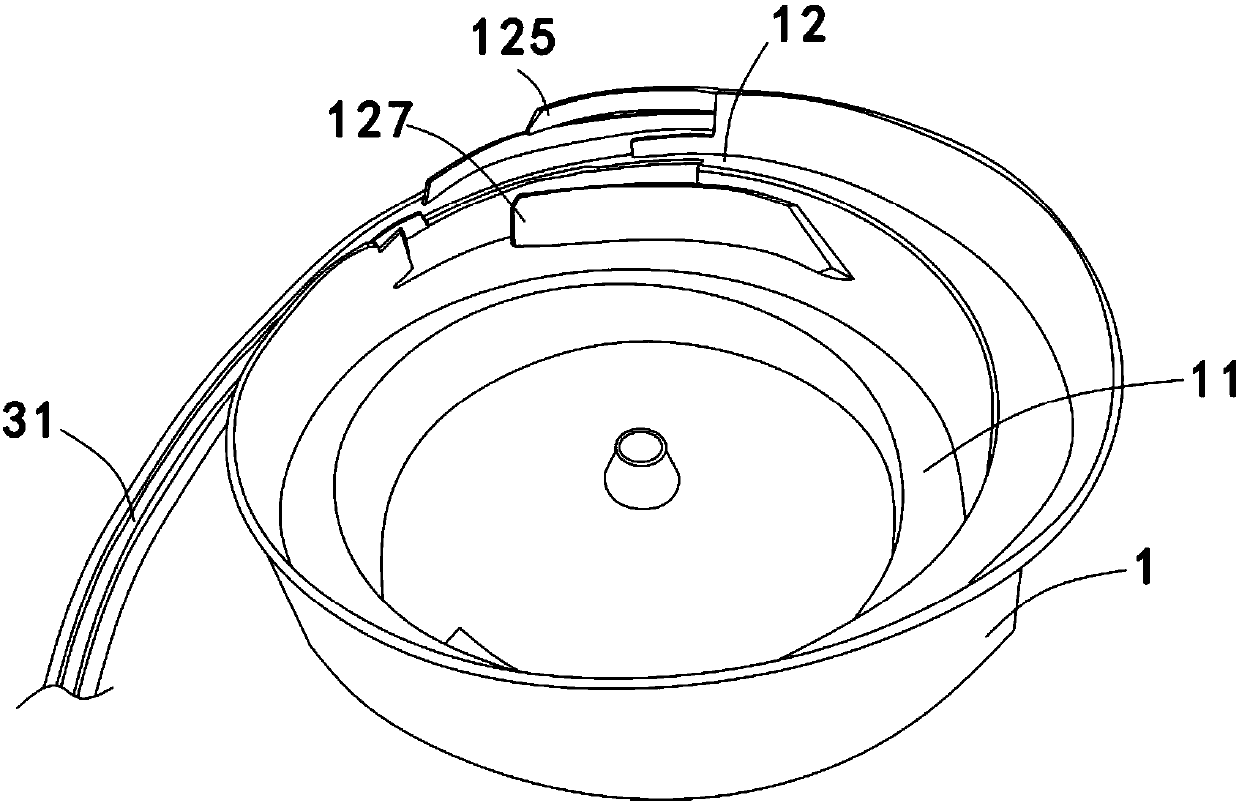

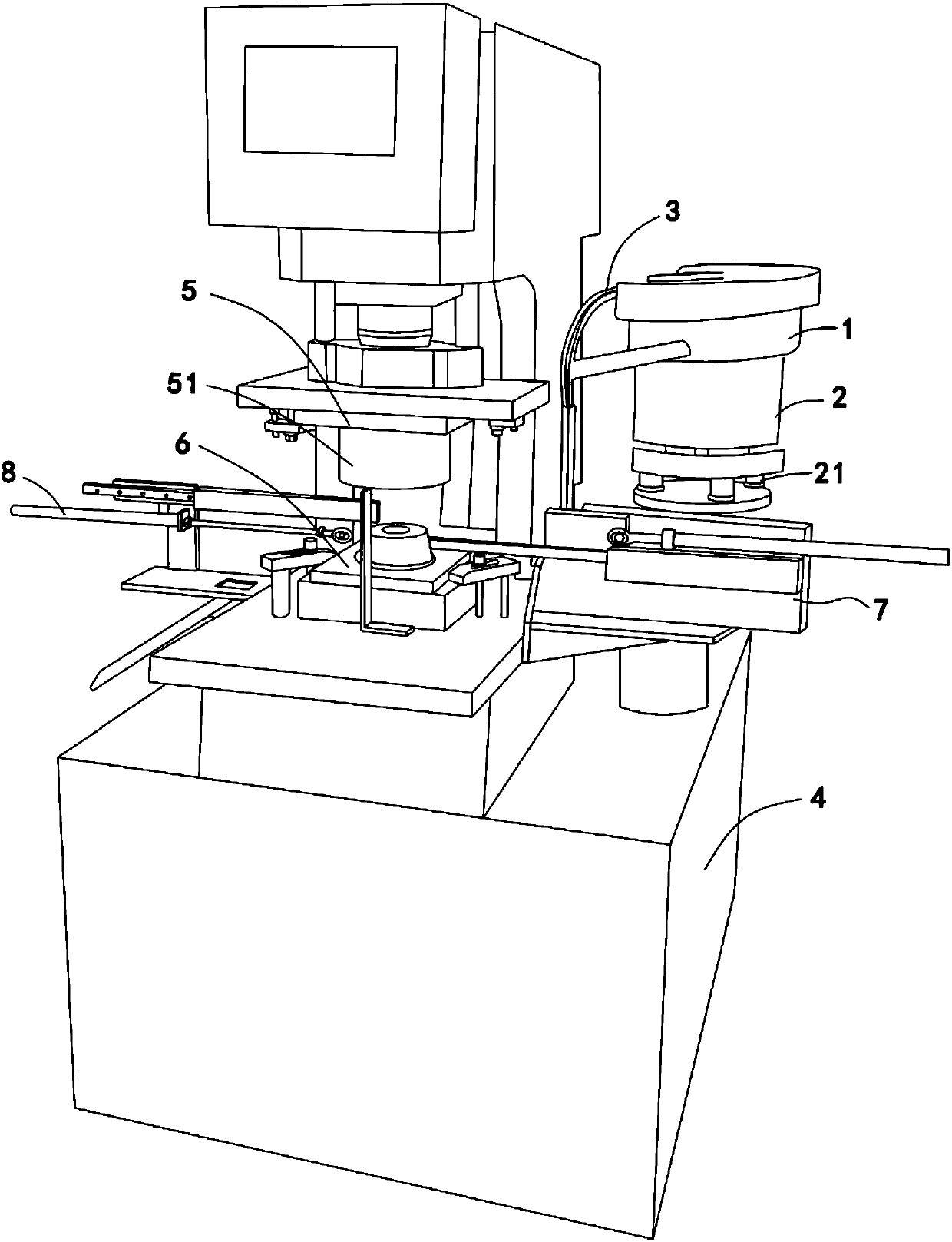

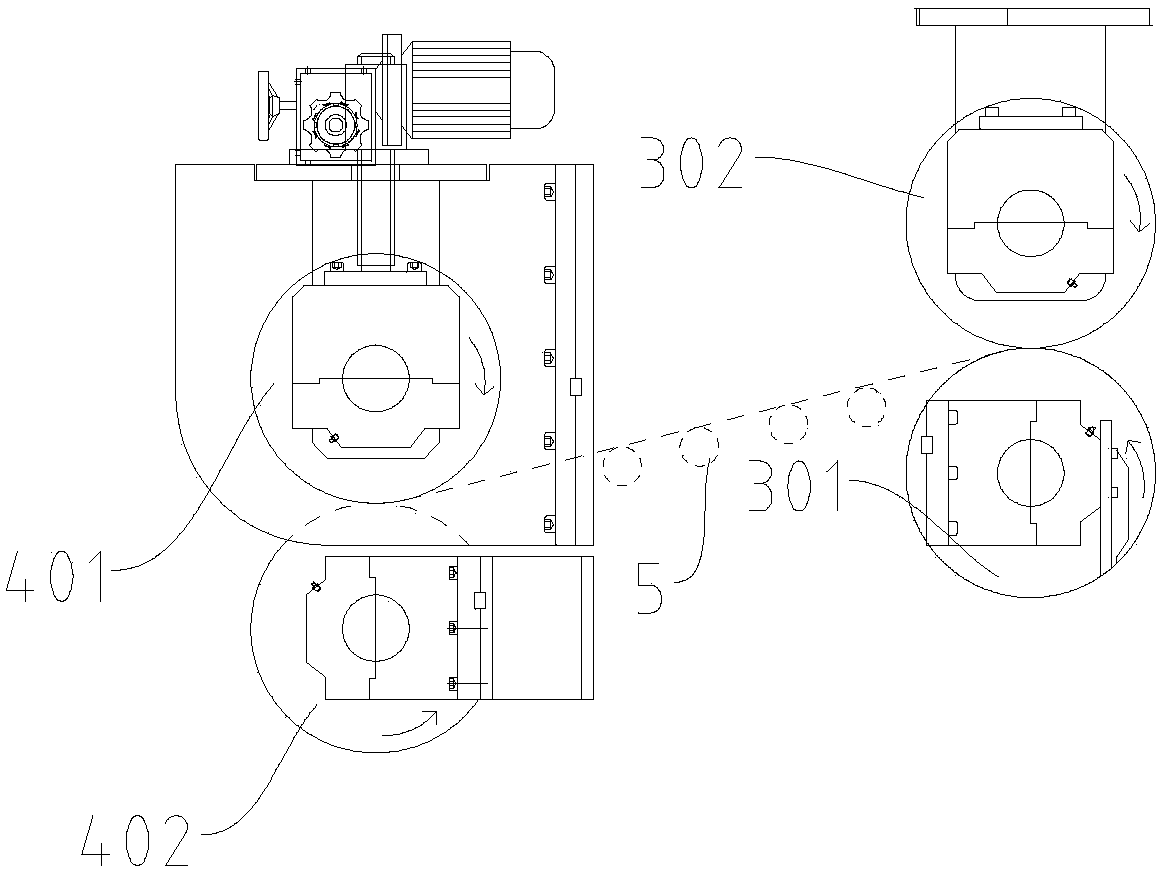

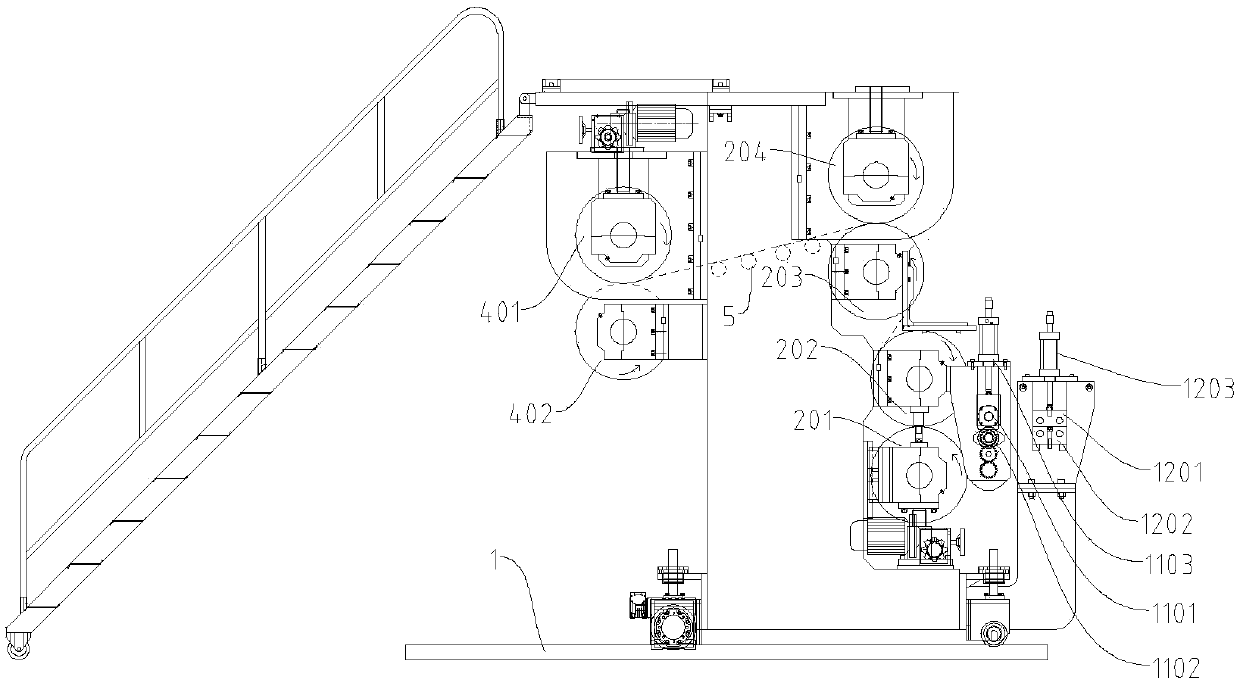

Vibrating feeding device, embossing equipment for chopsticks and production method

The invention discloses a vibrating feeding device which comprises a material storing barrel, a vibrating device and a discharging channel. A first material conveying channel ascending spirally from the bottom and a material tidying channel are formed in the inner wall of the material storing barrel. The material tidying channel comprises a first material tidying section, a third material tidyingsection and a second material tidying section. Spaces, used for containing materials to be processed, of the first material tidying section, the second material tidying section and the third materialtidying section are reduced gradually. The invention further discloses embossing equipment for the chopsticks. The embossing equipment comprises a rack, a pressing mechanism and a pressing die assembly. The pressing die assembly comprises an ejector rod capable of vertically moving up and down, a vibrating feeding device, a feeding mechanical hand mechanism used for moving the materials horizontally to the position above the ejector rod one by one, and a discharging mechanical hand mechanism used for taking out the materials from the pressing die assembly. The invention further discloses a production method of the embossing equipment. According to the vibrating feeding device, full-automatic embossing treatment is achieved, the materials are fed orderly and stably, the machining efficiencyis higher, the embossing effect is better, the yield is high, uniformity of output products is high, and the labor cost is reduced.

Owner:SUNCHA TECH CO LTD

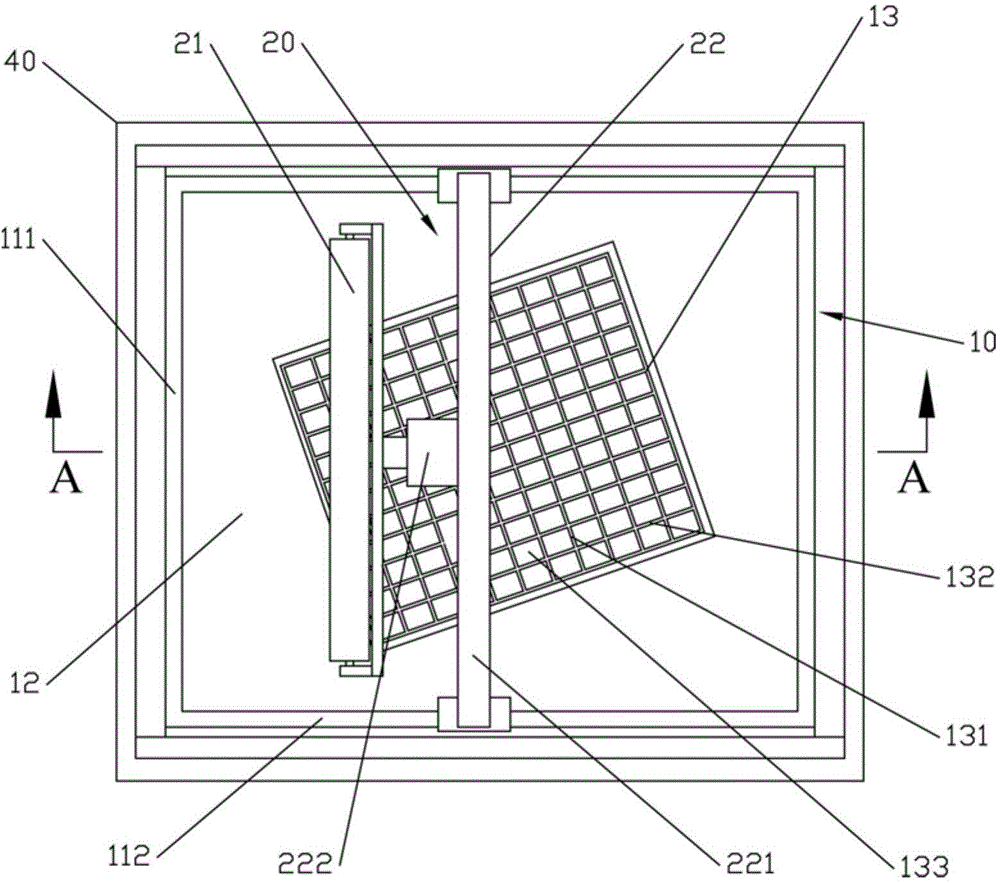

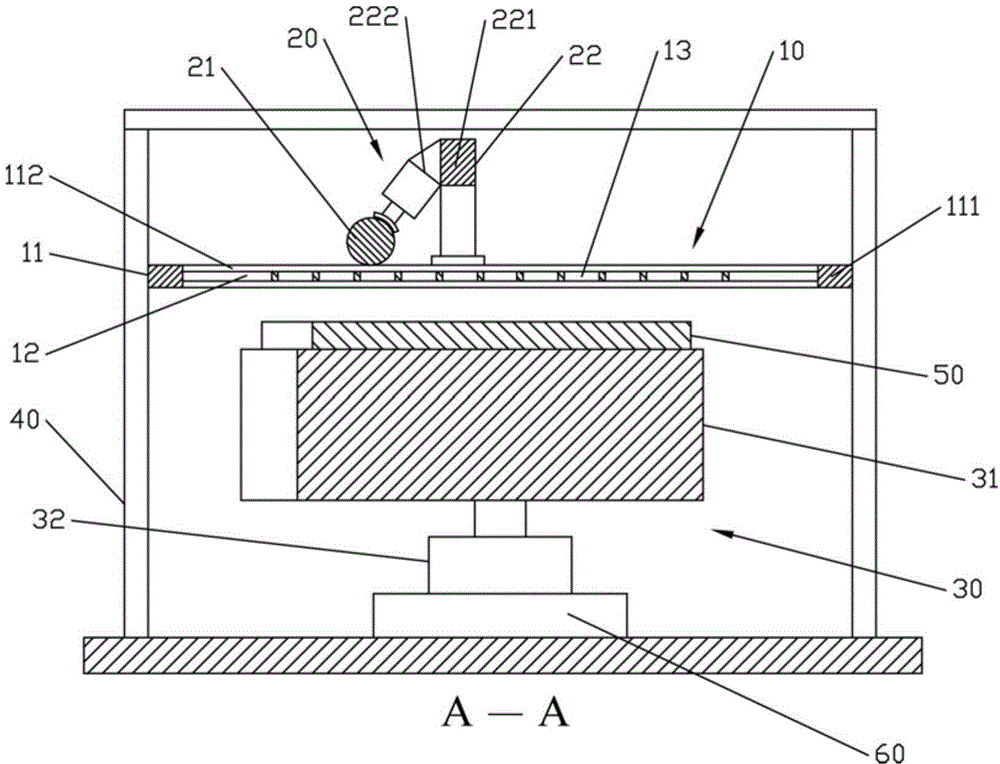

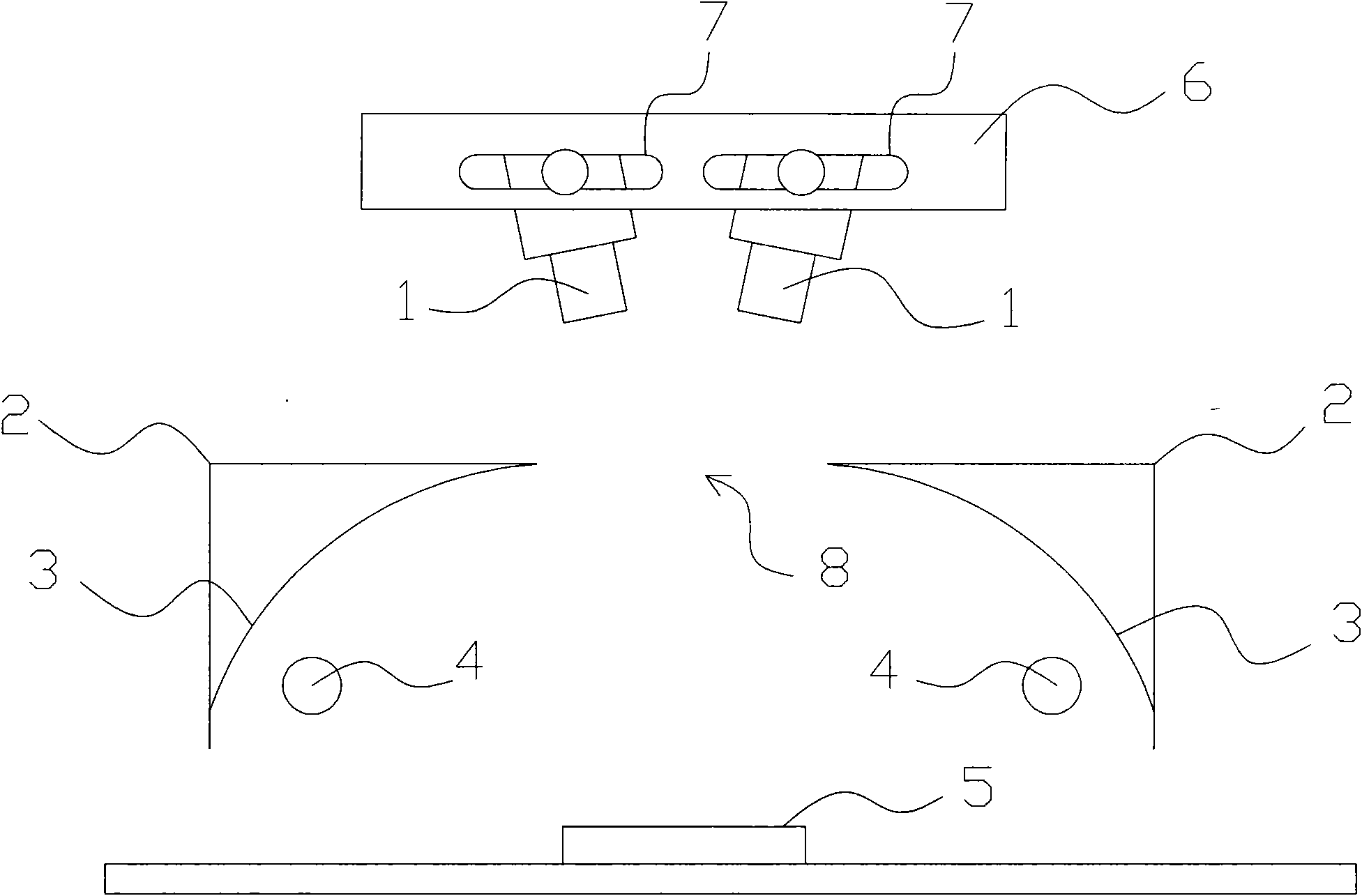

Quality detection device for concave-convex printed product

ActiveCN101614679AImprove embossing effectSolve the problem of bump defectsMaterial analysis by optical meansEngineeringNarrow gap

The invention discloses a quality detection device for a concave-convex printed product, which comprises a camera set, a closed type lamp box and a camera clamping mechanism, wherein the camera set is arranged on the upper part of a printed product to be detected through the camera clamping mechanism; the closed type lamp box is positioned between the camera set and the printed product to be detected, and a narrow gap is reserved in the middle of the lamp box; and the camera set shoots and acquires images of the printed product through the narrow gap. The quality detection device is characterized in that the camera set comprises two cameras which are symmetrically distributed; and the cameras can randomly adjust shooting angles through an adjustment device on the camera clamping mechanism. By adopting the technical scheme, the shot images have good concave-convex effect; shooting are performed by the two cameras in a symmetrical mode to obtain the images with complementary concave-convex effect to further solve the problem of roughness.

Owner:SHANGHAI SPINNING DYEING PRINTING PACKAGING +3

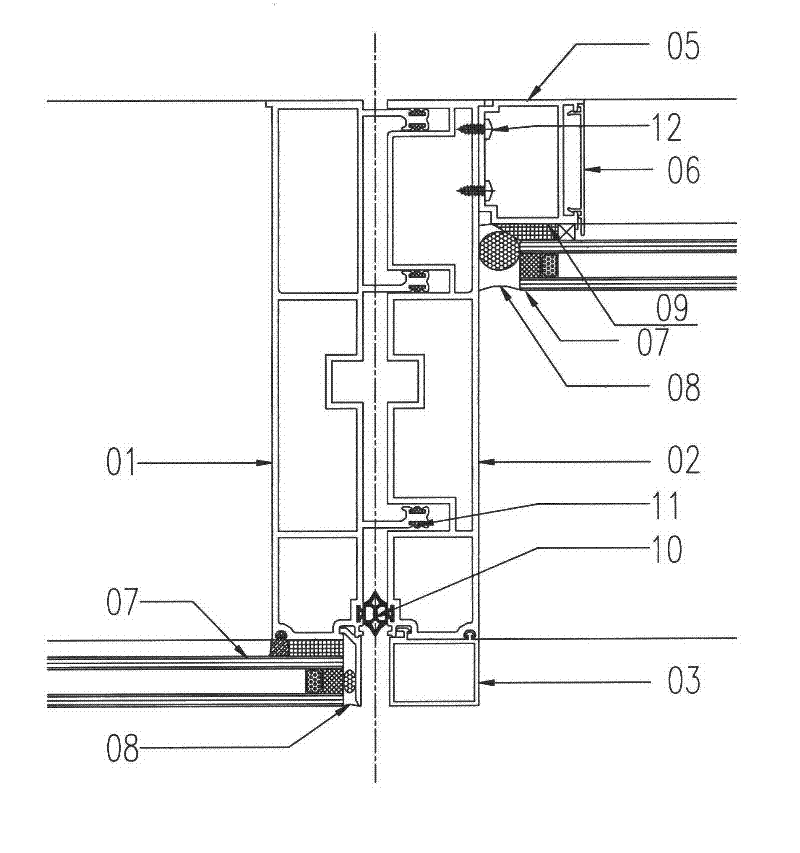

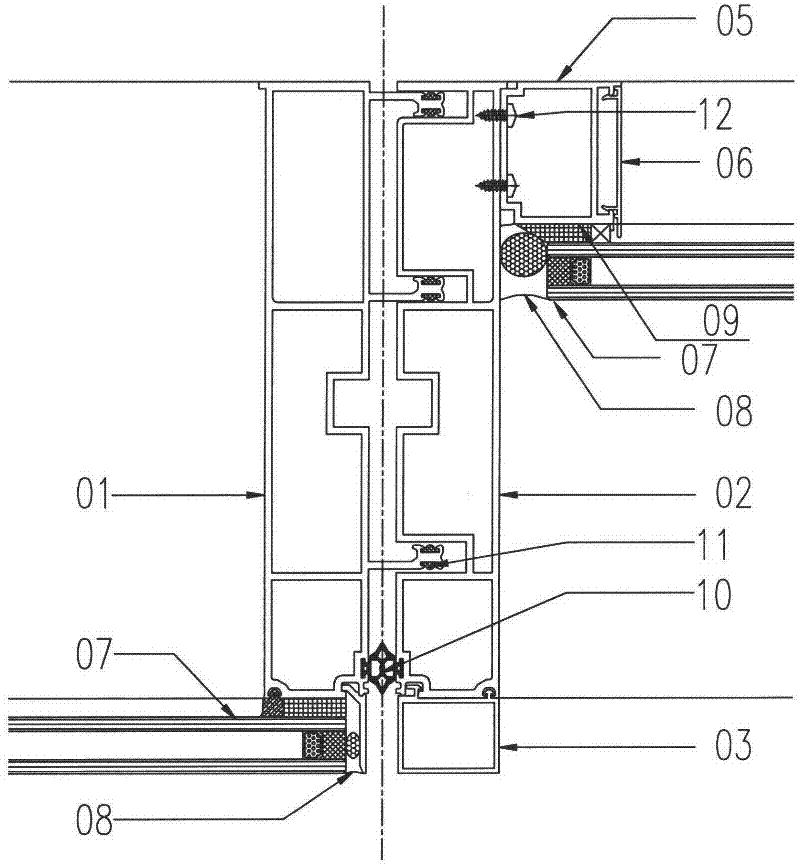

Concave-convex type unit curtain wall system

InactiveCN102392505AImprove embossing effectAnti-wind pressure protection and hardeningWallsEngineeringAir tightness

The invention discloses a concave-convex type unit curtain wall system which comprises a male upright post and a female upright post, wherein an alloy auxiliary frame is fixed on a positioning hole of the male upright post or the female upright post through a self-tapping screw; and hollow glass is placed on the aluminum alloy auxiliary frame, and a sealing glue and a foam rod are arranged between the hollow glass and the male upright post or the female upright post. The curtain wall system is provided with the positioning hole on the male upright post or the female upright post, and the aluminum alloy auxiliary frame is connected with the positioning hole on the male upright post or the female upright post through the self-tapping screw, thereby combining the aluminum alloy auxiliary frame with the male upright post or the female upright post together for forming the characteristics of inlet and outlet positions; the curtain wall system has a great concave-convex effect when the curtain wall system is seen from the front surface, and two plates with the adjacent concave and convex surfaces can adopt fixed glass plates which are connected or open window plates which are connected, thereby protecting and reinforcing wind pressure resistance, water tightness, air tightness and plane displacement coefficient; and the drainage principle and the equal-pressure principle of the curtain wall system are more ingenious, the design is novel and unique, the curtain wall system is aesthetic and elegant, and the whole vertical surface effect is more stereoscopic.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

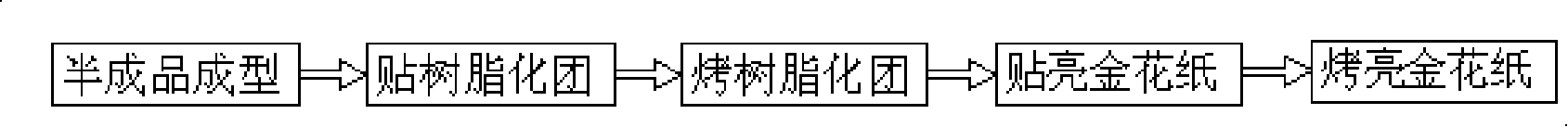

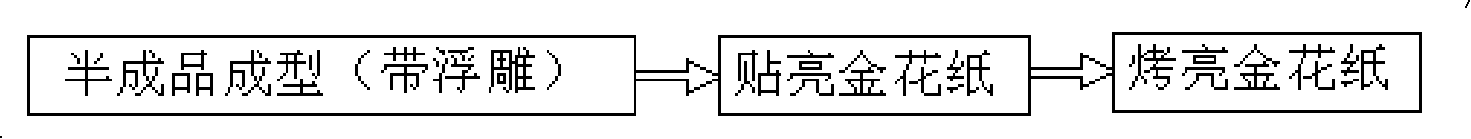

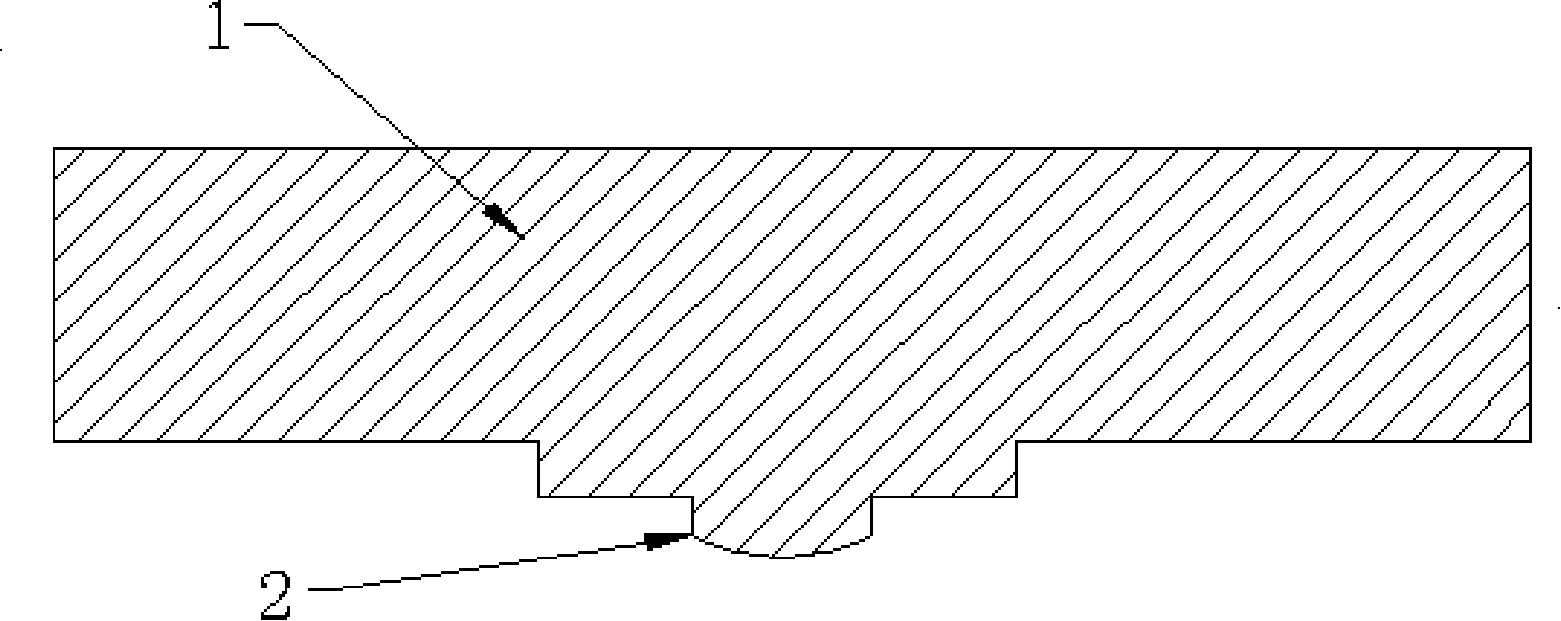

Special-purpose die for glass, bright gold embossing technique and products thereof

InactiveCN101239776ALow costSimple processDecorative surface effectsOrnamental structuresWork in processMetallurgy

Owner:SICHUAN YIBIN WULIANGYE GROUP

Embossed silica gel cloth forming method

The invention discloses an embossed silica gel cloth forming method. The method comprises the following steps that 1, embossing paper or a composite material with lines serves as an embossing material strip; 2, silica gel is rolled on the embossing material strip, and meanwhile cloth is attached to the silica gel face; 3, a product manufactured in the step 2 is fed into a baking channel to be subjected to baking and vulcanization for 4-20 minutes at the temperature of 100 DEG C-160 DEG C, and silica gel is solidified and formed; 4, the product baked and vulcanized in the step 3 is taken out, the embossing material strip is stripped, and the embossed silica gel cloth with the lines is obtained. The composite material with the lines comprises synthetic paper with the lines, and a high-temperature-resistant thin film material with the lines or a rolled material with the embossed surface is obtained. The step 2 further comprises the substeps of adding 2-30% of silica gel foaming agent into silica gel before rolling operation, and the foamed silica gel cloth is prepared. Compared with the prior art, the method has the beneficial effects of reducing the production cost, and being convenient to operate, good in embossing effect and the like.

Owner:薛志勇

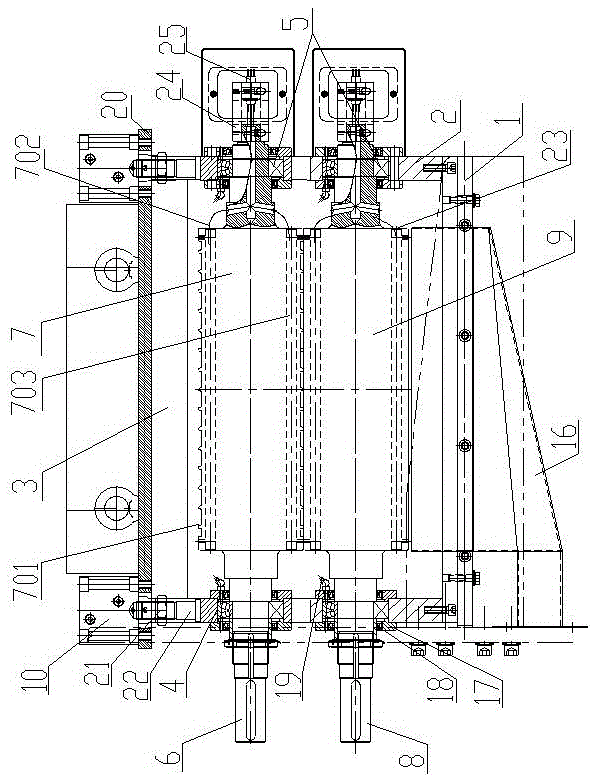

Cotton core embossing apparatus for diaper production line and embossing method thereof

ActiveCN105455967AImprove embossing effectWide applicabilityAbsorbent padsBaby linensProduction lineEngineering

The invention relates to a cotton core embossing apparatus for a diaper production line and an embossing method thereof, better embossing effects can be achieved through the embossing apparatus and the embossing method, and the embossing apparatus and the embossing method can be more widely applied. A sliding block is arranged in a groove of each of two cutter rest plates; the two sliding blocks are respectively provided with a through hole; an upper roll shaft is mounted between the two through holes through two bearings; and an embossing roll is arranged on the upper roll shaft. The two cutter rest plates are respectively provided with a shaft hole; a lower roll shaft is mounted between the two shaft holes through two bearings; and a heating roll is arranged on the lower roll shaft and under the embossing roll. Two cylinders which are vertically and downwardly arranged are respectively arranged on the two sides of the upper end surface of an upper fixing board at the upper portion, and the lower ends of piston rods of the two cylinders are respectively and fixedly connected to the upper ends of the two sliding blocks. The embossing apparatus is advantageous in that: 1, the cotton core embossing apparatus for the diaper production line compacts cotton cores through a hot-pressing manner, then patterns are formed on the surfaces of the cotton cores, and therefore better cotton core embossing effects can be achieved; 2, the cotton core embossing apparatus for the diaper production line can emboss the cotton cores with different thicknesses, so that the embossing apparatus can be more widely applied.

Owner:ZHEJIANG YONGCHUANG MACHINERY

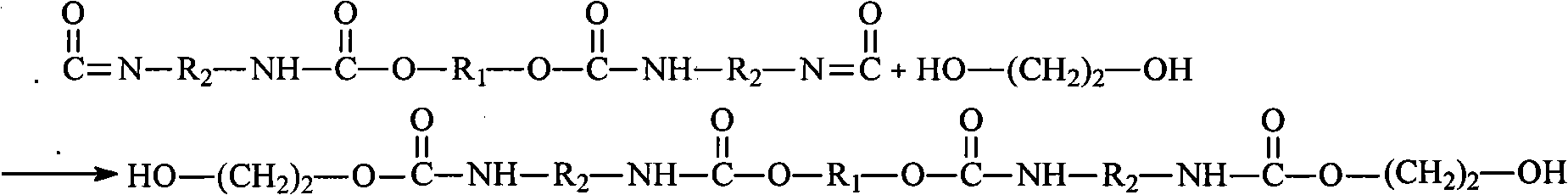

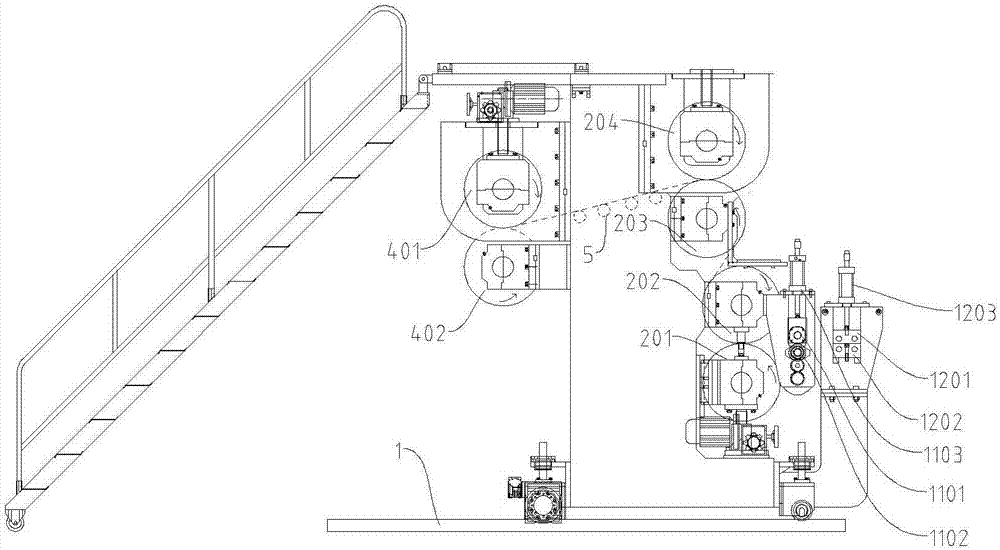

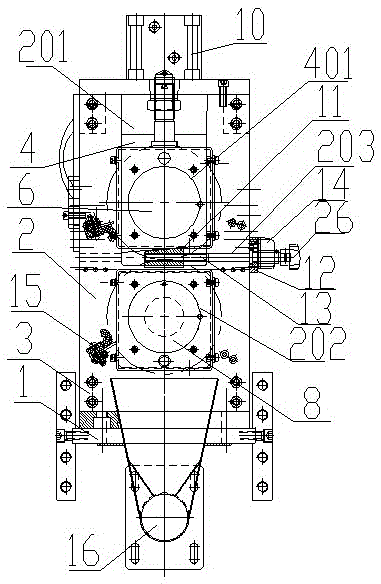

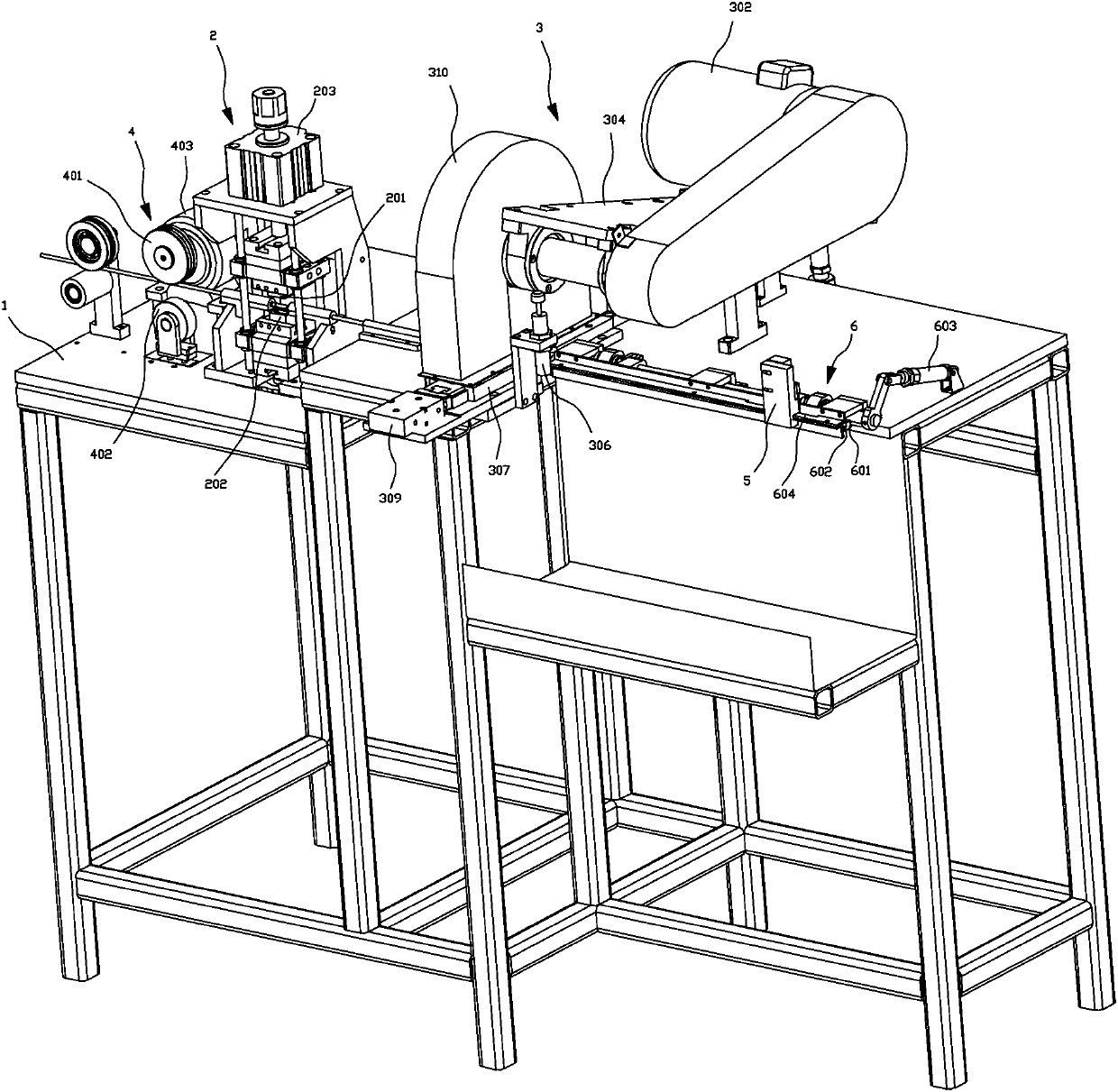

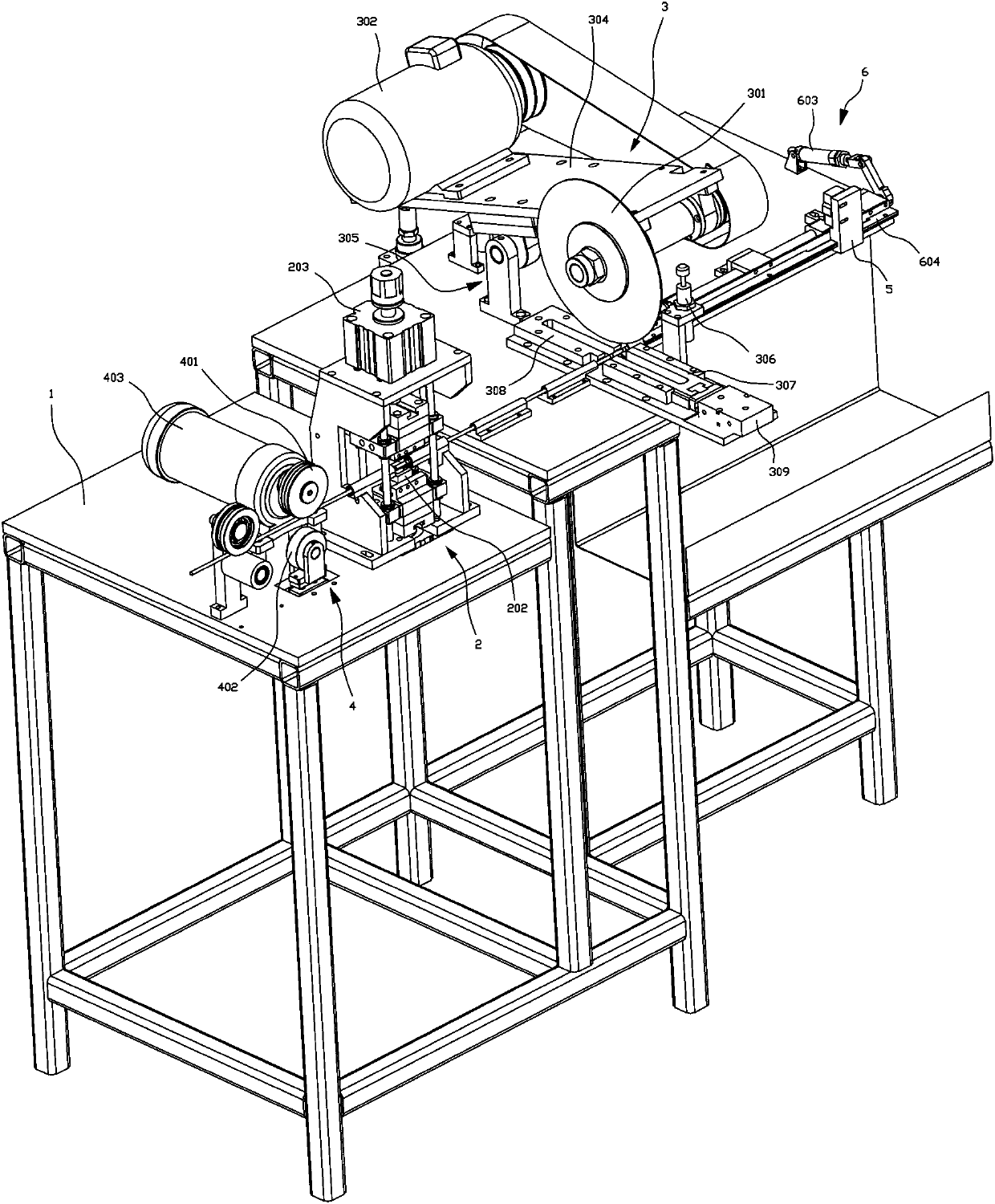

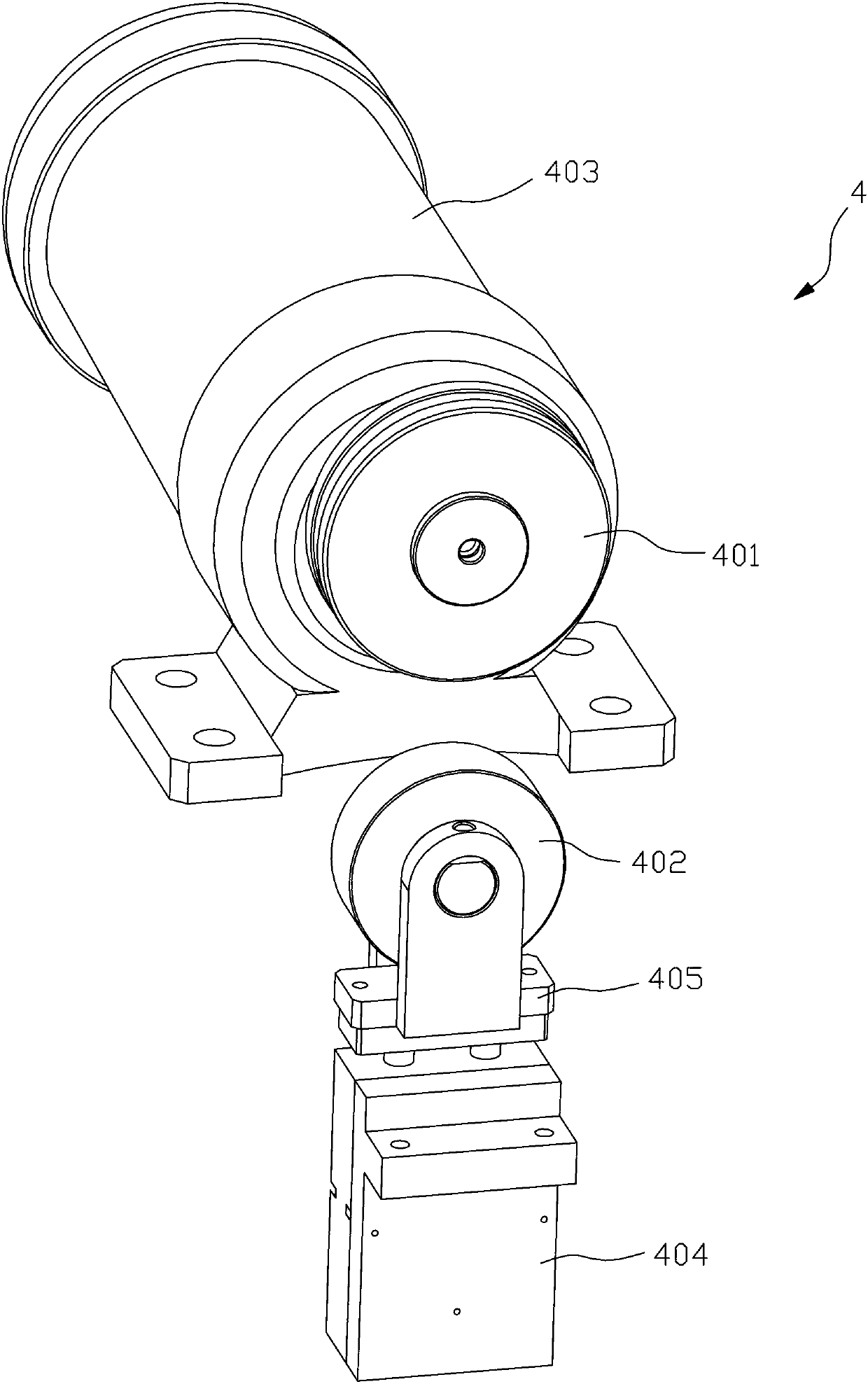

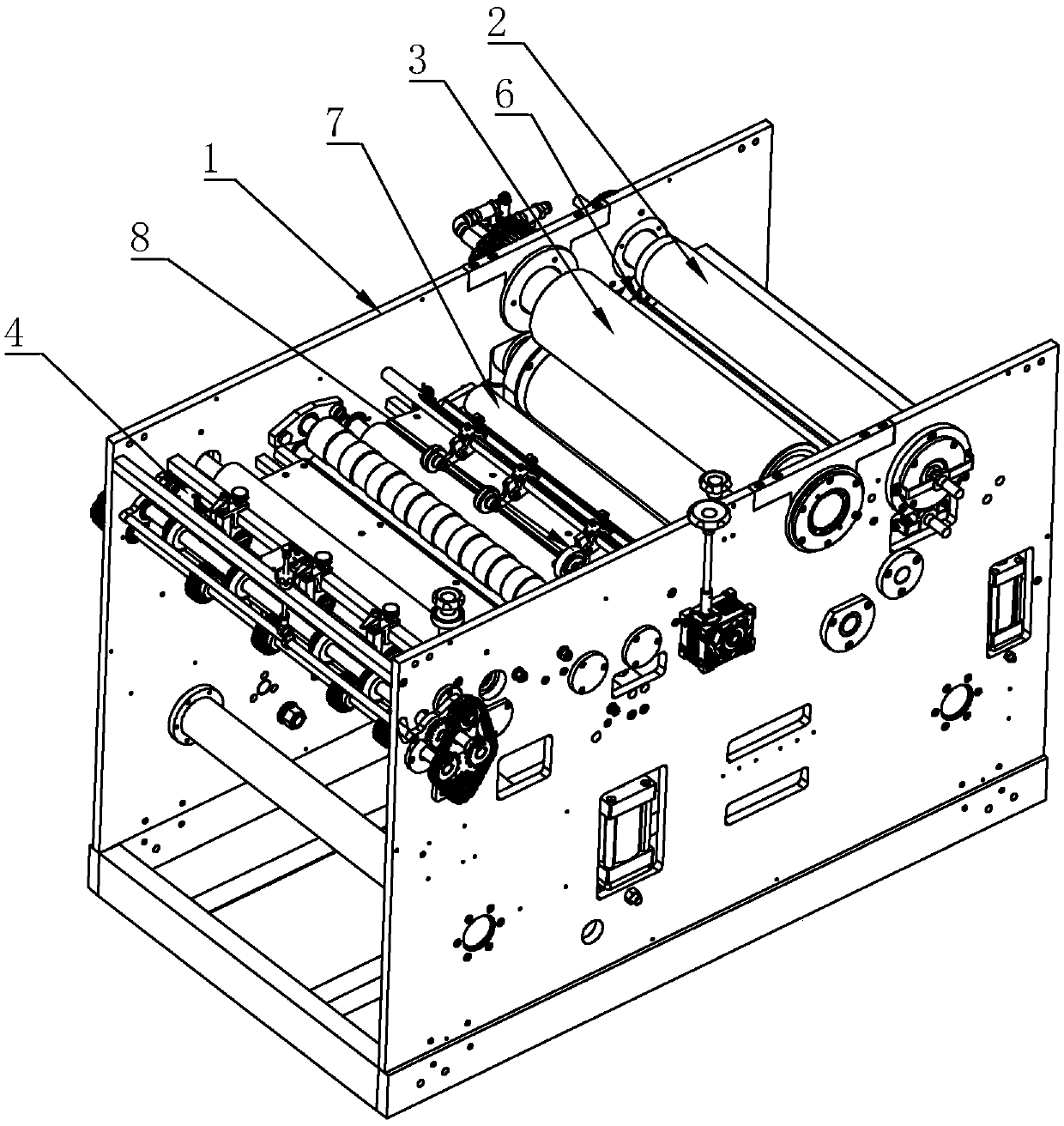

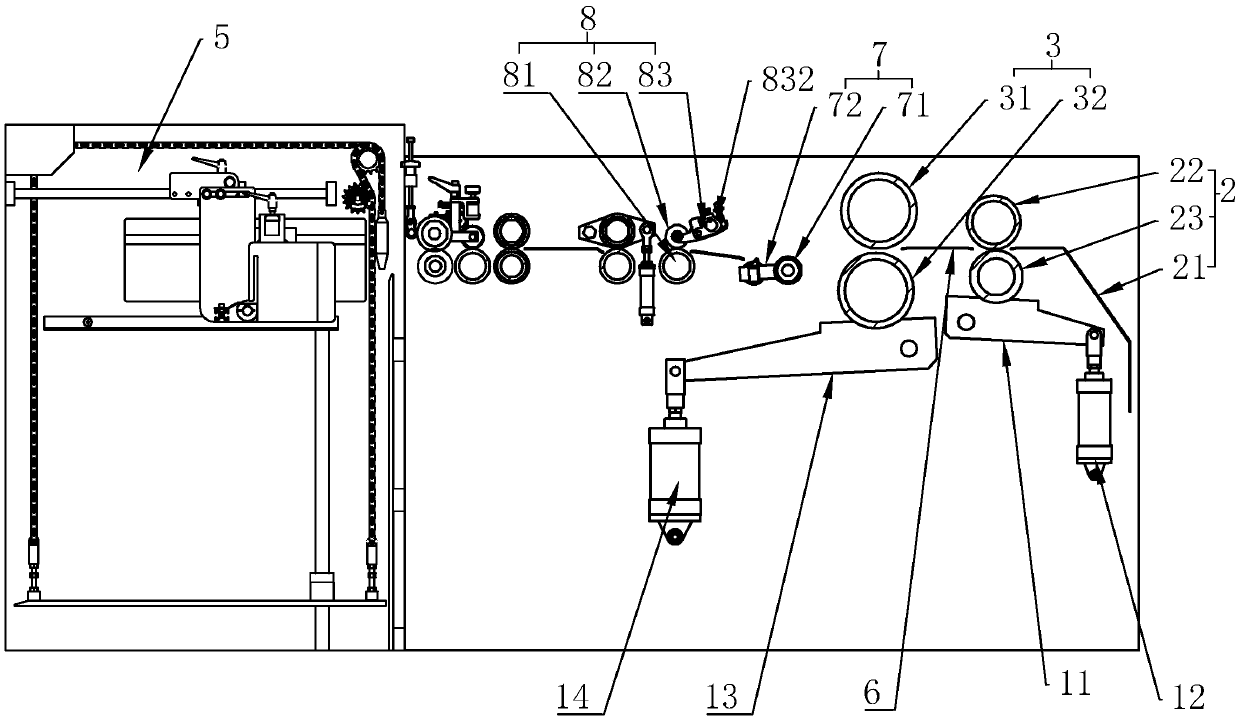

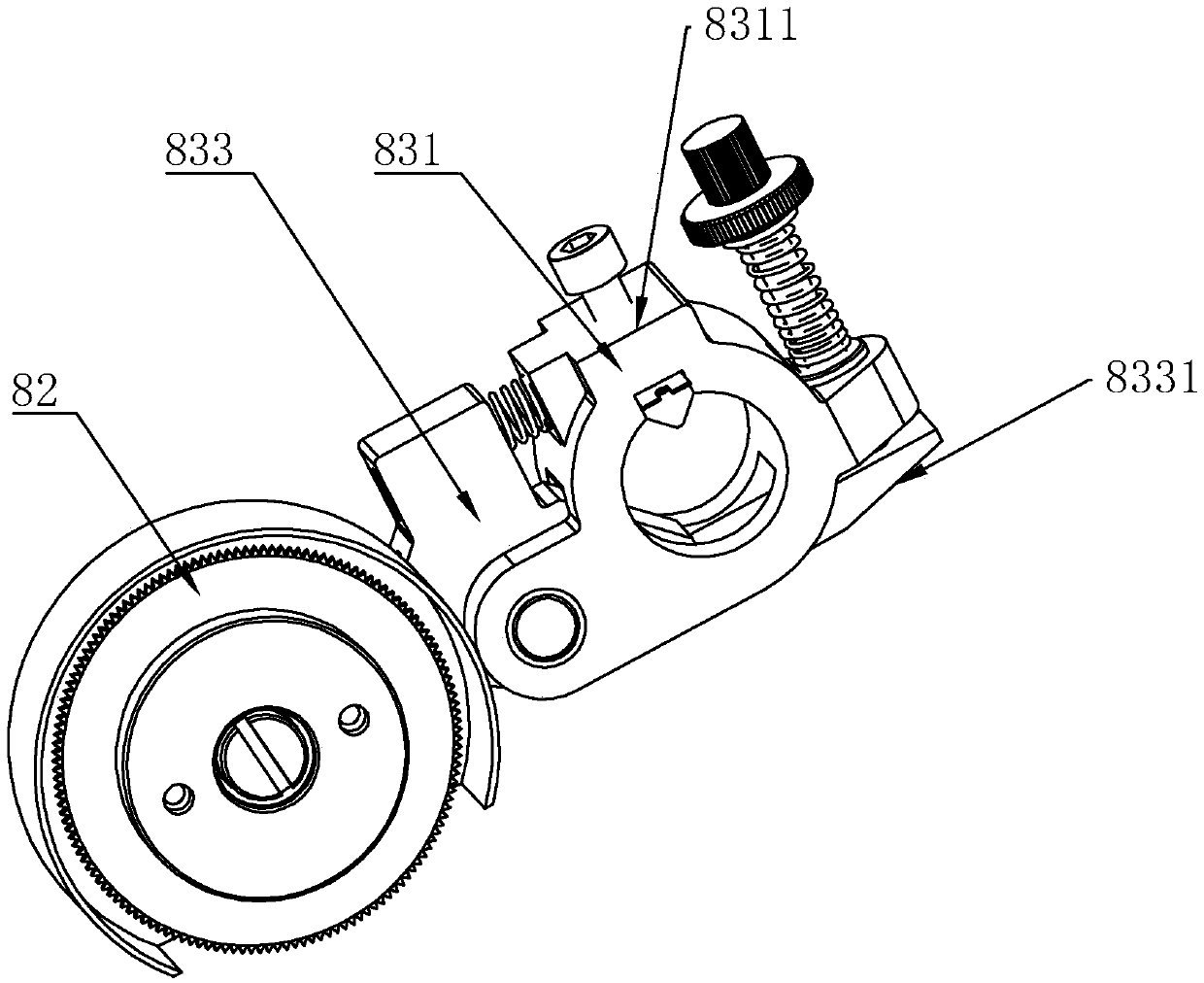

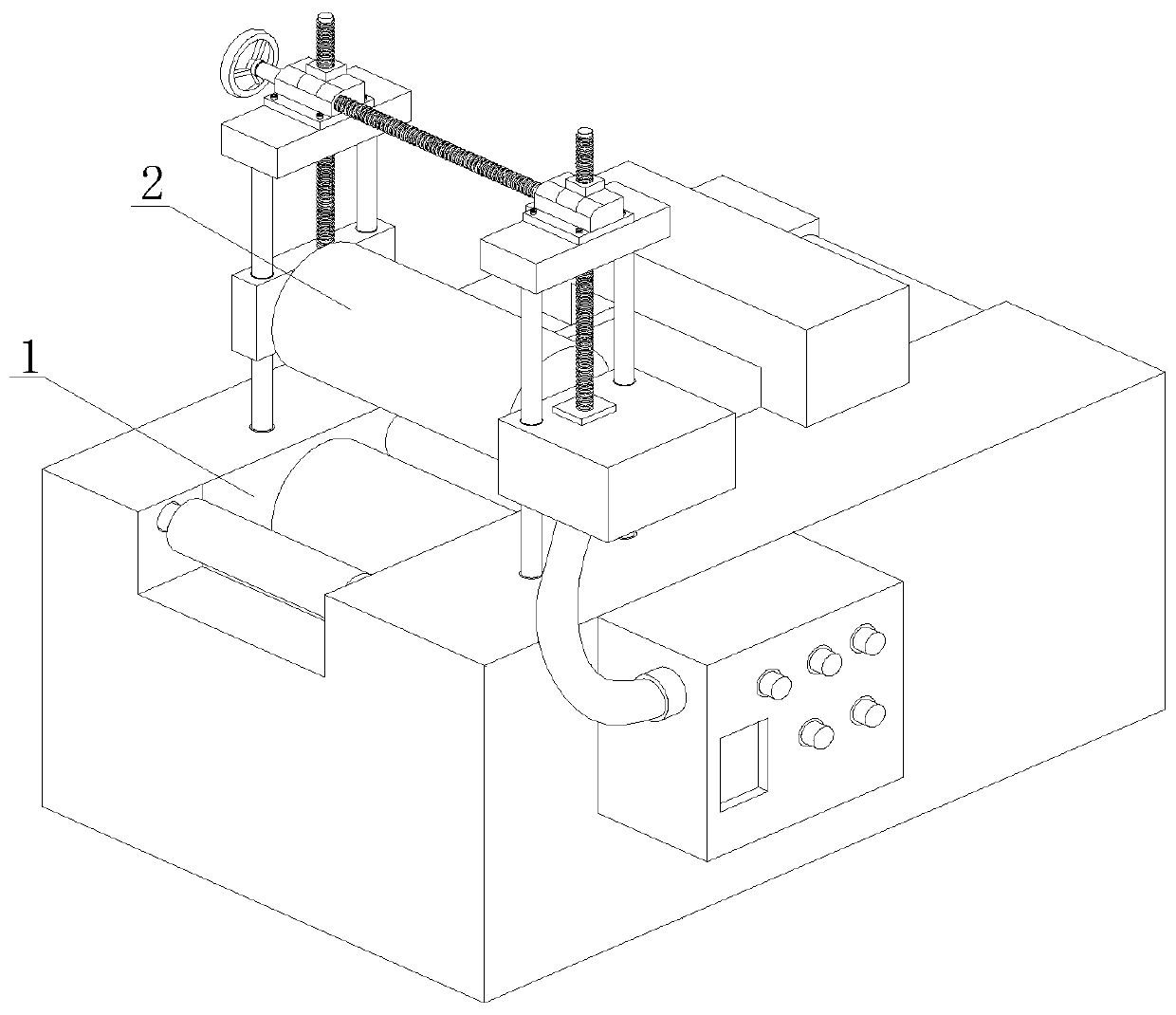

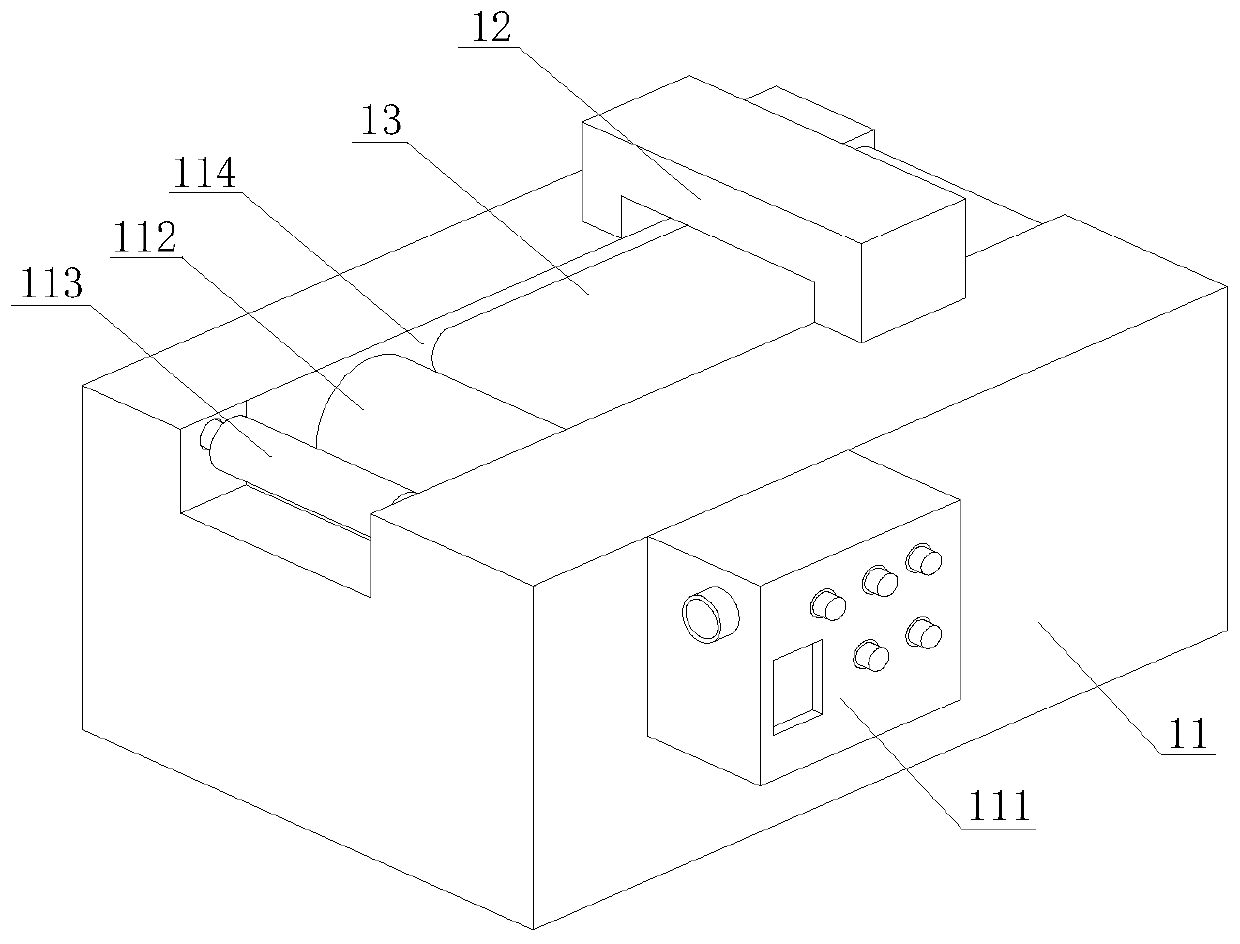

Hose embossing cutting-off machine

The invention discloses a hose embossing cutting-off machine. The hose embossing cutting-off machine comprises a worktable (1) which is horizontally and sequentially provided with a feeding device (4), an embossing device (2) and a cutting-off device (3), wherein electric control parts on the feeding device (4), the embossing device (2) and the cutting-off device (3) are all electrically connected with a same main controller; the embossing device (2) comprises an upper mould (201) and a lower mould (202), which are matched with each other and are used for embossing and molding a hose; the hose is located between the upper mould (201) and the lower mould (202); the two ends of the upper mould (201) and the lower mould (202), which extend along the direction of the hose, are respectively provided with embossing parts (205) which are matched with each other and are used for pressing two adjacent sections of threads; and the cutting-off device (3) comprises a cutting wheel capable of cutting off the hose from the two adjacent sections of threads. The hose embossing cutting-off machine disclosed by the invention is high in hose machining efficiency; and meanwhile, the labor cost is low.

Owner:NINGBO AUTO CABLE CONTROLS

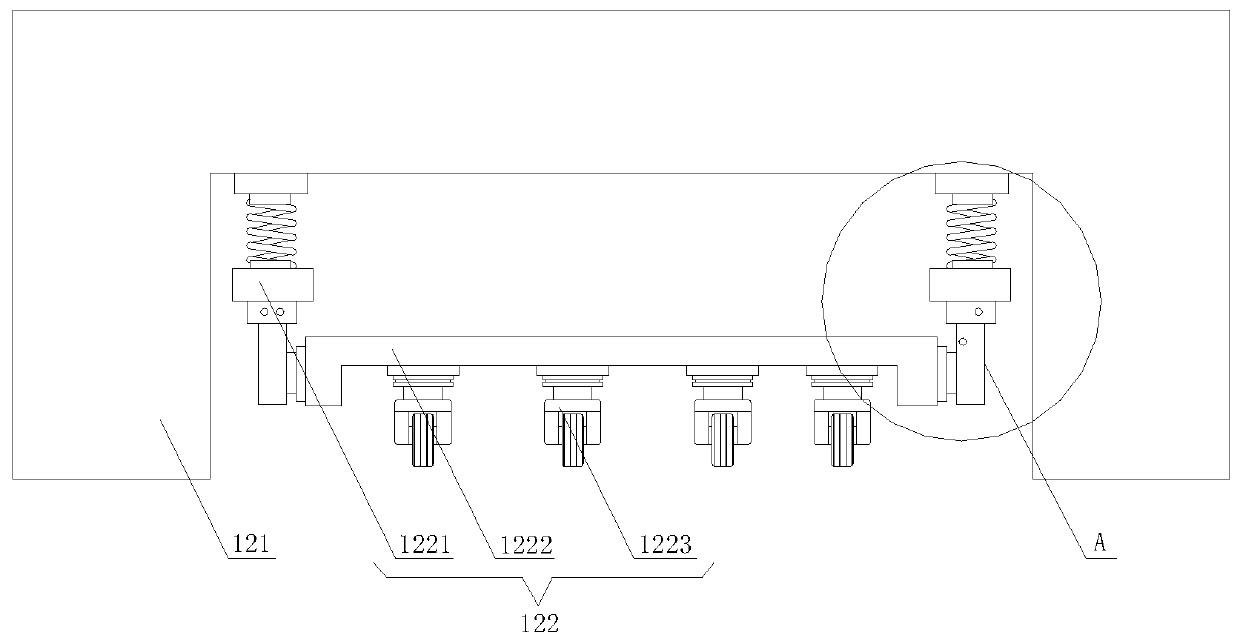

Multi-station button embossing device

The invention provides a multi-station button embossing device. The device comprises a base plate, supporting parts are fixed to the left side and the right side of the base plate correspondingly, supporting shafts are rotatably connected to the left side and the right side of the surface of the base plate, the bottoms and the tops of the supporting shafts are each of a thread structure, the supporting shafts are located on the inner sides of the supporting parts, shaft sleeves are rotatably connected to the contact face ends of the supporting shafts and the base plate, cylinders are rotatably connected to the upper ends of the supporting shafts, each cylinder is provided with a vertically through round through hole, the inner walls of the round through holes are of thread structures, annular grooves are formed in the side faces of the cylinders, inserting parts are arranged on the left side and the right side of a fixed table plate in a protruding manner, make contact with the annular grooves and enable the fixed table plate to be fixed to the cylinders, a moving assembly is arranged at the lower end of the fixed table plate, an embossing assembly is connected to the lower end of the moving assembly, and an adjustable button fixing assembly is fixed to the upper end of the middle of the base plate.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

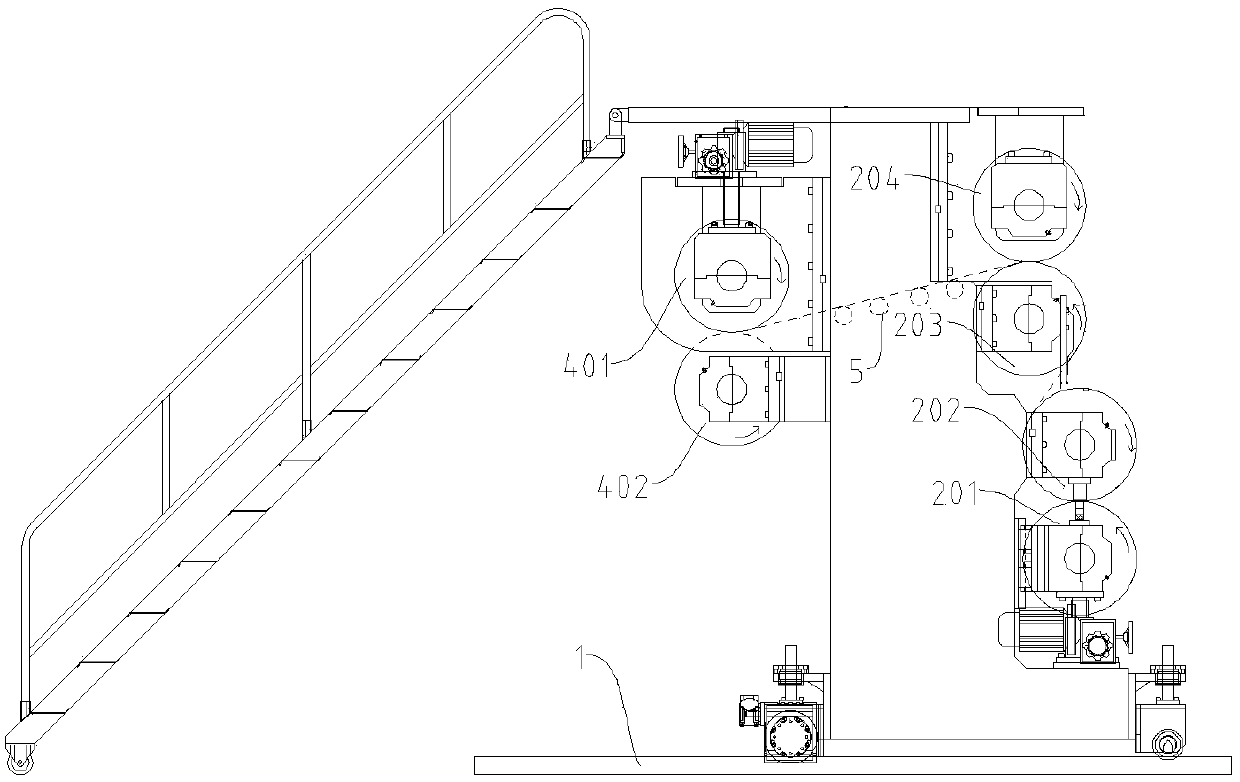

Calender, production line for foamed floor, and once-forming process for producing foamed floor

InactiveUS20190016024A1Improve embossing effectReduce the temperatureDomestic articlesFlooringProduction lineEngineering

A calender, comprising a base and a set of calendering rollers arranged on the base, wherein, the set of calendering rollers comprises a set of primary calendering rollers and a set of embossing rollers used for embossing a material to be processed; the set of primary calendering rollers and the set of embossing rollers are spaced apart for a distance to allow the material to be cooled before entering the set of embossing rollers from the set of primary calendering rollers. The calender can realize a better embossing effect, and integration production can be realized due to the use of the calender in a production of a foamed floor.

Owner:QINGDAO SANYI PLASTIC MACHINERY

Ink composition for ink jet recording and method of producing lithographic printing plate using the same

InactiveCN1715343AQuality improvementImprove embossing effectDuplicating/marking methodsPhotomechanical apparatusRadiation exposurePlanographic printing

An ink composition for inkjet recording, capable of being cured upon radiation exposure, is provided and contains: a coloring material; and a polymerizing compound. The polymerizing compound is a specific alpha-heteromethacryl compound. A method of producing lithographic printing plate is also provided and includes: ejecting an ink composition for inkjet recording onto a hydrophilic substrate, the ink composition containing a coloring material and a polymerizing compound; and irradiating the ink composition on the hydrophilic substrate to cure the ink composition, so as to form an image.

Owner:FUJIFILM CORP

Embossing splitting machine

PendingCN109650142AImprove deformationIncrease temperatureMechanical working/deformationArticle deliveryPulp and paper industry

The invention discloses an embossing splitting machine. The embossing splitting machine comprises a machine frame, a preheating device, an embossing device, a splitting device and a paper receiving device, wherein the preheating device, the embossing device, the splitting device and the paper receiving device are arranged on the machine frame in sequence; paper enters the preheating device, then,enters the splitting device after being embossed by the embossing device, and is received by the paper receiving device; a gap bridge plate is arranged between the preheating device and the embossingdevice and has the heating function; and the paper between the preheating device and the embossing device is subjected to secondary heating through the gap bridge plate. According to the embossing splitting machine, by arranging the gap bridge plate, the preheated paper can be further heated conveniently, and thus, the embossing device can conduct embossing operation better.

Owner:温州光明印刷机械有限公司

Calender, foaming floor production line and one-time forming production technology

PendingCN107738394AImprove environmental performanceReduce pollutionFlat articlesProduction linePulp and paper industry

A calender comprises a machine base and calender roller groups arrayed on the machine base. The calender is characterized in that each calender roller group comprises a main calender roller group andan embossing roller group for embossing to-be-machined materials; each main calender roller group and the corresponding embossing roller group are spaced at a certain distance so that the materials can be cooled before entering another roller group form one roller group. The calender can realize the better embossing effect. The calender is used for production of a foaming floor so that integratedproduction of the foaming floor can be realized.

Owner:QINGDAO SANYI PLASTIC MACHINERY

Plate embossing machine

PendingCN110712461AOperational securityLabor savingEmbossing decorationsEngineeringMechanical engineering

The invention discloses a plate embossing machine. The plate embossing machine comprises a supporting mechanism and an embossing mechanism. The embossing mechanism is fixedly mounted on the supportingmechanism. By arranging a conveying belt on a supporting box seat, the embossing machine needs no manual plate delivery when compared with a traditional embossing machine, operation is safer, and labor force is reduced; by fixedly arranging a plate fixing assembly above the conveying belt and arranging reset devices, a roller fixing rod and rollers on the plate fixing assembly, plates can be fixed during plate conveying, conveying is not affected, and the embossing effect is improved; and by arranging a height adjusting assembly on the embossing mechanism and connecting the height adjusting assembly to an embossing roller assembly, the distance between a main embossing roller and an auxiliary embossing roller can be adjusted through the height adjusting assembly, the embossing machine canbe used for embossing plates with different thicknesses, and the plate embossing machine is simple and practical.

Owner:HUNAN PROVINCE HUAIHUA CITY HONGHUA ELECTRONICS SCI & TECH

Preparing method of acrylate modified waterborne polyurethane emulsion for synthetic leather

InactiveCN104928943AImprove cold resistanceImprove water resistanceTextiles and paperLeather industryEmulsion

The invention discloses a preparing method of acrylate modified waterborne polyurethane emulsion for synthetic leather. According to the method, active double-bond acrylate modified waterborne polyurethane is introduced to main chains, polybutadiene dihydric alcohol is used as chain extender, active double-bonds are introduced to the polyurethane molecule main chains, the polyurethane molecule main chains are connected through acrylate monomers via double-bond polymerization, and then the acrylate modified waterborne polyurethane emulsion is compounded. The preparing method is simple in technology and easy to realize, and good technology implementation is achieved. The synthetic leather prepared through the method is soft in hand feeling, good in cold tolerance and water resistance and superior in knurling effect, and has wide application prospects in the synthetic leather industry.

Owner:郭小曼

Metal button and preparation method thereof

The invention provides a metal button and a preparation method thereof. The metal button is prepared from a zinc alloy material. The zinc alloy material comprises, by weight, 96.5-98.5 parts of zinc, 0.8-1.5 parts of copper, 0.2-0.5 parts of titanium, 0.03-0.06 parts of magnesium and 0.1-0.2 parts of a rare earth. The preparation method comprises preparing a button belt from the zinc alloy material, carrying out drawing, blank pressing and arc pressing on the button belt blank to obtain a button blank, removing oil on the button blank and carrying out electroplating to obtain a metal button. The metal button is prepared from the zinc alloy material. Through special oil removal treatment and electroplating treatment, good processing performances, shaping performances, welding performances, corrosion resistance and embossing performances are obtained so that brass button performances are obtained.

Owner:ZHEJIANG WEIXING IND DEV

After-finishing technique of shuttle fabric

InactiveCN101343834AConcave and convexThree-dimensionalFibre treatmentDry-cleaning apparatus for textilesIonWoven fabric

Disclosed is a post-finishing process of shuttle-woven fabric. The shuttle-woven fabric post-finishing process comprises the steps: firstly, the shuttle-woven fabric comprising a floating line part and an interweaving part which are mutually spaced are put into a prepared auxiliary agent solution, the bath ratio is 1 to 10 or 1 to 30, the fabric is soaked at the temperature of 60 to 80 DEG C for 10 to 35 minutes, the auxiliary agent solution comprises a shrinking agent with the content of 30 to 70 grams per liter and a non-ion penetrating agent with the content of 1 to 2 grams per liter, and the pH value of 1 weight percent of water solution of the shrinking agent is equal to or larger than 10; and secondly, water washing: water washing is performed to the soaked shuttle-woven fabric. The invention has the advantages that the surface of the shuttle-woven fabric after being treated with the post-finishing process presents obvious sags and crests, and has strong stereoscopic sensation, the fabric is very soft, the hand feeling is comfortable, meanwhile the weaving procedures are simplified, and the production efficiency is enhanced.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Tab and battery comprising same

PendingCN111834601AImprove rigidityImprove deformation resistanceFinal product manufactureElectrode carriers/collectorsEngineeringCopper foil

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD

Cylindrical plate cutting and embossing integrated device

InactiveCN108724335AEasy to cutImprove embossing effectRotary pressesMetal working apparatusMechanical engineeringIntegrated devices

The invention discloses a cylindrical plate cutting and embossing integrated device which comprises a circular cutting table and a hydraulic device arranged above the circular cutting table, wherein avertical cutting surface is arranged on the edge of the circular cutting table; a hydraulic rod of the hydraulic device faces down; a pressing plate is mounted at the lower end part of the hydraulicrod; a cutting cylinder is mounted on the lower end surface of the pressing plate; a sharp cutting blade structure is arranged on the lower end surface of the cutting cylinder; and the size, the upperposition and the lower position of the cutting cylinder are matched with those of the circular cutting table. According to the cylindrical plate cutting and embossing integrated device, two kinds ofequipment is integrated into one machine, and the two functions can be continuously completed; such a structure that an embossing plate is arranged inside a cutting sleeve is relatively ingenious andreasonable, the embossing plate has buffer action force through arranged springs, and the whole structure of the cylindrical plate cutting and embossing integrated device is relatively stable; the equipment cost and the equipment occupation space are greatly reduced; and the working efficiency is remarkably improved.

Owner:JURONG XINGWU PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com