Tab and battery comprising same

A technology of electrode tab and electrolytic copper foil, which is applied to the battery electrode tab and the battery field including the electrode tab, and can solve problems such as tab fracturing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments.

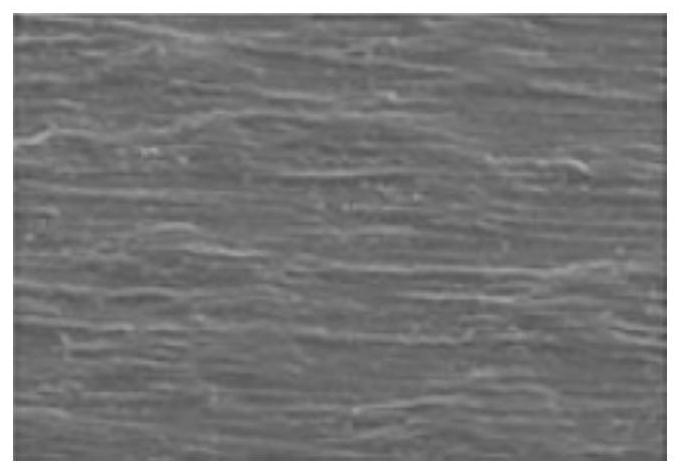

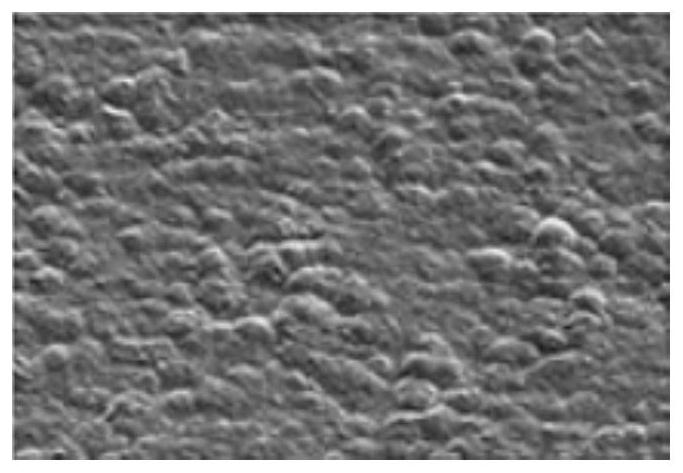

[0016] The tab of the present invention is a copper foil material. The side of the copper foil material with a large compressive stress is the S surface, and the side with a small compressive stress is the M surface, and the M surface is provided with indentations or reinforcing ribs.

[0017] For copper foils with different compressive stresses on both sides, if the compressive stress on one side is greater than the compressive stress on the other side, the residual stress of the foil appears as the compressive stress on the side with the smaller compressive stress, and the copper foil faces the side with the smaller compressive stress (M Surface) warpage, and the greater the residual stress, the greater the degree of warpage of the copper foil. In the present invention, by arranging indentations or reinforcing ribs on the surface of the copper foil material M, the residual s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com