Ink composition for ink jet recording and method of producing lithographic printing plate using the same

An ink composition, a technology for ink jet recording, applied in the directions of reproduction/marking methods, inks, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0224] "Preparation of Pigment Dispersions"

[0225] Dispersion 1 of each of yellow, magenta, cyan and black was prepared in the following manner. Specifically, each pigment is dispersed by using a known dispersing device under suitably adjusted dispersion conditions so that the average particle size of the pigment falls within the range of 0.2 to 0.3 μm, and then the dispersion thus obtained is filtered under heating. body, thus preparing the required dispersion 1.

[0226] (Dispersion of yellow pigment 1)

[0227] C.I. Pigment Yellow 12 10 parts by weight

[0228] Polymerized dispersant 5 parts by weight

[0229] (Solsperse Series, a product of Zeneca Inc.)

[0230] 85 parts by weight of octadecyl acrylate

[0231] (Dispersion of Magenta Pigment 1)

[0232] C.I. Pigment Red 57:1 15 parts by weight

[0233] Polymerized dispersant 5 parts by weight

[0234] (Solsperse Series, a product of Zeneca Inc.)

[0235] 80 parts by weight of octadecyl acrylate

[0236] (cyan p...

Embodiment 2 to 5

[0281] "Preparation of Ink"

[0282] Four types of magenta inks 2 to 5 were prepared in the following manner:

[0283] (magenta ink 2)

[0284] Dispersion 1 20 parts by weight of magenta pigment

[0285] 40 parts by weight of compound A-3 shown in Table 1

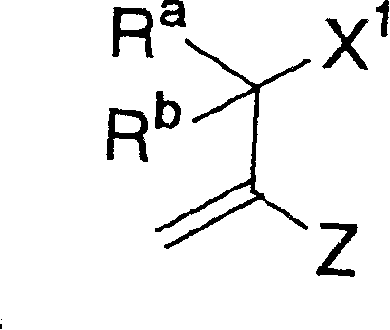

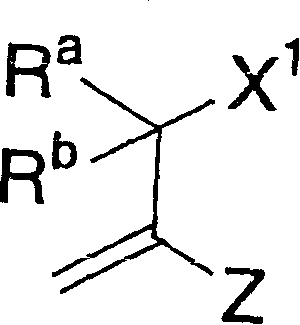

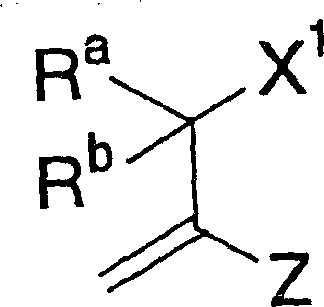

[0286] The bifunctional aromatic urethane acrylate shown below

[0287] (Molecular weight: 1,500) 10 parts by weight

[0288] The hexafunctional aliphatic urethane acrylate shown below

[0289] (Molecular weight: 1,000) 5 parts by weight

[0290] Polymerization initiator (IRGACURE 184, manufactured by Ciba Specialty Chemicals)

[0291] 5 parts by weight

[0292] (magenta ink 3)

[0293] Dispersion 1 20 parts by weight of magenta pigment

[0294] 50 parts by weight of compound A-18 shown in Table 1

[0295] Lactone-modified acrylates shown below

[0296] (Molecular weight: 458) 20 parts by weight

[0297] The hexafunctional aliphatic urethane acrylate shown below

[0298...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com