Special-purpose die for glass, bright gold embossing technique and products thereof

A technology of glass products and molds, which is applied in the field of glass products, can solve the problems of poor relief effect and cumbersome production process, and achieve the effects of cost saving, excellent light transmission performance and cost saving

Inactive Publication Date: 2008-08-13

SICHUAN YIBIN WULIANGYE GROUP

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the shortcomings of the existing bright gold embossed glass products, which are complicated in manufacturing process and poor in embossing effect, the technical problem to be solved by the present invention is to provide a glass that is simp

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0027] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

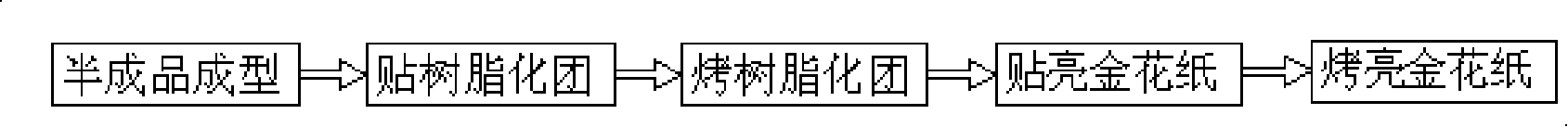

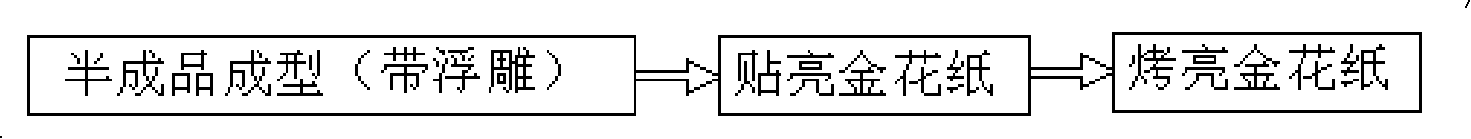

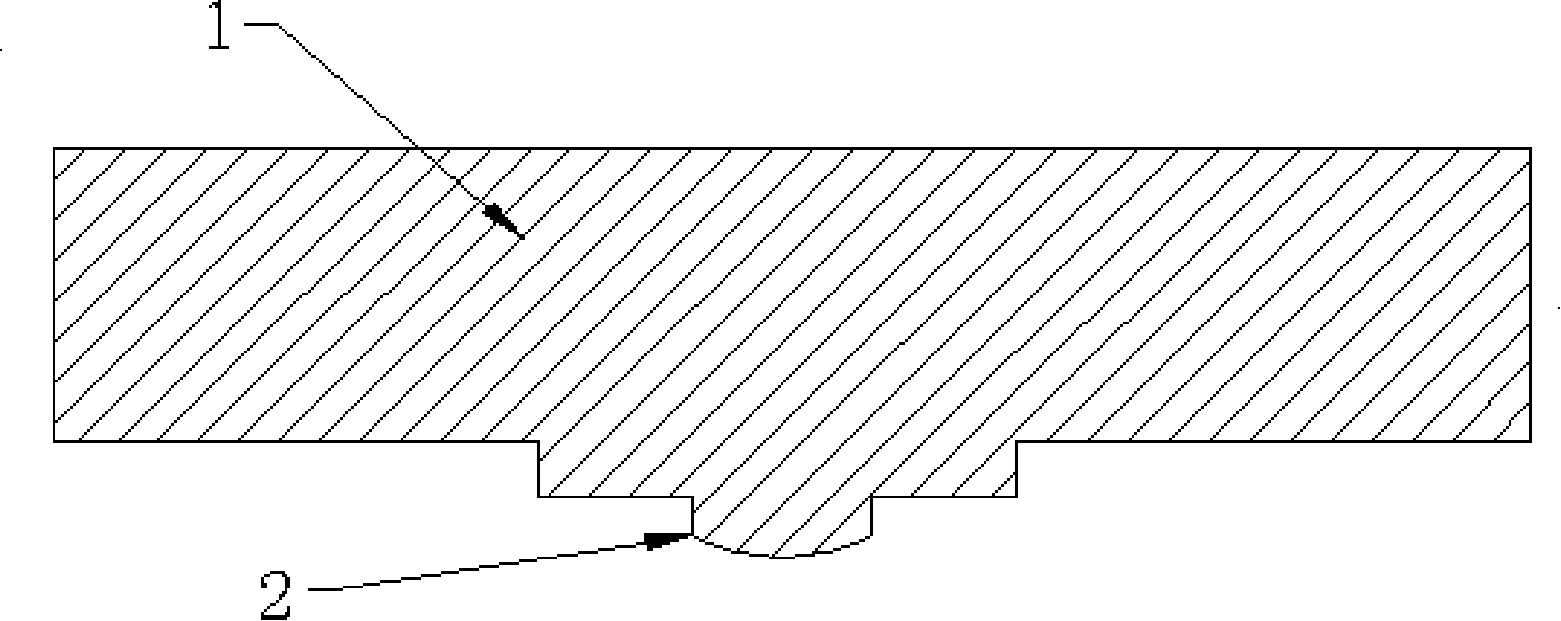

The present invention relates to the field of the glass product, and discloses a glass-specialized mold which is easier and has better relief effect, the glass-specialized mold adopts the combined mold and is engraved with the mold pattern corresponding with the glass pattern at the inner surface of the mold and is arranged with a gas discharging opening at the mold pattern. When the glass pattern is a relief pattern the glass-specialized mold is an embossed glass specialized mold. The invention also discloses a brightening bossy technique which comprises the technical processes of intermediate product molding, pasting the brightening stained paper, roasting the brightening stained paper, when the intermediate product is molded the embossed glass specialized mold is used for making the intermediate product with relief patterns. Therefore the invention also discloses a glass product with body integratedly molded with the glass pattern. The glass product can be made adopting the glass-specialized mold and can be applied with the brightening bossy technique to make the brightening embossed glass product. The invention can be broadly applied for various glass products that are produced with batch and is especially suitable for making the brightening relief glass bottle.

Description

technical field [0001] The invention relates to a glass product, in particular to a special mold for embossed glass used to make reliefs on the glass product and a process for making bright gold reliefs using the mold. Background technique [0002] Due to the viscosity of glass liquid, when making glass products with relief, it is difficult to directly form relief on the surface of the product. The announcement number of the announcement on May 11, 2005 is CN2698783Y. discloses a kind of glass in which resin groups are arranged at a predetermined position on the back of the glass, and a colored layer is covered on the surface of the cured resin groups so that the glass has a relief effect when viewed from the front. The color material of the colored layer can be gold, Silver, Copper, Aluminum, Nickel, Chromium. And the embossing effect varies greatly due to the viewing angle. The traditional bright gold embossing process is: first form a semi-finished product in a combined...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B11/06B44C3/04B44C1/00B44C5/00

CPCY02P40/57

Inventor 王国春彭国昌徐涛邓庆国皮熙芝陈宏伟吕惠敬

Owner SICHUAN YIBIN WULIANGYE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com