Calender, foaming floor production line and one-time forming production technology

A calender and flooring technology, which is applied to flat products, household appliances, and other household appliances, can solve problems affecting calendering and embossing performance, patterns rebound, and embossing cannot be pressed, so as to save labor costs, Reduce the scrap rate and improve the effect of embossing and embossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

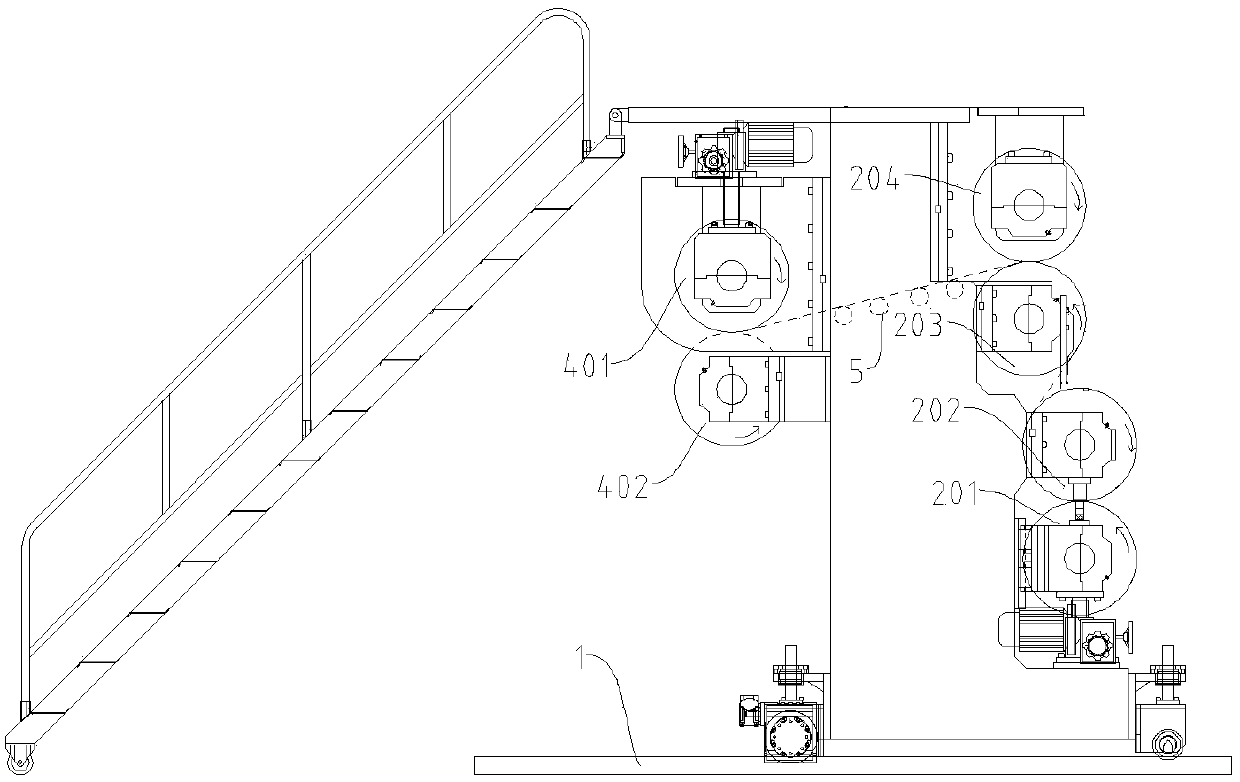

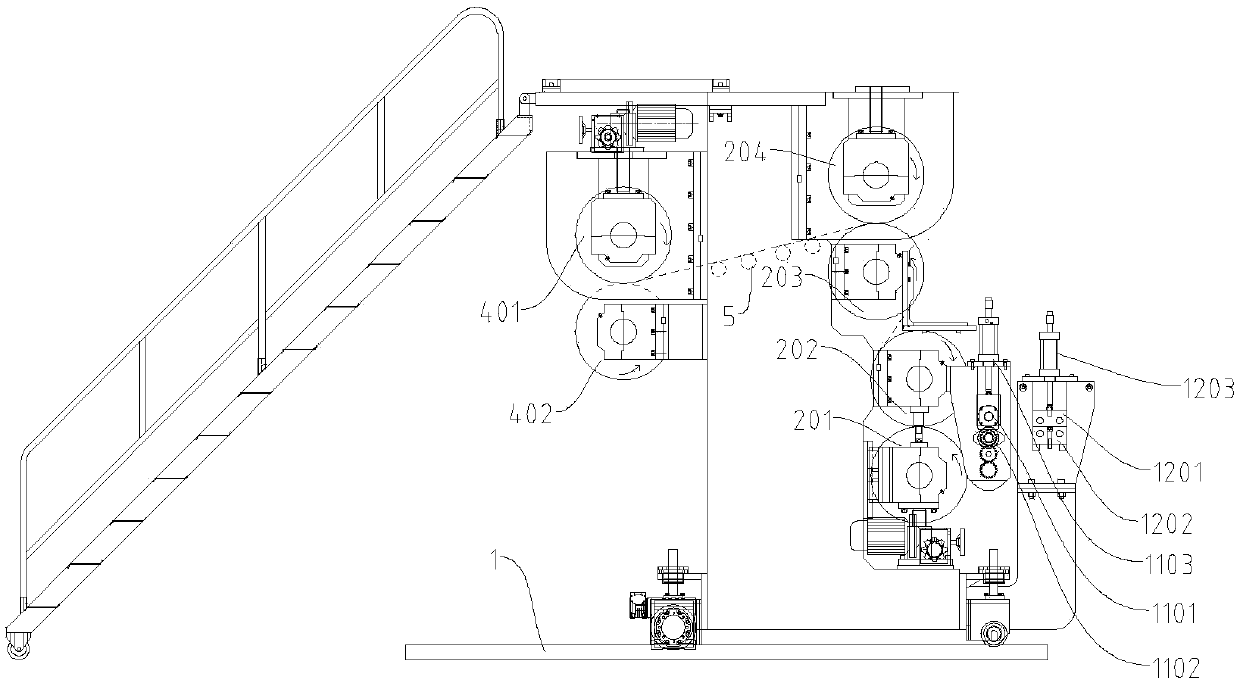

[0052] This embodiment provides a calender, which is used for one-time molding production of WPC wood-plastic flooring, and can complete foaming of the material to be processed, embossing or embossing on both sides of the bottom surface and the top surface, etc. Molding treatment. In this embodiment, WPC wood-plastic foamed floor is used as the material to be processed. In actual application, the material to be processed is not limited to the foamed floor.

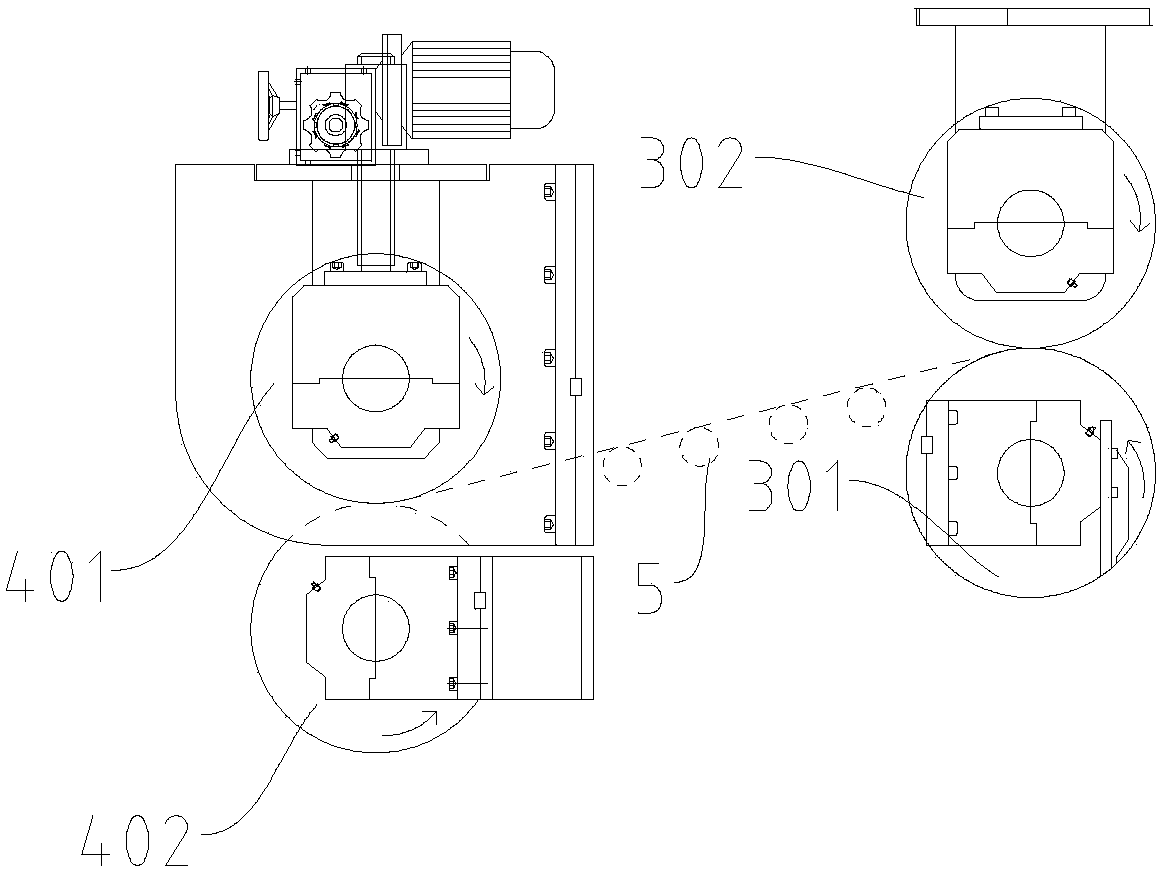

[0053] The calender includes a machine base 1 and a set of calendering rollers arranged on the machine base 1 . According to the material processing flow (foamed floor in this embodiment), the calendering roller group sequentially includes a mirror roller group and an embossing roller group for double-sided embossing of the foamed floor.

[0054] A schematic diagram of a calender embodiment for reference figure 1 .

[0055] Wherein, the main calender roll set refers to a roll set composed of calender rolls including mir...

Embodiment 2

[0086] This embodiment provides a foam floor production line using the calender in Embodiment 1 for foam floor production.

[0087] specific reference Figure 8According to the production process of the product, it includes a mixer 14 (shown in the figure as a mixer silo, which is used to simplify the representation of the mixer), a feeder 15, an extruder 16, a mold 17 and a calender 18 , the calender 18 in the calender embodiment 1, the structure thereof will not be repeated here.

[0088] The mixer 14 is used for mixing powder materials, and various materials used to produce the foamed substrate layer are introduced into the mixer 14 and stirred and mixed at a high speed. The mixed material after stirring is put into the feed bin of the spring feeder 15, and then fed to the hopper of the extruder by the rotation of the spring feeder 15.

[0089] It should be noted here that since the floor is made of multi-layer composite materials, two sides of the foam base layer are res...

Embodiment 3

[0095] This embodiment provides a production process for one-time molding of foamed flooring. The process specifically includes: one-step forming-health-preserving-cutting-grooving-testing and packaging-palletizing-warehousing and packing. Compared with the traditional production process, this process omits the steps of gluing and laminating, saving equipment and land occupation space.

[0096] Concrete technological process comprises the following steps:

[0097] Before the start-up of the production line, the mixer 14, the feeder 15, the extruder 16, the mold 17 and other temperature-operated equipment are preheated and kept warm in advance. The preheating time depends on the requirement. In this embodiment, the preheating time is 2 hours. The purpose of heating is to make the material change from the previous powder to the solution before starting the work of mixing and extrusion. The stability of preheating is between 150°C and 180°C. In this embodiment, 150°C, 160°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com