Ultra-soft wet process embossing-type polyurethane resin and preparation method and application thereof

A technology of polyurethane resin and wet method, which is applied in the direction of textiles and papermaking, can solve the problems of high production cost, texture limitation, complicated process flow, etc., and achieve the effect of reducing intermolecular force, reducing force, and solving complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

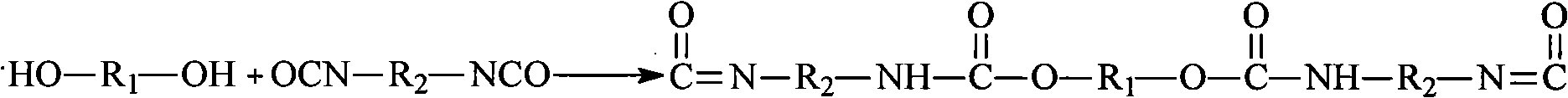

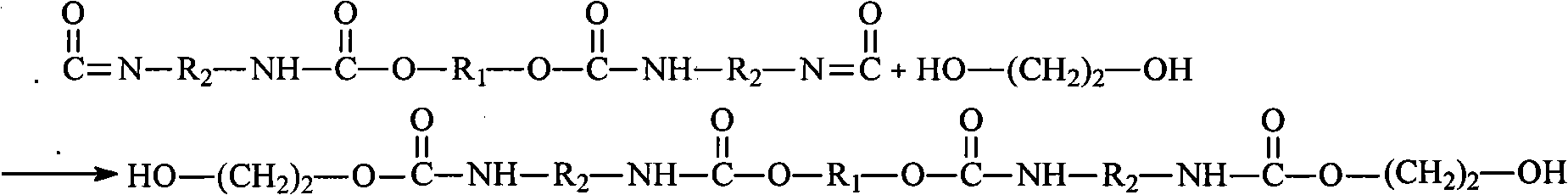

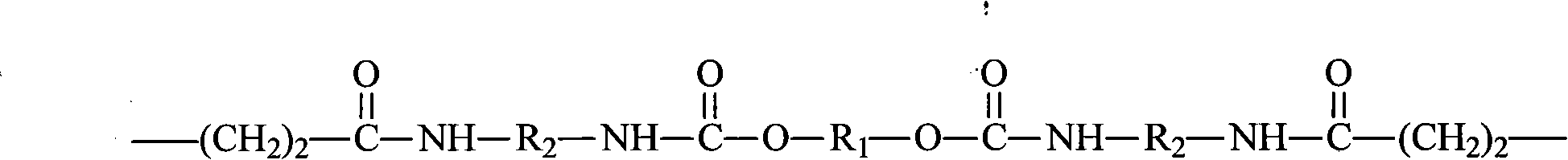

Method used

Image

Examples

Embodiment 1

[0056] Raw material name Weight (kg)

[0057] Polybutylene adipate adipate diol (number average molecular weight 3000) 550

[0058] Polyhexamethylene adipate-butylene glycol ester diol (number average molecular weight 4000) 1650

[0059] MDI (diphenylmethane-4,4`-diisocyanate) 750.71

[0060] EG (ethylene glycol) 73.88

[0061] 2,2-Dimethyl-1,3-propanediol 126.4

[0062] Antioxidant TPP 5.25

[0063] Catalyst (bismuth carboxylate) 0.055

[0064] DMF (N, N-dimethylformamide) 7352.31

Embodiment 2

[0066] Raw material name Weight (kg)

[0067] Polybutylene adipate diol (number average molecular weight 2000) 300

[0068] Polyhexamethylene adipate-butylene glycol ester diol (number average molecular weight 4000) 1800

[0069] MDI (diphenylmethane-4,4'-diisocyanate) 780.0

[0070] EG (ethylene glycol) 44.64

[0071] 2,2-Dimethyl-1,3-propanediol 137.28

[0072] Antioxidant TPP 5.1

[0073] Catalyst (bismuth carboxylate) 0.053

[0074] DMF (N, N-dimethylformamide) 7144.48

Embodiment 3

[0076] Raw material name Weight (kg)

[0077] Polybutylene adipate diol (number average molecular weight 3000) 500

[0078] Polyhexamethylene adipate-butylene glycol ester diol (number average molecular weight 4000) 1600

[0079] MDI (diphenylmethane-4,4`-diisocyanate) 793.35

[0080] EG (ethylene glycol) 70.27

[0081] 2-methyl-1,3 propanediol 132.6

[0082] Antioxidant TPP (triphenyl phosphite) 5.15

[0083] Catalyst (bismuth carboxylate) 0.053

[0084] DMF (N, N-dimethylformamide) 7224.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com