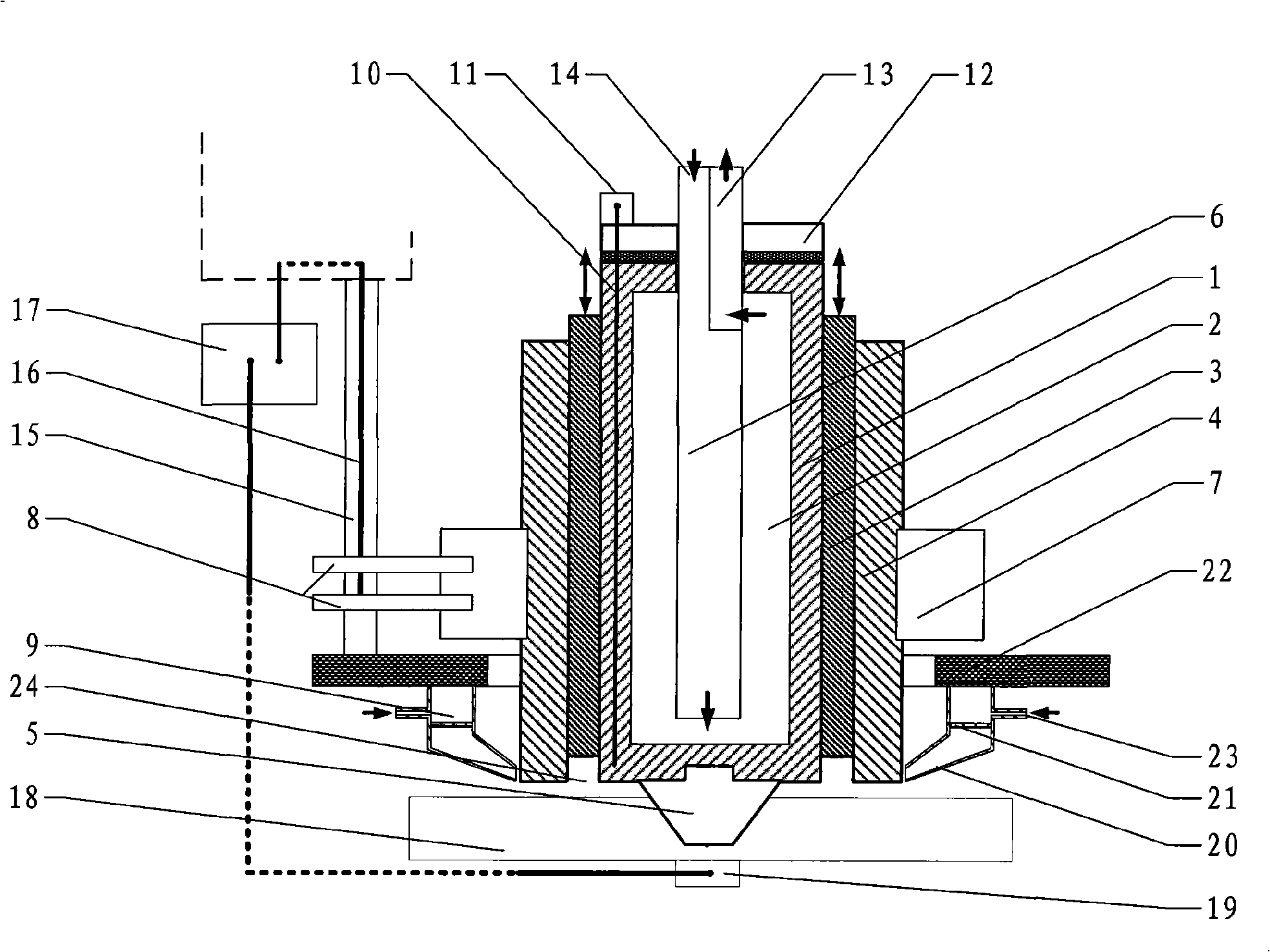

Integrated pin tool for friction stir welding and composite method of resistance-friction stir welding thereof

A technology of friction stir welding and friction stir, applied in the direction of resistance welding equipment, welding equipment, welding medium, etc., can solve the problems of high material preparation cost of the stirring head, difficulty in welding high melting point metals, high cost of the stirring head, etc., and achieve high-quality welded joints , improve service life, prevent oxidation and inclusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

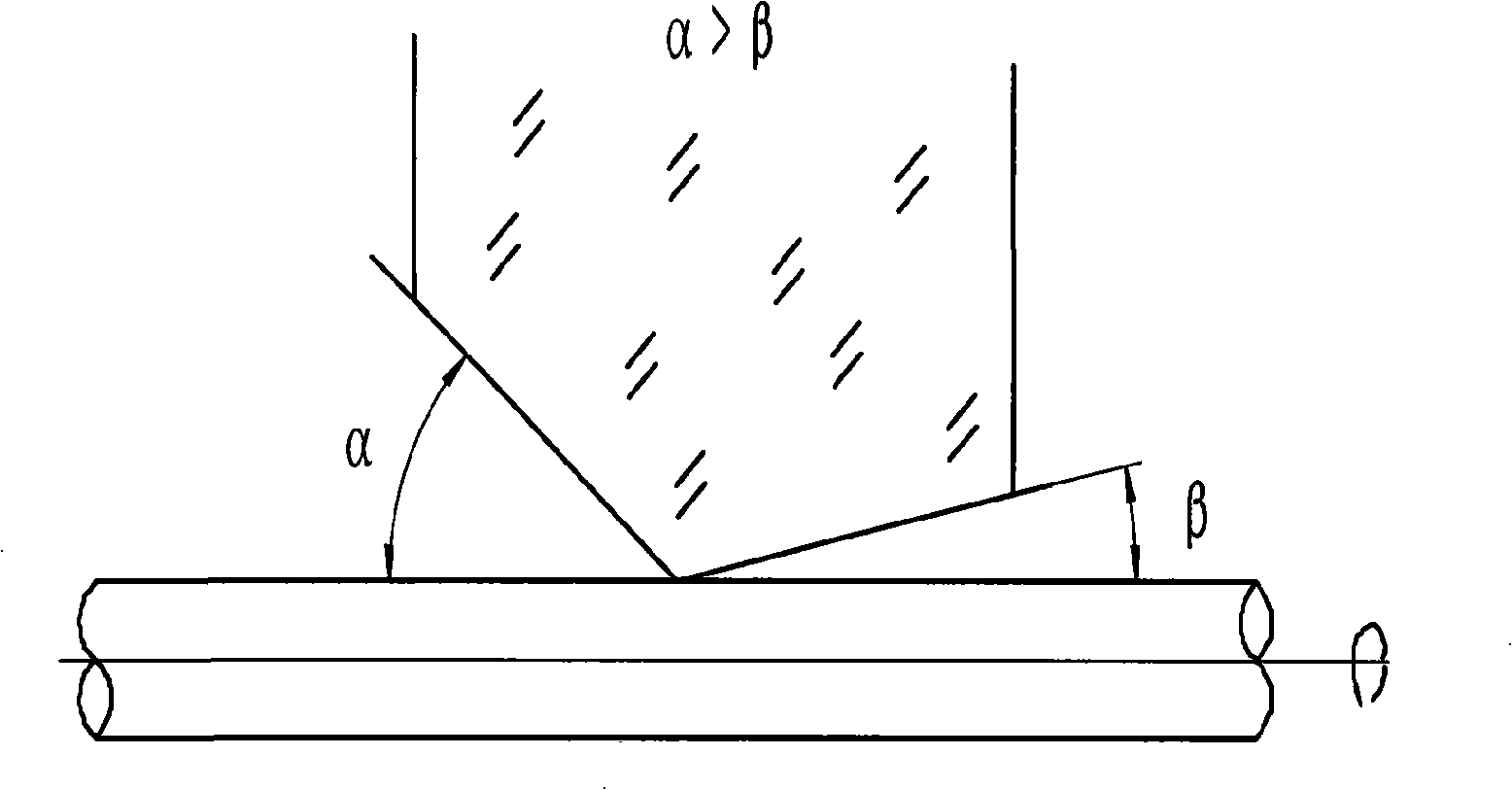

[0082] Example 1: Use this stirring head to conduct current-carrying friction stir welding of 3.2mm thick Q345R steel. The welding process parameters are as follows: digital arc welding DC power supply is used to provide auxiliary current, the auxiliary DC current is 400-800A, and the rotation speed of the stirring head is 800- 2000rmp, welding speed 60-200mm / min, argon protection 10-30L / min, down force 30-50kN.

[0083] The principle of determining the welding specification is: the form, shape, and size of the welding structure should be considered comprehensively, and reasonably matched with the welding process parameters, and the main process parameters of the welding should be optimized according to the actual welding objects and materials. At the same time, the external power supply should be considered. The impact of the heat input on the welding process, the reasonable and effective distribution and combination of friction heat and resistance heat, can ensure high-qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com