Matte multilayer polyester film

A polyester film, glossy technology, applied in the field of matt laminated polyester film, can solve the problems of easy mold, no matting, poor water vapor barrier properties, etc., to achieve excellent operability and excellent water vapor barrier properties. Effect

Inactive Publication Date: 2008-10-29

TORAY IND INC

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the oxygen barrier is indeed excellent, but the water vapor barrier is extremely poor, so moisture can easily pass through the film. After the wallpaper is laid, if the moisture in the adhesive moves to the surface of the film over time or the moisture adheres to the surface of the film, there are problems such as easy mold

Furthermore, a laminated film in which a highly crystalline polyester is laminated on one surface of a flexible film has been proposed (for example, see Patent Document 5). Although the above-mentioned laminated film is excellent in flexibility and transparency over time, it does not Obtain a film with matting properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Login to View More

Abstract

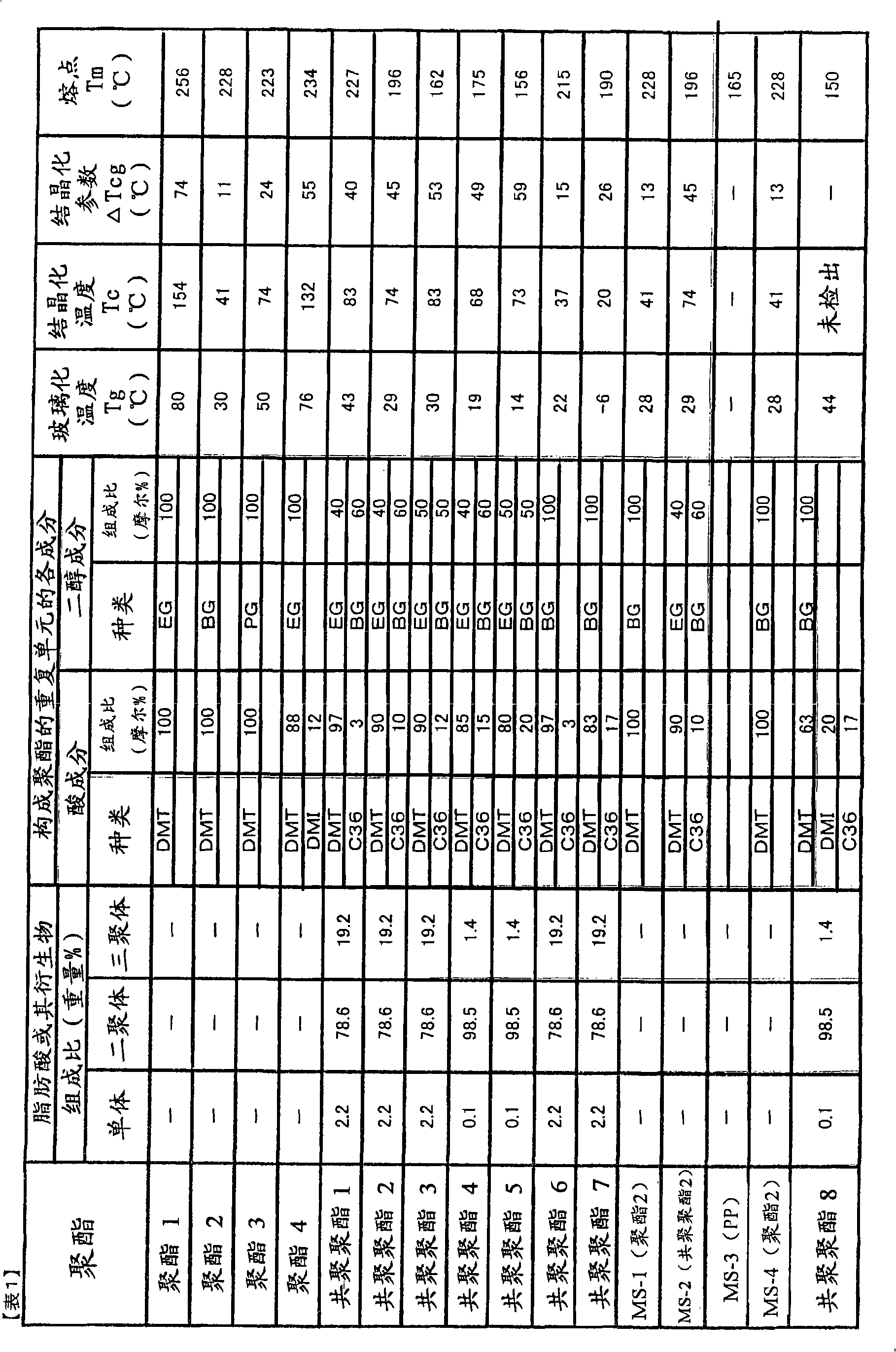

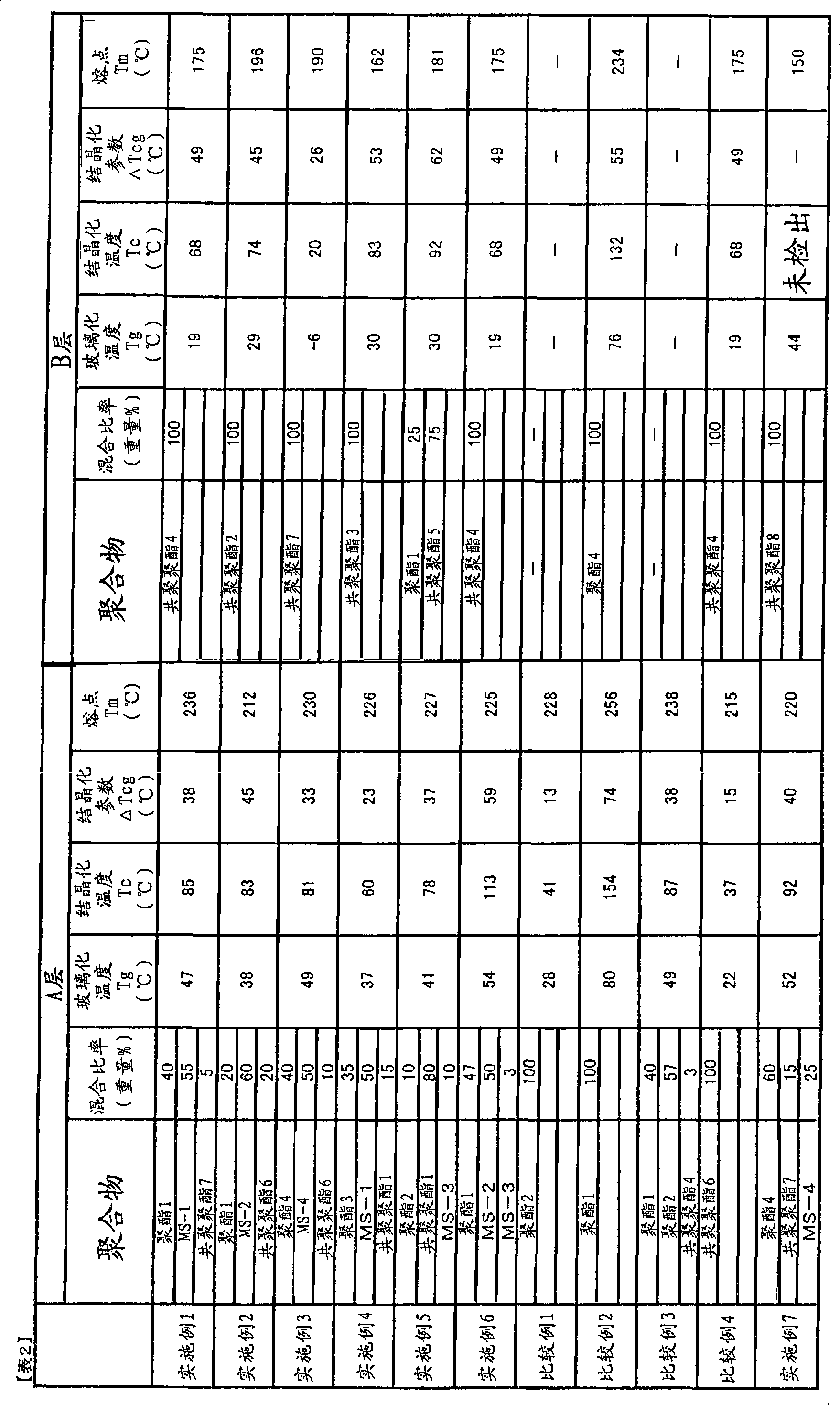

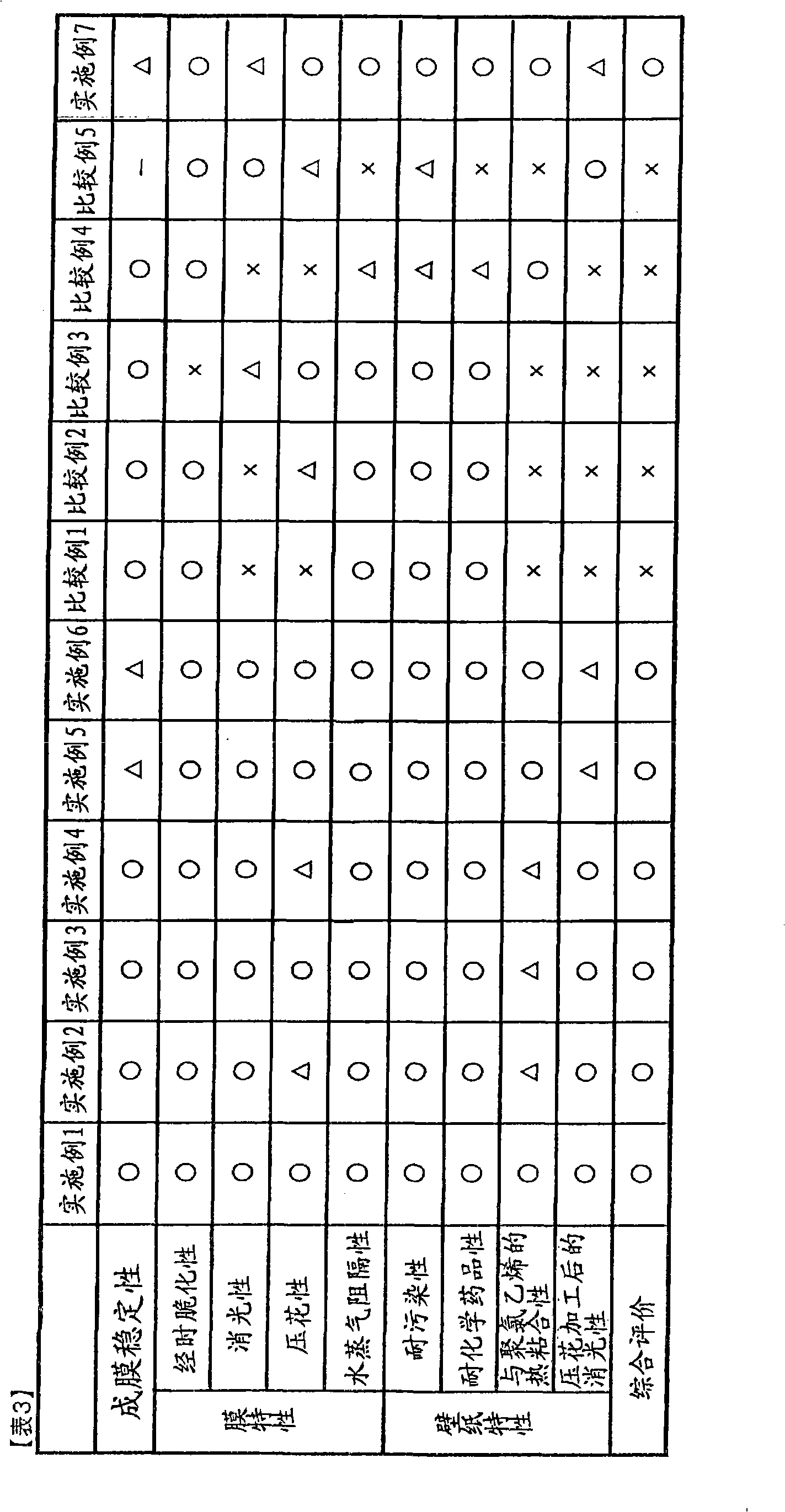

Disclosed is a matte multilayer polyester film excellent in contamination resistance, chemical resistance, formability, heat bondability, delustering properties, embossing properties, water vapor barrier properties and the like, which is particularly suitable for wallpapers. Specifically disclosed is a matte multilayer polyester film having at least a two-layer structure of A / B. The polyester of layer A is composed of a composition containing 60-95% by weight of a polyester (a) and 5-40% by weight of an incompatible resin (b), while having a glass transition temperature TgA of 30-70 DEG C. The polyester of layer B is mainly composed of a copolymerized polyester having a melting point TmB of 120-210 DEG C. The degree of surface glossiness of the layer A is less than 50%.

Description

technical field The present invention relates to improvements to existing flexible films, more particularly to stain resistance, chemical resistance, formability, thermal adhesion, matting, embossing, gas barrier properties, especially water vapor barrier A matte laminated polyester film with excellent durability, and a wallpaper formed using the above matte laminated polyester film, the above wallpaper can simultaneously achieve stain resistance, chemical resistance, embossability, and embossed It has excellent matting property and thermal adhesion to the base material, does not become embrittled with time, and has excellent handleability. Background technique A typical example of a conventional flexible film is a polyvinyl chloride film. The above-mentioned polyvinyl chloride film has excellent weather resistance, and at the same time is suitable for various processing such as embossing processing, etc., and can be produced inexpensively, and thus is increasingly used pre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/36C08L67/02D06N7/04

CPCB32B27/30B32B27/08B32B21/08C08L67/02B32B5/18Y10T428/31786Y10T428/31Y10T428/3179B32B27/36B32B27/32C08L101/00Y10T428/31794C08L2666/02B32B2307/408B32B2471/04B32B2367/00

Inventor 桥本幸吉药师堂健一木村将弘

Owner TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com