Light extinction polyester and low-gloss elastic composite fiber

An elastic composite fiber and low gloss technology, which is applied in the field of fiber forming and processing, can solve the problems of the influence of fiber mechanical properties, inability to achieve, etc., and achieve the effects of no environmental pollution, simple preparation method and low equipment performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

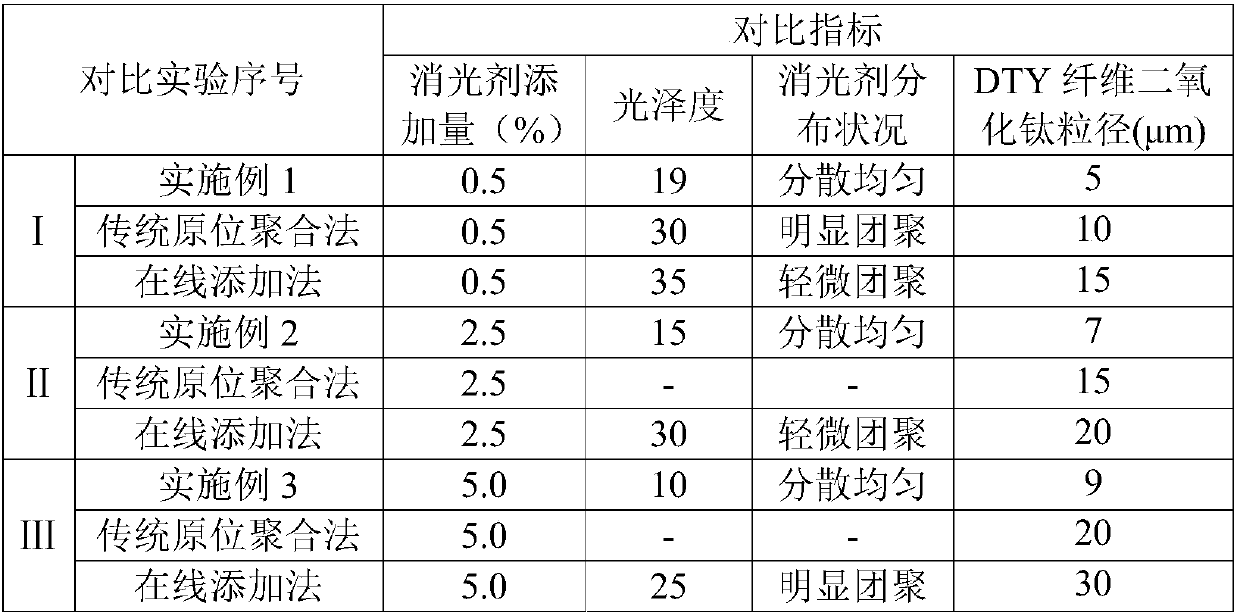

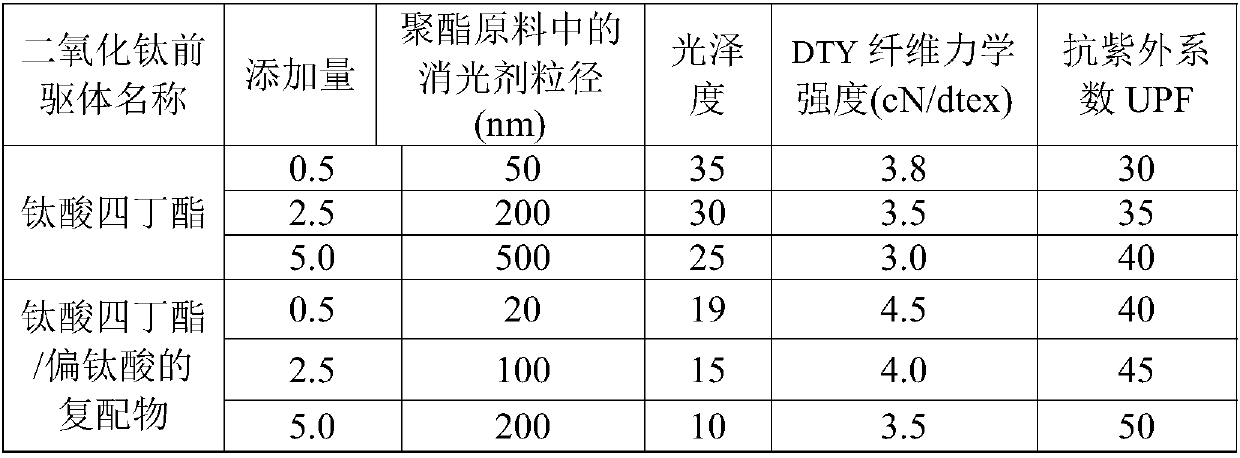

Embodiment 1

[0074] This embodiment provides a kind of preparation method of PET / PTT composite elastic fiber of low glossiness, and this preparation method is tetrabutyl titanate Ti(OC 4 h 9 ) 4 With metatitanic acid (TiO(OH) 2 ) compound is used as the precursor of titanium dioxide matting agent. During the synthesis of PET polyester and PTT polyester, the water generated by esterification is used for hydrolysis and self-driven in-situ polymerization to produce nano-sized titanium dioxide as a matting agent to obtain matting PET. Polyester and matte PTT polyester; then the matte PET polyester and matte PTT polyester are formed by side-by-side composite melt spinning to obtain a low-gloss composite elastic fiber, in which PET polyester and PTT polyester raw materials are both Containing a certain mass ratio of titanium dioxide matting agent; the specific steps of the method include:

[0075] (1) Preparation of matte PET polyester: Tetrabutyl titanate Ti(OC 4 h 9 ) 4 With metatitanic ...

Embodiment 2

[0091] This embodiment provides a kind of preparation method of PET / PTT composite elastic fiber of low glossiness, and this preparation method is tetrabutyl titanate Ti(OC4 h 9 ) 4 With metatitanic acid (TiO(OH) 2 ) compound is used as the precursor of titanium dioxide matting agent. During the synthesis of PET polyester and PTT polyester, the water generated by esterification is used for hydrolysis and self-driven in-situ polymerization to produce nano-sized titanium dioxide as a matting agent to obtain matting PET. Polyester and matte PTT polyester; then the matte PET polyester and matte PTT polyester are formed by side-by-side composite melt spinning to obtain a low-gloss composite elastic fiber, in which PET polyester and PTT polyester raw materials are both Containing a certain mass ratio of titanium dioxide matting agent; the specific steps of the method include:

[0092] (1) Preparation of matte PET polyester: Tetrabutyl titanate Ti(OC 4 h 9 ) 4 With metatitanic ac...

Embodiment 3

[0108] This embodiment provides a kind of preparation method of PET / PTT composite elastic fiber of low glossiness, and this preparation method is tetrabutyl titanate Ti(OC 4 h 9 ) 4 With metatitanic acid (TiO(OH) 2 ) compound is used as the precursor of titanium dioxide matting agent. During the synthesis of PET polyester and PTT polyester, the water generated by esterification is used for hydrolysis and self-driven in-situ polymerization to produce nano-sized titanium dioxide as a matting agent to obtain matting PET. Polyester and matte PTT polyester; then the matte PET polyester and matte PTT polyester are formed by side-by-side composite melt spinning to obtain a low-gloss composite elastic fiber, in which PET polyester and PTT polyester raw materials are both Containing a certain mass ratio of titanium dioxide matting agent; the specific steps of the method include:

[0109] (1) Preparation of matte PET polyester: Tetrabutyl titanate Ti(OC 4 h 9 ) 4 With metatitanic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com