Patents

Literature

207results about How to "Stable printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic Pigment, Pigment Dispersion Liquid, Metallic Pigment Ink Composition, and Ink Jet Recording Method

ActiveUS20090214833A1Stable printingGlossiness improvedMeasurement apparatus componentsLayered productsSpray nozzleMetal foil

This invention provides a metallic pigment, which can prepare a printed matter having metallic luster, can realize stable printing even in a printer with ink jet nozzles having a nozzle diameter of not more than 30 μm, can eliminate the need to carry out heat treatment and the like, and, thus, can realize ink jet recording without undergoing a limitation on printing media (recording media), an ink composition, and an ink jet recording method. The metallic pigment is a metal foil piece having an average thickness of 30 to 100 μm, having a 50% average particle diameter of not less than 0.5 μm and not more than 4.0 μm, and having such a particle size distribution that the maximum particle diameter is not more than 12 μm. An ink composition containing this metallic pigment and an ink jet head having a nozzle diameter of not more than 30 μm are provided, and the ratio between the average particle diameter of the metallic pigment and the nozzle diameter of the ink jet head (average particle diameter / nozzle diameter) is preferably brought to not more than 0.15.

Owner:SEIKO EPSON CORP

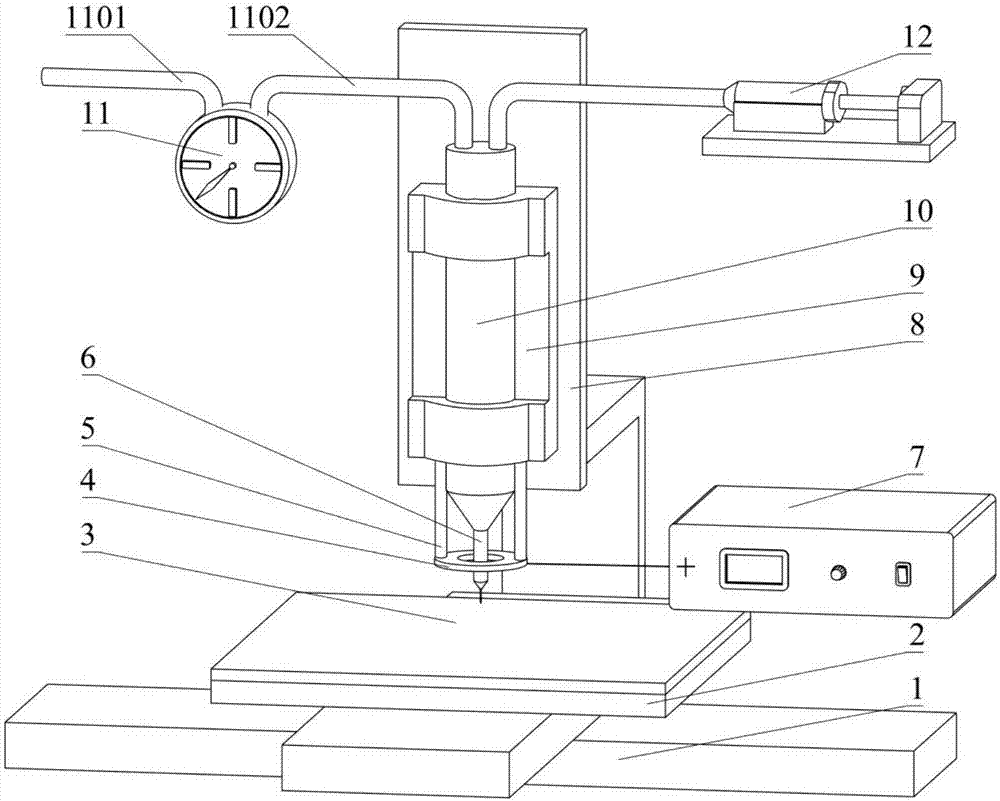

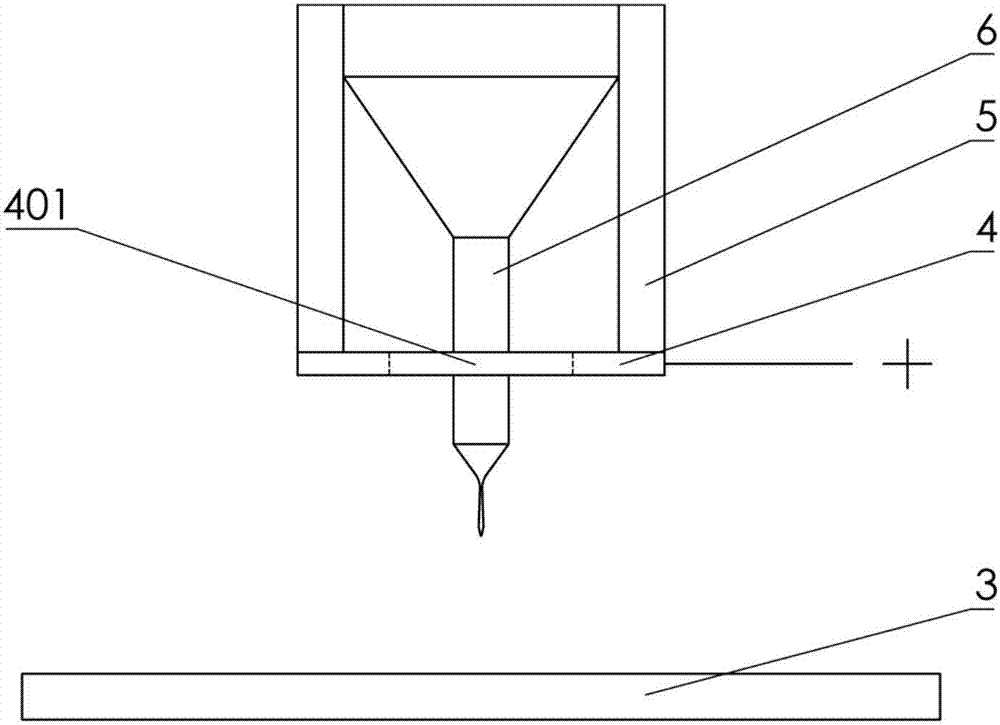

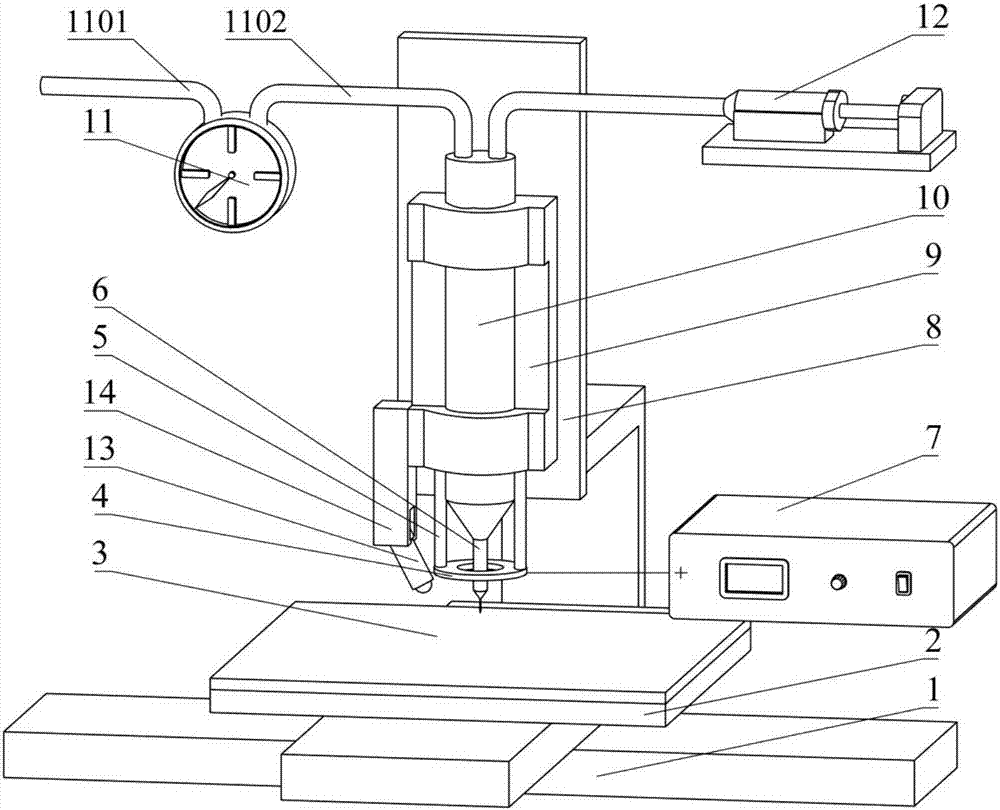

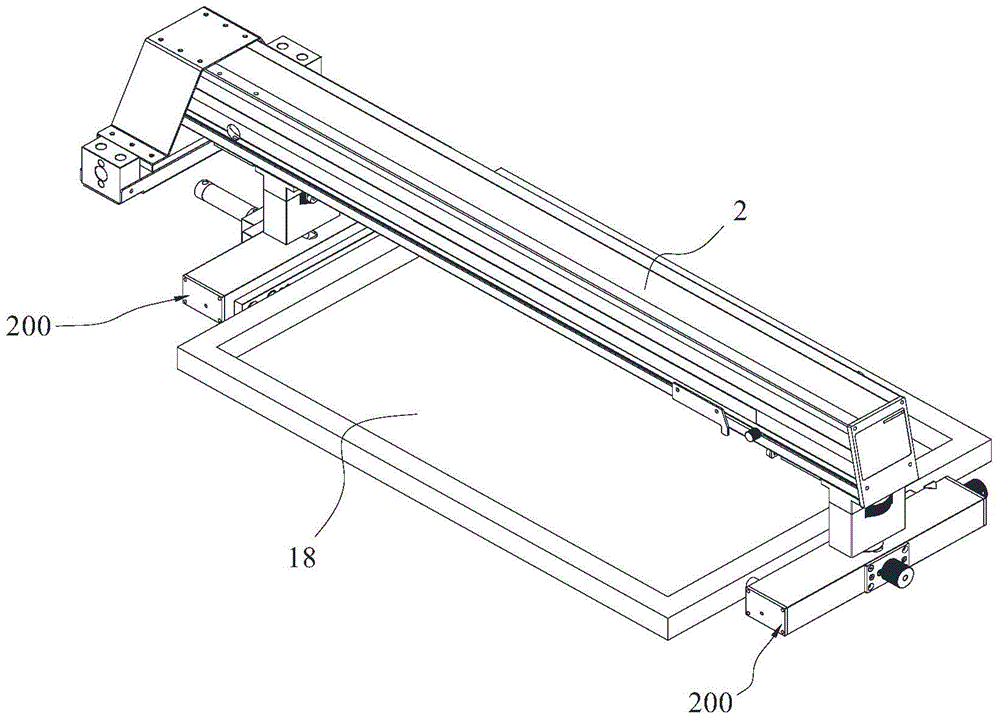

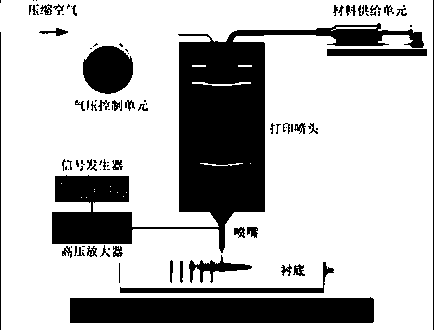

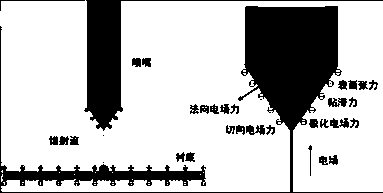

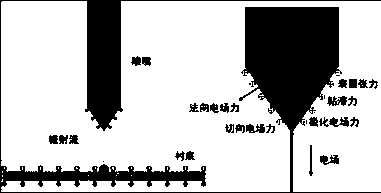

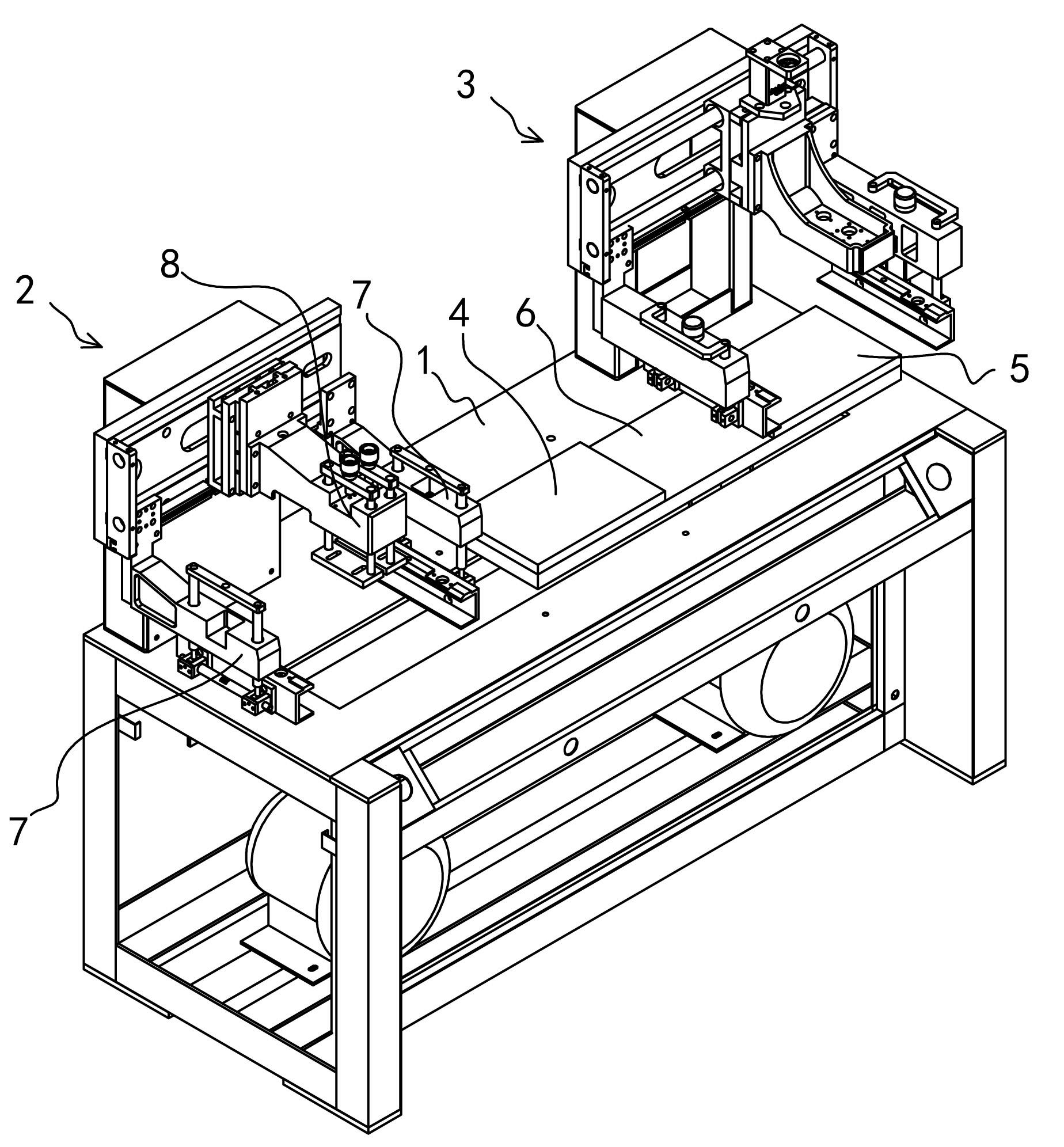

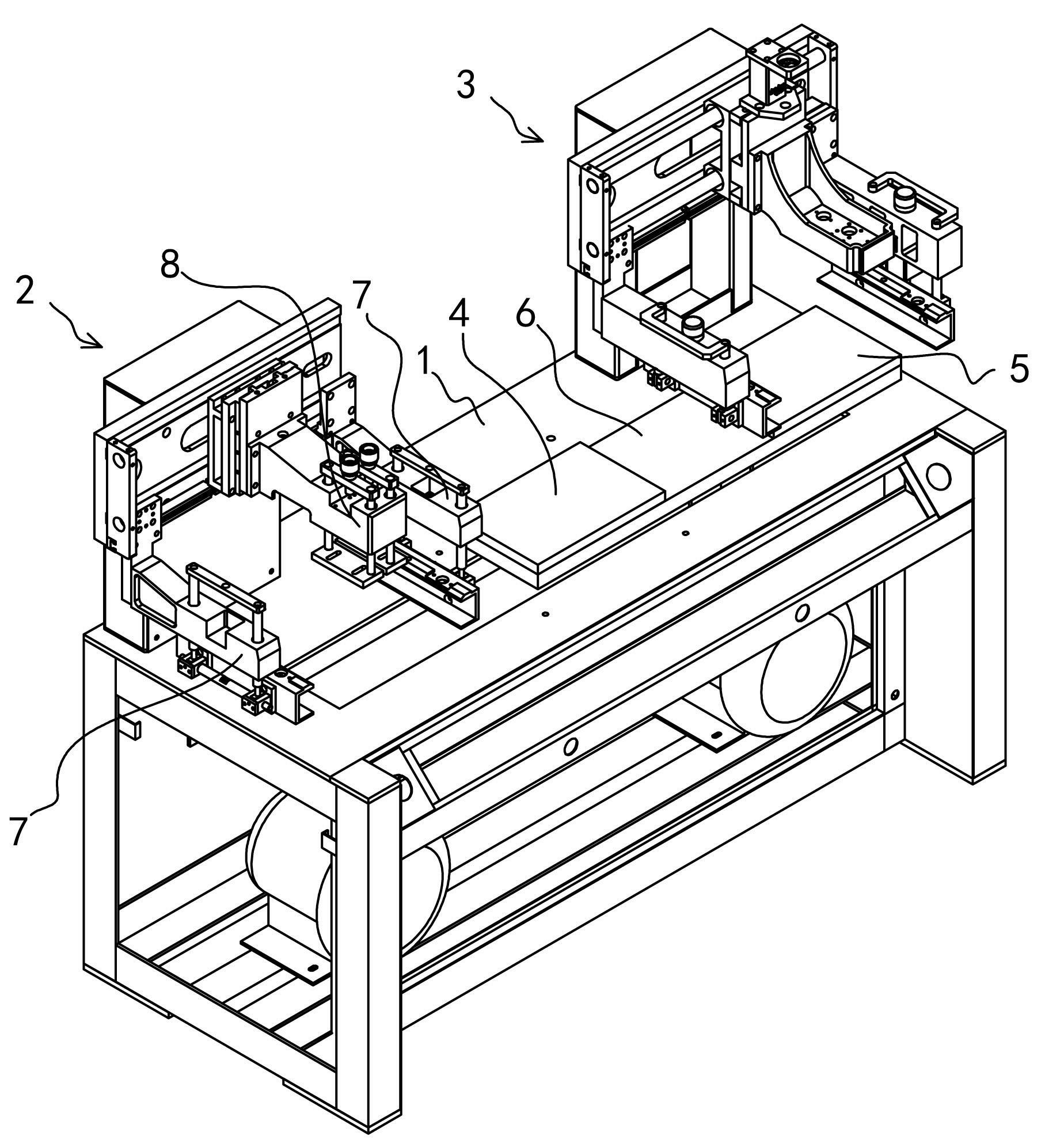

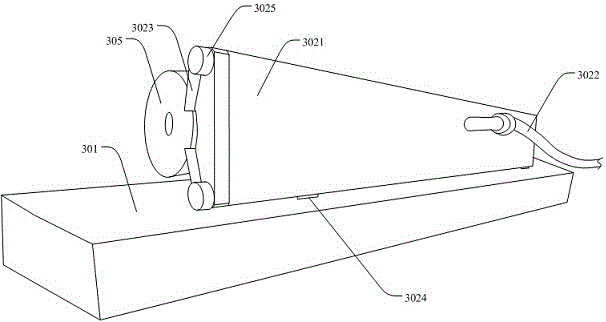

Electric field driving jetting deposition 3D printing device and working method thereof

ActiveCN107214945AStable printingConsider printing accuracyManufacturing driving meansCeramic shaping apparatusMulti materialElectric field

The invention discloses an electric field driving jetting deposition 3D printing device and a working method thereof. The limits of the aspects, such as printing materials, receiving substrates, the resolution, of existing material jetting deposition 3D printing are broken through, especially the multiple-spraying-head technology is combined, and multi-scale multi-material structure integration 3D printing can be realized. According to the technical scheme of the electric field driving jetting deposition 3D printing device, a two-dimensional worktable is included and provided with a printing platform; a receiving substrate is arranged on the printing platform in an adsorbed mode; a jetting unit is arranged on the upper portion of the receiving substrate correspondingly; the jetting unit is connected with a Z-direction worktable and comprises an electric field generating electrode and a printing spraying head; the printing spraying head is arranged in an electric field area formed by the electric field generating electrode; the electric field generating electrode is connected with a positive pole of a high-voltage pulsed power supply; the printing spraying head comprises a nozzle and a storage cylinder which are mutually connected; and the storage cylinder is connected with a back pressure control unit and a printing material supply unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

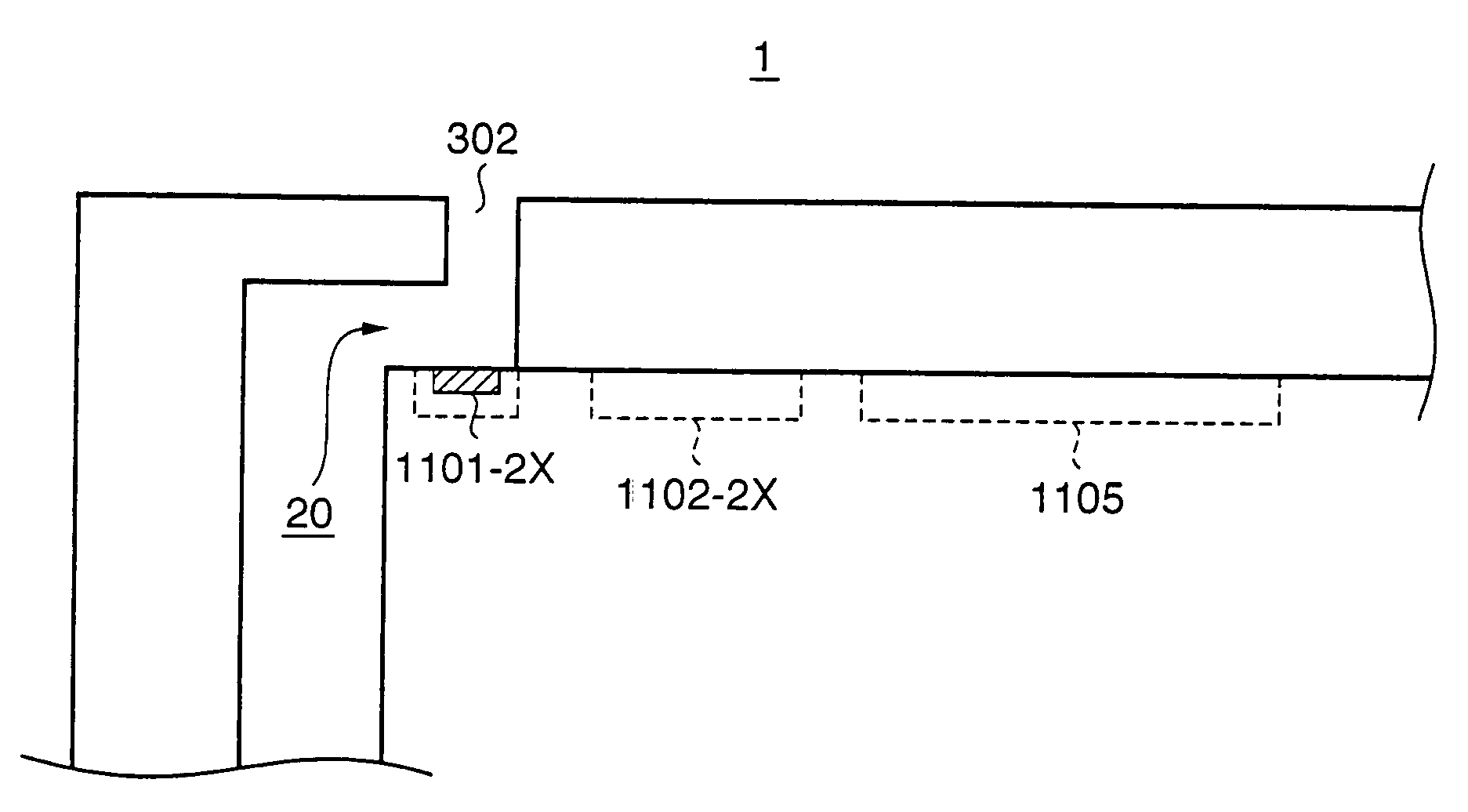

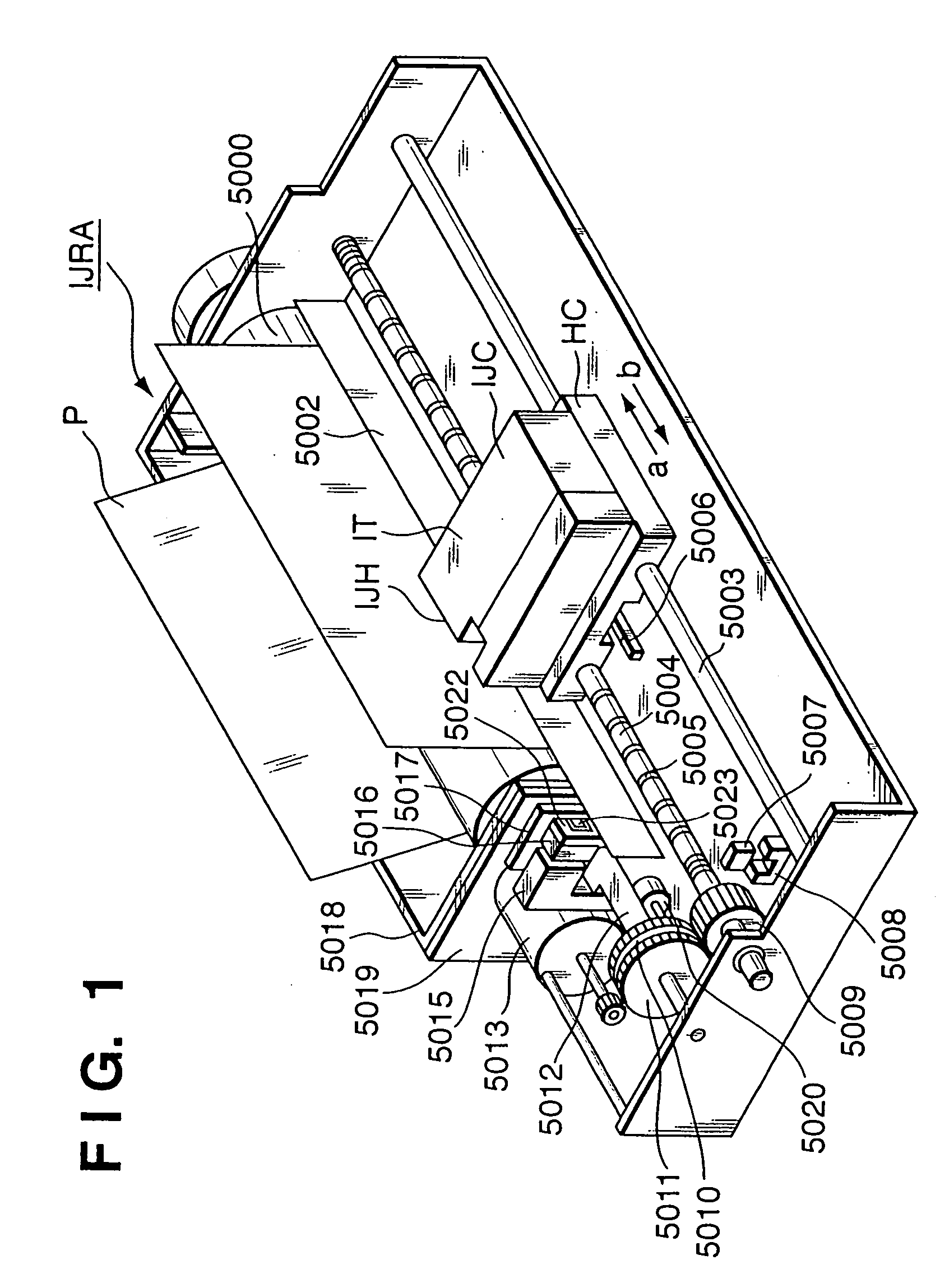

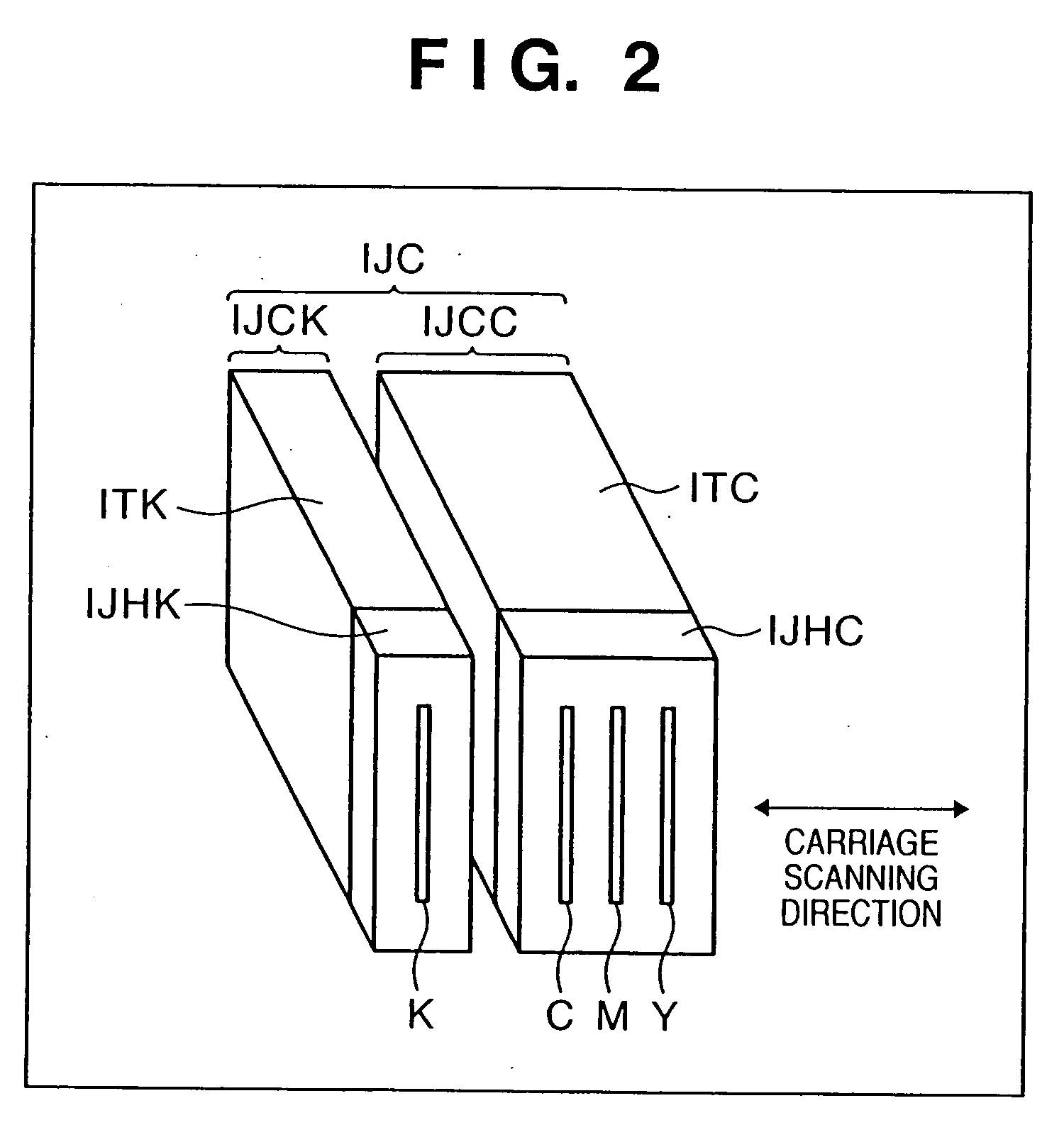

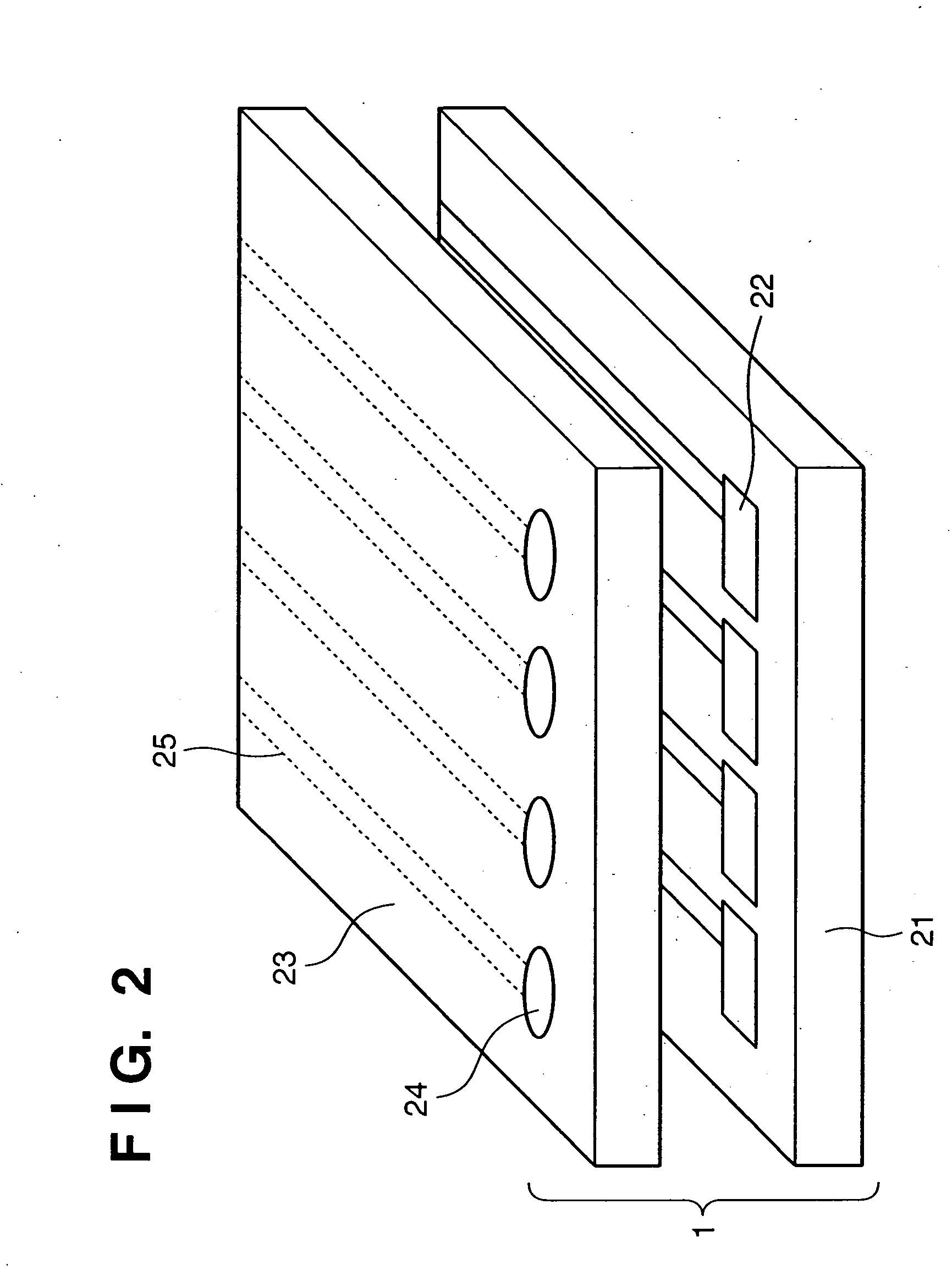

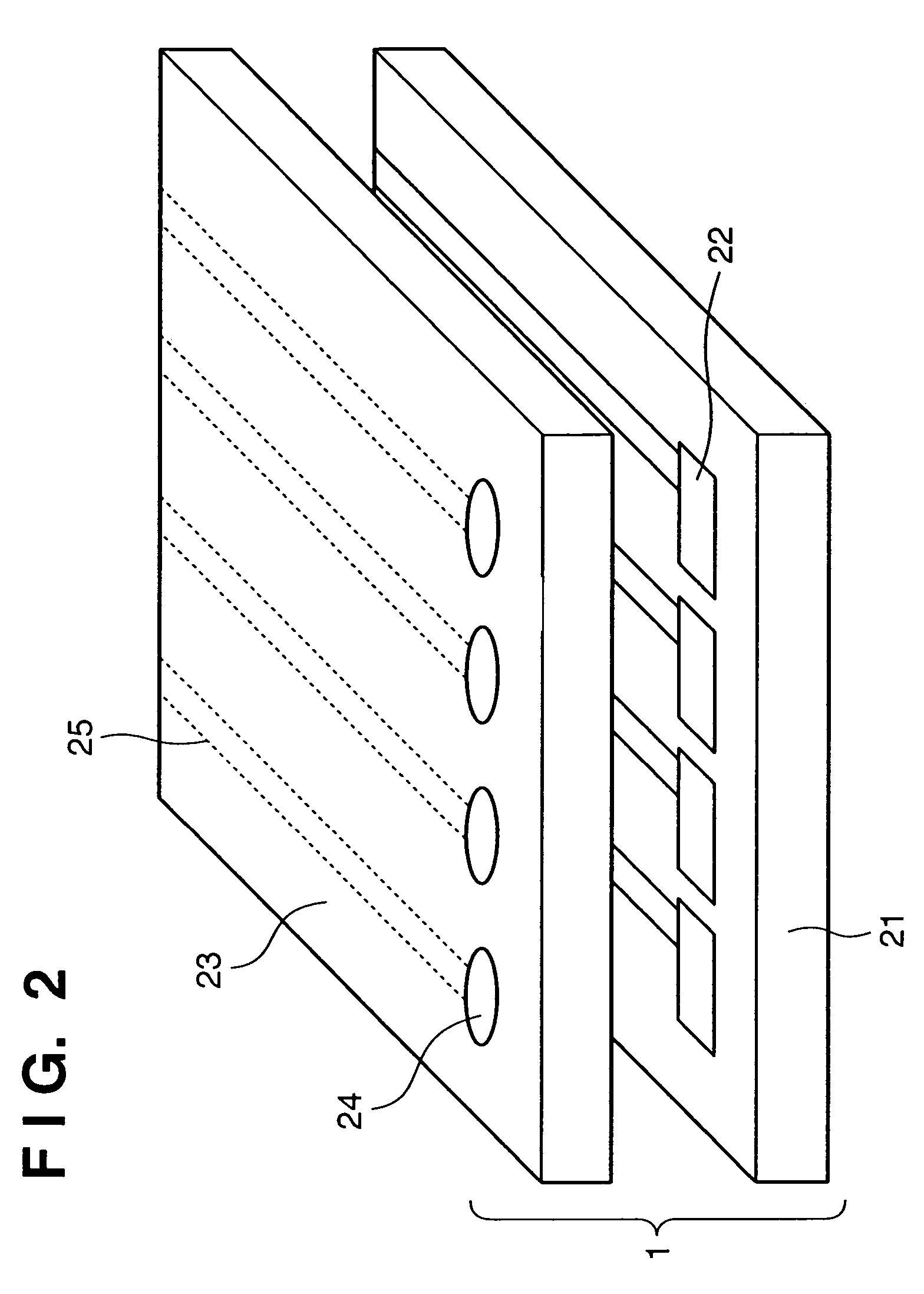

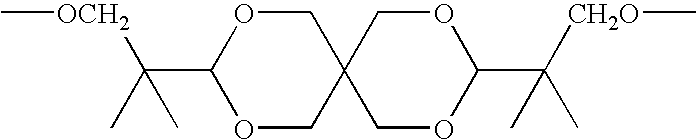

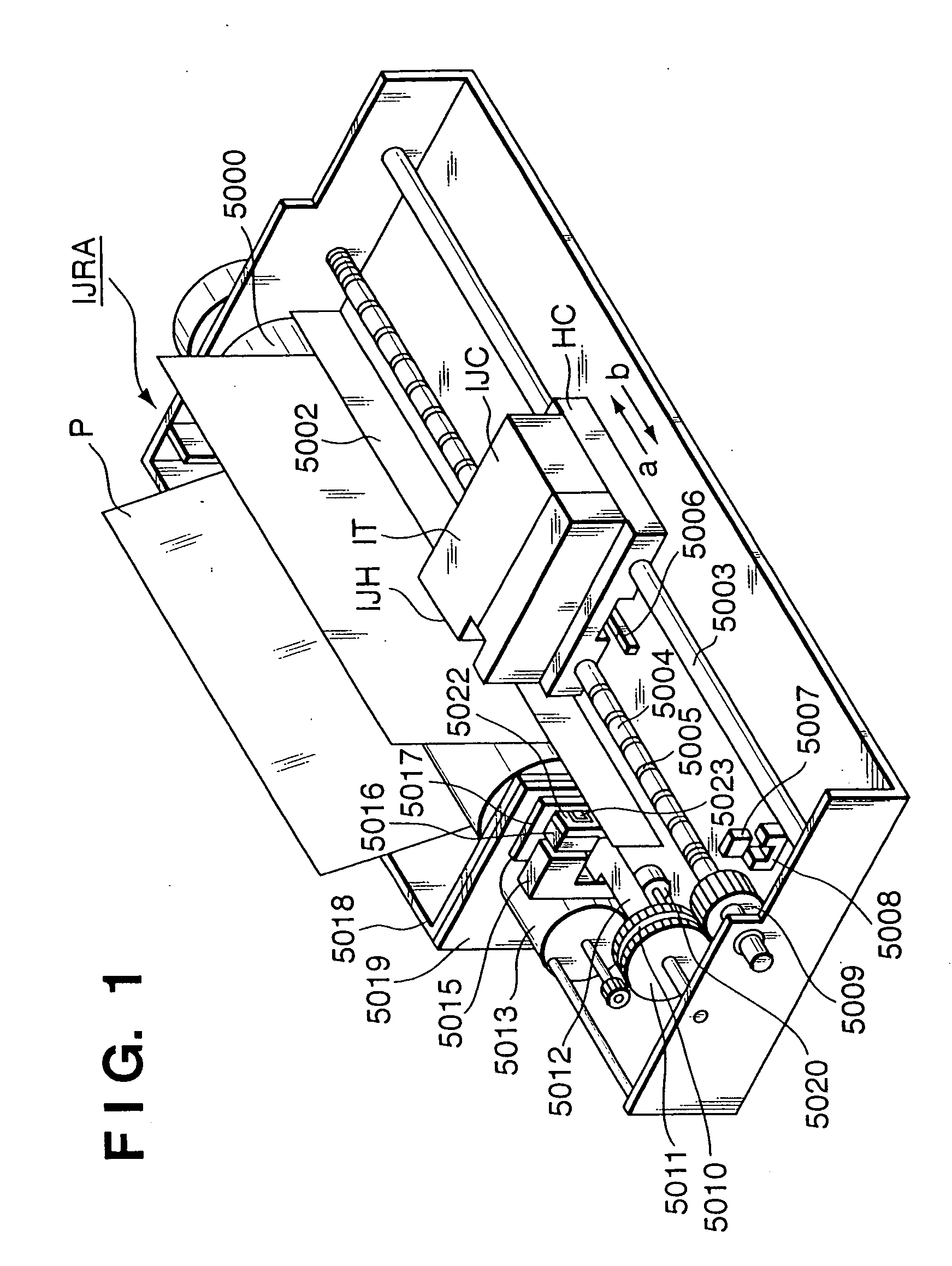

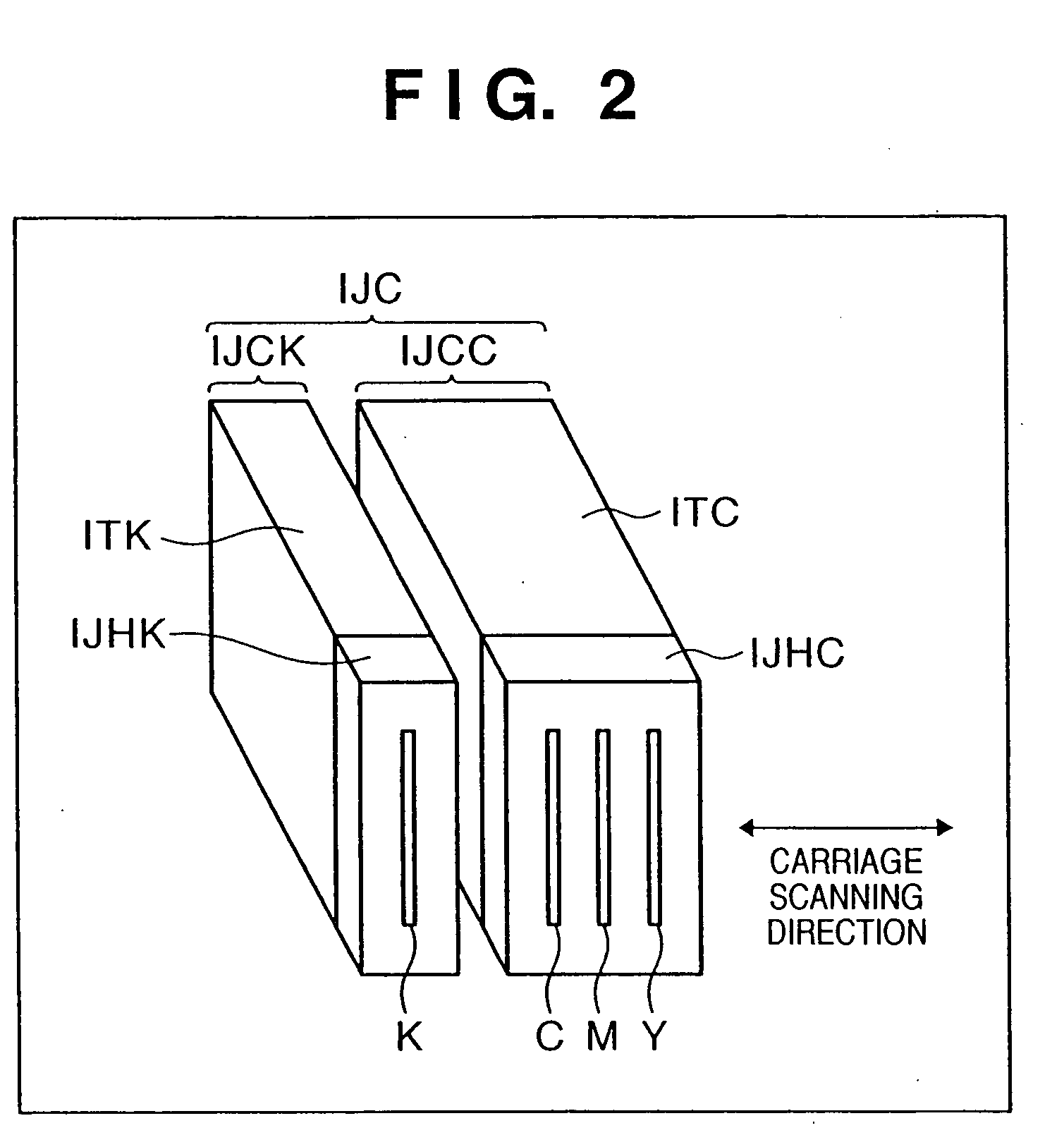

Printhead substrate, printhead, head cartridge, and printing apparatus

An object of this invention is to provide a driving circuit layout which suppresses an increase in the area of a head substrate in an inkjet printhead adopting a constant electric current driving method. To achieve this object, a plurality of printing elements and a plurality of switching elements which are very large in number are arrayed in the longitudinal direction of a head substrate. A terminal which receives a driving signal and a control signal that are used to drive the plurality of printing elements is arranged at the end of the board in the widthwise direction of the board. A electric current source for supplying a predetermined electric current is interposed in an area between these two areas.

Owner:CANON KK

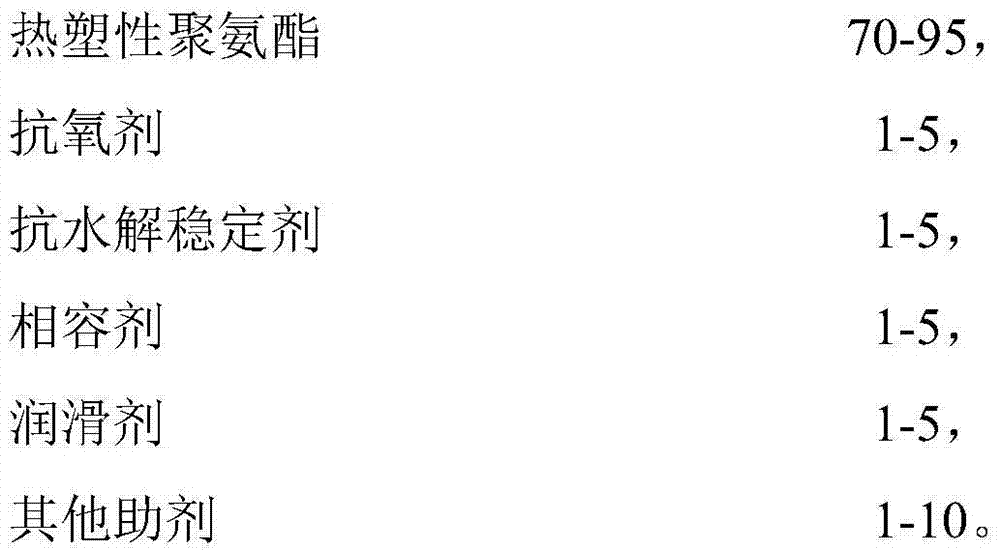

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

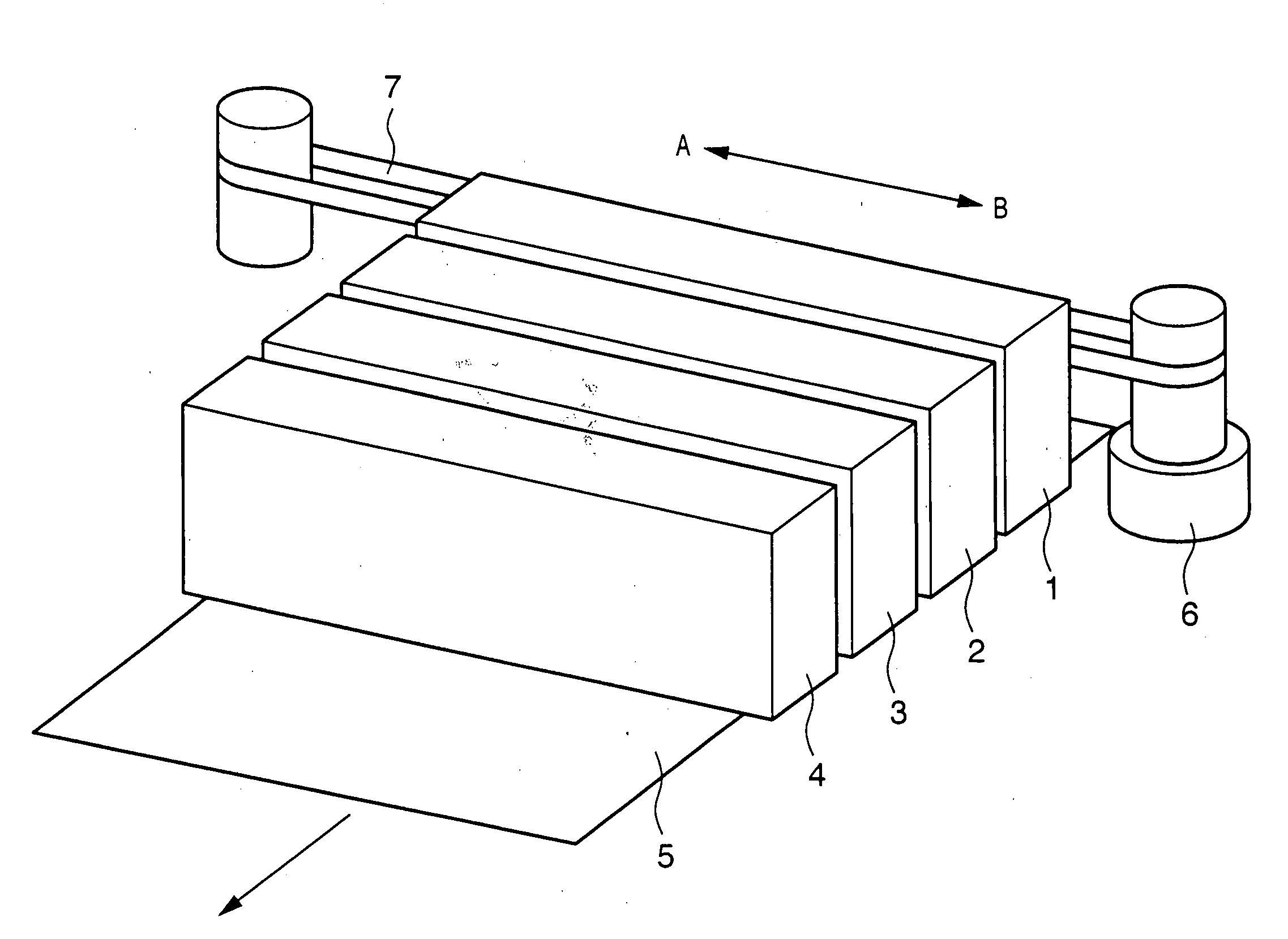

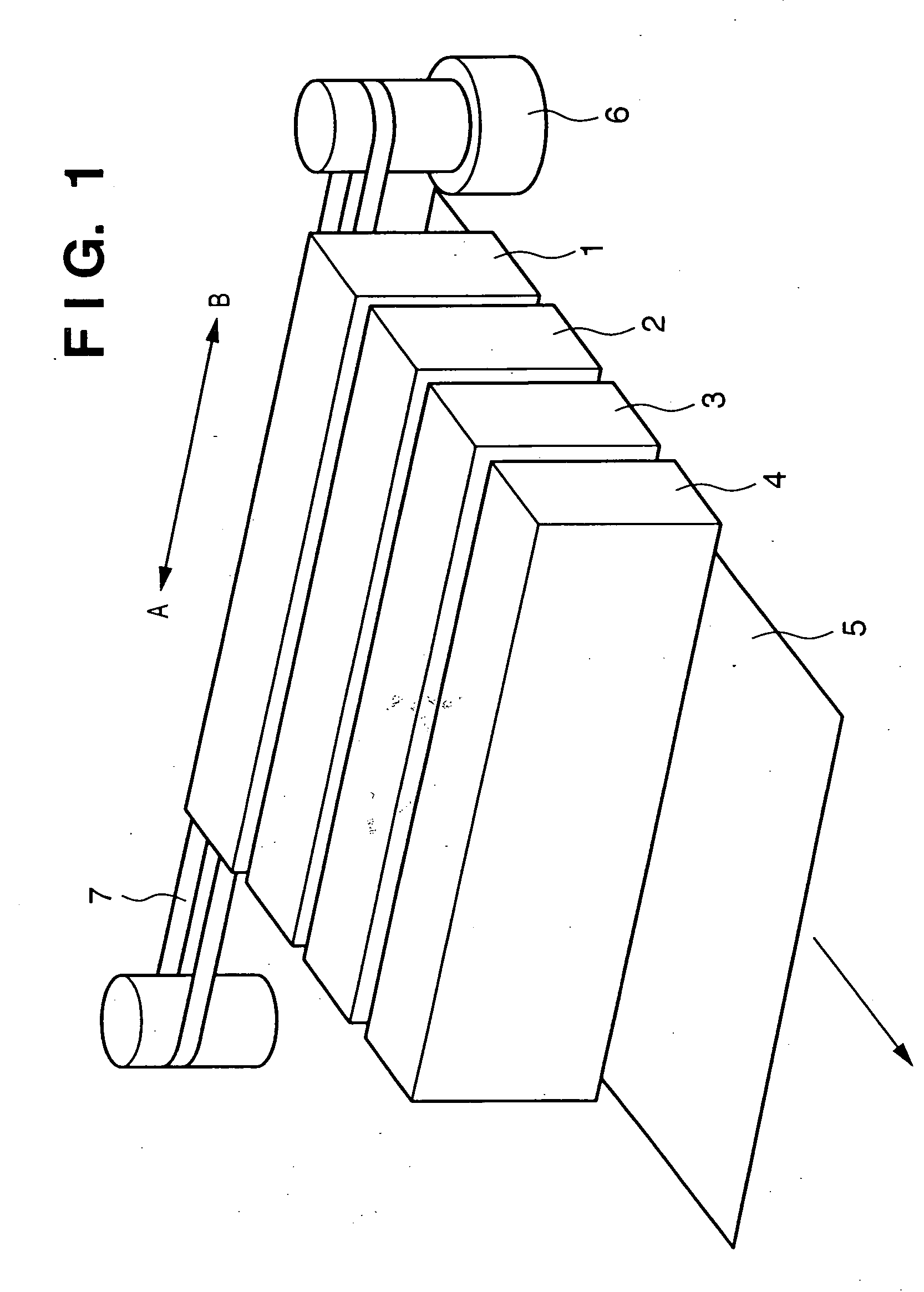

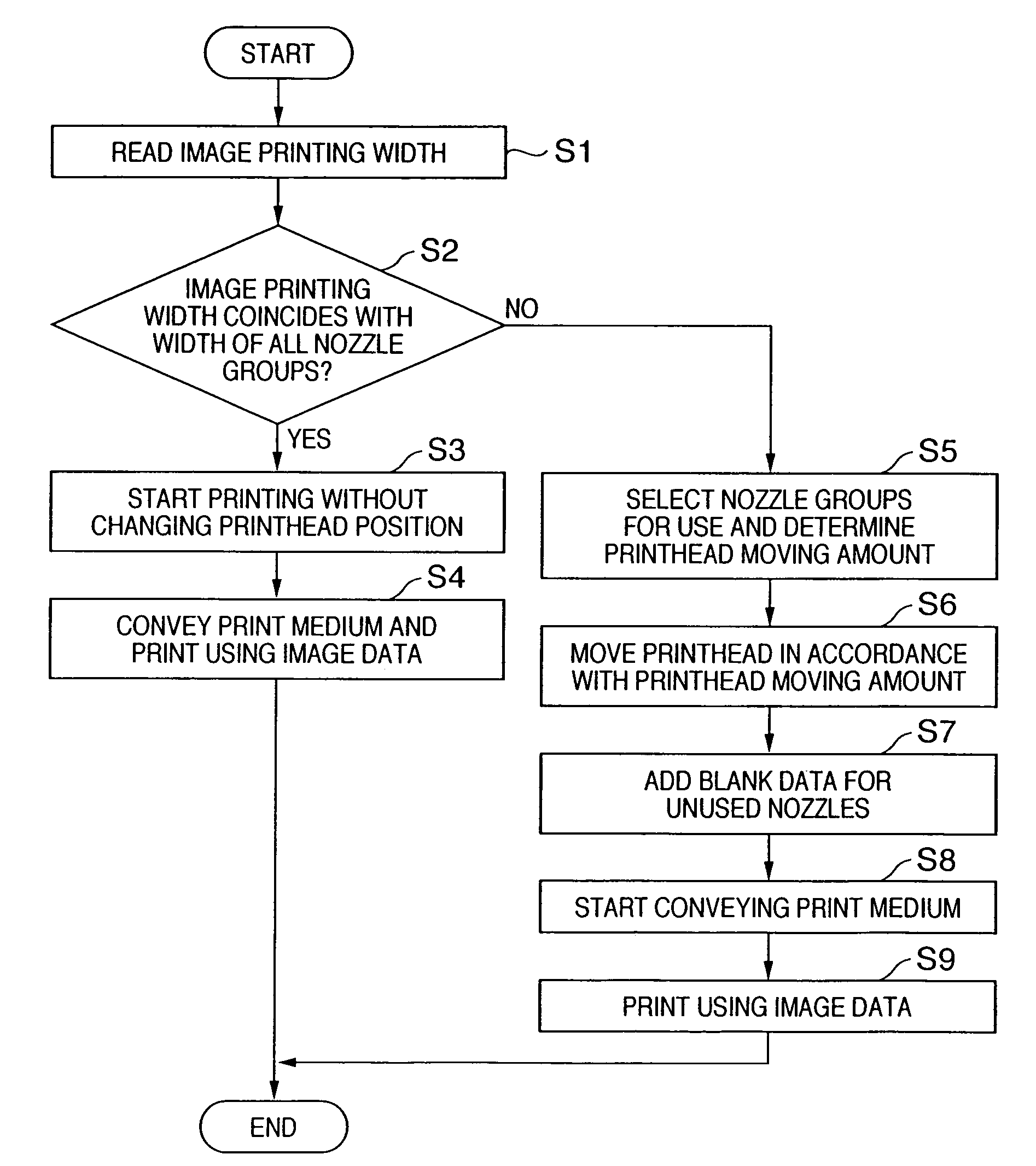

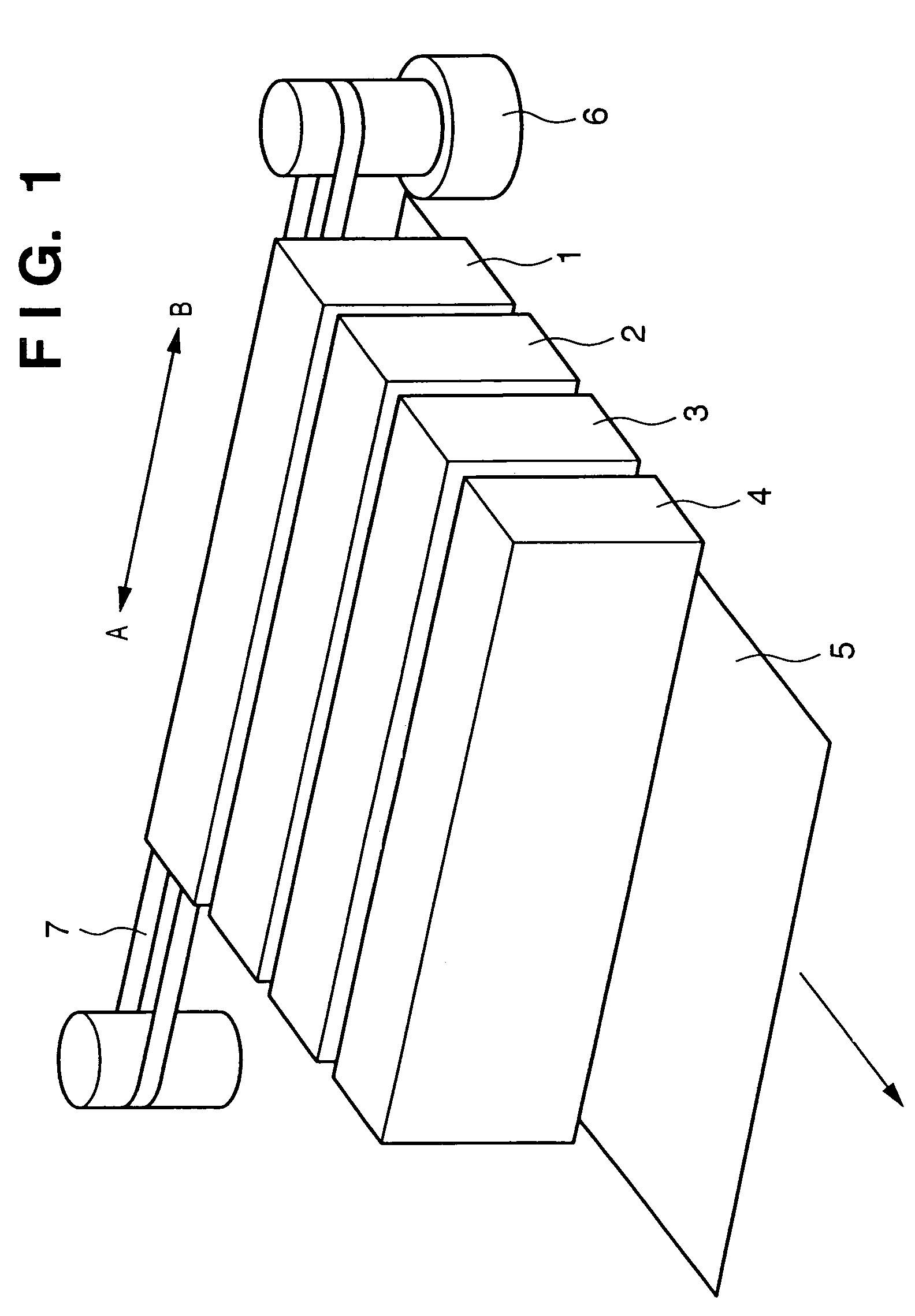

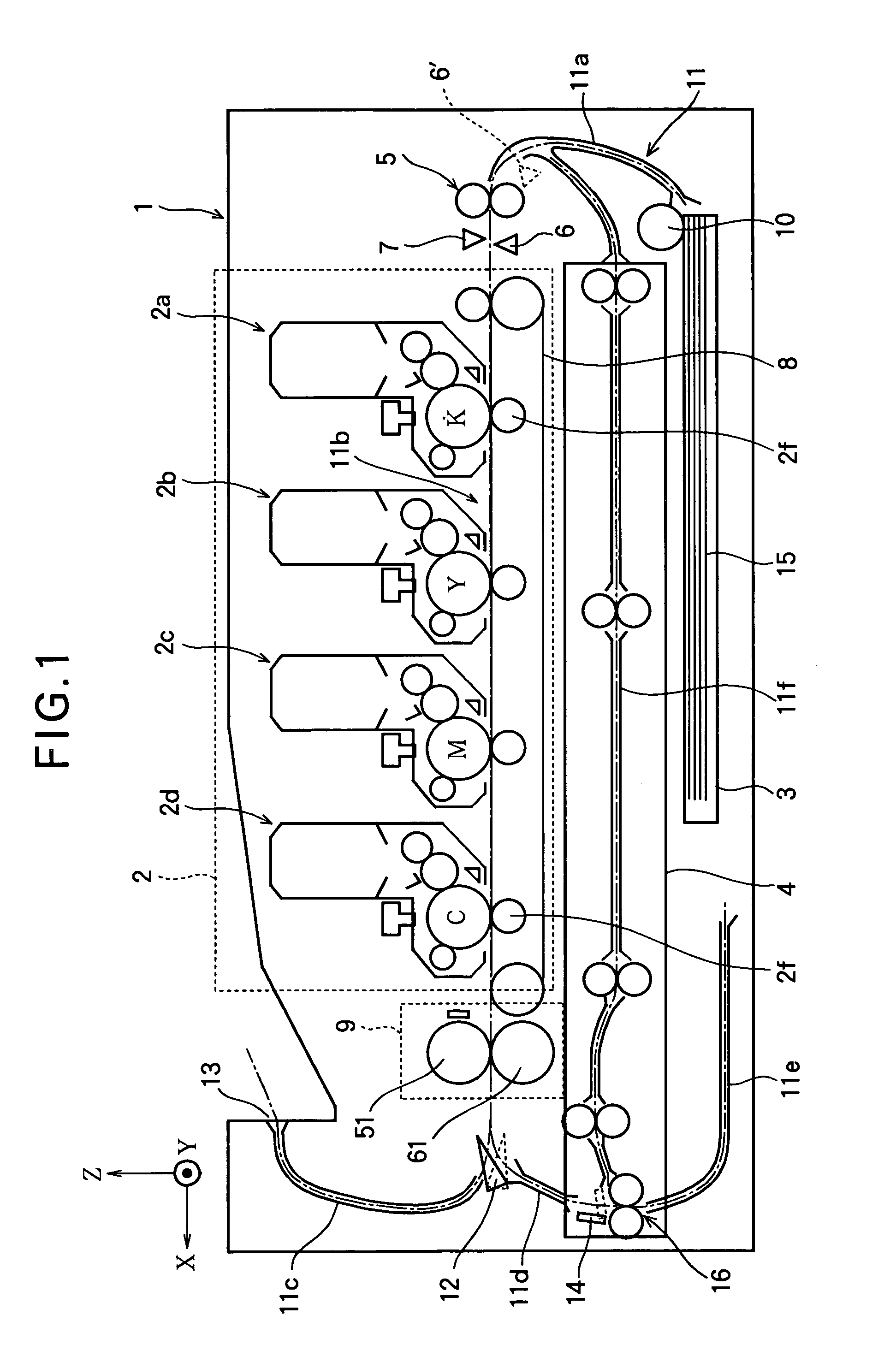

Printing apparatus and printing method

InactiveUS20050275684A1Low costHigh quality printingInking apparatusPower drive mechanismsPrint mediaImaging quality

This invention relates to a printing apparatus and printing method which can stably print at high image quality on print media of various sizes by using a full-line printhead. The printing method uses a full-line printhead which has a long printing width and is configured by arraying a plurality of substrates each prepared by arraying a plurality of printing elements and each having a given printing width. When printing is done by conveying a print medium in a direction different from the array direction of the printing elements having the long printing width, printing elements used for printing are selected in accordance with an input image printing width so that an area printed on the print medium by printing elements corresponding to the connected portions between the substrates becomes a visually least perceivable area on the print medium. The relative moving amount of the full-line printhead to the print medium is so determined as to print by using the selected printing elements. The relative position of the full-line printhead is moved by the determined relative moving amount, and printing is done using the selected printing elements at the position after movement.

Owner:CANON KK

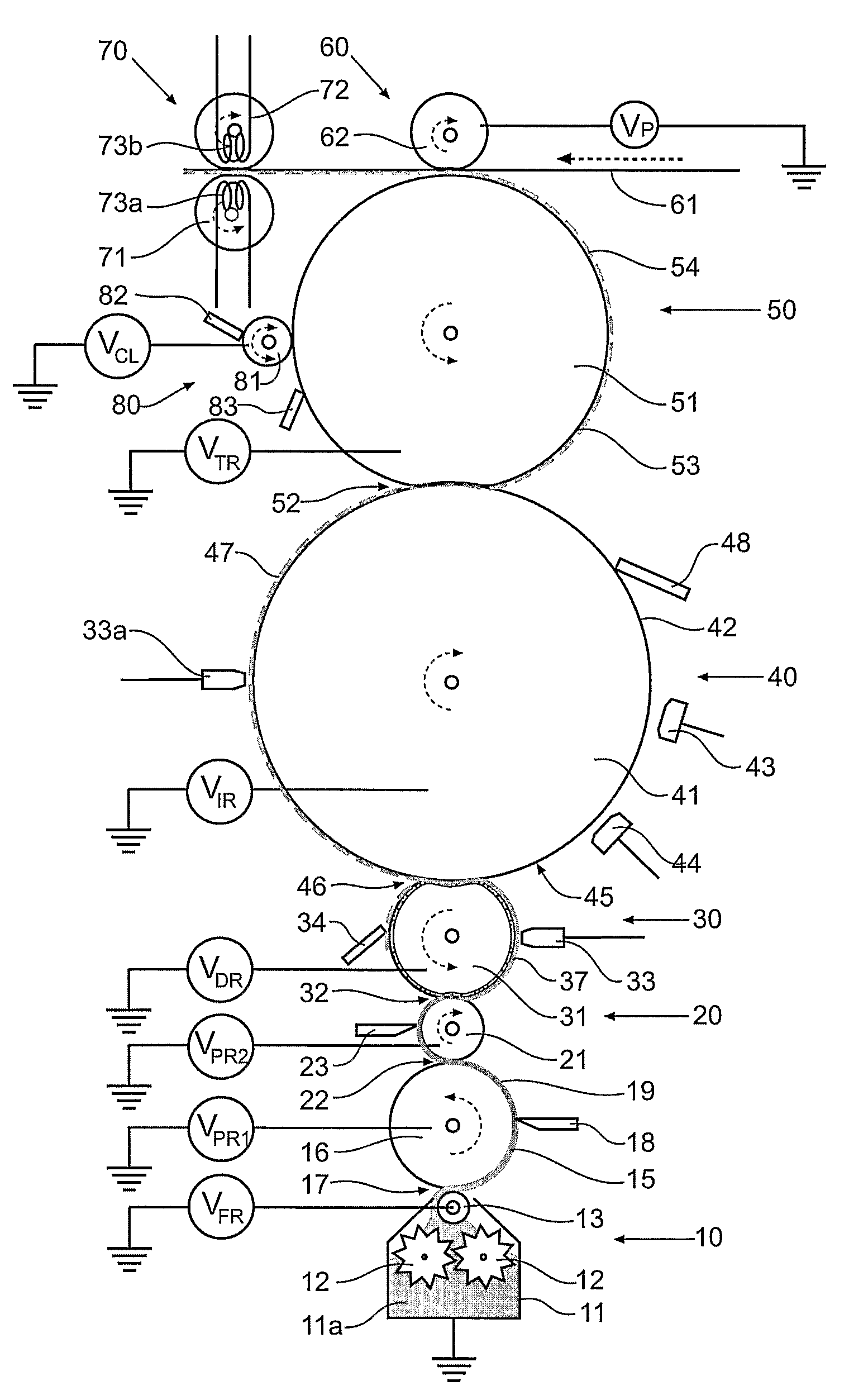

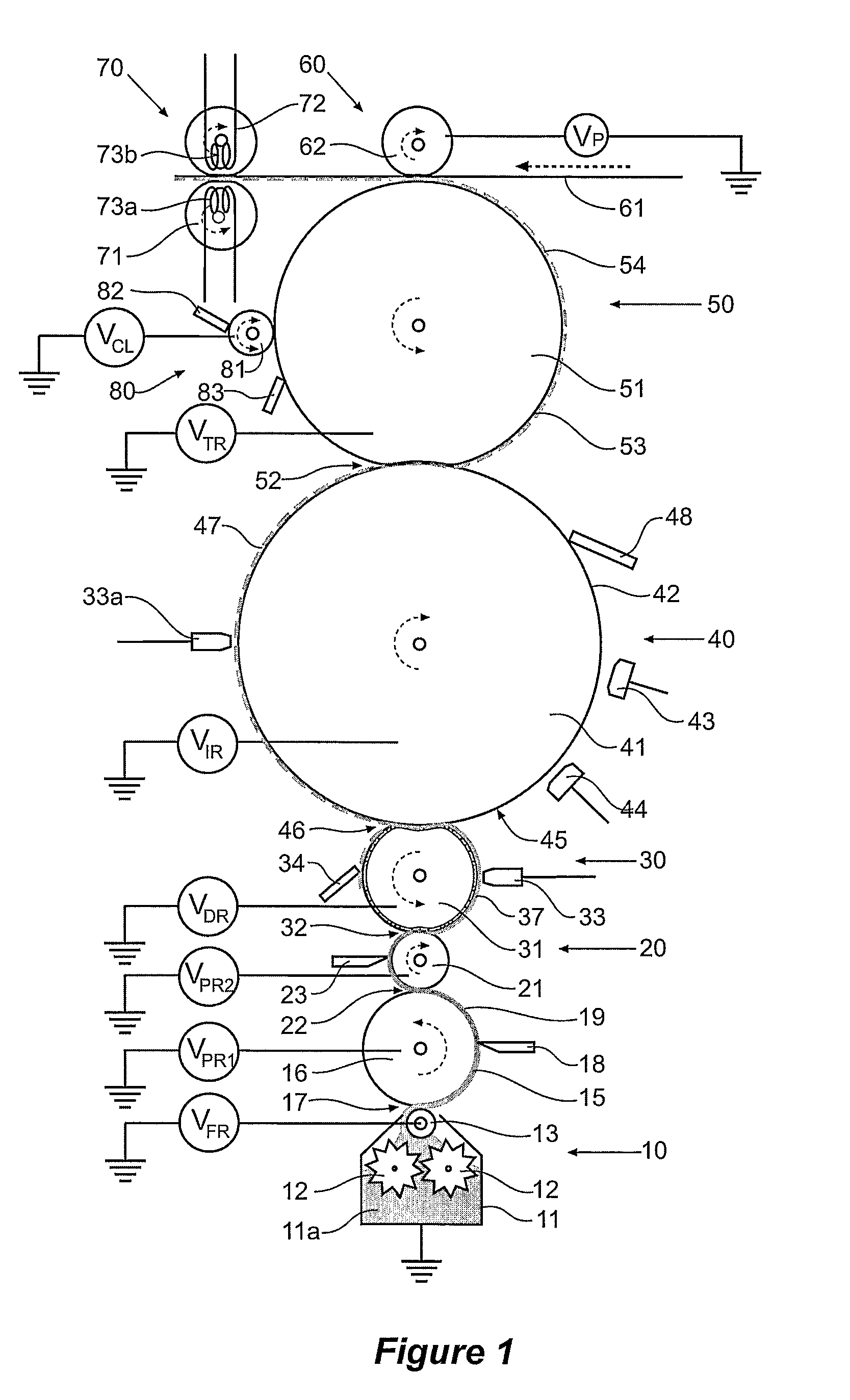

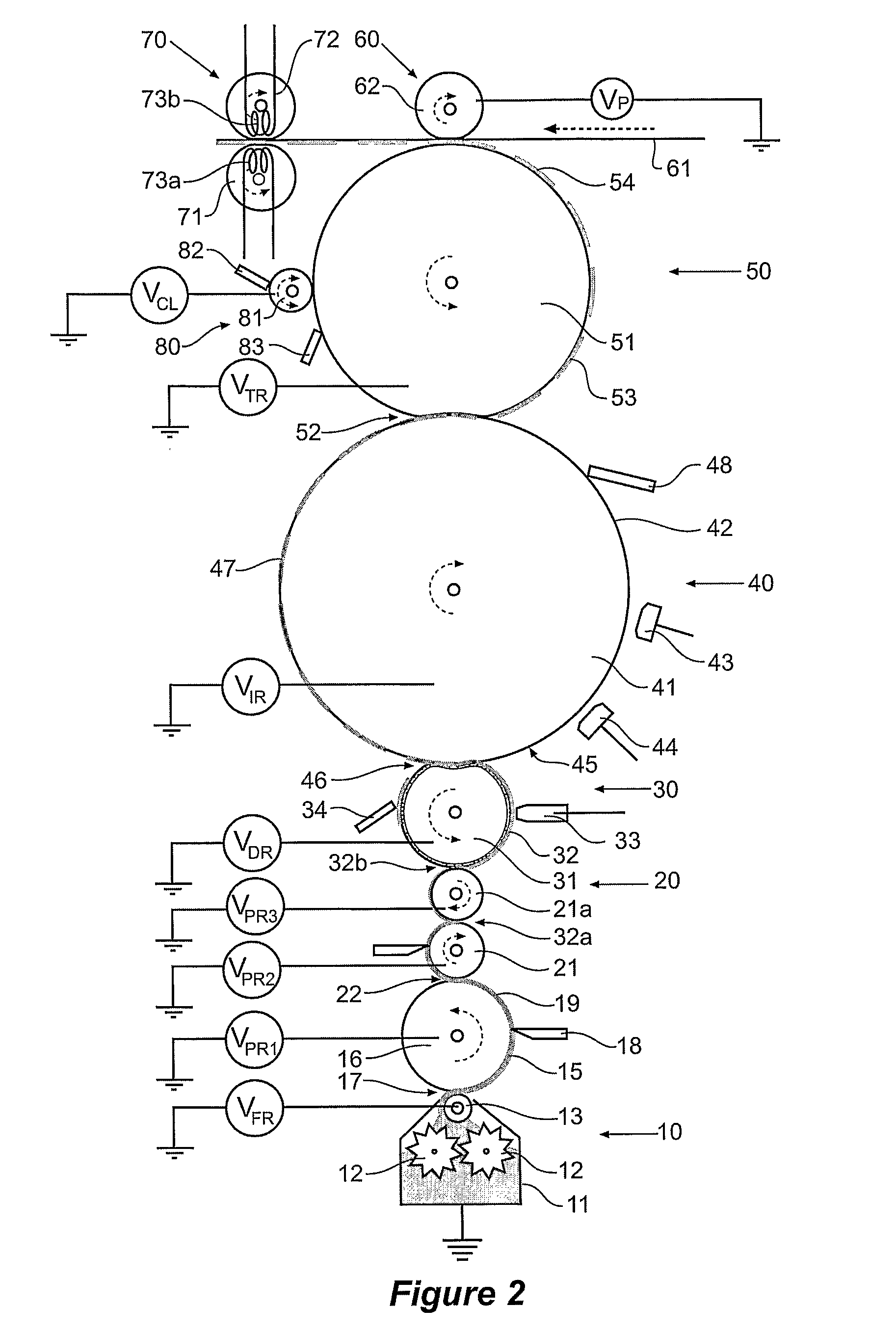

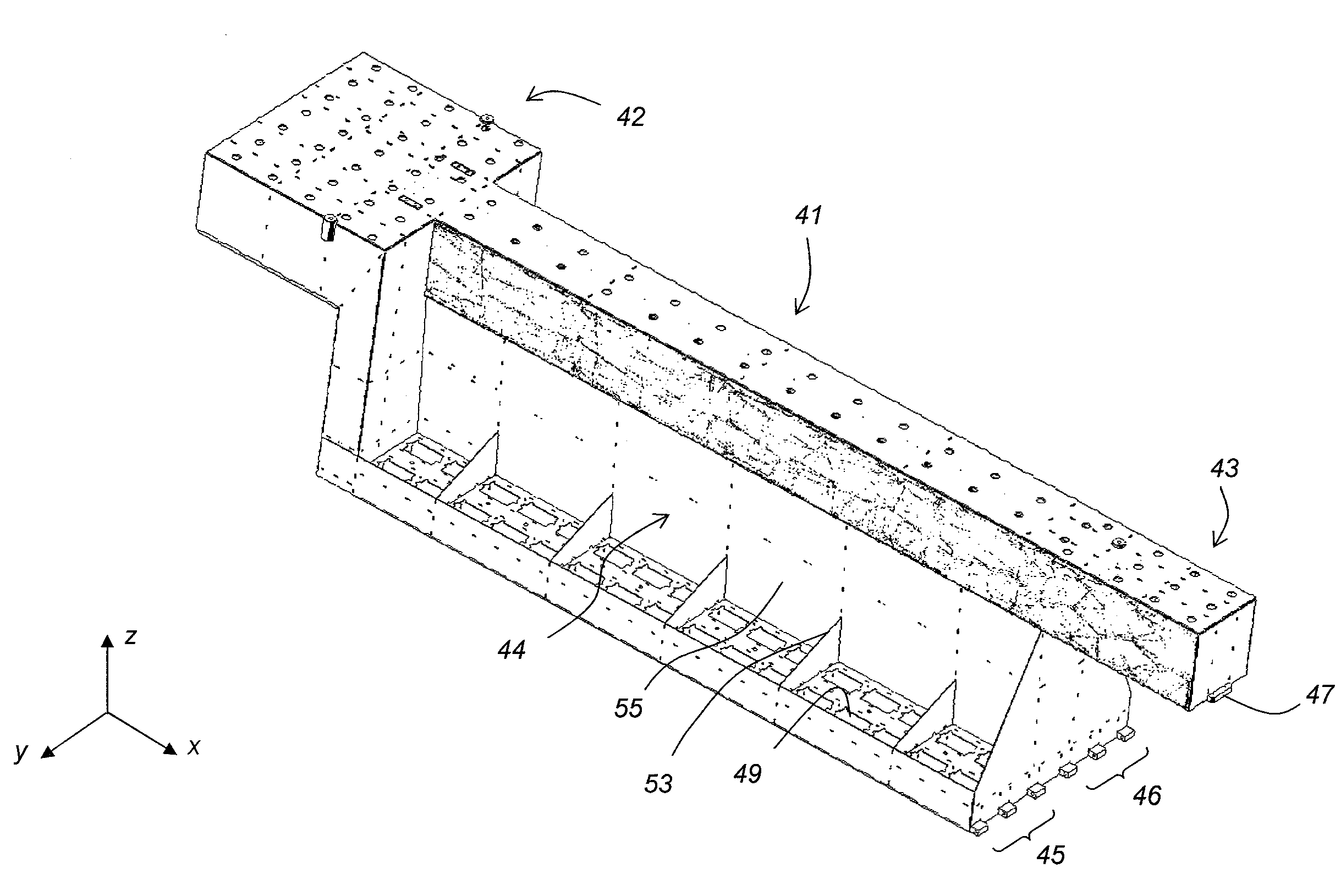

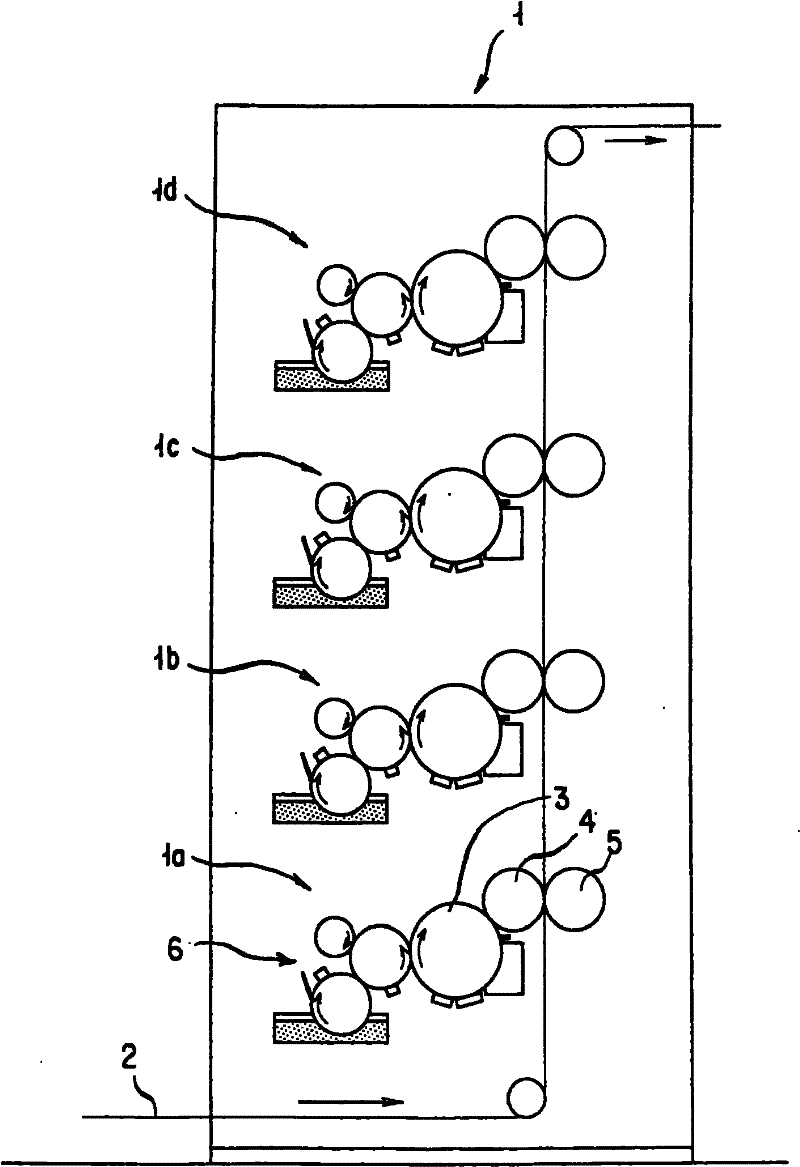

High Speed Electrographic printing

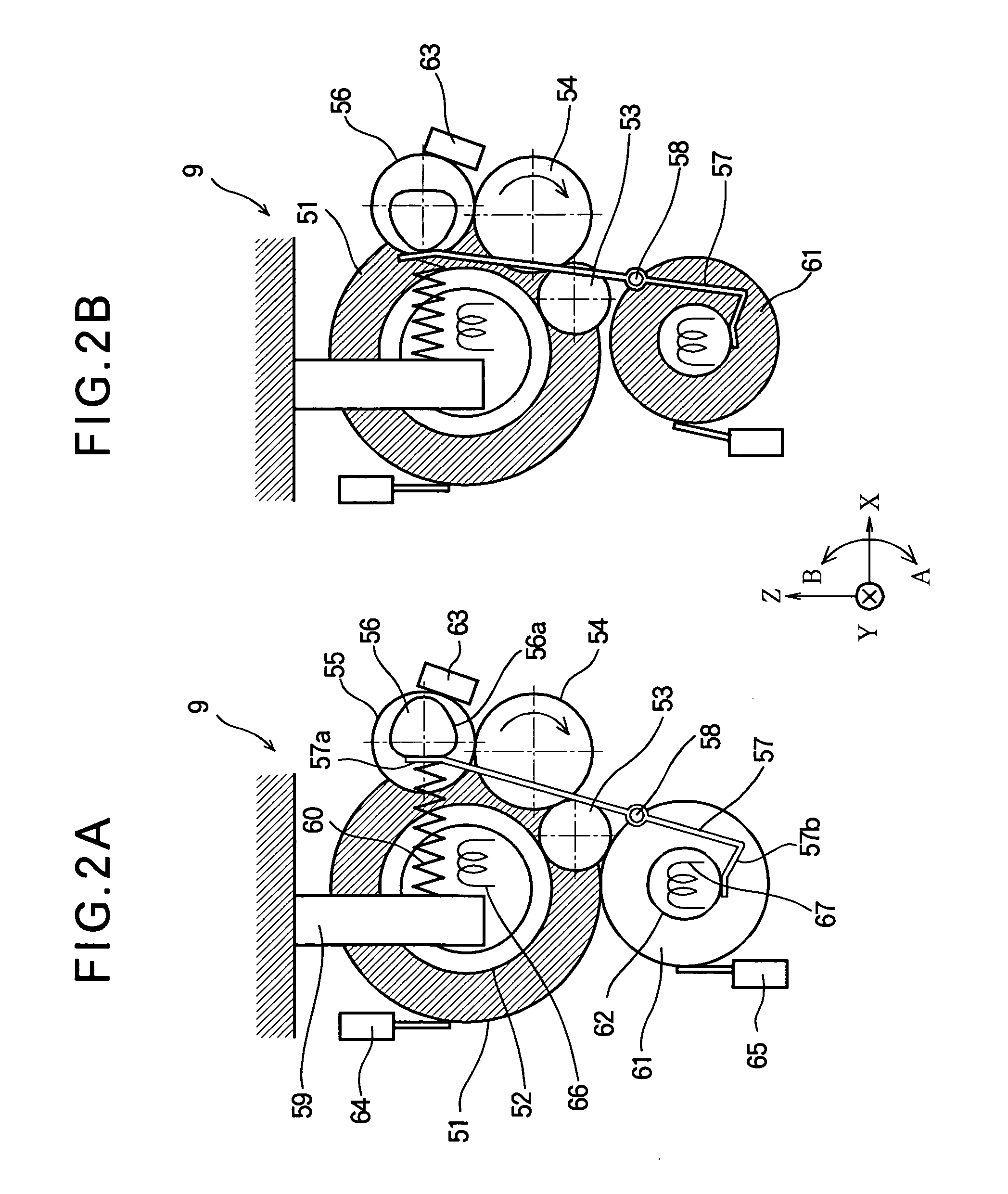

InactiveUS20090052948A1Increase the supply rateIncrease speedElectrographic process apparatusThin layerContact time

A high speed electrostatic printing machine has a toner supply to supply to a supply roller (13) a high viscosity highly concentrated toner; a pick-up roller (16) which is spaced from the supply roller by a first feed gap; a metering roller (21) which receives a thin layer of the toner from the pick-up roller; a doctor blade (23) bearing against the metering roller which bears against a development member (31) with an interference fit (32) to transfer a thin layer of the toner onto the development member; an image forming stage (40), the image forming stage comprising an image carrying member (41) having a surface adapted to retain an electrostatic latent image thereon with the development member engaging against the image carrying member with an interference fit (46) to give a selected contact time therebetween; a development stage in which toner particles in the thin layer on the development member are transferred to the image carrying member under the influence of the electrostatic latent image on the image carrying member to provide a developed image thereon; and a transfer stage (50) in which the developed image is transferred from the image carrying member onto a substrate (61), or a further member, such as an intermediate member (5). A carrier liquid displacement device (33) acts upon the thin layer of toner on the development member (31) to push toner particles in the thin layer towards the surface of the roller and to leave a carrier liquid rich layer on the outside of the thin toner layer.

Owner:XEIKON

Metallic pigment, pigment dispersion liquid, metallic pigment ink composition, and ink jet recording method

ActiveUS8313572B2Stable printingGlossiness improvedMeasurement apparatus componentsInksMetal foilPigment dispersion

This invention provides a metallic pigment, which can prepare a printed matter having metallic luster, can realize stable printing even in a printer with ink jet nozzles having a nozzle diameter of not more than 30 μm, can eliminate the need to carry out heat treatment and the like, and, thus, can realize ink jet recording without undergoing a limitation on printing media (recording media), an ink composition, and an ink jet recording method. The metallic pigment is a metal foil piece having an average thickness of 30 to 100 μm, having a 50% average particle diameter of not less than 0.5 μm and not more than 4.0 μm, and having such a particle size distribution that the maximum particle diameter is not more than 12 μm. An ink composition containing this metallic pigment and an ink jet head having a nozzle diameter of not more than 30 μm are provided, and the ratio between the average particle diameter of the metallic pigment and the nozzle diameter of the ink jet head (average particle diameter / nozzle diameter) is preferably brought to not more than 0.15.

Owner:SEIKO EPSON CORP

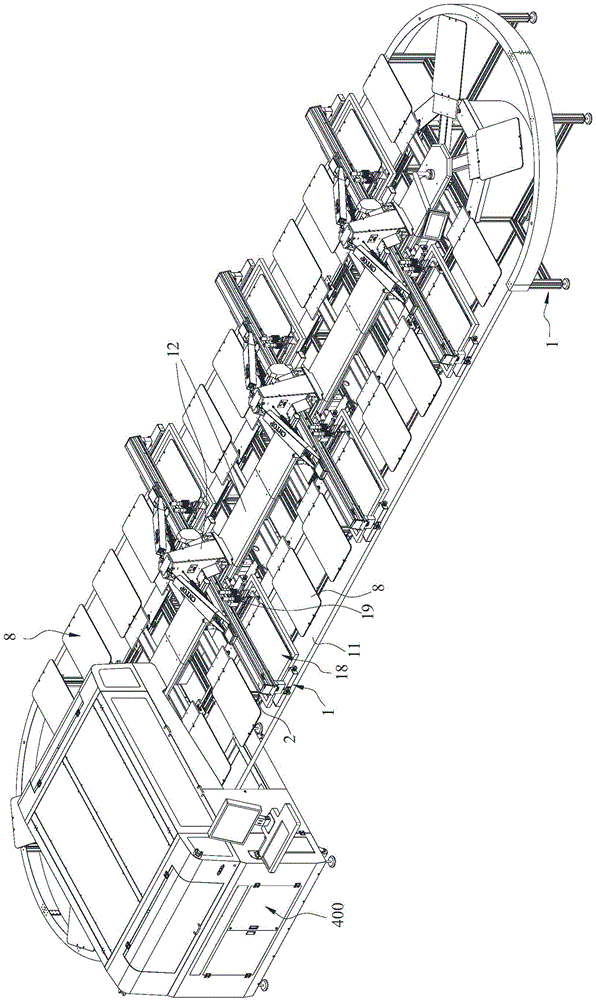

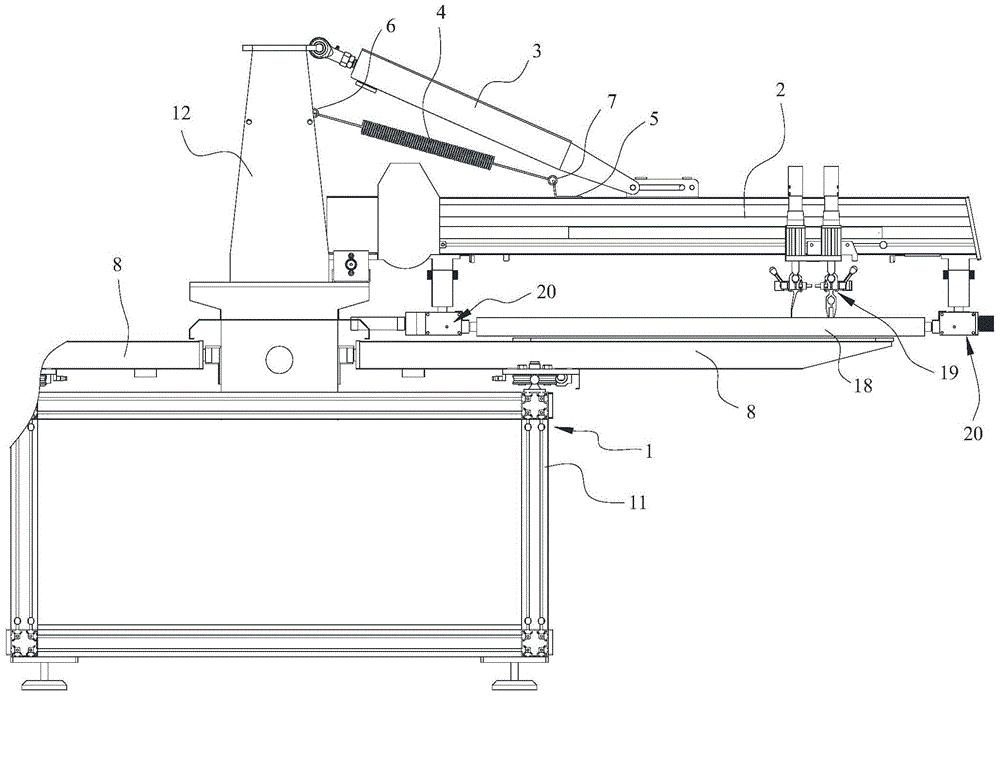

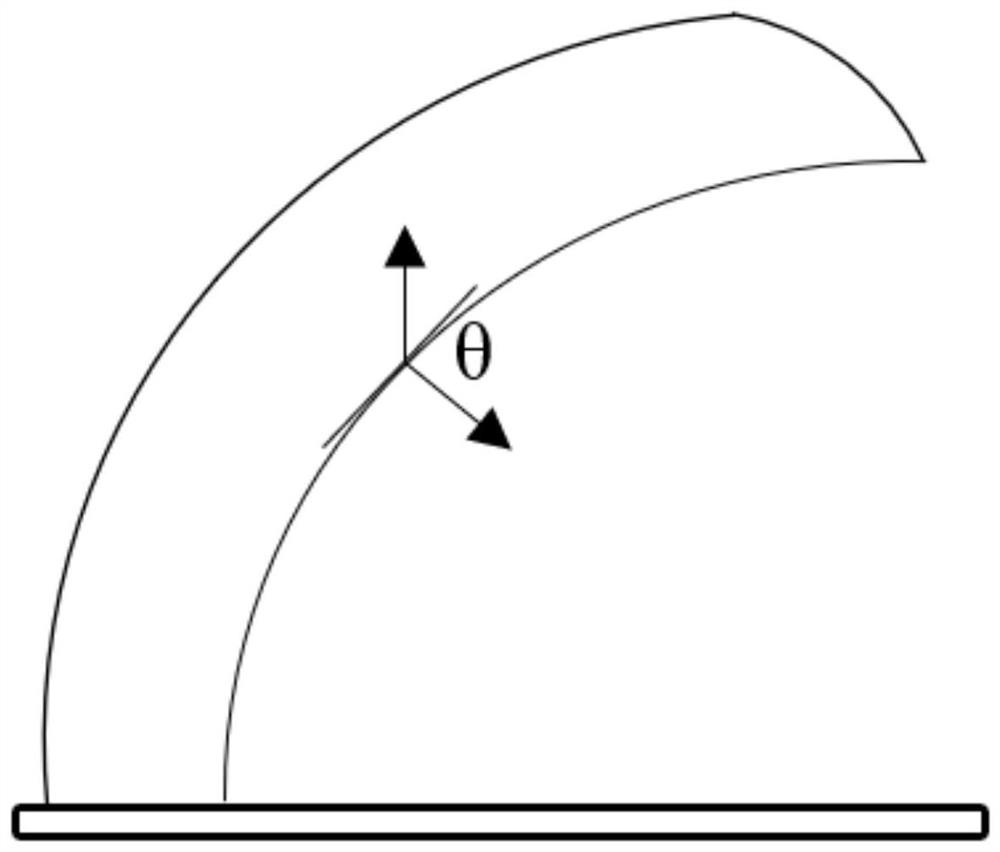

Novel decorating machine

The invention discloses a novel decorating machine. The novel decorating machine comprises a table rack, a printing arm, a cylinder, an extension spring, an elastic table plate, a screen frame, a scraper, and a screen frame fixing device, wherein the table rack comprises a rack leg and a fixed arm fixed on the rack leg, the fixed arm is linear, the rack leg wounds the periphery of the fixed arm, one end of the printing arm is hinged to the lower portion of the fixed arm, a piston rod of the cylinder extends out of one end of a cylinder body of the cylinder to be hinged to the upper end of the fixed arm, the other end of the cylinder body of the cylinder is hinged to the middle of the printing arm and is in sliding match with the printing arm in the direction of the length of the printing arm, one end of the extension spring is connected with the middle of the fixed arm, the other end of the extension spring is connected with the printing arm through a sliding plate, the sliding plate is in sliding match with the printing arm, and the bottom of the elastic table plate is in sliding match with the rack leg. The novel decorating machine is capable of buffering the action performed by the cylinder to lift or press the printing arm, greatly reducing vibration by the aid of an elastic force produced by the elastic table plate, and improving register accuracy.

Owner:SHENZHEN CNTOP DIGITAL EQUIP CO LTD

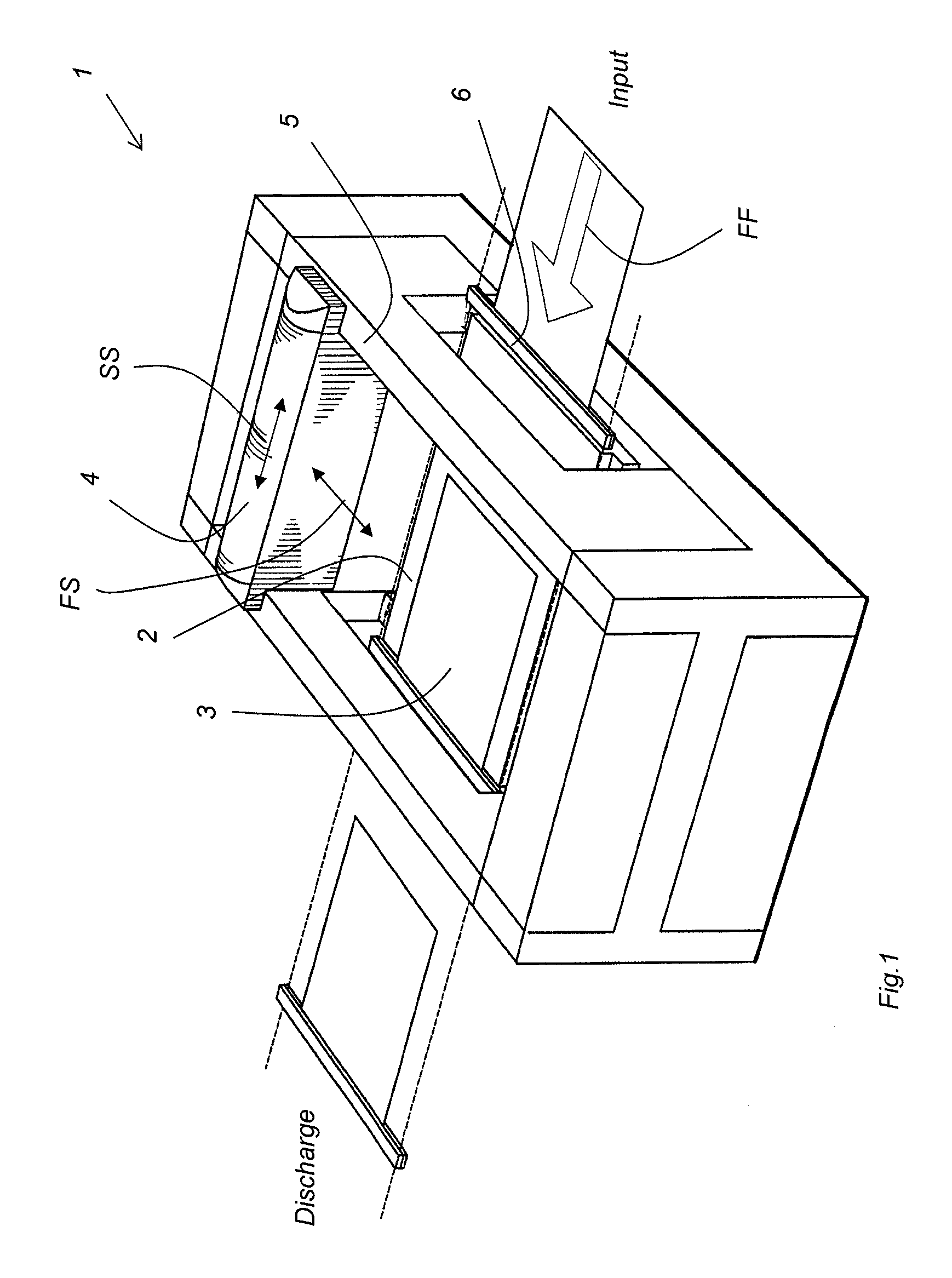

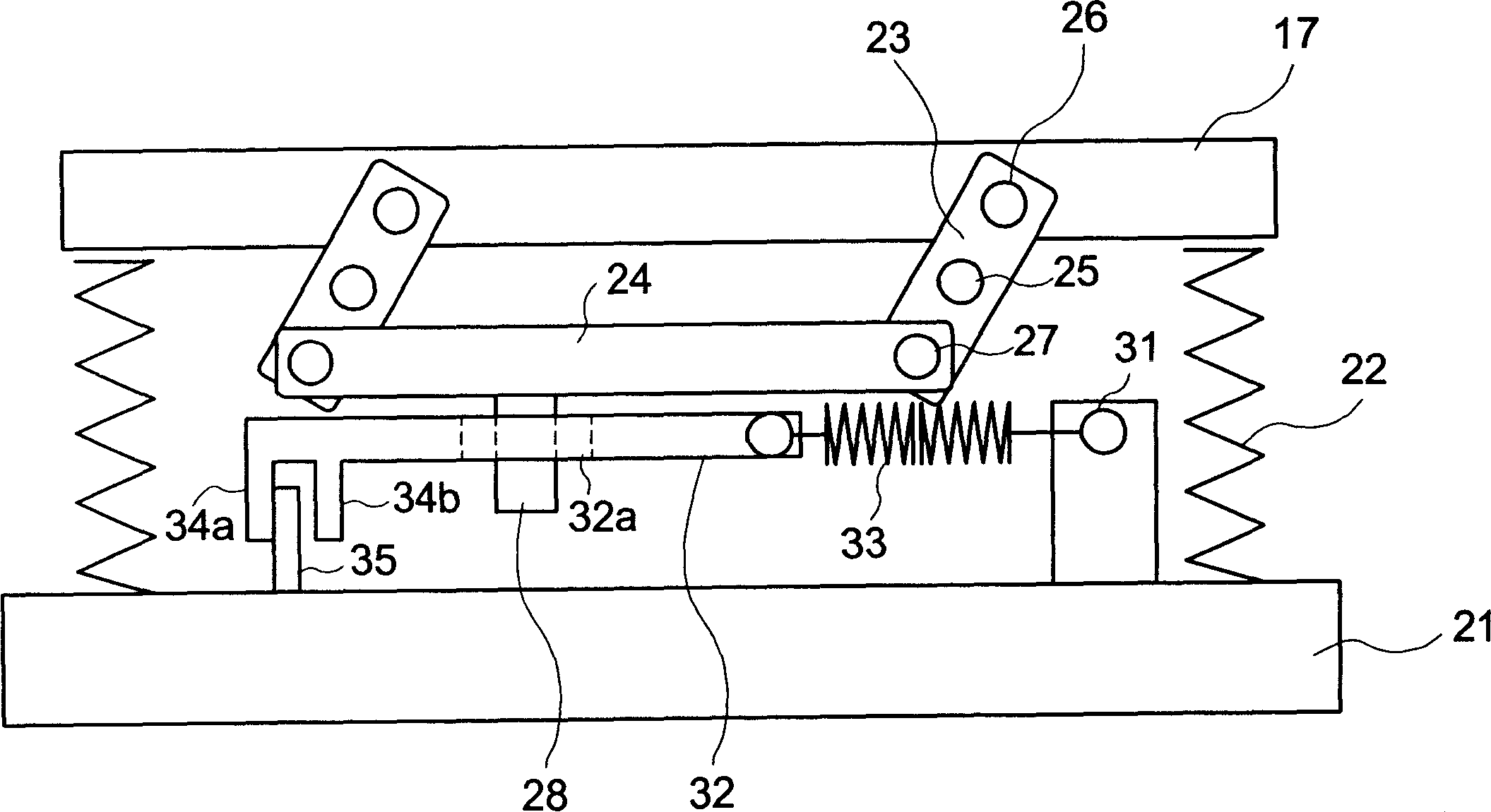

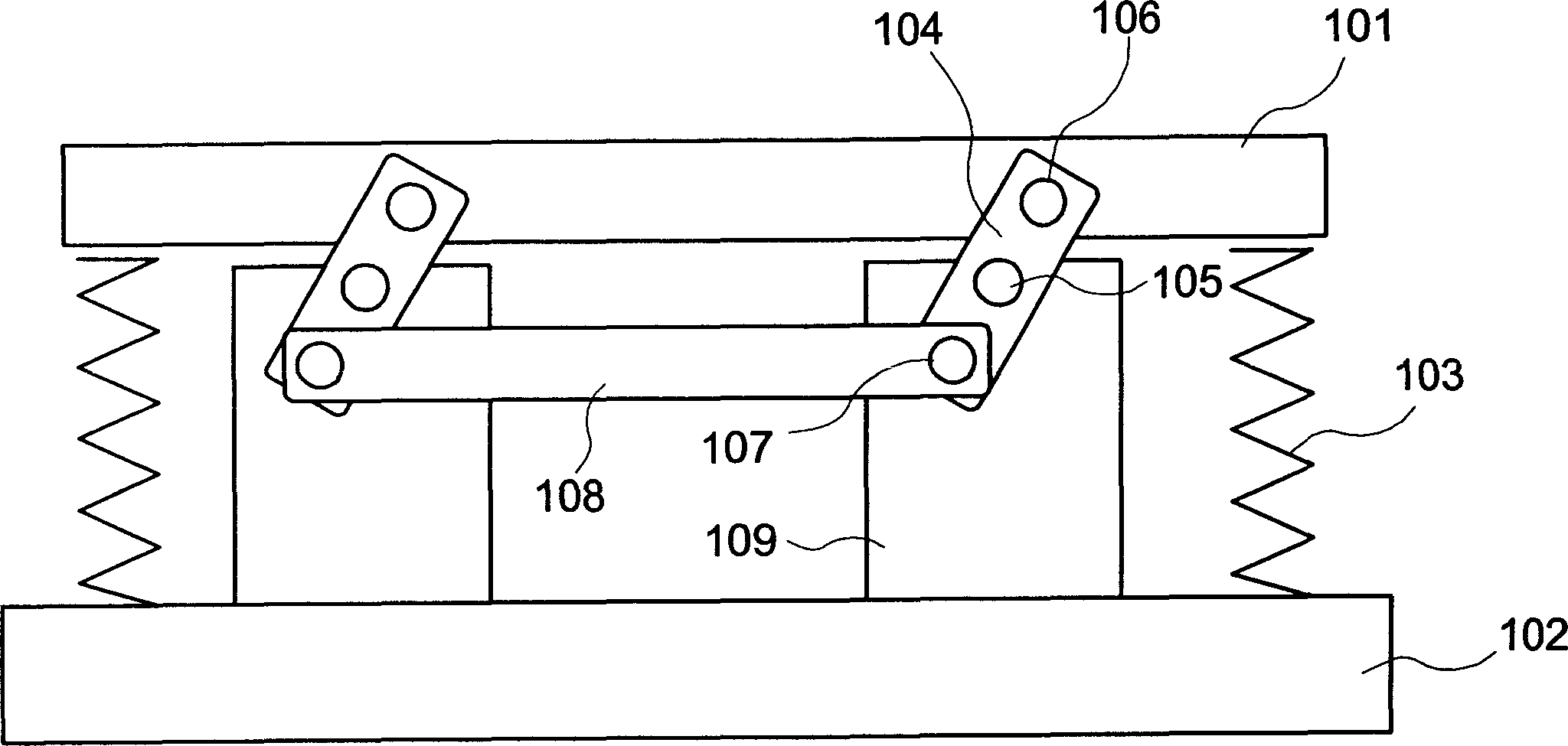

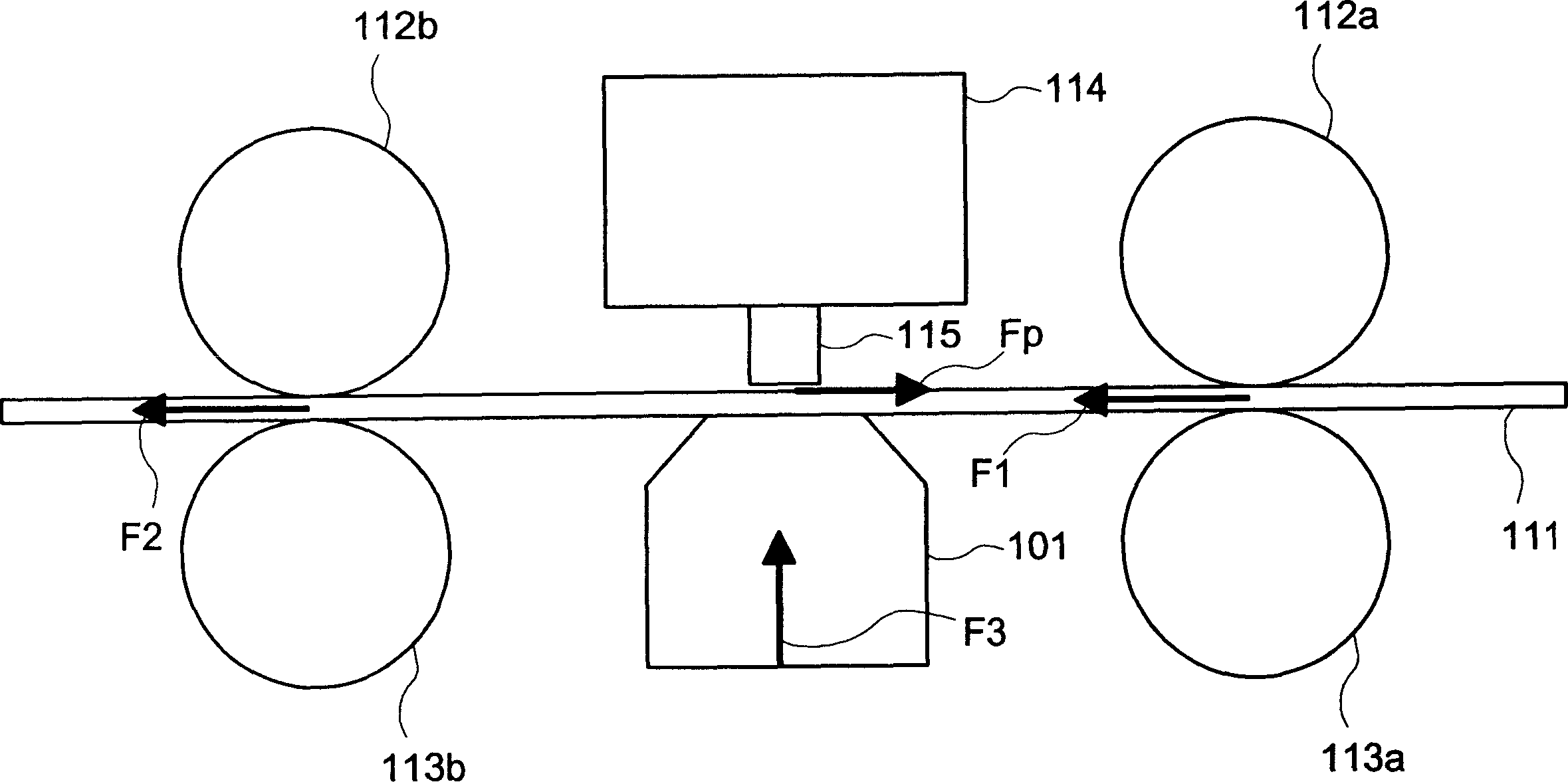

Printing apparatus and printing method

InactiveUS7278700B2Stable printingImprove image qualityInking apparatusPower drive mechanismsPrint mediaImaging quality

This invention relates to a printing apparatus and printing method which can stably print at high image quality on print media of various sizes by using a full-line printhead. The printing method uses a full-line printhead which has a long printing width and is configured by arraying a plurality of substrates each prepared by arraying a plurality of printing elements and each having a given printing width. When printing is done by conveying a print medium in a direction different from the array direction of the printing elements having the long printing width, printing elements used for printing are selected in accordance with an input image printing width so that an area printed on the print medium by printing elements corresponding to the connected portions between the substrates becomes a visually least perceivable area on the print medium. The relative moving amount of the full-line printhead to the print medium is so determined as to print by using the selected printing elements. The relative position of the full-line printhead is moved by the determined relative moving amount, and printing is done using the selected printing elements at the position after movement.

Owner:CANON KK

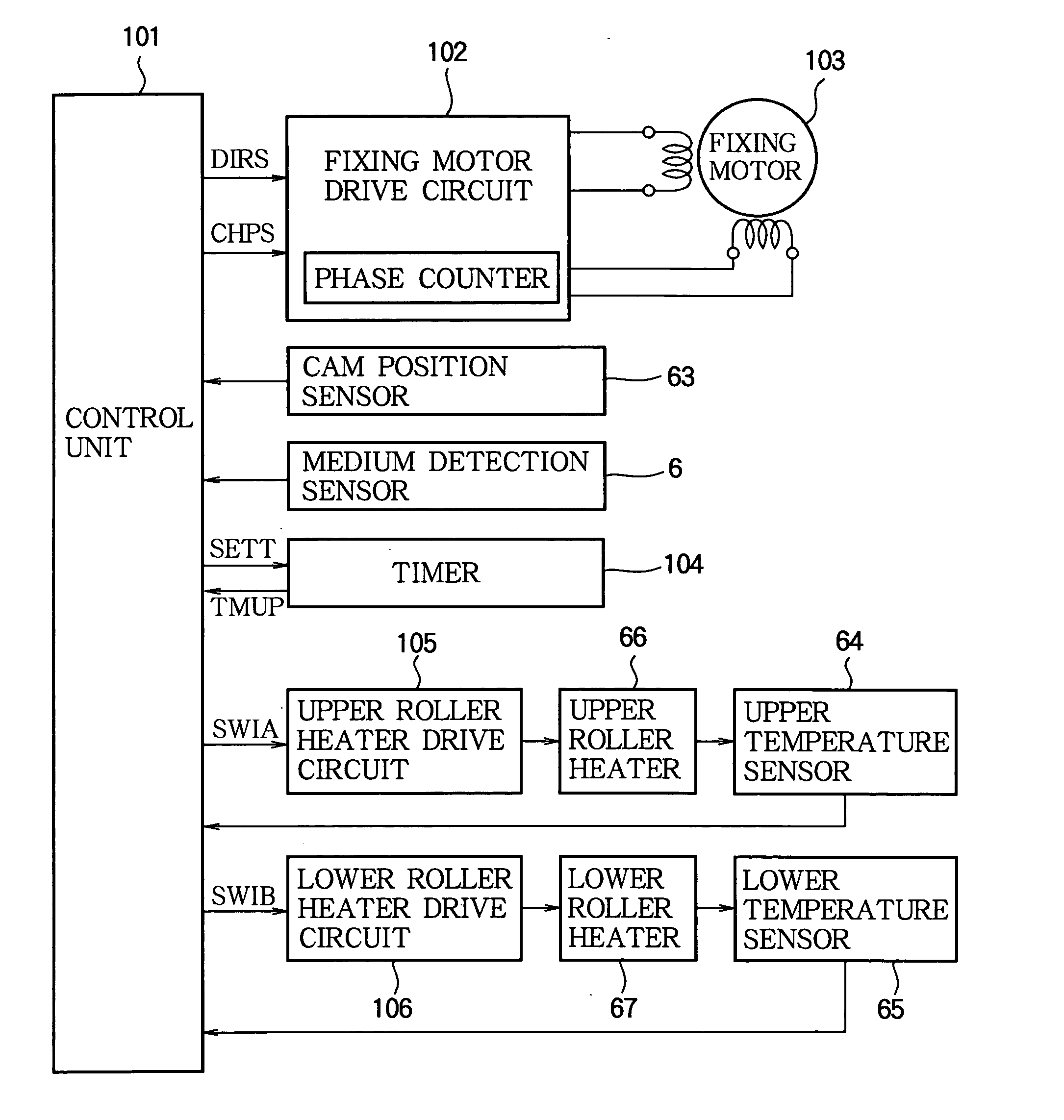

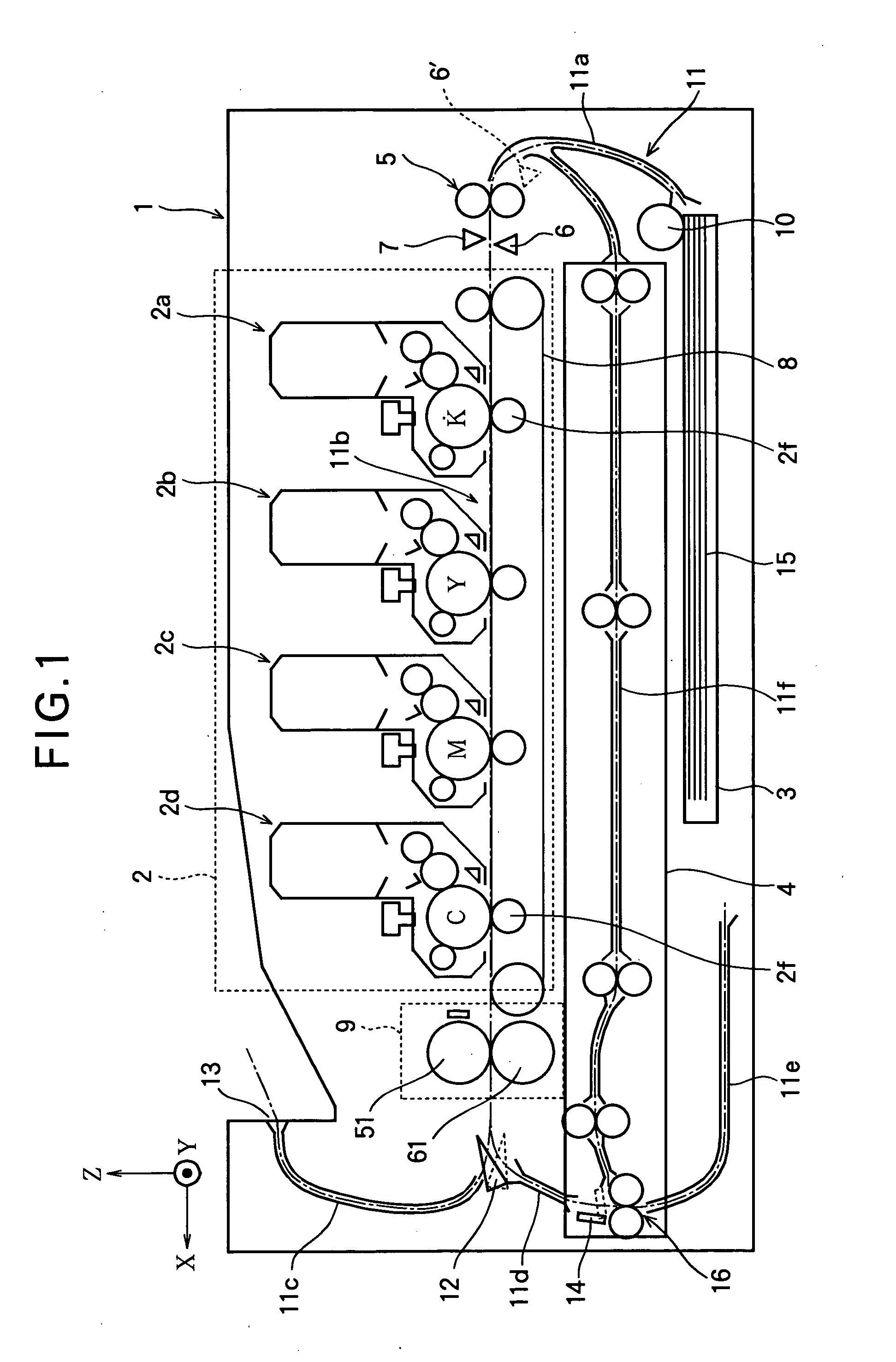

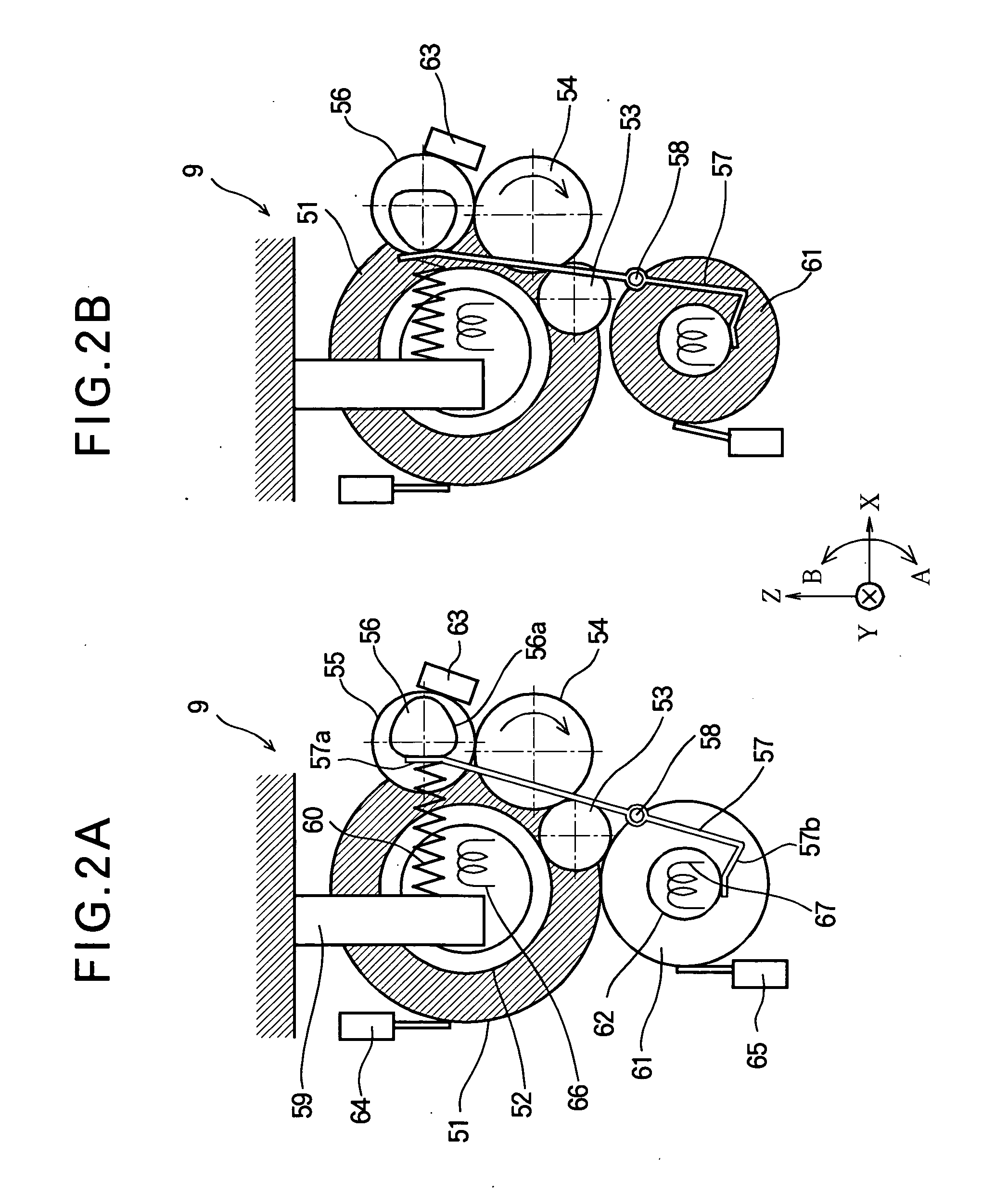

Image forming apparatus

InactiveUS20050025511A1Avoid overall overheatingStable printingElectrographic process apparatusImage formationEngineering

Owner:OKI DATA CORP

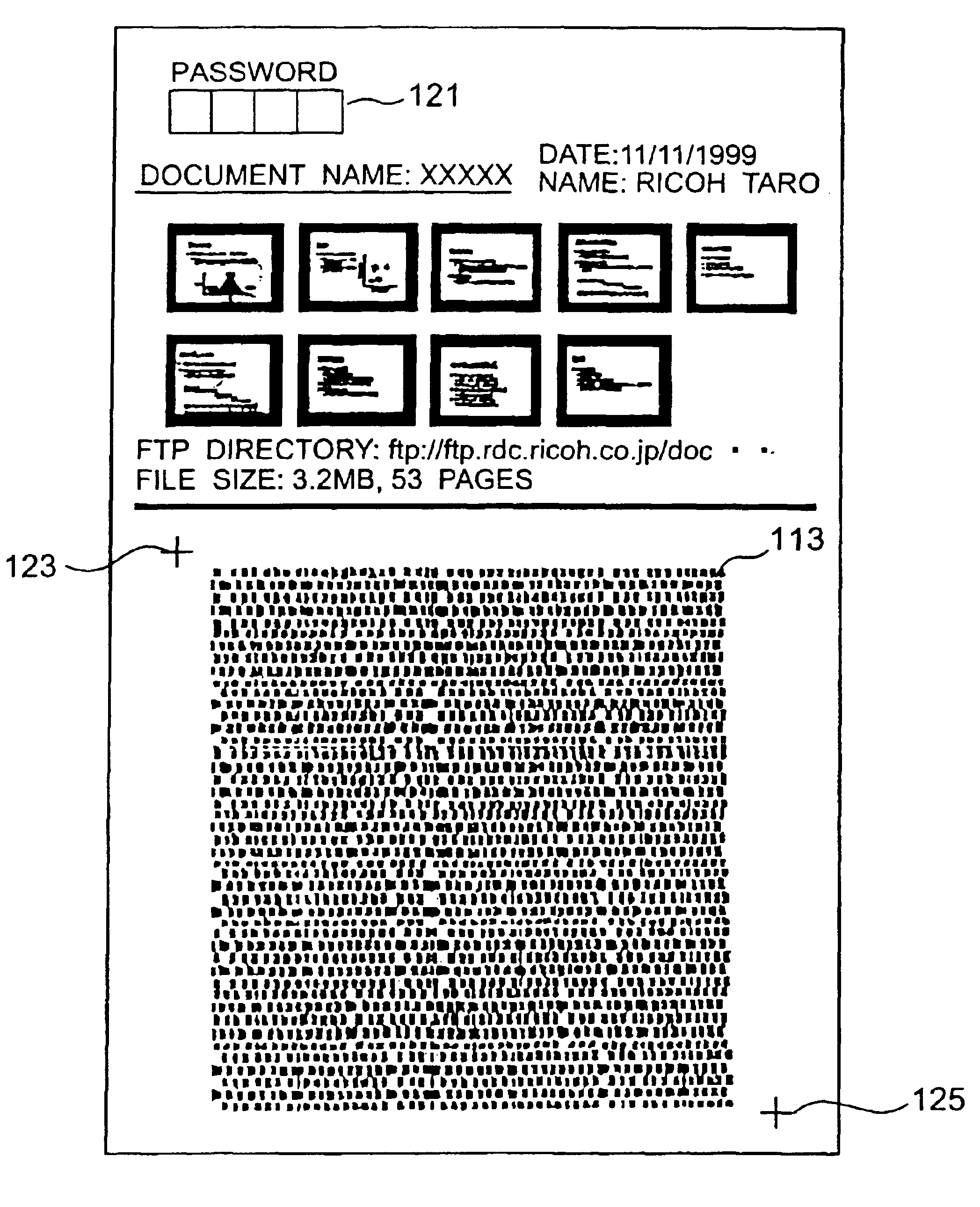

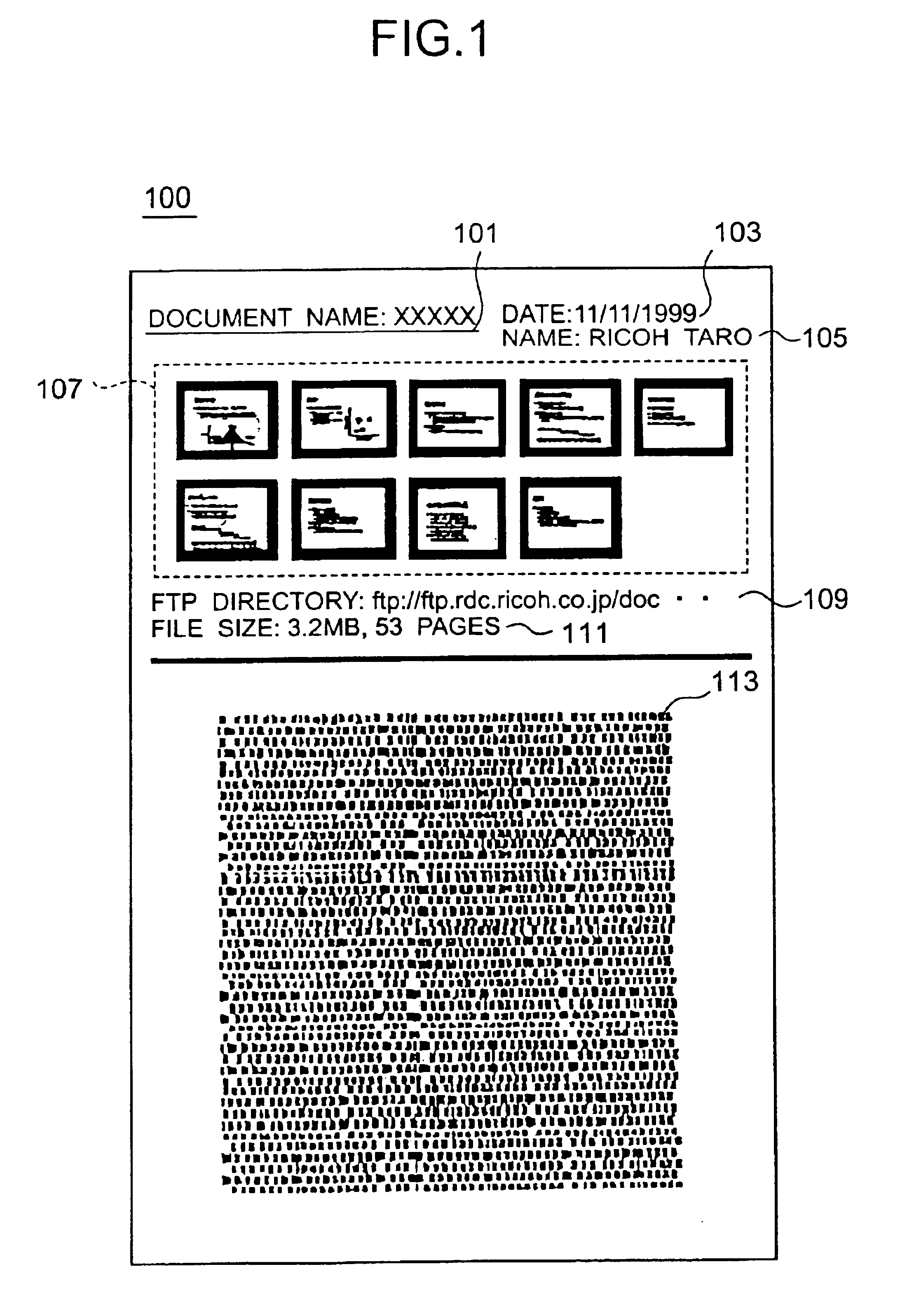

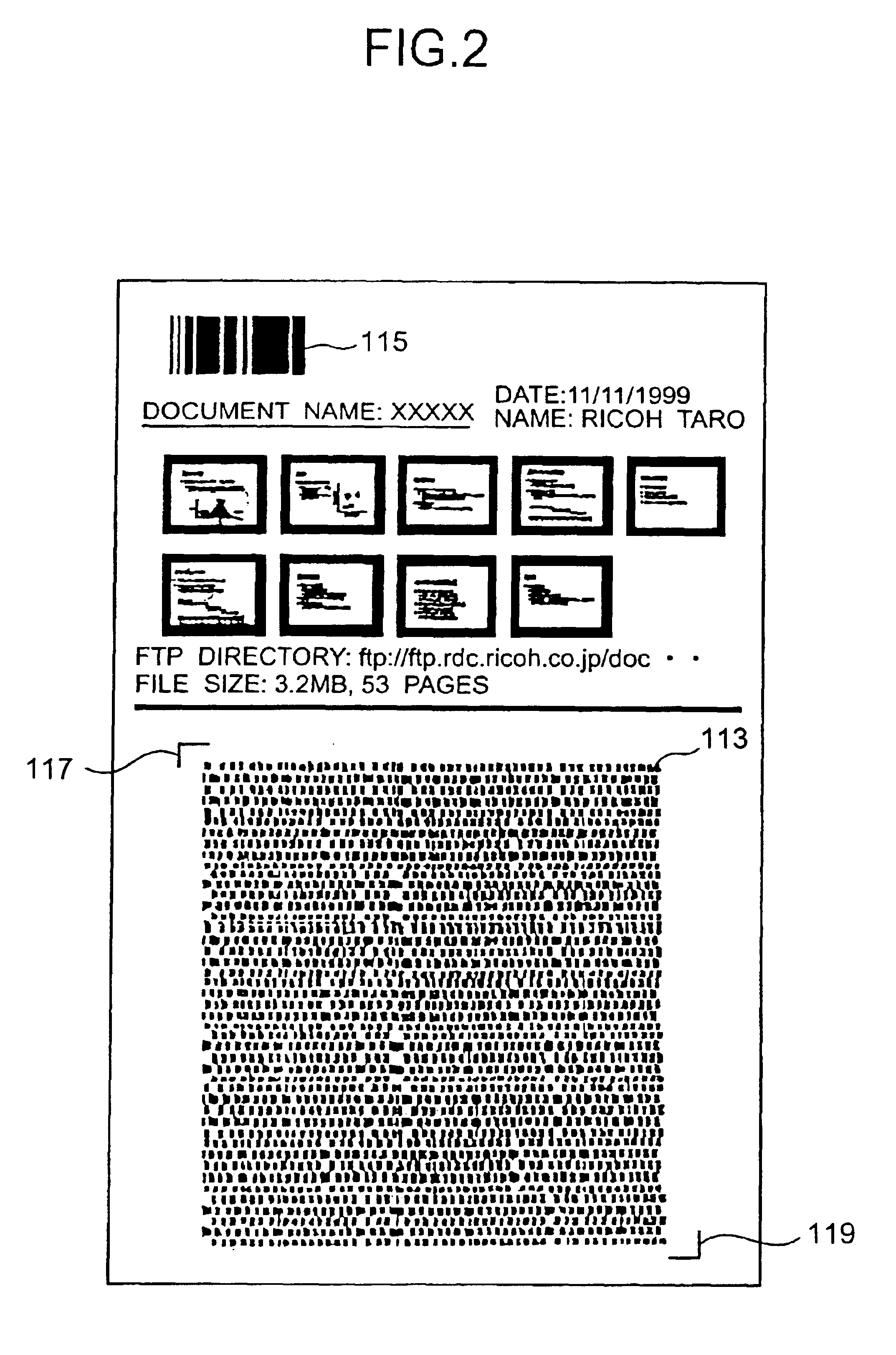

Data sheet and information management system using data sheet

InactiveUS6948654B2Stable printingErase informationCo-operative working arrangementsTypewritersElectronic documentDocumentation

A data sheet is composed of an upper part and a lower part. The upper part is used as a user interface including a reduced image of contents of a document. The lower part is an interface for a reading device such as a copy machine, including a code obtained by encoding the document. By use of the data sheet, the user can easily distribute or carry an electronic document data with the user. In addition, the user can recognize contents of the electronic document data by looking at the reduced image printed on the data sheet.

Owner:RICOH KK

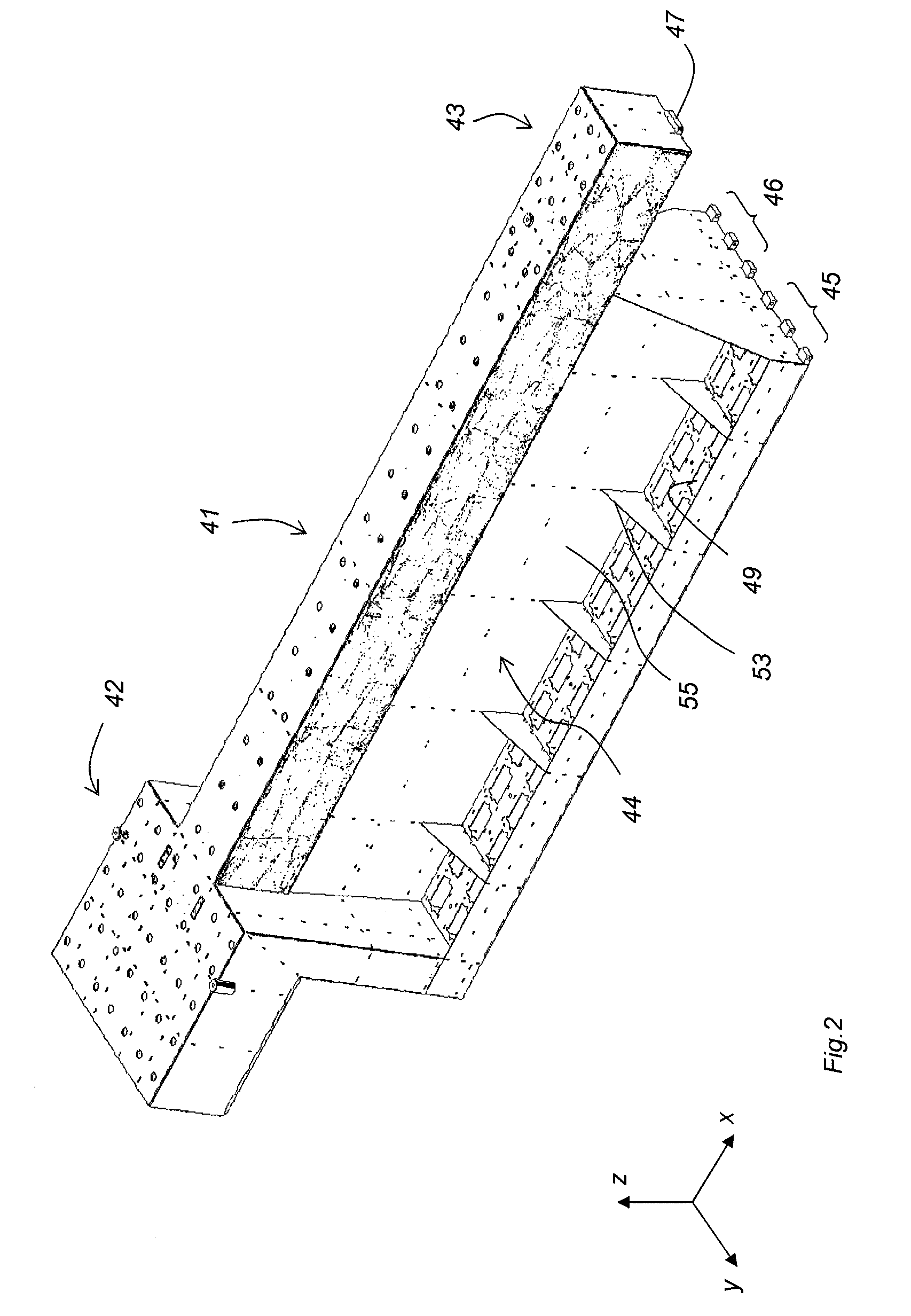

Print Head Shuttle with Active Cooling

InactiveUS20080273910A1Printing position is accurateStable printingInking apparatusPower drive mechanismsActive coolingEngineering

A print head carriage for holding a print head in a printing system includes a print head carriage framework having a plurality of print head positioning references for defining a position of the print head onto the print head carriage framework, and a cooling channel in thermal contact with the print head carriage framework for controlling the temperature of the print head carriage framework such that the positional stability of the plurality of print head positioning references on the print head carriage framework is preserved.

Owner:AGFA NV

Metallic pigment, pigment dispersion liquid, metallic pigment ink composition, and ink jet recording method

This invention provides a metallic pigment, which can prepare a printed matter having metallic luster, can realize stable printing even in a printer with ink jet nozzles having a nozzle diameter of not more than 30 [mu]m, can eliminate the need to carry out heat treatment and the like, and, thus, can realize ink jet recording without undergoing a limitation on printing media (recording media), an ink composition, and an ink jet recording method. The metallic pigment is a metal foil piece having an average thickness of 30 to 100 nm, having a 50% average particle diameter of not less than 0.5 [mu]m and not more than 4.0 [mu]m, and having such a particle size distribution that the maximum particle diameter is not more than 12 [mu]m. An ink composition containing this metallic pigment and an ink jet head having a nozzle diameter of not more than 30 [mu]m are provided, and the ratio between the average particle diameter of the metallic pigment and the nozzle diameter of the ink jet head (average particle diameter / nozzle diameter) is preferably brought to not more than 0.15.

Owner:SEIKO EPSON CORP

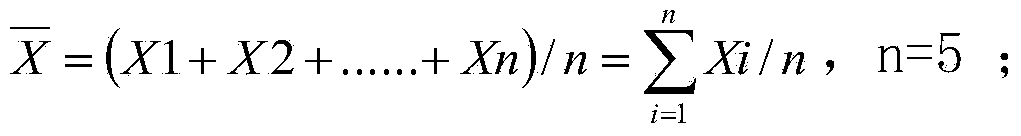

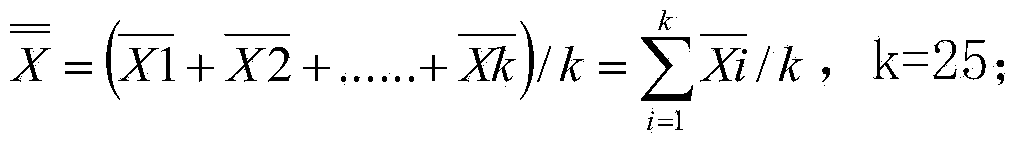

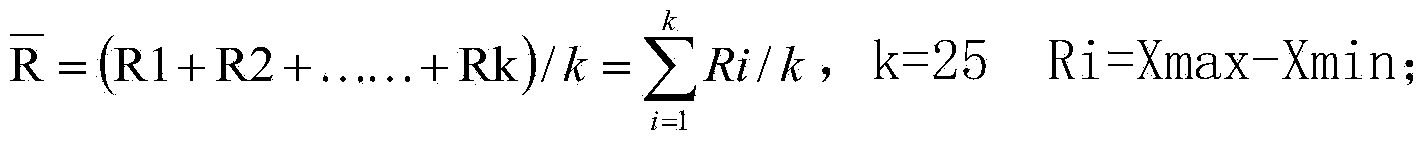

Printing quality evaluation and process control method

InactiveCN104339838AStable printingThe Road to Realize Printing StandardizationOther printing apparatusPrinting press partsInternational standardQuality control

The invention discloses a printing quality evaluation and process control method. The method comprises enterprise production standard establishment and printing process control, is based on the international standard, the national standard or industry standard of the printing industry and the SPC (statistical process control) advanced quality control technology instead of powerful software and hardware process, uses the principle of statistics, and helps an enterprise to establish own production data and enterprise quality standard, so that process control for production of printed matters is performed on the basis that printing is stable and the printed matters meet standard specification, and printing standardization is realized.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

Preparation method of ultra-fine and large-height-width-ratio grid transparent electrode

ActiveCN108859098AAchieve depositionAchieve high-precision manufacturingAdditive manufacturing apparatusApparatus for manufacturing conducting/semi-conducting layersUltra fineAlternating current

The invention discloses a preparation method of an ultra-fine and large-height-width-ratio grid transparent electrode, and belongs to the technical field of additive manufacturing and electronic devices. According to the preparation method of the super-fine and large-height-width-ratio grid transparent electrode, an electric field is used for driving the jet 3D printing and the charge-induced self-aligning to be combined. In one pulse period of the alternating-current pulse power supply, positive-voltage induction generates printing material micro-droplets with positive charges, the negative voltage induction generates the printing material micro-droplets with negative charges, after being deposited on the substrate, the micro-droplets of the charged printing material are in contact with each other, the positive and negative charges are neutralized, and then the charge-induced self-aligning is utilized to realize the accumulation of the charged printing material micro-droplets on the formed layer, and printing of the grid with the set number of layers is completed. The preparation method of the ultra-fine, large and high-width-ratio grid transparent electrode is wide in applicationrange, can obtain the high-conductivity and high-light-transmittance transparent electrode, and high-light-transmittance transparent electrode, and has good popularization and application values.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

High mesh size print cylinder mould production method

ActiveCN101284438AUniform thicknessExtended service lifePrinting pre-treatmentForme preparationPrinting inkEngineering

Owner:山东同大镍网有限公司

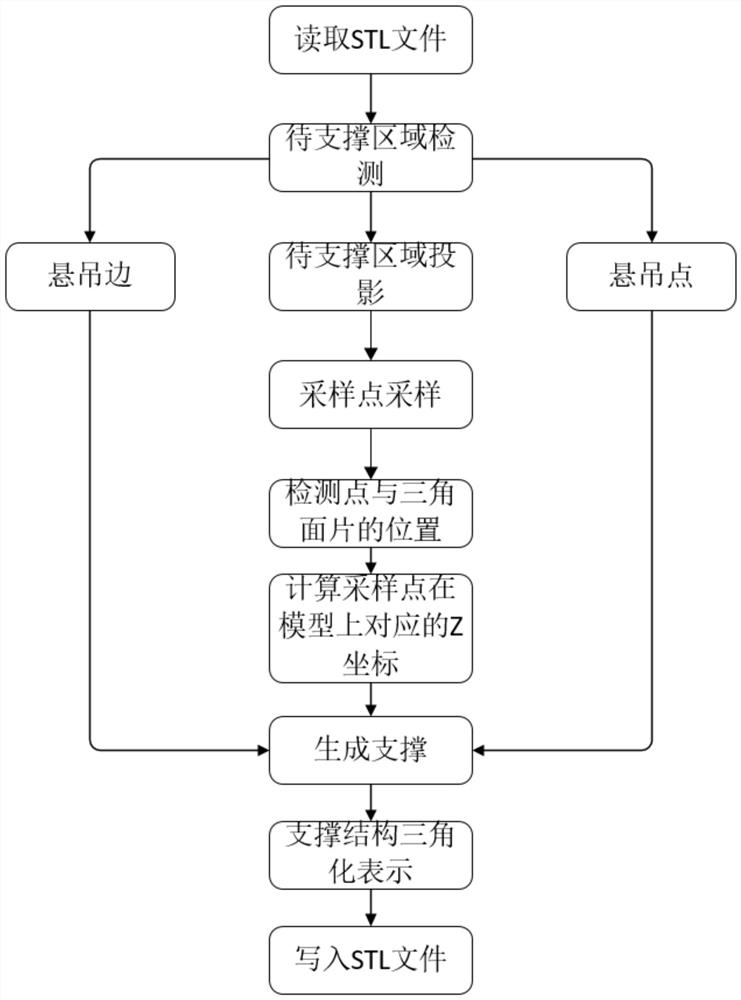

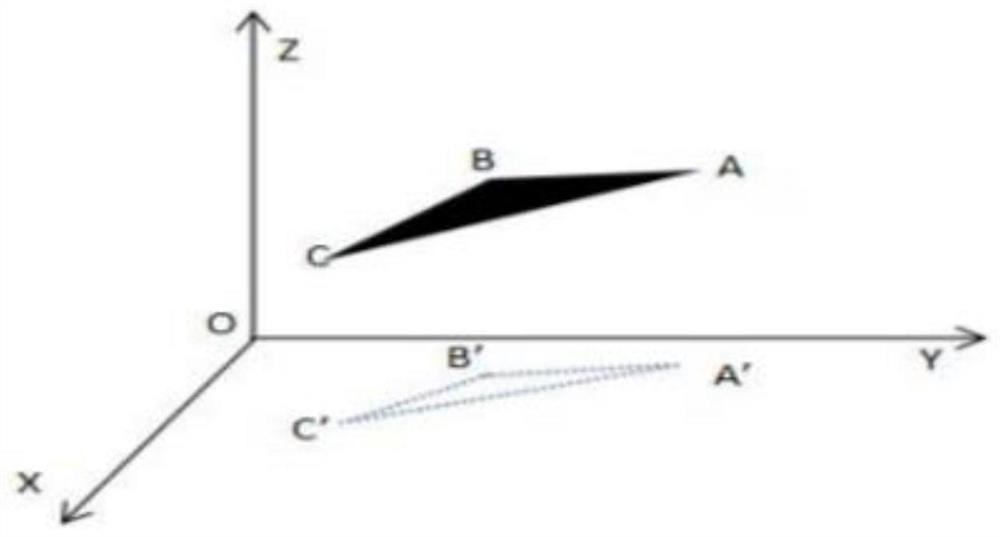

3D printing supporting structure design method based on STL file

PendingCN112590198AGood removal effectStable printingAdditive manufacturing apparatus3D object support structures3d printAlgorithm

A 3D printing supporting structure design method based on an STL file comprises the following steps that 3D modeling software is used for conducting three-dimensional modeling on a model, the STL fileis exported, the STL file is read, triangular patch vertex and normal vector information in the STL file is read, a critical angle is defined, the read triangular patch information is integrated, a to-be-supported area is projected to a working plane to form a two-dimensional projection area to obtain a part needing to be supported, sampling point sampling is carried out to generate a supportingstructure, and all vertex coordinates and normal vector coordinates are written into an STL file. Compared with the prior art, the problems that a traditional supporting structure is excessive in useamount, materials are wasted, the supporting structure is difficult to remove, and a to-be-supported area of a sharp-angled model including a suspension edge, a suspension point and the like cannot bedetected are solved, by means of the 3D printing supporting structure design method based on the STL file, the calculation efficiency is improved on the premise of guaranteeing that the model is tender and is consolidated and stably printed, the printing cost is saved, and the supporting structure is easier to remove.

Owner:HANGZHOU DIANZI UNIV

Manufacturing method of printing rotary screen with high mesh number and high aperture ratio

The invention relates to a manufacturing method of a printing rotary screen with high mesh number and high aperture ratio. The manufacturing method comprises the following steps: (1) first, manufacturing a 125-405-mesh mould and compressing hole patterns; (2) placing the manufactured mould in a plating bath filled with a plating liquid, and preparing a primary plating single net on the surface tendon line of the mould by using nickel as the anode and the mould as the cathode; (3) placing the single net in the plating bath filled with the plating liquid by taking nickel as the anode and the single net as the cathode, adding an additive consisting of butynediol diexthoxyl ether, propynol propoxyl ether, pyridinium propyl sulfobetaine and pyridinium hydroxy propyl sulfobetaine, and thickening the single net so as to secondarily plate; and (4) taking out the secondarily plated single net, washing and drying. The additive added controls the longitudinal and transverse growth ratios of the single net tendon line, and the 125-405-mesh printing rotary screen with high mesh number and high aperture ratio is obtained. The manufacturing method overcomes the deficiencies of high manufacturing cost, environmental pollution and the like in the prior art.

Owner:江苏东方镍网有限公司

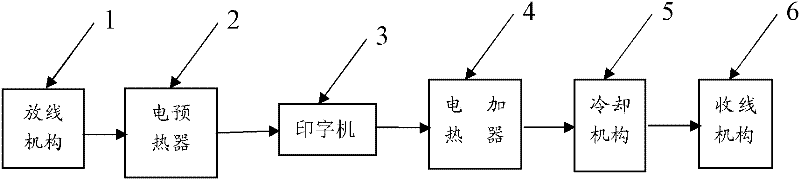

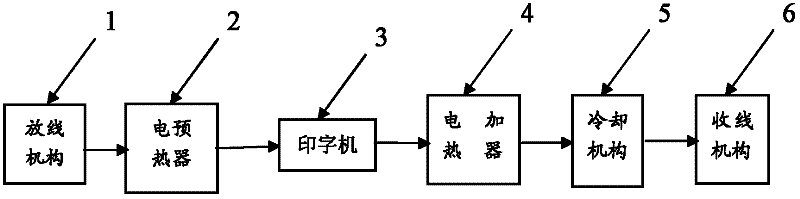

Fluoroplastic electric wire and cable surface lettering method and device

The invention provides a fluoroplastic electric wire and cable surface lettering method. The method comprises the following steps of: preheating a fluoroplastic electric wire in an electrical heating preheater, lettering on a high-temperature printing ink lettering wheel, heating the lettered electric wire in an electric heater, cooling the electric wire and the like. The invention also provides a corresponding lettering device which comprises a paying-out mechanism, the electric preheater, a high-temperature printing ink roll wheel lettering machine, the electric heater, a cooling mechanism and a cable coiling mechanism through which the electric wire successively passes. The method has the beneficial effects that the fluoroplastic surface of the electric wire is preheated to a required temperature firstly, then lettering is carried out on the fluoroplastic surface of the electric wire by use of high temperature printing ink, then the lettered fluoroplastic surface of the electric wire is heated to the required temperature so as to be firmly adhered to the fluoroplastic surface of the electric wire and cable, and subsequently, and cooling is performed, so that the lettering is firm and clear, the price is economic and cheap. Thus, the method and device provided by the invention are suitable for national conditions of China.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

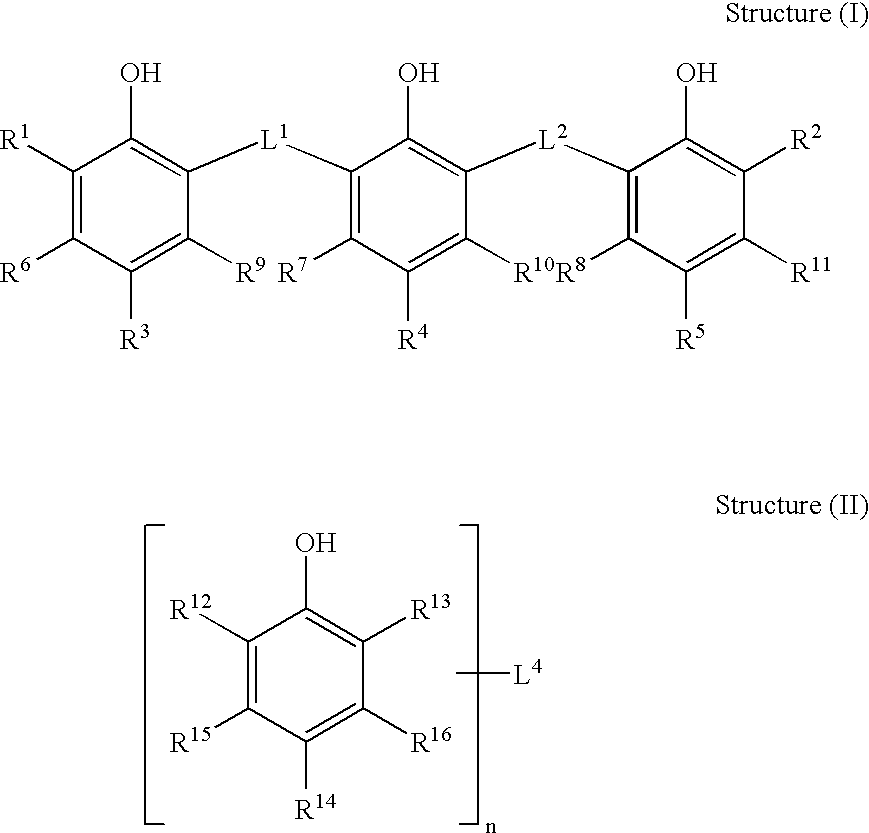

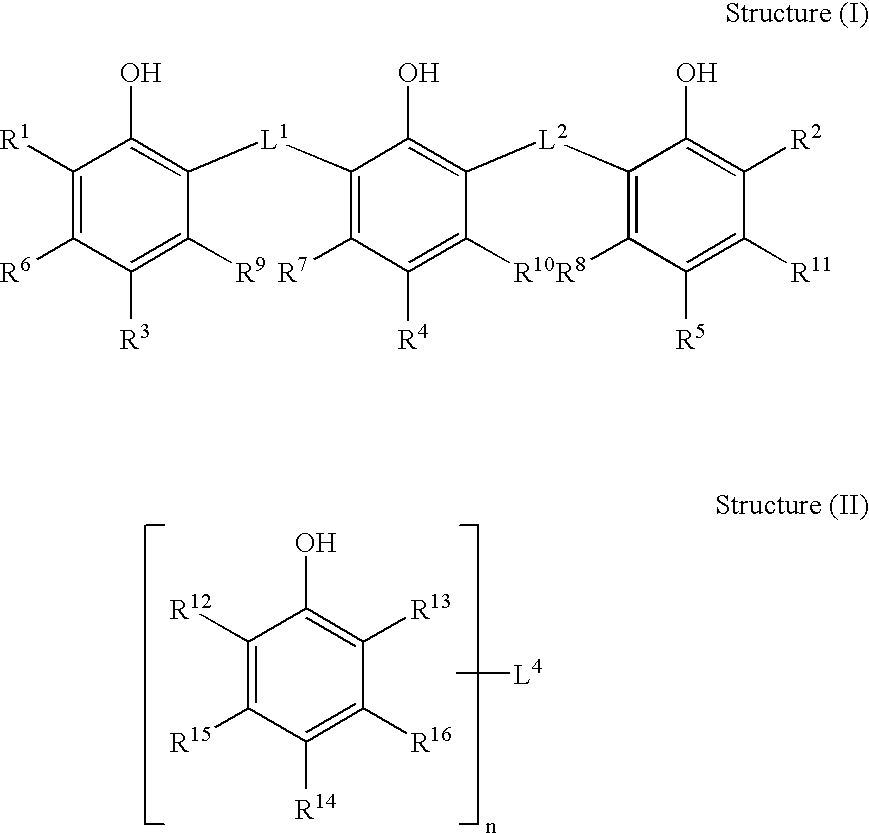

Thermally developable materials containing reducing agent combinations

InactiveUS20080057450A1Improved Silver EfficiencyLittle changePhotosensitive materialsMulticolor photographic processingHeat sensitiveMaterials science

Owner:CARESTREAM HEALTH INC

Printhead substrate, printhead, head cartridge, and printing apparatus

An object of this invention is to provide a driving circuit layout which suppresses an increase in the area of a head substrate in an inkjet printhead adopting a driving method for supplying a predetermined current to a heater. To achieve this object, a plurality of printing elements and a plurality of switching elements which are very large in number are arrayed in the longitudinal direction of a head substrate. A plurality of terminals which receive a driving signal and a control signal that are used to drive the plurality of printing elements are arranged at the end of the board in the longitudinal direction of the board at positions opposite to the array of the plurality of printing elements. A constant electric current source for supplying a predetermined electric current is interposed between these two regions.

Owner:CANON KK

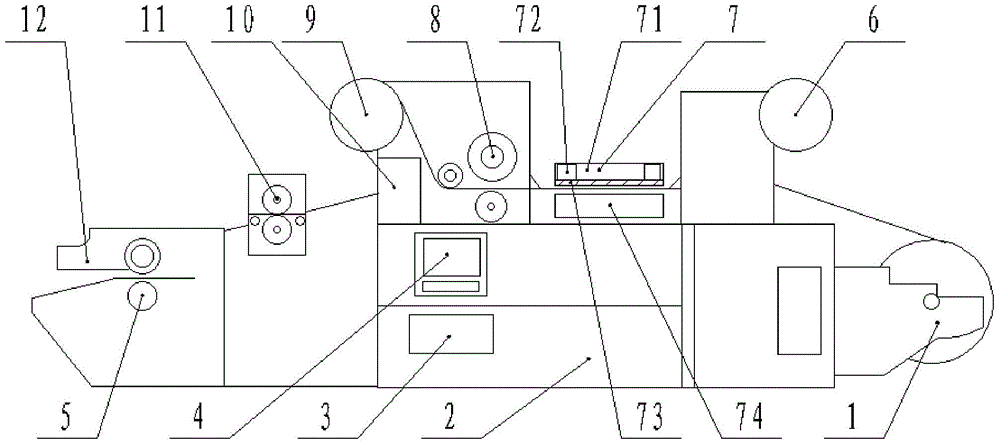

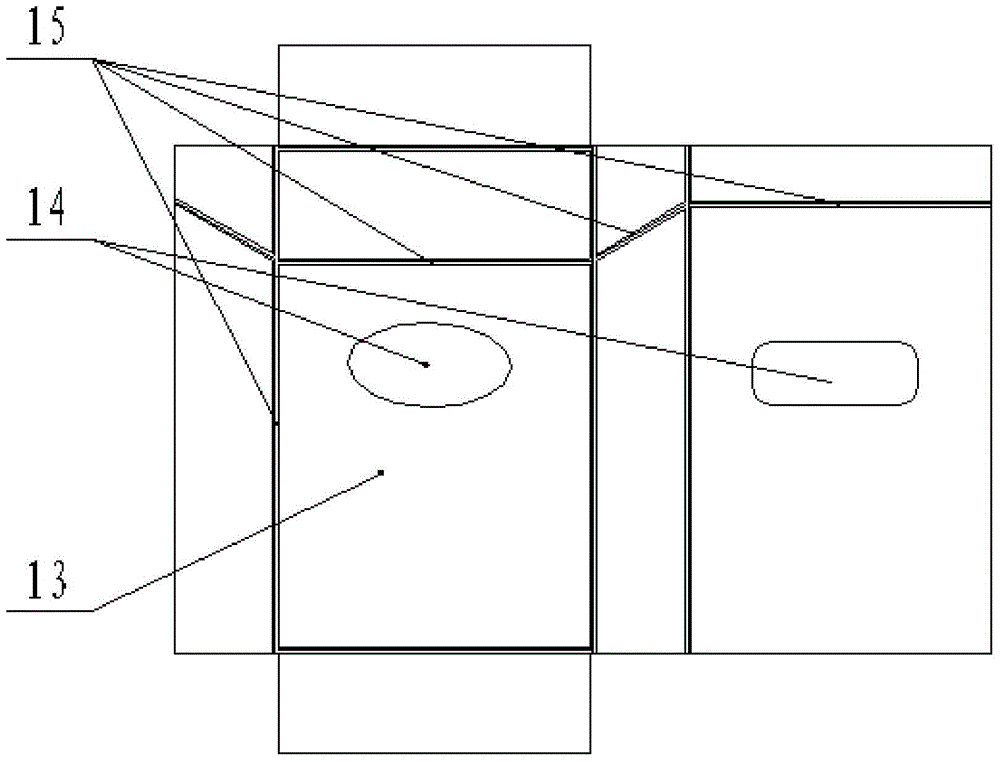

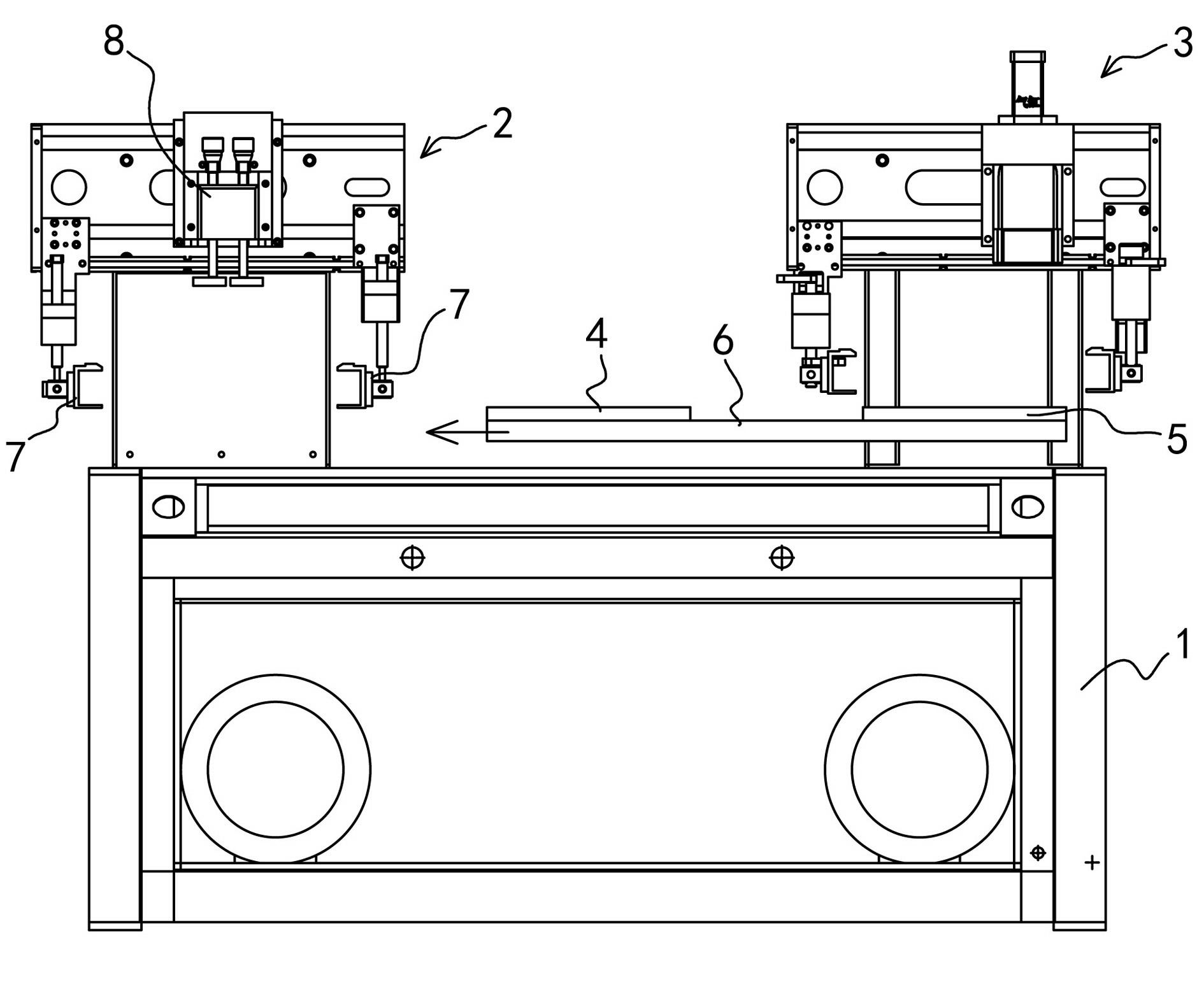

Processing method and integrated processing device for hard shell cigarette packaging box

InactiveCN104626738AIncrease productivityAvoid rubbingRotary pressesBronze printingCardboardEngineering

The invention belongs to the technical field of printing and packaging devices, and particularly relates to a processing method and integrated processing device for a hard shell cigarette packaging box. The processing method comprises the following steps that white cardboard rolls are uncoiled, gilded and printed to form semi-finished paperboards; the paperboard are dried; the pressing mark technology is carried out on the semi-finished paperboards to form a plurality of folding marks; die cutting is carried out on the semi-finished paperboards to form packaging paper; the packaging paper is folded and stuck to form the square and strips-shaped hard shell cigarette packaging box. The integrated processing device comprises a rack, an uncoiling mechanism, a gilding film paying-off device, a gilding mechanism, a printing mechanism, a waste film taking-up mechanism, a drying device, a pressing mark mechanism and a die cutting mechanism which are sequentially arranged on the rack. The gilding mechanism comprises an upper gilding and printing film and a gilding bearing base. A heating disc and a temperature sensor are arranged on the upper gilding and printing film. According to the processing method and device, the cigarette packaging and printing quality is better ensured, the production efficiency is high, and the production cost is saved.

Owner:CHUXIONG JIXING COLOR PRINTING

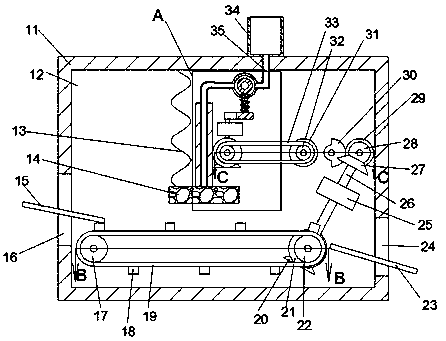

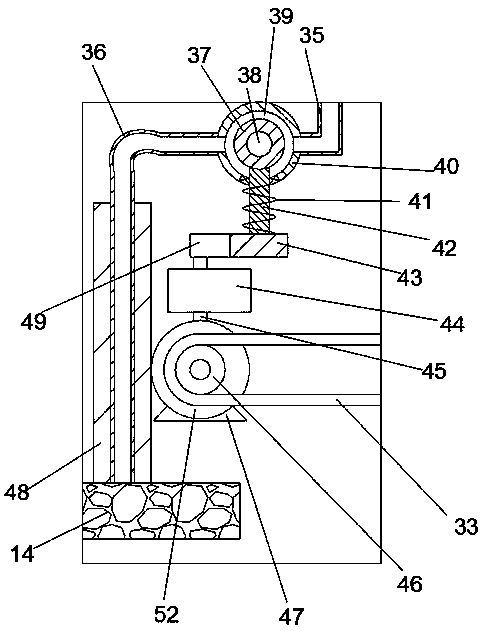

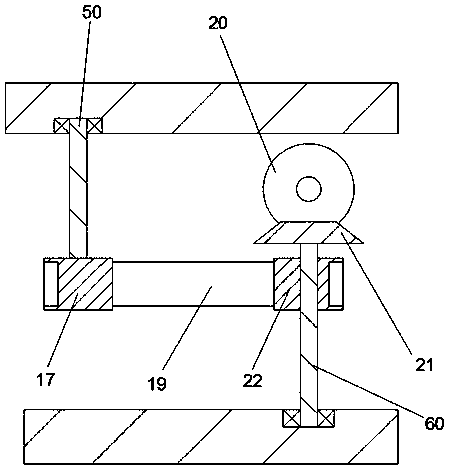

Carton printing device capable of automatically adding ink at regular time

InactiveCN110843332AGuarantee clearStable printingRotary pressesOther printing apparatusMechanical engineeringIndustrial engineering

The invention discloses a carton printing device capable of automatically adding ink at regular time. The carton printing device comprises a casing, wherein a working cavity is formed in the casing, atransmission assembly is arranged on an inner wall of the rear side of the working cavity, and a printing assembly is arranged on the inner wall of the rear side of the working cavity. With the adoption of an ink adding assembly, when a second sector gear is in meshed connection with a valve gear, orientation of a valve through hole is changed, so that an inlet pipeline communicates with a rubberpipeline, ink is supplemented for the printing device at regular time through the inlet pipeline, the valve through hole and the rubber pipeline, an appropriate amount of ink exists in the printing device all the time, and clearness of fonts or patterns during printing is guaranteed; with the adoption of a first sector gear, when the first sector gear is in meshed connection with a second gear, the printing assembly is driven to print a to-be-printed carton, and when the first sector gear is in meshed connection with a first gear, the transmission assembly is driven to convey the carton, andstable and orderly carton printing is guaranteed.

Owner:XIAMEN QIALE STATIONERY CO LTD

Dual-station desk-top flat-bed screen printing machine

InactiveCN102126333AEnough operating spaceImprove printing efficiencyScreen printersScreen printingPrinting press

Owner:杜全玉

Image forming apparatus

InactiveUS7120370B2Avoid overall overheatingStable printingElectrographic process apparatusImage formationEngineering

Owner:OKI DATA CORP

Printer

InactiveCN1809463AStable printingAvoid skewPower drive mechanismsOther printing apparatusSpring forceEngineering

A printer has a platen which vertically moves with respect to a printing head to press a medium against a guide member from below. In this printer, the platen is attached to a support member through a spring member to be urged upward by the spring member, and the arrangement is such that when the thickness of the medium is more than a predetermined value, the platen is further urged upward by a spring force reinforcing mechanism, whereby the force with which the platen presses the medium can be suitably controlled according to the thickness of the medium, so that printing can be performed in a stabilized manner.

Owner:OKI ELECTRIC IND CO LTD

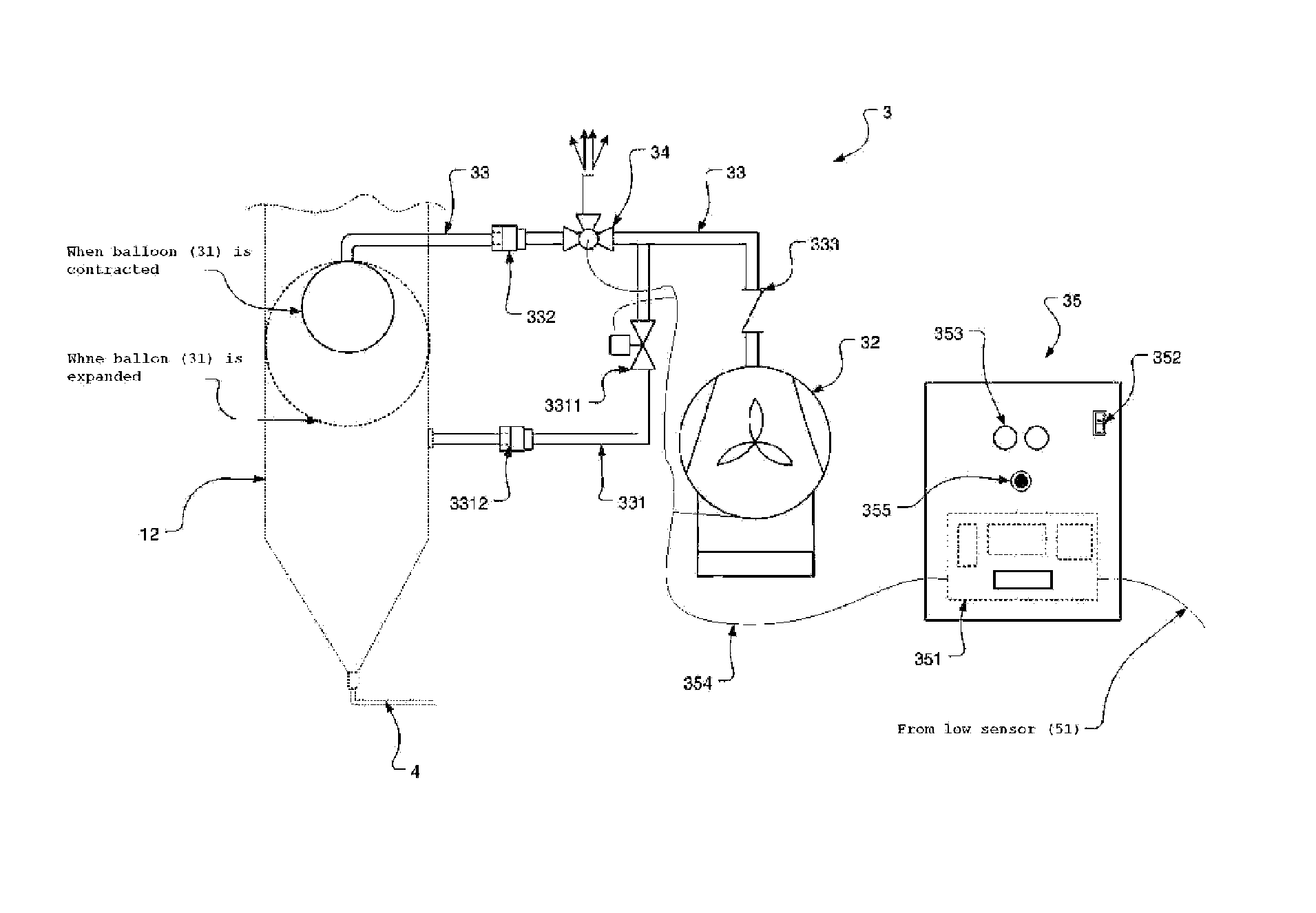

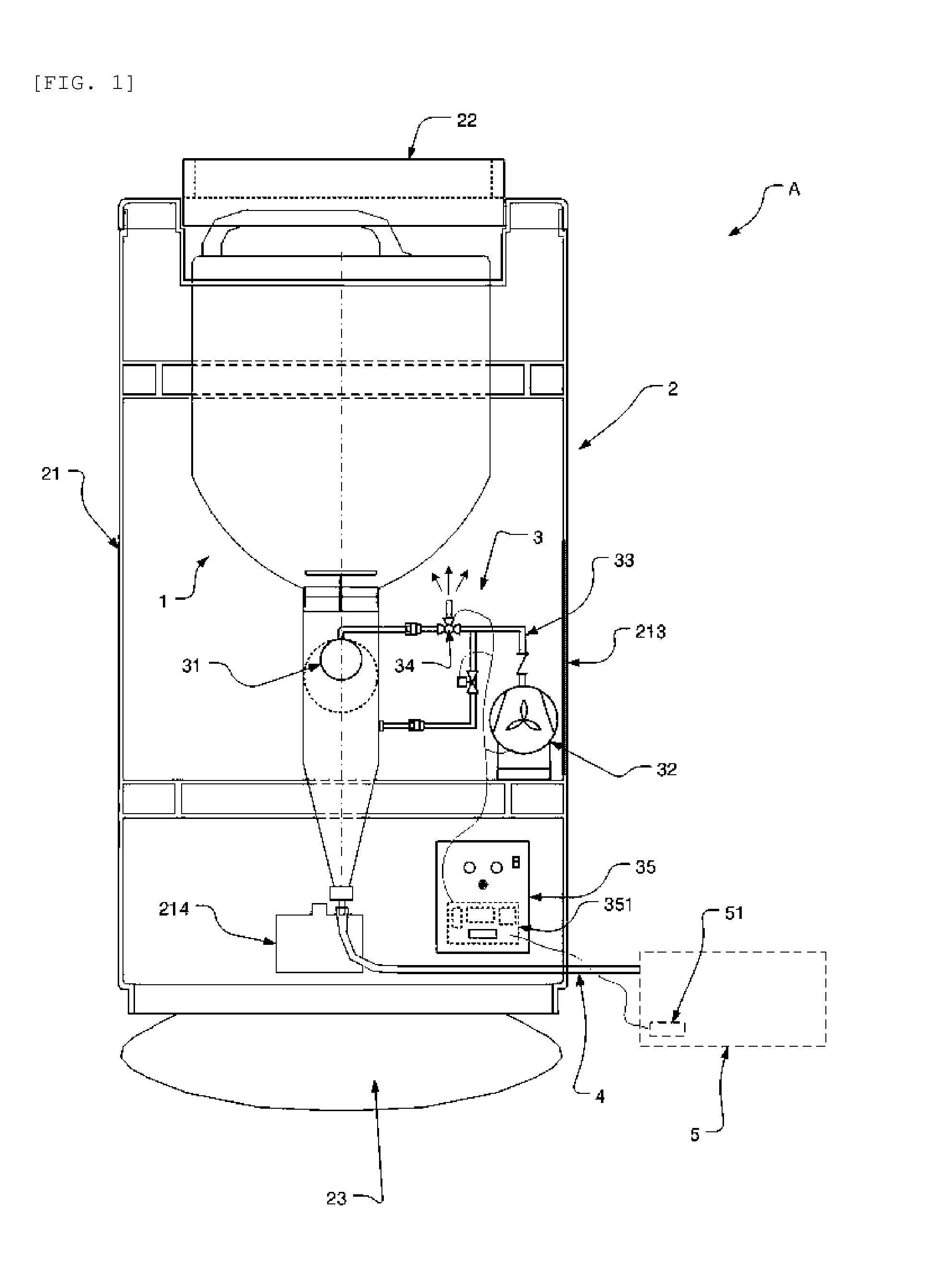

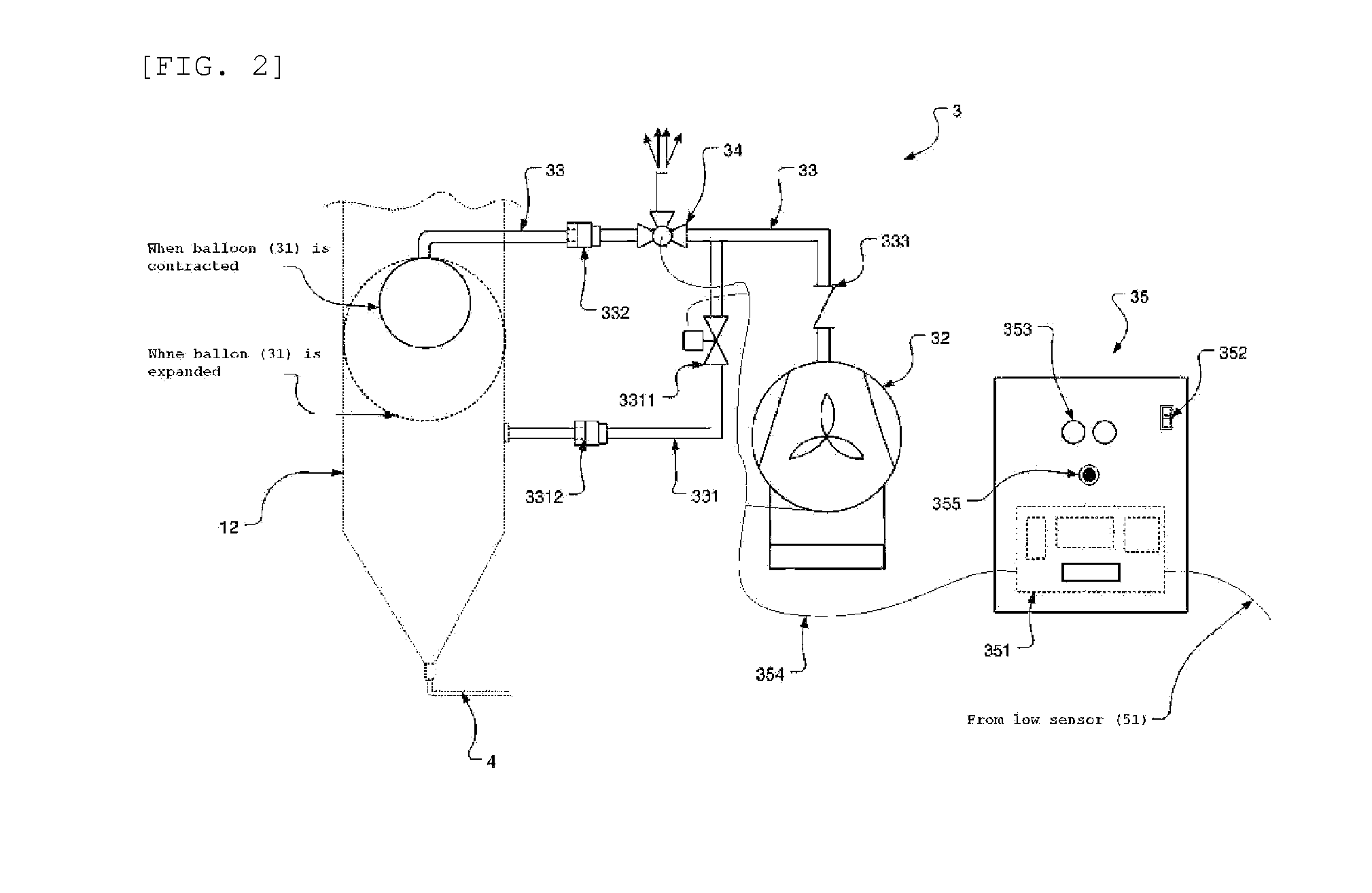

Device for automatically supplying toner to toner cartridge

ActiveUS20130308985A1Reduce the possibilityShortage of the toner may be preventedWind motor with solar radiationBatteries circuit arrangementsEngineeringControl valves

The device for automatically supplying a toner to a toner cartridge of the present invention includes: a toner storage container for storing toners to be refilled; an outer container for containing the toner storage container; a toner supplying unit for supplying the toner stored in the toner storage container to the toner cartridge; and a toner supply hose for sending the toner to the toner cartridge, wherein the toner supplying means consists of: a balloon, which expands and contracts when air is supplied to or discharged from the inside, so that the toner at the bottom is pushed in towards the cartridge or the toner at the top moves to supplement the bottom; an air pump for supplying air to the balloon; an air pipe for connecting the balloon and the air pump; a control valve; and a controller for operating the control valve, enabling the present invention to print stably by preventing toner shortage.

Owner:KIM TAE SOO

Printing and forming process of environment-friendly APET plastic products

InactiveCN106827598AStable printingBeautiful printPattern printingFlat articlesScreen printingPlastic film

The invention relates to a processing process of APET plastic products, in particular to a printing and forming process of environment-friendly APET plastic products. The printing process comprises the following steps:1) making an APET plastic plate; 2) embossing a leading wire on the APET plastic plate and laminating a film on the APET plastic plate; 3) cutting the APET plastic plate; 4) carrying out silk-screen printing; 5) coating the APET plastic plate with a protective film layer; 6) pressing sides; 7) carrying out die-cutting forming; and 8) carrying out high-frequency splicing. According to the process, the APET plastic is used as an original material of the plastic products so that the environment can be protected, the resources can be recycled, and the processing cost can be reduced; the reasonable printing process is adopted so that the pattern printing and the pattern die-cutting forming of the APET plastic sheet material can be smoothly completed in shortest time and in most convenient operation steps; and the most suitable forming process is adopted, so that the APET sheet material can be stereoscopically formed smoothly, and the APET plastic products which are attractive in printing, stable in quality and energy-saving can be obtained.

Owner:东莞市巨泓彩色印刷有限公司

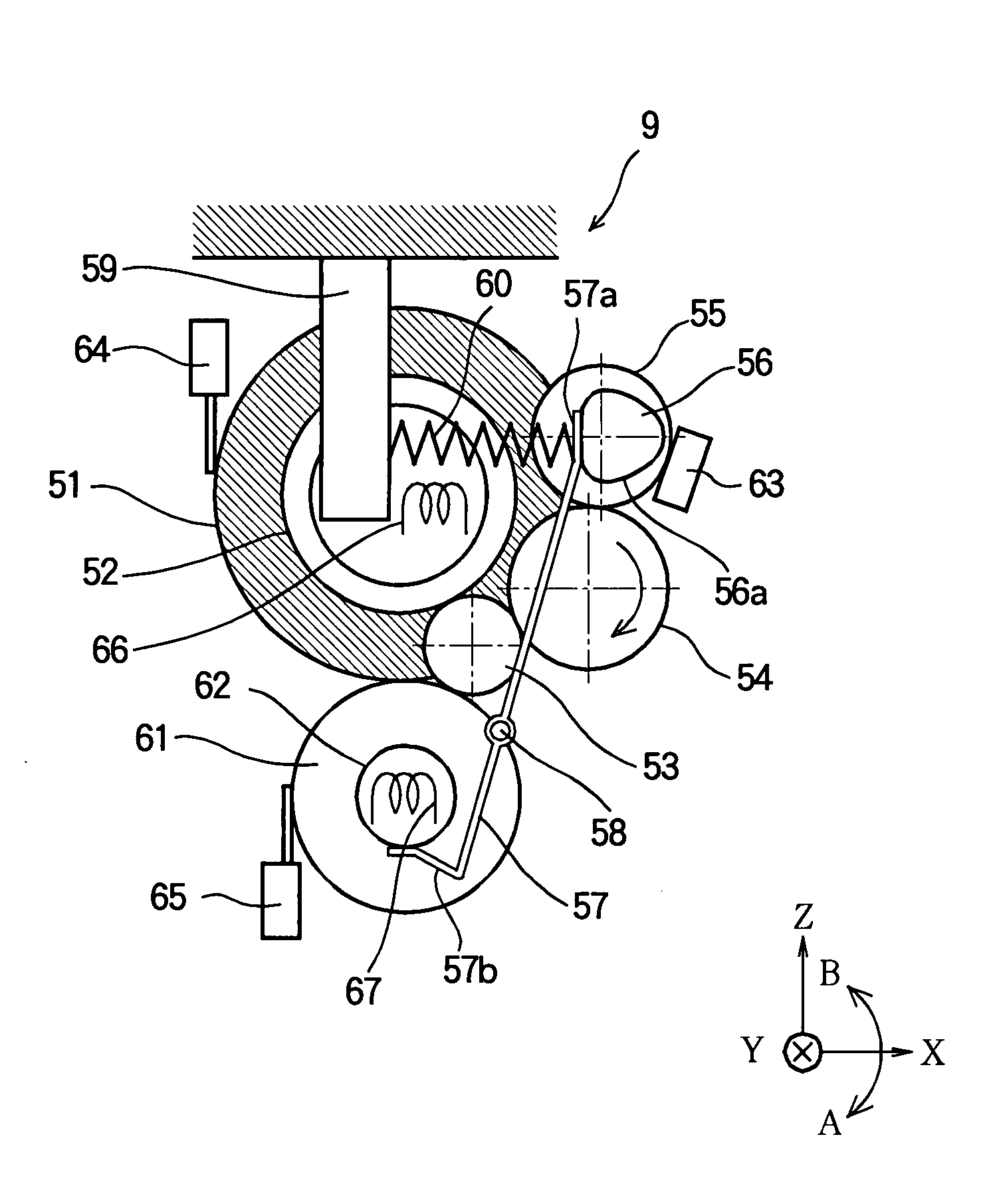

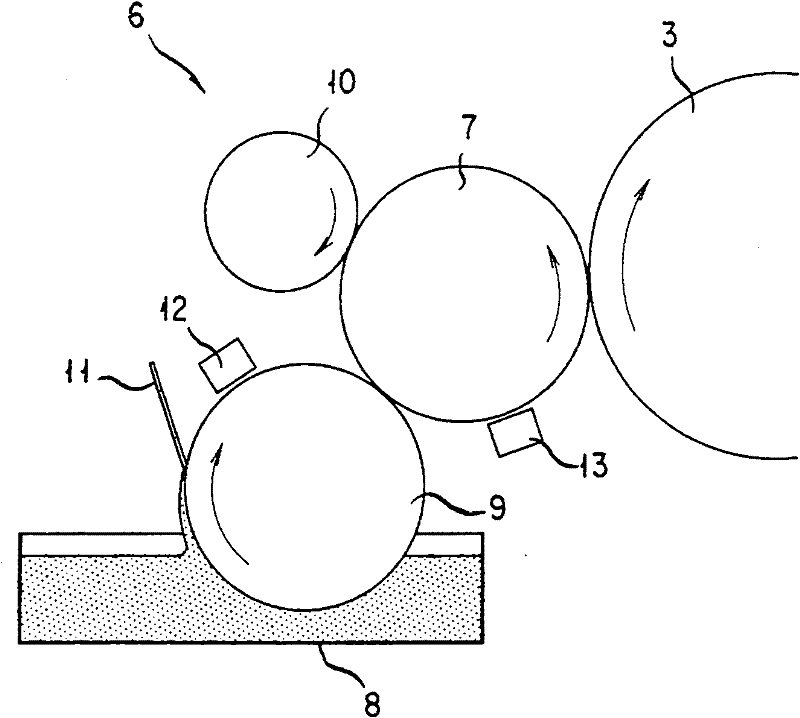

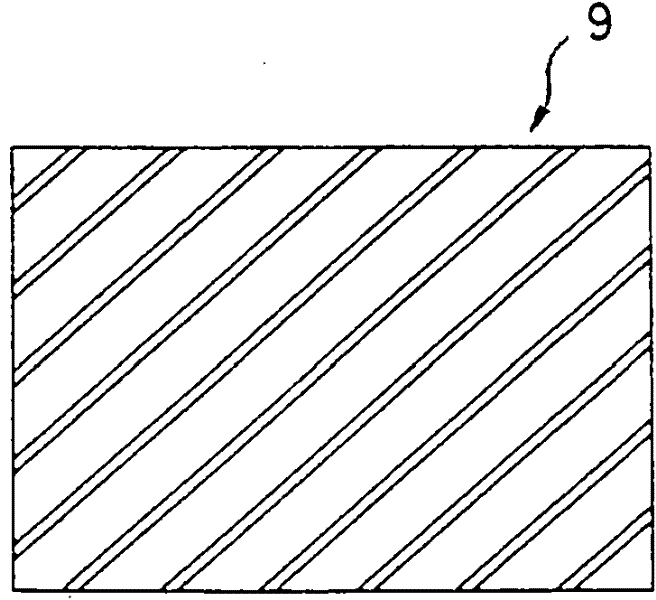

Wet type developing apparatus and wet type developing method

InactiveCN102213935AImprove correspondencePrevents deterioration of printing qualityElectrographic process apparatusMechanical engineeringPhysical property

A wet type developing apparatus is provided which allows printing in a quality that is stable at an increased printing speed and also with changes in physical property of a liquid developer. The wet type developing apparatus to this end includes a liquid developer feed pathway which comprises a developing roller 7 for feeding the liquid developer onto a photoconductor drum 3; an anilox roller 9 immersed in part in the liquid developer and driven to rotate in rotational contact with the developing roller; and a doctor blade 11 disposed in contact with a surface of the anilox roller for controlling the rate of drawing up of the liquid developer. The developing and anilox rollers have their peripheral surfaces moving in an identical direction and at an identical rate of movement in an area of their rotational contact. A toner charger 12 is disposed opposite to a surface of the anilox roller downstream of an area of contact of the doctor blade with the anilox roller and upstream of an area of rotational contact of the anilox roller with the developing roller in a rotation direction of the anilox roller.

Owner:MIYAKOSHI PRINTING MACHINERY

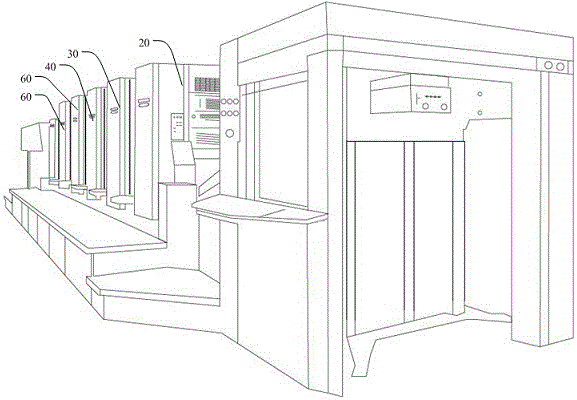

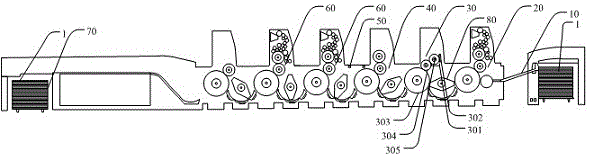

Combined printing device and printing method

InactiveCN106113925AUniform and thick printingFine and clear printingOther printing apparatusRotary letterpress machinesPrinting inkPulp and paper industry

The invention discloses a combined printing device and a printing method. The printing method comprises the steps that a paper conveying mechanism conveys paper to a first offset printing mechanism; the first offset printing mechanism prints paper through an offset printing technology, and the paper is conveyed to a flexible printing mechanism; the flexible printing mechanism prints the paper through a flexible printing technology, and the paper is conveyed to second offset printing mechanisms; a drying mechanism dries flexible printing ink in the paper conveying process; a plurality of second offset printing mechanisms sequentially print the paper through the offset printing technology; a paper collection mechanism carries out collection and stacking on the printed paper. Flexography color groups are combined on an offset printing machine, on the premise of meeting rapid printing, lines, characters and lattice points on single paper are clear, patterns on a printing undertint on-site area on the single paper are uniform and thick, high-speed stable printing is achieved, operation is carried out only according to the working procedure of an offset printing device, and the operation requirement is low.

Owner:SHENZHEN JINJIA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com