Dual-station desk-top flat-bed screen printing machine

A double-station, screen printing machine technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of limited operating space and low printing efficiency, and achieve improved printing efficiency, good line of sight, and energy saving The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

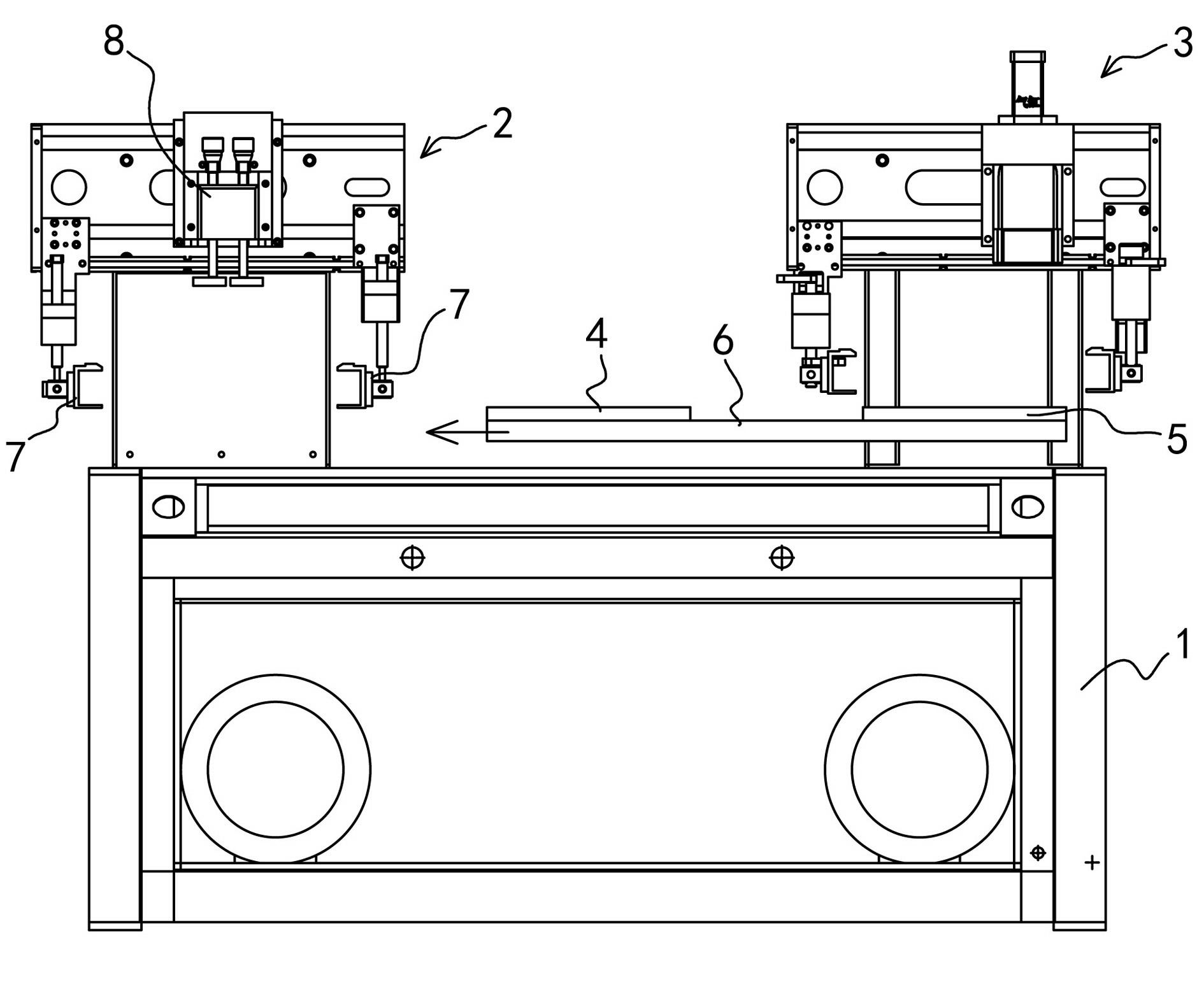

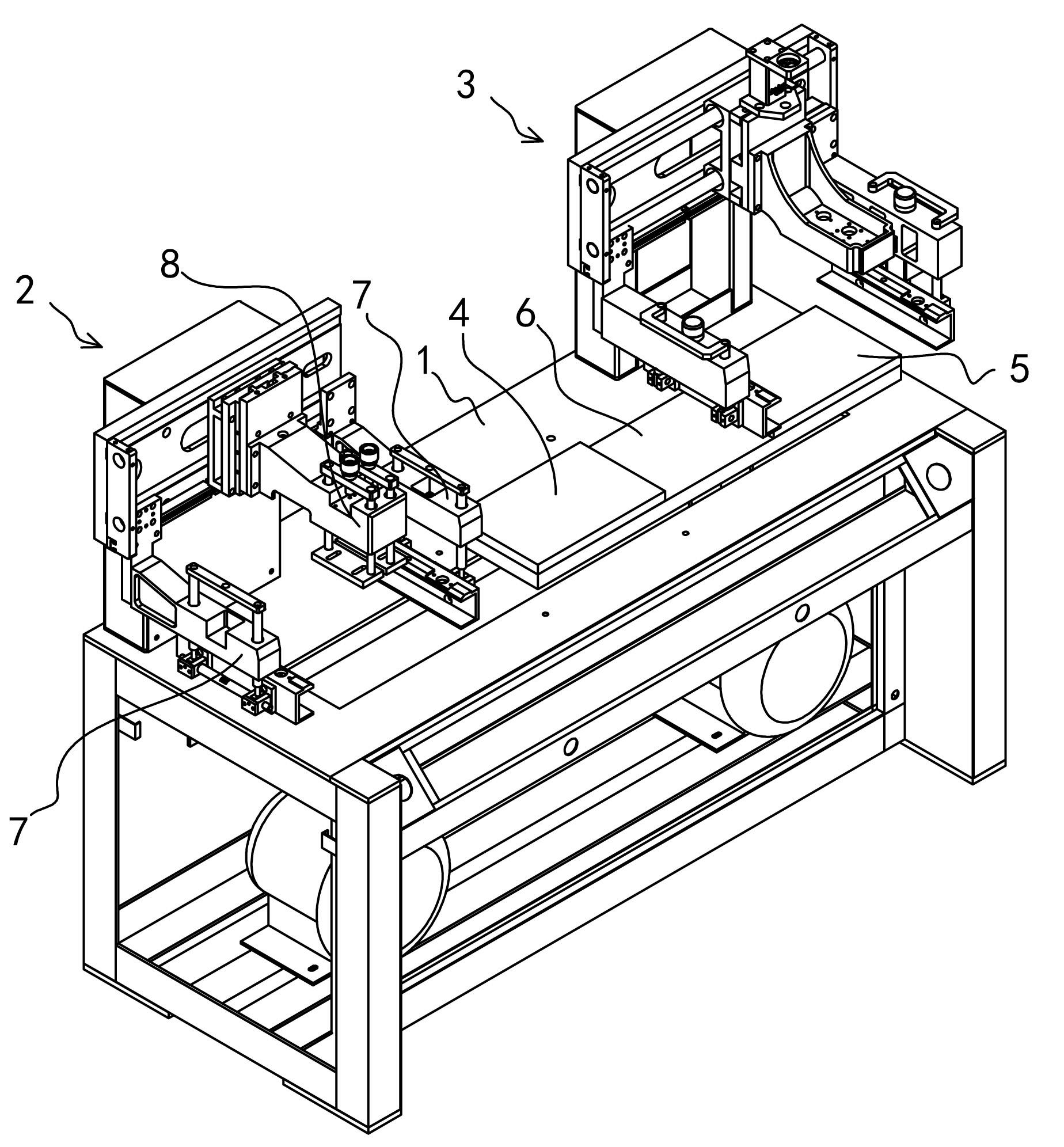

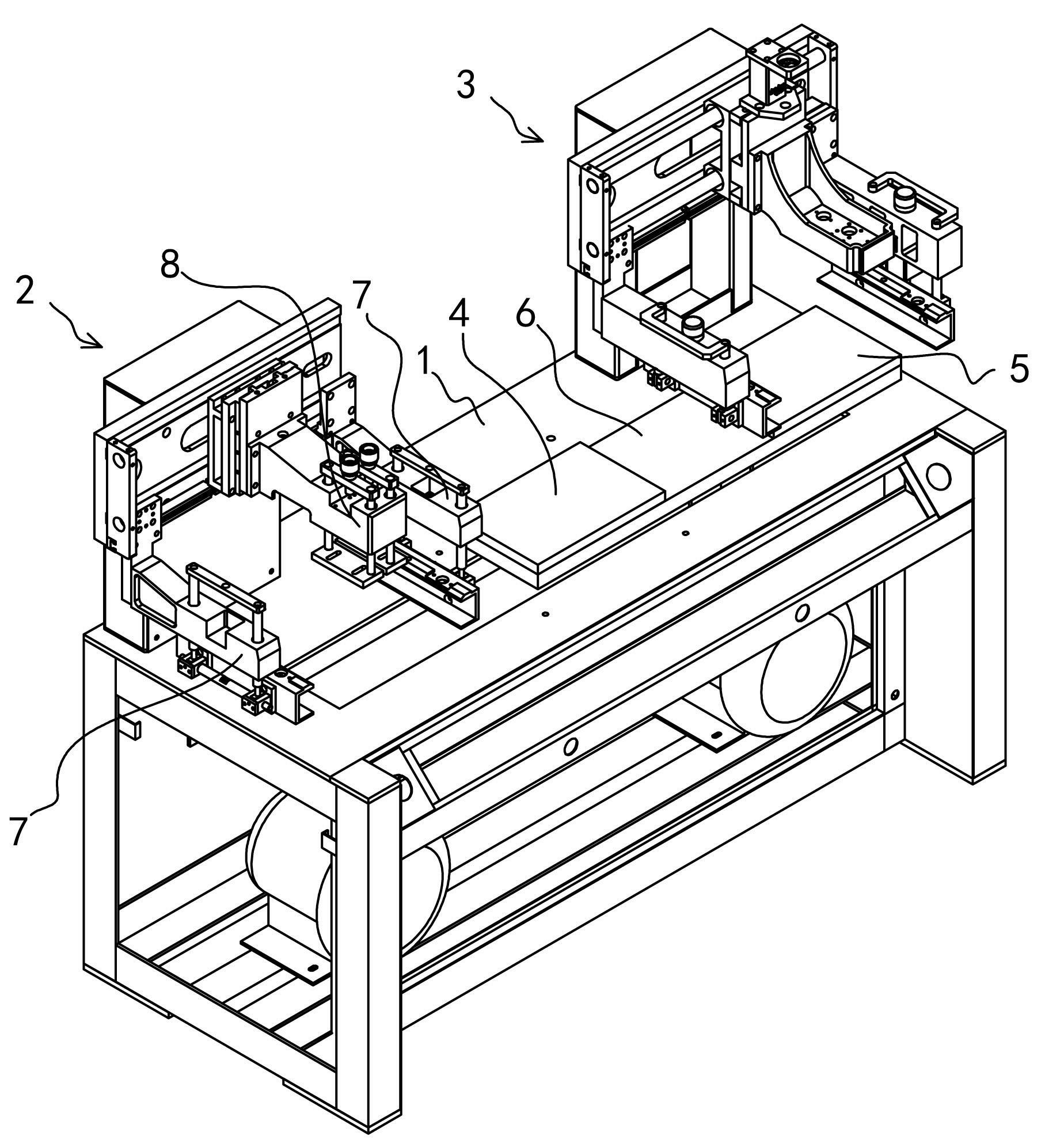

[0021] Example: see attached Figure 1~2 Shown:

[0022] A double-station running table flat screen printing machine comprises a frame 1, two left and right printing head assemblies 2, 3 and two left and right printing table tops 4, 5. The left and right printing head assemblies 2 and 3 are arranged at the left and right ends of the frame 1 respectively. The left and right printing head assemblies 2 and 3 each include a screen (the screen is not shown in the figure), a clamp arm 7 for holding the screen, a printing scraper 8, and the like. The two left and right printing tables 4 and 5 are arranged side by side on the frame 1 with their faces upward and left and right, and are slidably connected with respect to the frame 1 in the left and right directions.

[0023] Specifically, the two printing tables 4 and 5 are both arranged on a mobile platform 6 that is slidingly connected to the frame, and the mobile platform 6 functions as a translational drive device, and the two pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com