Fluoroplastic electric wire and cable surface lettering method and device

A wire and cable and fluoroplastic technology, which is applied to the field of printing on the surface of wires and cables, can solve the problems of high printing danger, unsafe, expensive printing equipment, etc., and achieve the effect of economical and cheap price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

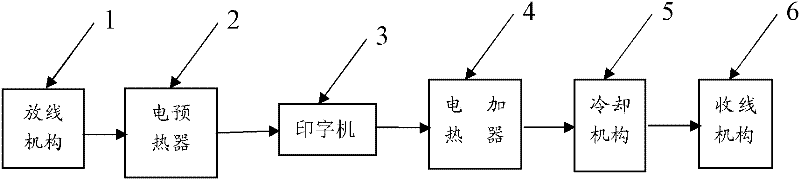

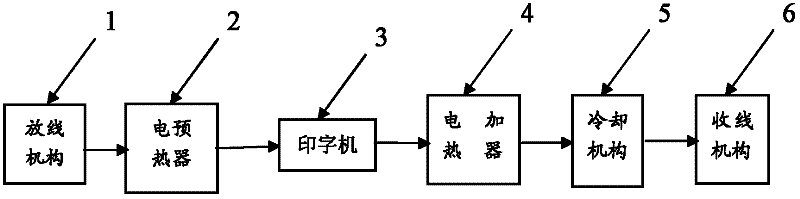

[0018] Such as figure 1 As shown, firstly, the fluoroplastic wire to be printed is preheated to the optimum temperature and time in the electric heating preheater, which requires controlling the speed of the wire walking in the preheater, and the speed generally depends on Depending on the diameter of the wire, we use stepless speed regulation to control the running speed of the wire. Usually, the speed of the wire is 30-50 m / min;

[0019] Then the wire runs on the printing wheel of high-temperature ink to print, and then the wire enters the electric heater for heating. After heating, the printing should be firm and clear, which requires that the heating temperature range should be just right, the temperature range is 450°C±20°C, so the power of the electric heater is also very important, and finally the wire can be cooled to complete the printing (put The printed electric wire is received on the take-up spool again).

[0020] Experiments have proved that the preheating temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com