Wet type developing apparatus and wet type developing method

一种显影装置、湿式的技术,应用在电记录术、光学、仪器等方向,能够解决调色剂粒子分散性恶化、液体显影剂使用量多、制造成本升高等问题,达到调整作业容易、品质控制容易、移动性变好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

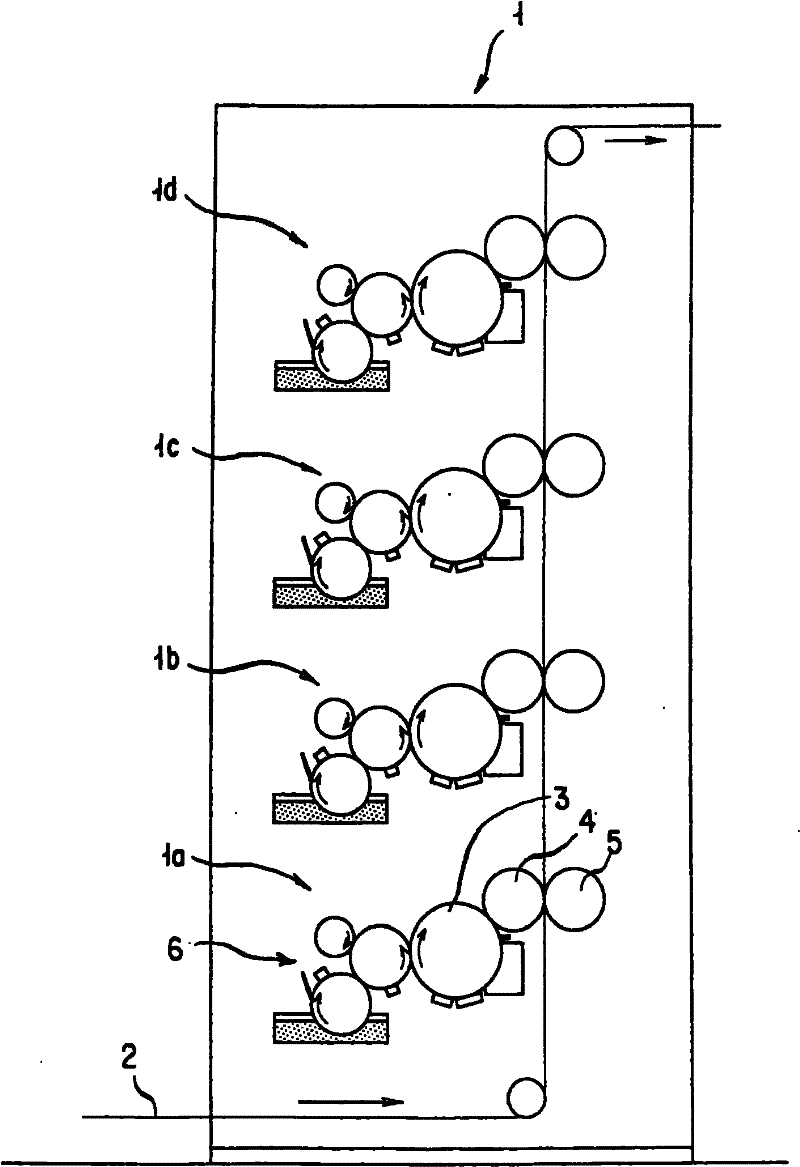

[0047] based on Figure 1 to Figure 3 , to illustrate the first embodiment of the present invention.

[0048] figure 1 It is a diagram showing a wet electrophotographic printing apparatus 1 in which a plurality of (four) wet electrophotographic printing machines 1a, 1b, 1c, and 1d using a wet developing device are arranged in parallel in the vertical direction. In this wet electrophotographic printing apparatus 1 , multi-color printing is performed by passing continuous paper 2 from the bottom of the wet electrophotographic printer 1a through the upper wet electrophotographic printers 1b, 1c, and 1d.

[0049] Since the aforementioned wet electrophotographic printers 1a to 1d have the same configuration, the wet electrophotographic printer 1a at the lowest level will be described below.

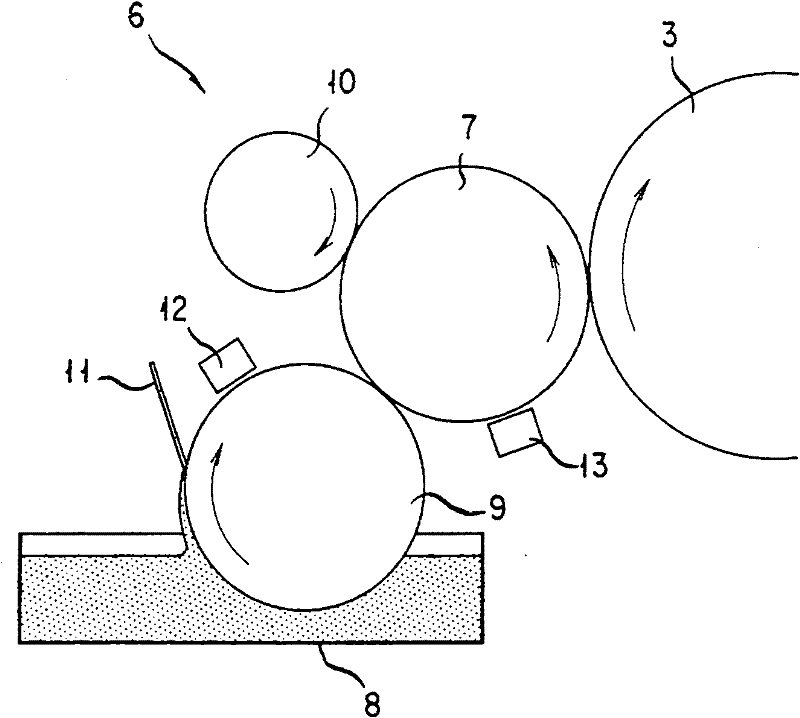

[0050] In the figure, 3 is a photoreceptor drum, 4 is a transfer roller in rotational contact with the photoreceptor drum 3, and 5 is a support roller in rotational contact with the transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com