3D printing supporting structure design method based on STL file

A support structure and 3D printing technology, applied in the field of 3D printing, can solve problems such as inability to achieve 100% detection, difficult removal of support structures, and troublesome post-processing stages, so as to save printing costs, save printing time, and be easy to remove Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

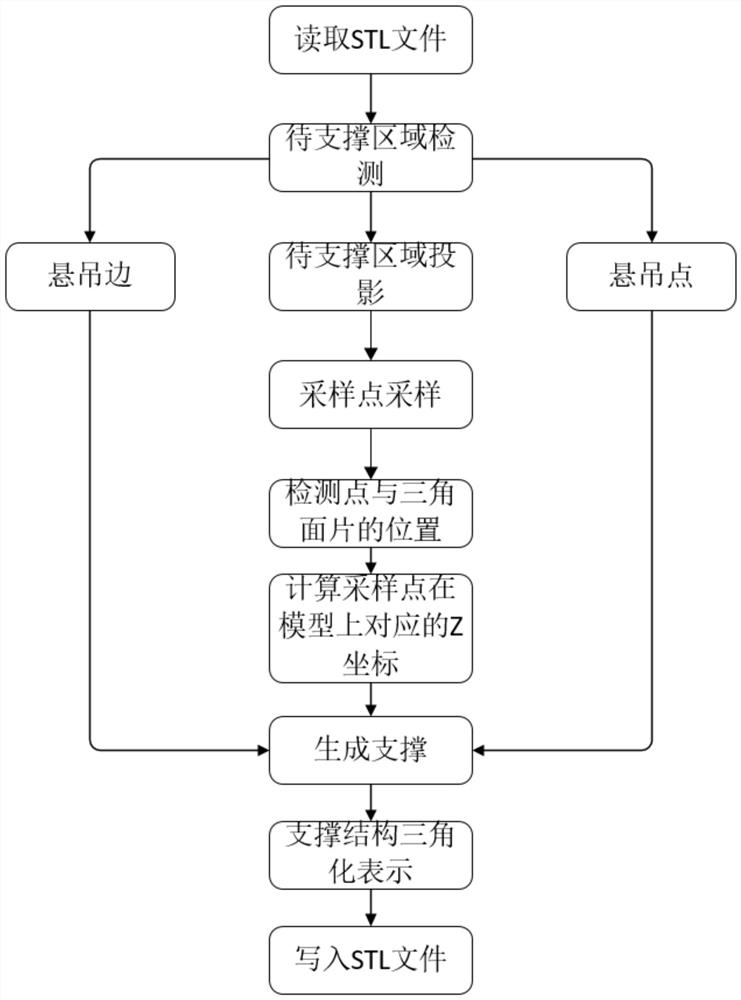

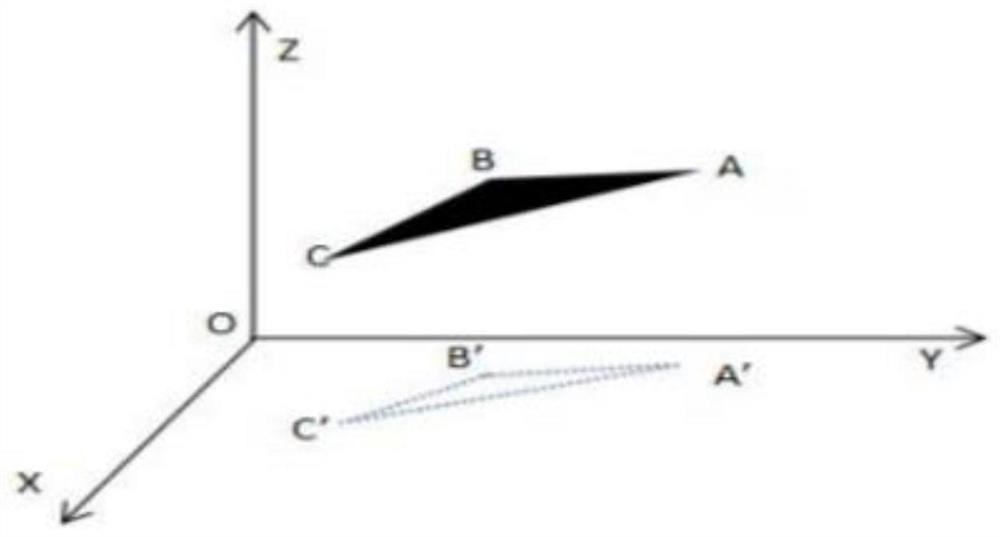

[0040] Such as Figure 1-9 As shown, a 3D printing support structure design method based on STL files includes the following steps:

[0041] S1. Use 3D modeling software to carry out 3D modeling of the model and export STL files. The 3D modeling software used can provide any 3D modeling software in STL format such as UG and Solidworks.

[0042] S2. Read the STL file by reading the STL file in Matlab, read the vertices and normal vector information of the triangular patches therein, and save all the vertex and normal vector information of the triangular patches into the rectangle variable.

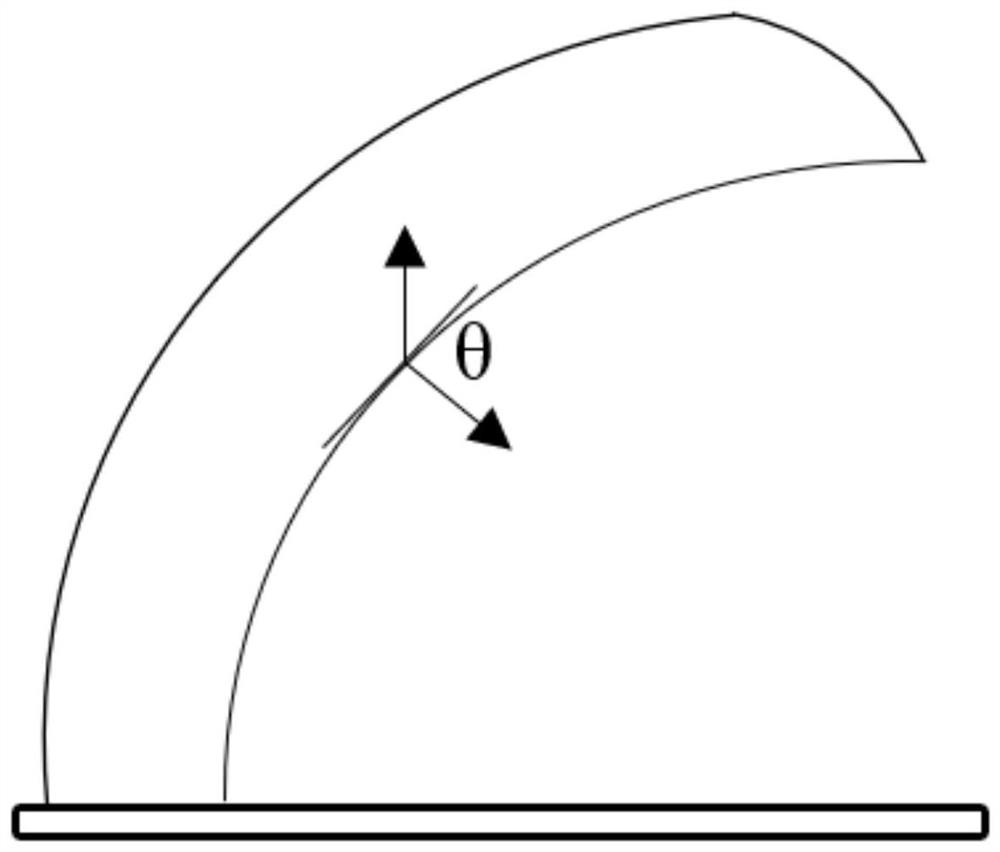

[0043] S3. Define the critical angle, and compare the angle between the external normal vector of the triangular surface and the positive direction of the Z axis with the critical angle, according to the formula: n·v=|n|·|v|cosθ, where the Z axis is positive The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com