Patents

Literature

275 results about "Valve gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing gear. It is sometimes referred to as the "motion".

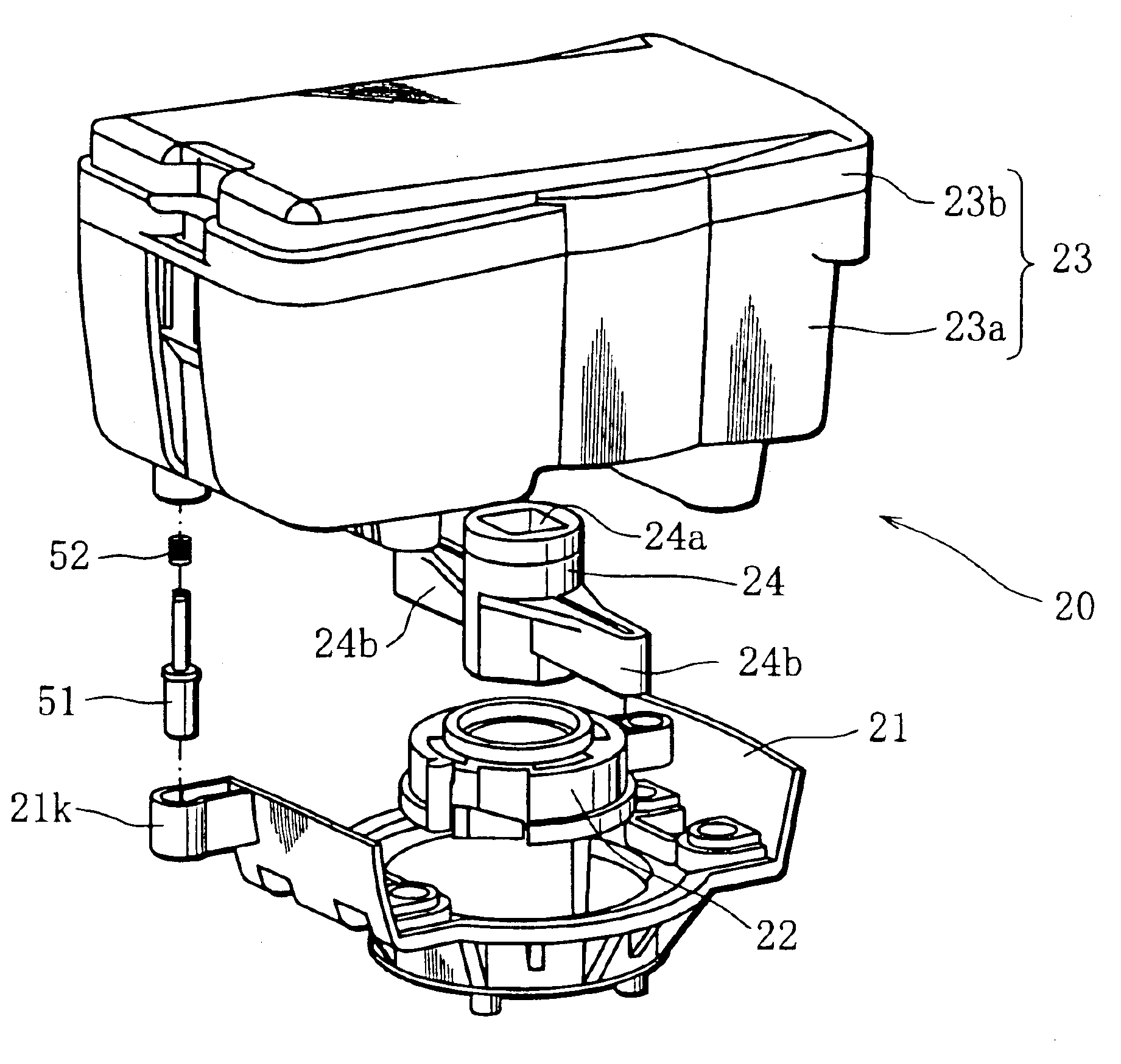

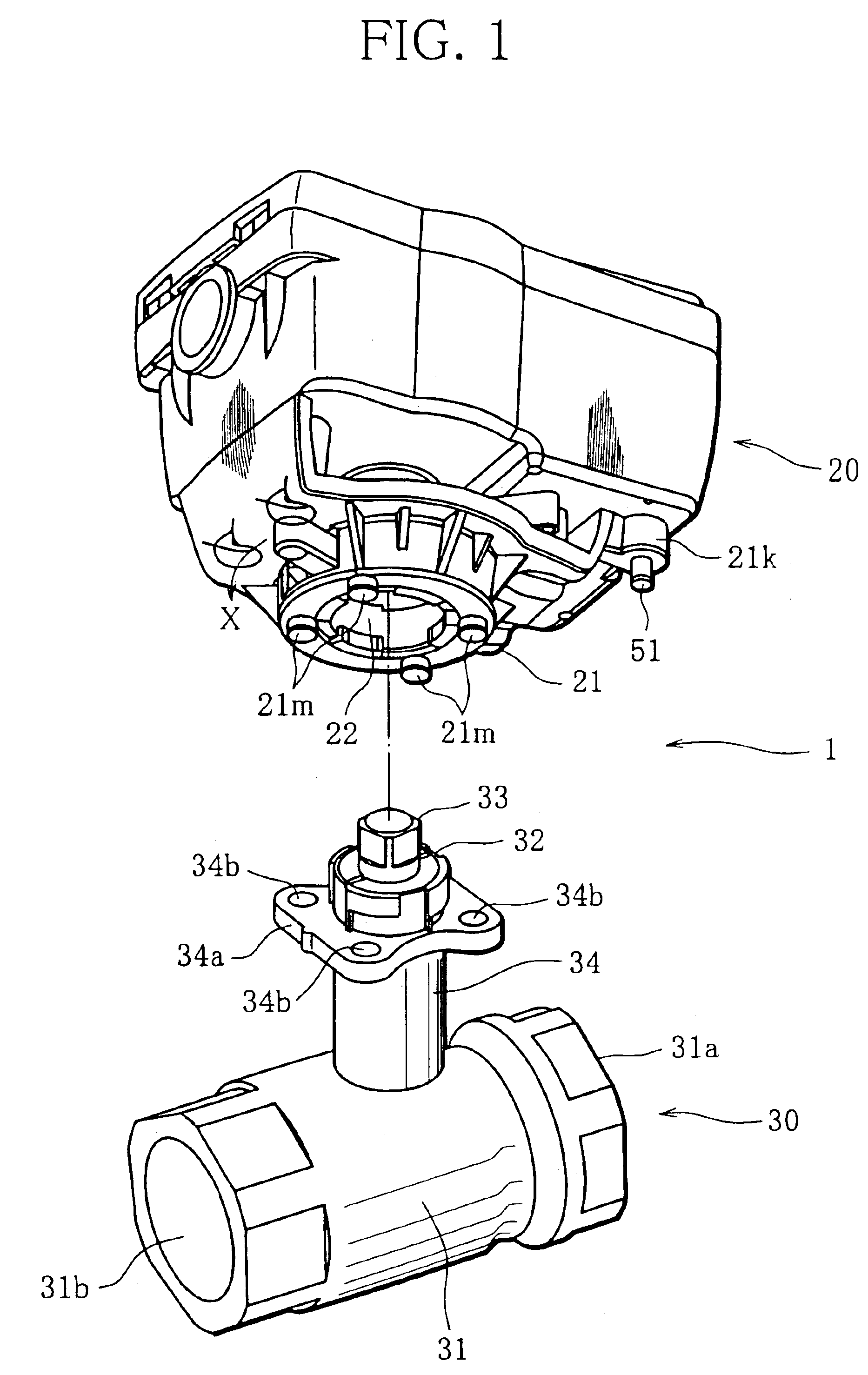

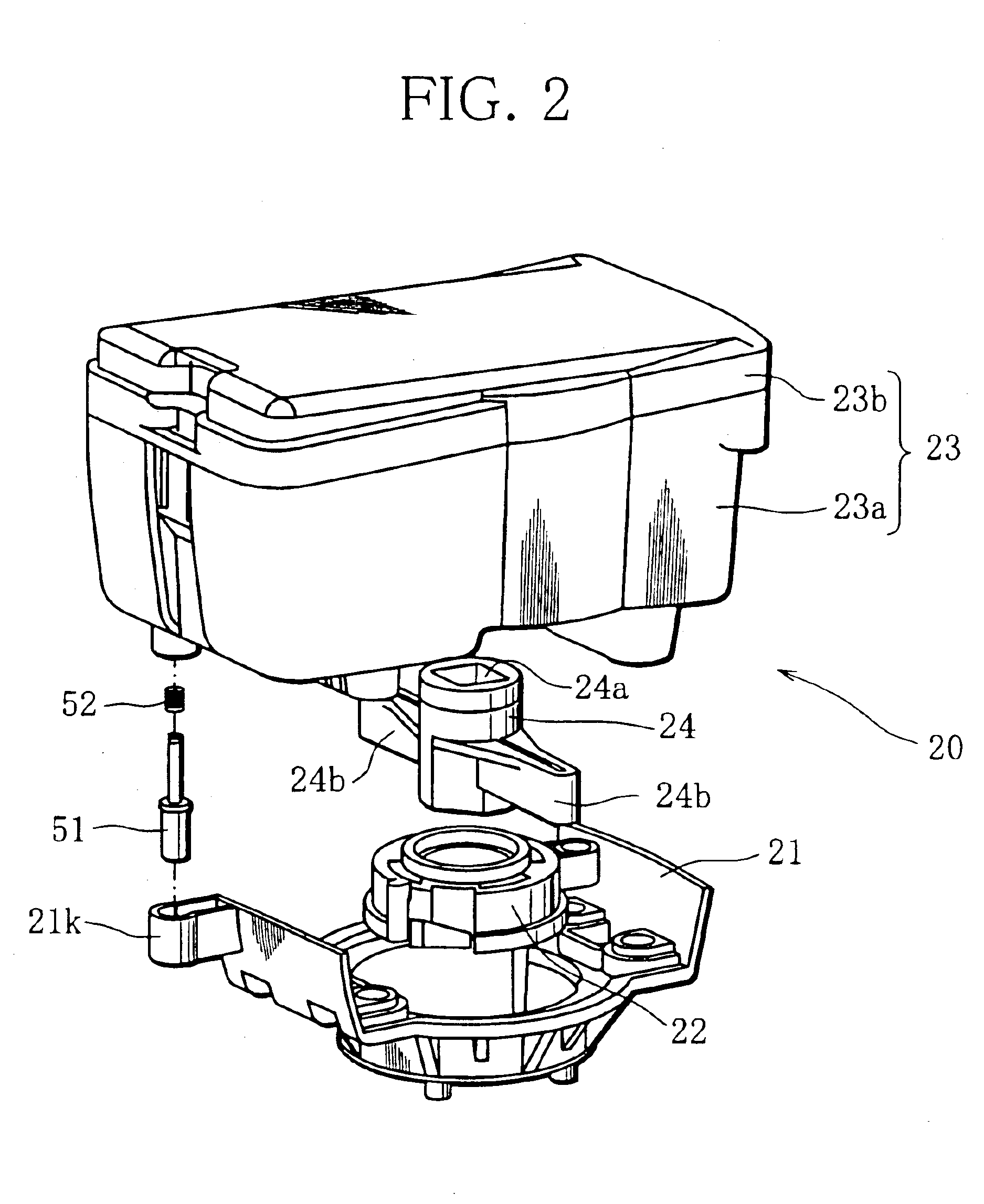

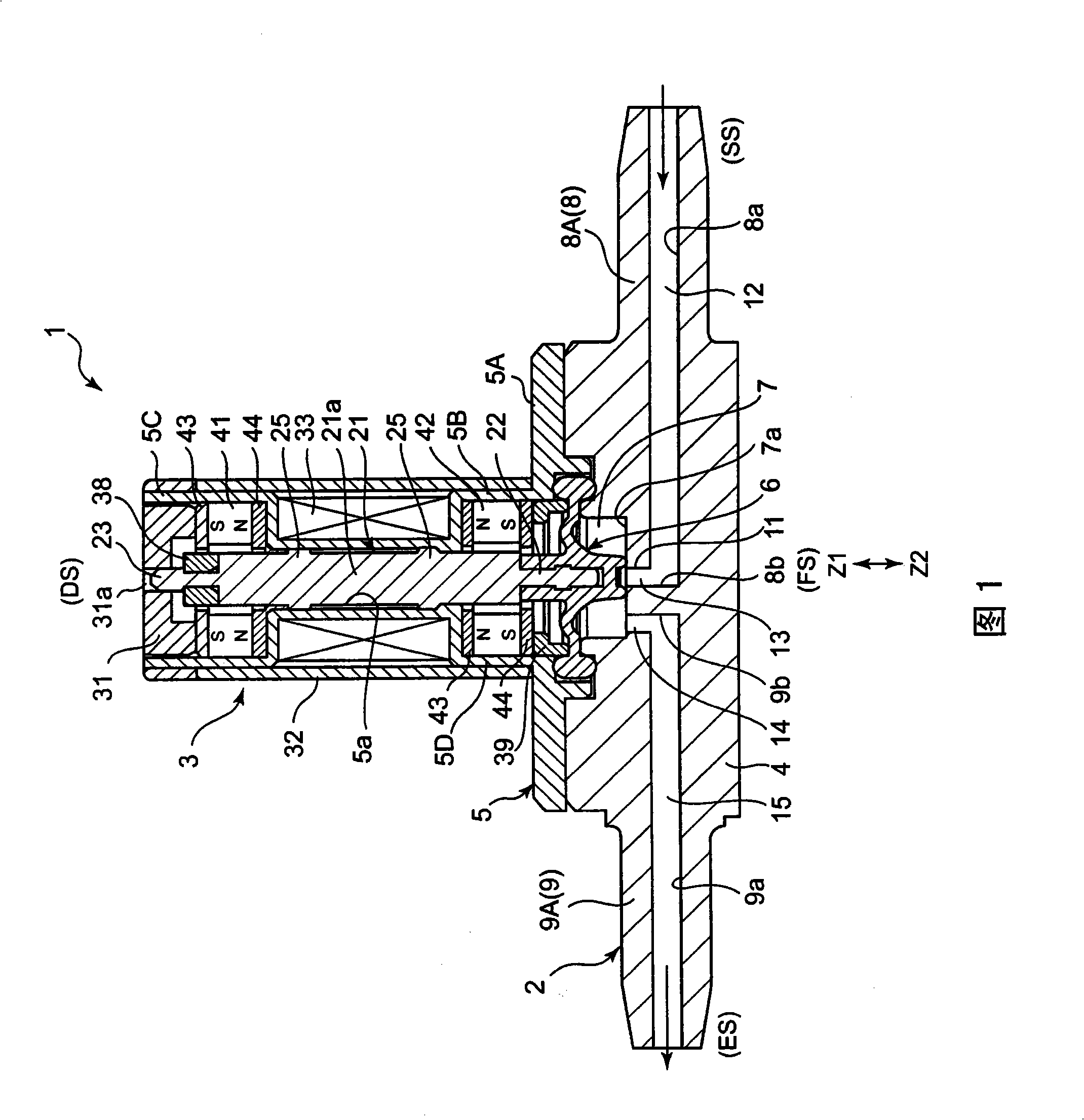

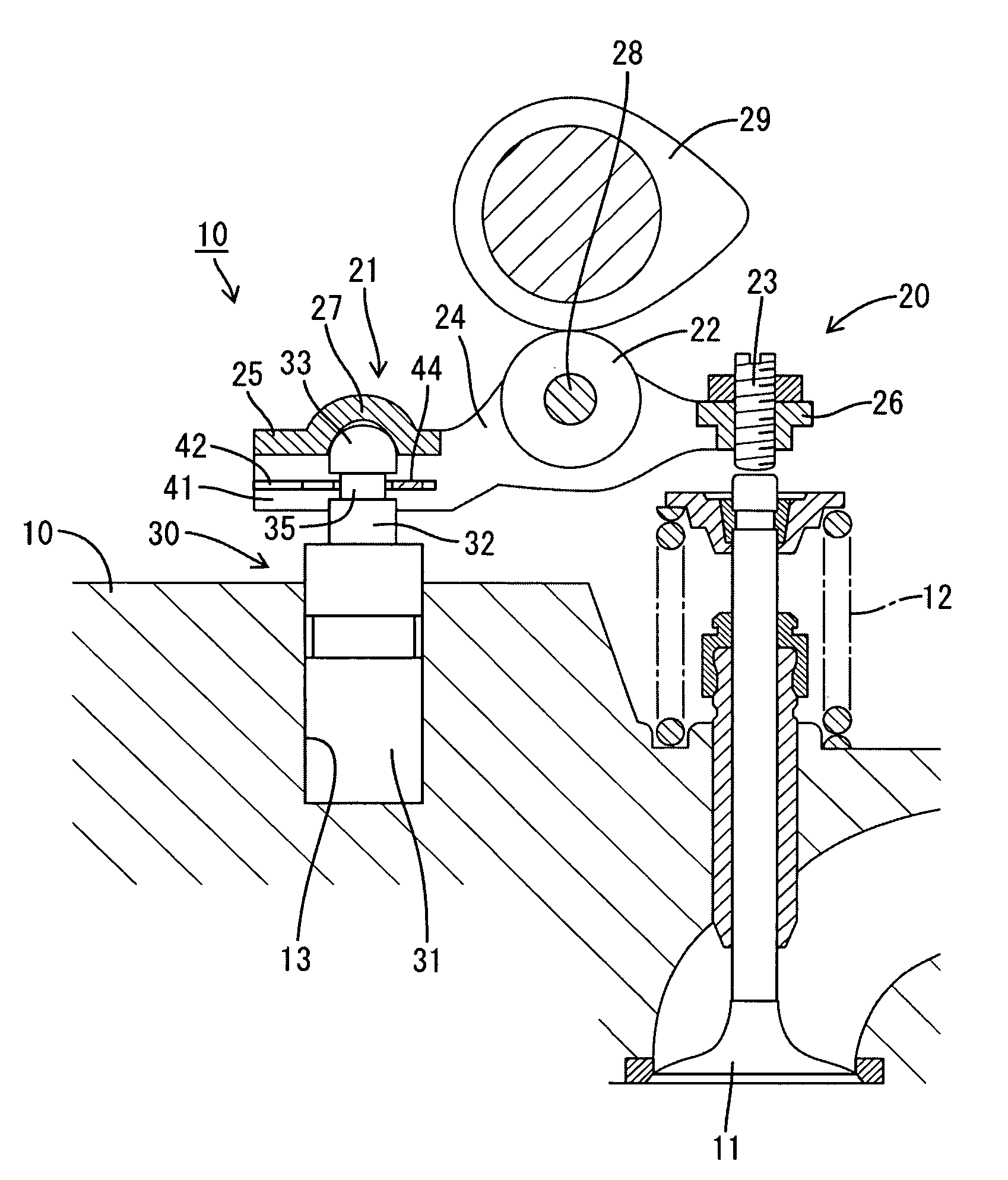

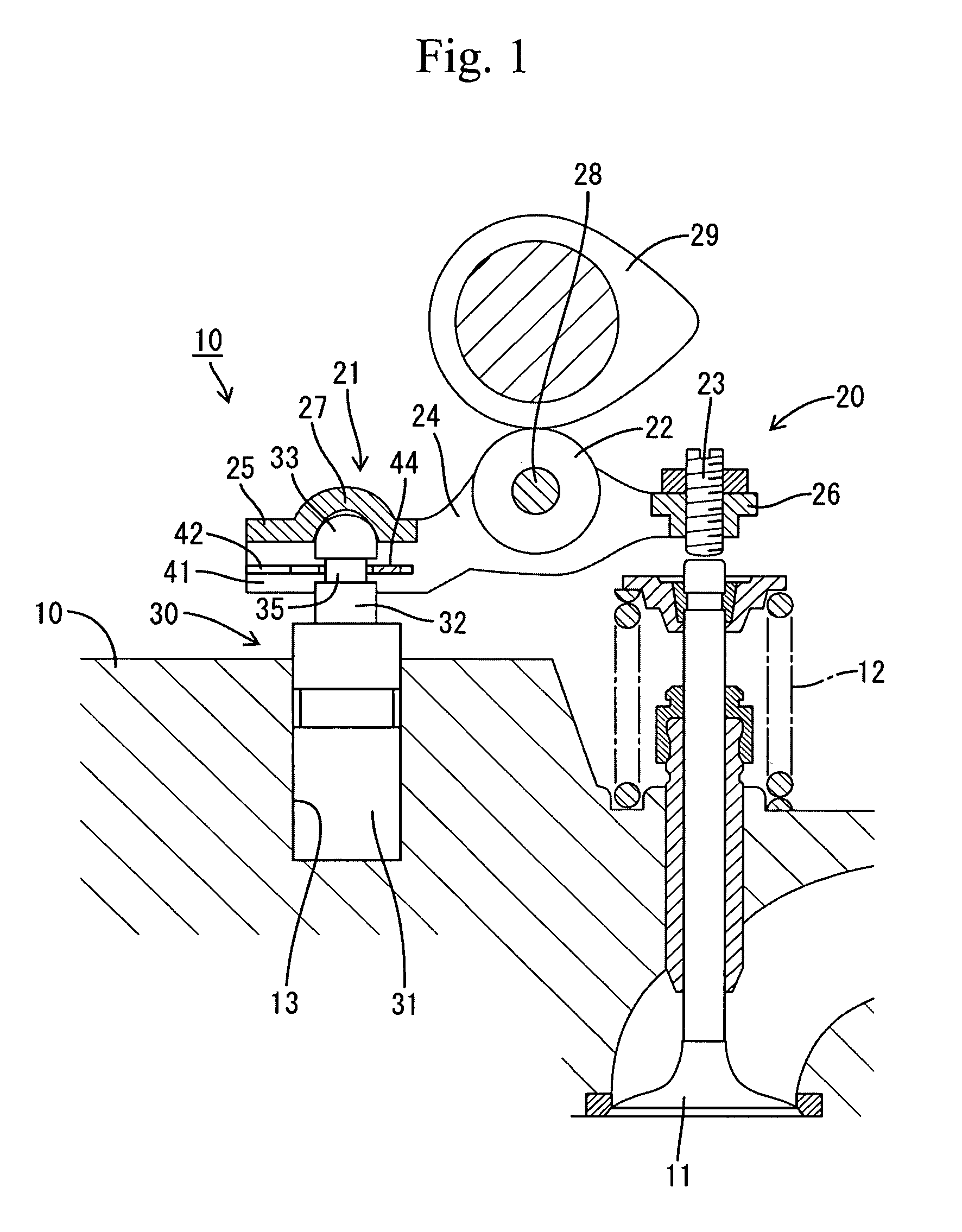

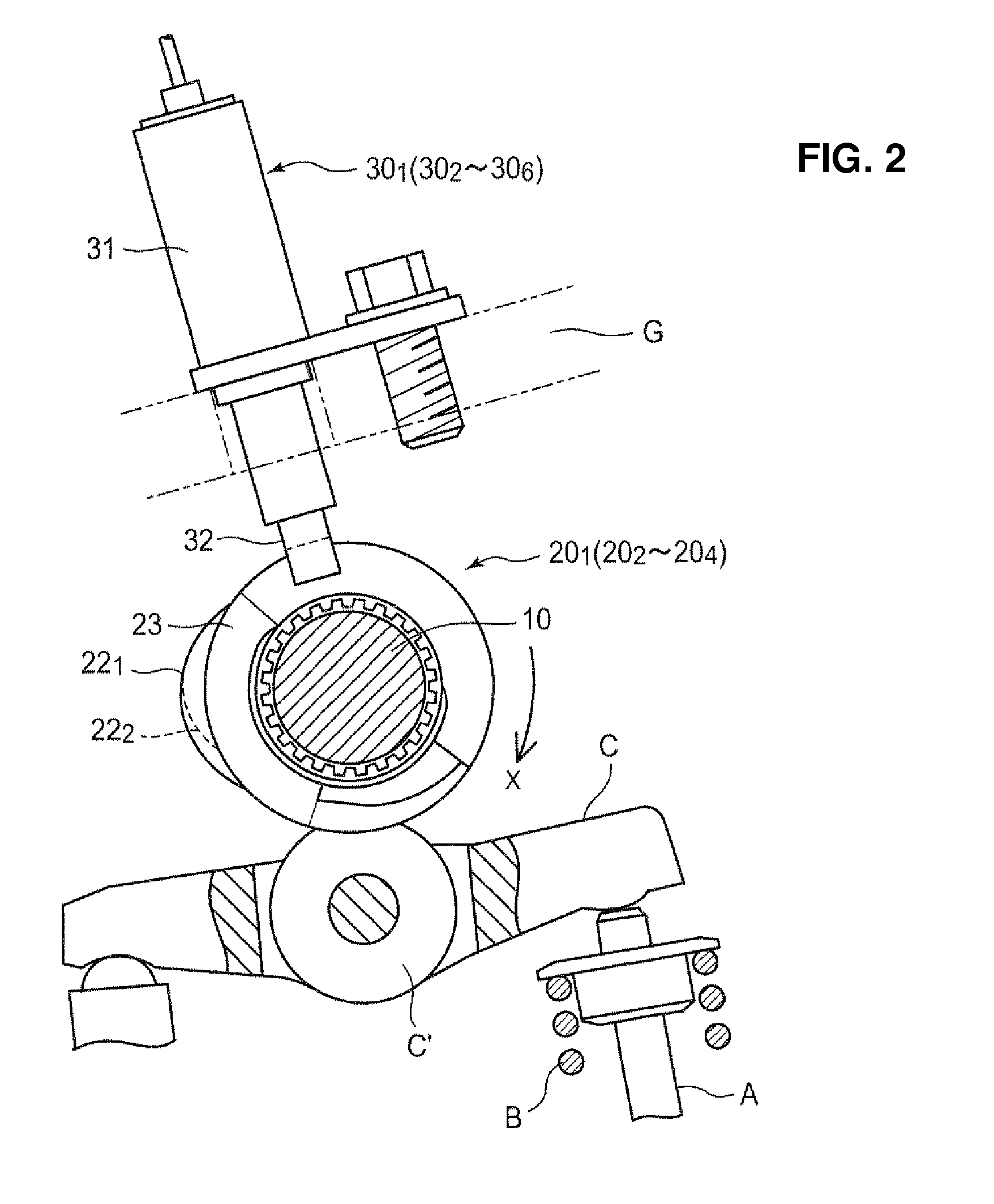

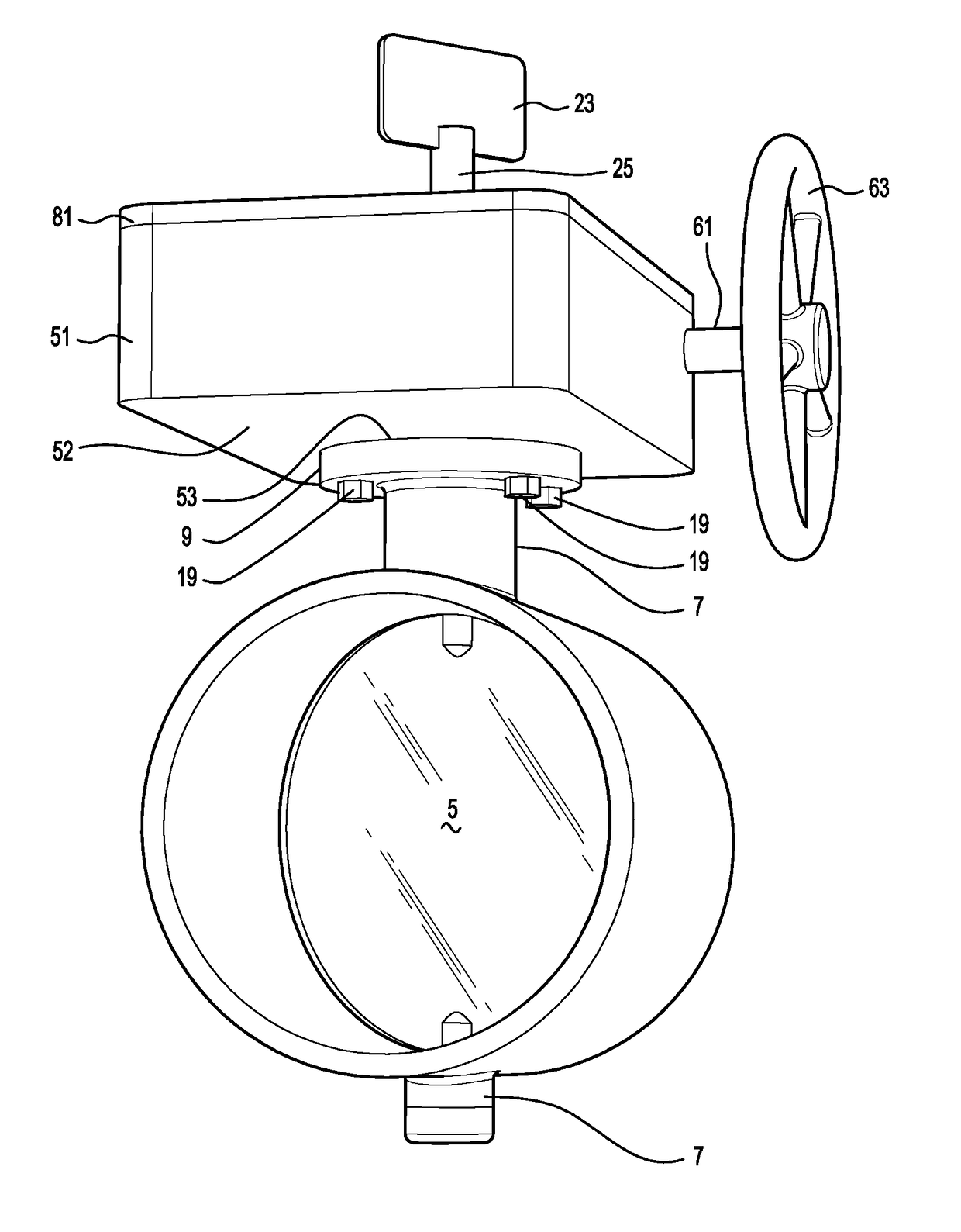

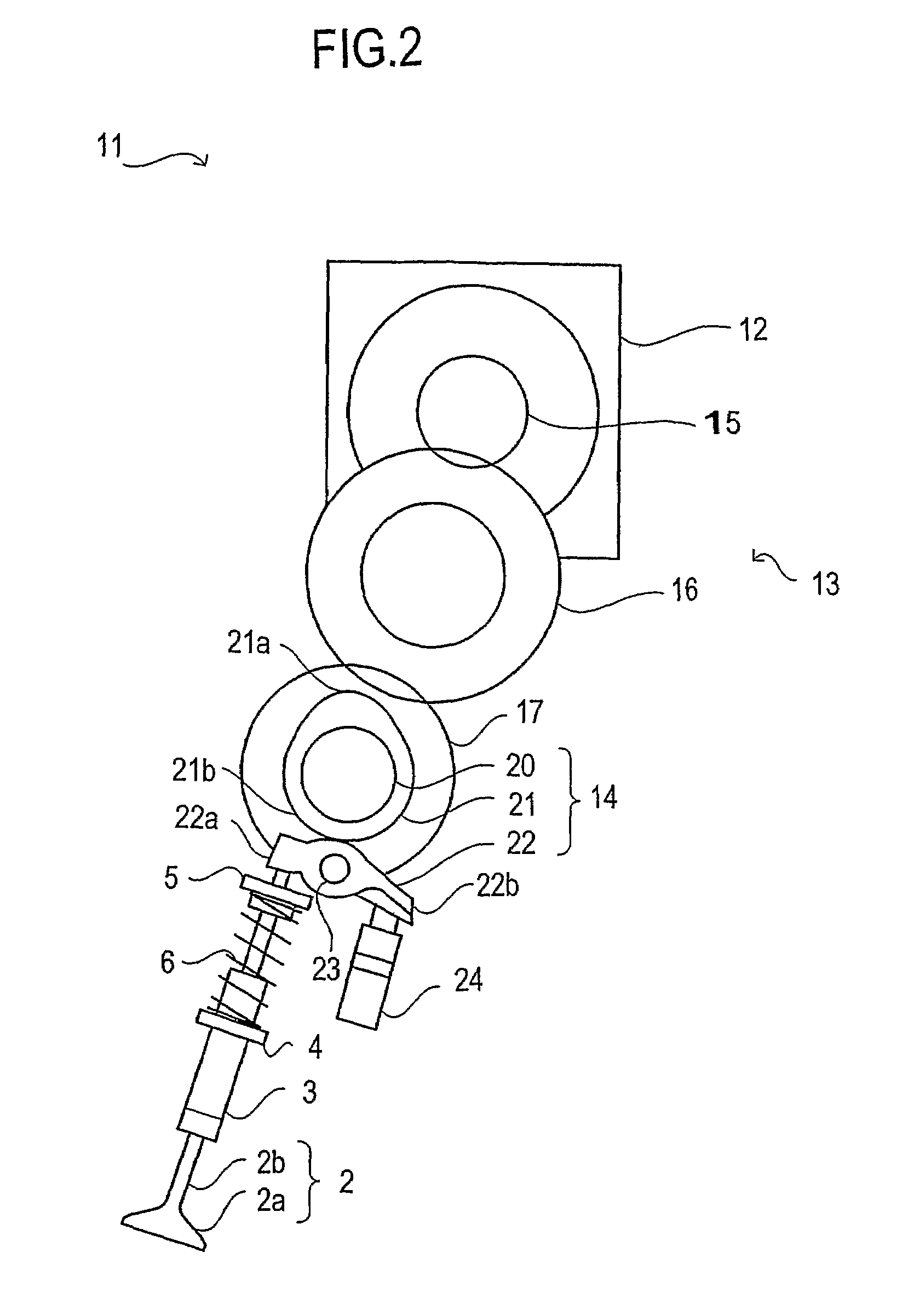

Actuator for driving rotary valve actuator and valve device with the actuator

InactiveUS6880806B2Improve securityImprove machinabilityOperating means/releasing devices for valvesPipeline systemsRotary valveEngineering

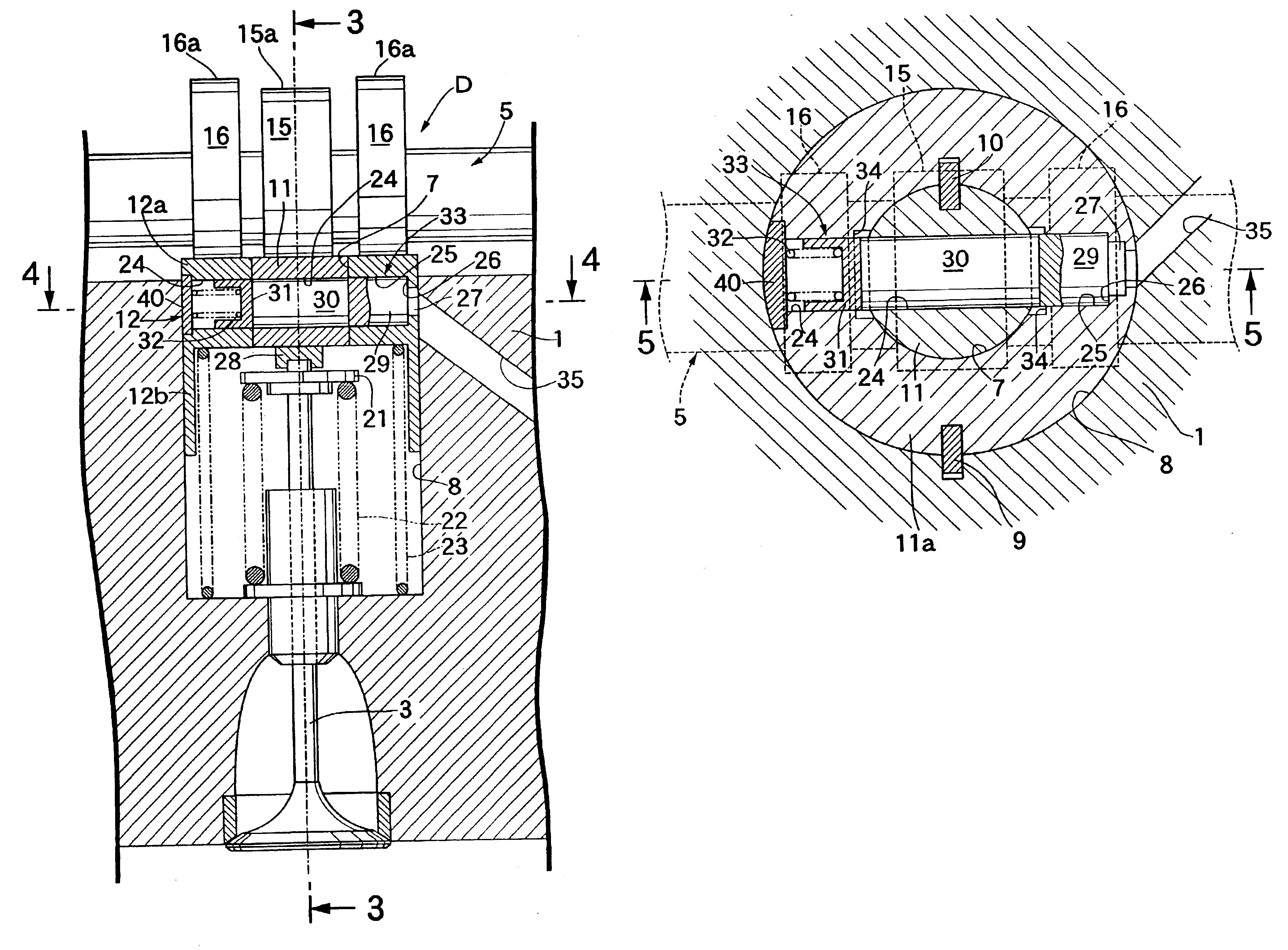

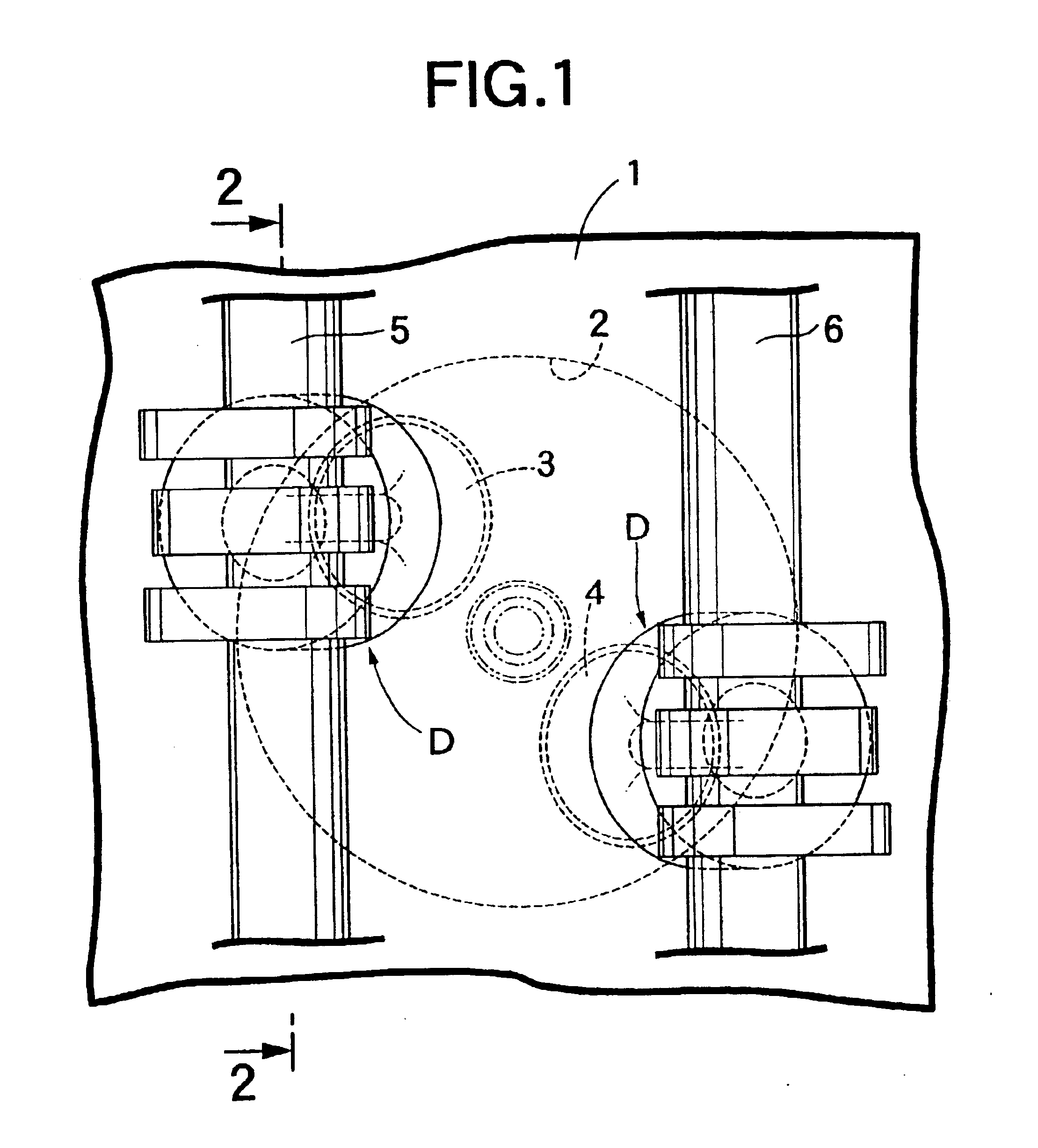

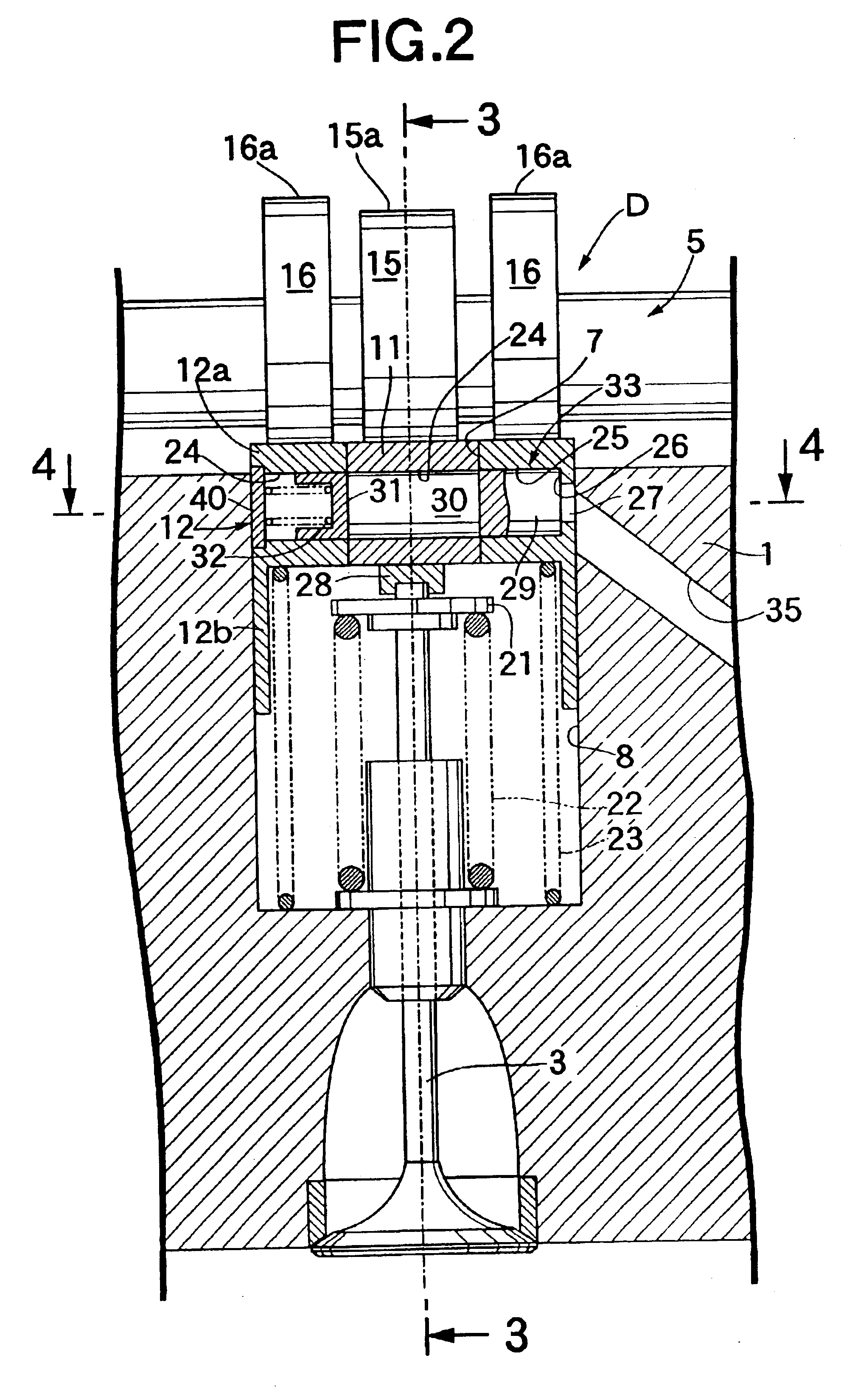

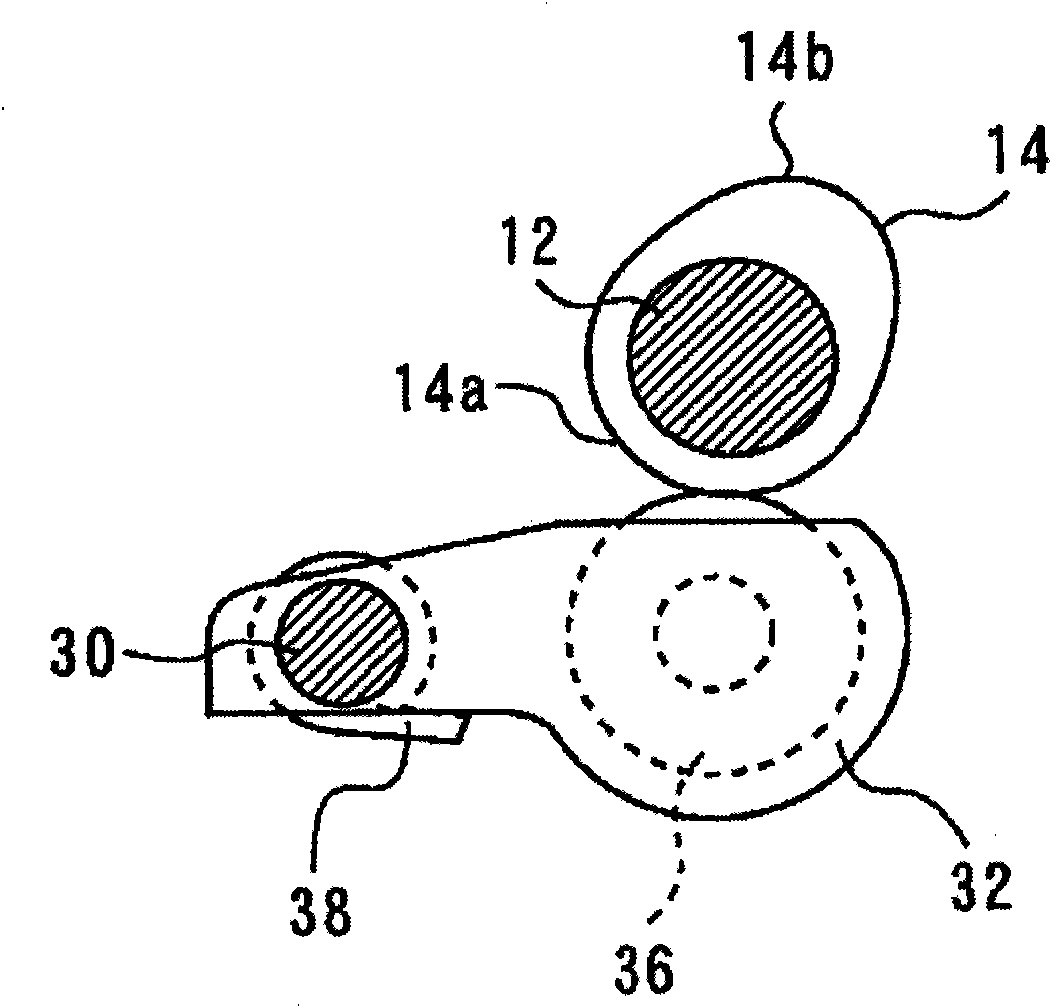

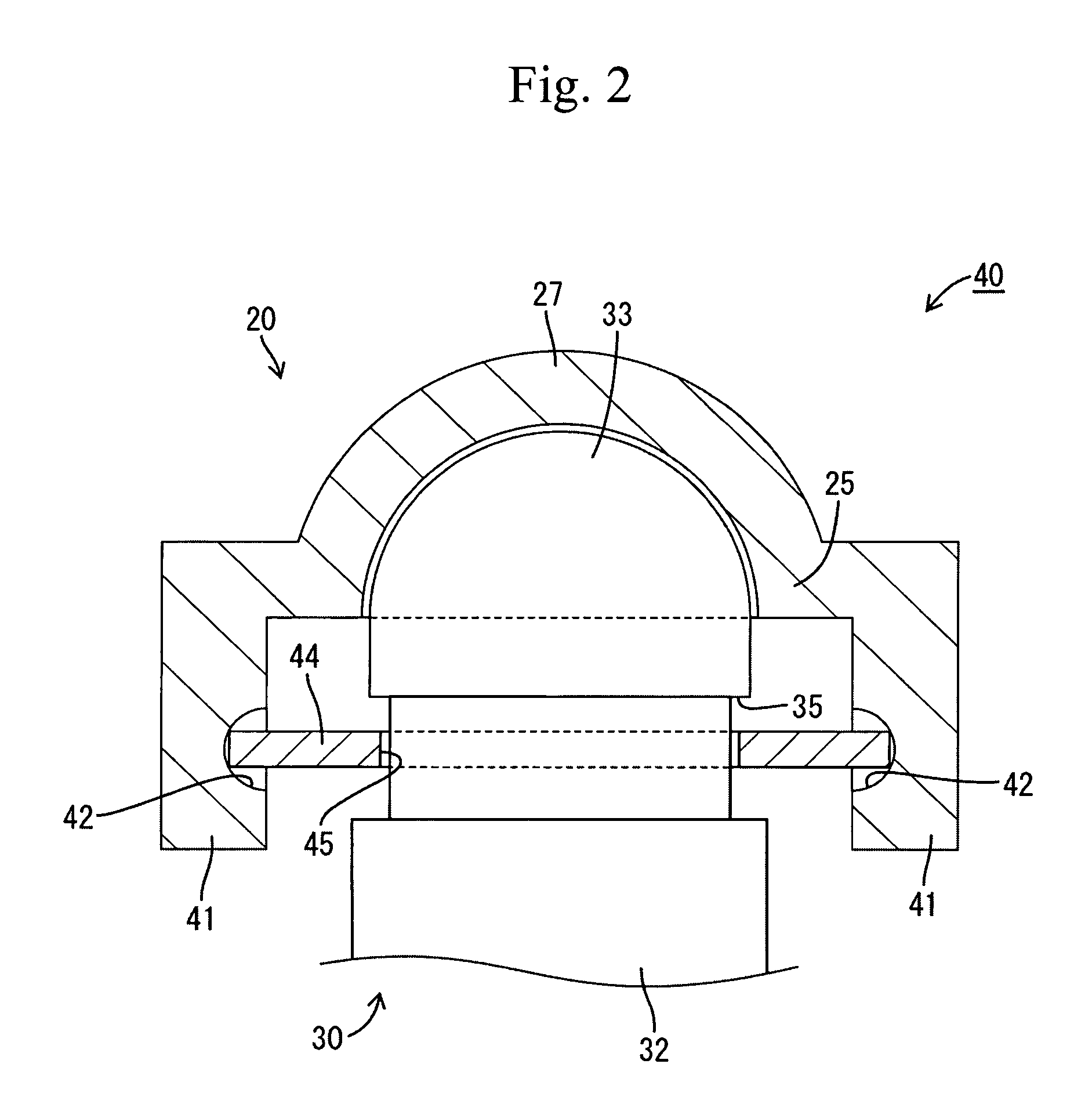

A valve gear includes a valve (30), which controls a flow rate of a fluid and an opening of which is determined according to a rotational position of a valve element, an actuator (20) for providing a rotational force to a rotary valve shaft that changes the opening of the valve (30), and attaching / detaching means. The attaching / detaching means includes a locking element (32) formed at its prescribed positions with locking concave / convex portions and an engaging element (22) formed at its prescribed positions with engaging concave / convex portions. The locking element (32) and the engaging element (22) are relatively rotatable around the rotary valve shaft up to a prescribed angle, and prevent the actuator (20) from coming off the valve (30) at an engaging position where the engaging concave / convex portions and the locking concave / convex portions are engaged with one another, and allow the actuator (20) and the valve (30) to be detached from each other at a disengaging position.

Owner:YAMATAKE HONEYWELL CO LTD

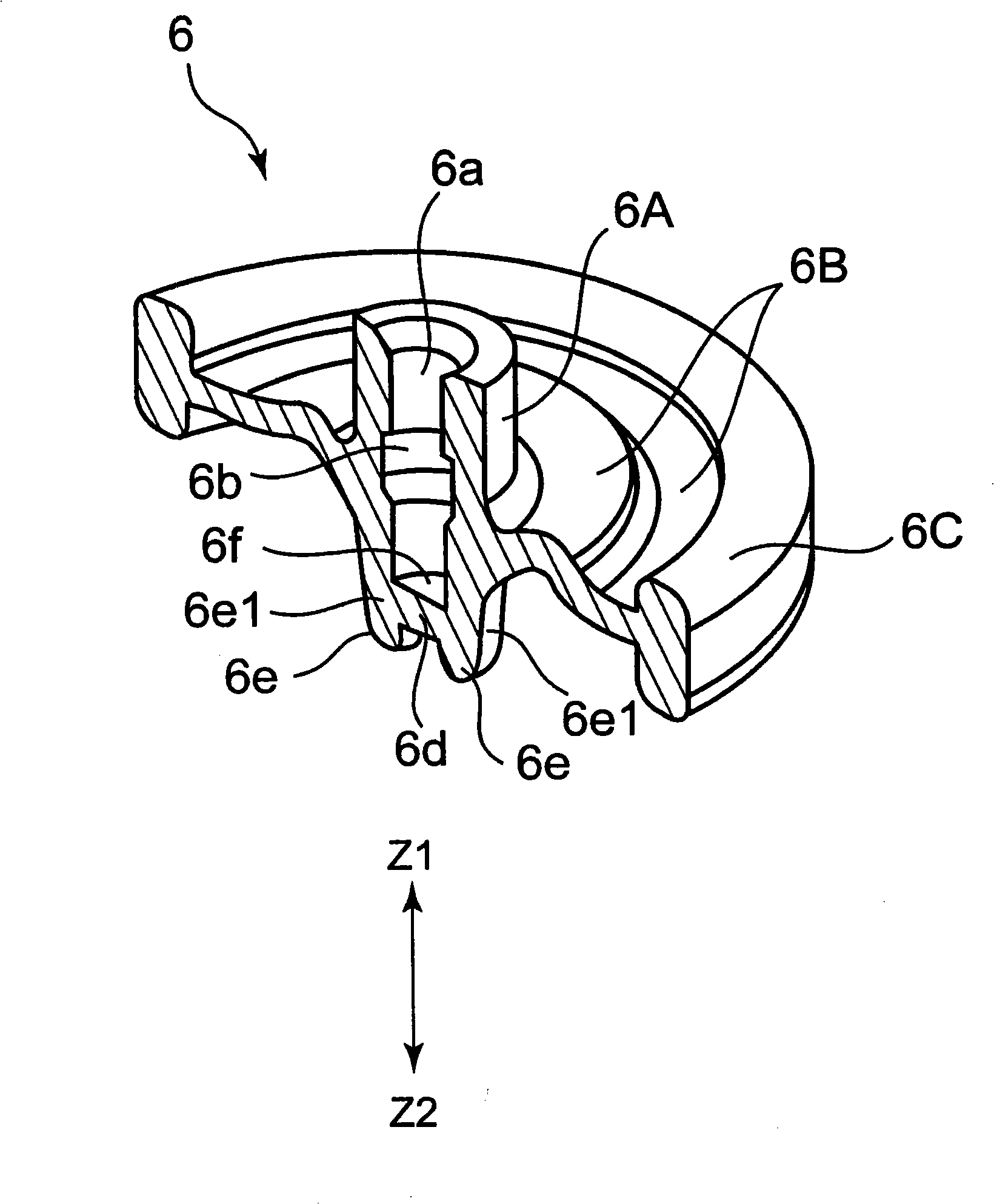

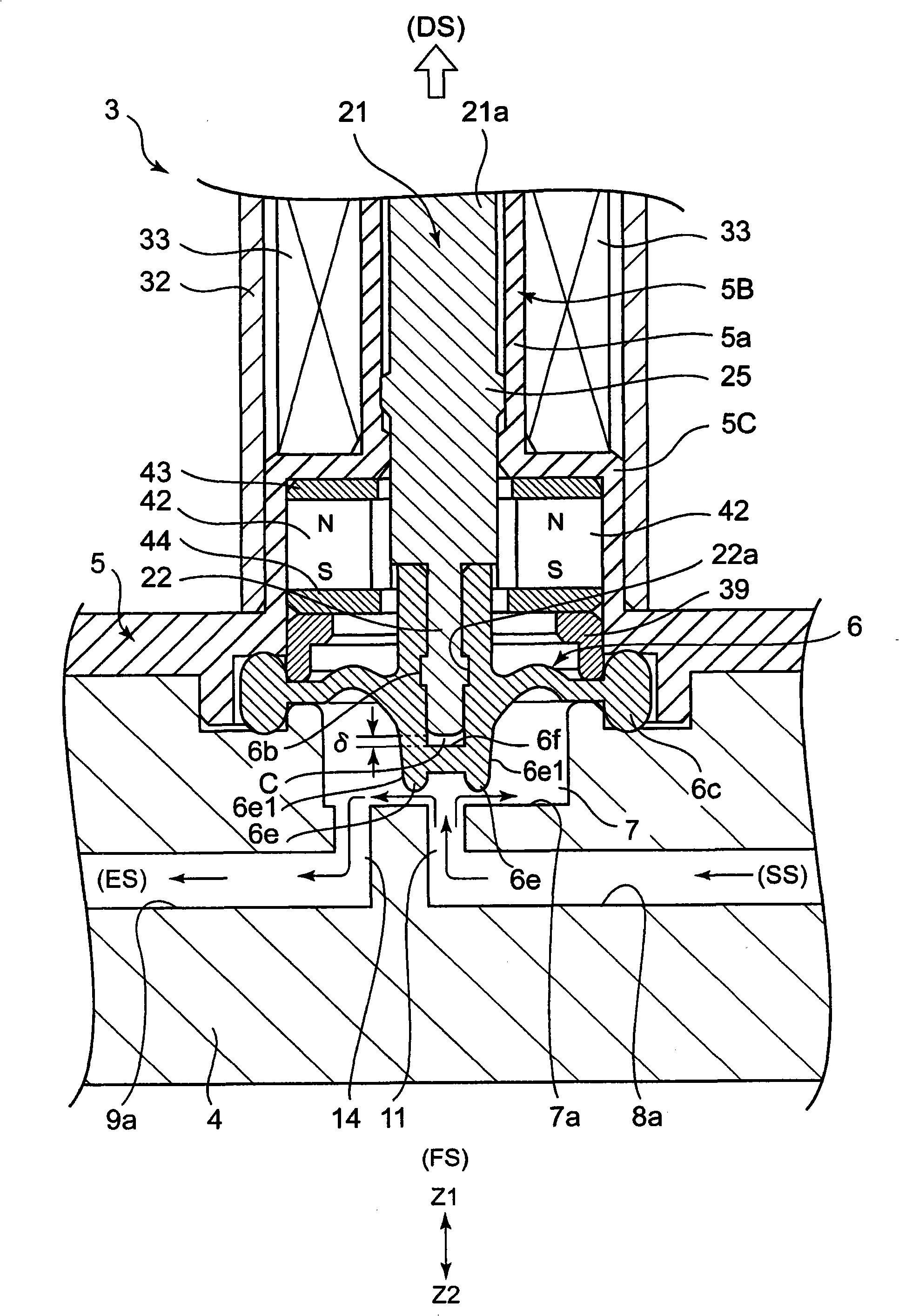

Valve gear

InactiveCN101311589AReliable closureReliable and smooth switchingDiaphragm valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention provides a valve device, wherein a valve is reliably sealed even if by small force with little leakage. Under the cutting state of a movable axis (21) moving downwards, a ring rib (6e) bunts against an open end of a first perforation hole (11) which forms an inflow path (12) around thereby jamming the path. A cavity part (C) is formed between an inner bottom (6f) inside an insertion part (6a) of a valve (6) at the front of the movable axis (21), therefore, the ring rib (6e) can fully performs elastic deformation, to reliably seal the open end of the first perforation hole (11), and obtain a valve device with little leakage.

Owner:ALPS ALPINE CO LTD

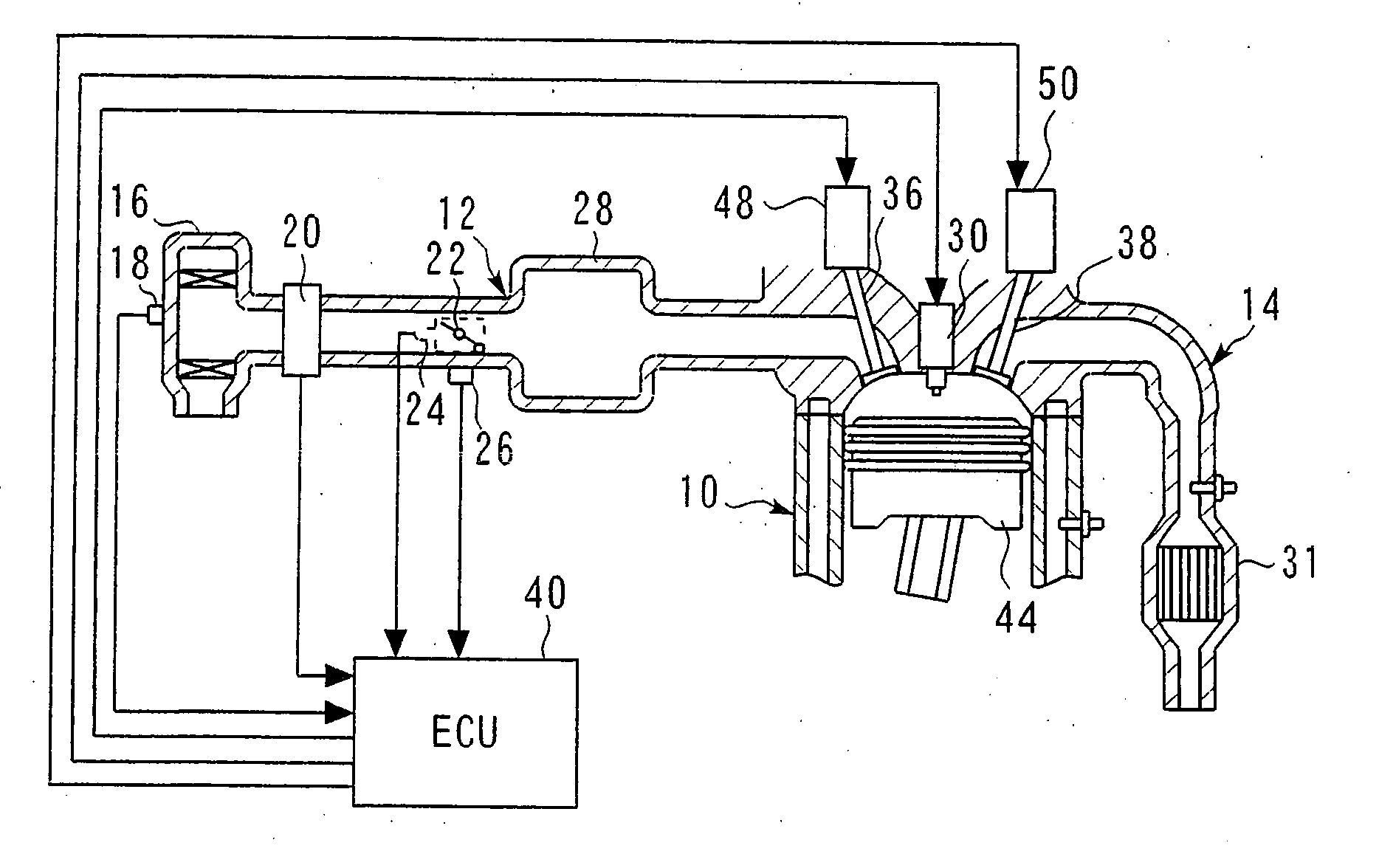

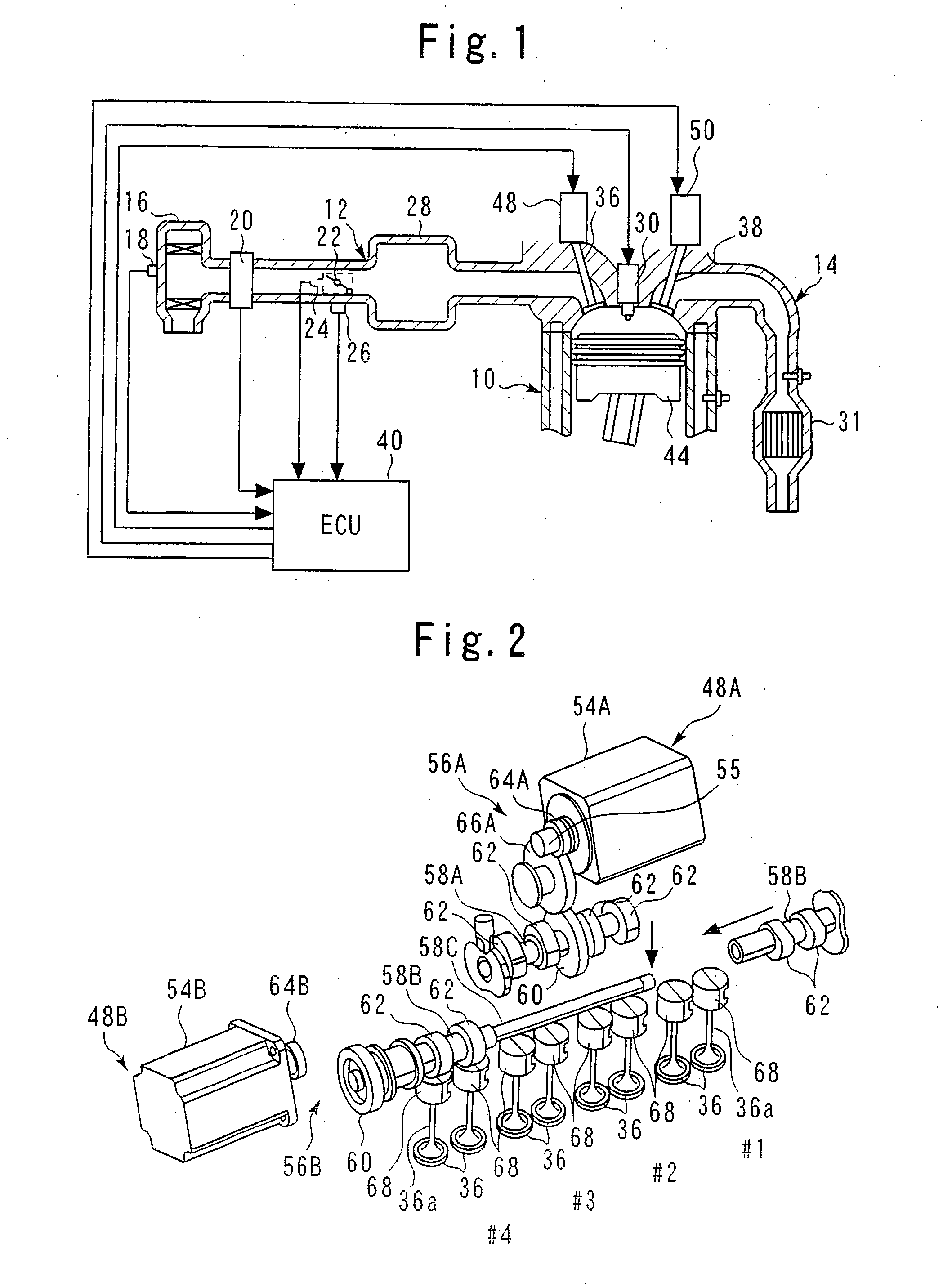

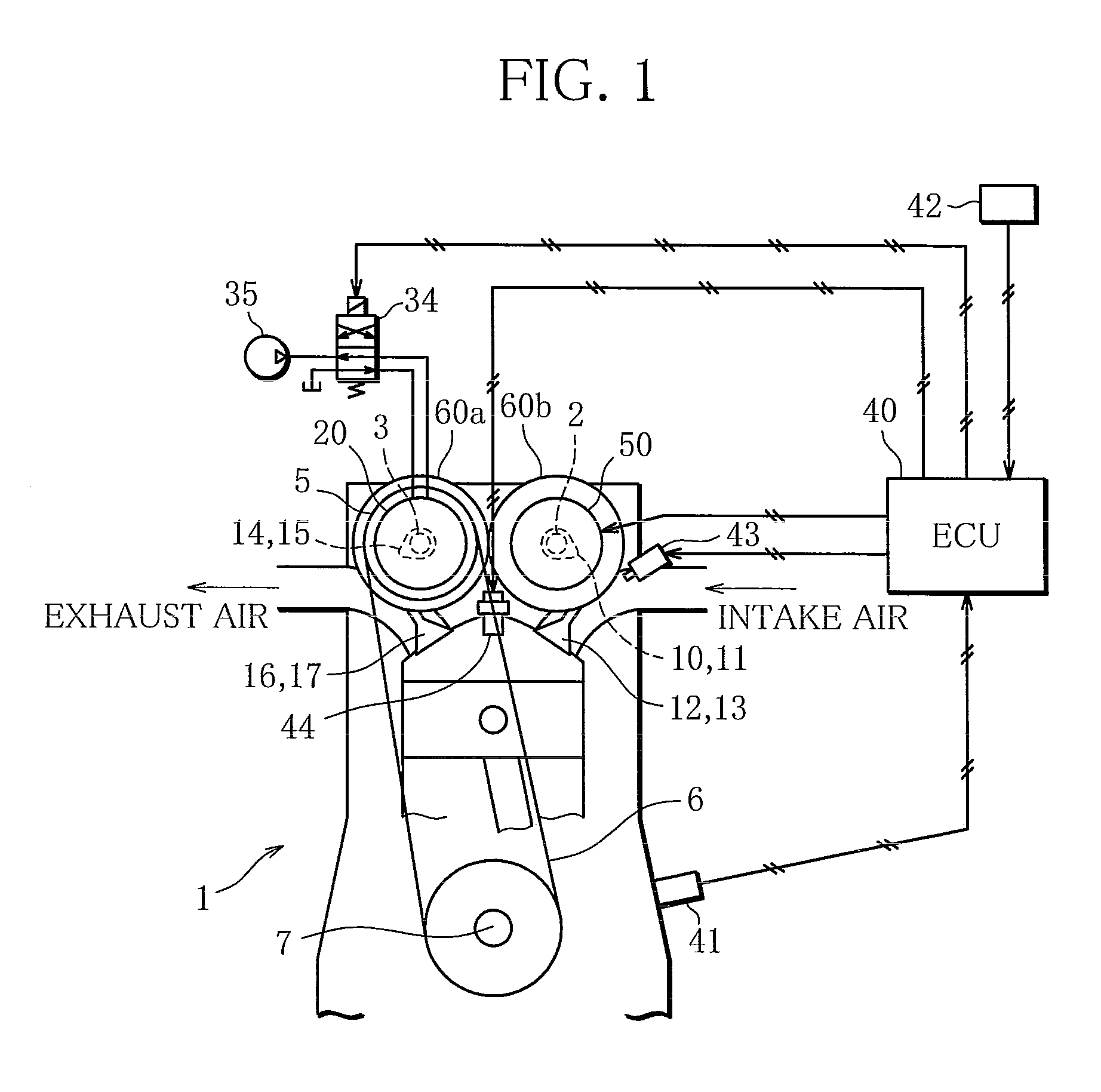

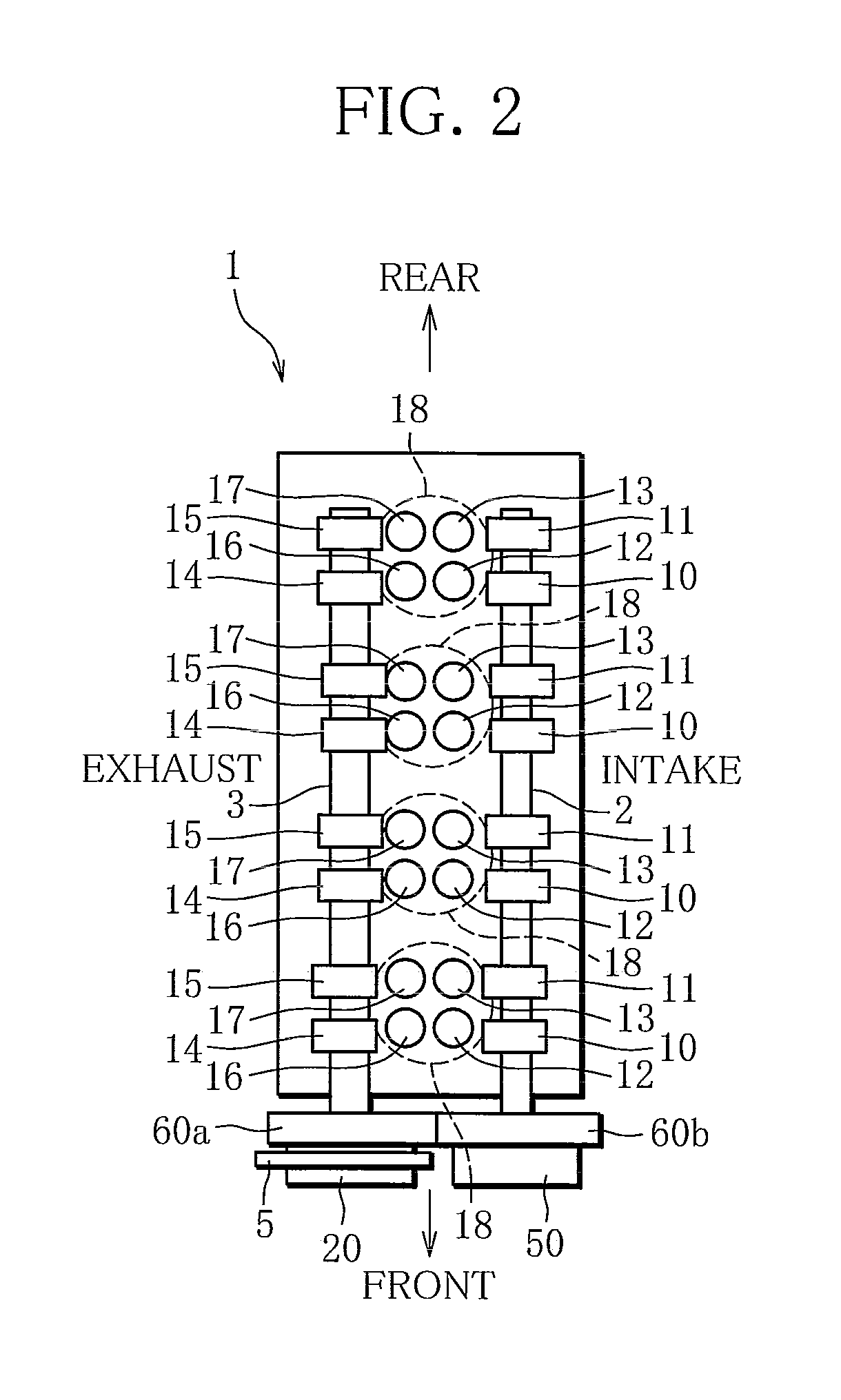

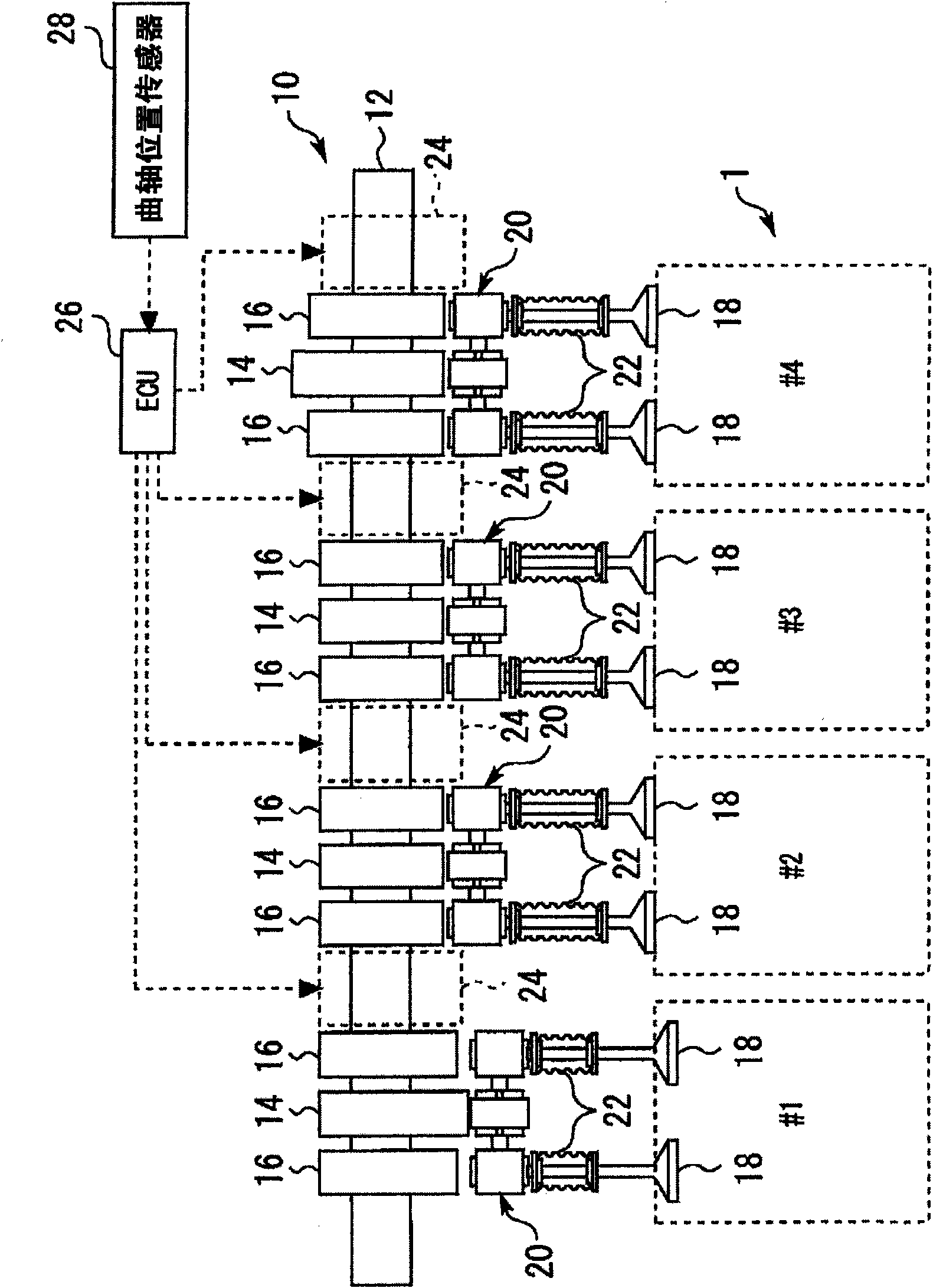

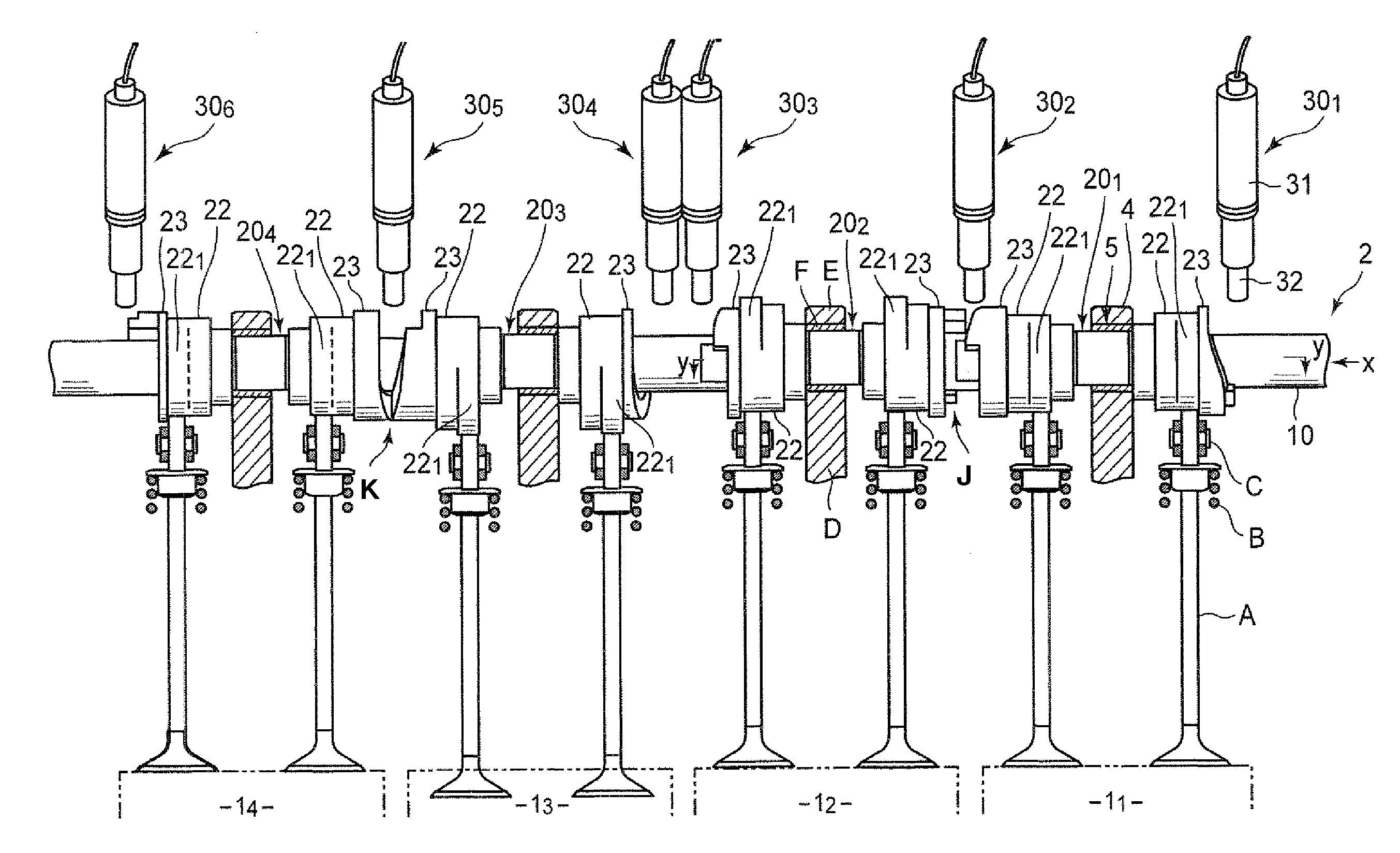

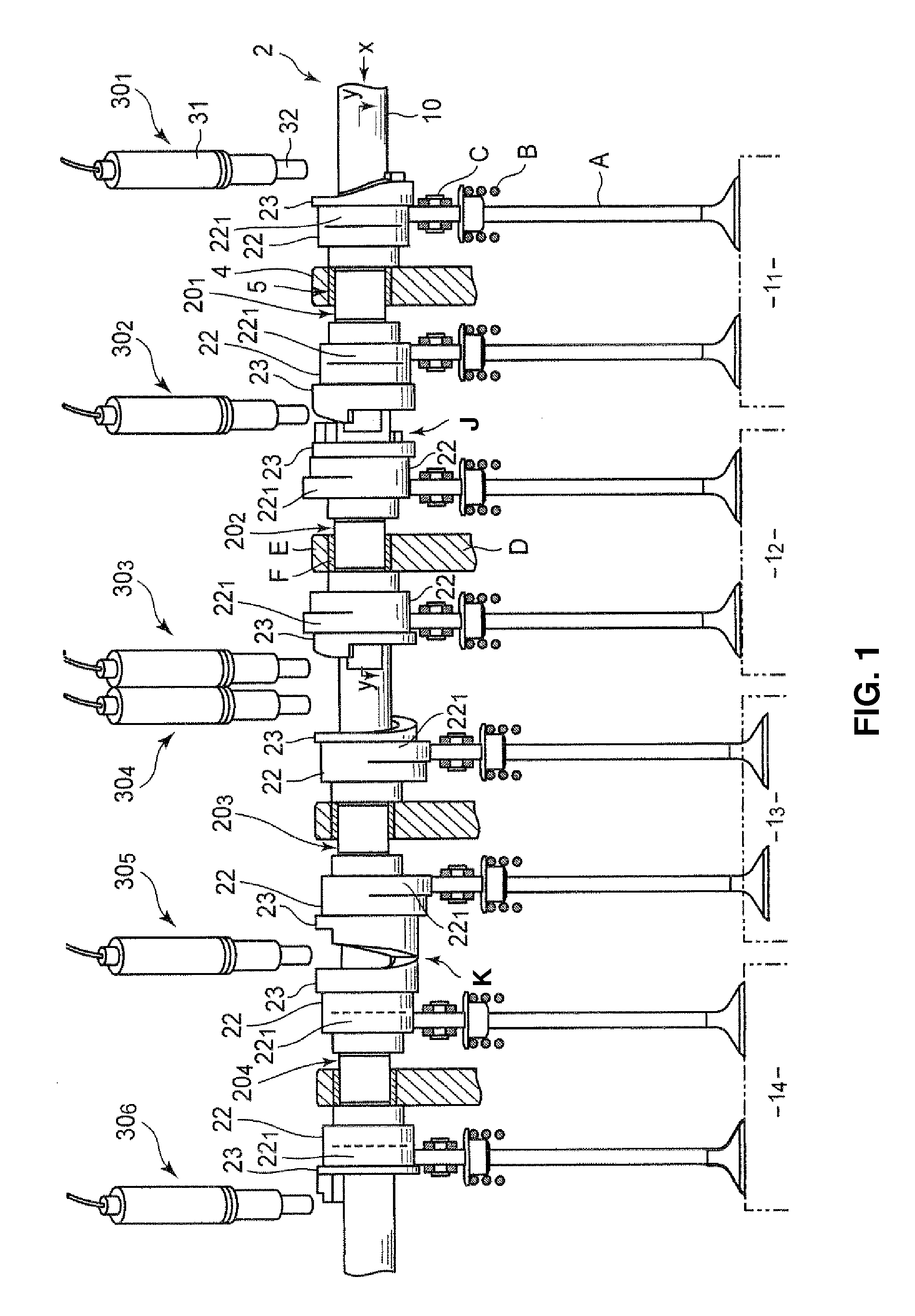

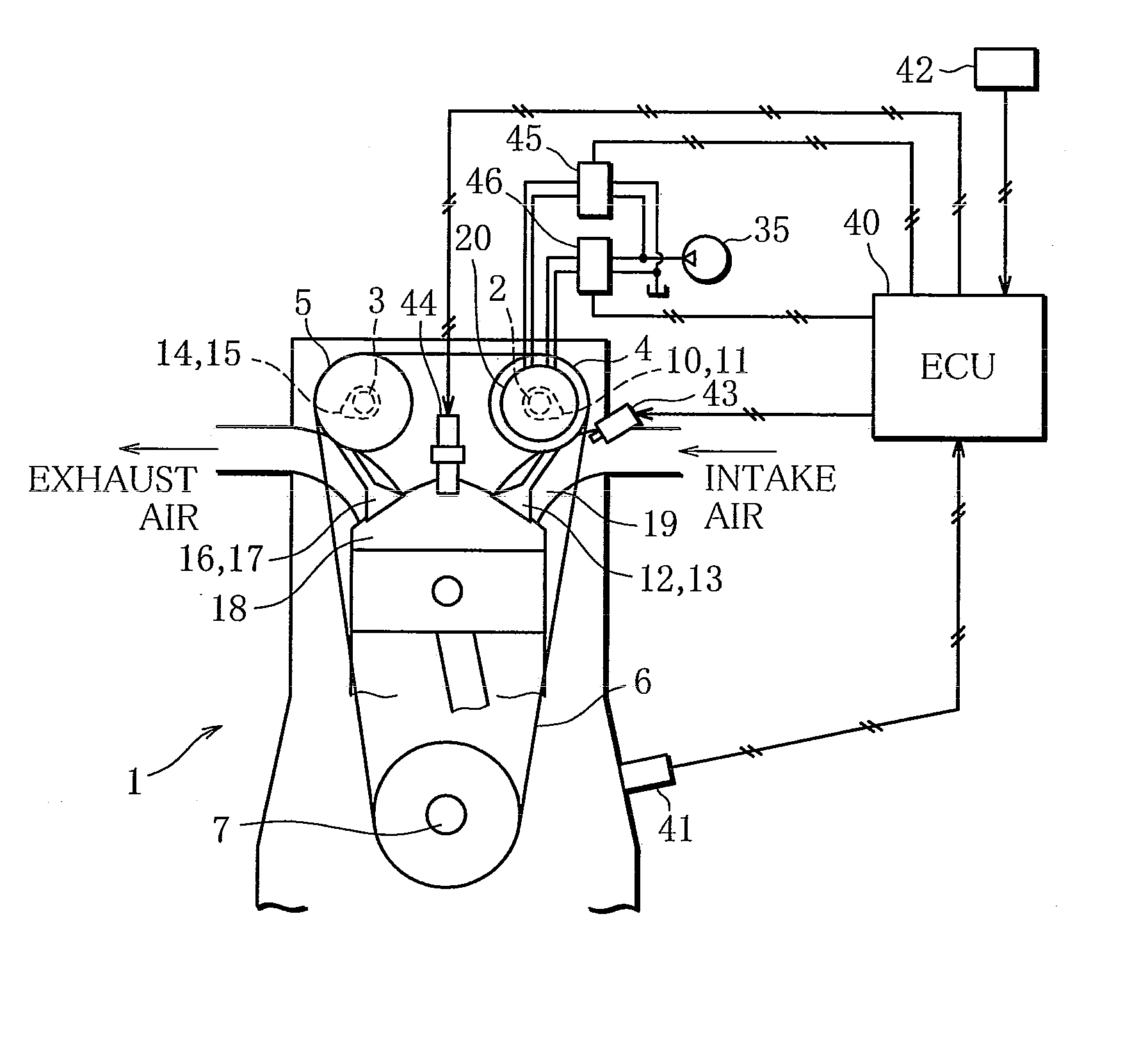

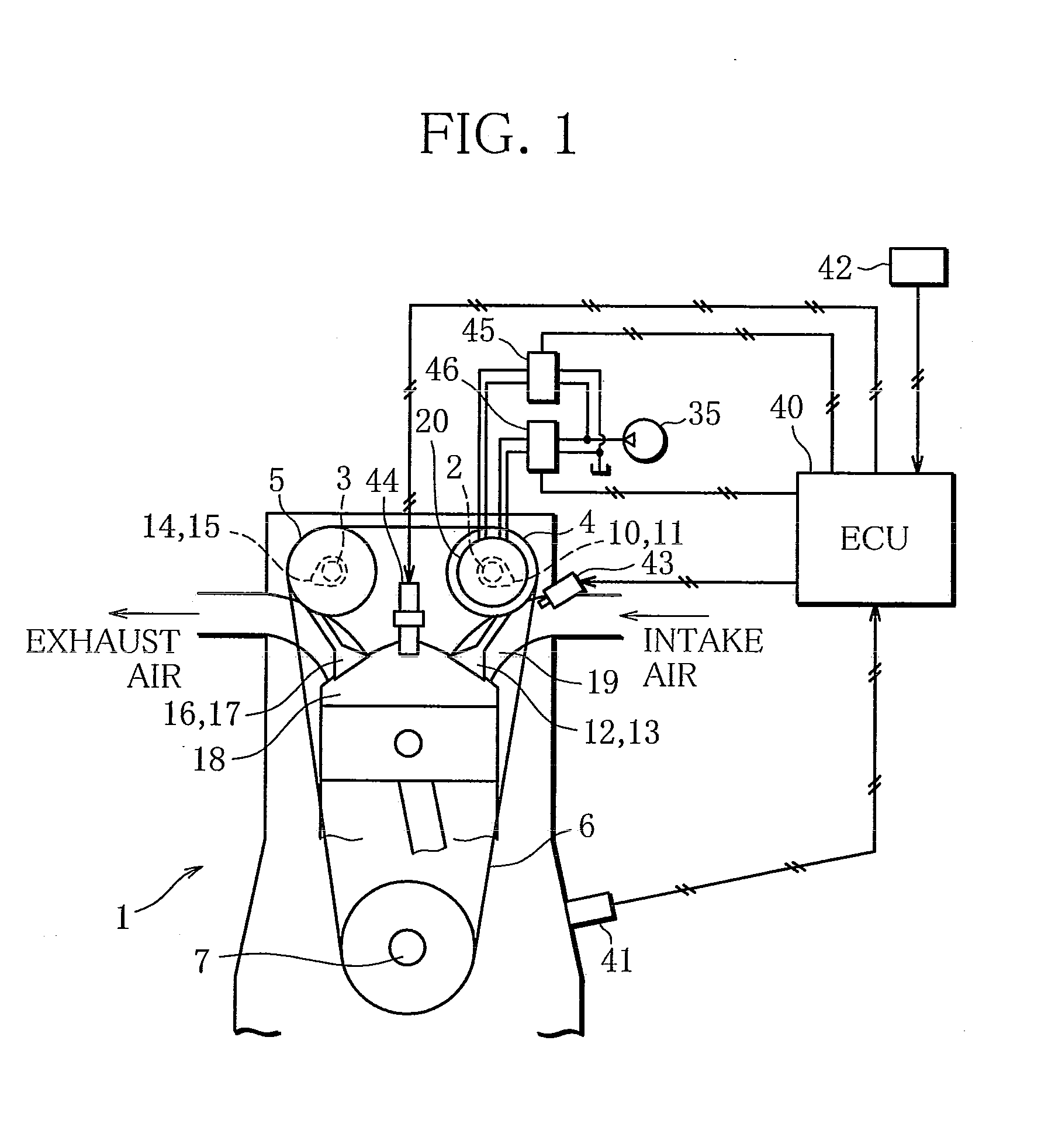

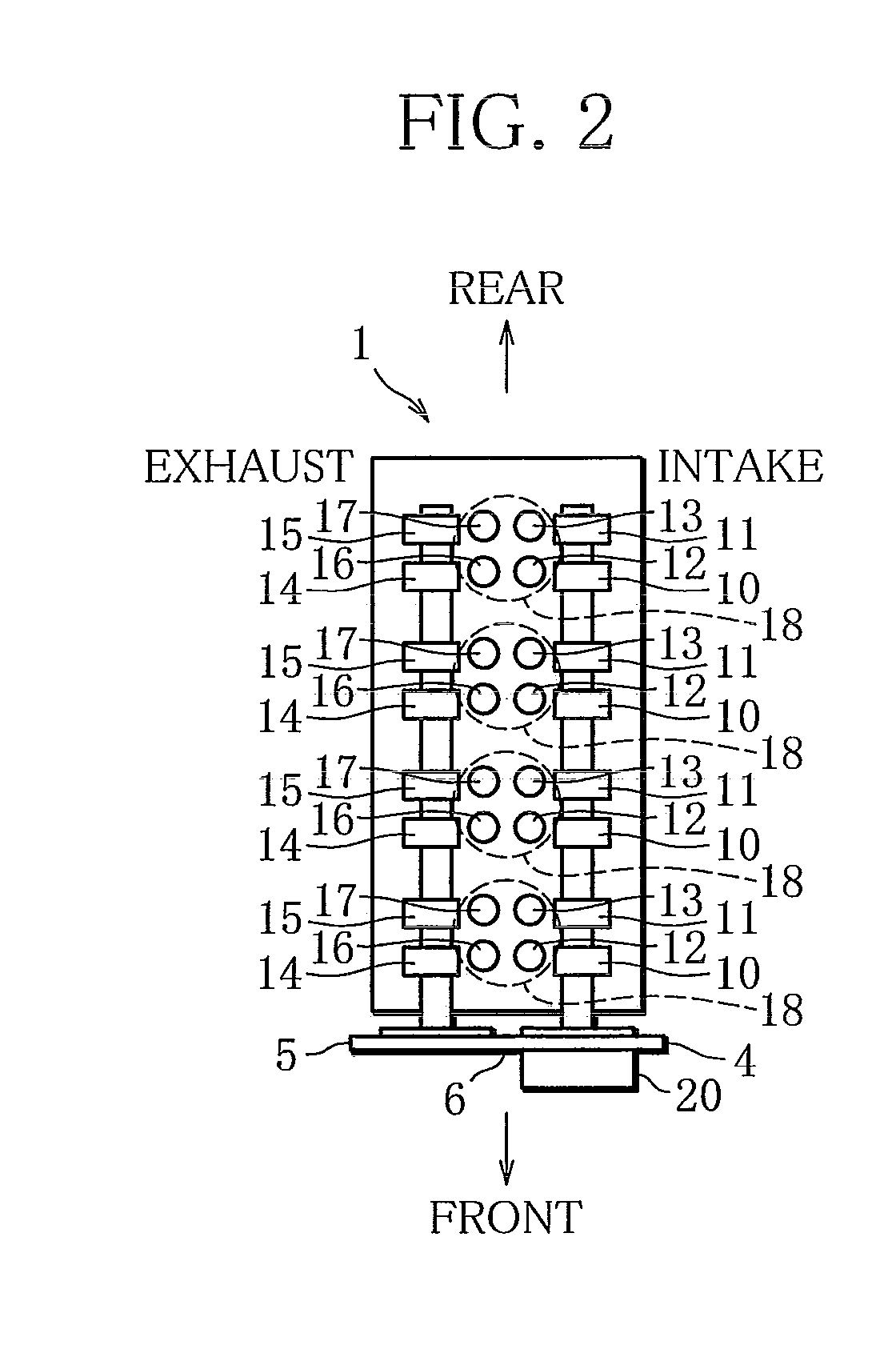

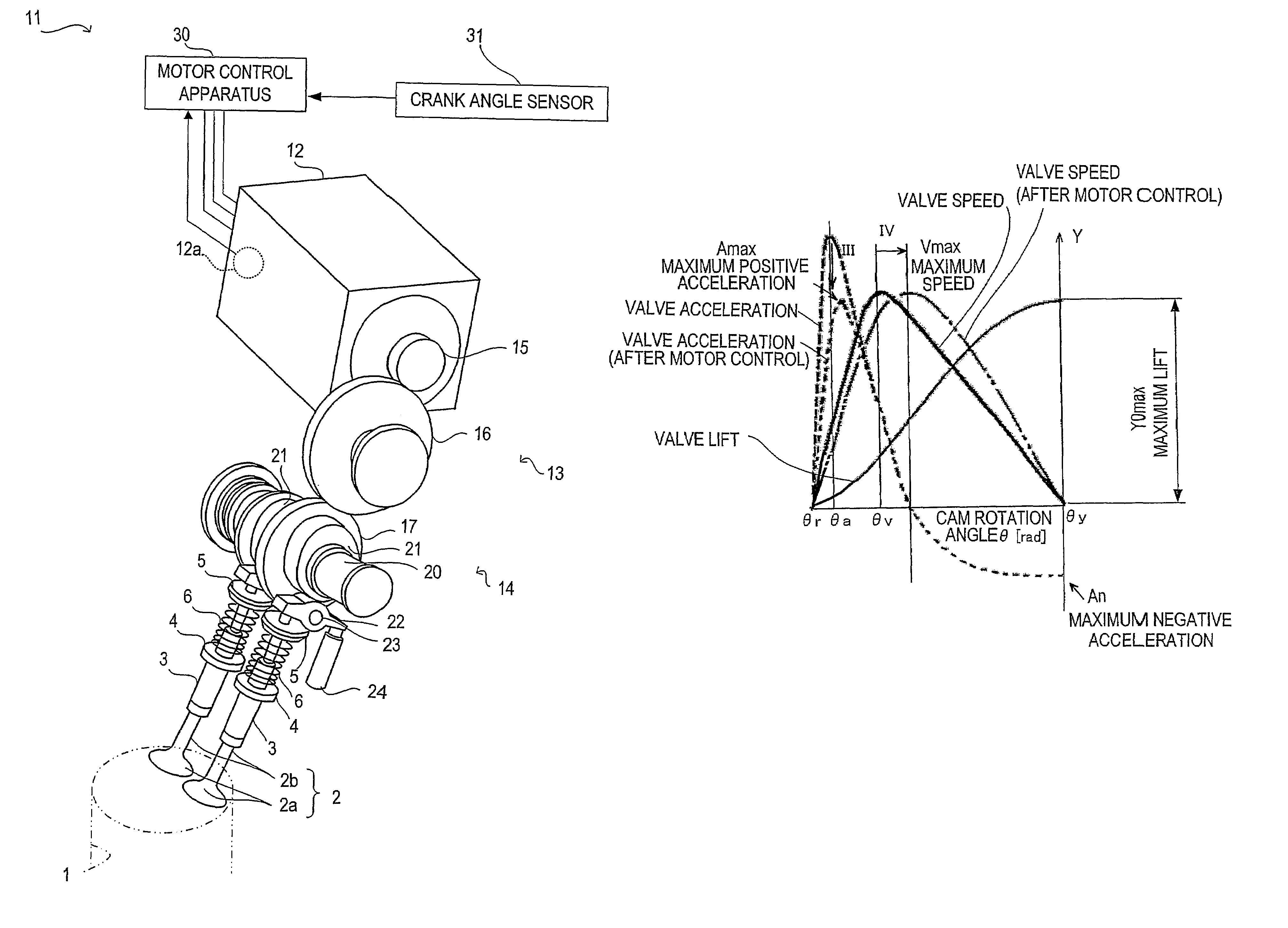

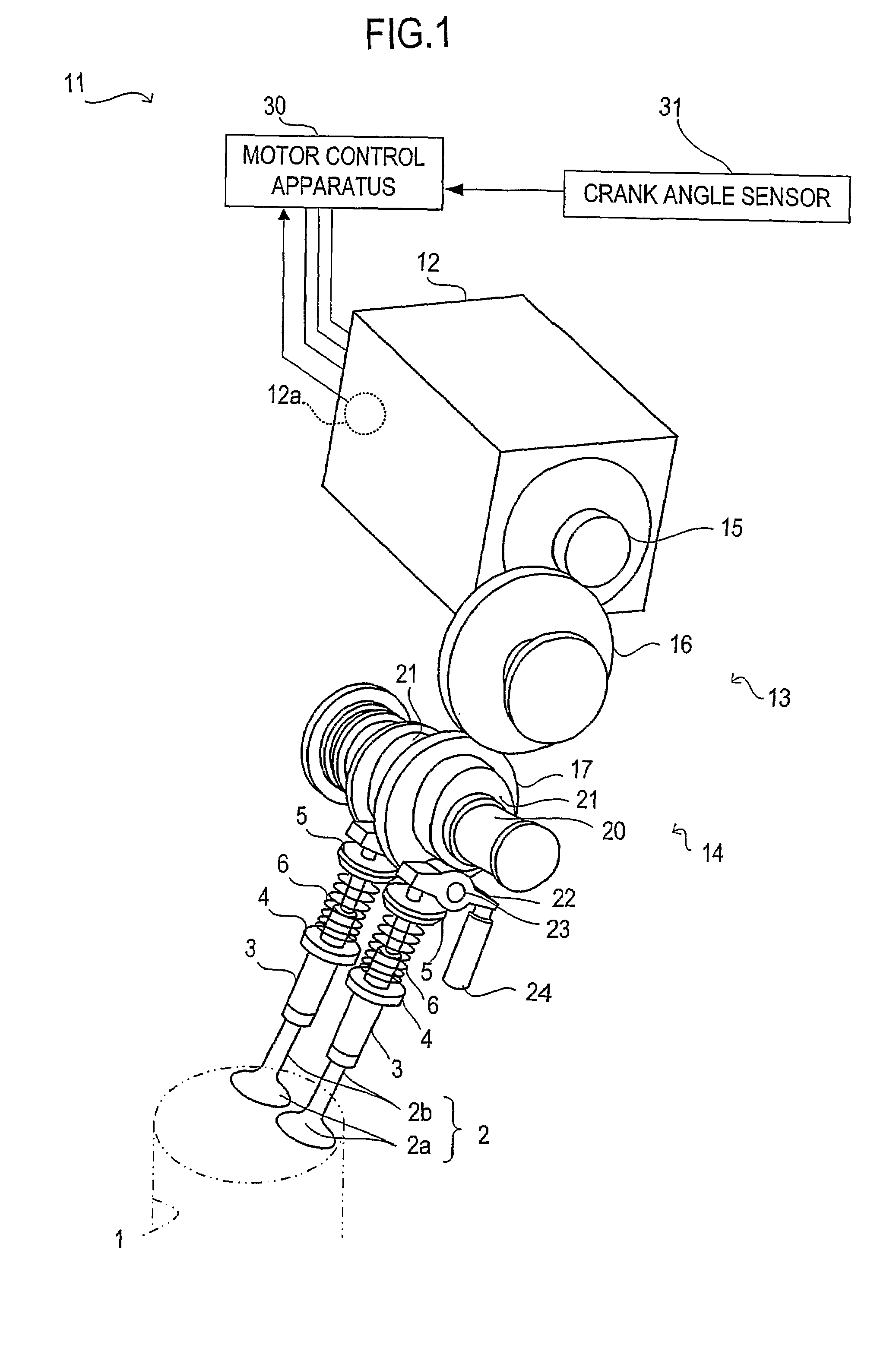

Valve Gear of Internal Combustion Engine

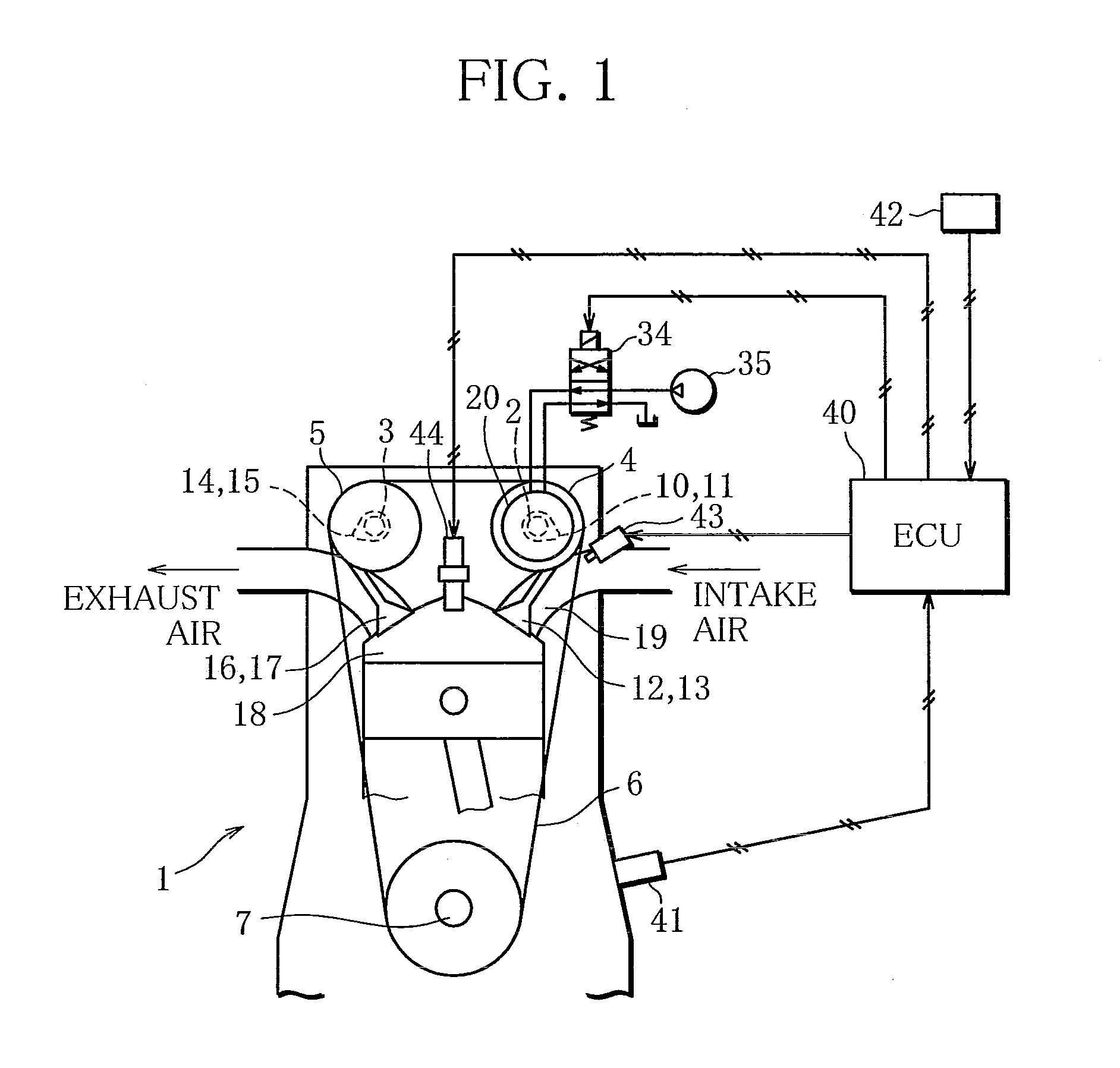

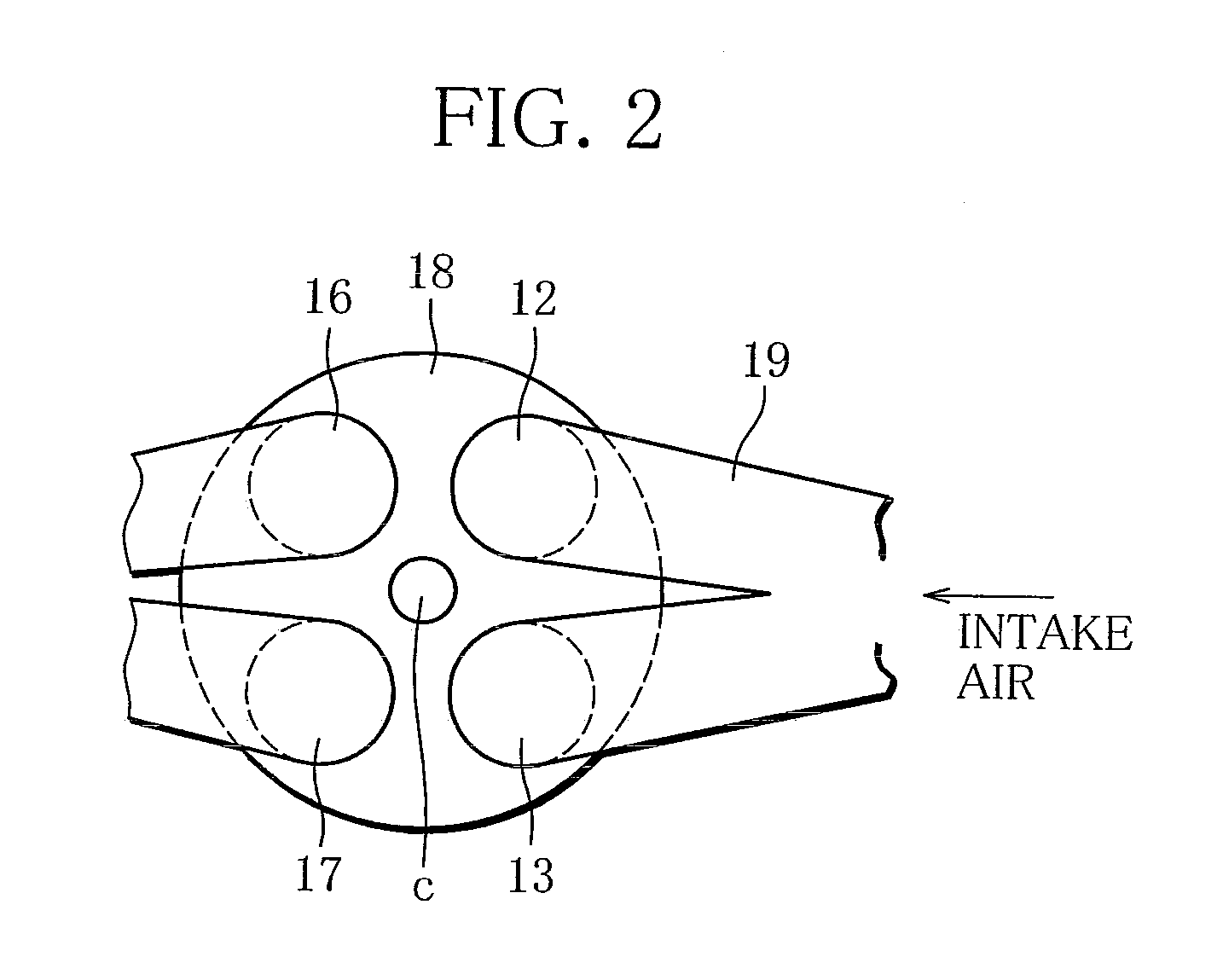

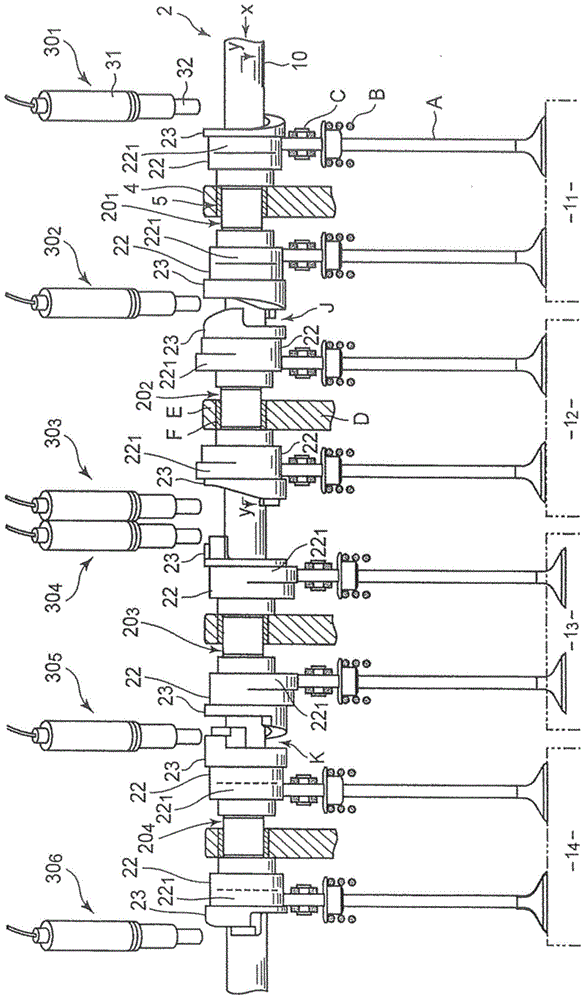

InactiveUS20090277407A1Level of torqueDeterioration of driveability can be suppressedElectrical controlInternal combustion piston enginesMotor driveInlet valve

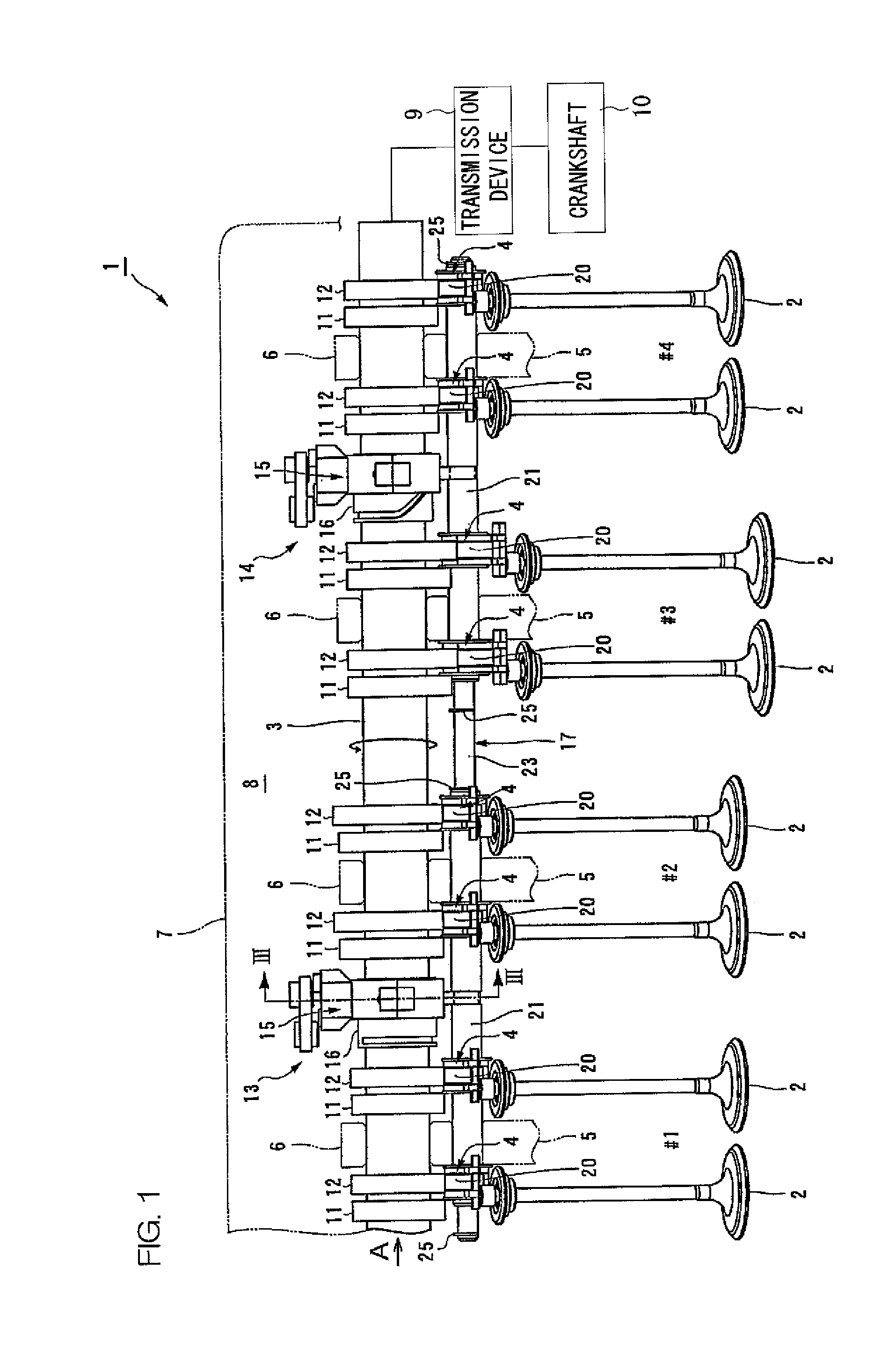

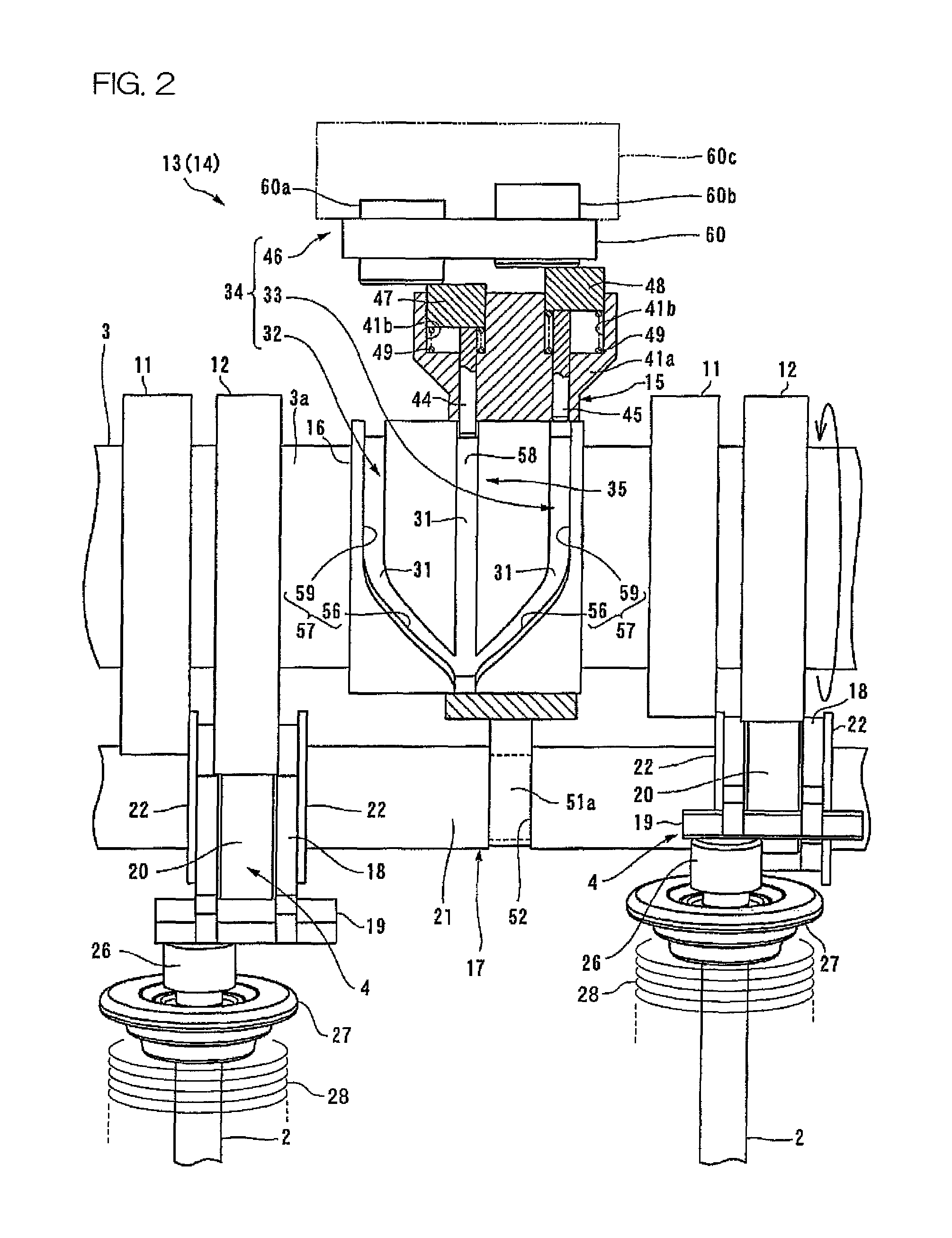

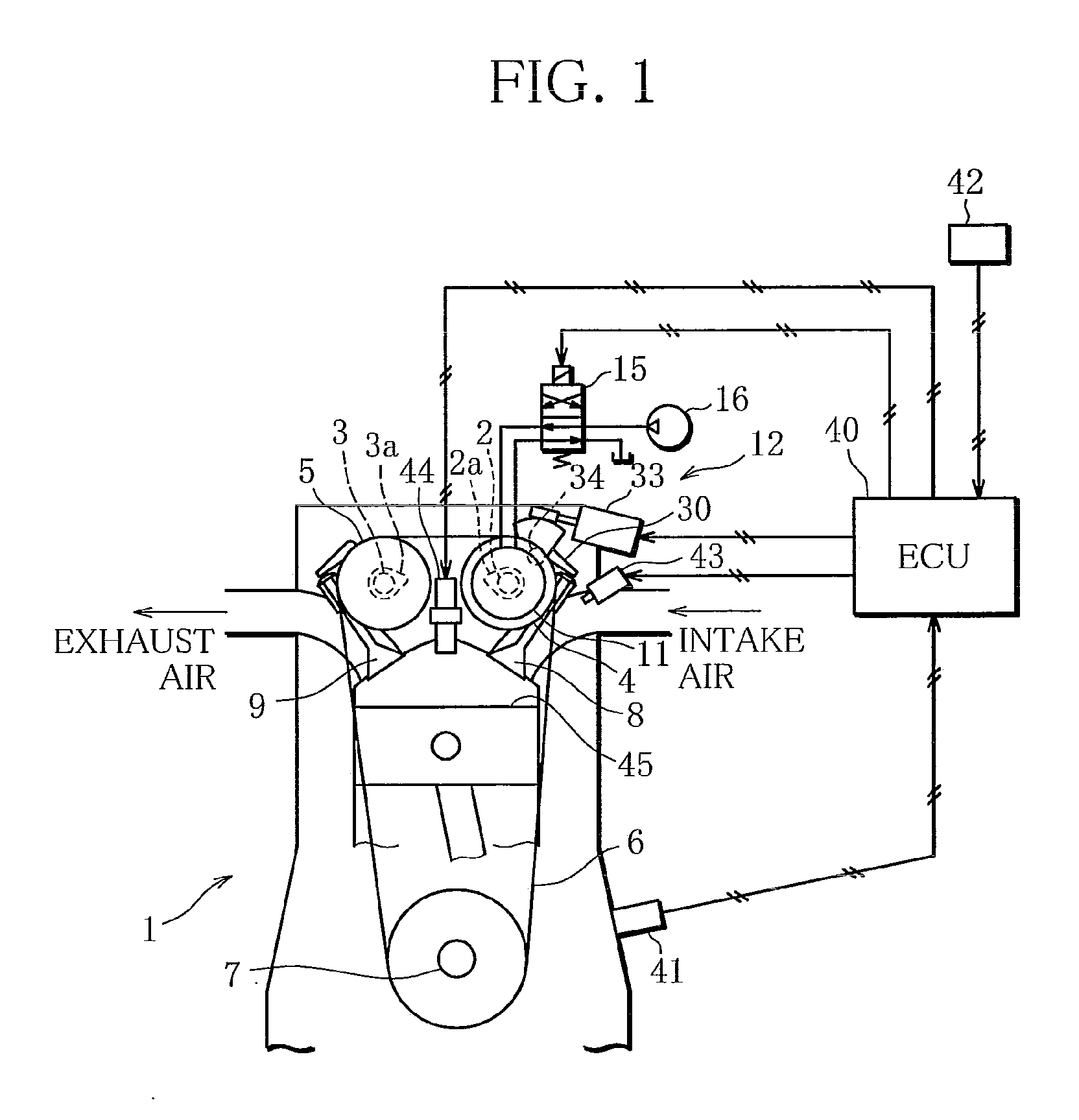

A valve train for an internal combustion engine that uses motors to open / close intake valves of cylinders. The motors drive the intake valves for each of a plurality of groups of cylinders that perform an explosion stroke at substantially equal crank angle intervals. Since the intake valves are driven for each of the plurality of groups of cylinders that perform an explosion stroke at substantially equal crank angle intervals, the explosion stroke is performed regularly even when an operation is conducted with only a particular group of cylinders. This makes it possible to inhibit driveability deterioration.

Owner:TOYOTA JIDOSHA KK

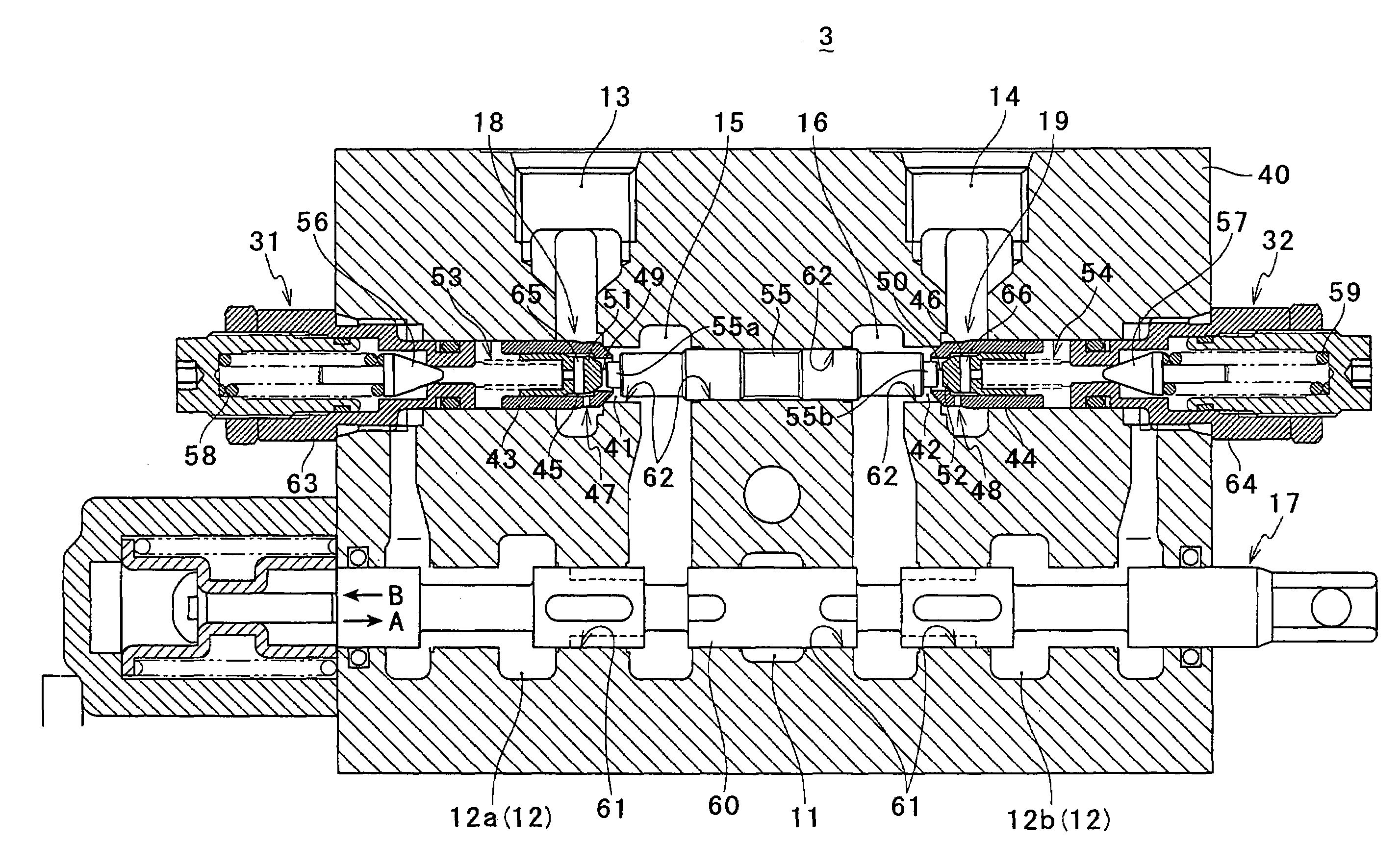

Valve gear of internal combustion engine

A valve operating system for an internal combustion engine including a main valve lifter, a subsidiary valve lifter, a low-speed cam operating the main valve lifter, a high-speed cam operating the subsidiary valve lifter, a connecting device switched over between a non-connecting state in which the valve lifters are disconnected from each other, and a connecting state in which the valve lifters are connected to each other, a valve spring for biasing the valve in a closing direction, a lifter spring for biasing the subsidiary valve lifter toward the cam; thus, in a low-speed mode, that is non-connected states, an influence of a load of the lifter spring on the valve can be prevented, and in a high-speed mode, that is connected states, a sum total of loads of the valve spring and the lifter spring cap be applied to both of the valve lifters to improve the closing responsiveness of the valve.

Owner:HONDA MOTOR CO LTD

Internal combustion engine with variable valve gear

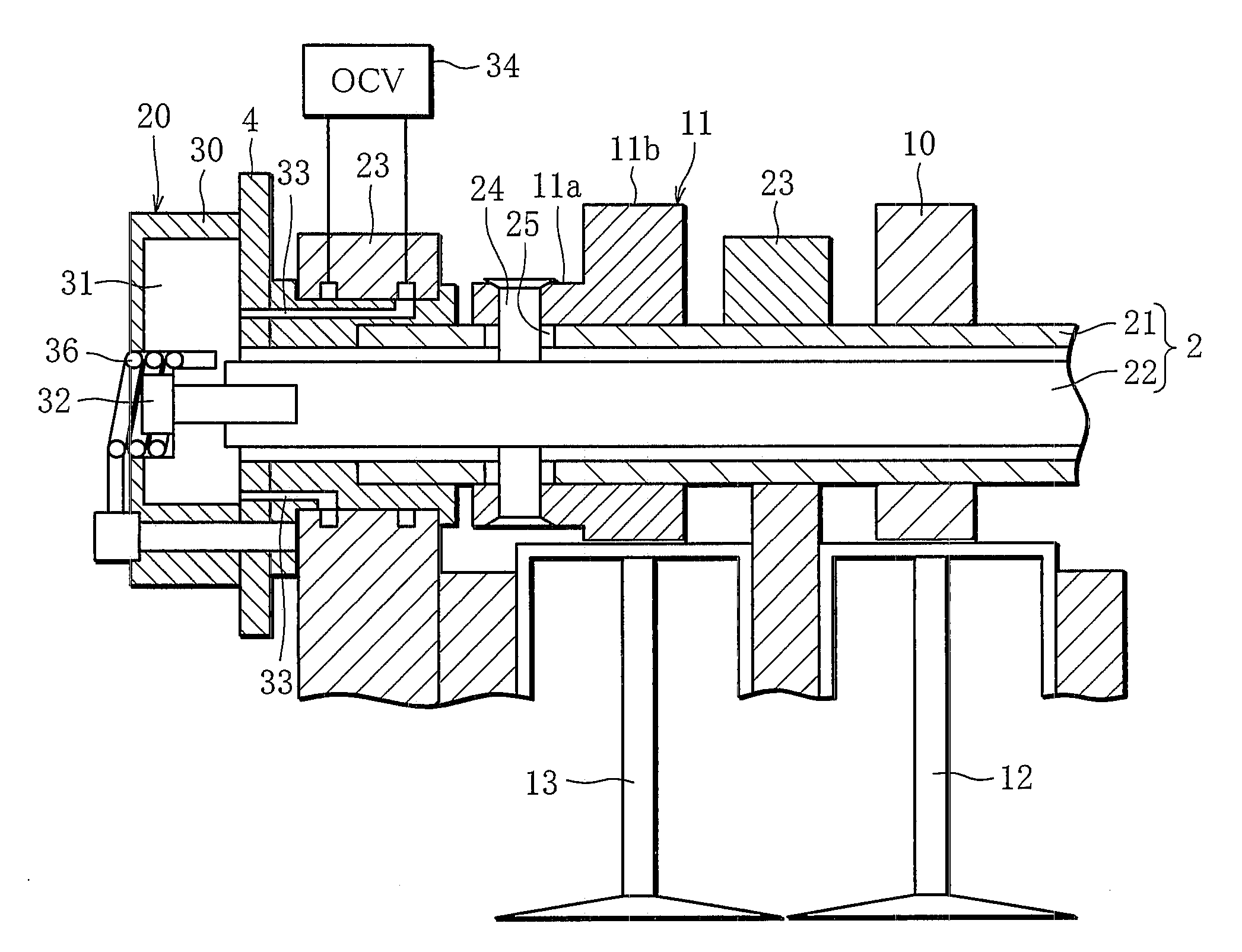

ActiveUS8205587B2Easy to controlValve arrangementsYielding couplingExternal combustion engineInlet valve

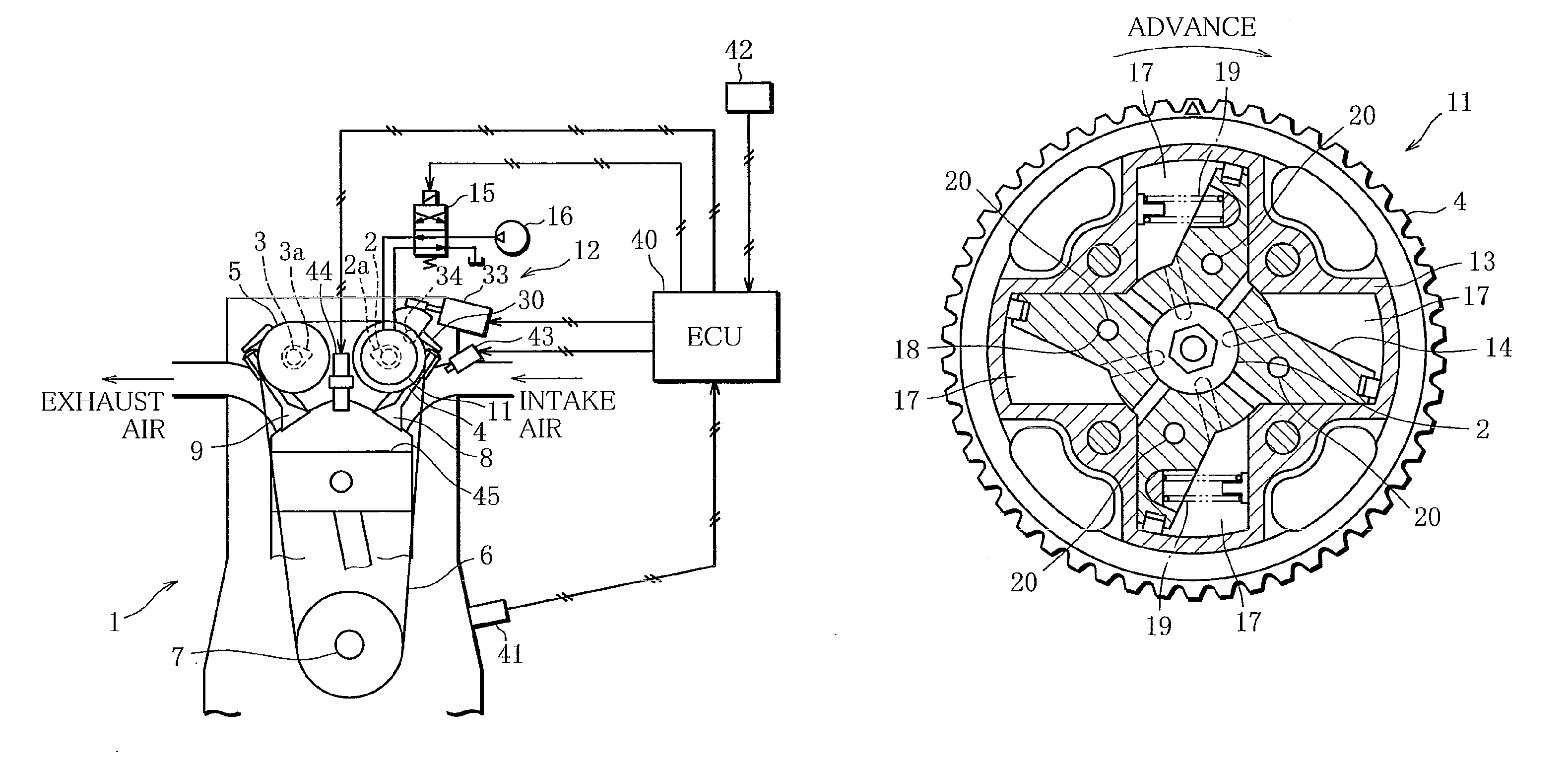

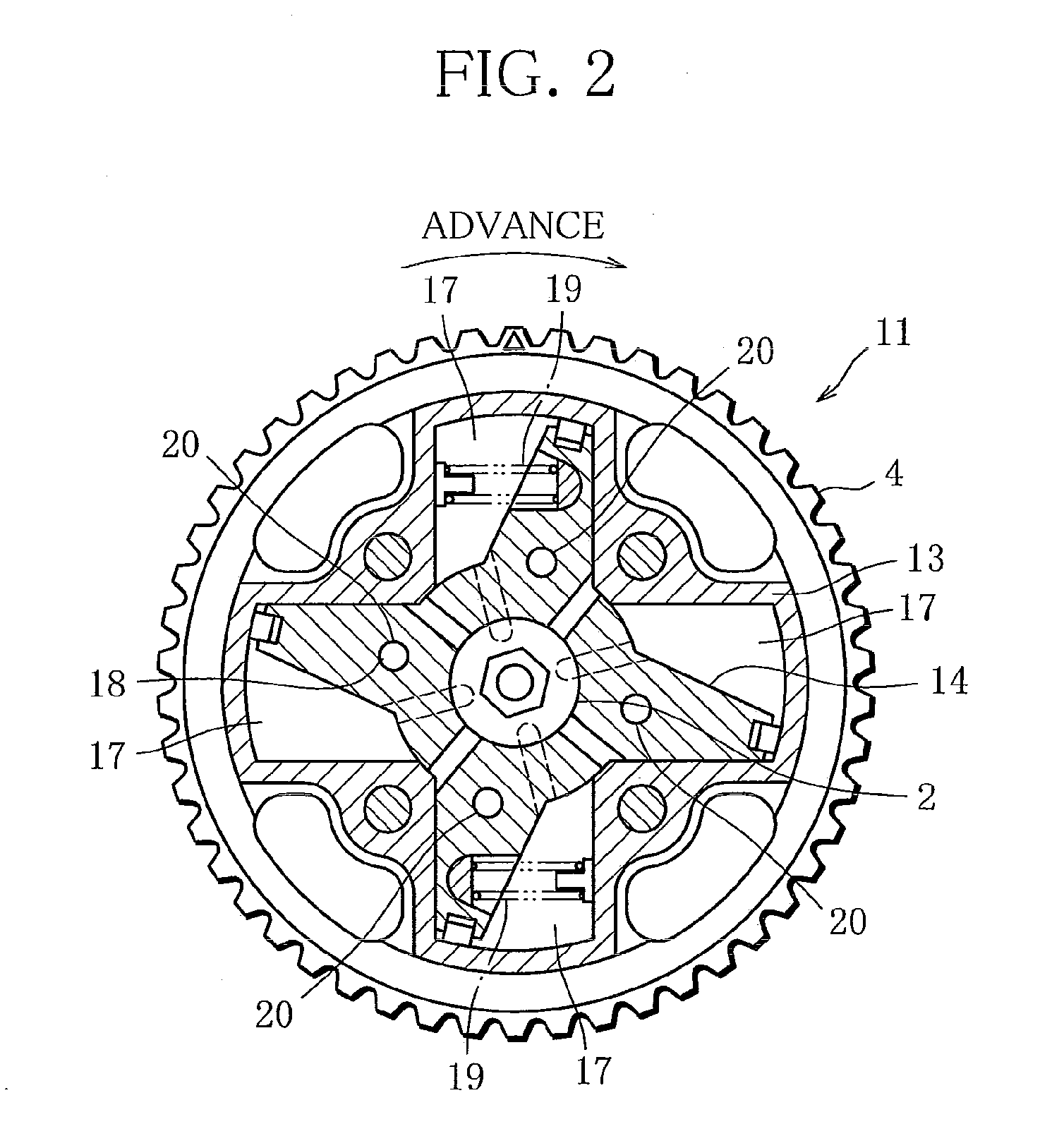

In an engine with a cam phase change mechanism which is disposed on one end portion of an intake camshaft and variably changes a phase of a drive cam of an intake valve relative to a crankshaft, the cam phase change mechanism is configured so that two vane-type hydraulic actuators of which variable-phase torques produced at the same supplied oil pressure are different are arranged axially relative to the intake camshaft.

Owner:MITSUBISHI MOTORS CORP

Internal combustion engine with variable valve gear

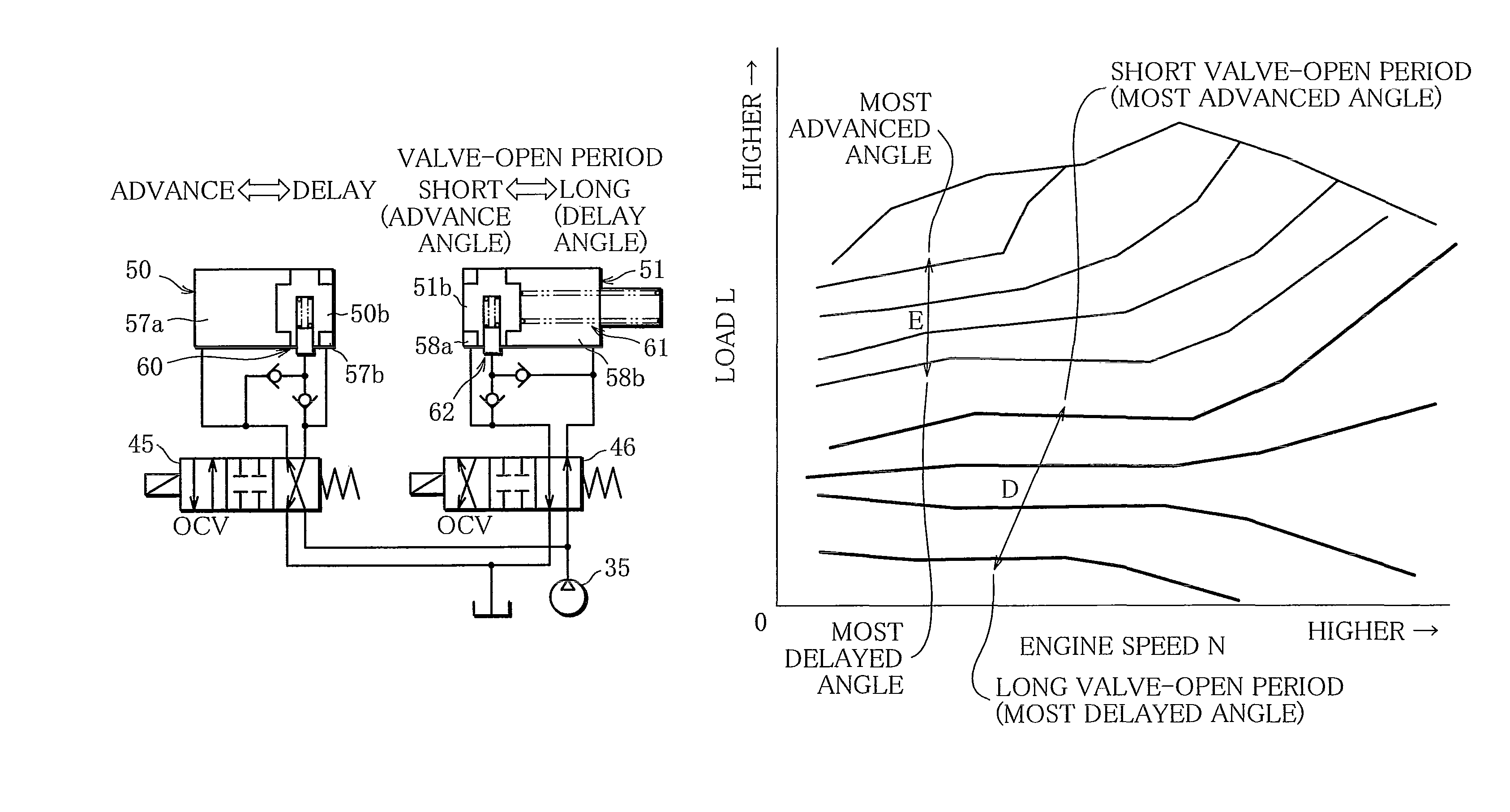

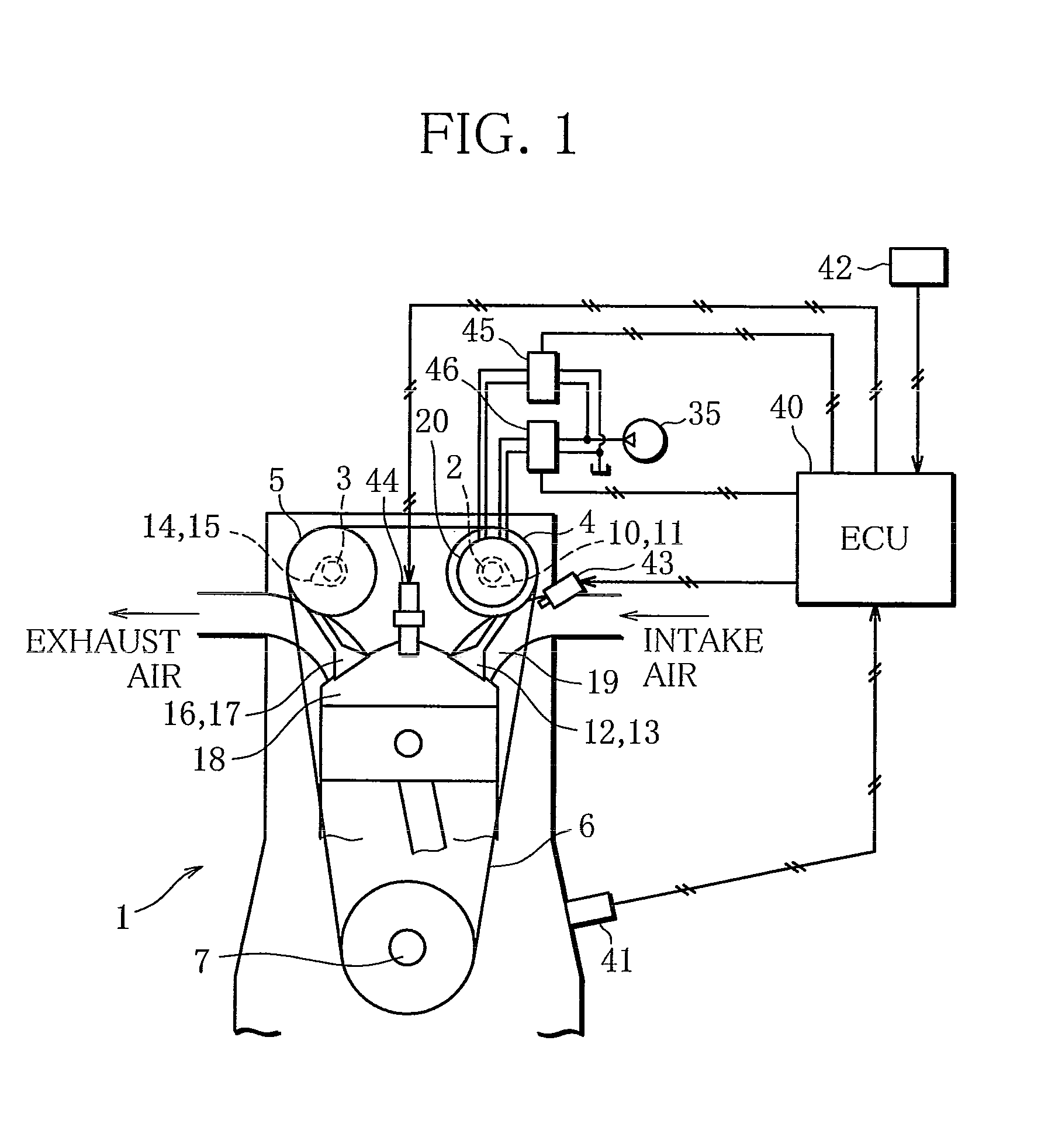

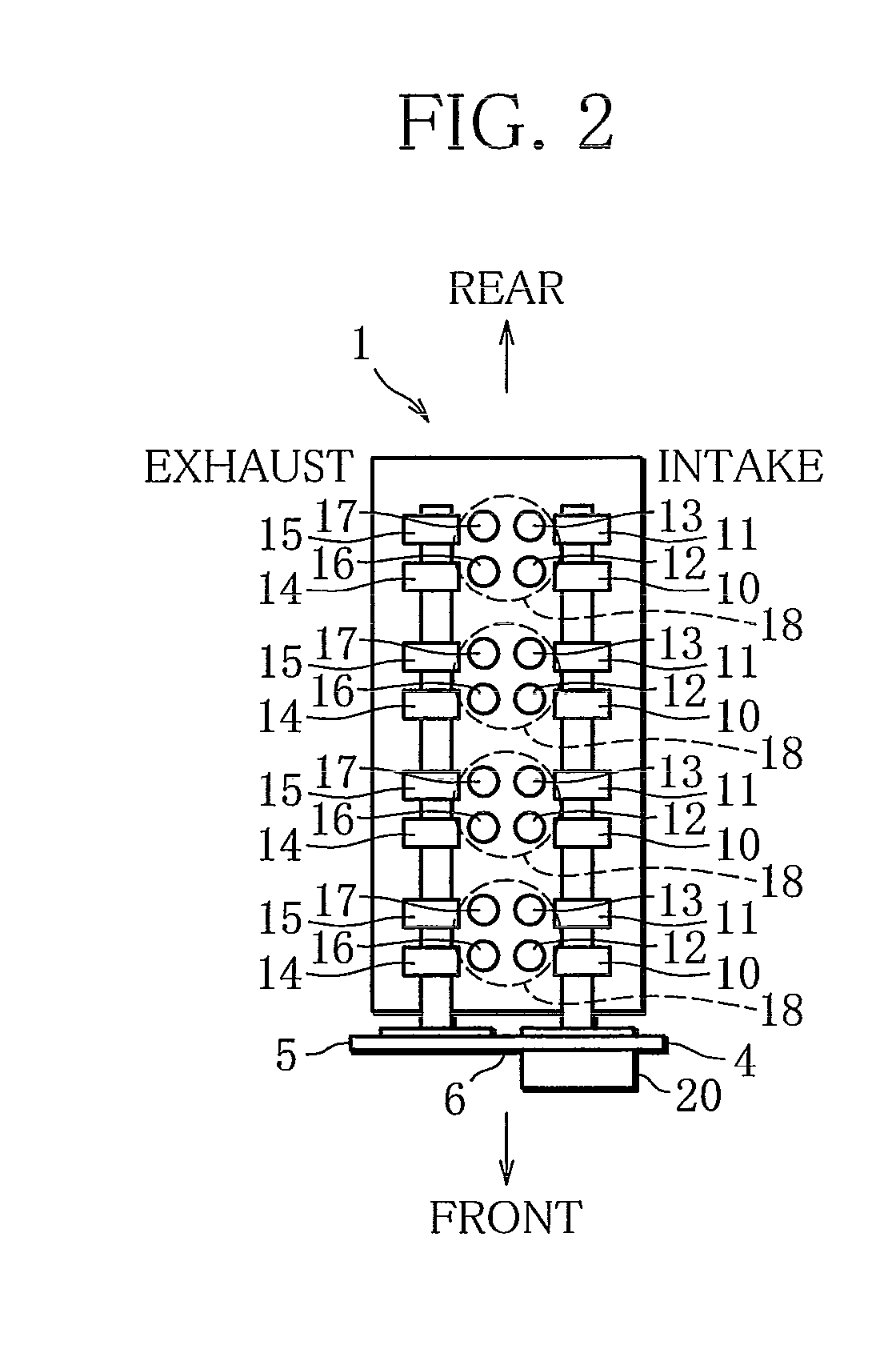

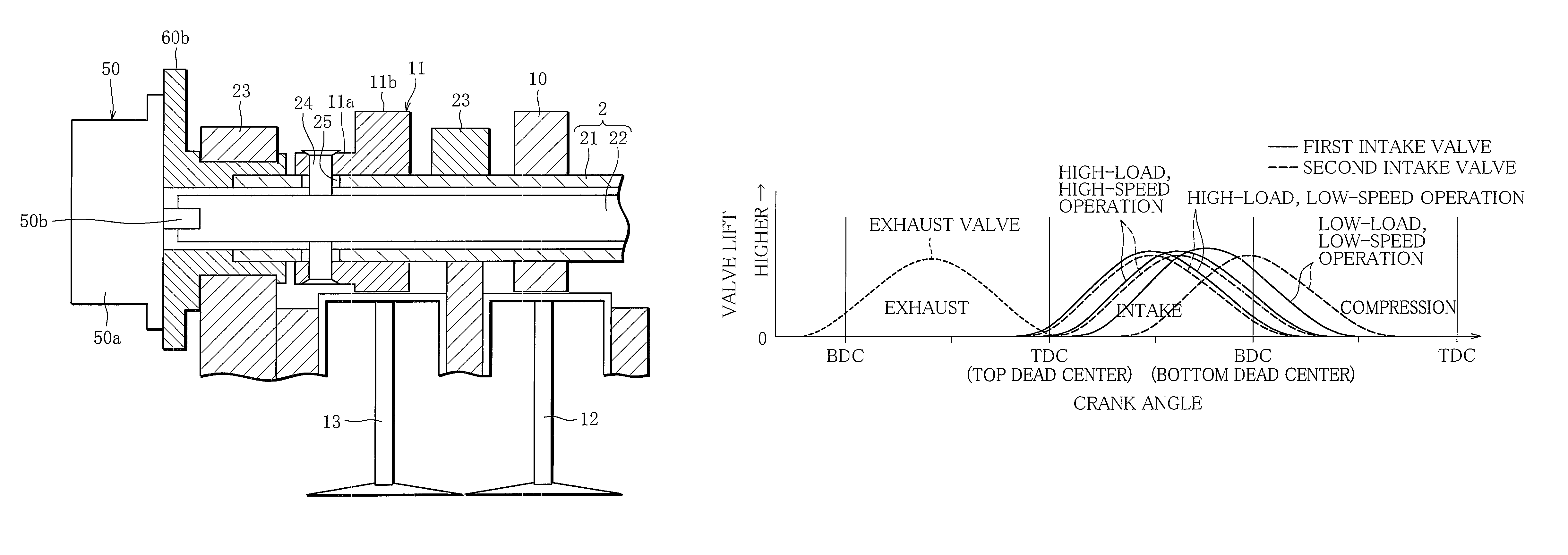

ActiveUS8235015B2Extended maintenance periodMitigating pumping lossValve arrangementsYielding couplingGear wheelInlet valve

Each cylinder is provided with a first intake valve and a second intake valve, and a first intake cam for driving the first intake valve and a second intake cam for driving the second intake valve are coaxially pivotally supported on an intake camshaft. A first cam phase change mechanism which varies respective phases of the first and second intake cams relative to a crankshaft of the internal combustion engine is combined with a second cam phase change mechanism which varies a phase of the second intake cam relative to the first intake cam. The second cam phase change mechanism is set to have a variable-phase angular range wider than that of the first cam phase change mechanism.

Owner:MITSUBISHI MOTORS CORP

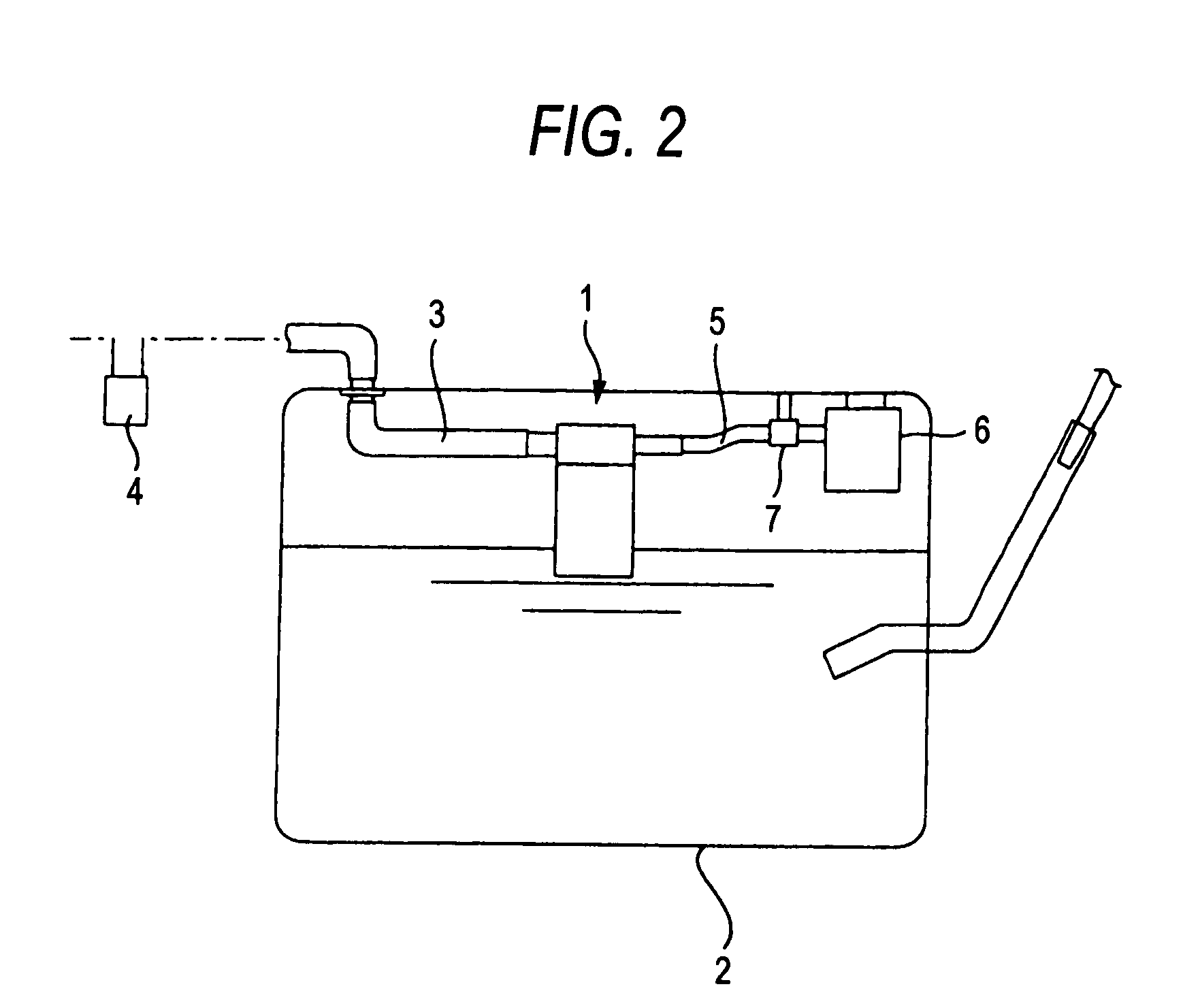

Liquid shutoff valve gear

InactiveUS7770594B2Firmly preventing liquid from flowing outEasy to shapeLarge containersVenting valvesExhaust valveClosed chamber

A liquid exhaust valve gear includes a housing divided into an upper chamber and a lower chamber by being partitioned by a partition plate having an opening portion, and a float slidably contained at inside of the lower chamber and moved up by receiving liquid inside of the hermetically sealed vessel. An upper end portion of the float is provided with valve means for closing the opening portion of the partition plate in accordance with moving up the float, further, a partition wall in a cylindrical shape is provided to extend in an upper direction from a peripheral edge of the opening portion at inside of the upper chamber, the partition wall is opposed to an opening of an exhaust port, and a notched portion which is not opposed to the opening of the exhaust port.

Owner:PIOLAX CO LTD

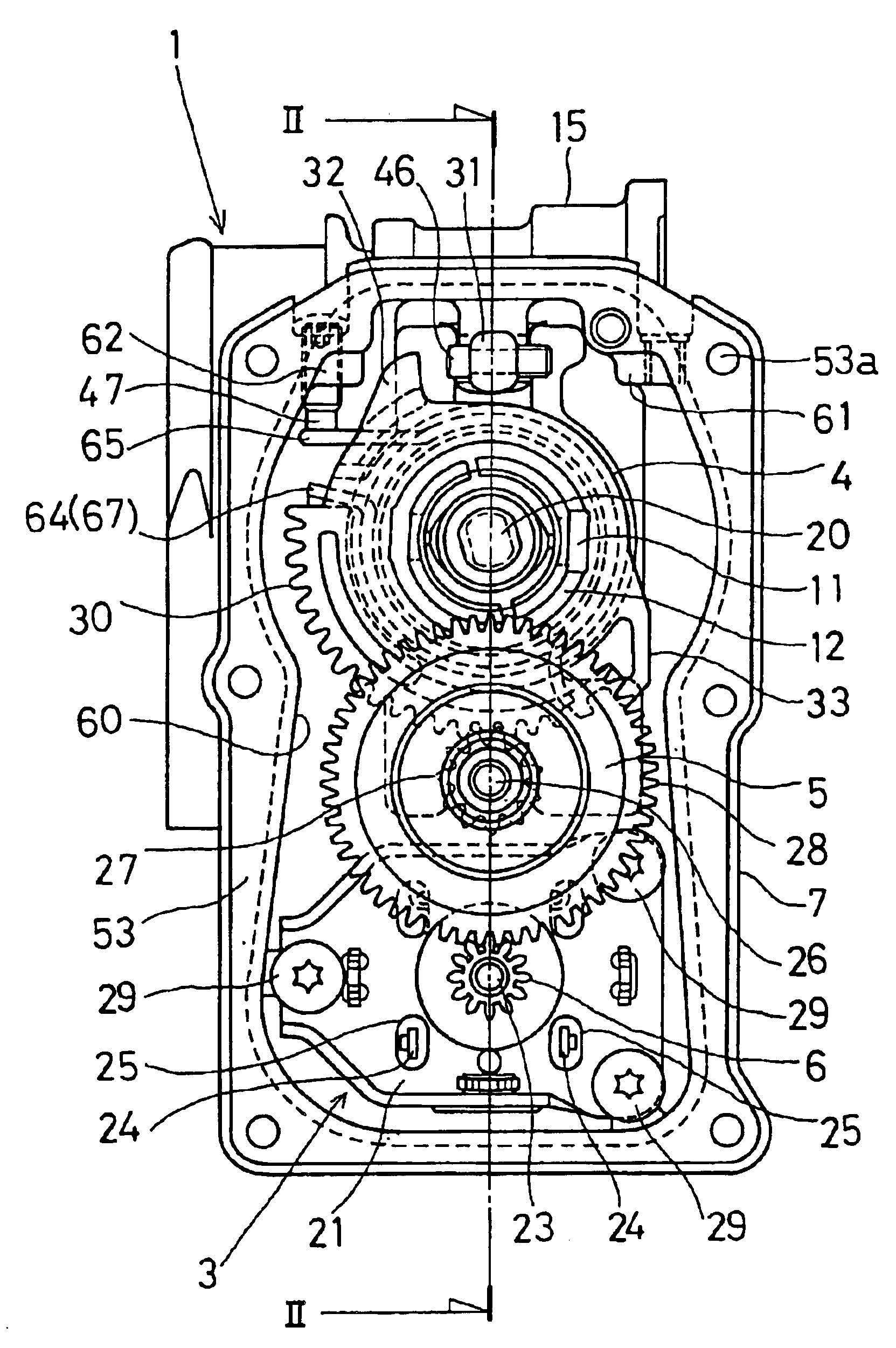

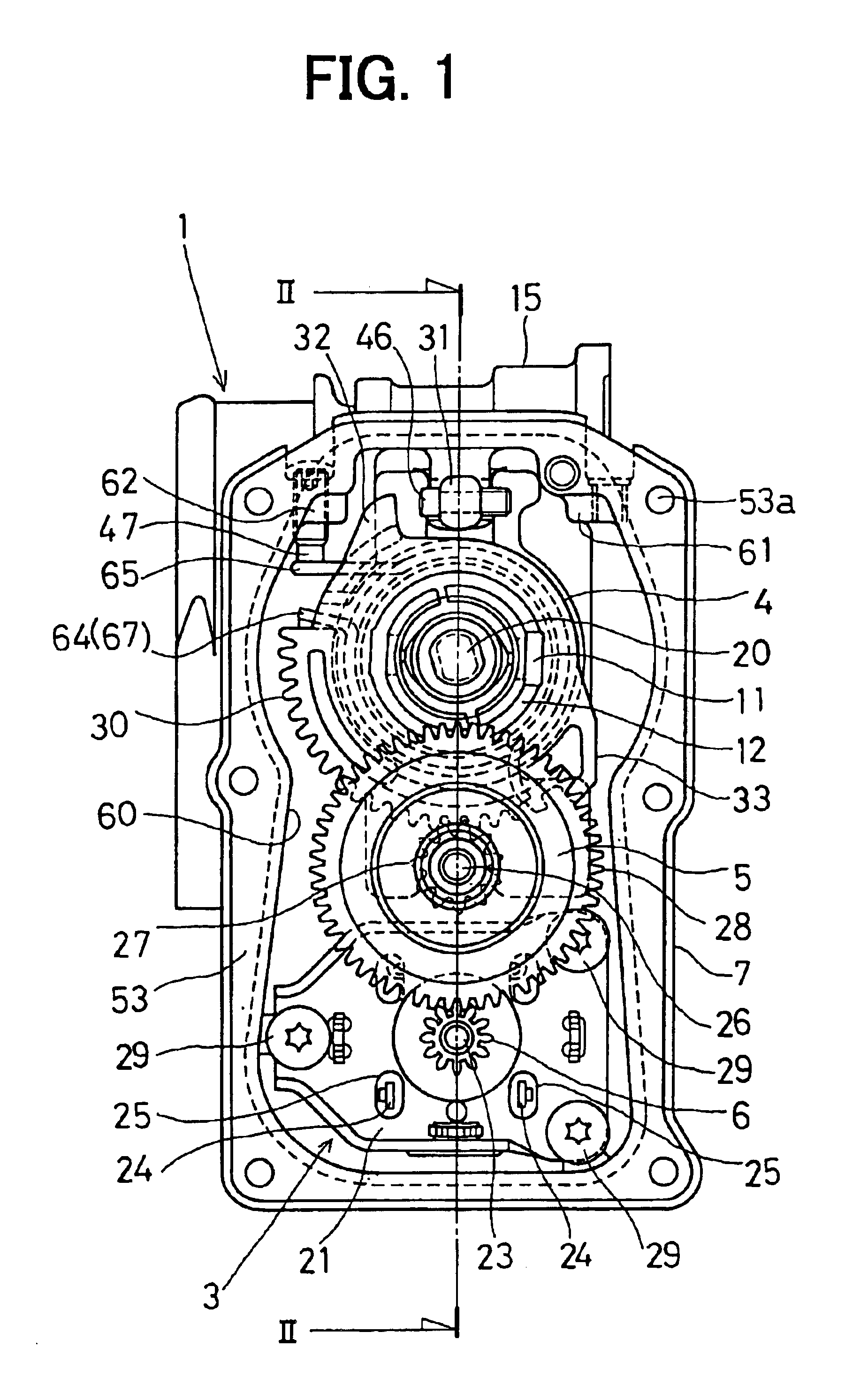

Electronically controlled throttle control apparatus

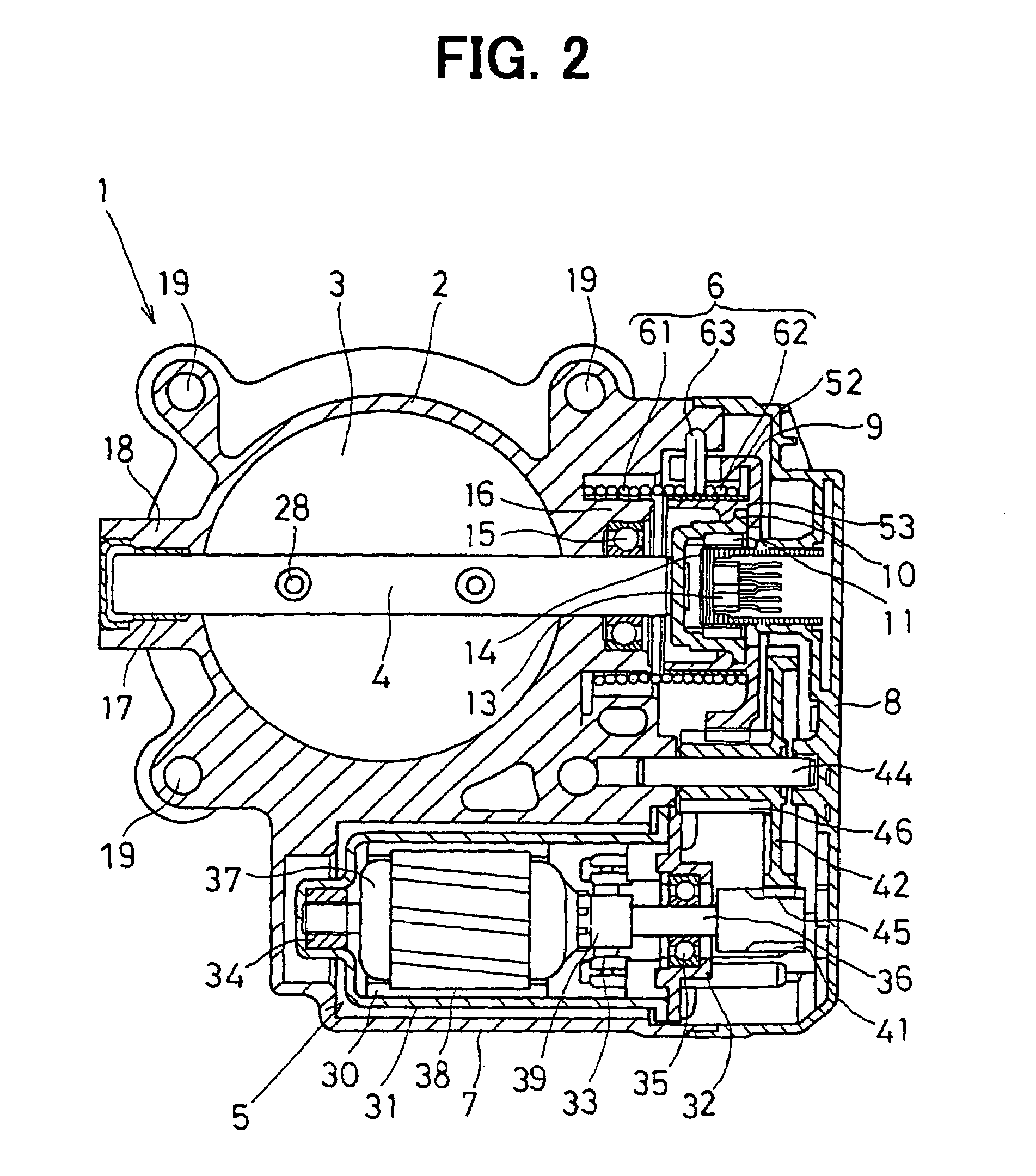

ActiveUS6912994B2Reduce in quantityLow costOperating means/releasing devices for valvesEngine controllersCar modelThrottle control

In a gear case of a throttle body, a valve gear is fixed to one end of a throttle shaft, an intermediate reduction gear is rotatable around an intermediate shaft, a pinion gear is fixed to a motor shaft of a drive motor, and a full close position stopper is provided for defining the full close position of a throttle valve. Those are provided all in alignment with the longitudinal centerline of the gear case. For car models where the throttle body bore inside diameter is identical but the rotation direction of the drive motor differs, only some components in the gear case need be replaced and the other components in the gear case can be used as common components.

Owner:DENSO CORP

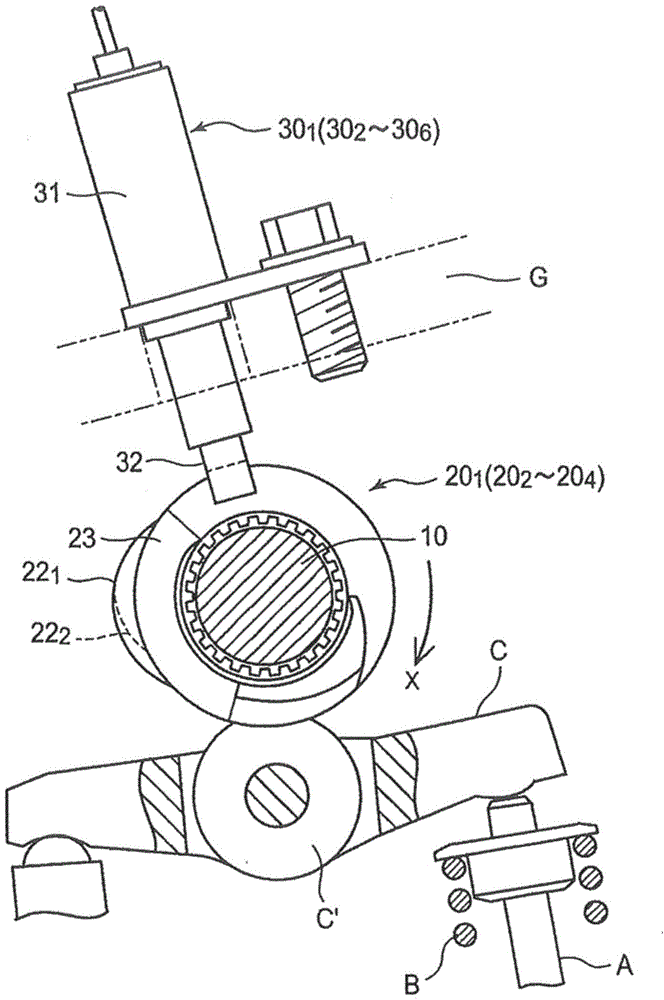

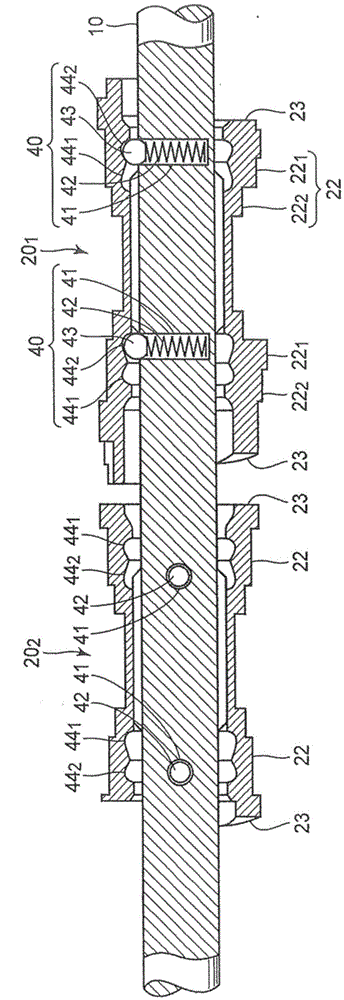

Variable valve gear for an internal combustion engine

InactiveUS20090241877A1Simple structureRestrict movementValve drivesMachines/enginesDrive shaftEngineering

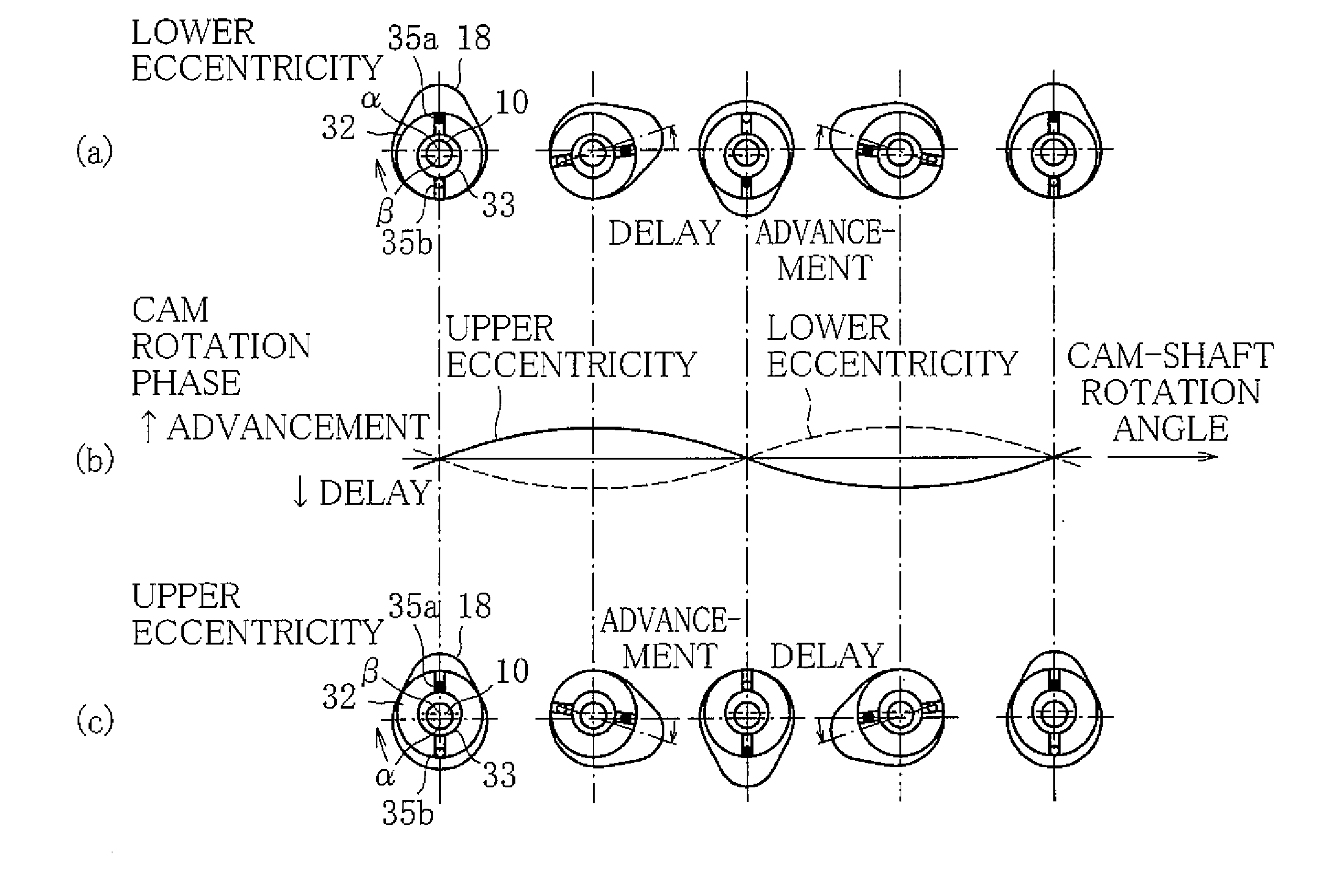

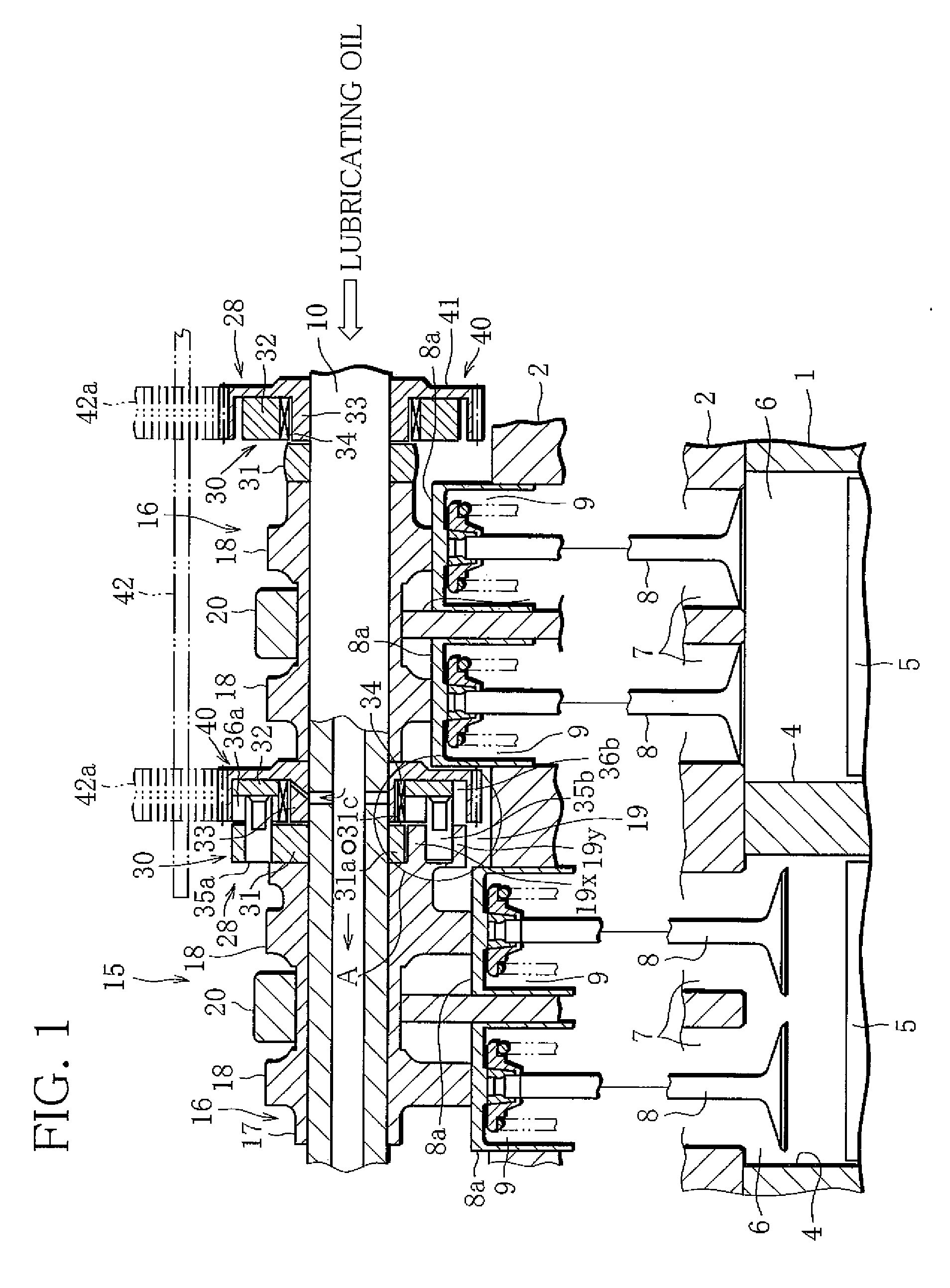

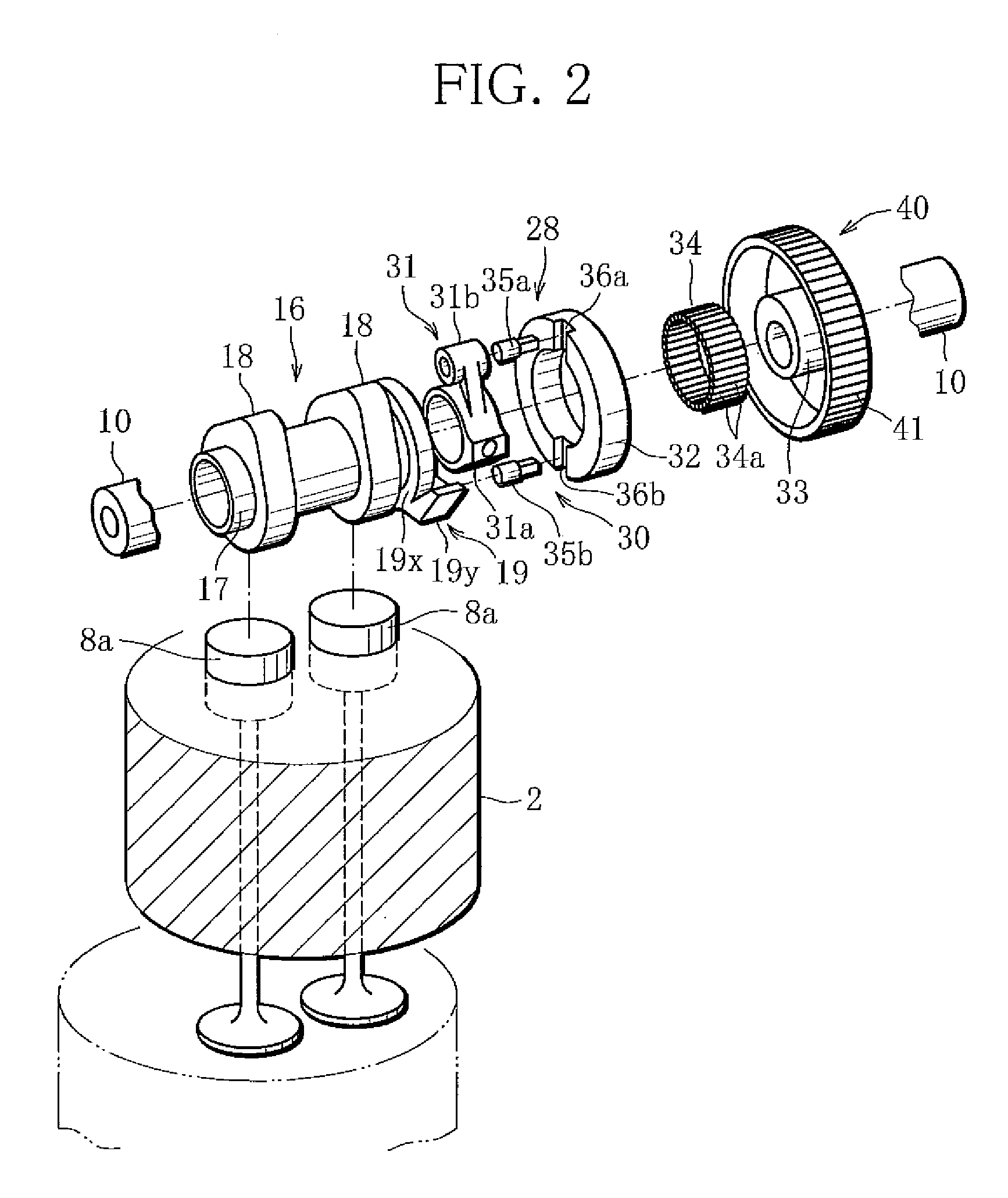

The variable valve gear for an internal combustion engine includes a cam lobe that is rotatably supported by a cam drive shaft, and a variable valve mechanism that includes a drive arm fixed adjacent to one end of the cam lobe in the cam drive shaft, an eccentric shaft member that is swivelably supported at a position opposite to the cam lobe with respect to the drive arm in the cam drive shaft, has an outer circumferential surface eccentric to an axis of the cam drive shaft, and is adjustable in eccentricity, and an intermediate rotary member that is rotatably supported through a bearing member around the eccentric shaft member, and is connected to the drive arm, wherein the drive arm includes an end face that overlaps with an end face of the bearing member, when projecting along the axis of the cam drive shaft, and the end face of the drive arm is protruding further than the end face of the cam lobe toward the bearing member.

Owner:MITSUBISHI MOTORS CORP

Valve gear of engine

InactiveUS8714125B2Reduce power lossLow production costControlling membersValve arrangementsExhaust valveCylinder head

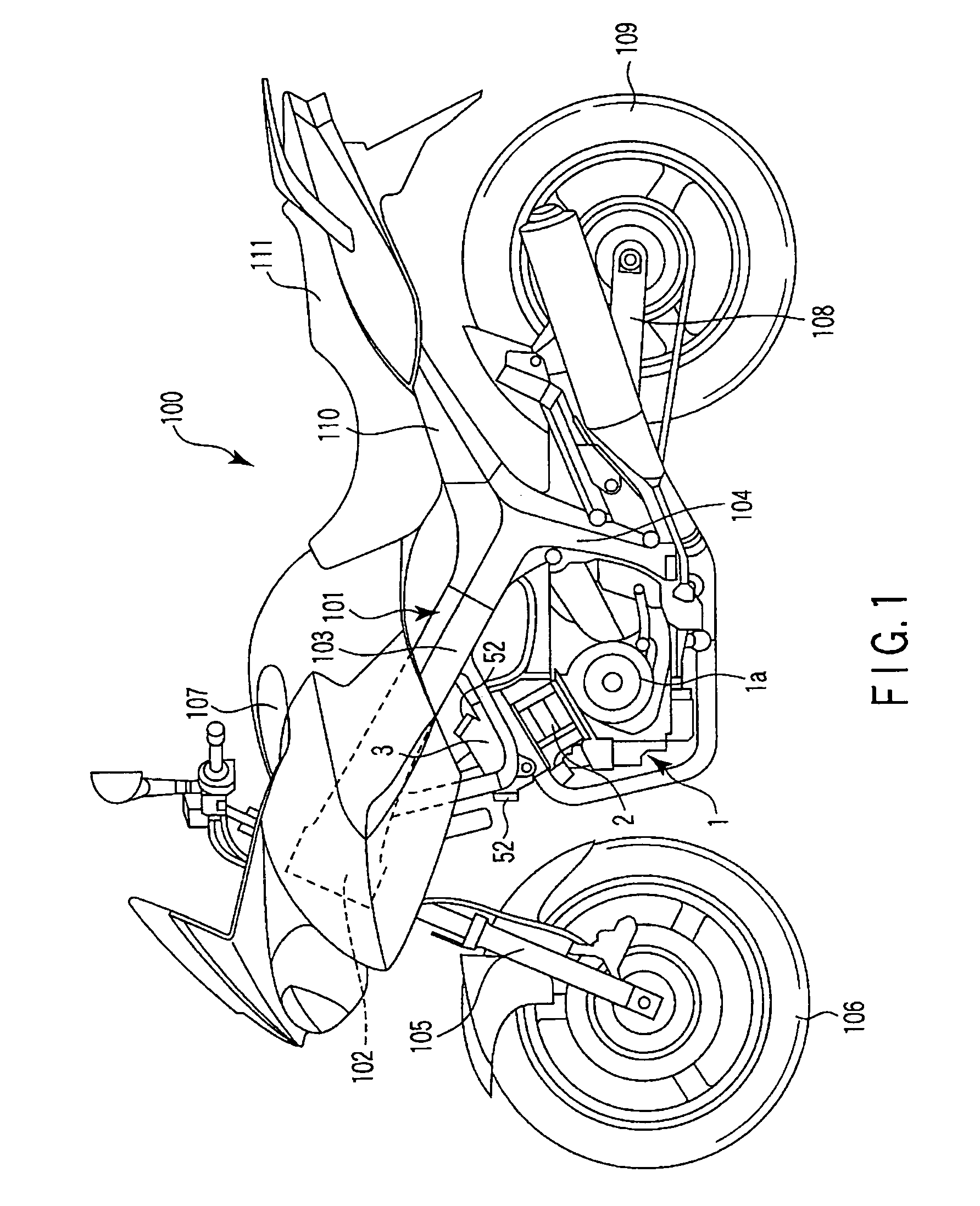

A valve drive system of an engine includes a camshaft that is supported by a cylinder head of the engine and on which a plurality of cams having different valve lift characteristics are arranged at predetermined intervals, a rocker shaft that is supported by the cylinder head so as to be parallel or substantially parallel to the camshaft, and a rocker arm that is swingably supported by the rocker shaft. The rocker arm is arranged between one of the cams and an intake valve or an exhaust valve and is arranged so as to be movable in an axial direction of the rocker shaft. A presser of the rocker arm that presses the intake valve or the exhaust valve extends in the axial direction and has a length greater than an interval between the cams. The valve drive system includes a drive unit that moves the rocker arm toward one side or toward an opposite side in the axial direction by the interval between the cams.

Owner:YAMAHA MOTOR CO LTD

Valve operating mechanism with roller rocker arm, 4-cycle engine, and motorcycle having 4-cycle engine mounted thereon

ActiveUS7204219B2Reduce loadPreventing buckling loadLubrication of auxillariesCam-followersGear wheelEngineering

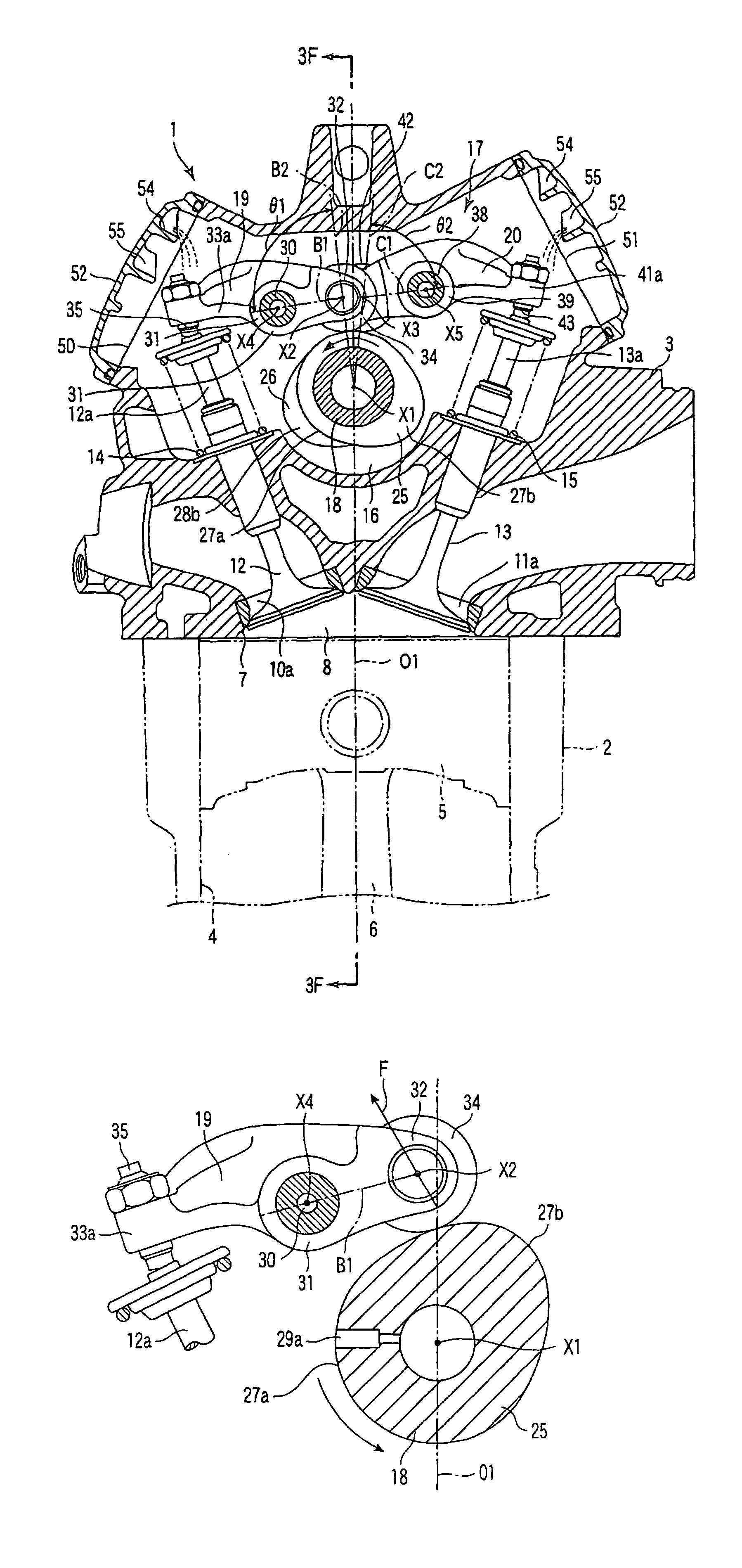

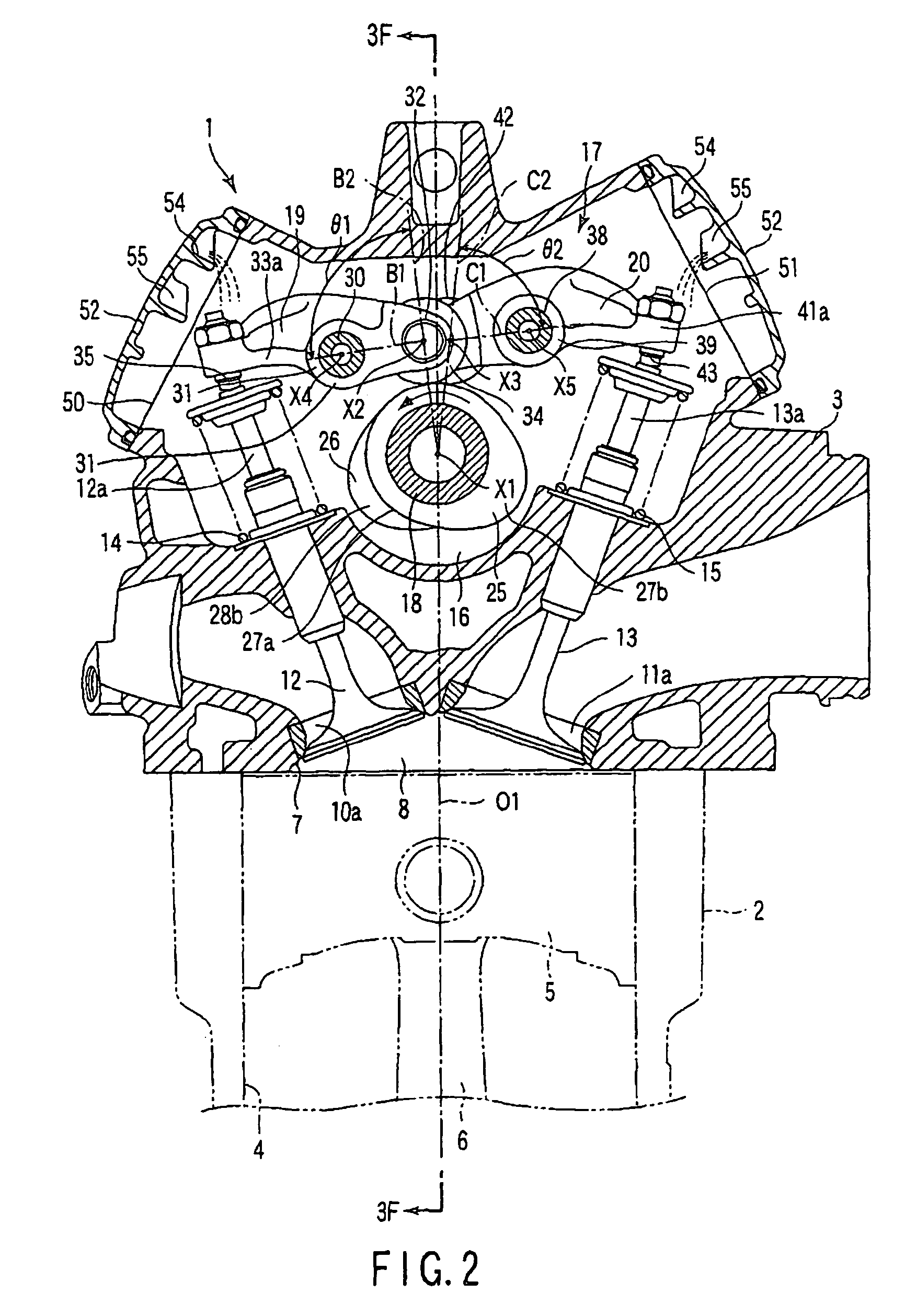

A valve gear includes a camshaft having valve gear cams, first and second rocker shafts, a first rocker arm supported on the first rocker shaft, and a second rocker arm supported on the second rocker shaft: The valve gear cams, respectively, include a cam nose projecting from a base circle, and the first rocker shaft supporting the first rocker arm is positioned forwardly of a center line, which passes through a center of the camshaft to extend axially of a cylinder, in a direction of rotation of the camshaft:. The first rocker shaft is shifted closer to the camshaft than a center of rotation of a roller bearing is, when the roller bearing won the first rocker arm contacts with the base circle of the valve gear cam.

Owner:YAMAHA MOTOR CO LTD

Electric parking brake for a vehicle

ActiveCN105015530AEasy accessSimple structureBraking action transmissionPump/compressor arrangementsElectric parking brakeElectrical control

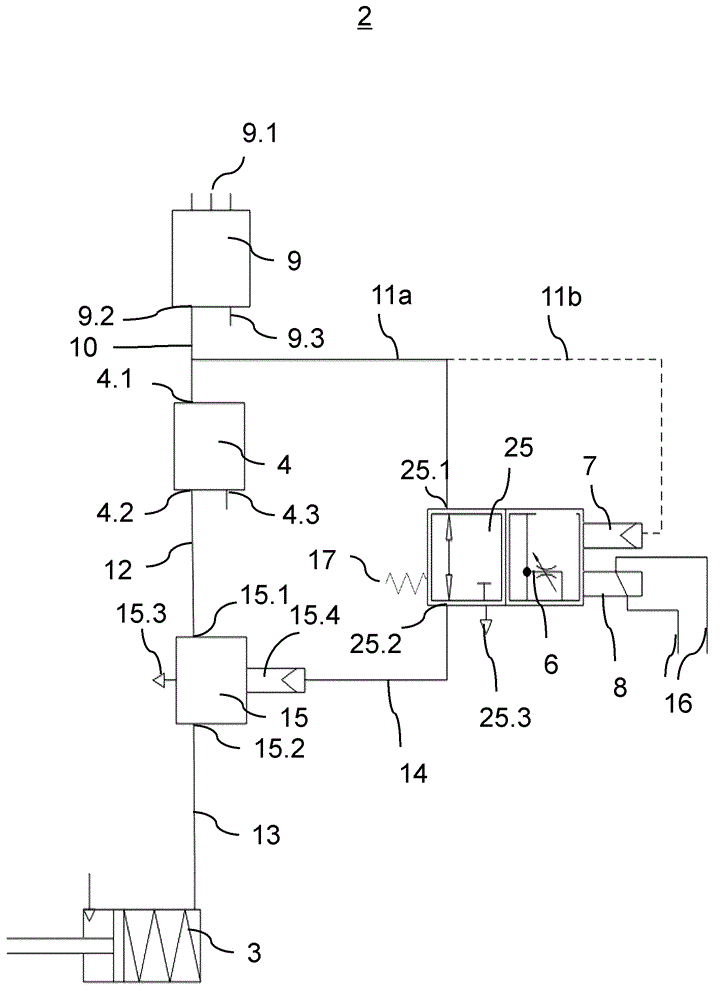

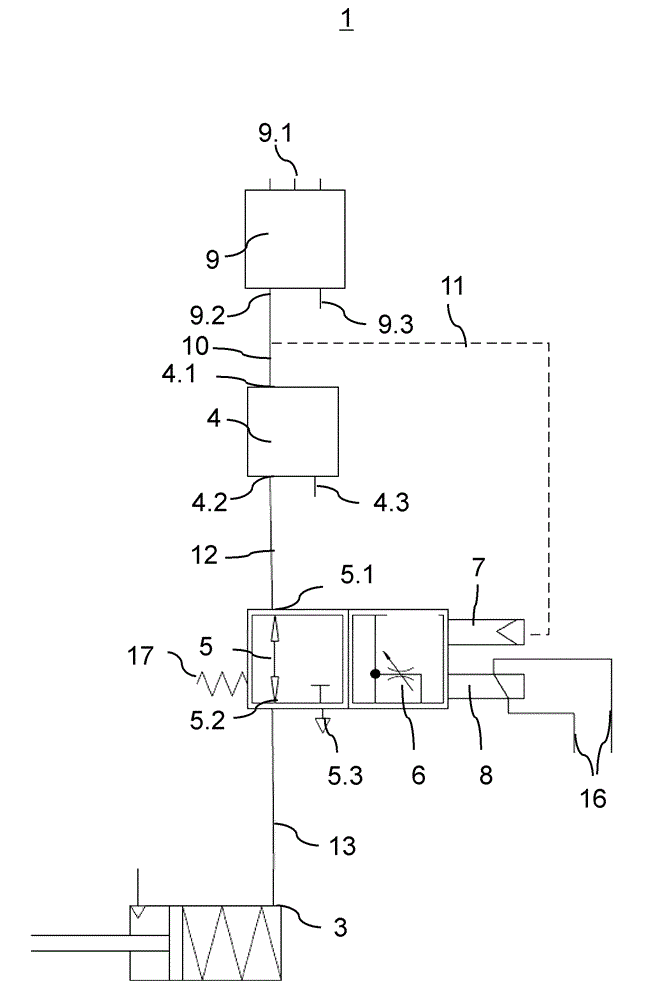

The invention relates to a parking brake for a vehicle, preferably for a commercial vehicle, including at least a spring energy-storage brake cylinder (3), an electrical controlling first valve gear (4), which is designed according to an electrical control signal, a venting and / or ventilation of the at least one spring energy-storage brake cylinder (3). The parking brake also includes a switchable second valve gear (5), a pneumatic control input (7) and an electric control input (8), which is executed, a venting of the at least one spring energy-storage brake cylinder (3) to take when the pneumatic control input (7), a pneumatic pressure above the predetermined threshold is smaller than one, and if the electric control input (8) no electricity is available.

Owner:MAN TRUCK & BUS AG

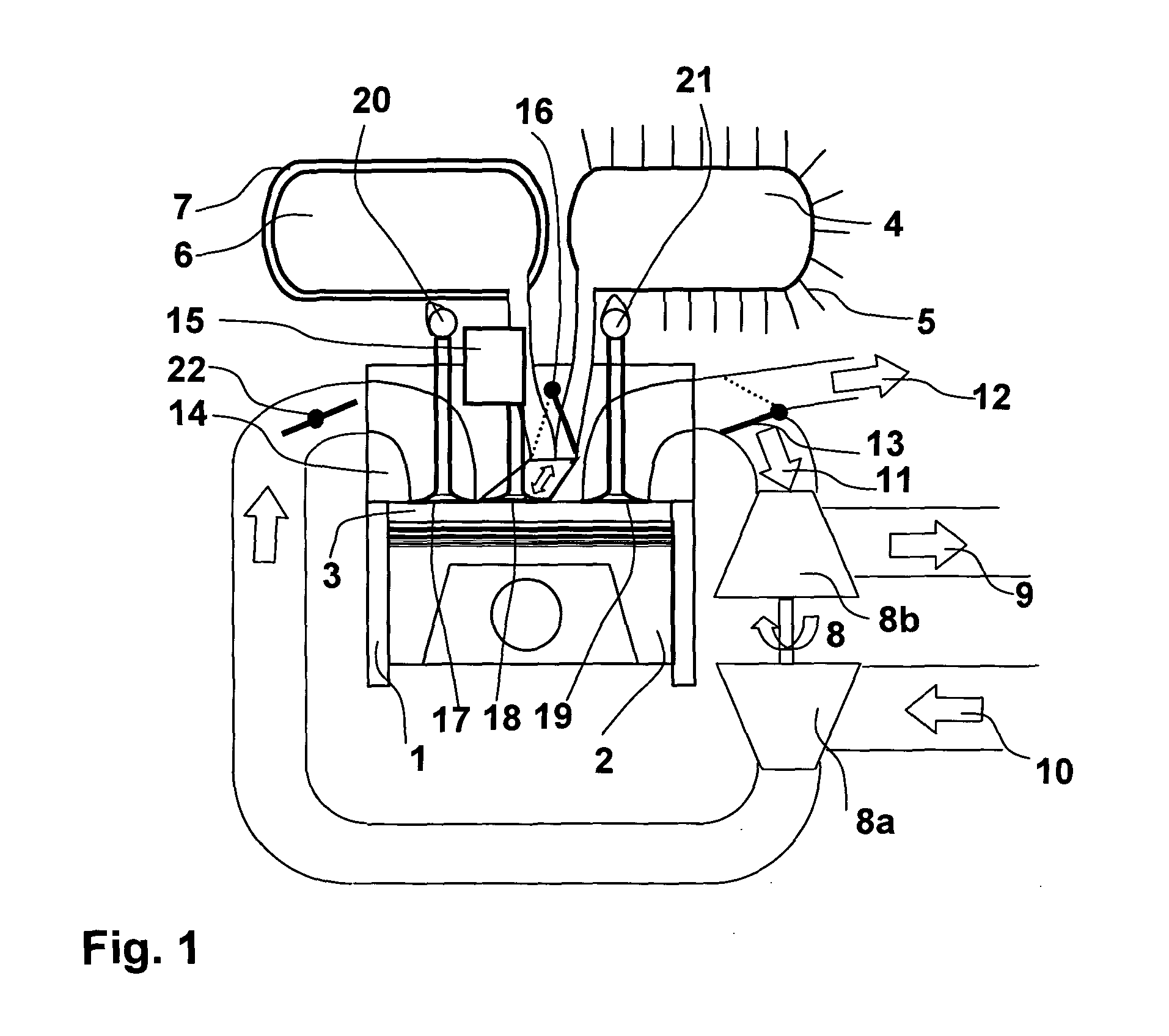

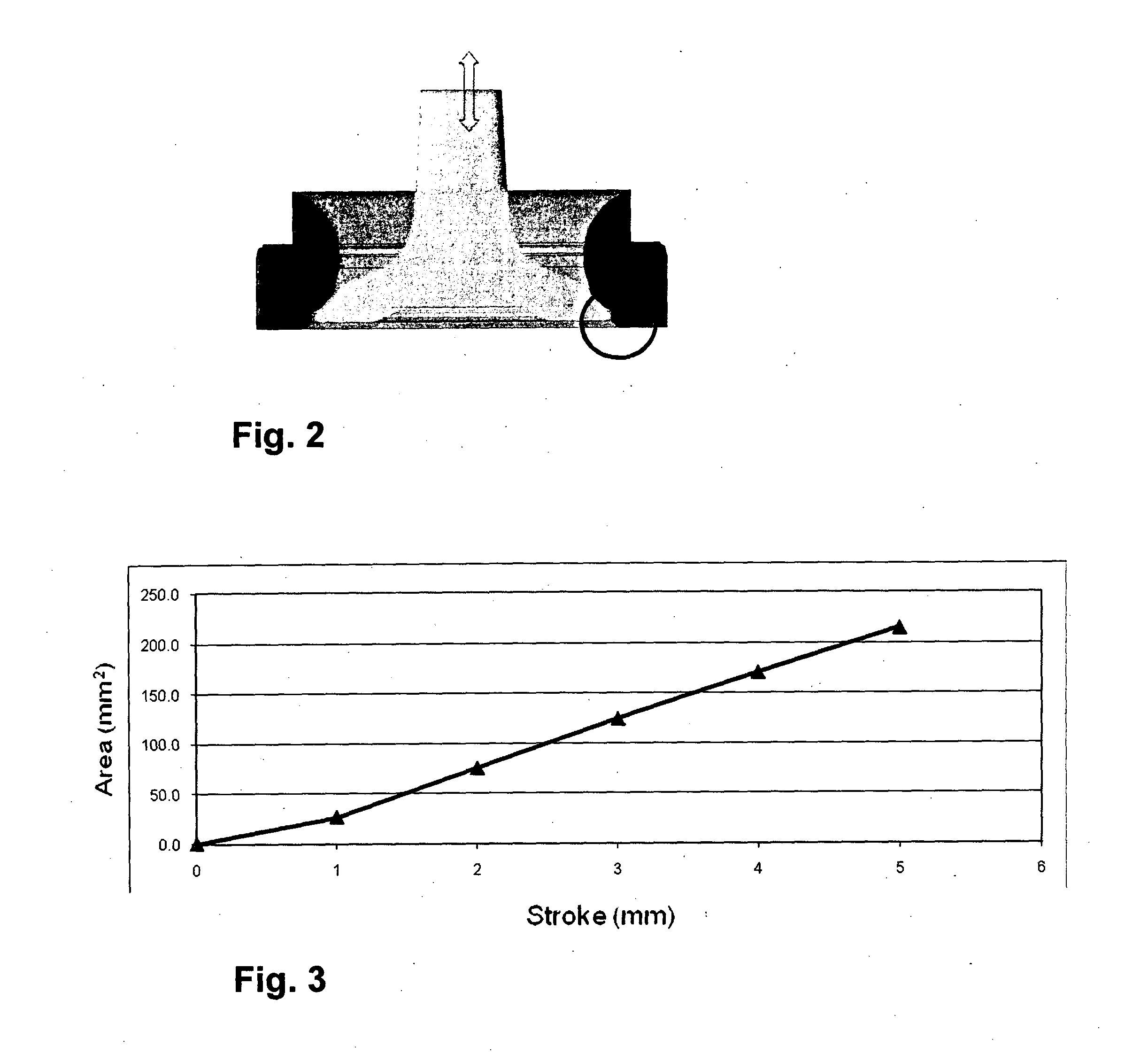

Pneumatic hybrid internal combustion engine on the basis of fixed camshafts

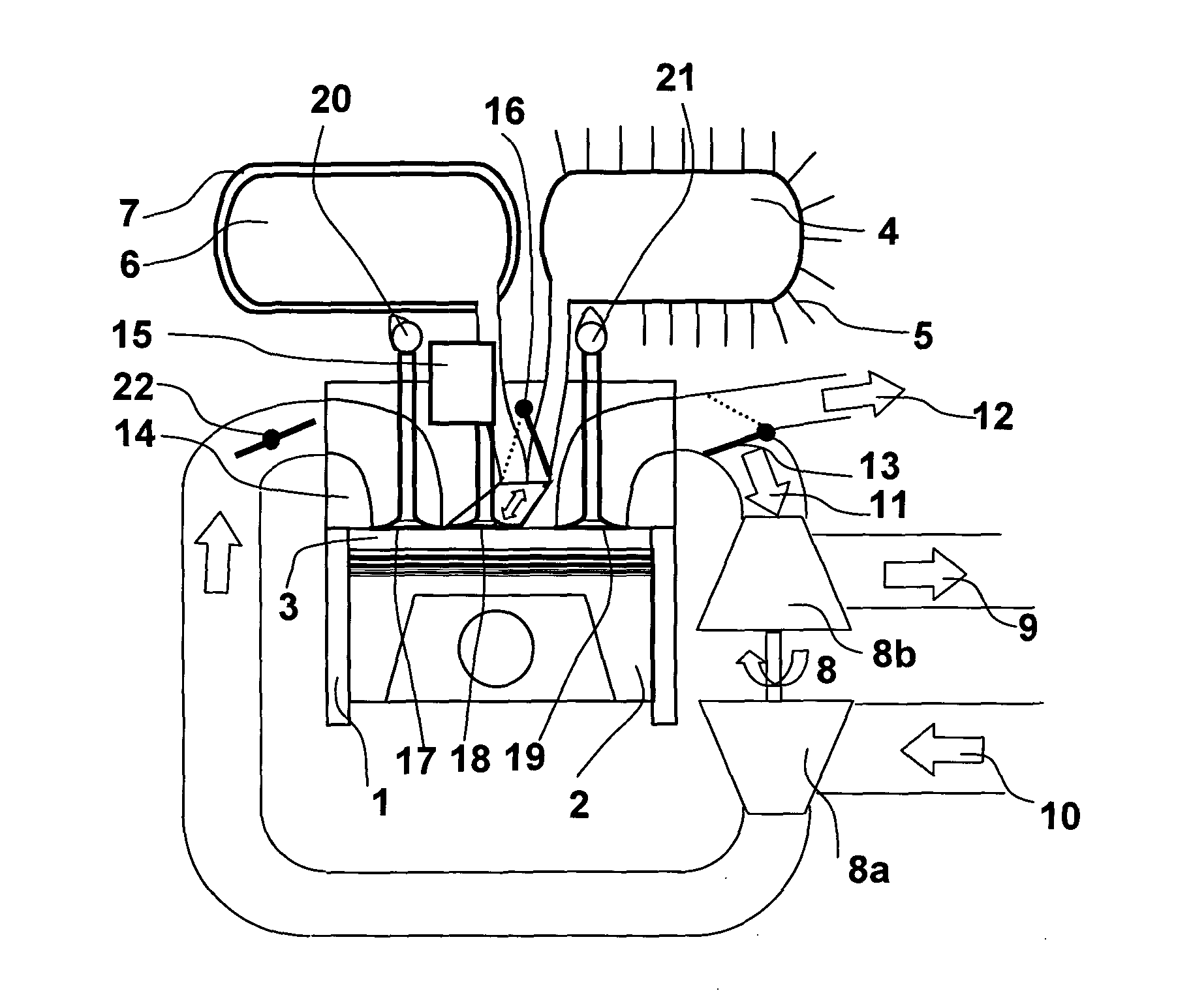

ActiveUS20110023820A1Simple and yet efficient setupImprove efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveCombustion chamber

The present disclosure relates to an pneumatic hybrid internal combustion engine with at least one combustion chamber composed of a cylinder in which a piston is arranged mechanically interconnected to a crank shaft via a piston rod. An inlet valve and an exhaust valve are both mechanically interconnected via a valve gear to the crank shaft. The engine further includes at least one charge valve which is actuated by a charge valve actuator in a fully variable manner such that the engine can be operated in a four stroke hybrid mode.

Owner:ETH ZZURICH

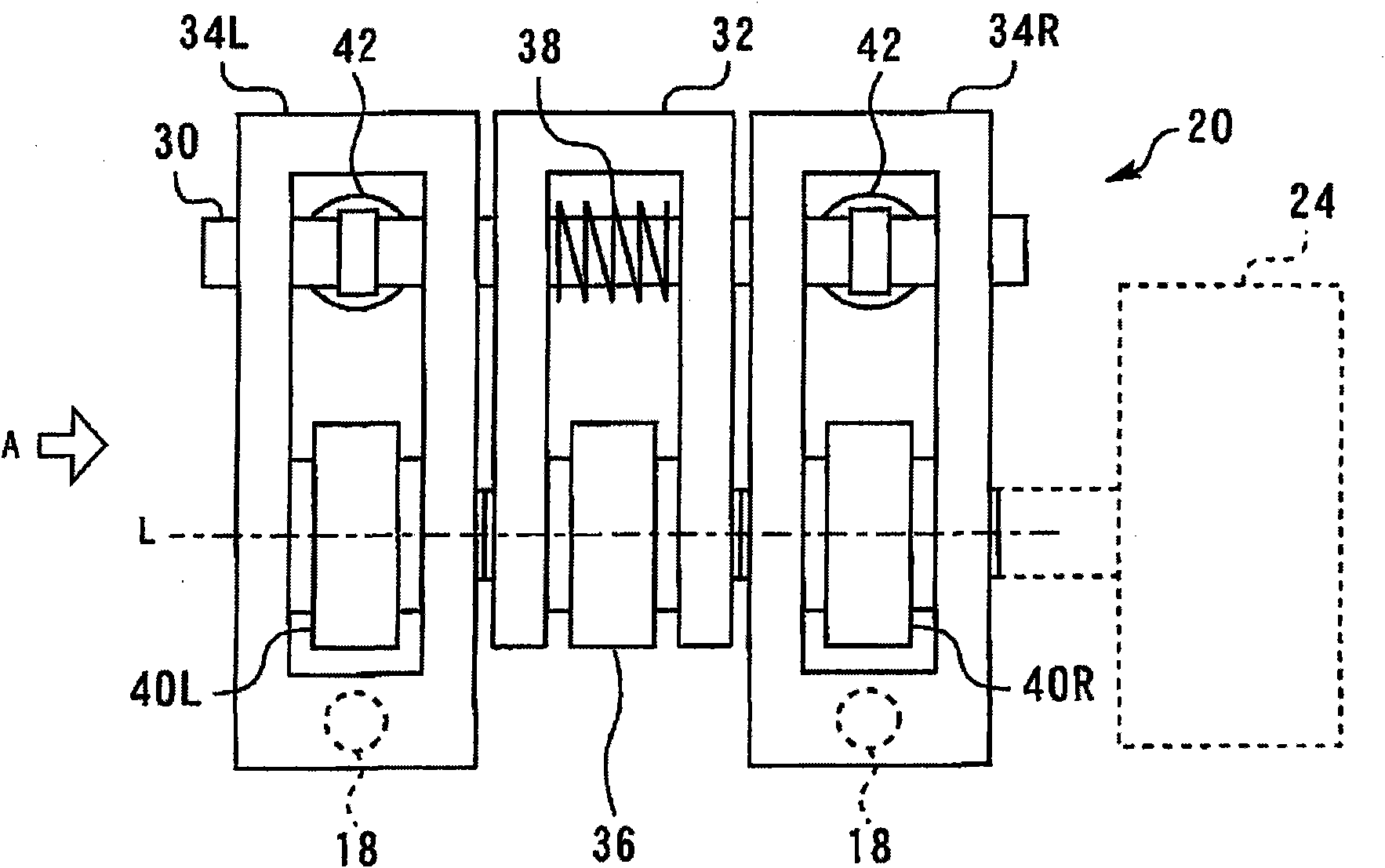

Valve gear for internal combustion engine

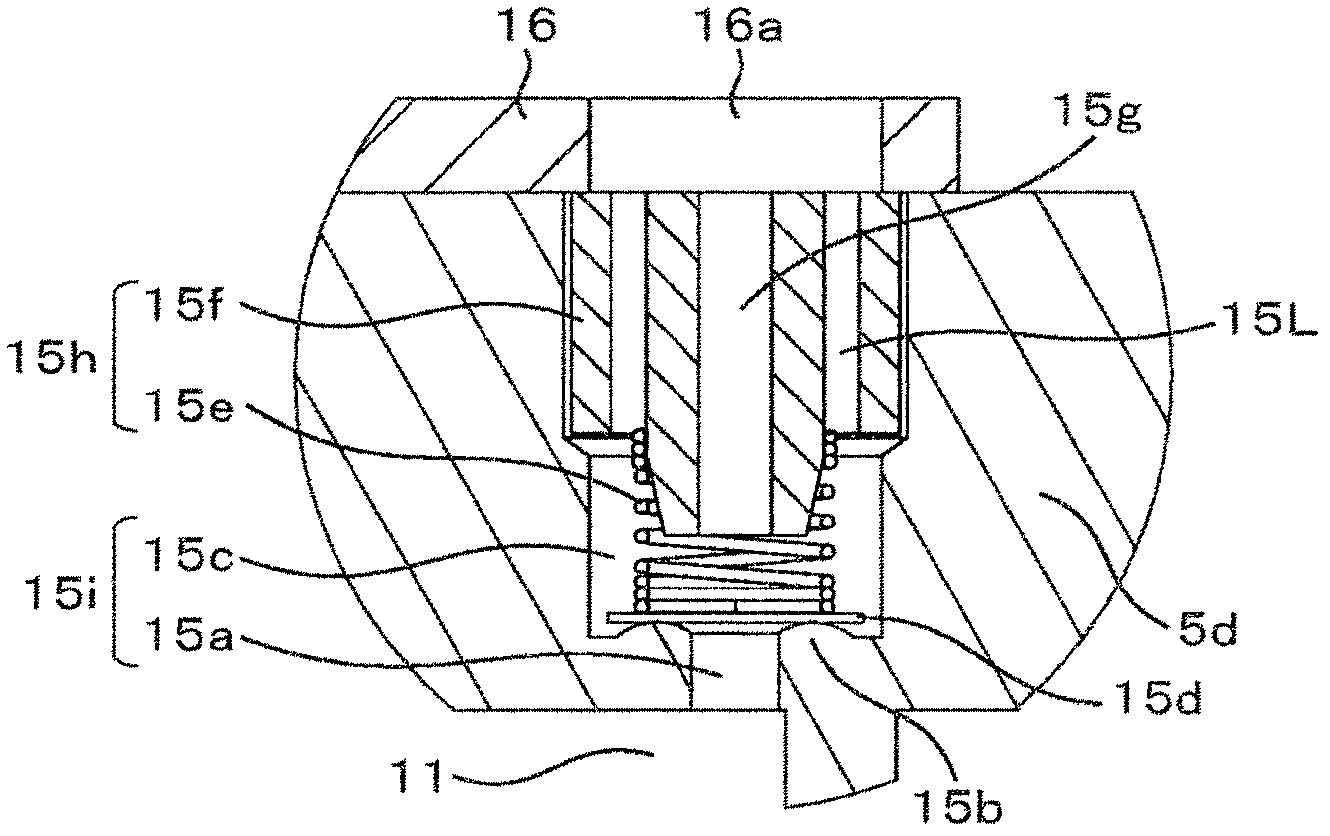

InactiveCN101802351AValve opening characteristic changesChange valve opening characteristicsMachines/enginesValve camshaftsEngineeringInternal combustion engine

A valve gear mechanism for an internal combustion engine, capable of changing valve-opening characteristics of a valve. The mechanism can smoothly change valve-opening characteristics by using a simplified structure without causing an increase in the number of parts and without causing an increase in sliding friction. A valve gear has a switching mechanism (24) for switching connection and disconnection between rocker arms (32, 34) arranged between a valve (18) and cams (14, 16). When a slide pin (58) reaches an displacement end (Pmax2) in the direction in which a slide pin (58) is retracted,the urging force of a return spring (56) acting on switching pins (48, 54L, 54R) is received by an engaging portion, formed between a notch (58e) provided in the slide pin (58) and a rock pin (70), with the engaging portion separated from a camshaft (12).

Owner:TOYOTA JIDOSHA KK

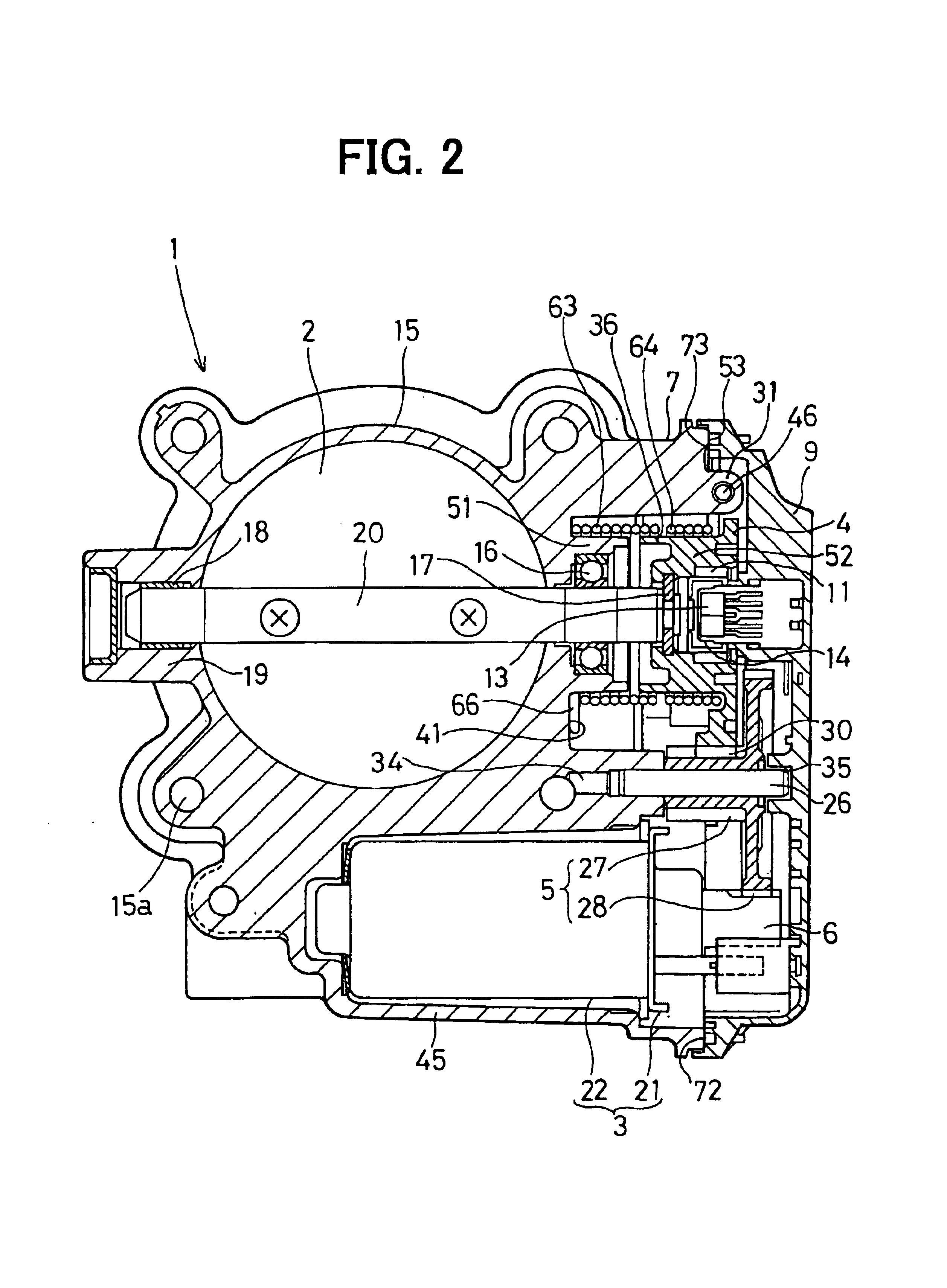

Electronically controlled throttle control apparatus

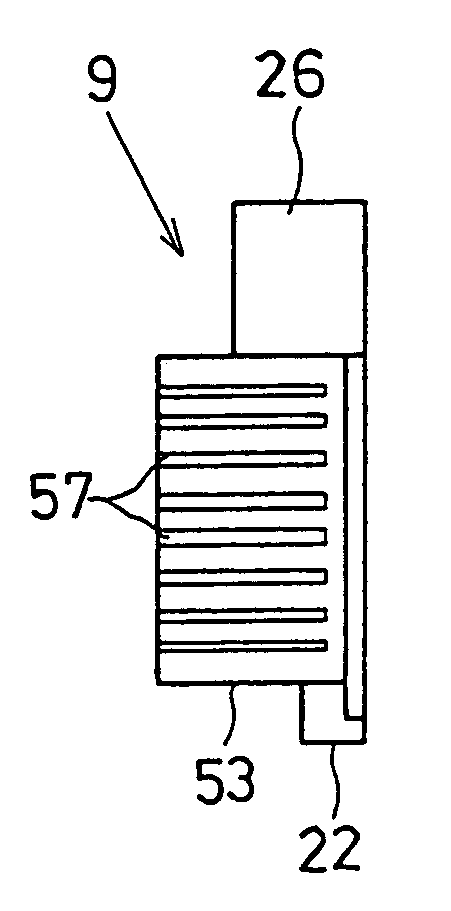

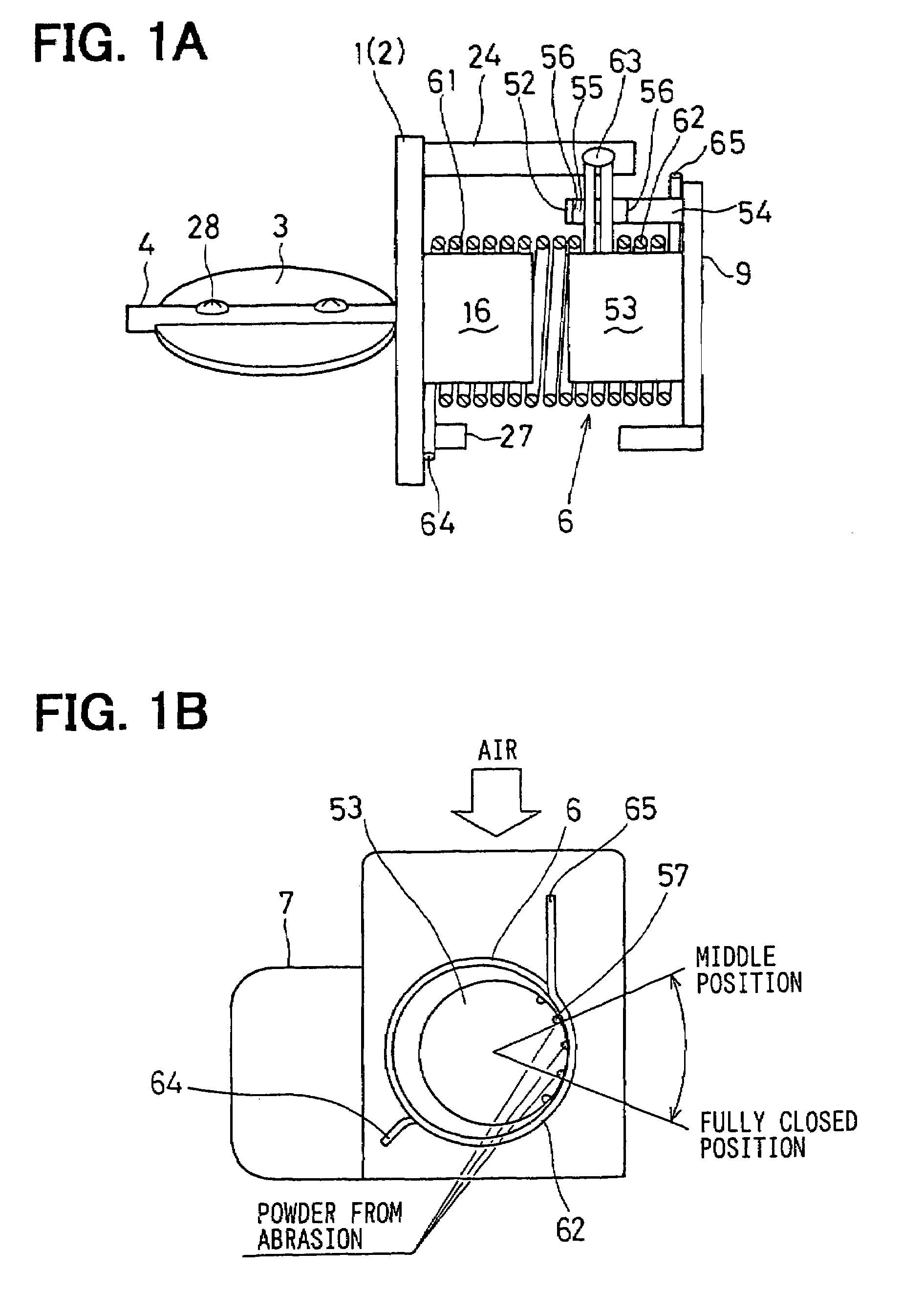

ActiveUS6986336B2Avoid throttlingAvoid failureElectrical controlOperating means/releasing devices for valvesThrottle controlCoil spring

An electronically controlled throttle control apparatus prevents a throttle valve from malfunctioning due to deterioration in sliding resistance ascribable to abrasive dust at a sliding contact portion between a valve gear of a geared reduction device and a coil spring. The outer periphery of a spring inner periphery guide is provided with a plurality of groove portions as abrasive dust removing means for removing abrasive dust at least from a sliding contact portion between the outer periphery of the spring inner periphery guide and the inner periphery of a default spring, so that individual edge portions of the plurality of groove portions can rub the inner periphery of the default spring to scrape off abrasive dust from the inner periphery of the default spring and direct the abrasive dust into the plurality of groove portions.

Owner:DENSO CORP

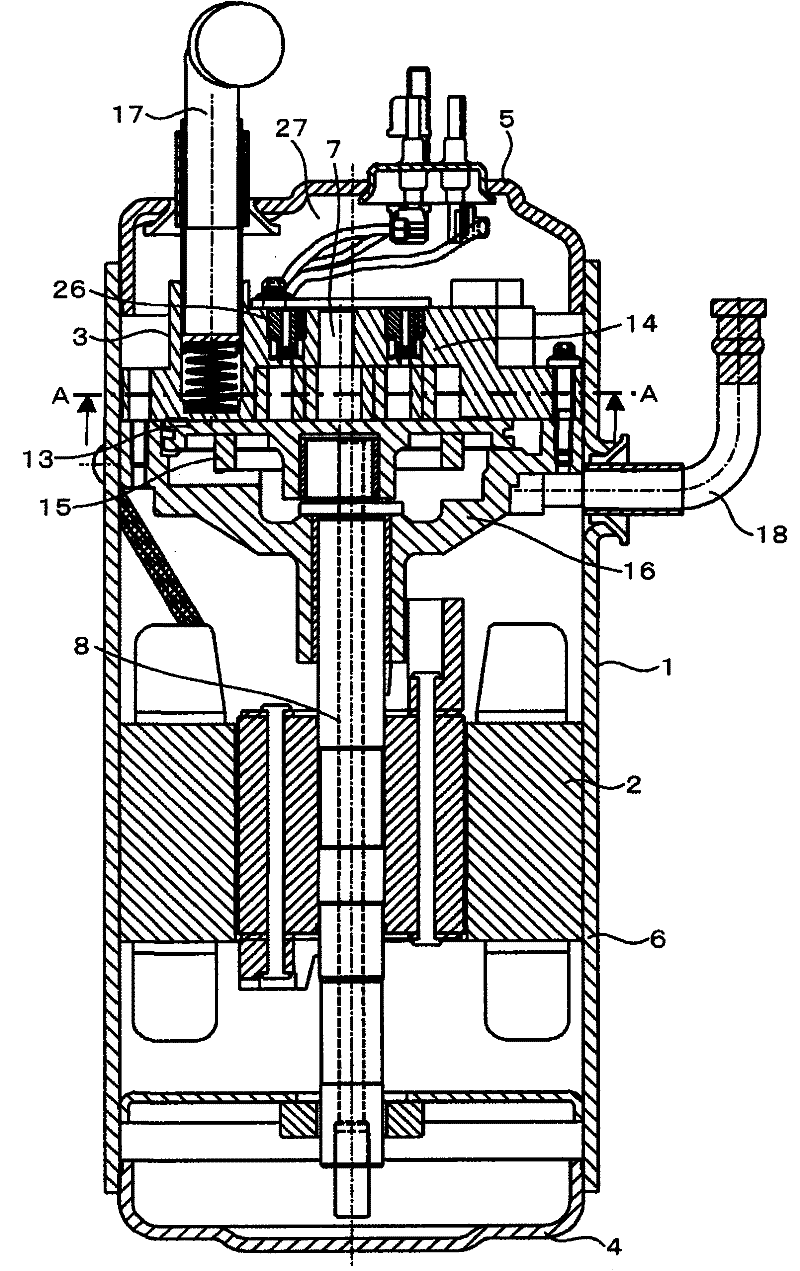

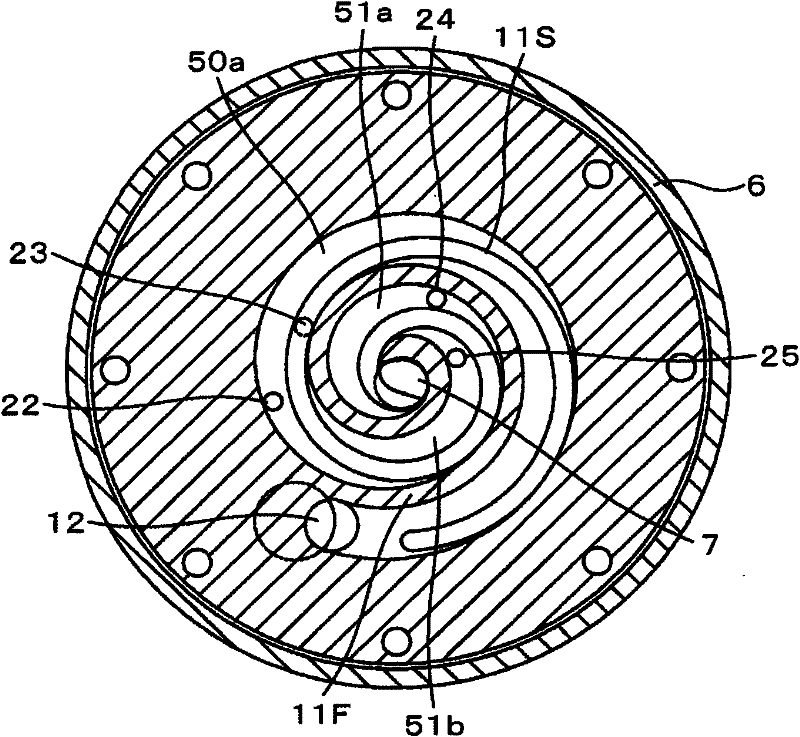

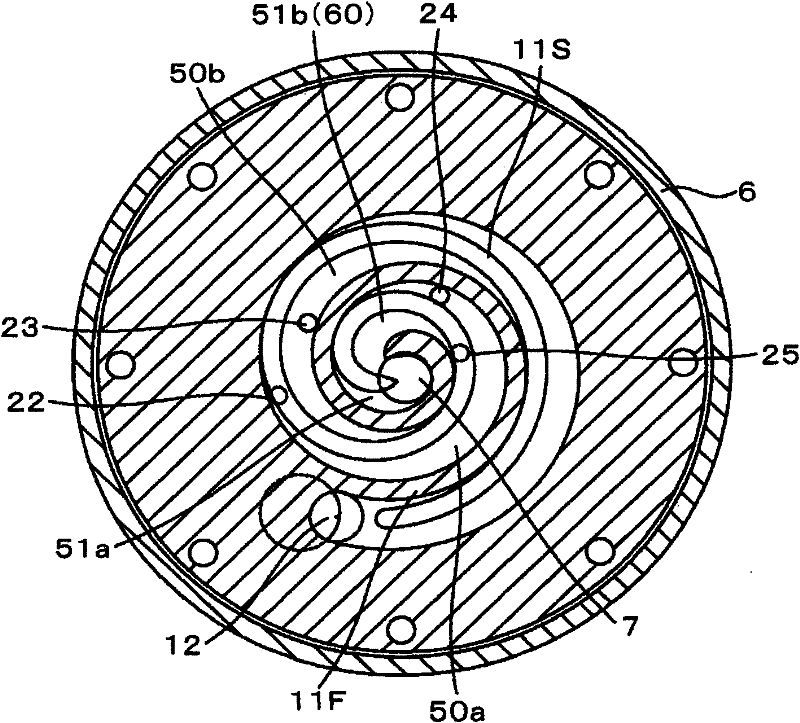

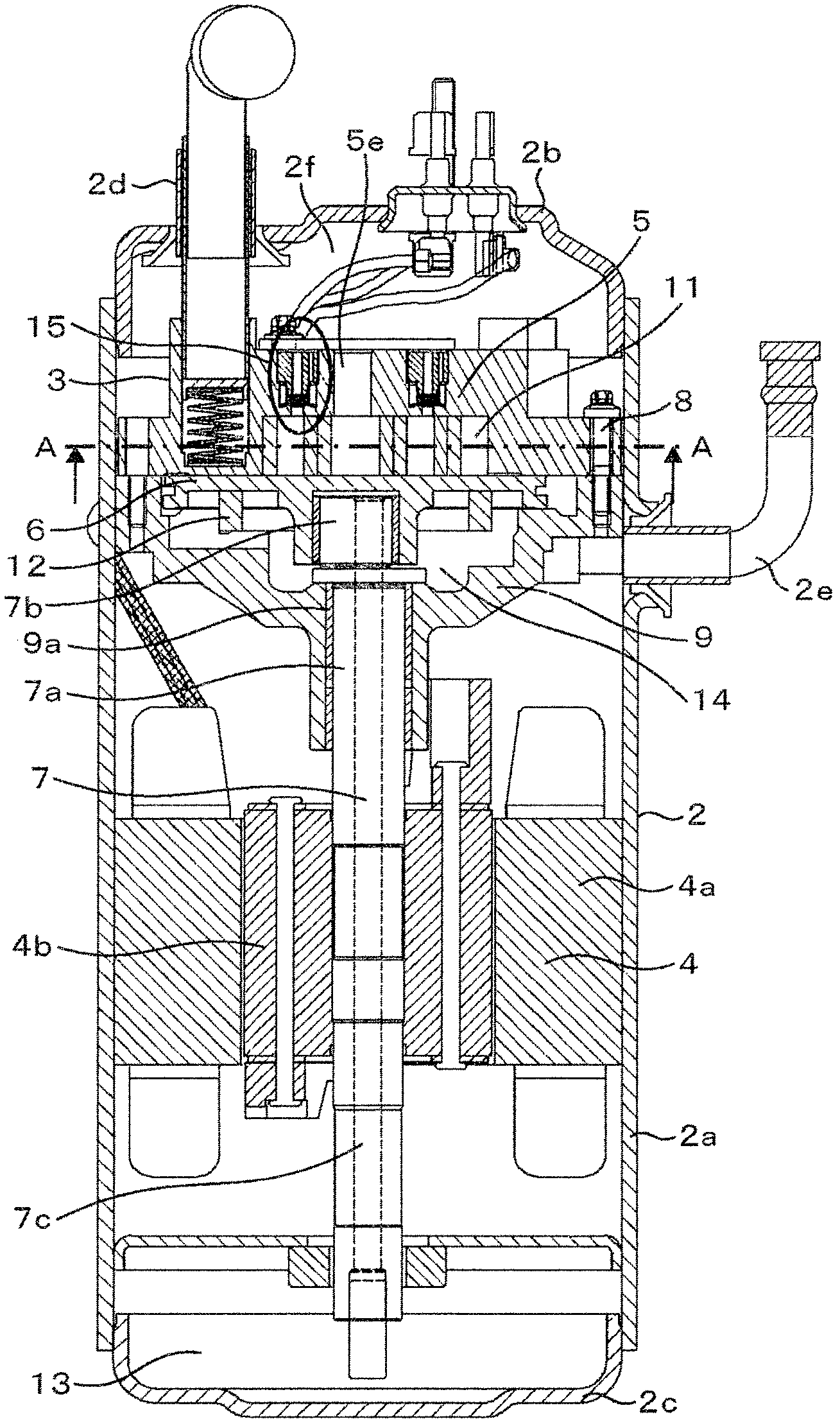

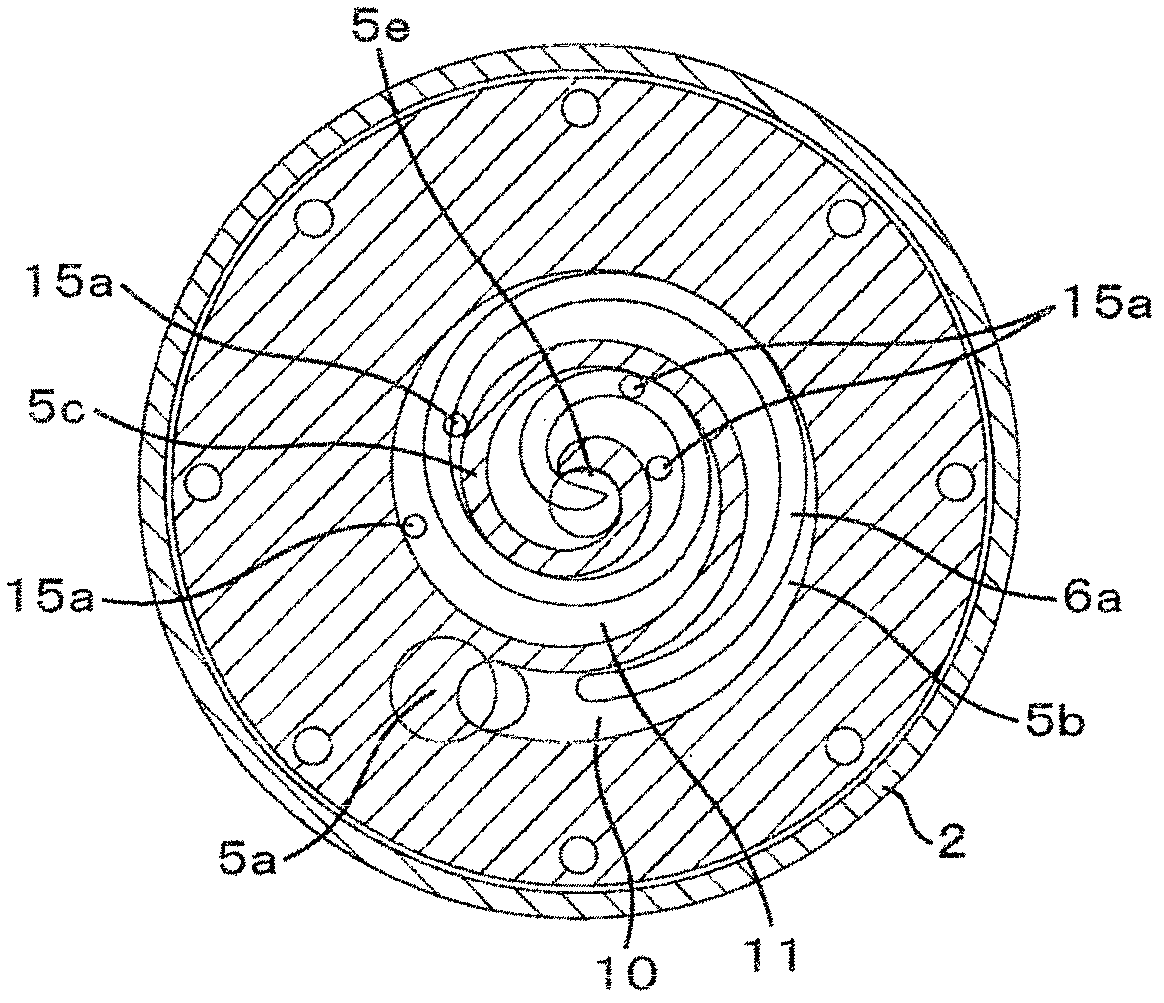

Scroll compressor

InactiveCN102052310AImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsHigh pressureRefrigerant

During the over-compression, high pressure refrigerant is released from a bypass hole. The sprayed pressure loss in inverse proportion to the cross section of the bypass hole is generated when the refrigerant passes through the bypass hole.The aim of the invention is to improve the compression efficiency of the over-compression region.The invention provides a scroll compressor equipped with two venting valve gears.The two venting valve gears are respectively arranged in two compression chambers closest to an ejection opening.The two compression chambers are paired chambers with respect to a voluted center.The two venting valve gears are arranged in an asynmmetric configuration with respect to the voluted center.At least one of the venting valve gears communicates with the injection outlet when the two compression chambers are under the following two states: one state is that the two compression chambers is about to communicate with the injection outlet; the other state is that the two compression chambers progress 180 degree and communicate with the injection outlet.

Owner:HITACHI APPLIANCES INC

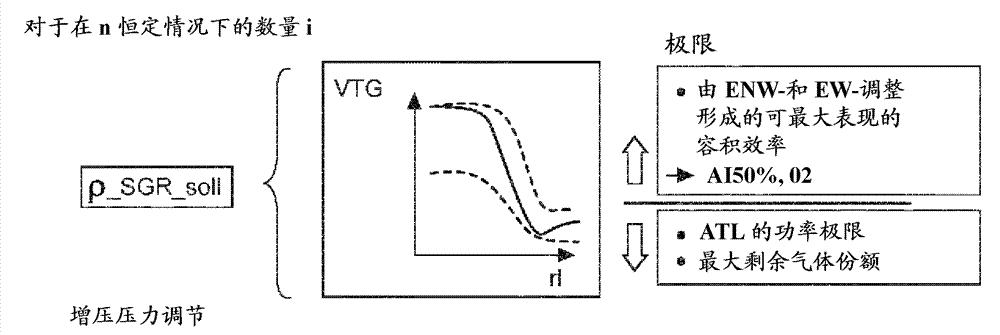

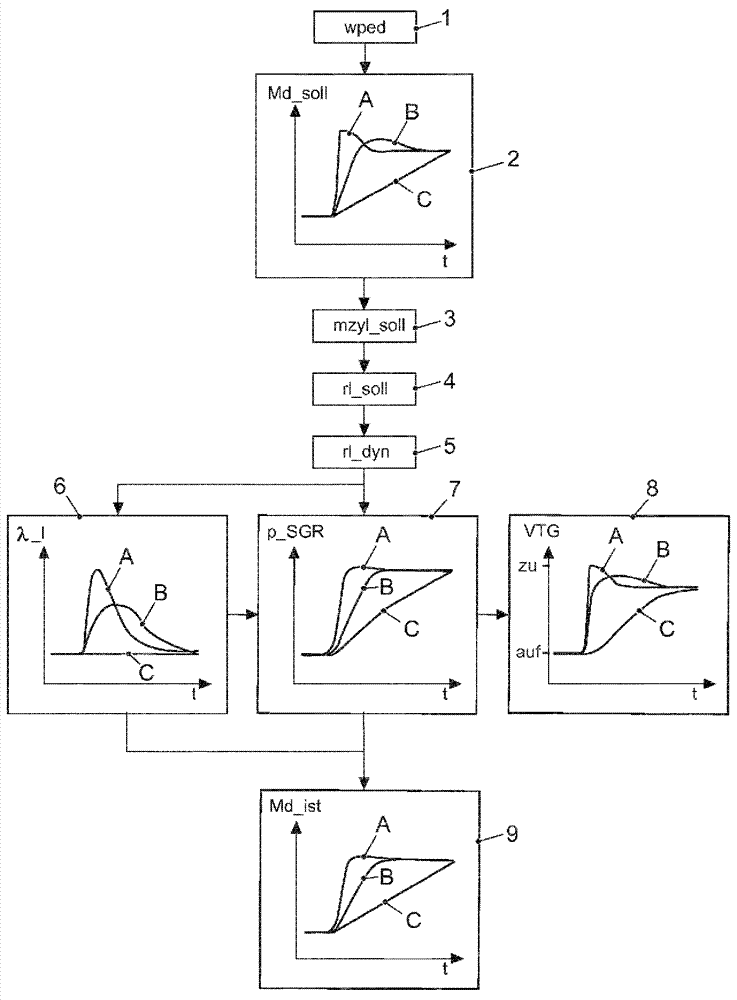

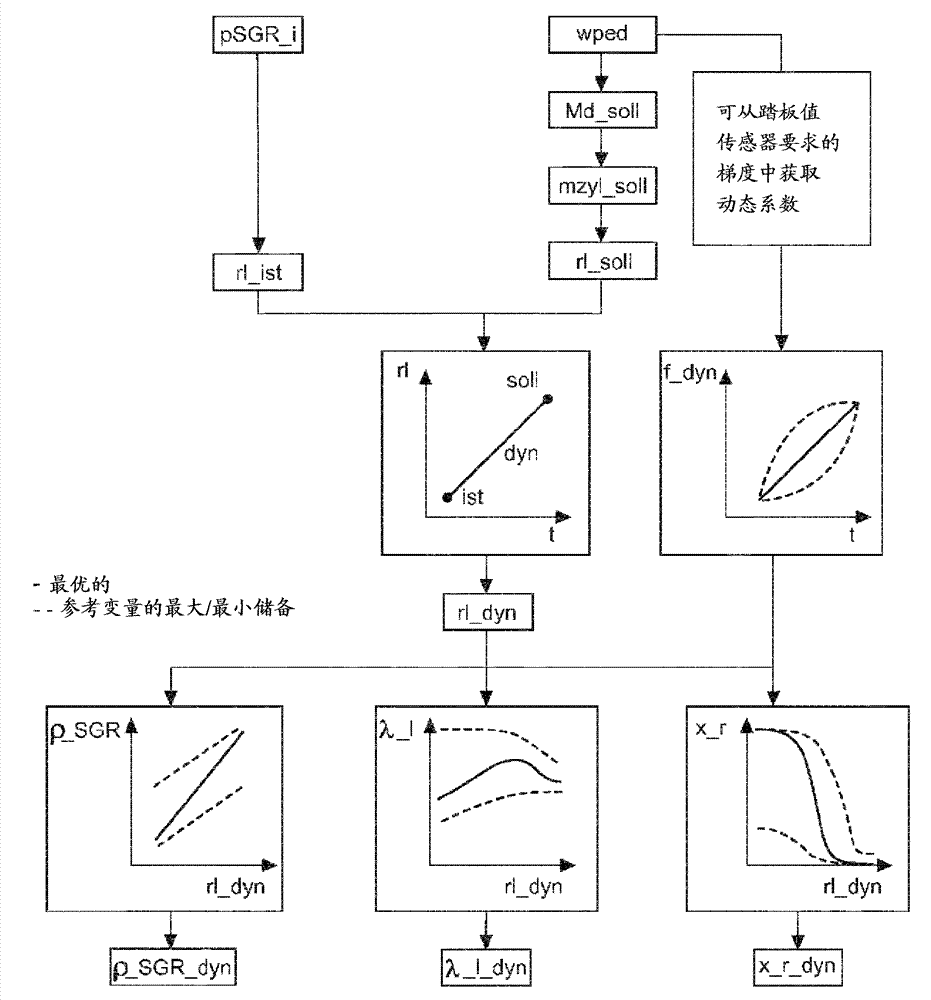

Method for operating an internal combustion engine

ActiveCN104508282AImprove dynamic characteristicsImprove efficiencyValve arrangementsElectrical controlCurrent loadExternal combustion engine

The present invention relates to a method for operating an internal combustion engine (51). The internal combustion engine (51) comprises a compressor (52) for setting a charge density (p_SGR) in an intake pipe of the internal combustion engine and adjusting means (53), for example variable valve gear, for setting a volumetric efficiency (lambda_Iota) of the internal combustion engine (51). In the method, a dynamic setpoint value (rl_dyn) is determined for the internal combustion engine (51) as a function of a difference between a load request (rl_soll) on the internal combustion engine (51) and a current load output (rl_ist) of the internal combustion engine (51). The volumetric efficiency (lambda_Iota) and the charge density (p_SGR) are set as a function of the dynamic setpoint value (rl_dyn).

Owner:VOLKSWAGEN AG

Scroll compressor

ActiveCN102878078AAvoid deformationDampen crashRotary piston pumpsRotary piston liquid enginesValve gearRetaining ring

Subject of the present invention is to provide a vortex compressor, which can inhibit by setting the overflow valve pressure of valve gear body pressure into the cause of fixed vortex plate deformation, and the inhibition caused by collision of retainer and valve pressure deformation of the body or a collision. Fixed vortex dish with overflow valve device, the pressure of compression chamber rises above to set pressure, open flow so that the compression chamber and pressure chamber connected from the overflow valve device is connected the overflow of the compression chamber and jet pressure chamber flow, overflow valve open and close the overflow flow, configuration between the relief valve and the retainer and the elasticity of the overflow valve is given according to the pressure of the valve pressure, limiting valve pressure of the moving range of retainer, the overflow valve closed state of the overflow mouth and open the overflow state of flow in any conditions, all press pressure the valve pressure by elastic body pressure against the retaining ring.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Internal combustion engine with variable valve gear

ActiveUS20100212618A1Improve combustibilityImprove exhaust performanceValve arrangementsInternal combustion piston enginesExternal combustion engineInlet valve

In an engine which comprises a first intake valve and a second intake valve for each cylinder, configured to be driven by a first intake cam and a second intake cam, respectively, and a cam phase change mechanism configured to vary the phase of the second intake cam, the cam phase change mechanism is controlled so that the opening timing of the second intake valve is advanced ahead of that of the first intake valve in a start mode.

Owner:MITSUBISHI MOTORS CORP

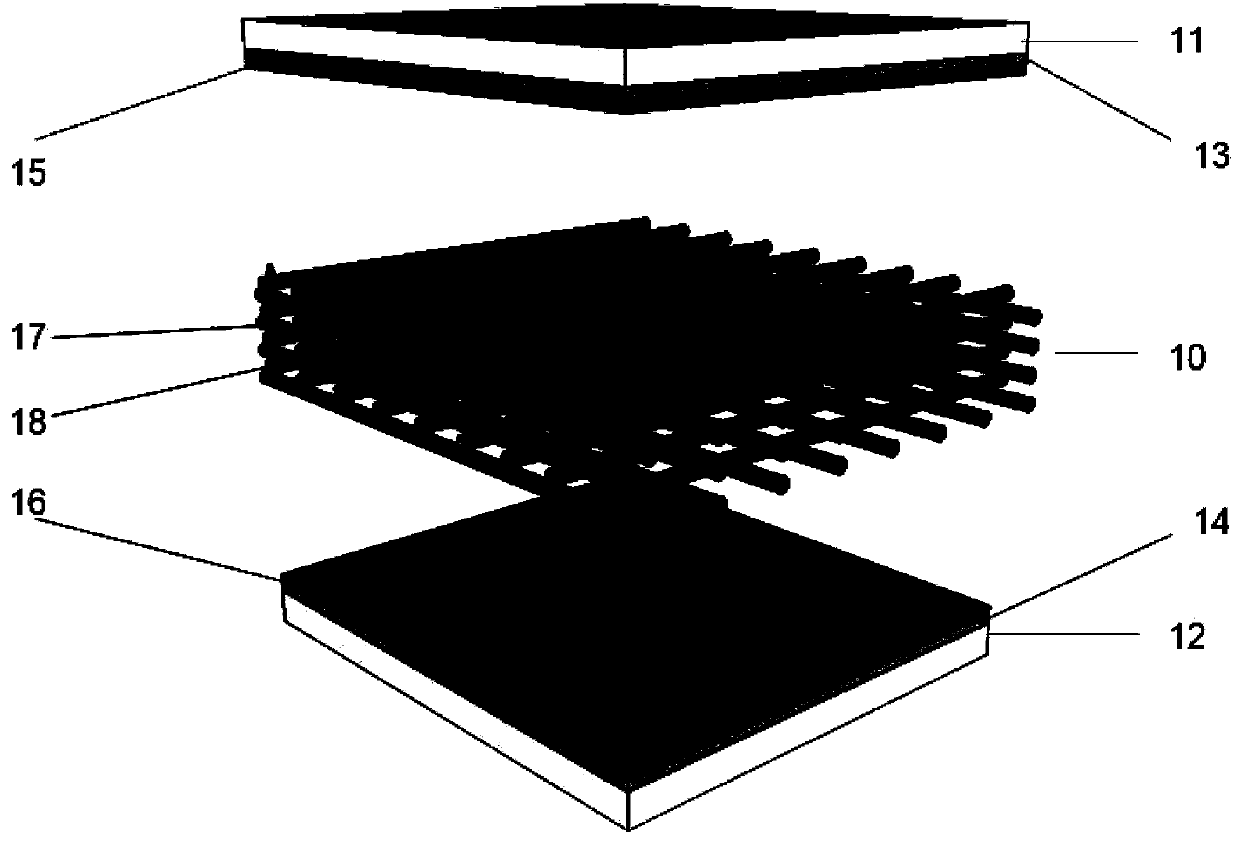

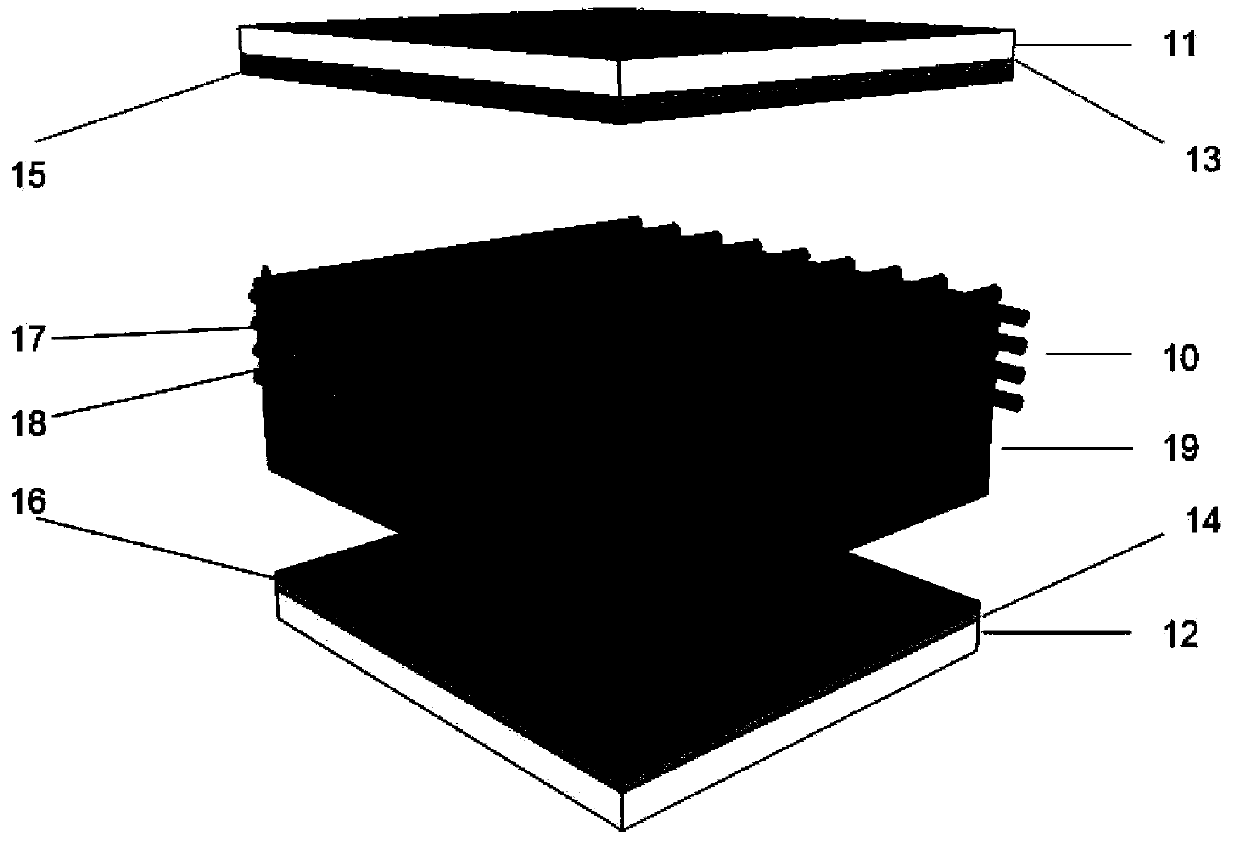

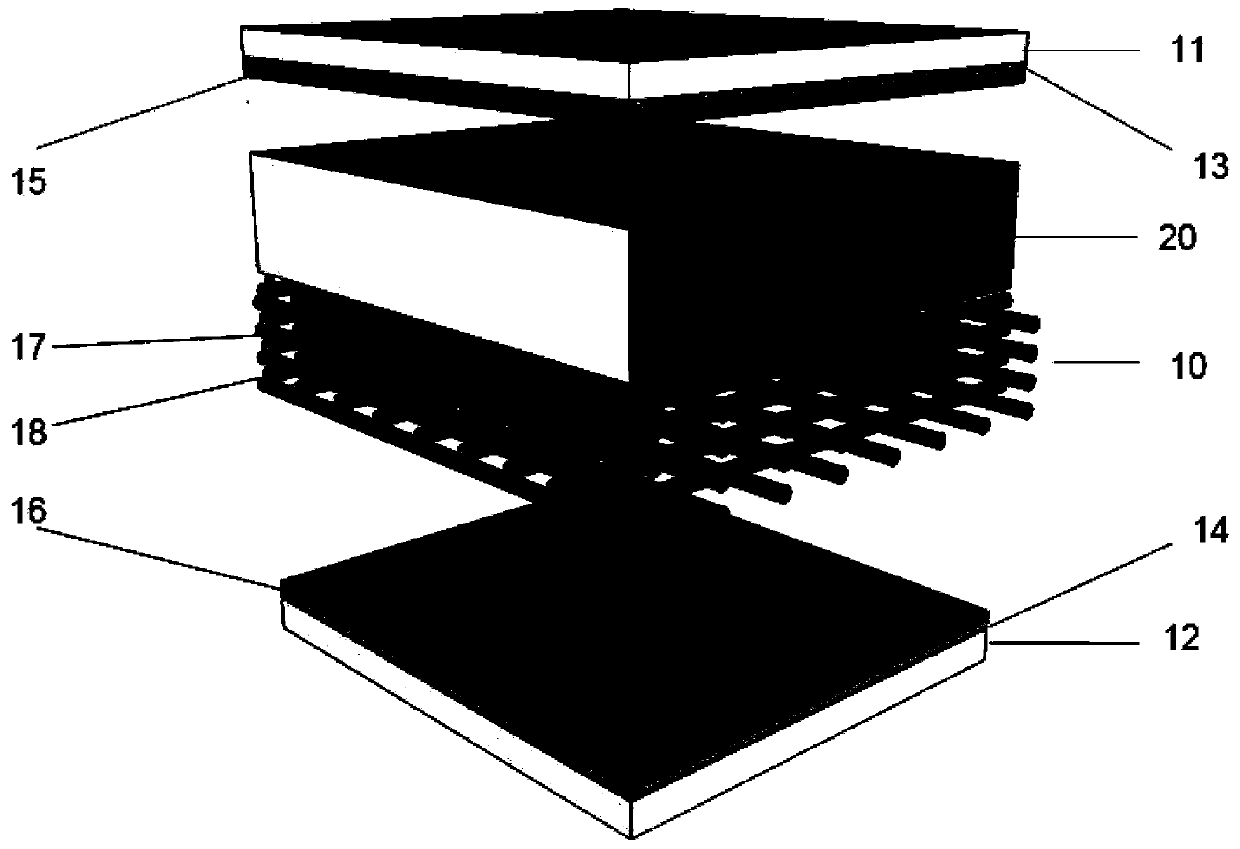

Microfluid valve gear based on electrowetting technology

InactiveCN103470852ARealize dynamic manipulationImprove conductivityValve arrangementsCircuit elementsEngineeringDielectric layer

The invention discloses a microfluid valve gear based on electrowetting technology. The microfluid valve gear comprises an upper substrate, a lower substrate and a microfluid interlayer. The microfluid interlayer is positioned between the upper substrate and the lower substrate. An upper conducting layer (13) and a lower conducting layer (14) are respectively arranged on one side of the upper substrate (11) and the lower substrate (12) close to the microfluid interlayer (10), an upper dewatering dielectric layer (15) is arranged on a lower surface of the upper conducting layer (13), and a lower dewatering dielectric layer (16) is arranged on an upper surface of the lower conducting layer (14). The microfluid interlayer (10) is made of porous spongy material. The outer surface and the interior structure surface of the microfulid interlayer (10) are both covered by a medium dewatering dielectric layer (17). Voltage is applied between the microfluid interlayer and a certain substrate, so that waterborne fluid between the substrate and the interlayer is filtered to the other side of the interlayer by the aid of electrowetting property. Correspondingly, voltage is applied between the other substrate and the interlayer, so that the waterborne fluid can be filtered back to the original side, and accordingly a dynamic and adjustable fluid valve function can be achieved.

Owner:SOUTHEAST UNIV

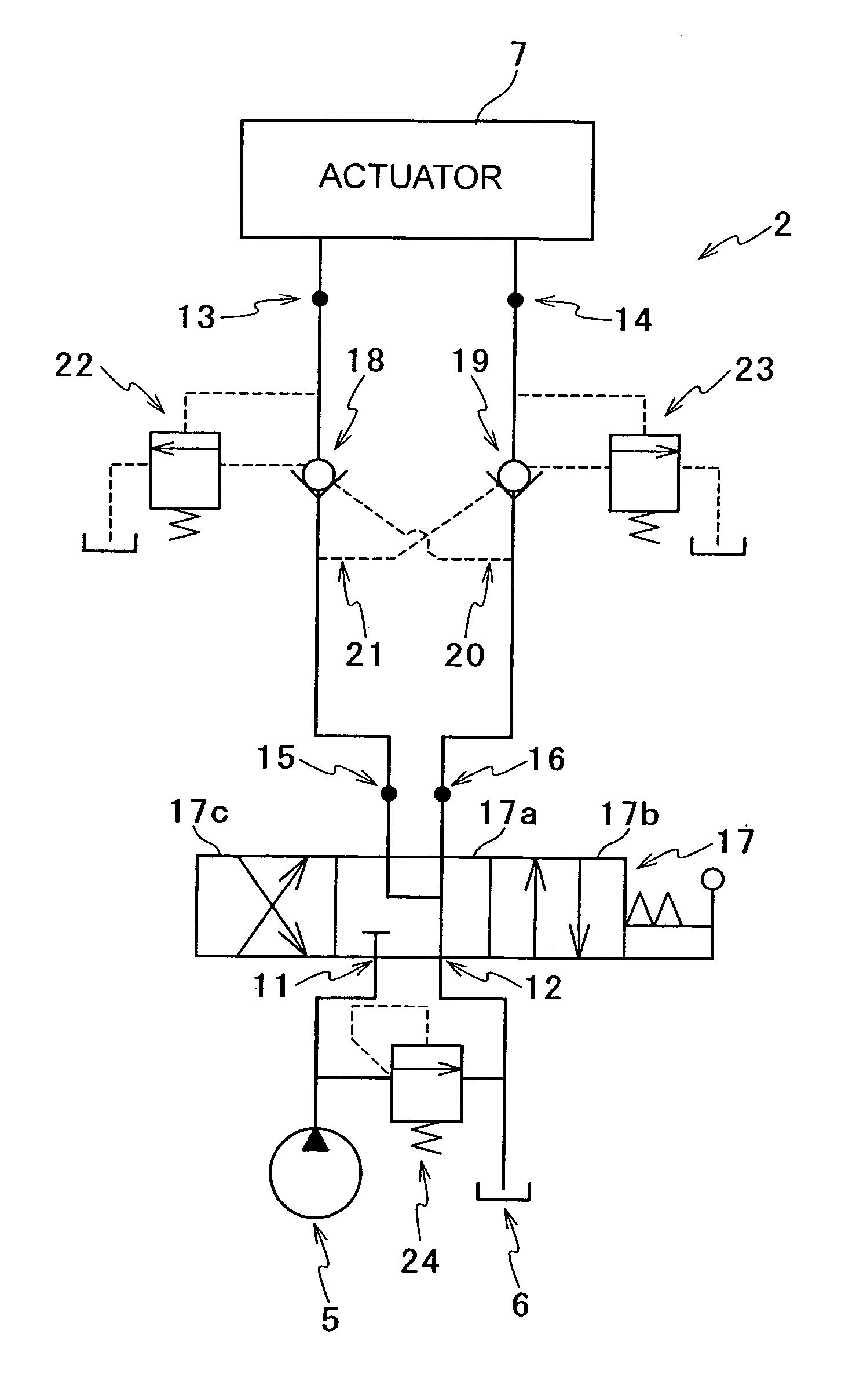

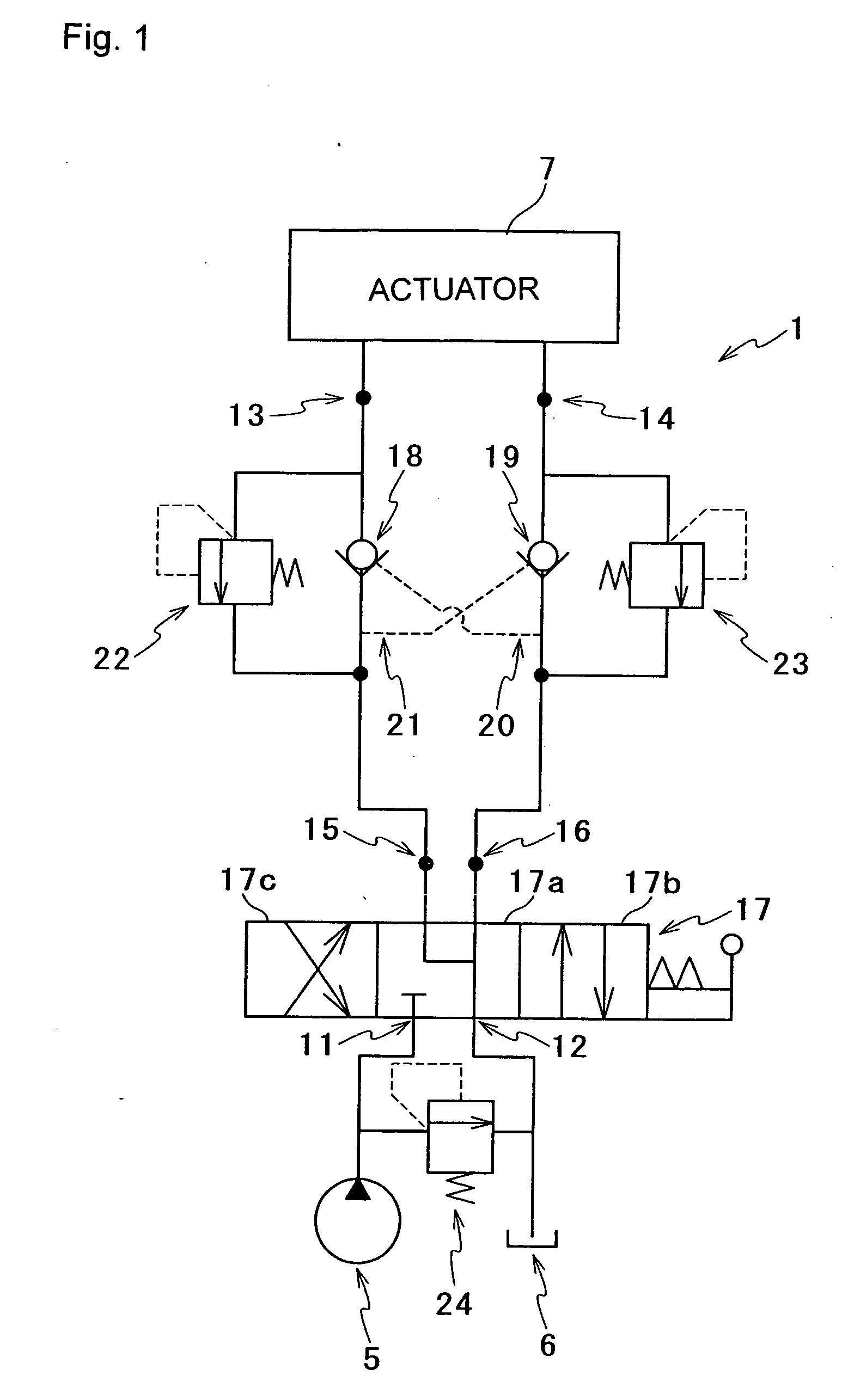

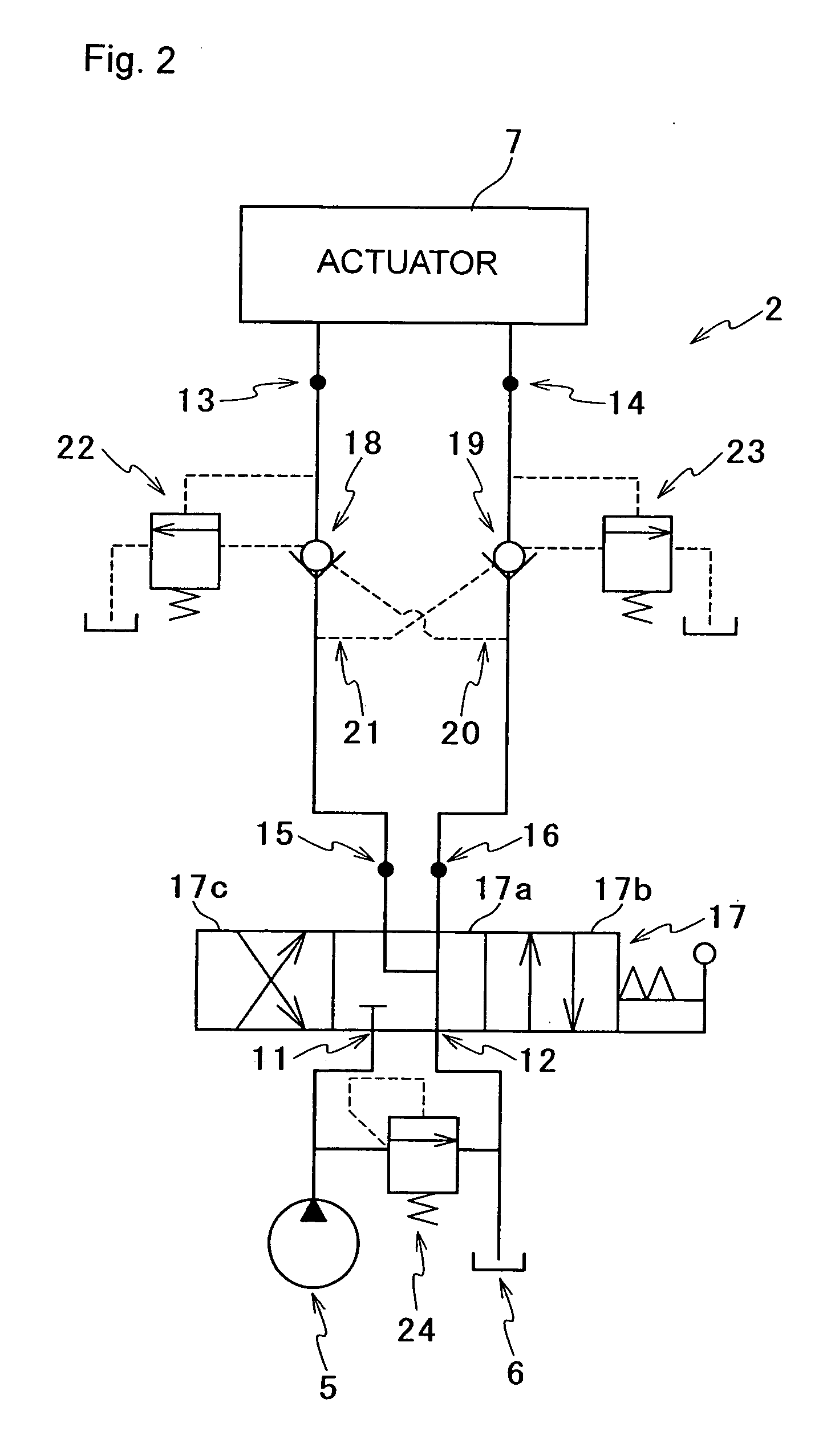

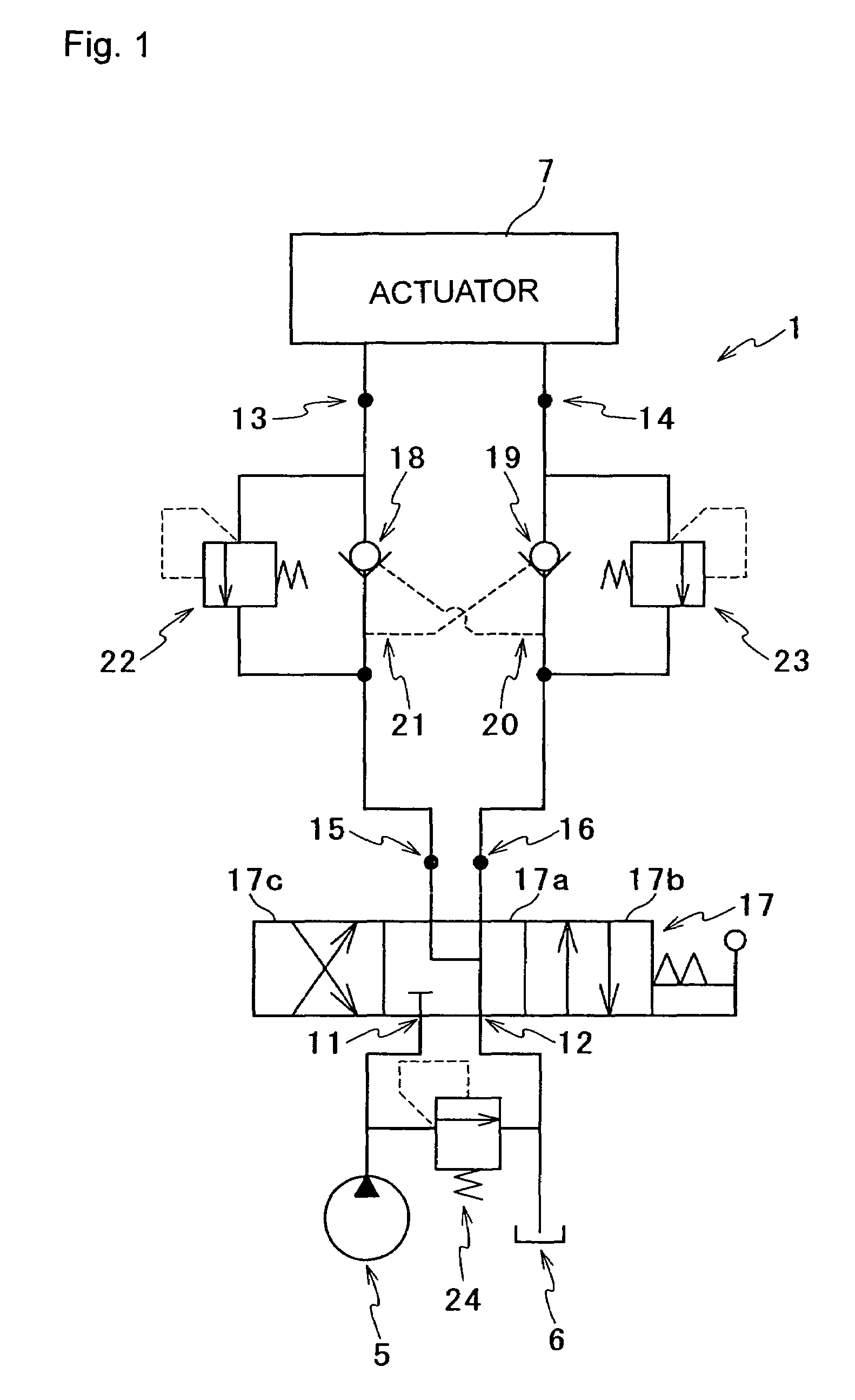

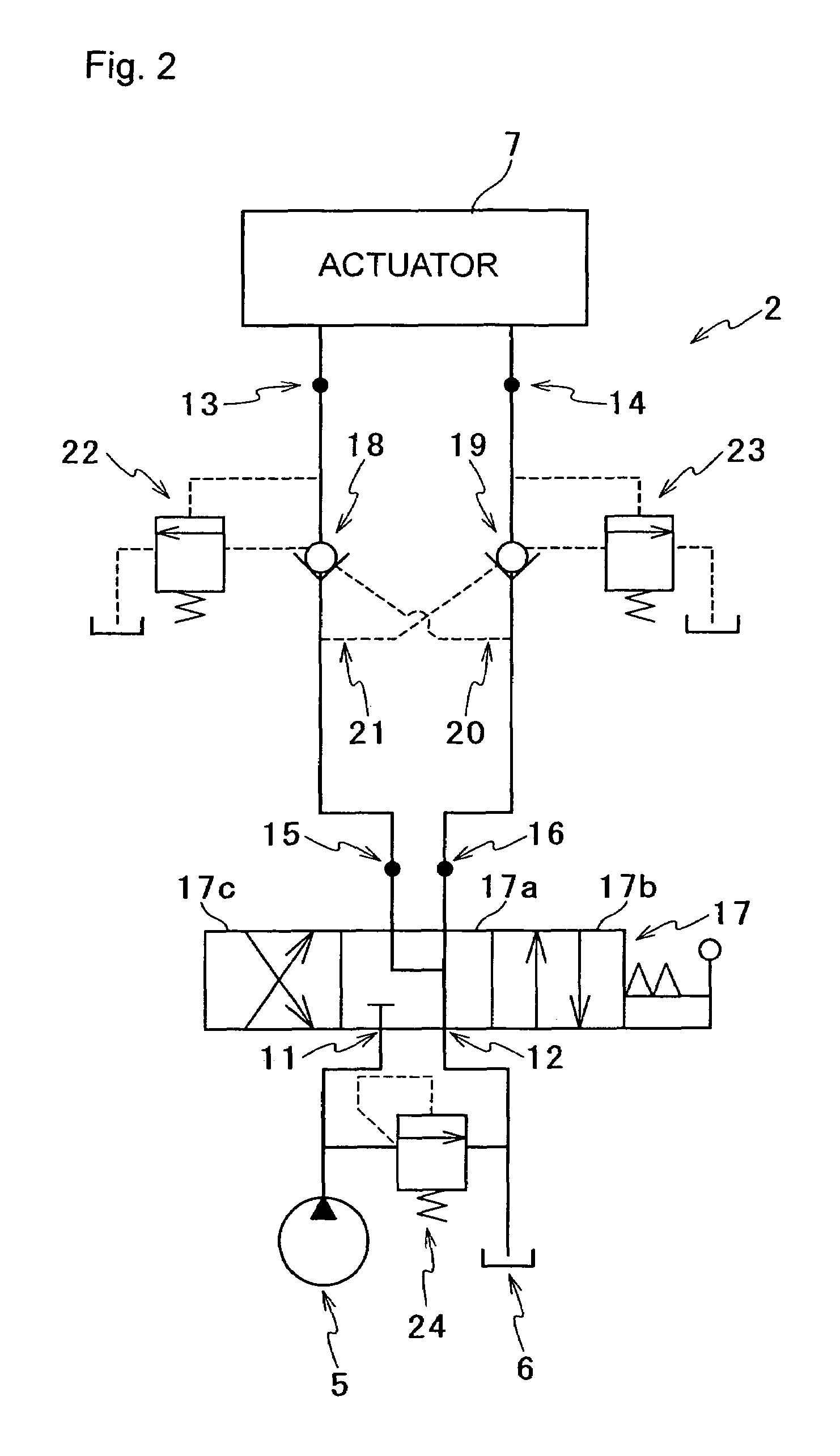

Hydraulic circuit and its valve gear

InactiveUS20060249016A1Reduce the number of processesSimple circuit structureServomotor componentsServomotorsHydraulic circuitEngineering

To simplify a circuit structure and a path structure in a hydraulic circuit having a pilot check valve and an overload relief valve and to reduce the size of a gear. The hydraulic circuit includes a pump port; a tank port; a first actuator port; a second actuator port; a first supply and discharge port; a second supply and discharge port; a direction changing valve; a first pilot check valve; a second pilot check valve; a first pilot path; and a first overload relief valve. The direction changing valve has a neutral position to communicate the first supply and discharge port with the tank port. The first overload relief valve is arranged in parallel with the first pilot check valve and is arranged between the first supply and discharge port and the first actuator port.

Owner:NABLESCO CORP

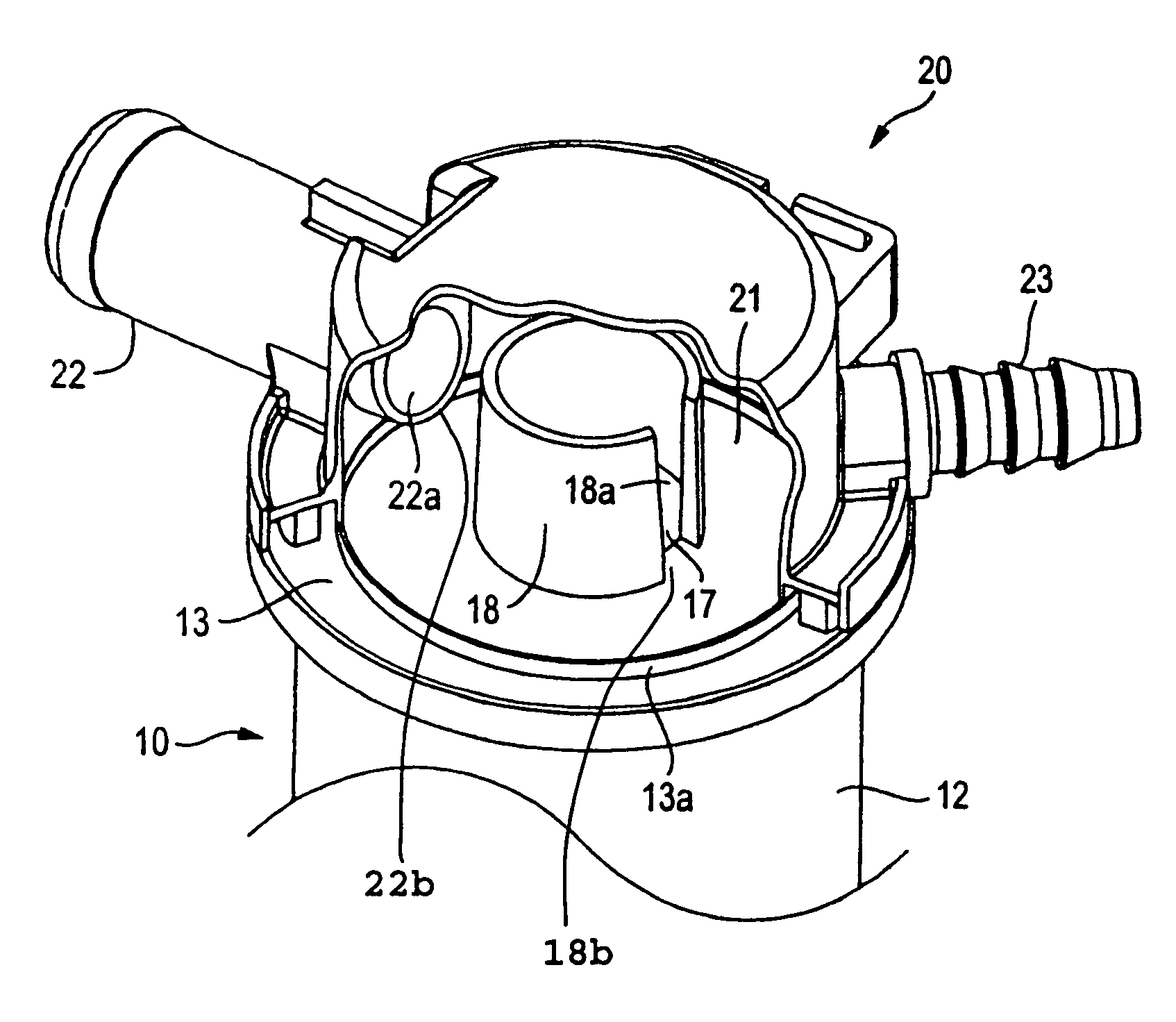

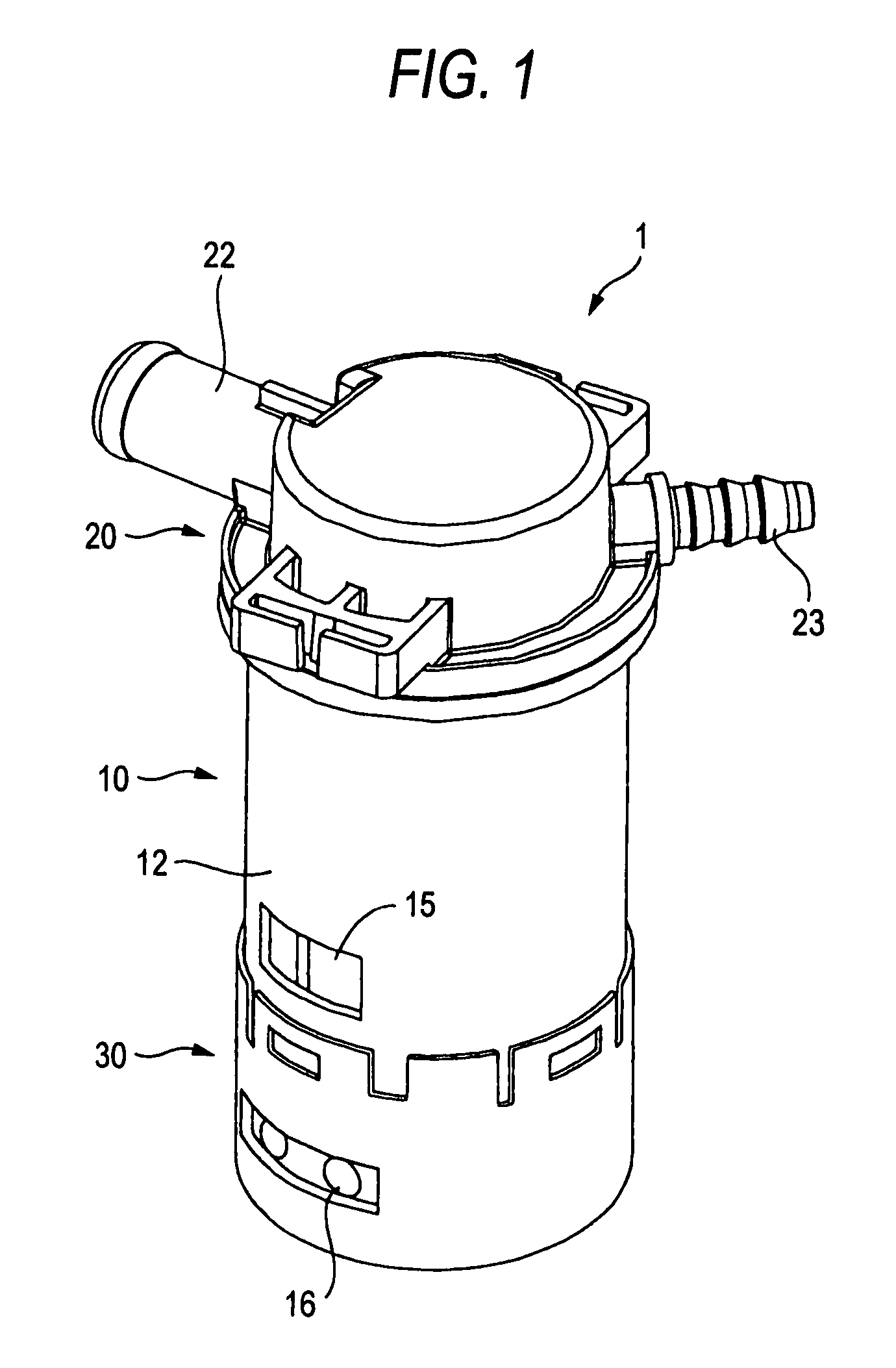

Valve gear and rocker ARM unit

A valve gear comprises a cylinder head, a supporting member fixed to the cylinder head, a rocker arm which is mounted on the supporting member so as to be placed on the latter, a substantially plate-shaped clip mountable to the rocker arm, the clip having a fitting hole in which an outer periphery of the supporting member is fitted so that the clip is prevented from falling off, a pair of walls which is formed on the rocker arm so as to be opposed to each other with the supporting member being located therebetween, and a pair of locking portions formed in inner faces of the walls so that outer edges of the clip are elastically engaged with the locking portions thereby to be locked, respectively.

Owner:OTICS CORP

Variable valve gear for internal combustion engine

ActiveUS20100116231A1InterferenceEasy to controlValve arrangementsYielding couplingExternal combustion engineVariable valve timing

Disclosed is a variable valve gear comprising a camshaft phase change mechanism, which variably controls a phase of an intake cam with respect to a crankshaft, and a variable valve lift mechanism, which changes an opening timing of an intake valve more than a closing timing and basically continuously varies a lift and an open period of the intake valve. The lift and the open period are set lest the intake valve interfere with a piston of an engine, with the phase controlled to be most advanced by the camshaft phase change mechanism and the lift controlled to be maximal by the variable valve lift mechanism.

Owner:MITSUBISHI MOTORS CORP

Valve gear of engine

ActiveUS20150075468A1Accurate compactionContinuous operationValve drivesMachines/enginesCamValve gear

A cam element portions is configured such that respective maximum lift portions (lift ending points) of both-side end-face cams thereof are provided at respective phases which are different from each other in a rotational direction and that a maximum value of a length, in an axial direction, between respective cam faces of the both-side end-face cams which are provided at the same phase is set to be a distance, in the axial direction, between a first operational member and a second operational member or smaller. Accordingly, in a valve gear of an engine in which cams operative to control opening / closing of a valve are switchable, it can be properly prevented that a camshaft locks and stop rotating because of an operational malfunction of an operational member or the like.

Owner:MAZDA MOTOR CORP

Internal combustion engine with variable valve gear

ActiveUS20100212617A1Easy to controlValve arrangementsYielding couplingGear wheelExternal combustion engine

In an engine with a cam phase change mechanism which is disposed on one end portion of an intake camshaft and variably changes a phase of a drive cam of an intake valve relative to a crankshaft, the cam phase change mechanism is configured so that two vane-type hydraulic actuators of which variable-phase torques produced at the same supplied oil pressure are different are arranged axially relative to the intake camshaft.

Owner:MITSUBISHI MOTORS CORP

Hydraulic circuit and its valve gear

InactiveUS7263924B2Simple circuit structureSimple structureServomotor componentsServomotorsHydraulic circuitEngineering

To simplify a circuit structure and a path structure in a hydraulic circuit having a pilot check valve and an overload relief valve and to reduce the size of a gear. The hydraulic circuit includes a pump port; a tank port; a first actuator port; a second actuator port; a first supply and discharge port; a second supply and discharge port; a direction changing valve; a first pilot check valve; a second pilot check valve; a first pilot path; and a first overload relief valve. The direction changing valve has a neutral position to communicate the first supply and discharge port with the tank port. The first overload relief valve is arranged in parallel with the first pilot check valve and is arranged between the first supply and discharge port and the first actuator port.

Owner:NABLESCO CORP

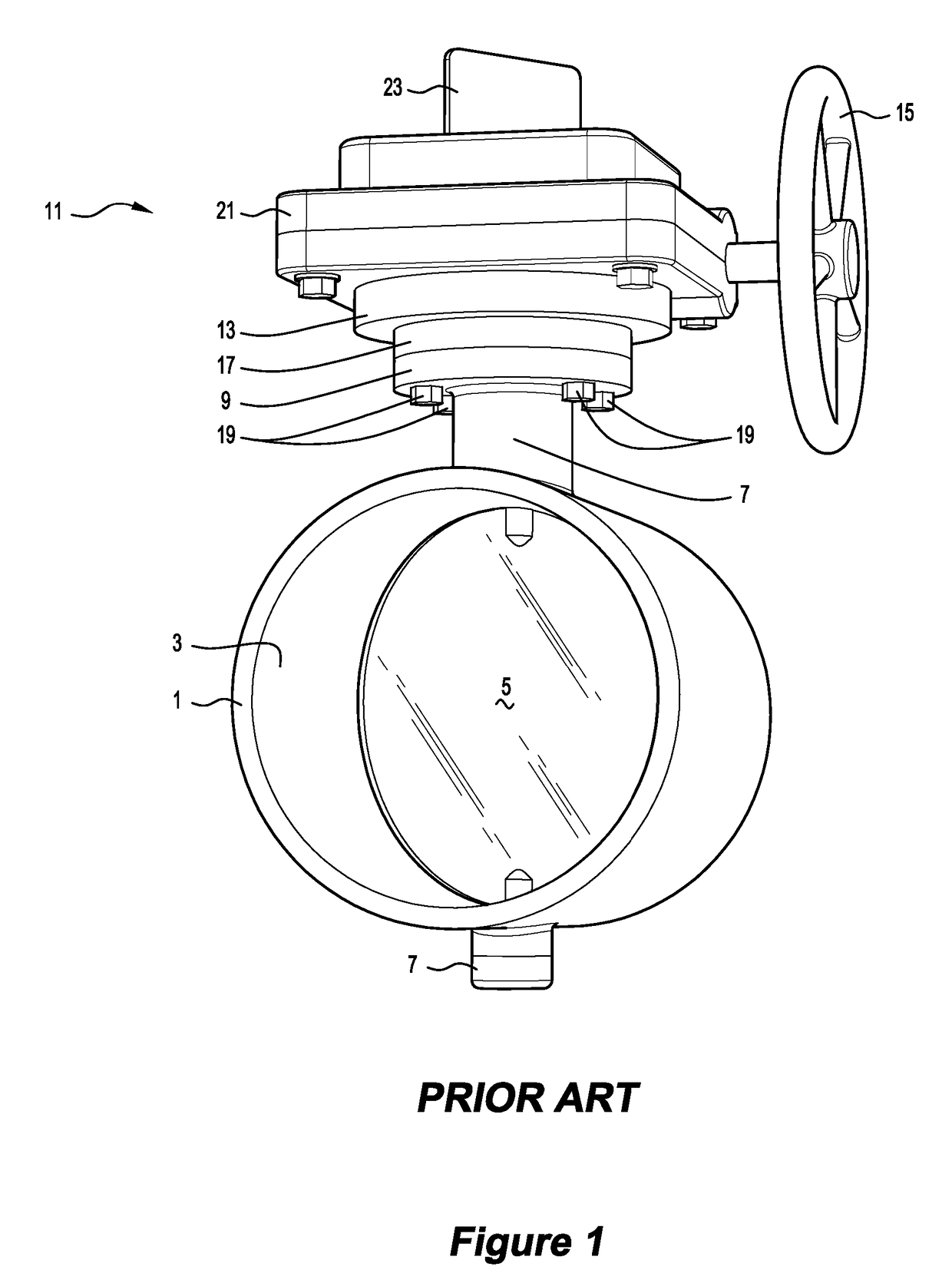

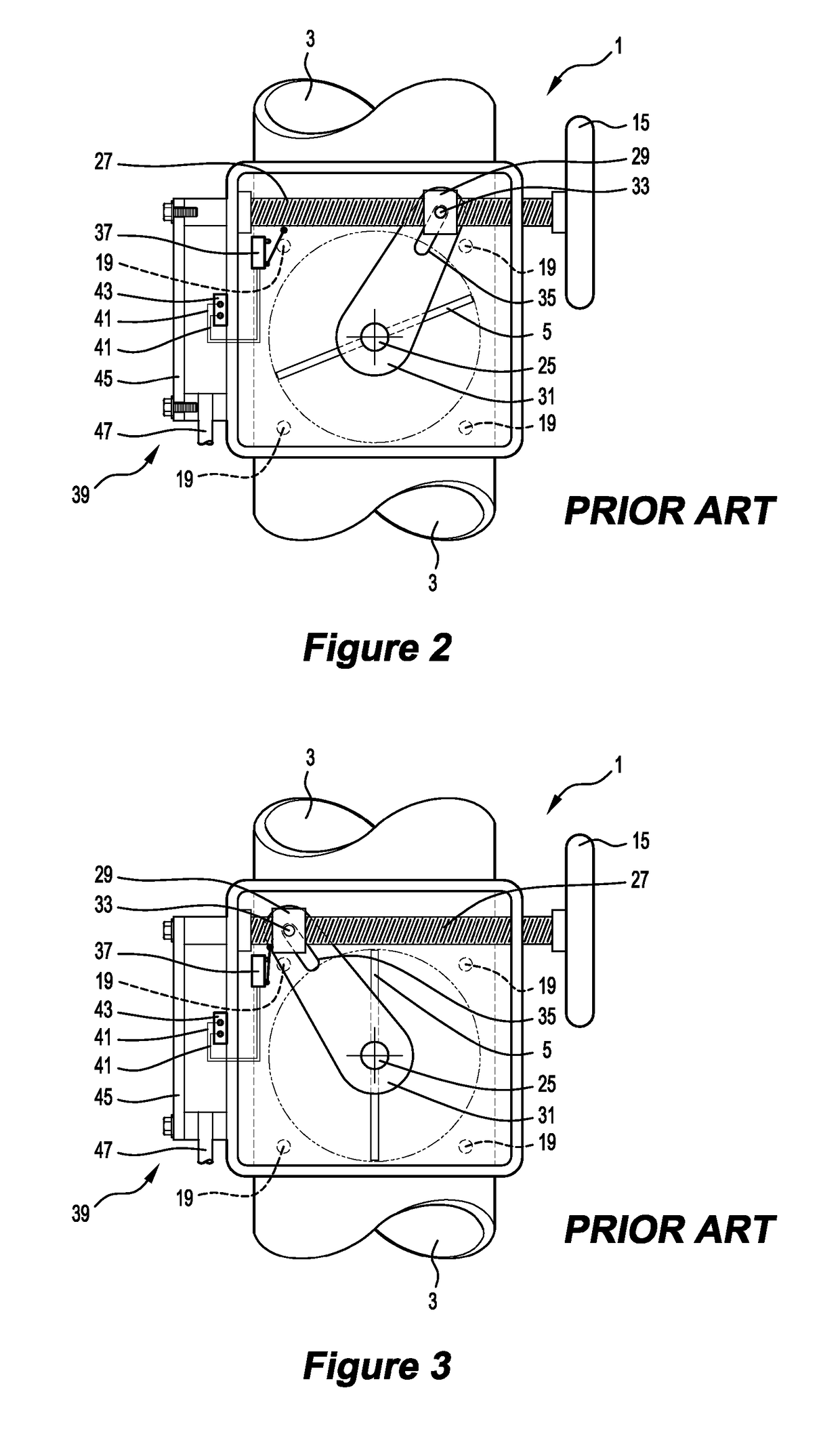

Valve monitoring

ActiveUS20170232285A1Prevent tamperingOperating means/releasing devices for valvesFire rescueGear driveValve gear

A valve gear box has a valve monitoring function. The valve gear box is for mounting to a valve that has a fluid passageway and a gate therefor, the gear box providing a gear driven link for moving the gate between open and closed conditions of the fluid passageway, the valve gear box being in a housing that has a mounting for permitting operative connection to the valve via a mounting flange of the valve. The mounting and the mounting flange have a valve monitoring sensor operatively positioned therewith, the sensor being settable in one state when the mounting and the mounting flange are in assembled relationship to each other but being configured to change from the one state if there is a separation of the fastened connection of the mounting and the mounting flange, whereby a change in state from the one state can be used to monitor a separation of the assembled relationship of the mounting and the mounting flange and trigger an alarm condition.

Owner:AMTRON VALVE MONITORING DEVICE

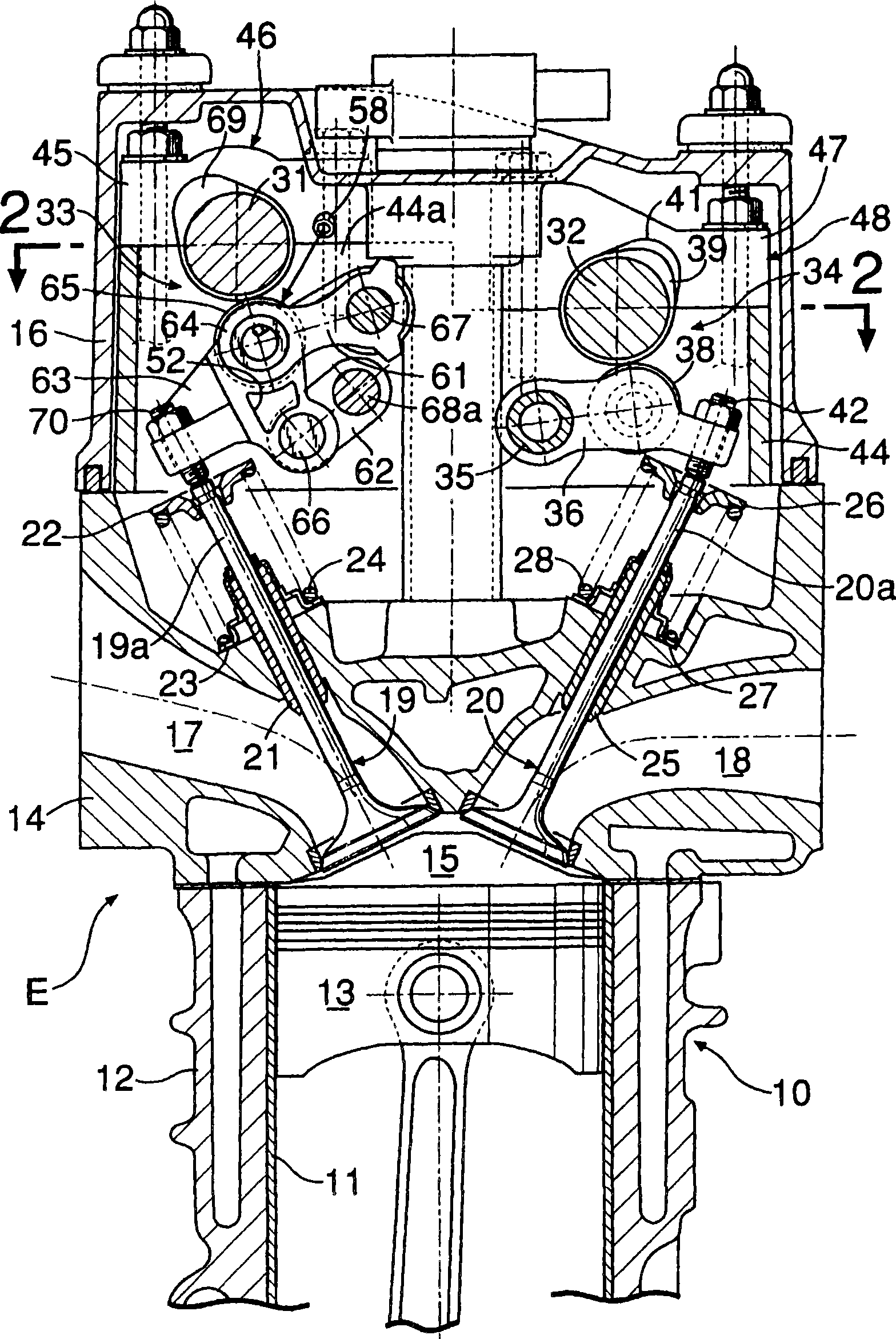

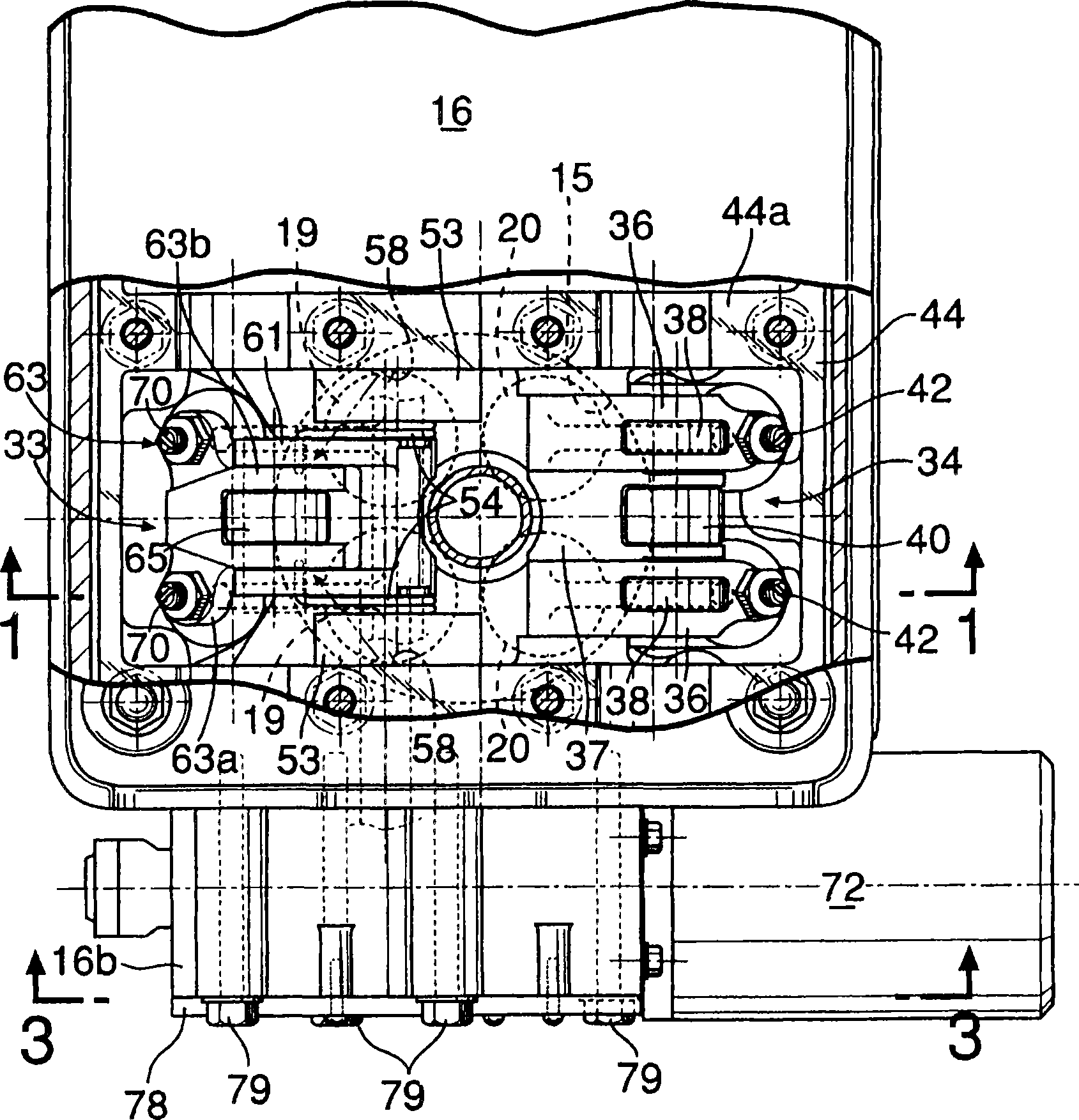

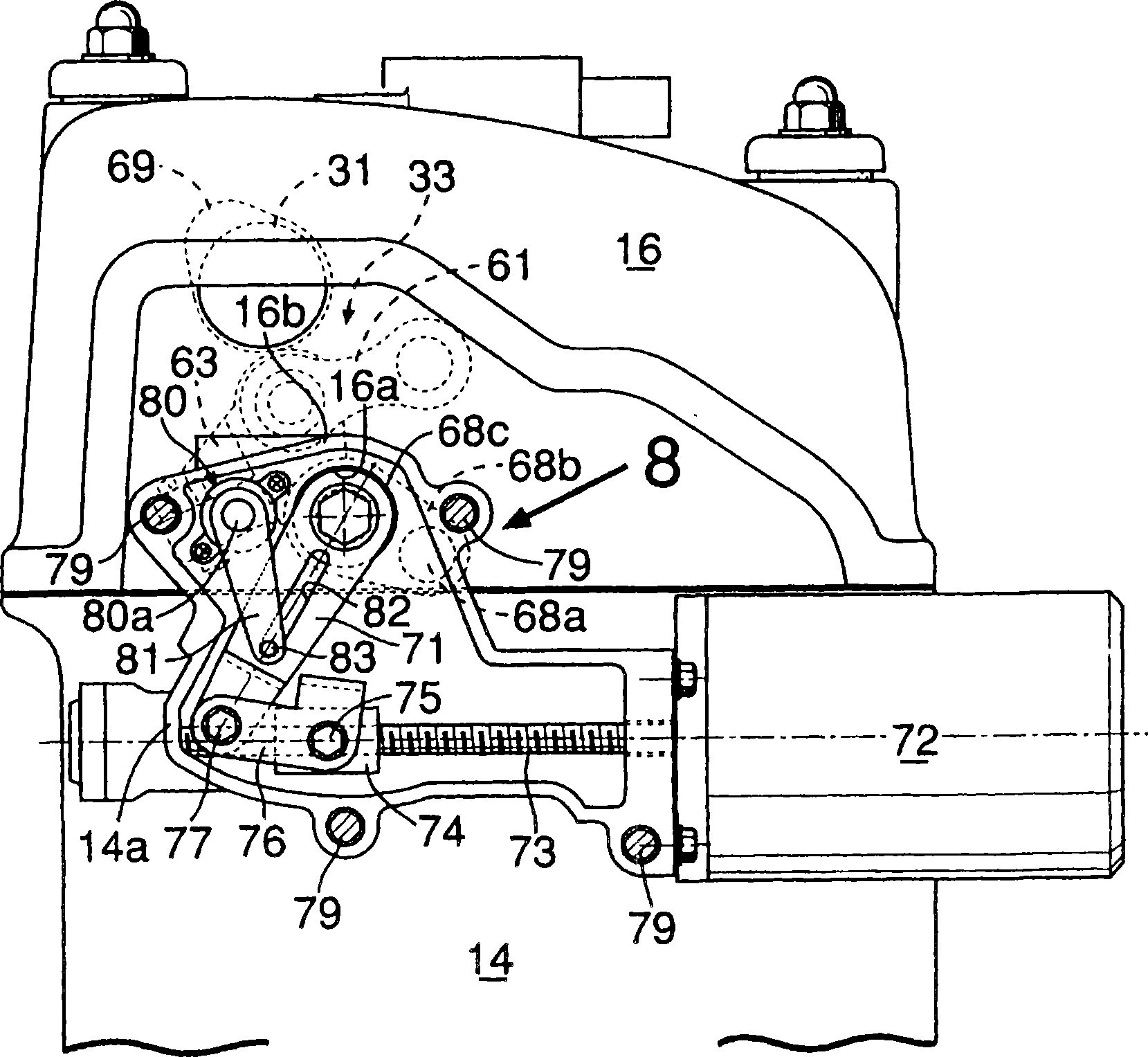

Valve operating device for engine

InactiveCN1910348AHigh control precisionMiniaturizationValve arrangementsMachines/enginesEngineeringCam

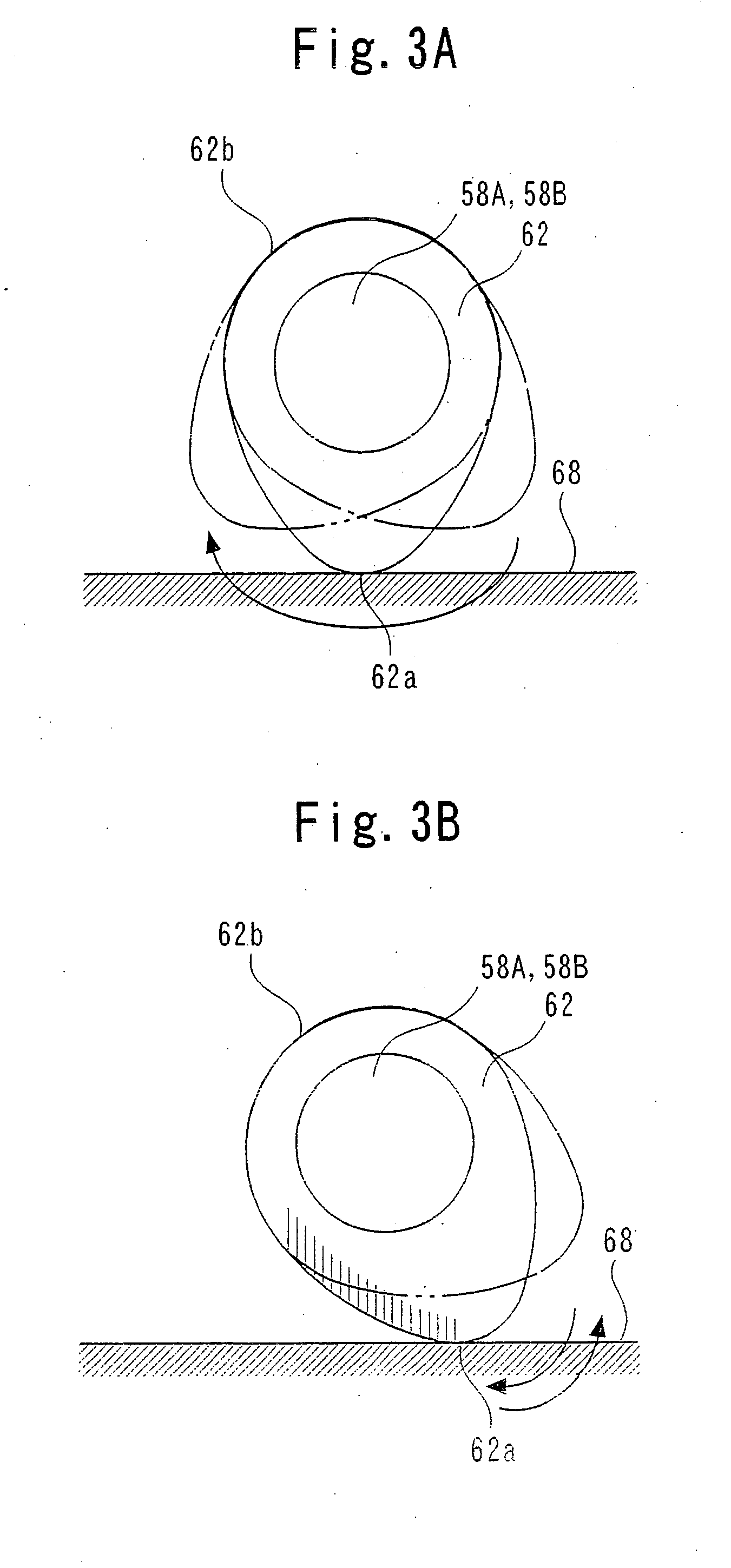

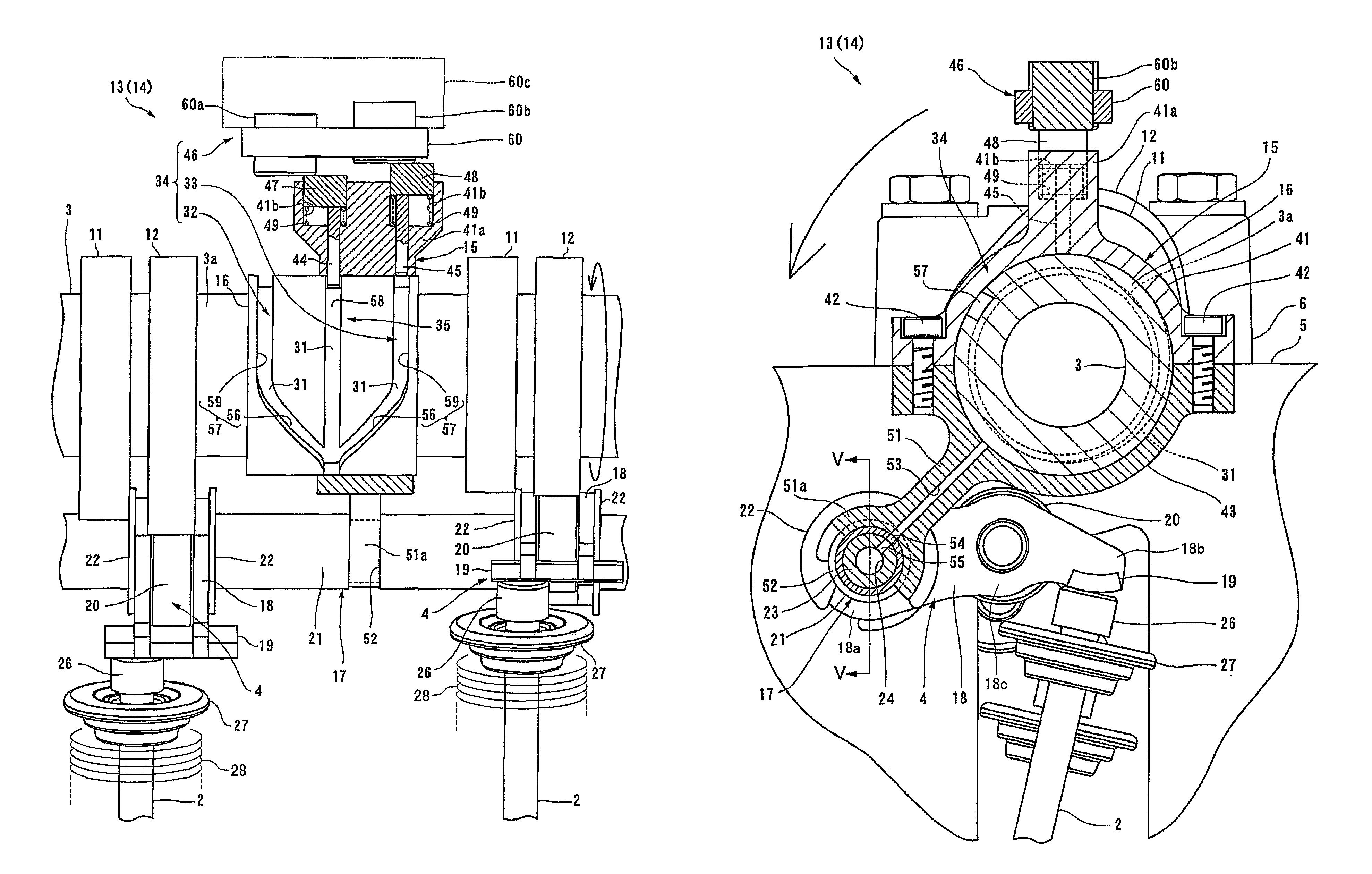

A valve gear of an engine is constituted so that a rocker arm 63 having a cam abutting part 65 abutting on a valve system cam 69 and interlocked and connected so as to apply valve opening directional force to the engine valve 19 energized in the valve closing direction by a valve spring 24, is rotatably connected with one end part of a first link arm 61 rotatably supported by a fixing position of an engine body and the other end part of a second link arm 62 rotatably supported by a displaceable movable shaft 68a; and the rocker arm 63 is energized in the direction for allowing the cam abutting part 65 to abut on the valve system cam 69 by a rocker arm energizing spring 54 separate from the valve spring 24. This ensures follow-up ability of the opening / closing operations and enables a reduction in the size of the system, while allowing the lift amount of the engine valve to vary continuously. It is also possible to improve the accuracy with which the lift amount is controlled when the engine valve is to be slightly opened.

Owner:HONDA MOTOR CO LTD

Valve gear transmission apparatus of engine

A valve gear transmission apparatus of an engine, wherein an operation mechanims for switching a cam part of a cam unit part is provided with: an end operation part arranged on an axial end side of a cam unit part; and an actuator capable of driving the end operation part so that the end operation part is moved between an operation position and a back position. The end operation part is arranged in a manner that: when the end operation part moves to the operation part, the end operation part is engaged with a lift part of the cam at one end side so that the cam unit part moves to the other axial side for switching the cam part which opens and cloths the valve gear. The cam unit part is provided with a reversion reset inclined part which is positioned at a rotating delay side relative to a maximum lift part of a end side cam engaged with the end operation part and is formed in a manner that the more far away from an external peripheral surface of the rotating delay side, the less is the radius, so that the cam unit can be prevented from being switched or the operation part is free from bieng damaged due to reversion of the engine.

Owner:MAZDA MOTOR CORP

Valve gear of internal combustion engine

InactiveUS7513231B2High control precisionInertia torque of the cam shaft is increasedCam-followersValve drivesLinear motionInlet valve

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com