Scroll compressor

A scroll compressor and compression chamber technology, applied in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of reducing the number of scrolls, lack of pressure, residual gas, etc. The effect of improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

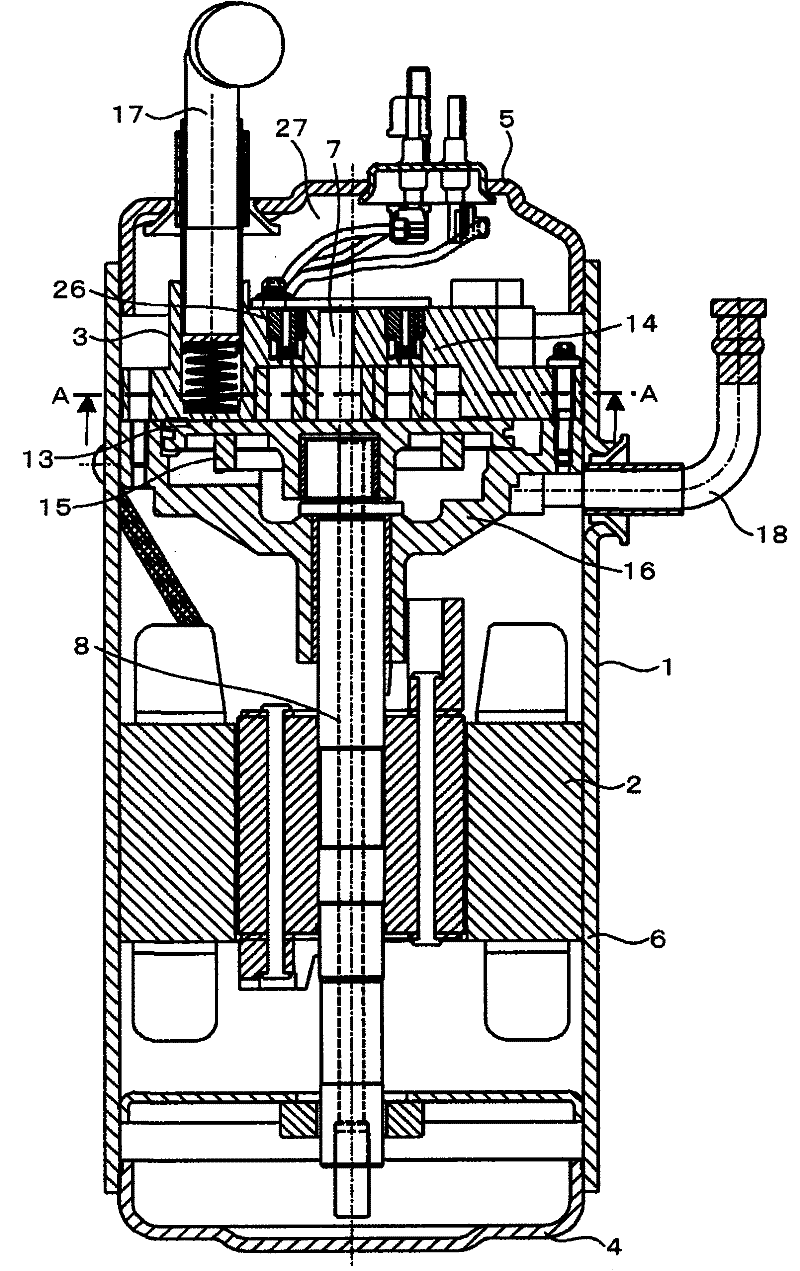

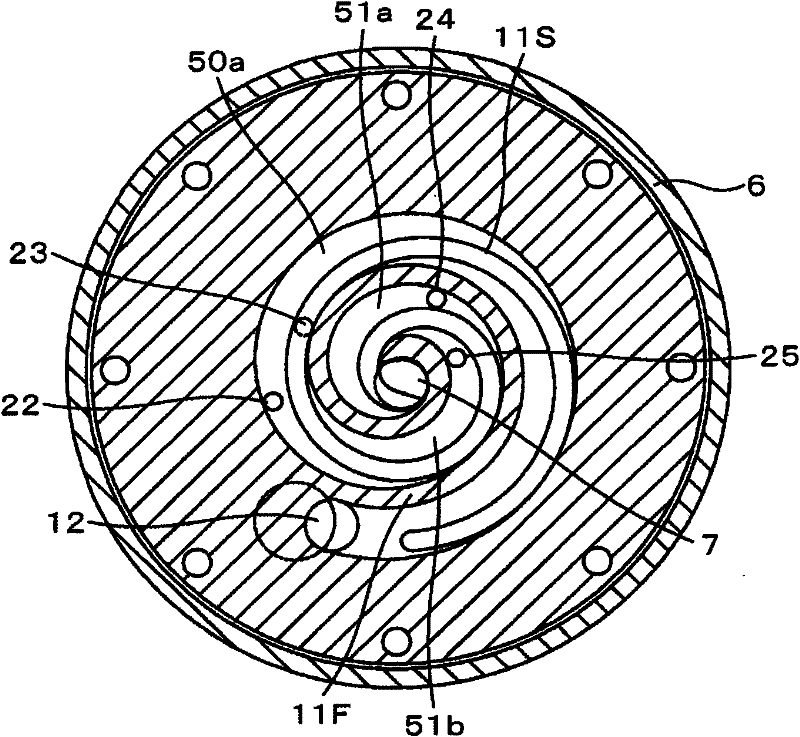

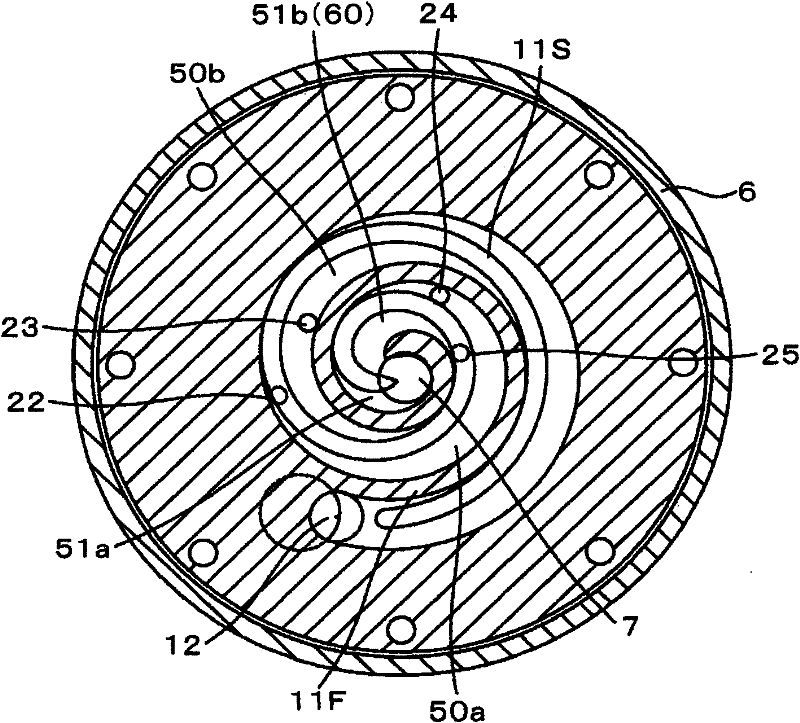

[0059] Below, refer to Figure 1 ~ Figure 3 One embodiment of the present invention will be described.

[0060] figure 1 It is a sectional view of a vertical scroll compressor. As the main structure, a mixed refrigerant of at least one or more than two kinds of fluorinated hydrocarbon-based refrigerants is used as a refrigerant, and a motor 2 and a motor driven by the motor 2 are arranged inside the airtight container 1. The scroll compression mechanism 3 that compresses the mixed refrigerant between the orbiting scroll 13 and the fixed scroll 14 also has an Oldham ring 15 inside the airtight container 1 as an anti-rotation component. The orbiting scroll 13 is supported and guided between the scroll 14 and the fixed member 16 so that the orbiting scroll 13 orbits relative to the fixed scroll 14 without rotating.

[0061] The compression mechanism 3 is formed by meshing a fixed scroll 13 and an orbiting scroll 14 . The orbiting scroll 14 receives the rotation of the motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com