Microfluid valve gear based on electrowetting technology

A microfluidic and valve device technology, applied in the field of ultra-light graphene-based microfluidic valve device, can solve problems such as complex processing technology, achieve excellent electrical conductivity, meet electrowetting working conditions, and realize the effect of dynamic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

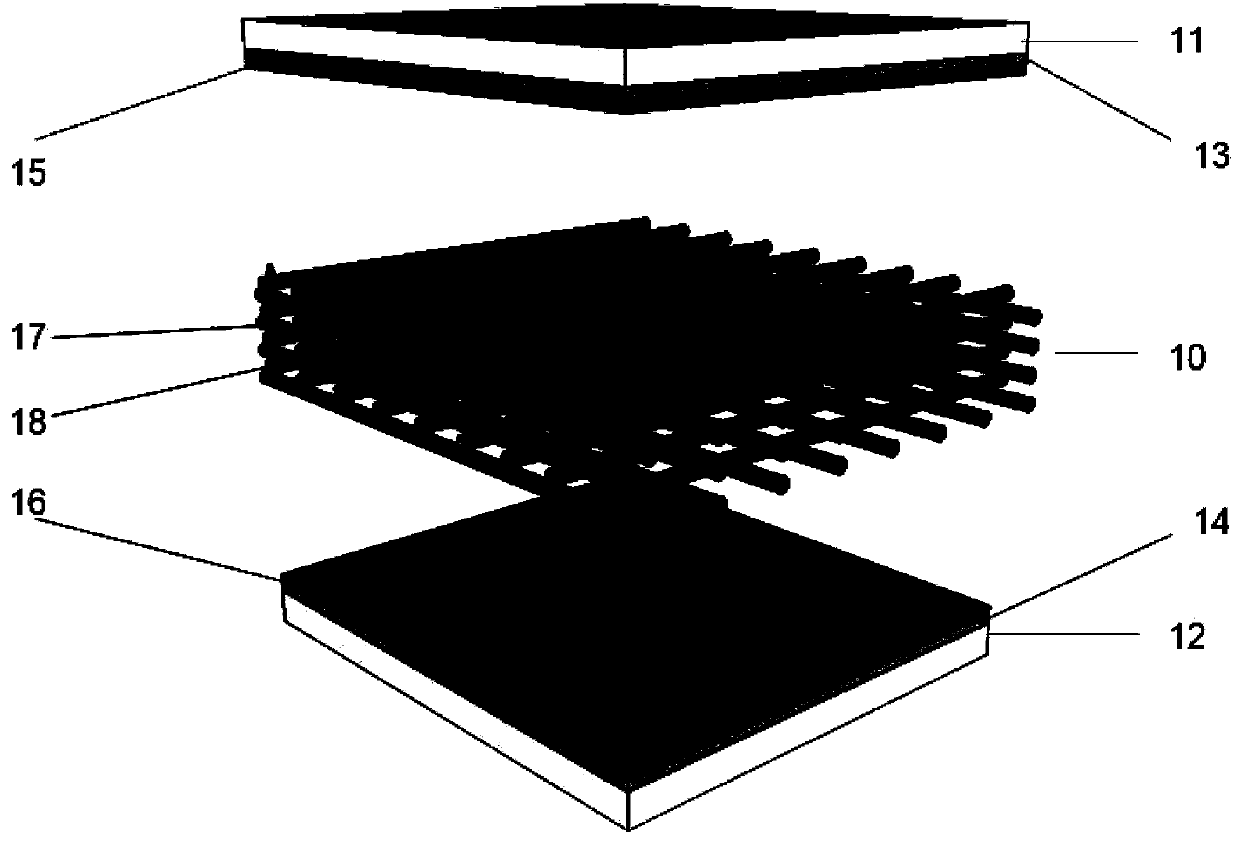

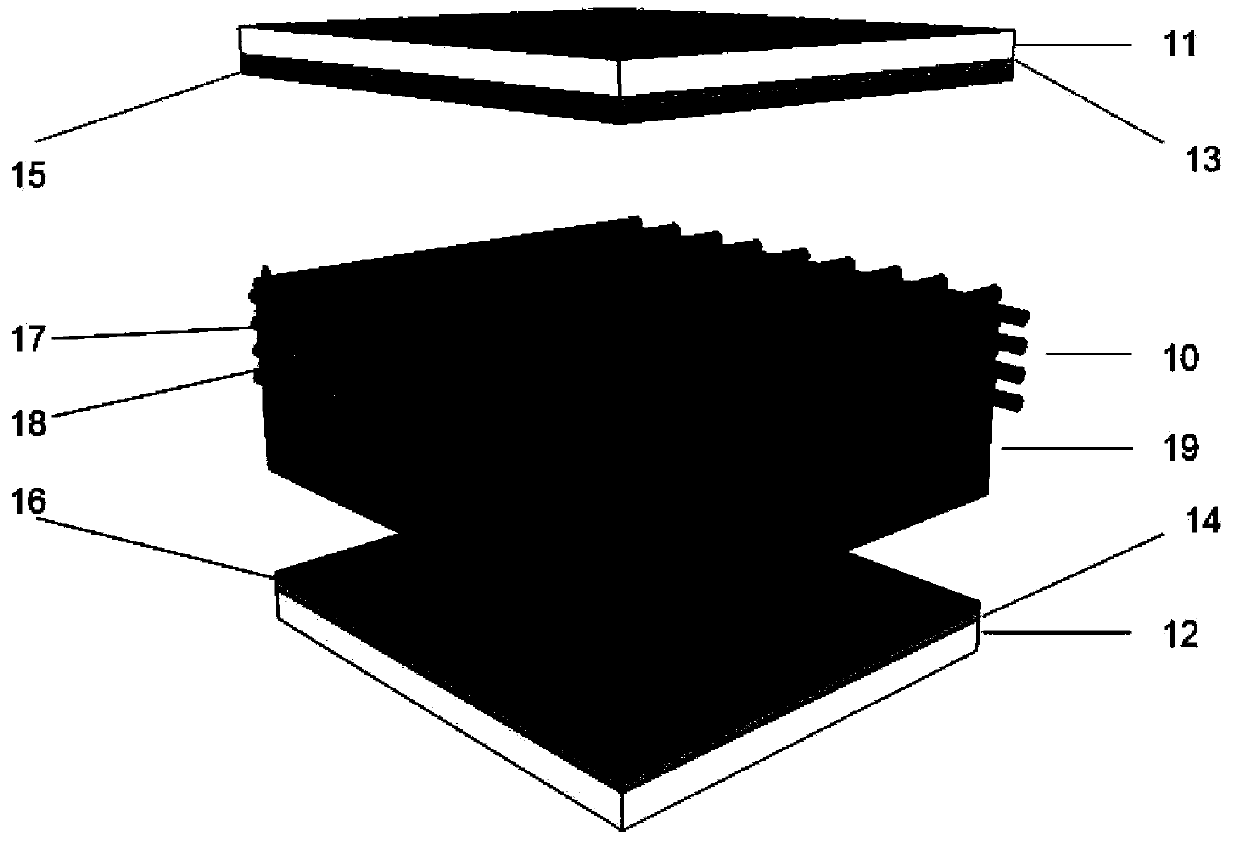

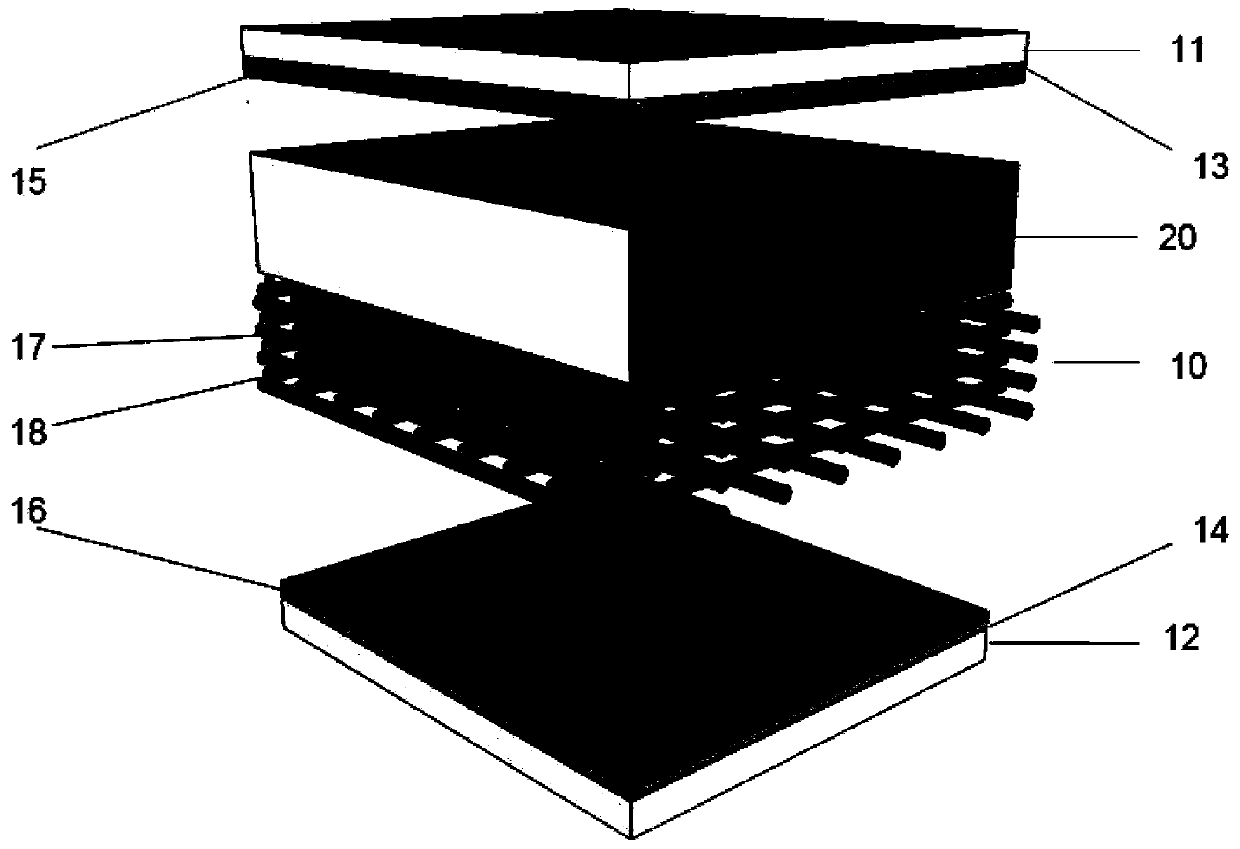

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

[0014] The microfluidic valve device of the present invention comprises a microfluidic interlayer and two upper and lower substrates; the microfluidic interlayer is made of bulk porous material; the outer surface of the microfluidic interlayer and the surface of the porous inner structure are covered with a layer of hydrophobic The medium layer can be made of fluorine-containing polymers, such as polytetrafluoroethylene; the microfluidic barrier has lipophilicity and superhydrophobicity, and the contact angle with oily fluid is less than 90°, and the contact angle with aqueous fluid is greater than 150° The upper and lower substrates are respectively distributed on both sides of the microfluidic interlayer; the upper and lower substrates have a conductive layer on the surface close to the interlayer, and the surface of the conductive layer is evenly covered with a hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com