Valve operating device for engine

A technology of engine valves and transmissions, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of reduced valve lift control accuracy, achieve good followability, reduce installation space, and realize miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

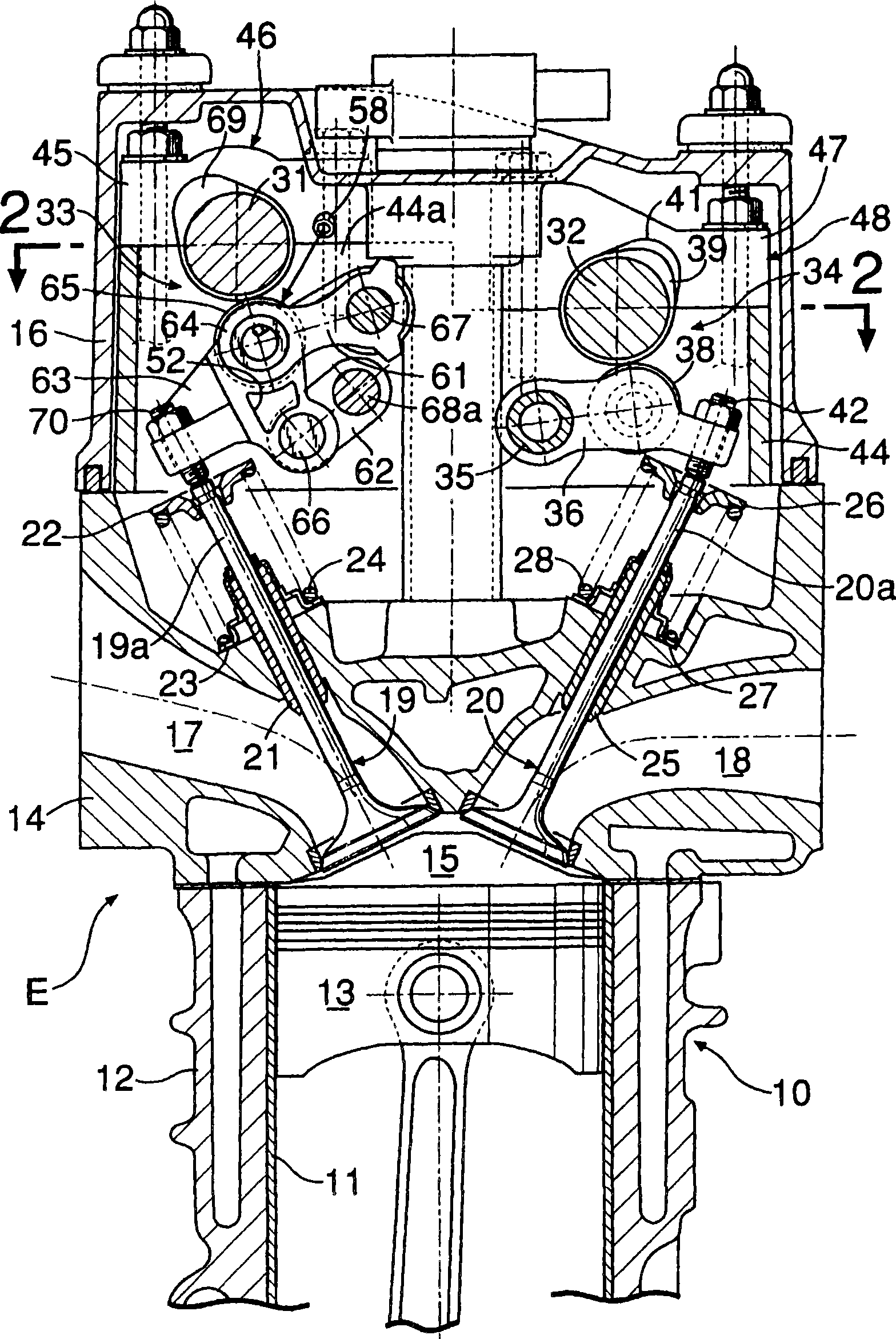

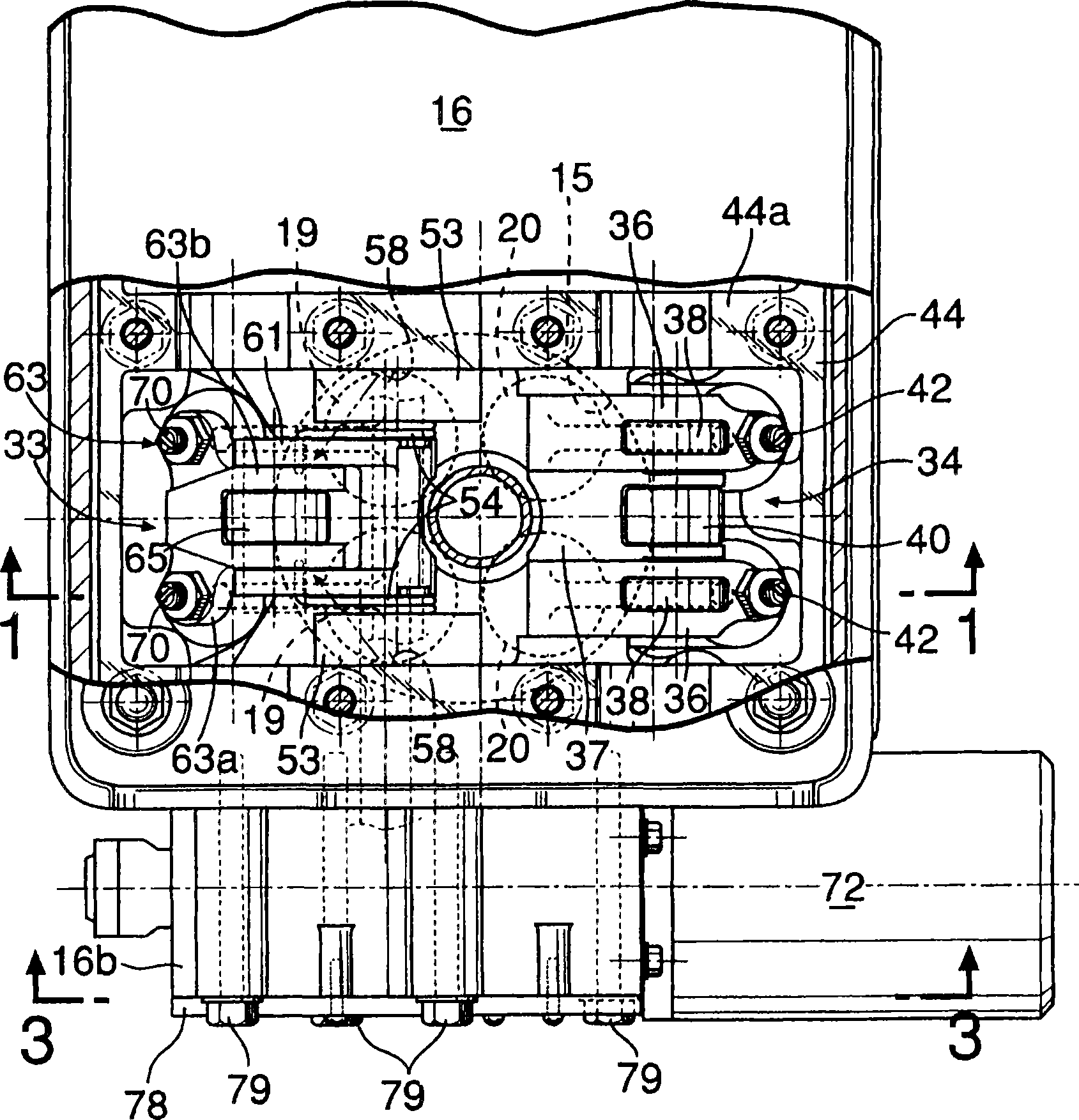

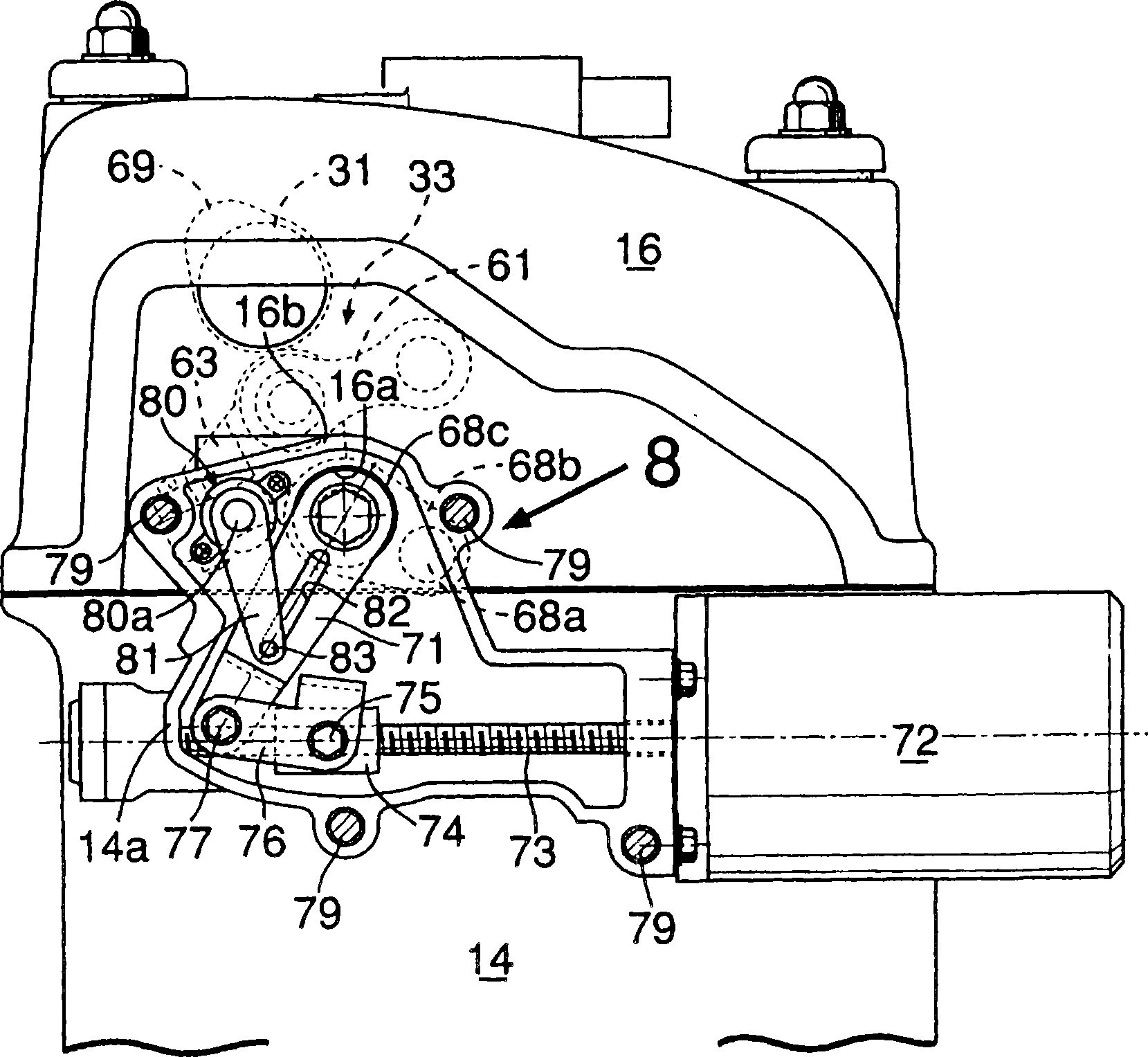

[0040] Figure 1 to Figure 12 shows an embodiment of the present invention. first in figure 1 Among them, the engine body 10 of the in-line multi-cylinder engine E has: a cylinder block 12, which is provided with a cylinder bore 11 inside; a cylinder head 14, which is joined with the top surface of the cylinder block 12; a cylinder head cover 16, which is connected to the cylinder head The top surface of 14 is joined, and in each cylinder bore 11 ..., piston 13 ... is slidably fitted, and the combustion chamber 15 ... facing the top of each piston 13 ... is formed between the cylinder block 12 and the cylinder head 14 .

[0041] On cylinder head 14, be provided with intake port 17 ... and exhaust port 18 ... that can communicate with each combustion chamber 15 ..., and each intake port 17 ... is respectively opened by a pair of intake valves 19 ... as engine valves. Each exhaust port 18 is opened and closed by a pair of exhaust valves 20... respectively. The push rod 19a of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com