Valve gear transmission apparatus of engine

A transmission and engine technology, applied in the direction of engine components, valve driving devices, machines/engines, etc., can solve problems such as engine reversal, damage, and cams are accidentally switched, and achieve the effect of preventing damage to operating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

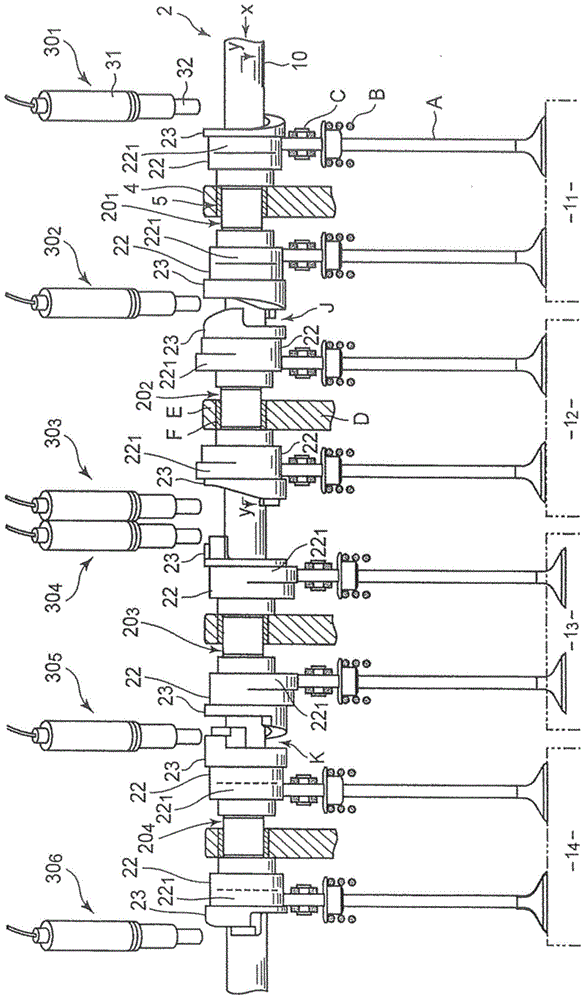

[0032] Hereinafter, embodiments of the present invention will be described by taking a valve train of a four-cylinder, four-valve DOHC engine as an example.

[0033] [Outline structure of valve train]

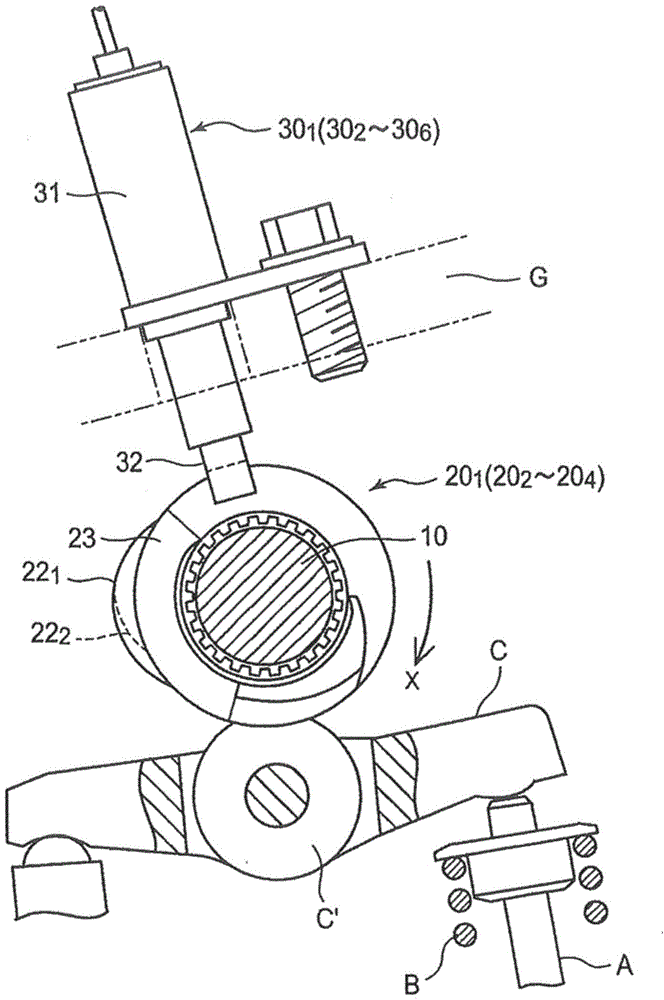

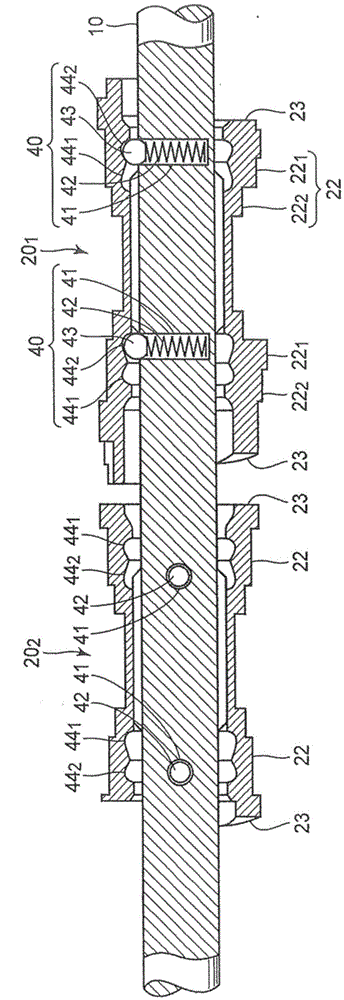

[0034] figure 1 The configuration of the exhaust side of the valve train according to the present embodiment is shown. On the unshown cylinder head, for the first to fourth cylinders 1 1 ~1 4 Each has two exhaust valves A...A in total. The valve transmission device used to drive these exhaust valves A...A includes: return spring B...B, which exerts a force in the closing direction on the exhaust valve A...A; camshaft 2, which is arranged on the upper part of the cylinder head, The arms C...C overcome the force of the return springs B...B and drive the exhaust valves A...A in the opening direction; the operating mechanism 30 is arranged above the camshaft 2 .

[0035] The camshaft 2 is rotatably supported by the bearings F...F of the cylinders 1 on the cylinder head, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com