Scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve the problems of pressure deviation of relief valve, difficult relief valve, change of spring pressing force, etc., so as to suppress deformation or impact sound and improve performance and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

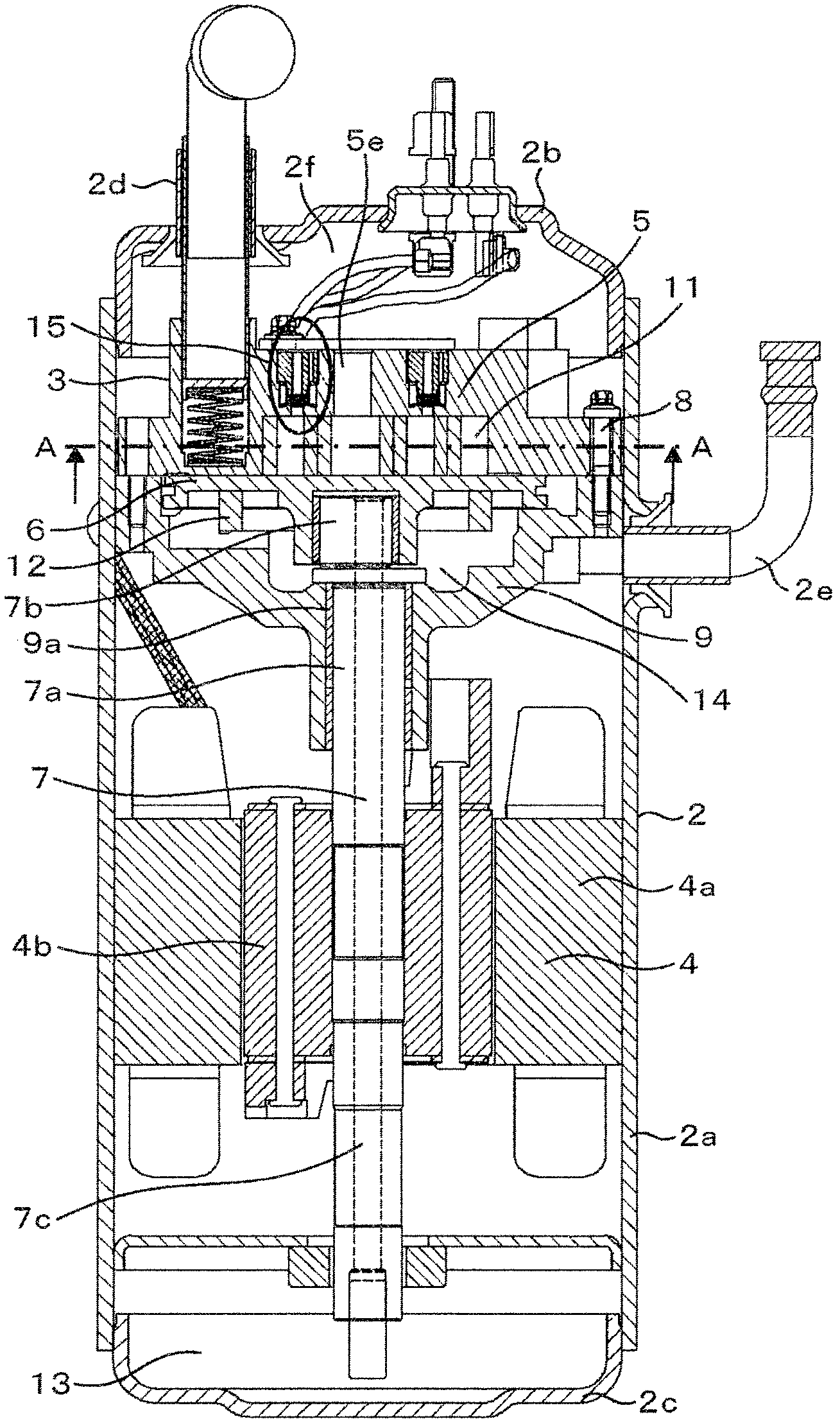

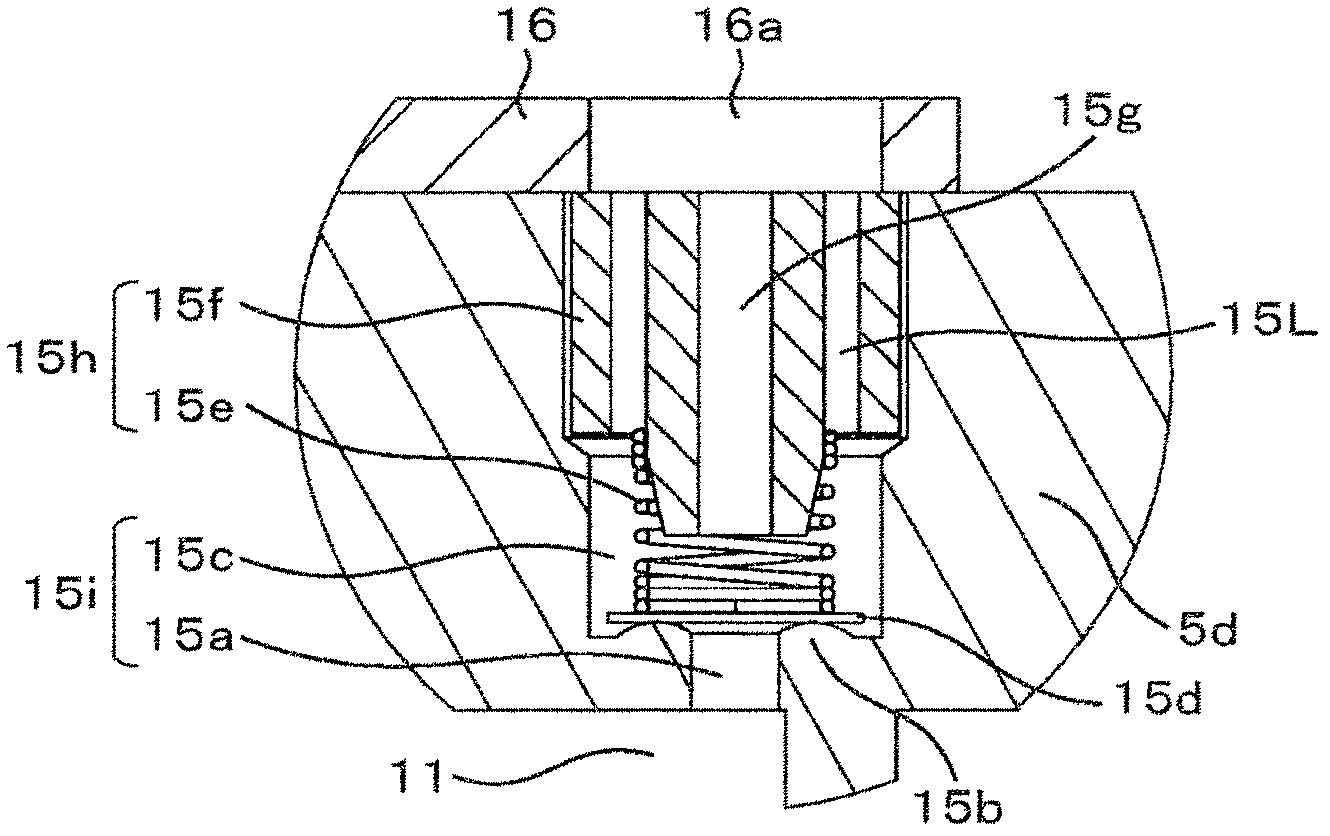

[0072] Below, use Figure 1 ~ Figure 7 The embodiments of the present invention will be described. figure 1 It is a cross-sectional view of the vertical scroll compressor 1. Inside the airtight container 2 of the scroll compressor 1, there are: an electric motor 4; a scroll compression mechanism 3, which is configured by meshing a fixed scroll 5 with an orbiting scroll 6 driven by the electric motor 4, and compresses the refrigerant The European-style ring 12 as a rotation restricting member supports and guides the orbiting scroll 6 between the fixed scroll 5 and the frame 9 so that the orbiting motion relative to the fixed scroll 5 does not rotate.

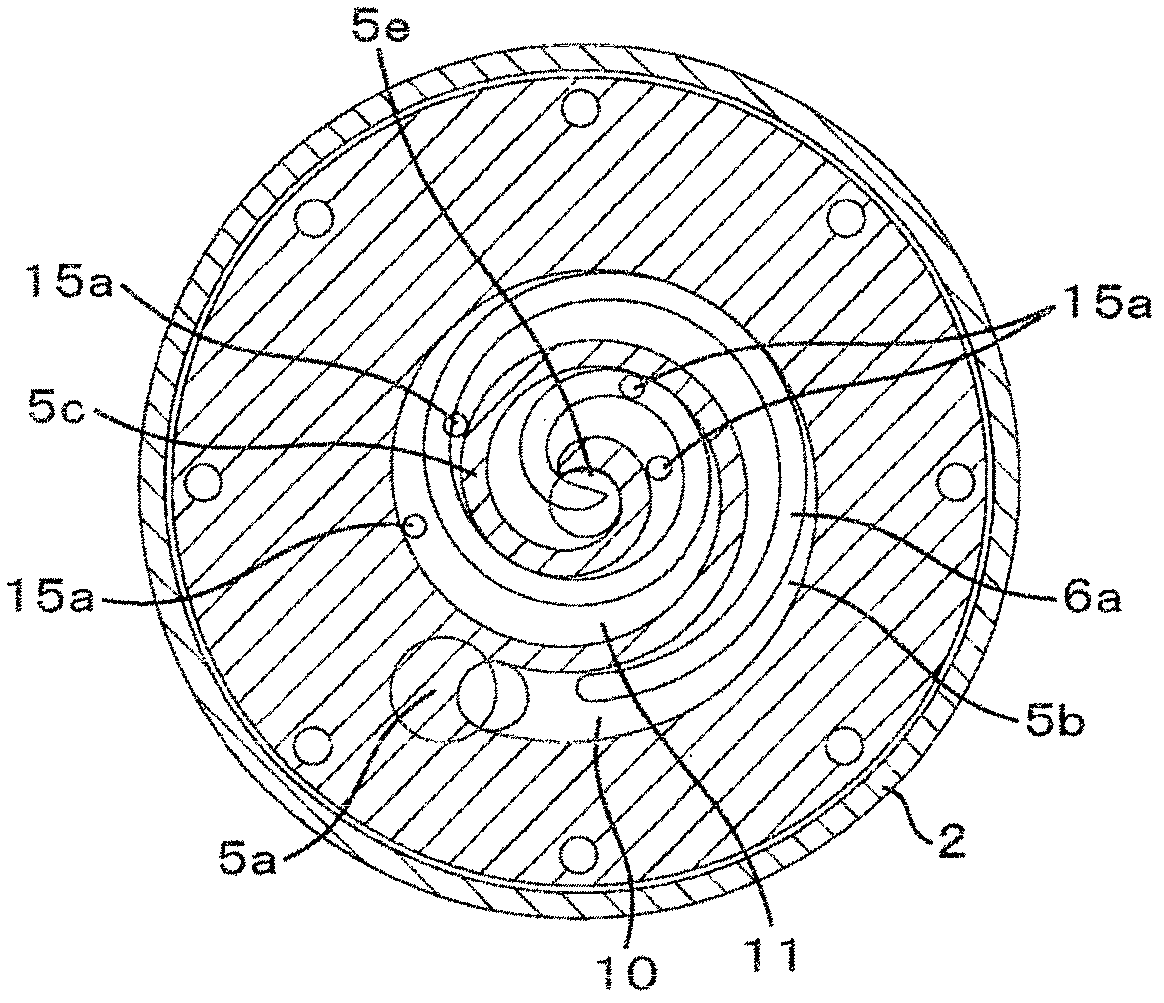

[0073] figure 2 Yes figure 1 A cross-sectional view of the compression mechanism along the line A-A. The orbiting scroll 6 receives the rotation of the electric motor 4 via the crankshaft 7 and is driven to orbit while being restricted by the Euro ring 12. The refrigerant gas sucked in from the suction port 5a is compressed and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com