Patents

Literature

70results about How to "Avoid throttling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

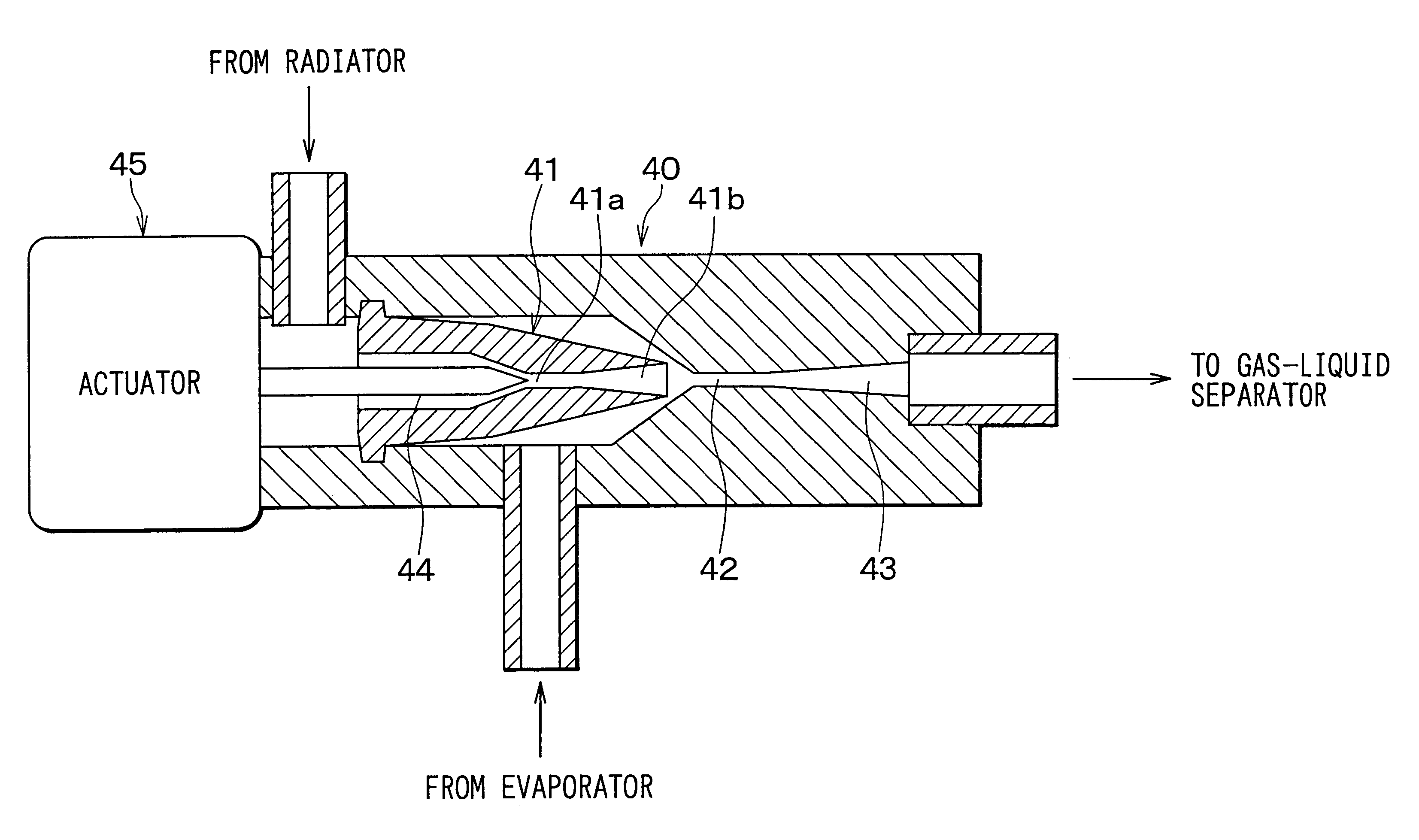

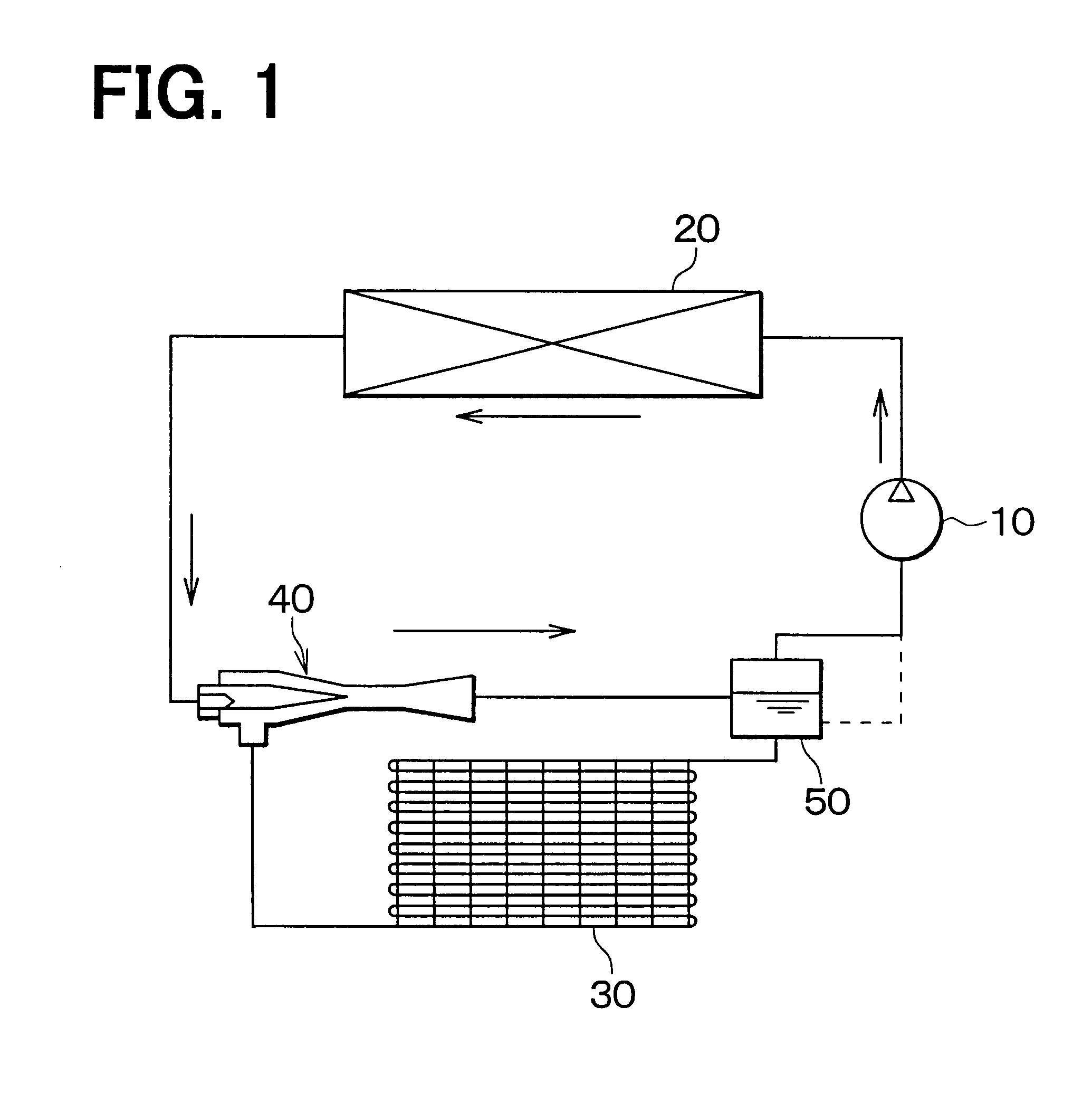

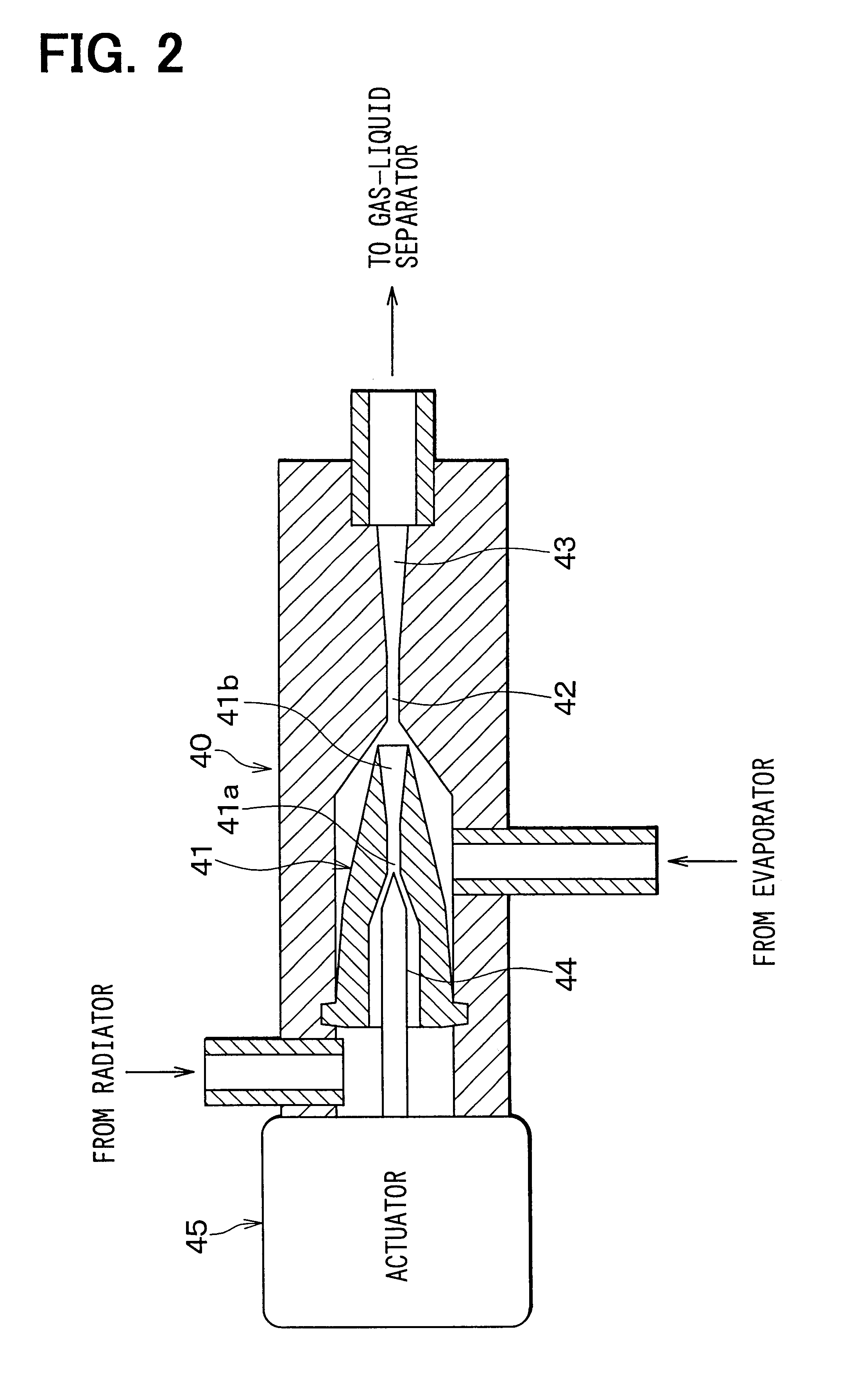

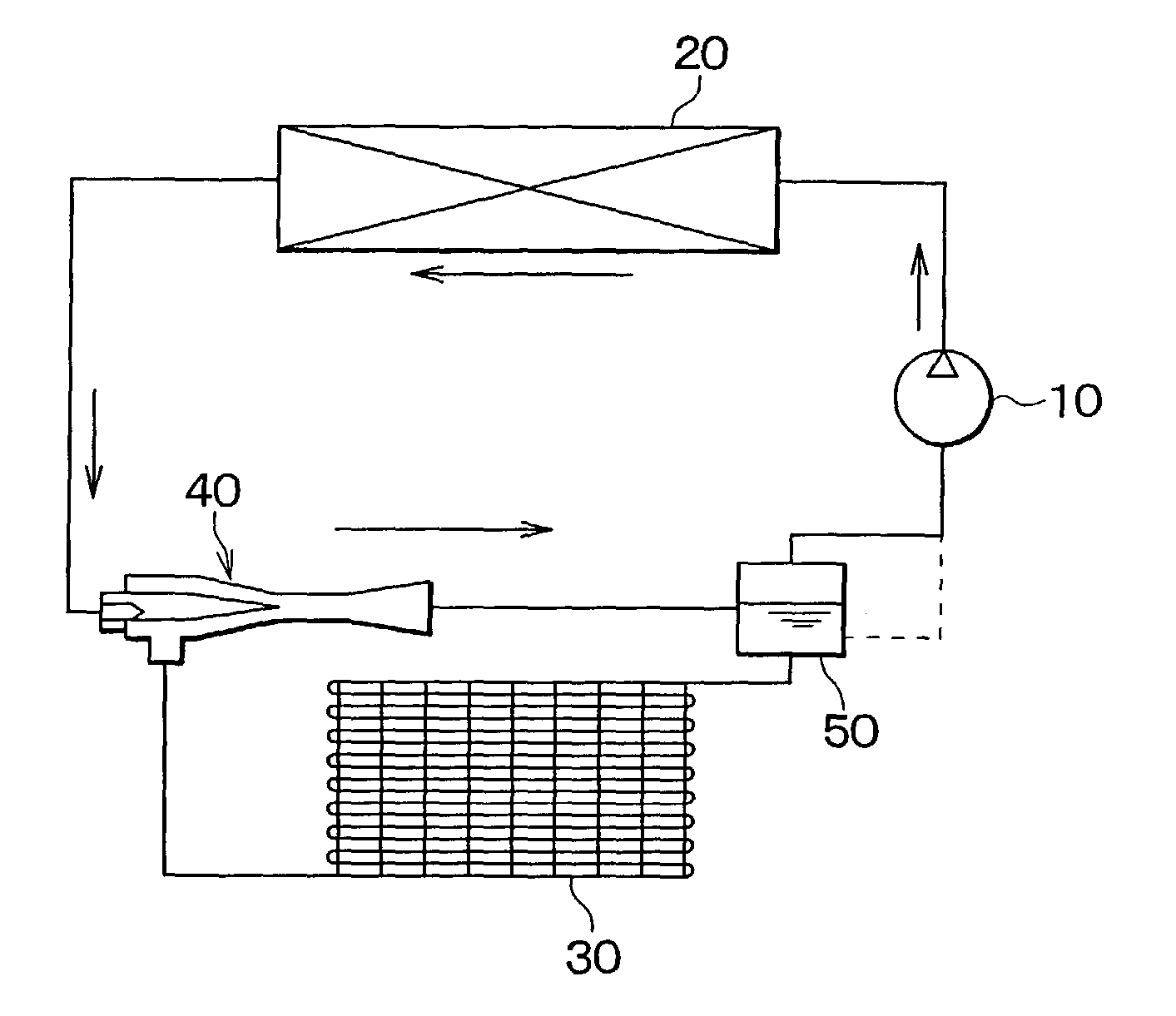

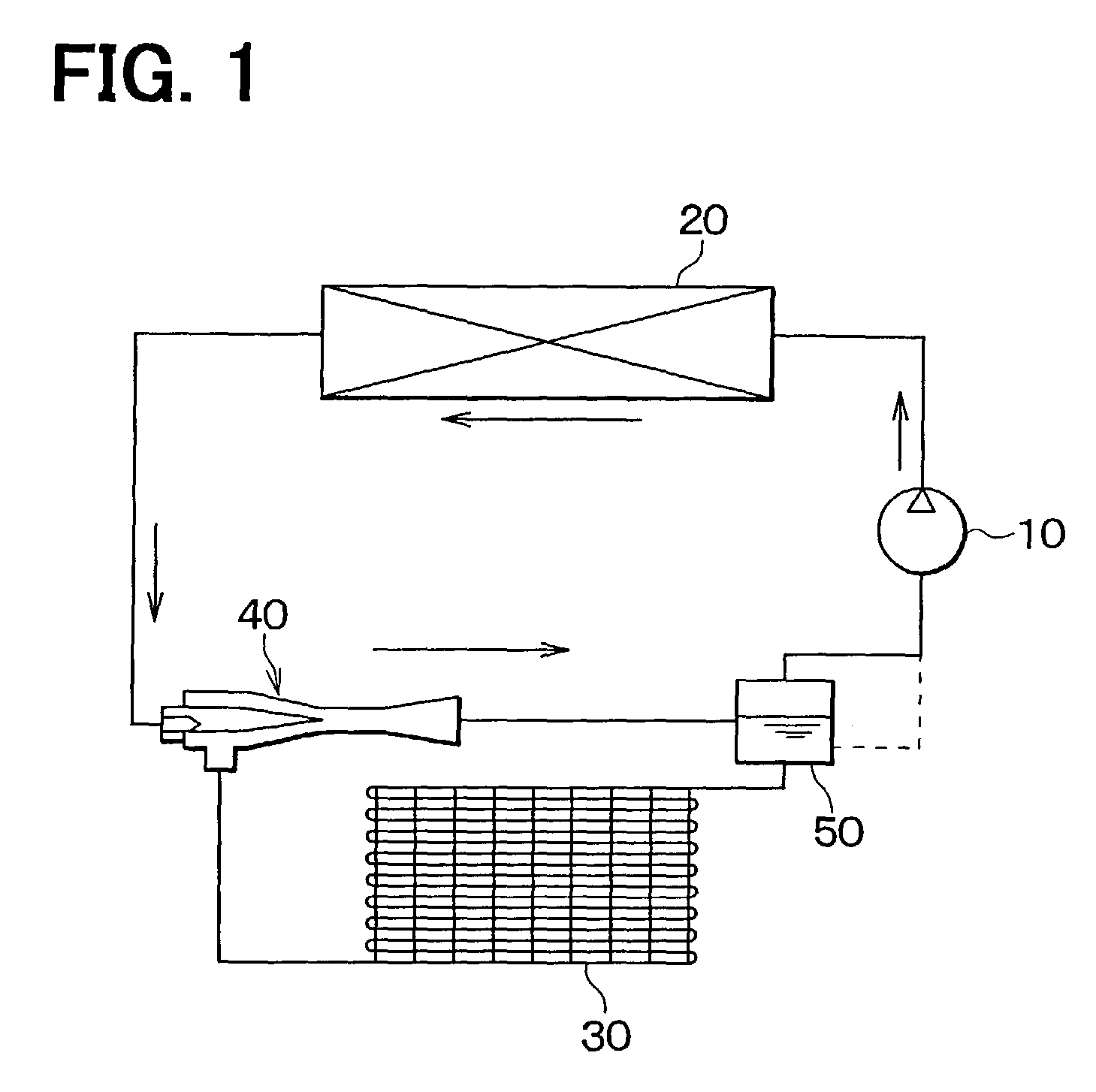

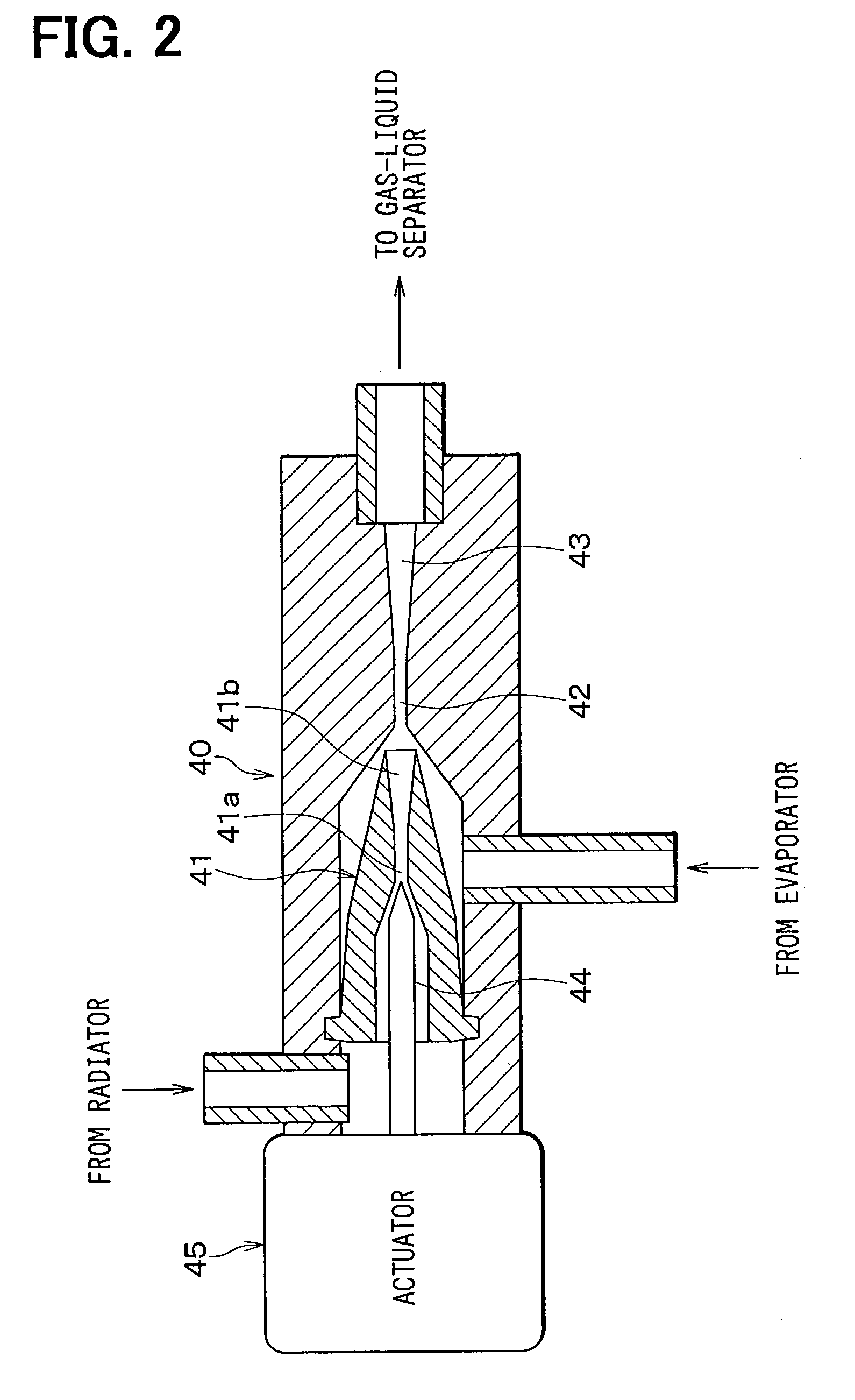

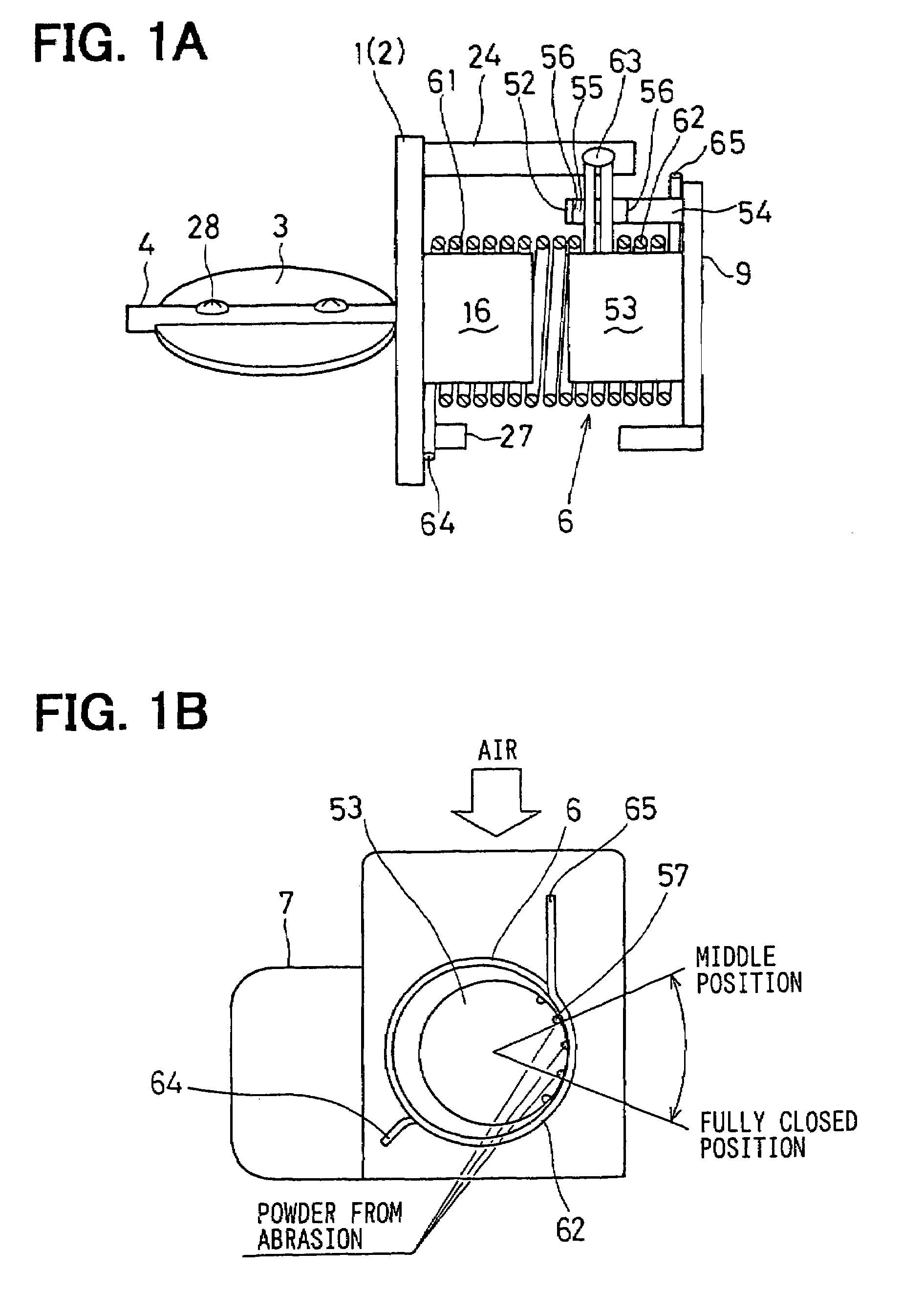

Ejector decompression device with throttle controllable nozzle

InactiveUS6729158B2Reducing ejector efficiencyReduce the total massCompression machines with non-reversible cycleJet pumpsPhase stateEngineering

An ejector for a refrigerant cycle includes a nozzle having therein a refrigerant passage, and a needle valve provided in the refrigerant passage of the nozzle upstream from a throat portion of the nozzle. The needle valve is disposed in the nozzle to define therebetween a throttle portion that is positioned upstream from the throat portion. A top end portion of the needle valve and an inner wall of the nozzle are formed, so that refrigerant is decompressed to a gas-liquid two-phase state at upstream of the throat portion. Accordingly, a throttle degree of the nozzle can be variably controlled while ejector efficiency is not deteriorated.

Owner:DENSO CORP

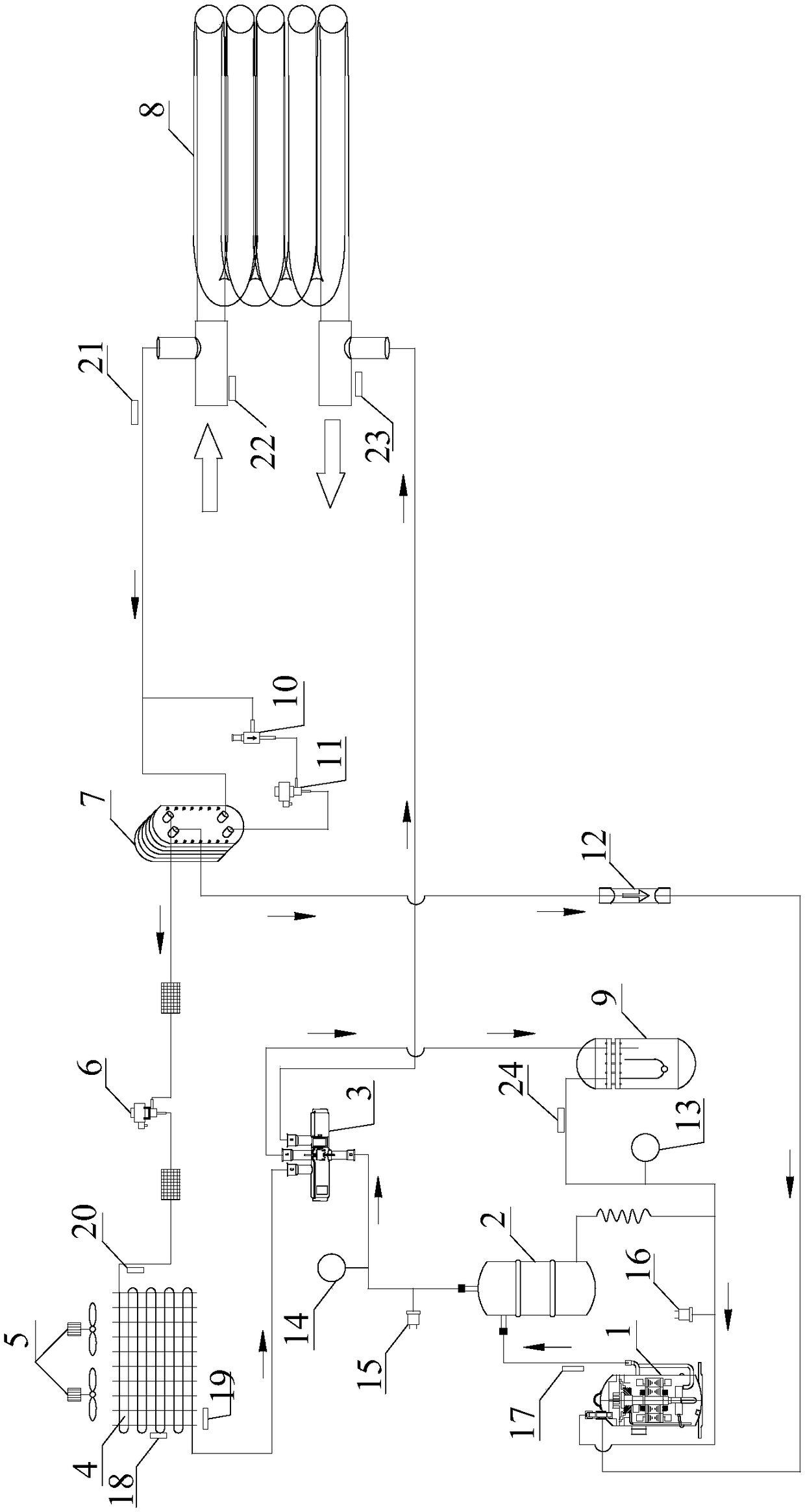

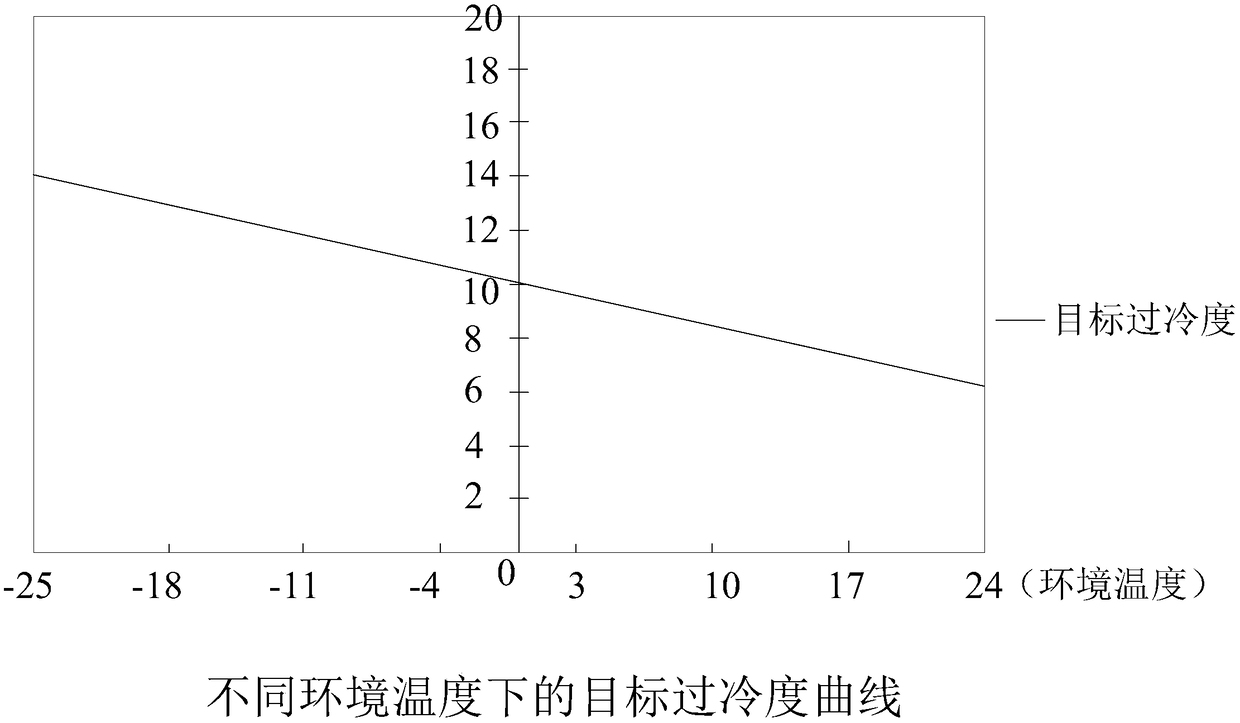

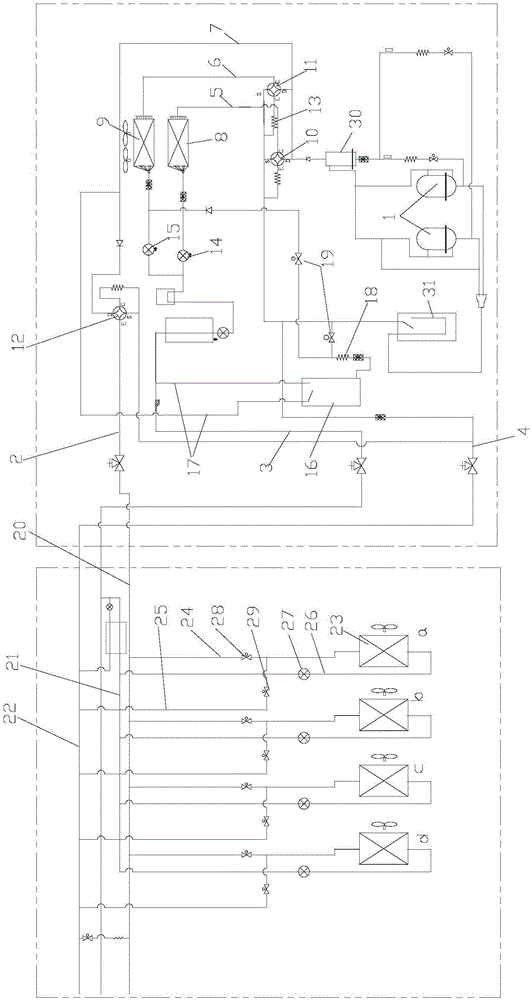

Gas supplementing and enthalpy increasing control method of low-temperature type direct-current variable-frequency heat pump system

ActiveCN109282545AAssurance controlIncrease refrigerant mass flowRefrigeration safety arrangementElectricityElectromagnetic valve

The invention discloses a gas supplementing and enthalpy increasing control method of a low-temperature type direct-current variable-frequency heat pump system. The key of the method is as follows, anexhaust temperature of the system is detected, when the exhaust temperature is larger than or equal to 70 DEG C, and when an exhaust superheat degree is larger than or equal to 25 DEG C, an enthalpyspraying electromagnetic valve (10) is electrified and started, and an enthalpy spraying auxiliary path is circulated; an enthalpy spraying electronic expansion valve (11) is started, an initial opening degree is 100 PLS and kept for 3 minutes, then adjusting is carried out according to an actual supercooling degree, when the actual supercooling degree is larger than or equal to a target supercooling degree, the opening valve control of the enthalpy spraying electronic expansion valve (11) is carried out; and when the actual supercooling degree is less than the target supercooling degree, theclosing valve control of the enthalpy spraying electronic expansion valve (11) is carried out, when the exhaust superheat degree is less than 20 DEG C, the enthalpy spraying electronic expansion valve(11) is closed, the enthalpy-spraying auxiliary path is not circulated, and the safety and reliability of a compressor are guaranteed. According to the gas supplementing and enthalpy increasing control method of the low-temperature direct-current variable-frequency heat pump system, the problems that in an actual application project, the heating performance of the variable-frequency heat pump system is attenuated and the system reliability is poor in a low-temperature use environment are solved.

Owner:宁波市海智普智能科技有限公司

Ejector decompression device with throttle controllable nozzle

InactiveUS20030145613A1Reduce the total massReduce the cross-sectional areaCompression machines with non-reversible cycleJet pumpsPhase stateRefrigerant

An ejector for a refrigerant cycle includes a nozzle having therein a refrigerant passage, and a needle valve provided in the refrigerant passage of the nozzle upstream from a throat portion of the nozzle. The needle valve is disposed in the nozzle to define therebetween a throttle portion that is positioned upstream from the throat portion. A top end portion of the needle valve and an inner wall of the nozzle are formed, so that refrigerant is decompressed to a gas-liquid two-phase state at upstream of the throat portion. Accordingly, a throttle degree of the nozzle can be variably controlled while ejector efficiency is not deteriorated.

Owner:DENSO CORP

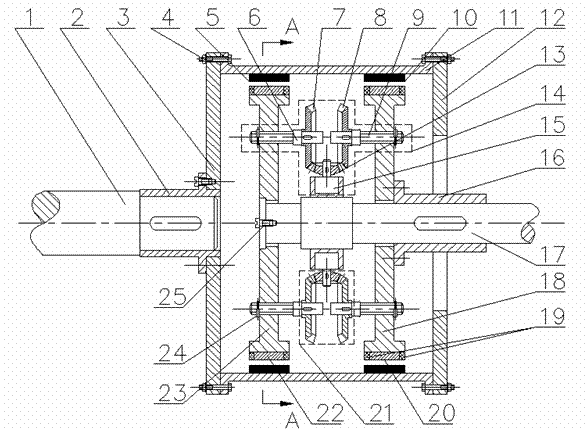

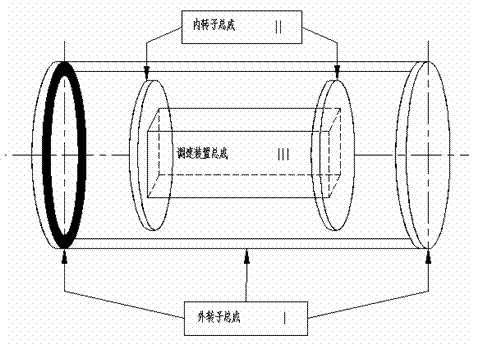

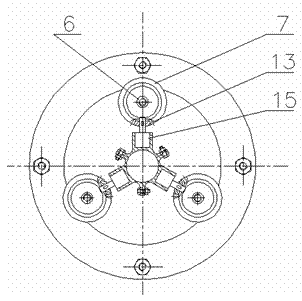

Meshing-area-adjusting type synchronous magnetic torque converter and speed regulation method thereof

InactiveCN102931806AImprove transfer efficiencyAvoid centeringDynamo-electric gearsDrive shaftElectric machine

The invention discloses a meshing-area-adjusting type synchronous magnetic torque converter and belongs to the technical filed of transmission in mechanical engineering. The torque converter comprises an outer rotor assembly, an inner rotor assembly and a speed regulation device assembly, wherein single thread screws are driven to rotate through controlling of rotation of a micro electrical motor and through a reducing mechanism, a thread ends of the single thread screws are in threaded connection with an inner rotator body in the inner rotor assembly, screwing directions of threads at two ends of two single thread screws in the same group are the same, the rotating directions are opposite, and when a single thread screws rotates around an axis, a left inner rotor body and a right inner rotor body can move in and move out along a driven shaft, so that the meshing area between a left permanent magnet and a left copper bar and the meshing area between the right permanent magnet and a right copper bar are changed simultaneously, the air-gap field strength is regulated, the output of different rotating speeds and torques is achieved; and each group of speed regulation mechanisms are distributed and installed at an interval of 120 degrees axially and evenly, so that a balanced state of the whole device during operation is guaranteed, and the reliability and the stability of the operation of the device are guaranteed.

Owner:JIANGSU UNIV

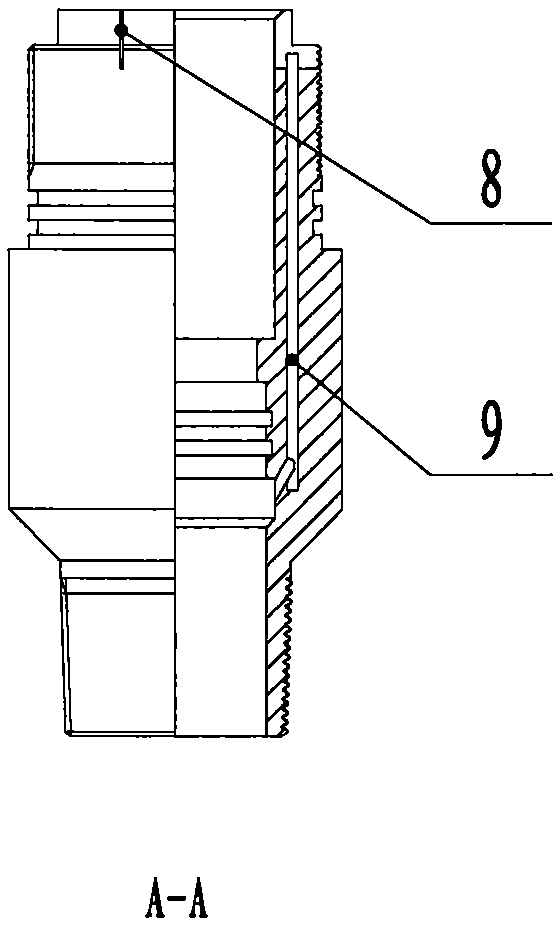

Heat recovery external unit system and air conditioner system

PendingCN107178833AAvoid throttlingReduce heat transfer areaEnergy recovery in ventilation and heatingMechanical apparatusOutdoor temperatureEngineering

The invention discloses a heat recovery external unit system and an air conditioner system. The heat recovery external unit system comprises a compressor (1), a high-pressure air pipe (2), a first branch (5), a second branch (6) and a third branch (7); the first branch (5), the second branch (6) and the third branch (7) are arranged in parallel; a first outdoor heat exchanger (8) is arranged on the first branch (5); a second outdoor heat exchanger (9) is arranged on the second branch (6); and when the air conditioner system is positioned in a low temperature refrigeration mode where the outdoor temperature is lower than a first preset temperature, or is positioned in a high temperature heating mode where the outdoor environment temperature is higher than a second preset temperature, one of the first branch (5) and the second branch (6) is connected and the other one is disconnected, and the third branch (7) communicates with the high-pressure air pipe (2), wherein the first preset temperature is lower than the second preset temperature. According to the heat recovery external unit system, a situation that rapid refrigeration is realized in a low temperature environment or rapid heating is realized in a high temperature environment can be ensured, and the use comfort of an air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

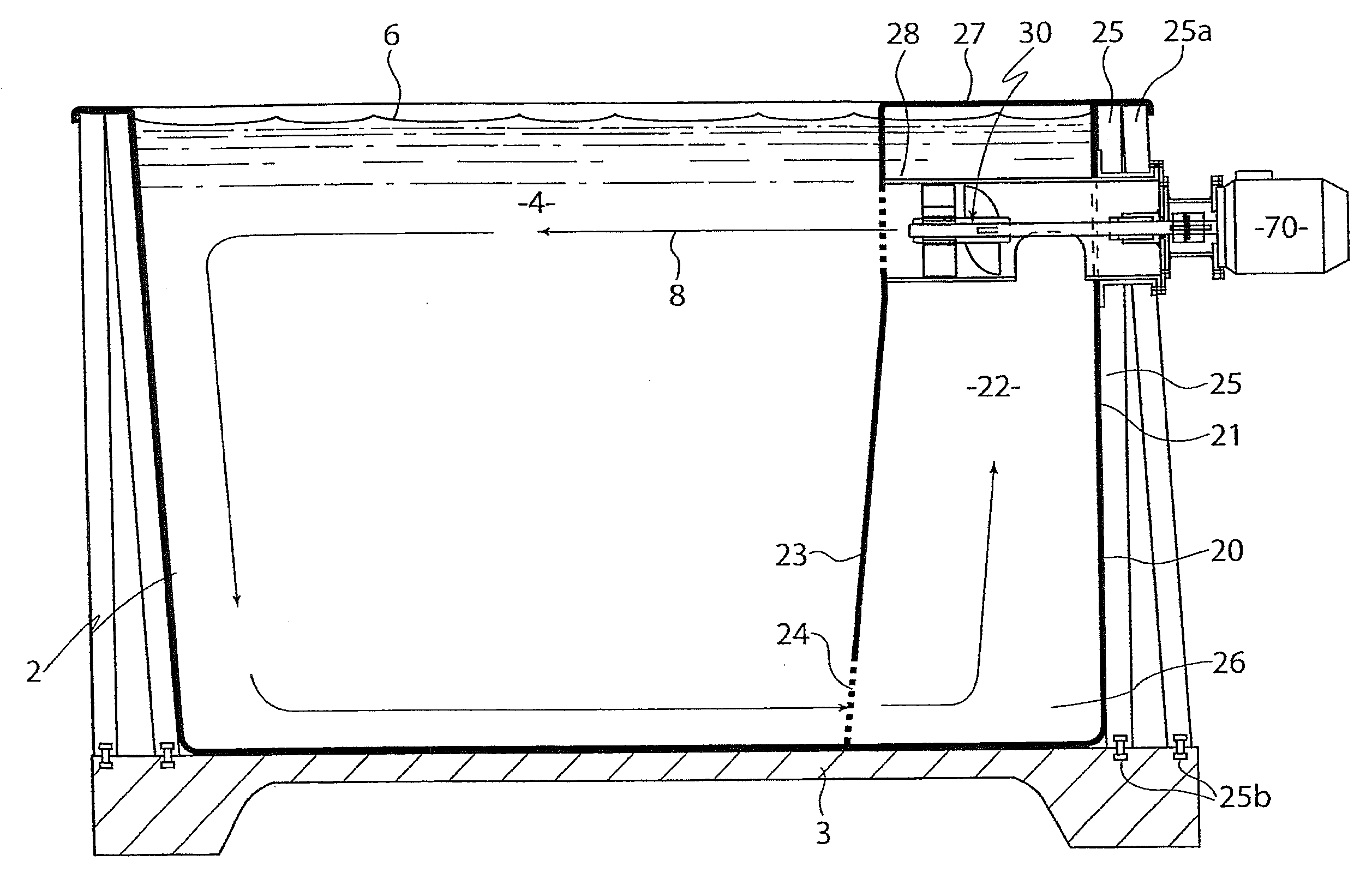

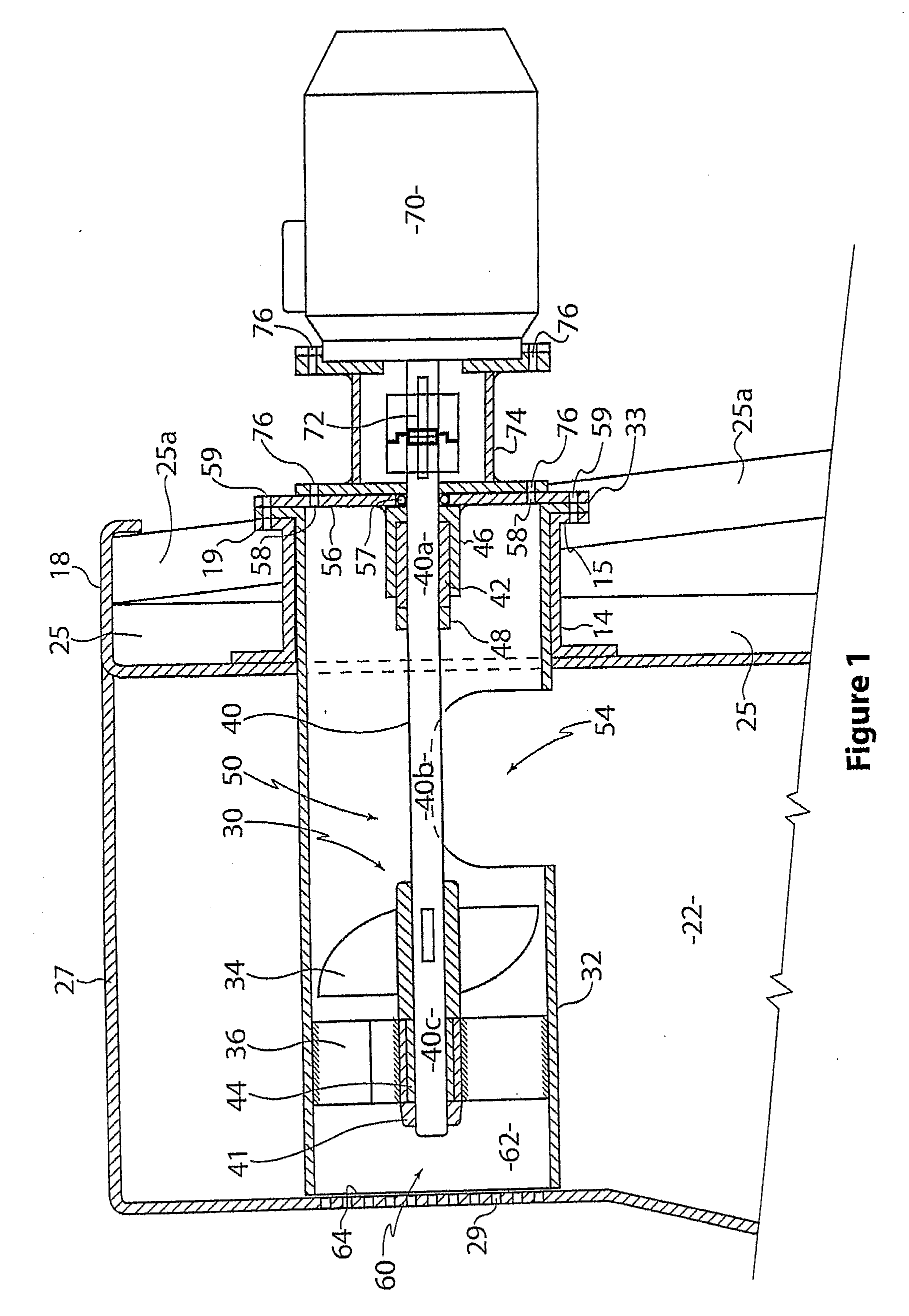

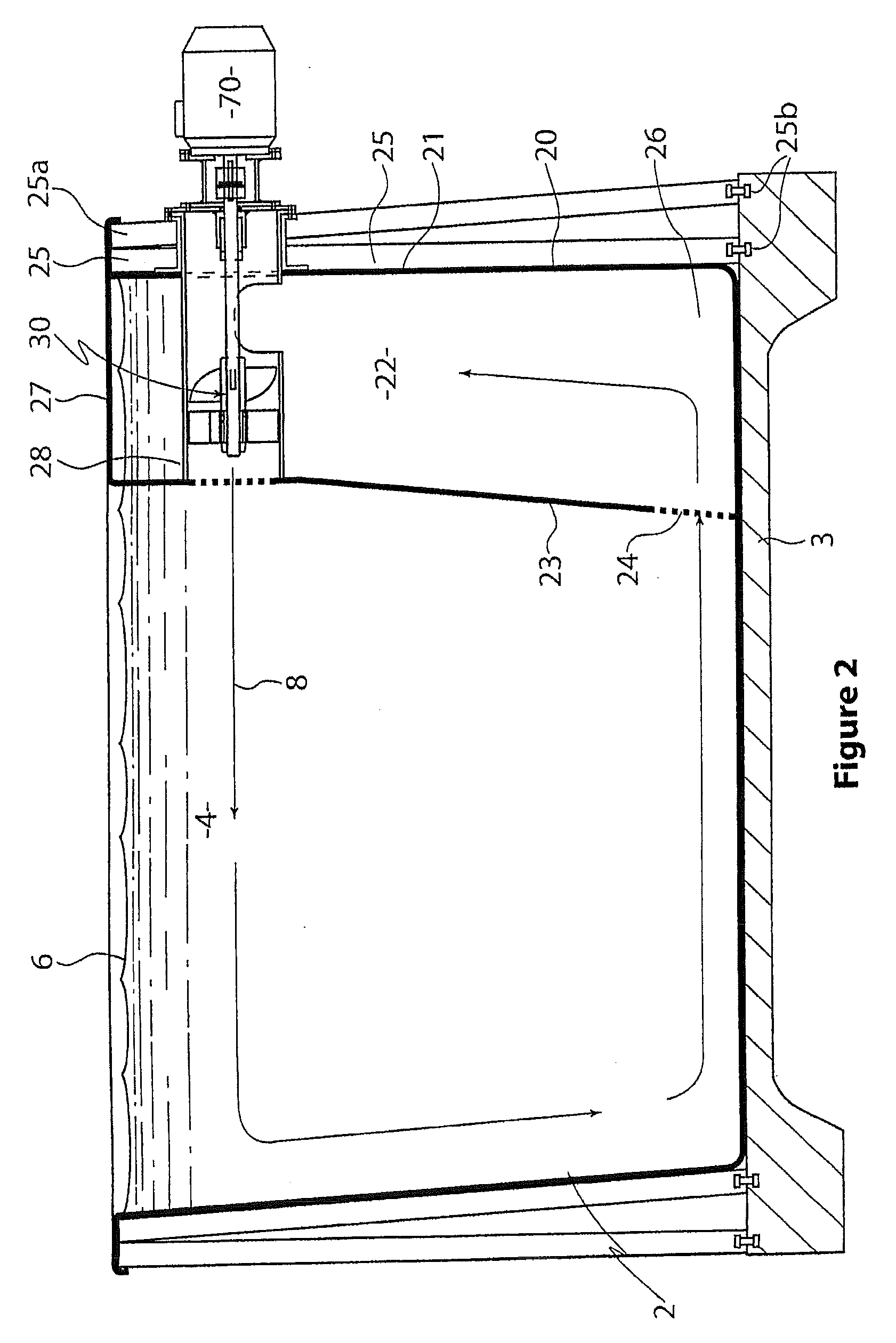

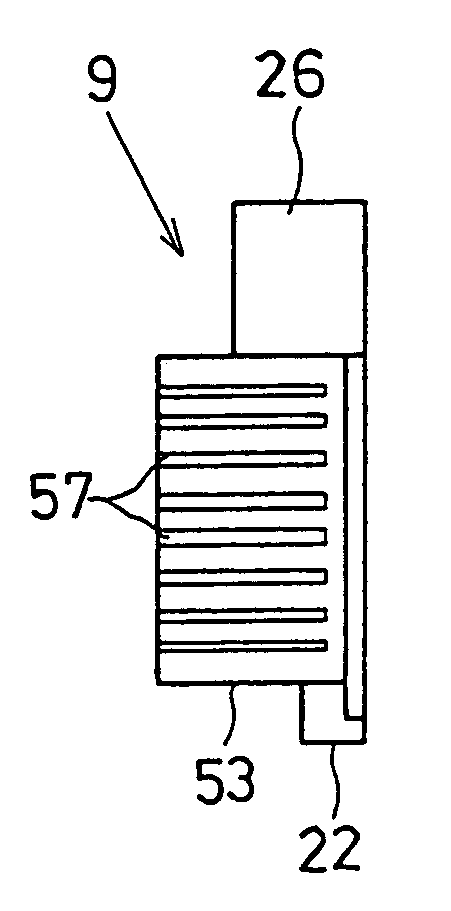

Apparatus for generating a current in a pool

InactiveUS20100058528A1Increase volumeReduce the average velocityPump componentsPump controlPower flowDrive shaft

An apparatus for generating a current in a pool, the apparatus including:a) a shell including an upwardly extending intake chamber in fluid communication with the pool, the intake chamber having a liquid intake zone located in a lower end of the intake chamber;b) an axial pump having an upstream suction-side and a downstream discharge-side, the pump located at an upper end of the intake chamber, the pump having a guide means arranged to direct liquid to flow longitudinally in the discharge-side channel substantially without swirling, the guide means being located downstream of the pumping element; andc) drive means adapted to drive the drive shaft, wherein driving the drive shaft produces a discharge of liquid through the discharge-side outlet, to create a current in the pool for a swimmer to swim against.

Owner:CLAREY MICHAEL

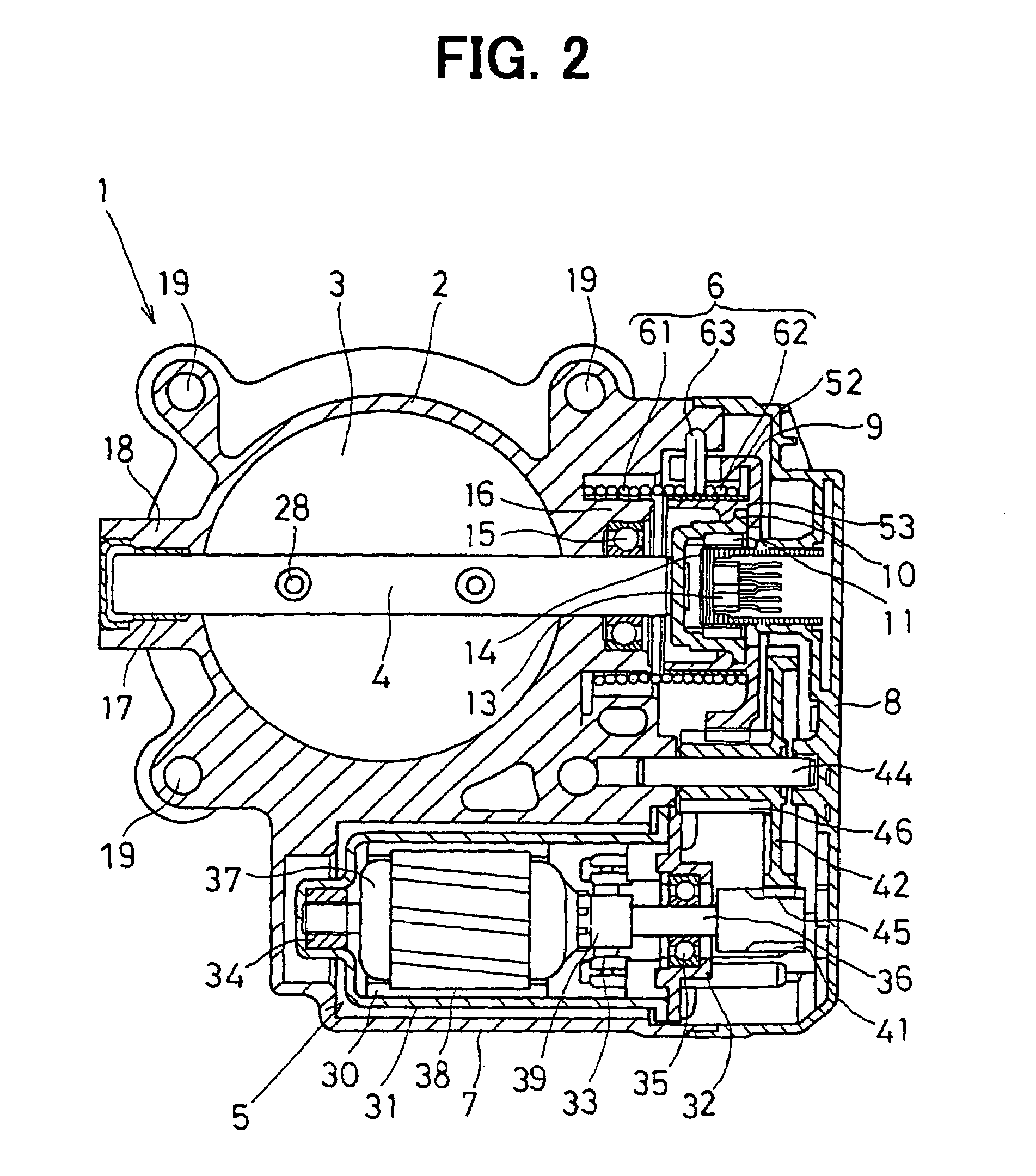

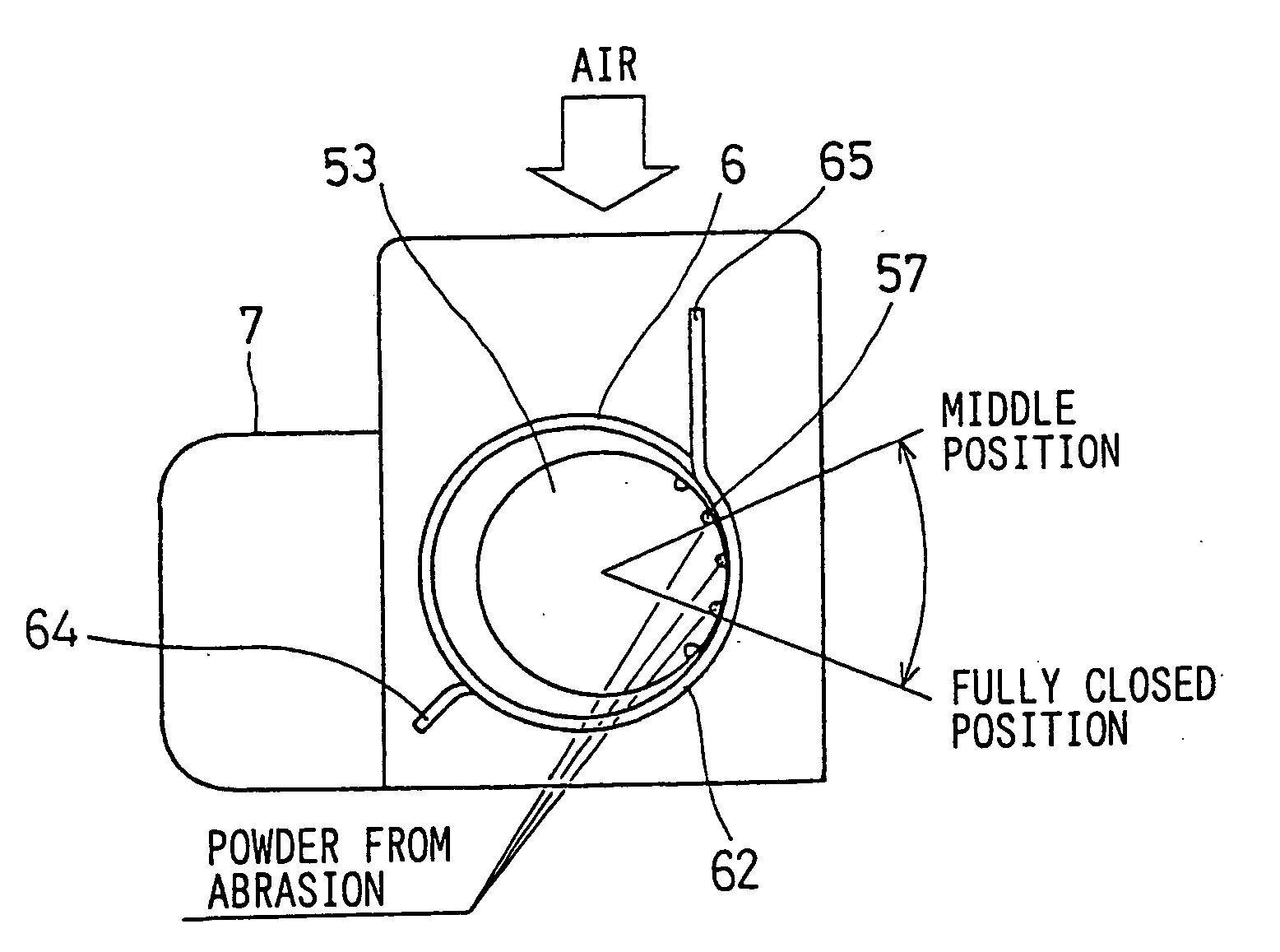

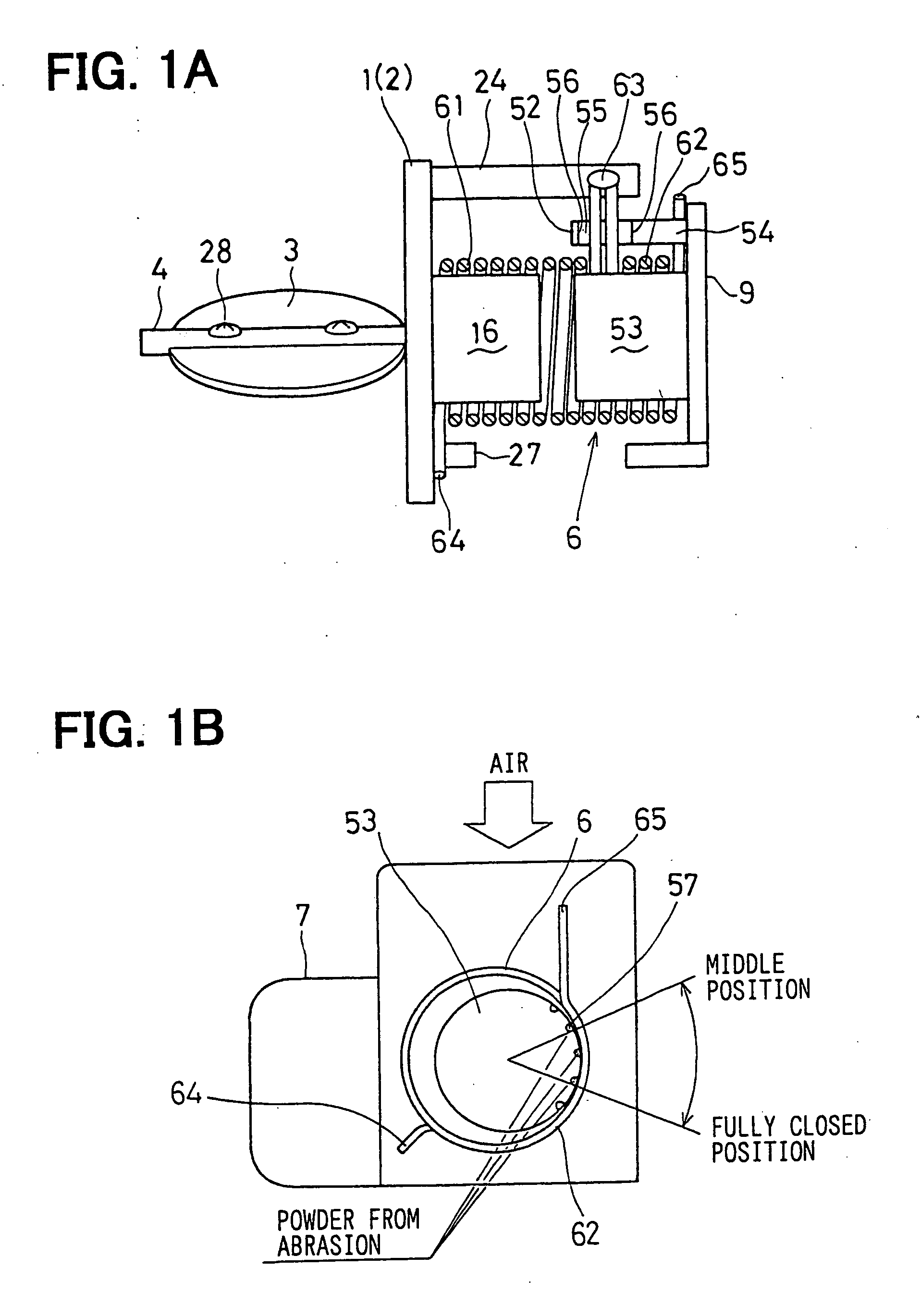

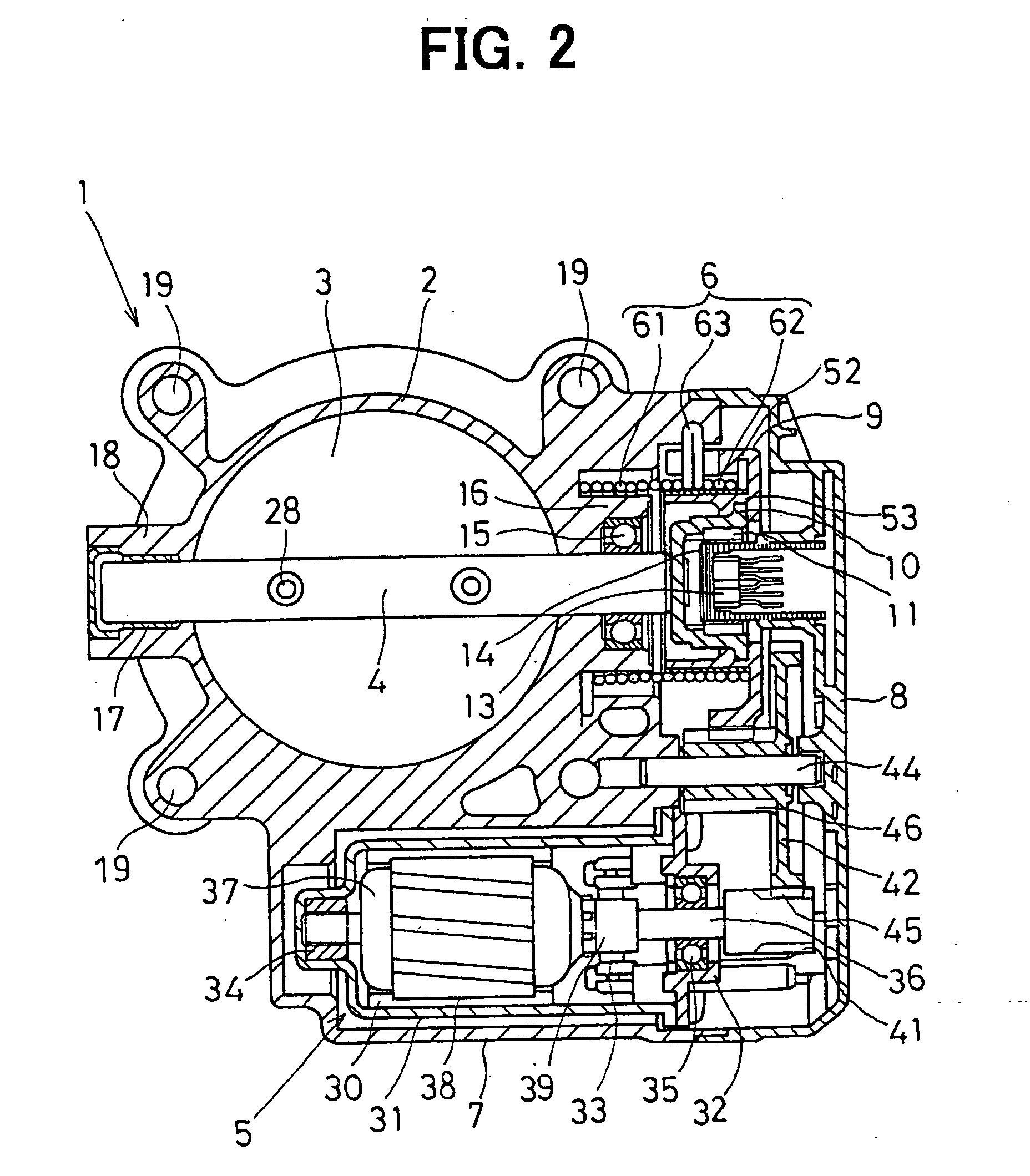

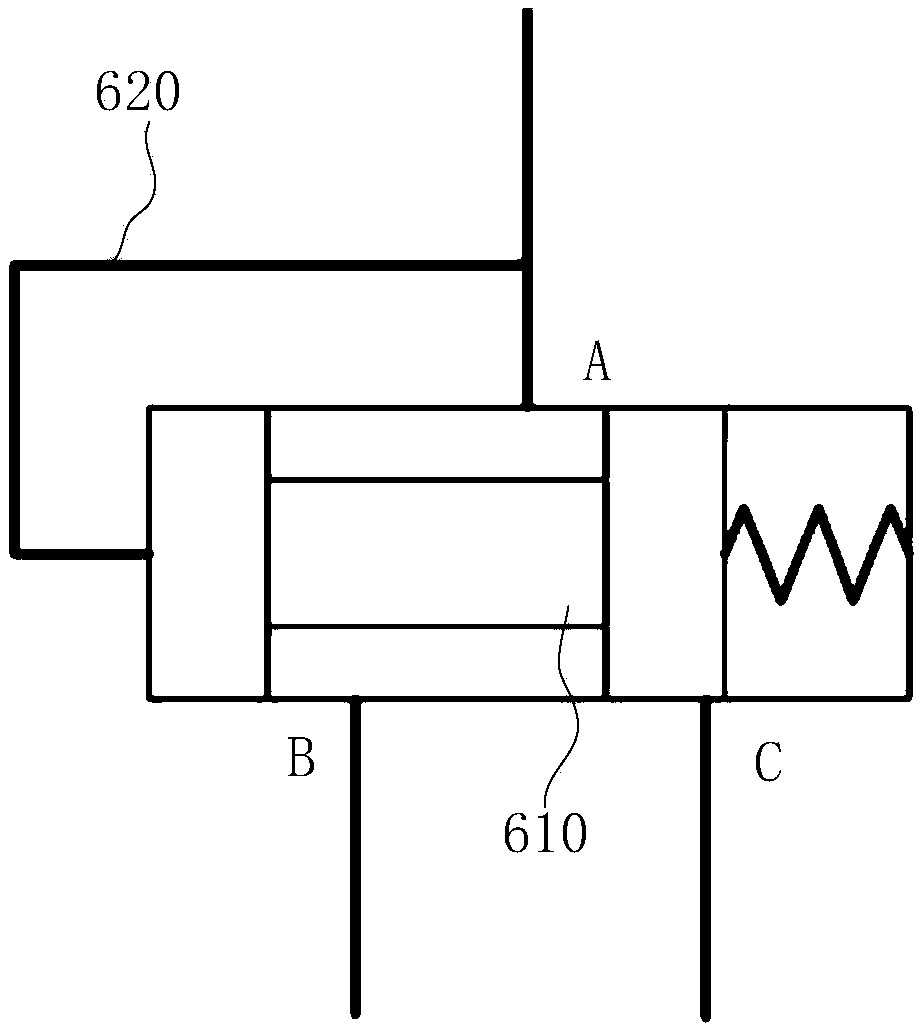

Electronically controlled throttle control apparatus

ActiveUS6986336B2Avoid throttlingAvoid failureElectrical controlOperating means/releasing devices for valvesThrottle controlCoil spring

An electronically controlled throttle control apparatus prevents a throttle valve from malfunctioning due to deterioration in sliding resistance ascribable to abrasive dust at a sliding contact portion between a valve gear of a geared reduction device and a coil spring. The outer periphery of a spring inner periphery guide is provided with a plurality of groove portions as abrasive dust removing means for removing abrasive dust at least from a sliding contact portion between the outer periphery of the spring inner periphery guide and the inner periphery of a default spring, so that individual edge portions of the plurality of groove portions can rub the inner periphery of the default spring to scrape off abrasive dust from the inner periphery of the default spring and direct the abrasive dust into the plurality of groove portions.

Owner:DENSO CORP

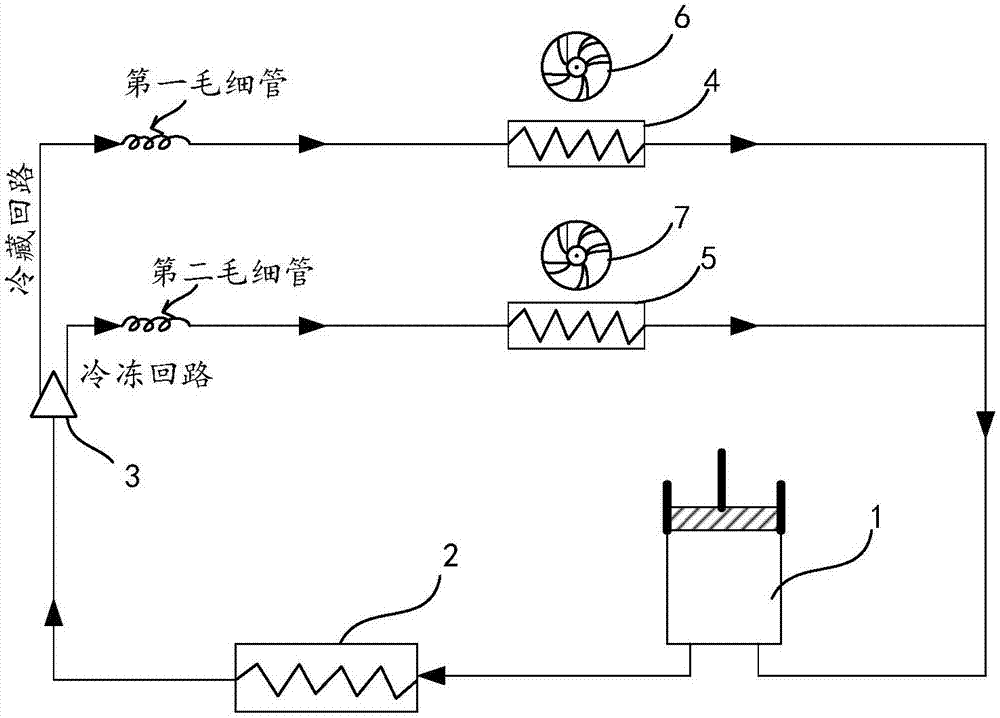

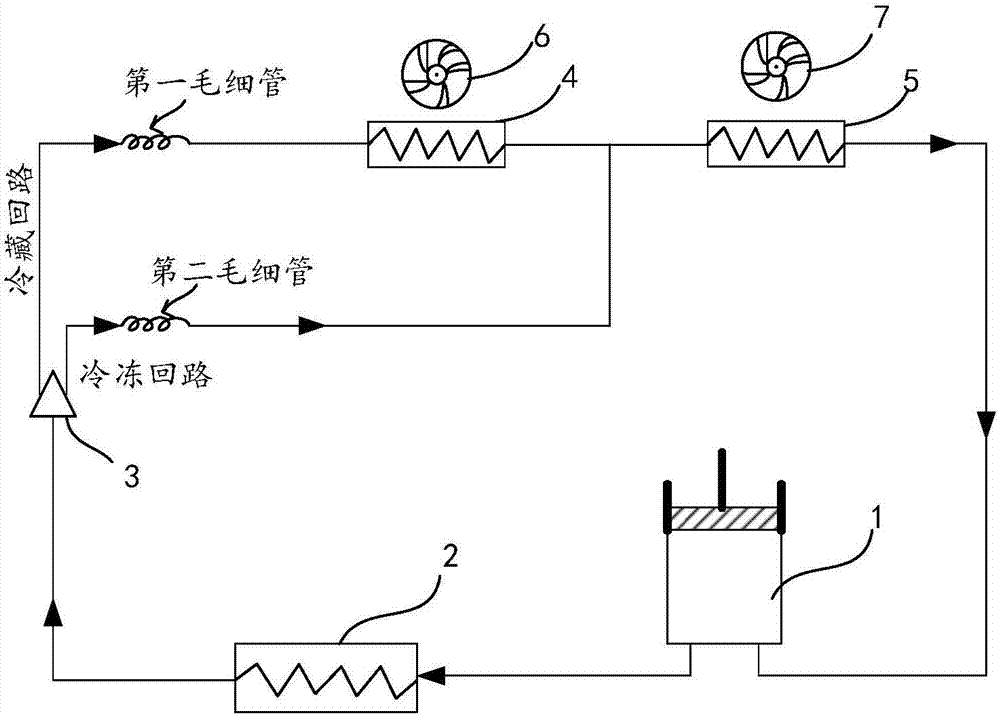

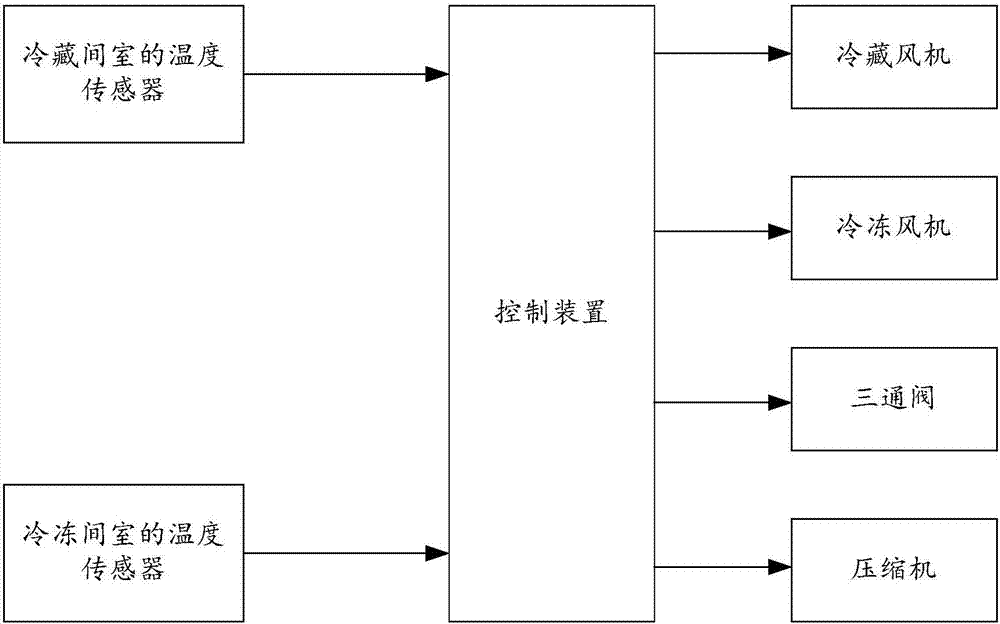

Control method and control device for dual-system refrigerator and refrigerator

ActiveCN107084577AAvoid upscalingAvoid throttlingLighting and heating apparatusDomestic refrigeratorsTemperature controlProcess engineering

The invention embodiment provides a control method and a control device for a dual-system refrigerator and a refrigerator, and relates to the technical field of refrigeration. The precision of temperature control of the refrigerator can be improved, so that the energy consumption is reduced and the compartment temperature stability is promoted. The control method for the dual-system refrigerator comprises the steps that the current compartment temperature of each compartment of the refrigerator is detected in the stopped state of a compressor; when the situation that the current compartment temperature of each compartment is greater than or equal to the corresponding pre-starting temperature is determined, the compressor is controlled to be started, and the corresponding compartment is refrigerated by a first evaporator on a current default communicated refrigerating circuit; and the pre-starting temperature of the compartment is lower than a starting temperature of the compartment.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

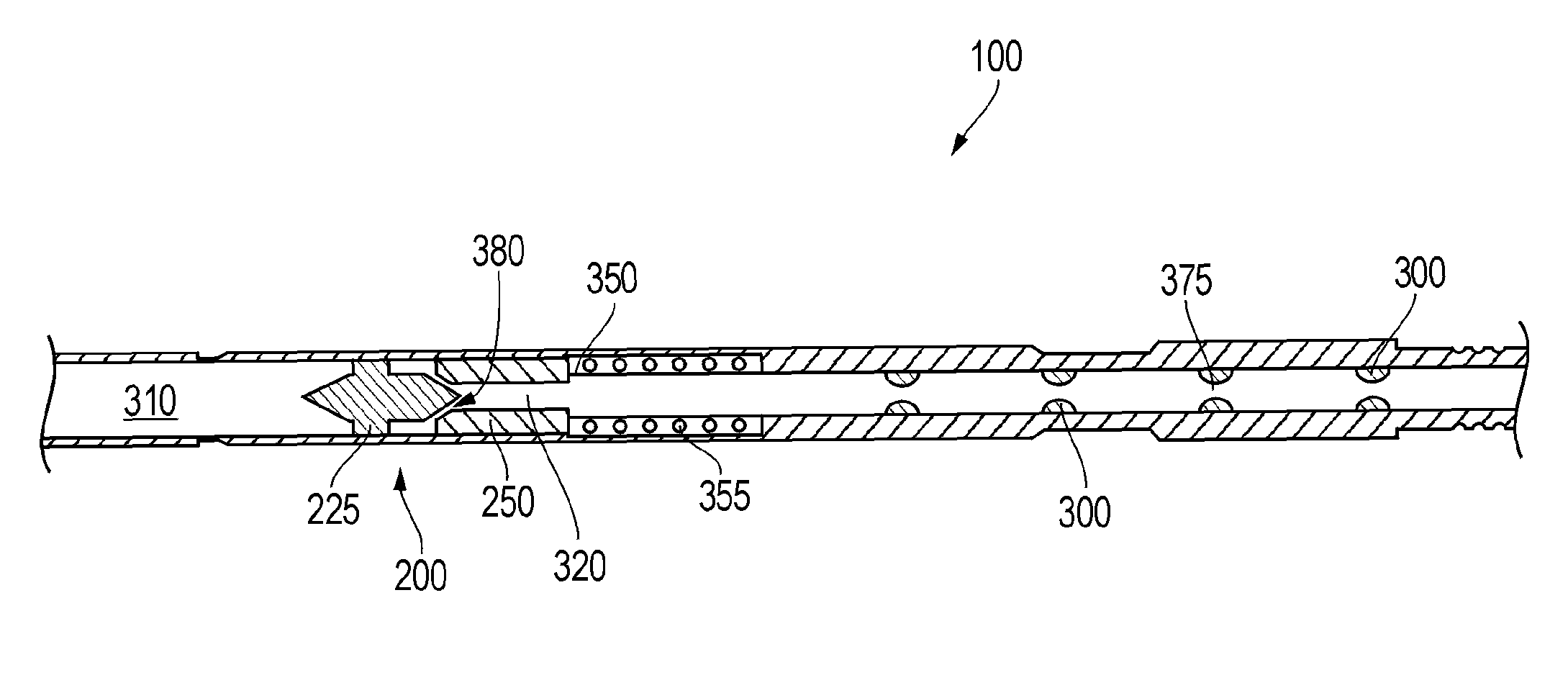

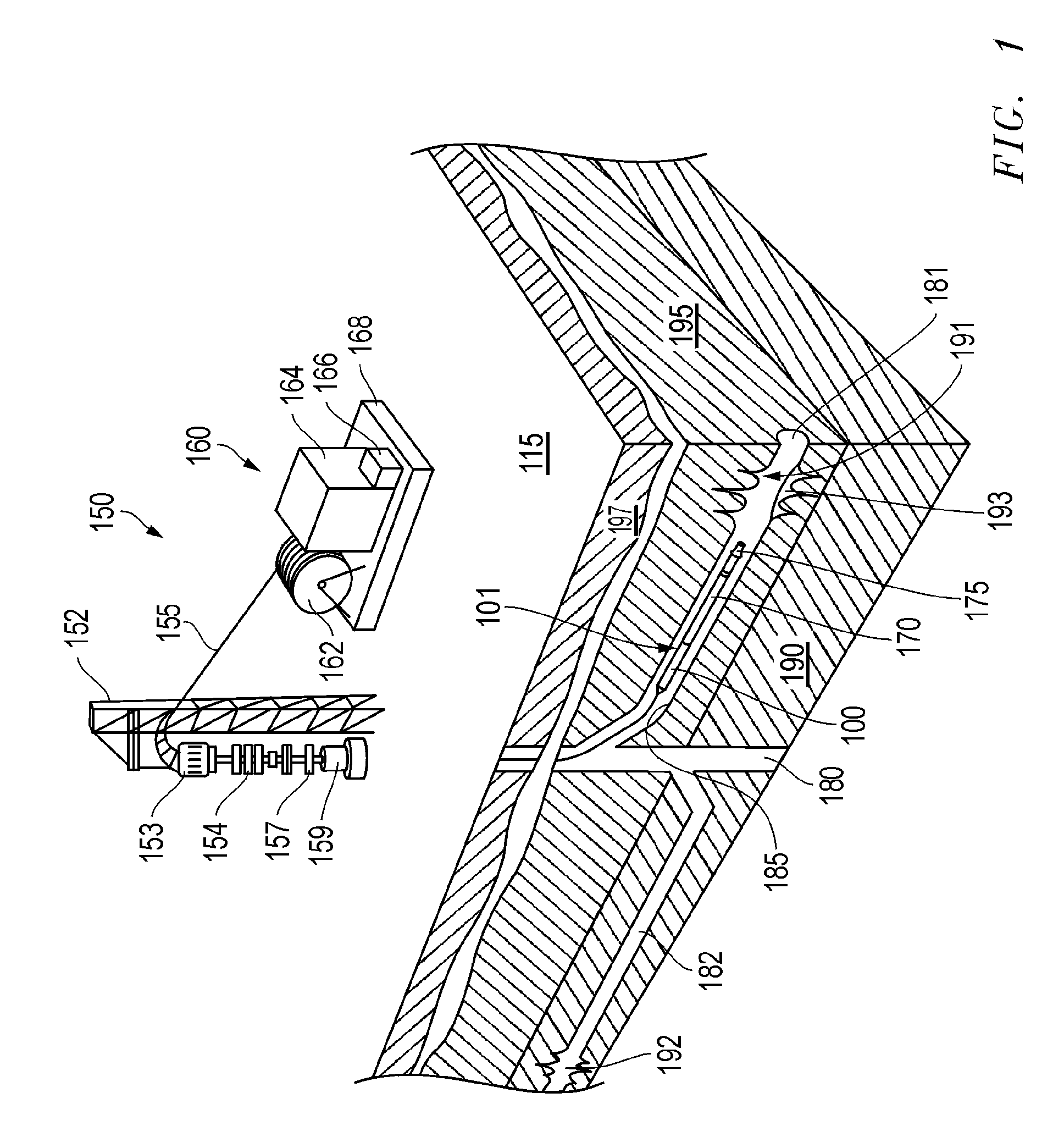

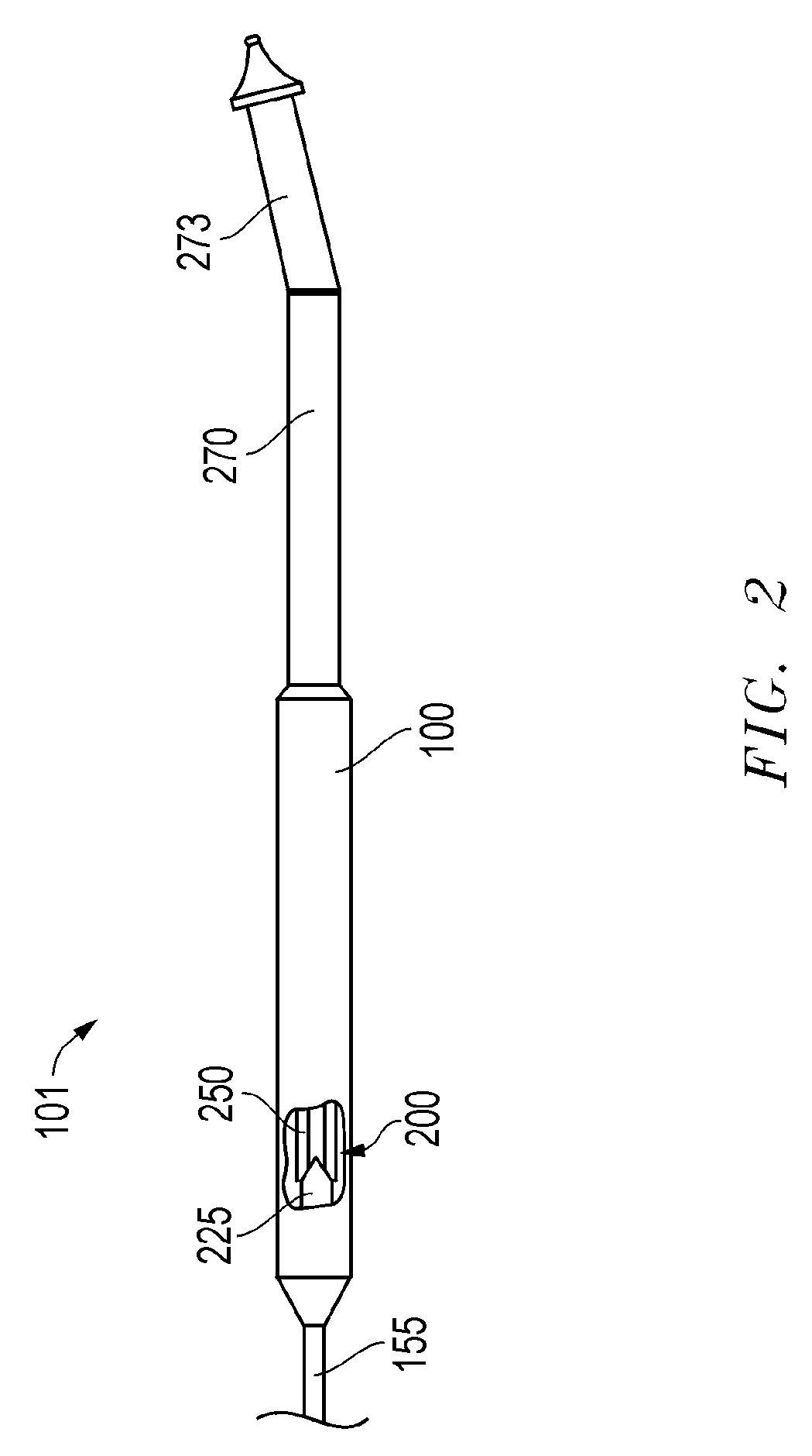

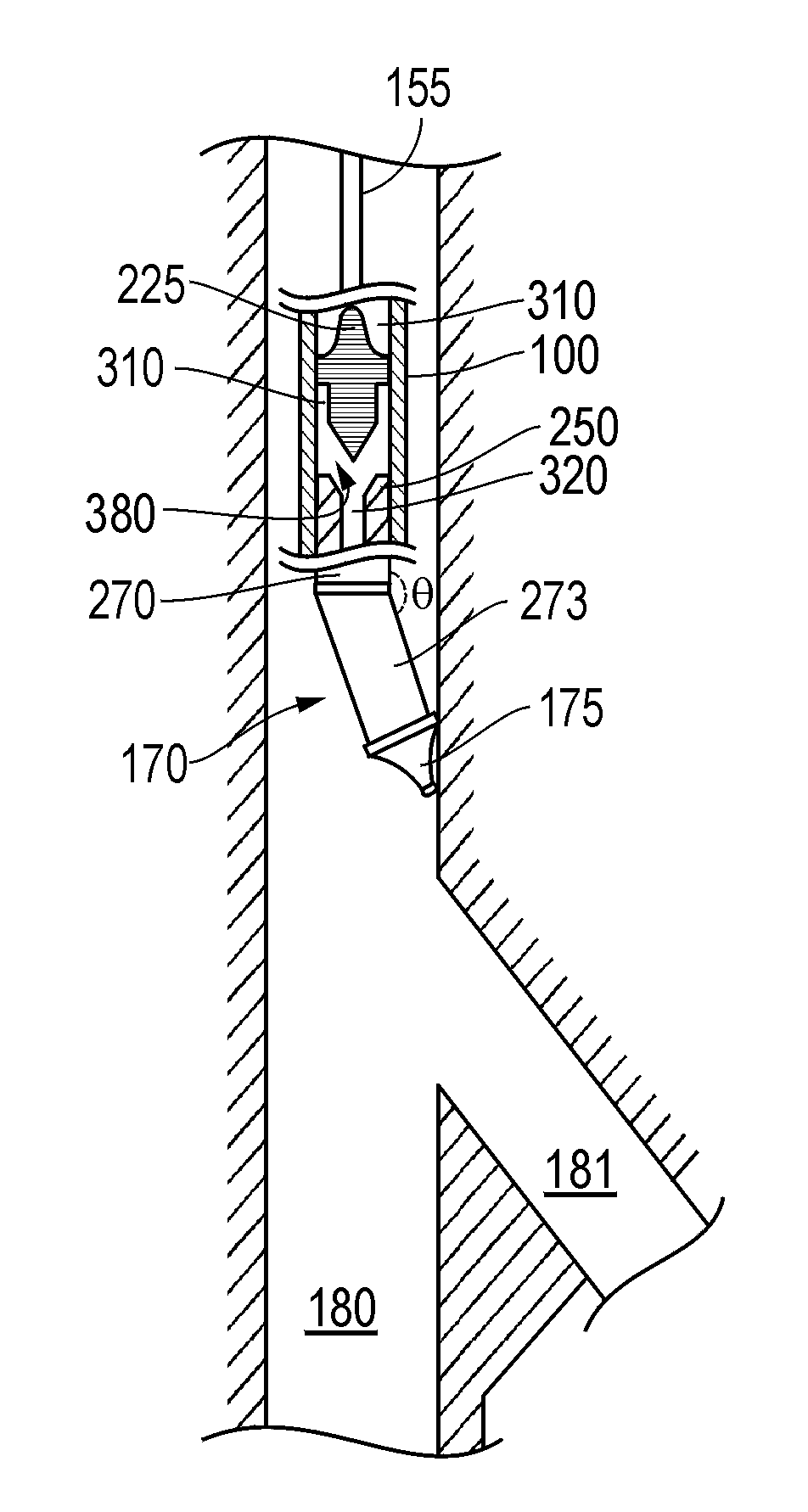

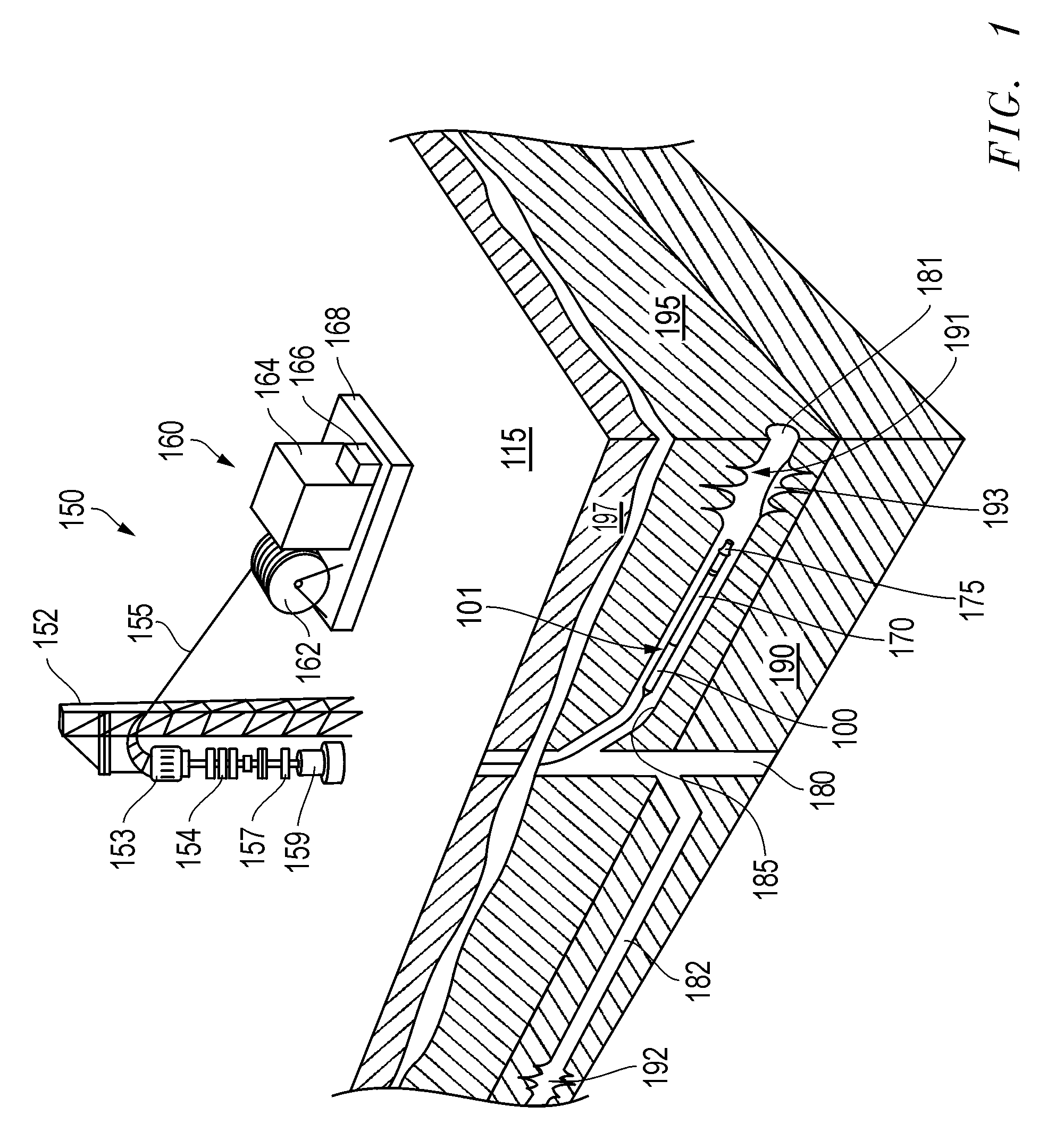

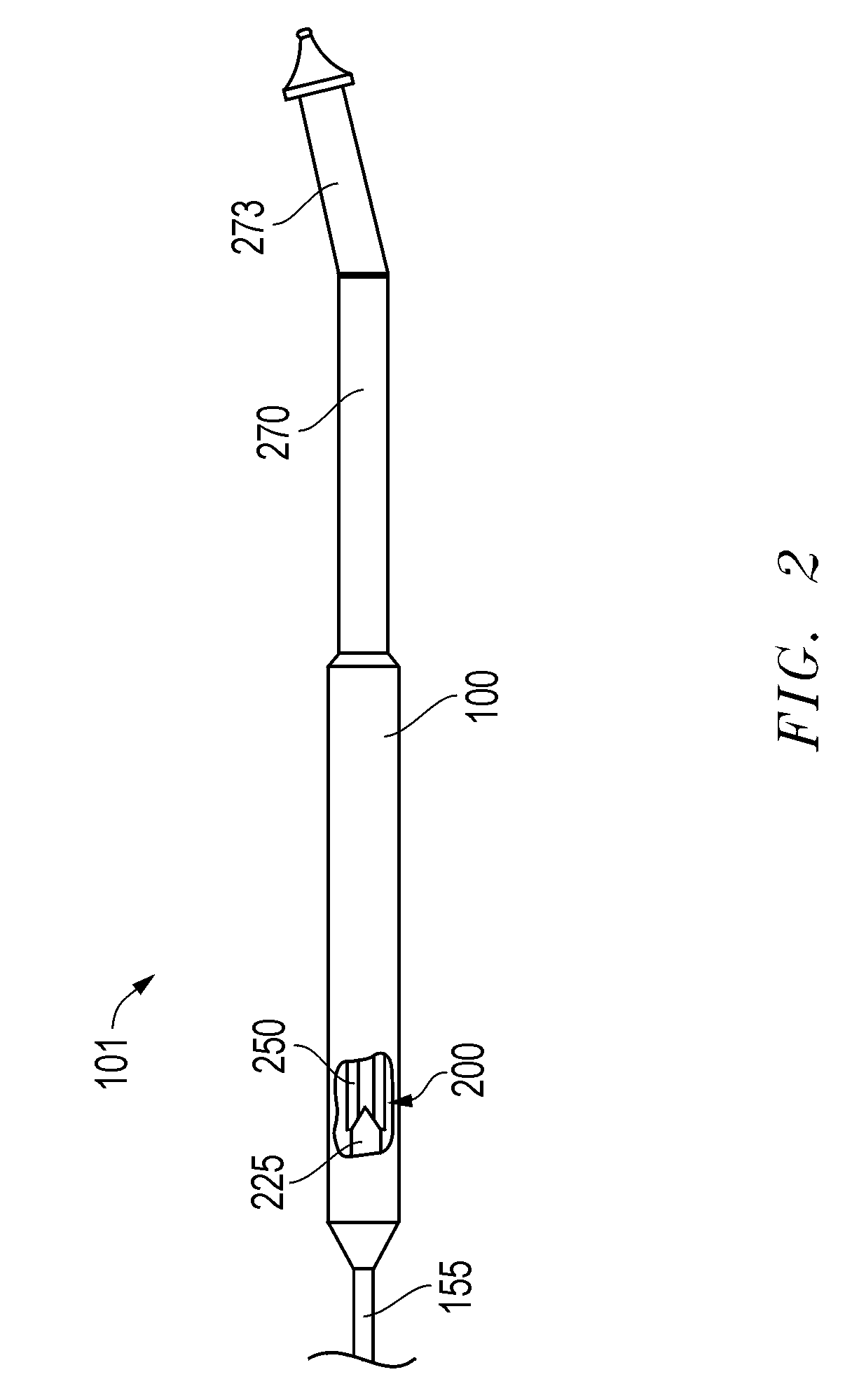

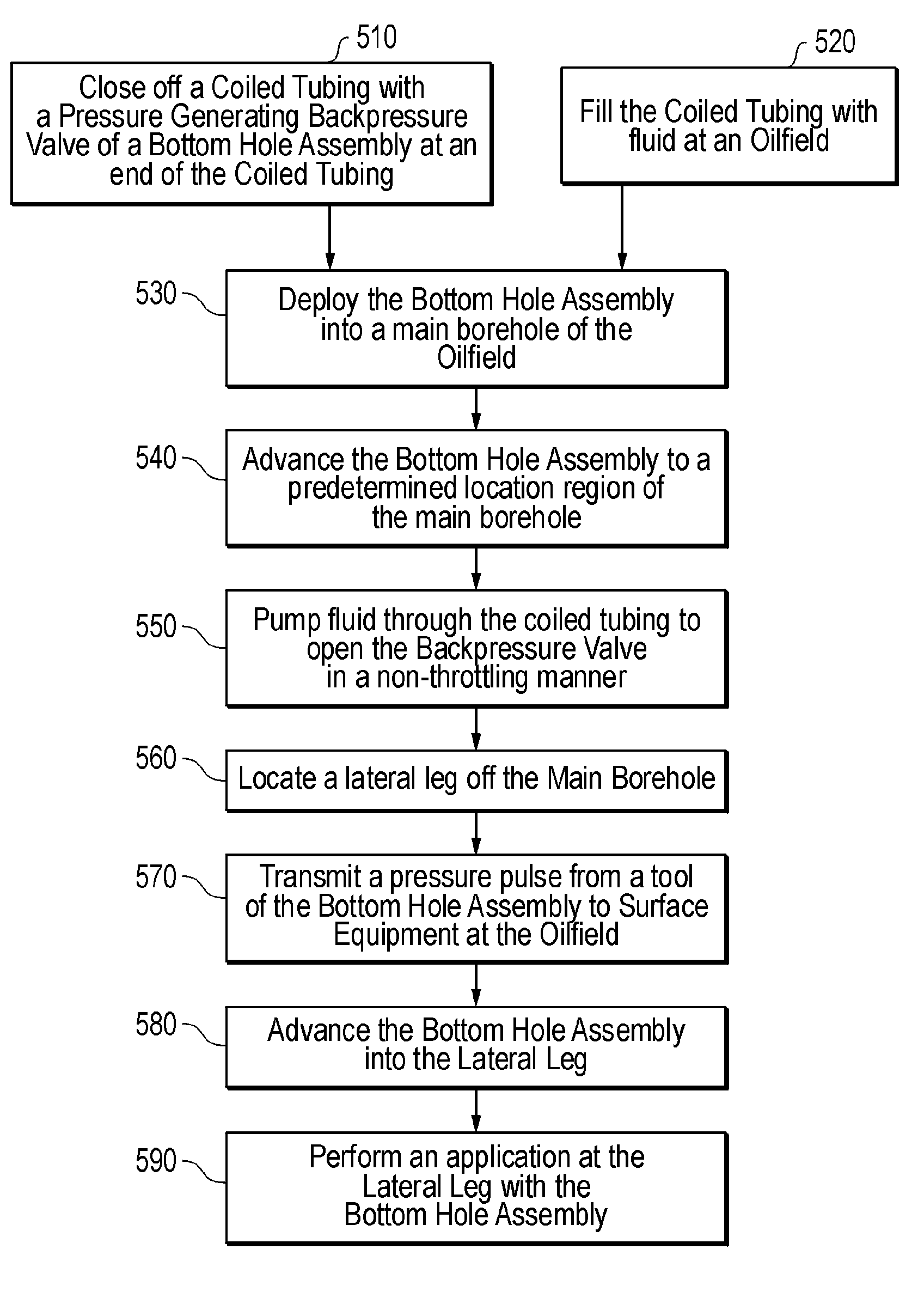

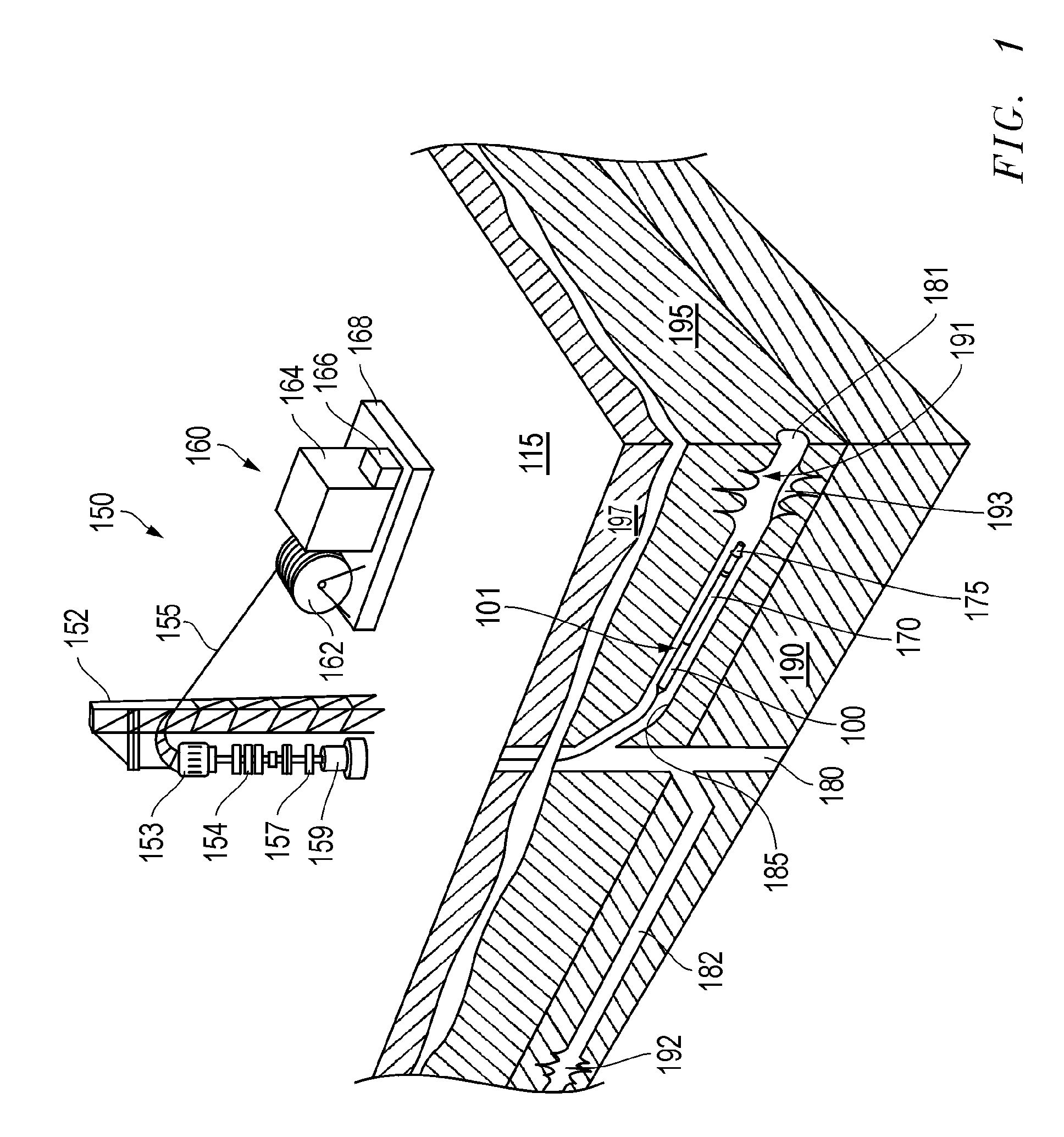

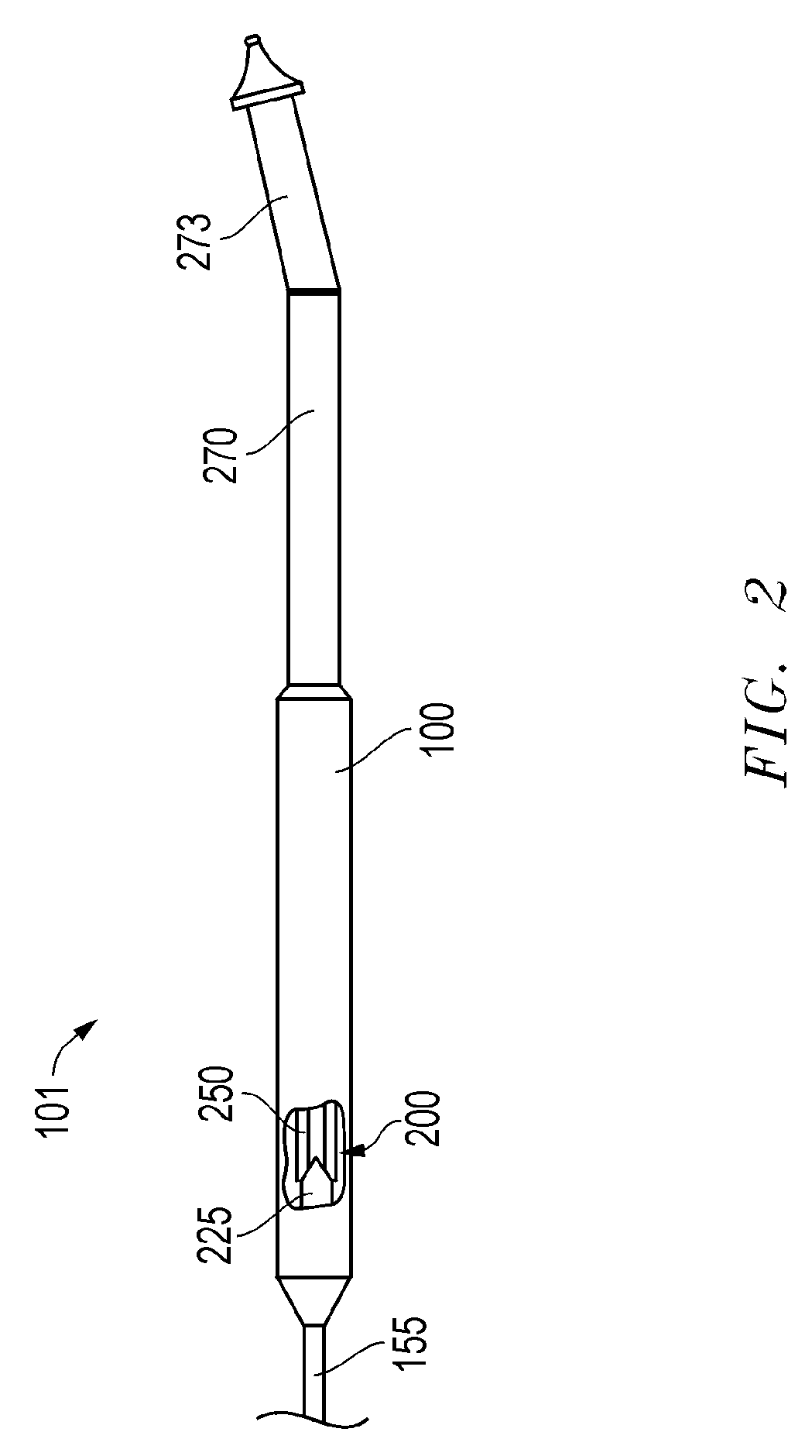

Backpressure valve for wireless communication

A backpressure valve. The backpressure valve may be configured to maintain a substantially controlled pressure in coiled tubing uphole thereof while simultaneously being compatible with a pressure pulse tool downhole thereof. The backpressure valve includes pressure generating capacity below its internal valve assembly so as to avoid the tendency of the assembly to throttle open and closed. Furthermore, the pressure generation is achieved in a manner avoiding cavitation. As a result, once the backpressure valve is opened, the pressure pulse tool is able to reliably communicate with surface equipment at the oilfield.

Owner:SCHLUMBERGER TECH CORP

High temperature refrigeration controlling method and air conditioner

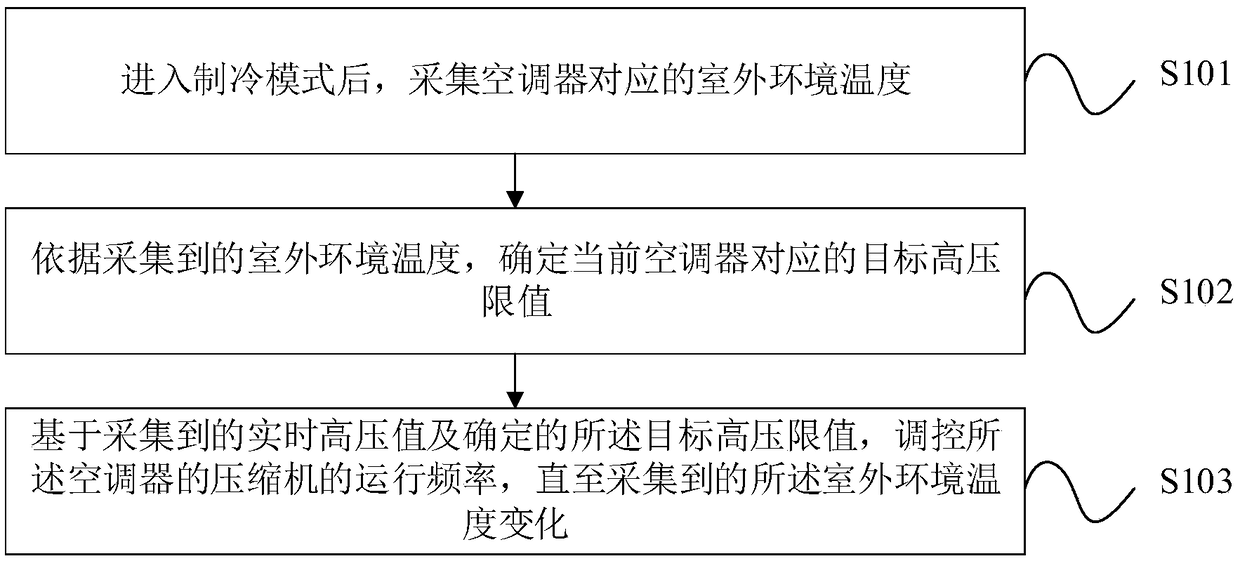

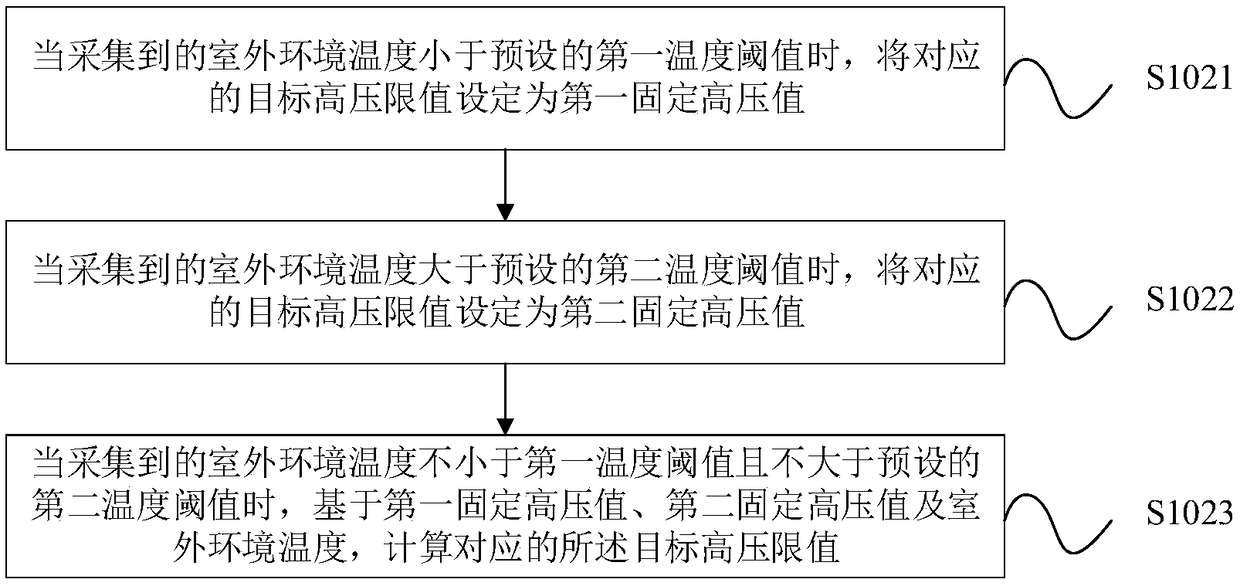

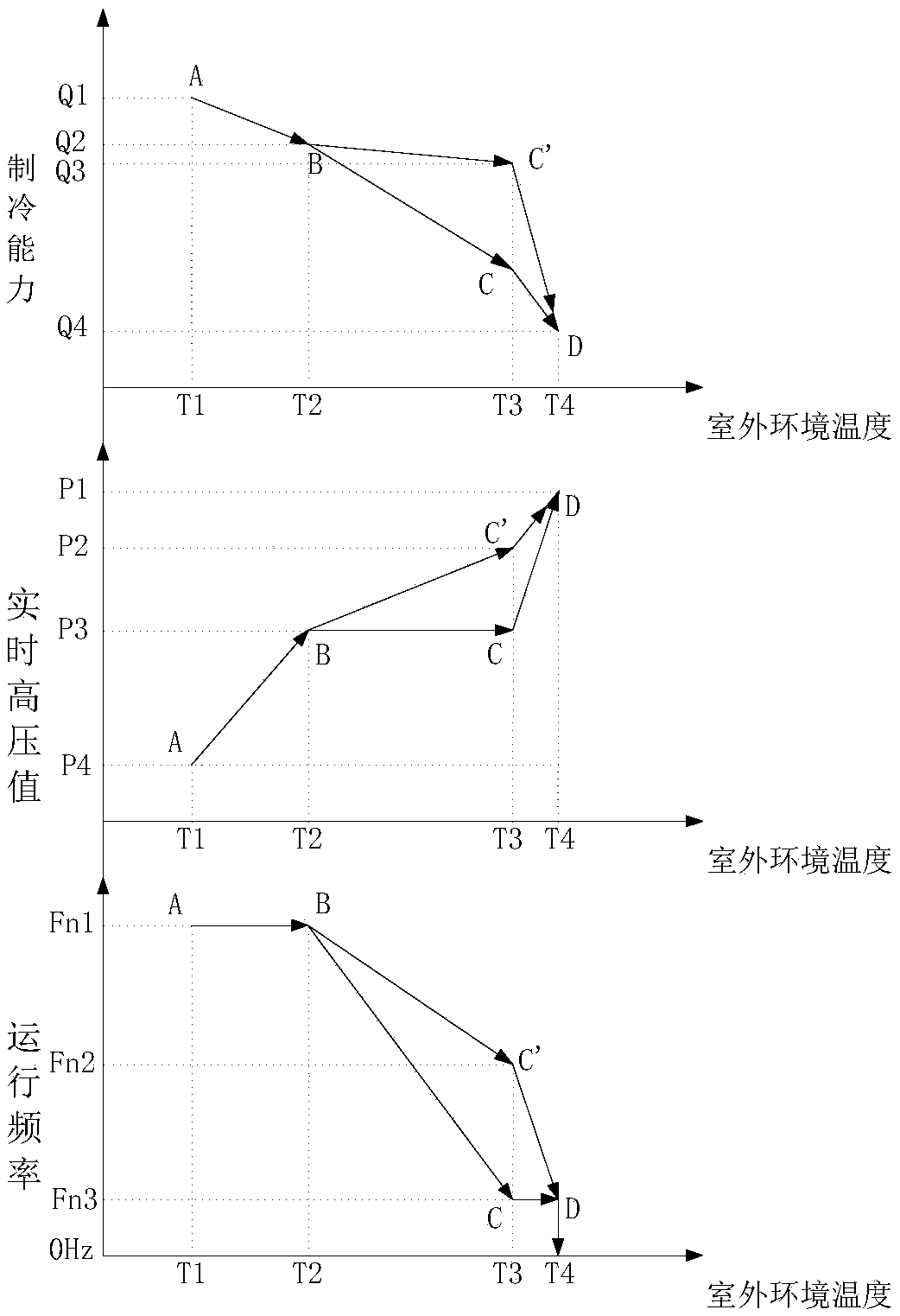

InactiveCN109405219AImprove decay speedImprove experienceMechanical apparatusSpace heating and ventilation safety systemsEngineeringLimit value

The invention provides a high temperature refrigeration controlling method and an air conditioner. The high temperature refrigeration controlling method comprises the following steps that when a refrigeration mode is started, the outdoor environment temperature corresponding to the air conditioner is collected; according to the collected outdoor environment temperature, the current target high pressure limit value corresponding to the air conditioner is determined; and according to the collected real-time high pressure value and the determined target high pressure limit value, running frequency of a compressor of the air conditioner is adjusted and controlled until the the outdoor environment temperature change is collected. The current pressure limit which the air conditioner can bear canbe more accurately represented according to the target high pressure limit value obtained based on the outdoor environment temperature. High pressure shutdown protection is ensured not to occur, andunnecessary frequency falling is avoided. The decay rate of the refrigeration performance is improved, and user experience is improved.

Owner:NINGBO AUX ELECTRIC +1

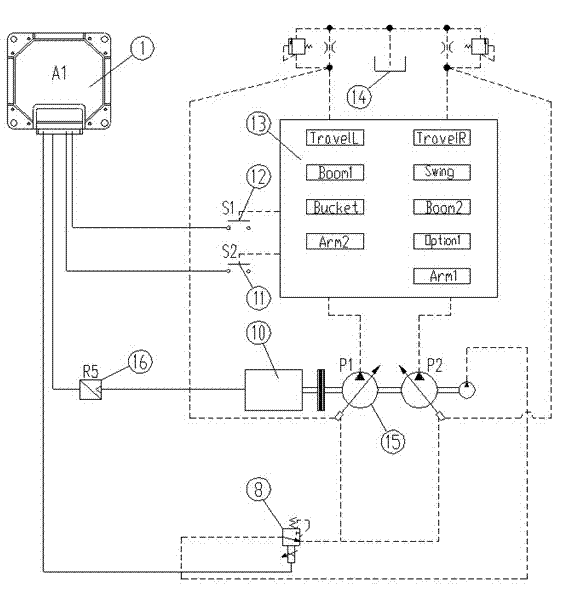

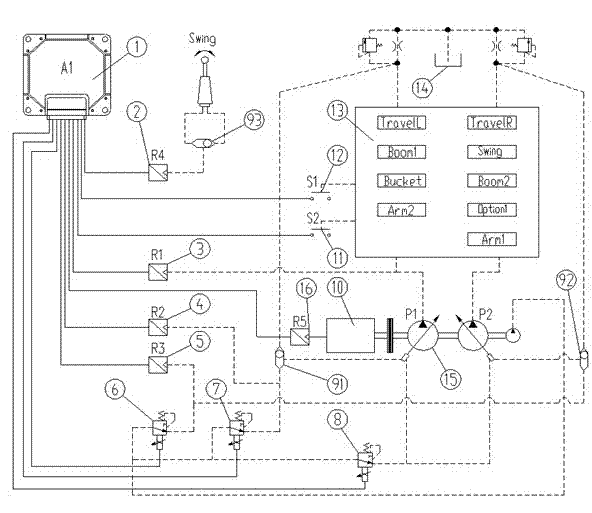

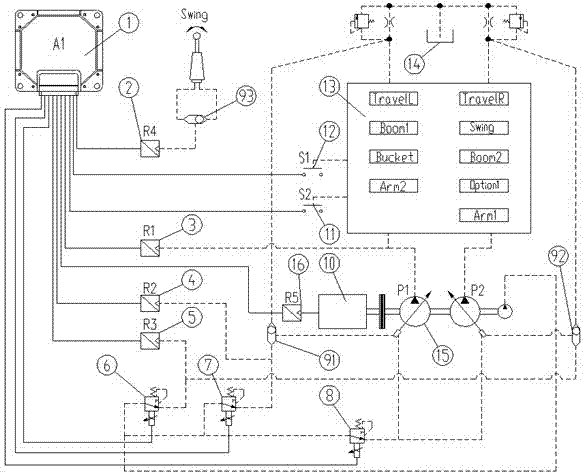

Novel excavator current-limiting control system

ActiveCN102493523AIncrease flexibilityAvoid damageSoil-shifting machines/dredgersModel selectionClosed loop

The invention discloses a novel excavator current-limiting control system, belonging to the field of electrohydraulic control of hydraulic excavators. The novel excavator current-limiting control system comprises a master controller, a main pump proportional valve, a getting-down pressure switch S2, a getting-on pressure switch S1, and a rotation speed sensor and further comprises a revolution pilot pressure sensor, a P1-pump outlet pressure sensor, a P1-pump current-limiting pressure sensor, a P2-pump current-limiting pressure sensor, a P2-pump maximum-flow control proportional valve and a P1-pump maximum-flow control proportional valve, which are respectively and electrically connected with the master controller. The novel excavator current-limiting control system has the beneficial effects that: the flexibility in model selection of hydraulic elements can be enhanced, meanwhile, a rotary motor and a travelling motor can be prevented from being damaged by overlarge flow of a hydraulic system; in addition, the actions in need of current limitation can be judged through a detection device so as to prevent 'one size fits all' type current limitation, the pump displacement of two single pumps can be limited through controlling the current of the two current-limitation proportional valves, closed-loop control is adopted for a current control loop of the proportional valves, and thus the accurate current-lamination control is realized.

Owner:XCMG EXCAVATOR MACHINERY

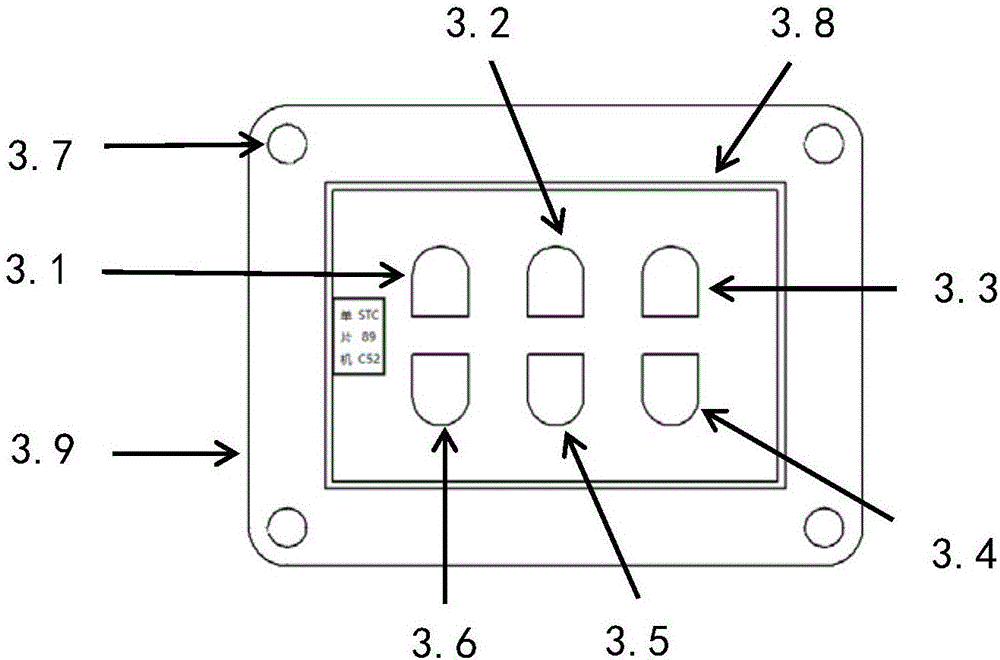

Fuzzy intelligent switch device and fuzzy intelligent speed change control method applied to range hood

InactiveCN106482185ALarge adjustment rangeNo vibrationProgramme controlDomestic stoves or rangesPower inverterDriving current

The invention discloses a fuzzy intelligent switch device and a fuzzy intelligent speed change control method applied to a range hood. The fuzzy intelligent switch device comprises a fuzzy controller, an ionic smoke sensor, a current regulator, a speed change regulator, a warning module, a power inverter and a PMU power management unit; the power inverter is connected with the fuzzy controller, the warning module, the current regulator, the speed change regulator and the ionic smoke sensor through the PMU power management unit; the ionic smoke sensor is used for sensing smoke, transforming the information into a voltage value and sending to the fuzzy controller; the fuzzy controller is used for driving the current regulator to control the current in a circuit; the speed change regulator is used for changing the power of a motor of the range hood to realize intelligent speed regulation; and the warning module runs automatically when the smoke concentration is too high. The device disclosed by the invention can realize intelligent speed regulation of the range hood in environments different in smoke concentration, can also realize safety alarming and reminding when the smoke concentration is relatively high, can prevent human body injuries caused by high-concentration smoke and inconveniences caused by frequent start and stop of the range hood in daily use, and can also improve the working performances of the range hood.

Owner:CHINA JILIANG UNIV

Downhole application for a backpressure valve

A backpressure valve. The backpressure valve may be configured to maintain a substantially controlled pressure in bottom hole assembly while simultaneously being compatible with a pressure pulse tool downhole thereof. The backpressure valve includes pressure generating capacity below its internal valve assembly so as to avoid the tendency of the assembly to throttle open and closed. Furthermore, the pressure generation is achieved in a manner avoiding cavitation. As a result, once the backpressure valve is opened, the pressure pulse tool is able to reliably communicate with surface equipment at the oilfield.

Owner:SCHLUMBERGER TECH CORP

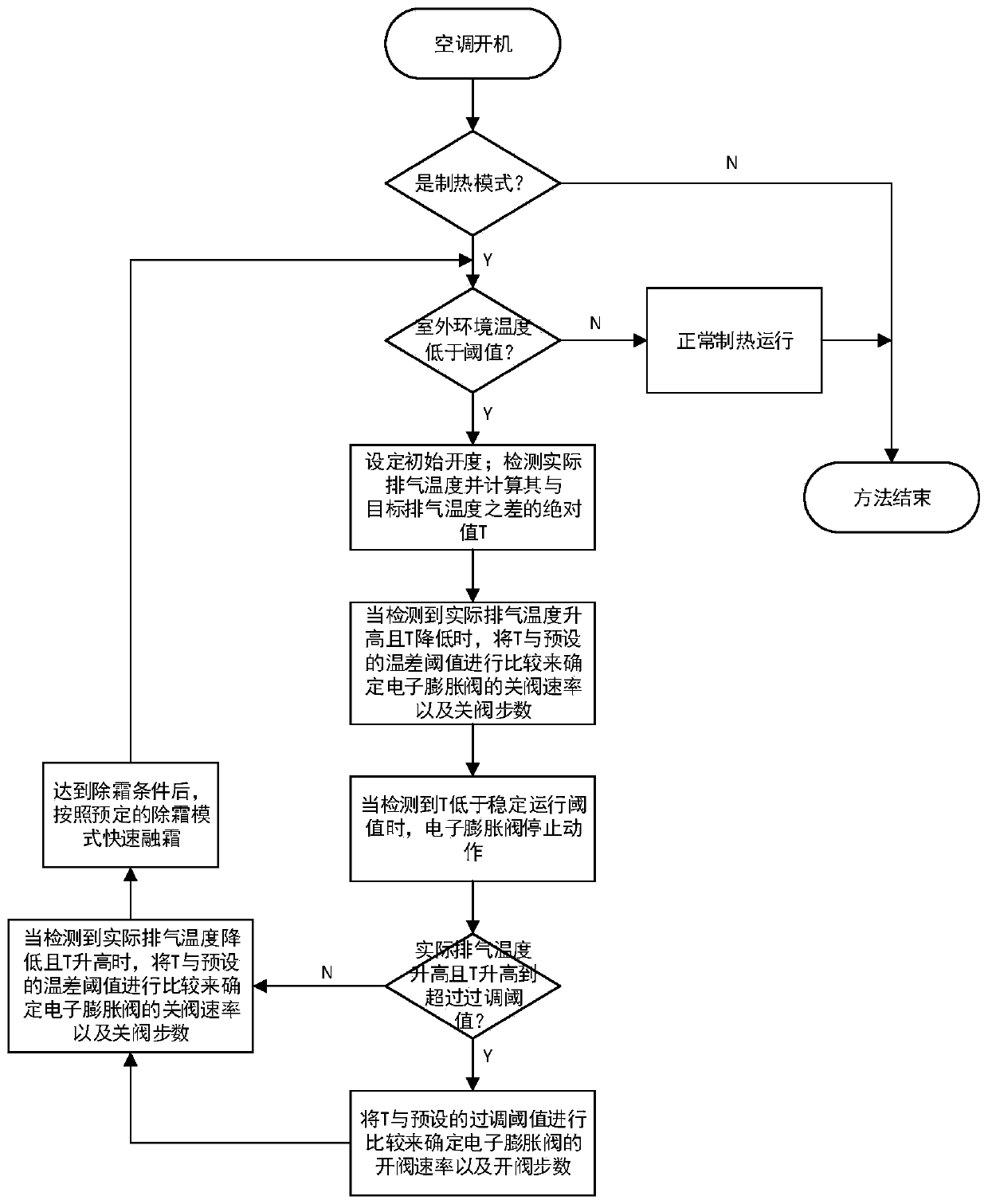

Electronic expansion valve control method for prolonging frosting period and air conditioner

ActiveCN111023458ASpeed up the flowFrosting evenlyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses an electronic expansion valve control method for prolonging the frosting period and an air conditioner. When the air conditioner is in a heating mode and the outdoor environment temperature is lower than a preset temperature threshold value, the air conditioner operates according to the following modes: the initial opening degree is set, the actual exhaust temperature is detected in real time, and the absolute value T of the difference between the actual exhaust temperature and the preset target exhaust temperature is calculated; when it is detected that the actual exhaust temperature is increased and T is decreased, T is compared with a preset temperature difference threshold value to determine the valve closing speed and the valve closing step number of an electronic expansion valve; when it is detected that T is lower than a stable operation threshold value, the electronic expansion valve stops acting; and when it is detected that the actual exhaust temperature is reduced and T is increased, T is compared with the preset temperature difference threshold value to determine the valve closing speed and the valve closing step number of the electronic expansion valve. Judgment and adjustment are conducted according to the actual exhaust temperature and the change condition of the absolute value of the difference between the actual exhaust temperature and the target exhaust temperature, and the low-temperature heating capacity can be effectively improved.

Owner:四川长虹空调有限公司

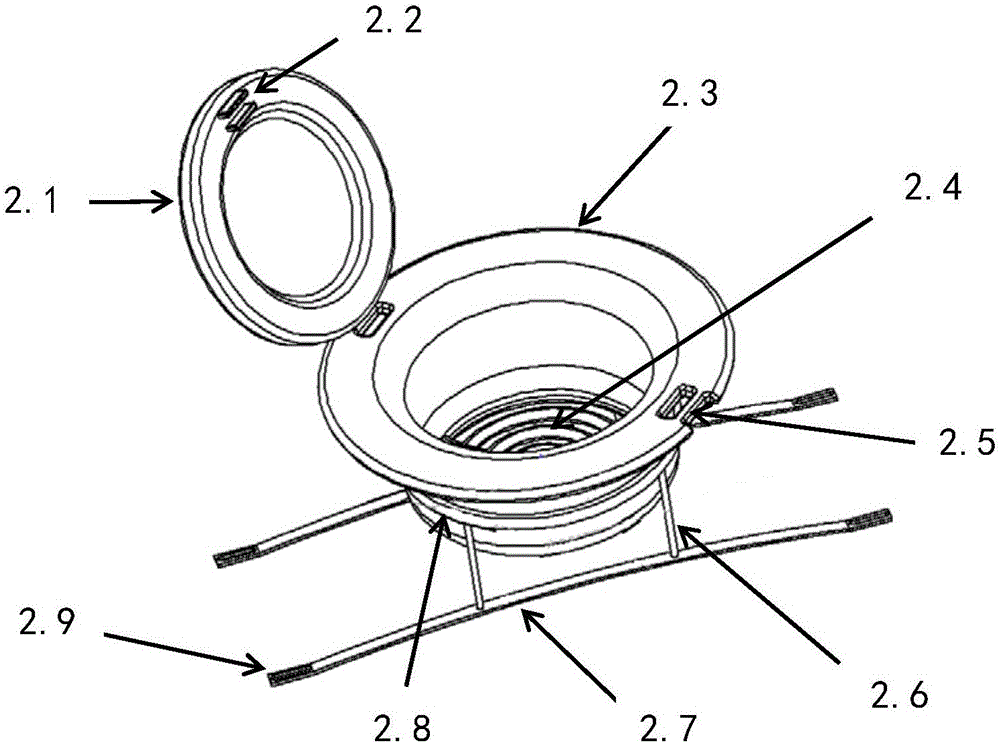

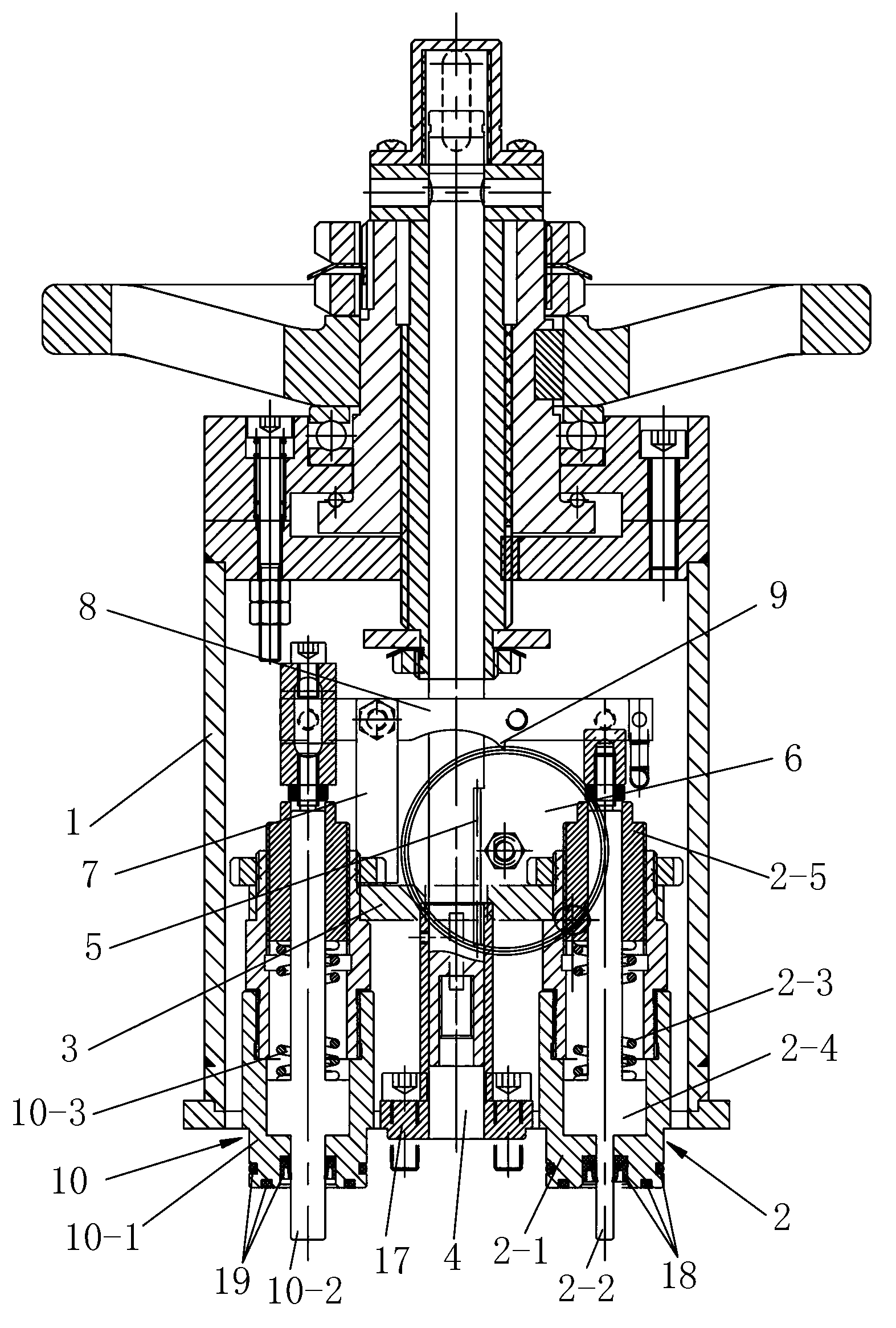

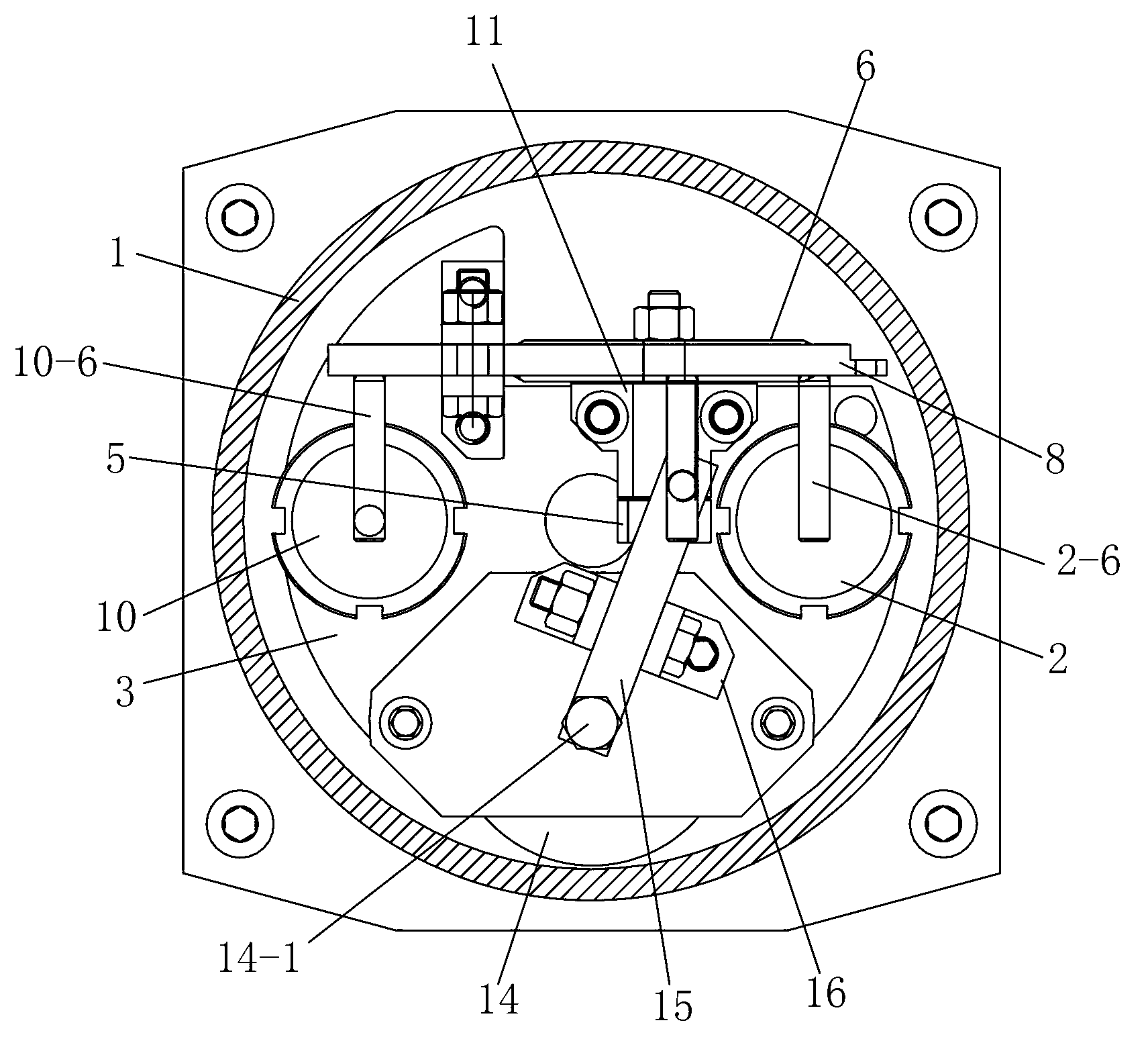

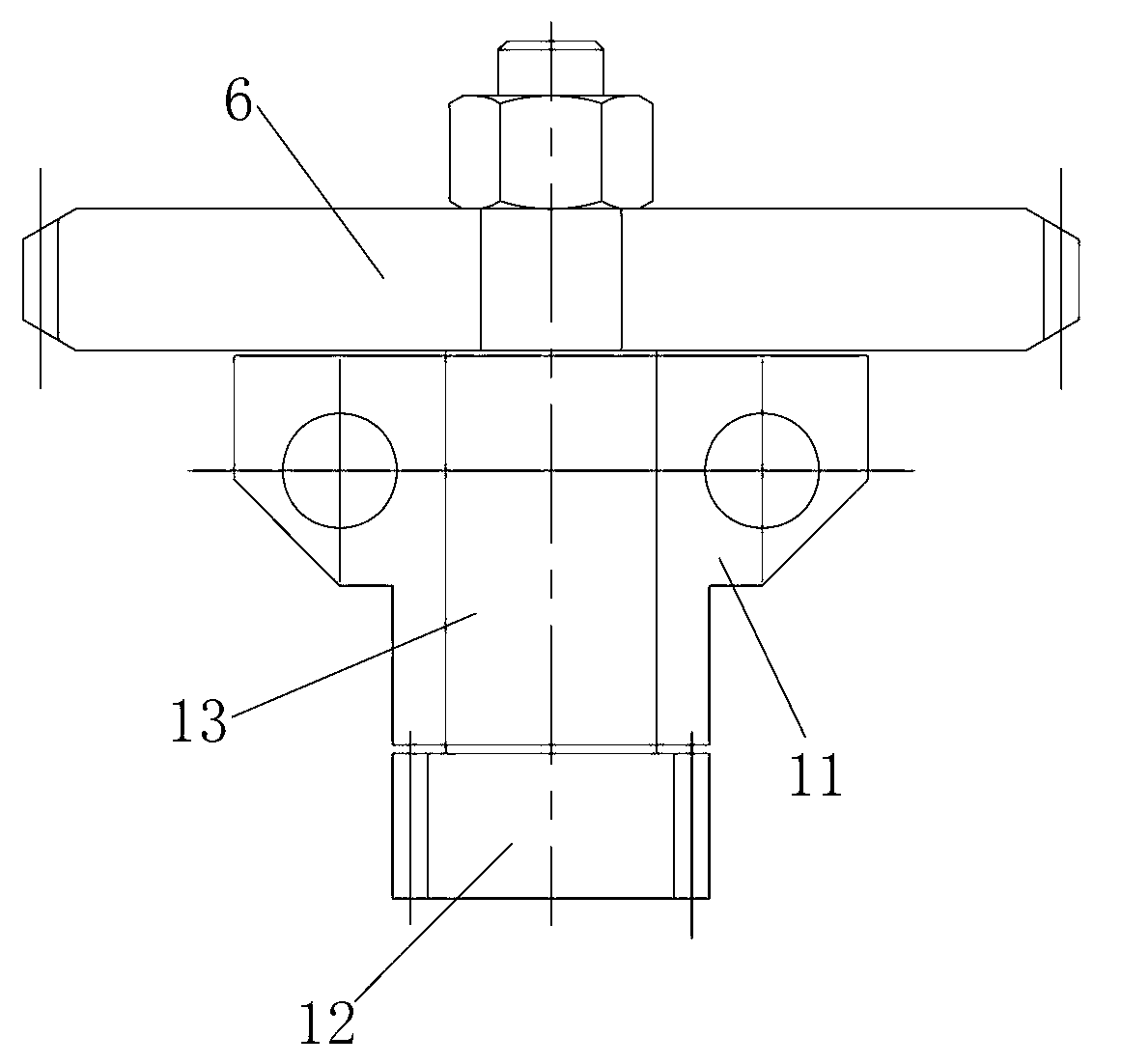

Pilot-operated type solenoid valve for gas well wellhead and valve plug lifting mechanism

ActiveCN102704889ASimple structureNovel and reasonable designWell/borehole valve arrangementsSealing/packingSolenoid valveDrive shaft

The invention discloses a lifting mechanism for a valve plug of a solenoid valve. The lifting mechanism comprises a supporting plate arranged above a valve cap, wherein the upper end of a lifting rod of a main valve plug penetrates through the supporting plate; a rack extending along the length direction of the lifting rod is arranged on the lifting rod; a connector I is arranged on the upper surface of the supporting plate; a transmission shaft is rotatably arranged on the connector I; a gear which is engaged with the rack is arranged on one end of the transmission shaft; a ratchet wheel is arranged on the other end of the transmission shaft; the lifting rod is vertically arranged on the upper surface of the supporting plate; a long lever which is horizontally distributed is rotatably connected on the upper end of the supporting rod; the connection point of the supporting rod and the long lever deviates from the centre in the length direction of the long lever; the long lever is arranged above the ratchet wheel; and a pawl which is matched with the ratchet wheel is fixedly arranged on the long lever. The invention further discloses a pilot-operated type solenoid valve for a gas well wellhead adopting the valve plug lifting mechanism. The pilot-operated type solenoid valve for the gas well wellhead and the valve plug lifting mechanism can greatly increase the opening height of the solenoid valve main valve plug, increases the yield and prevents throttling.

Owner:北京众博达石油科技有限公司

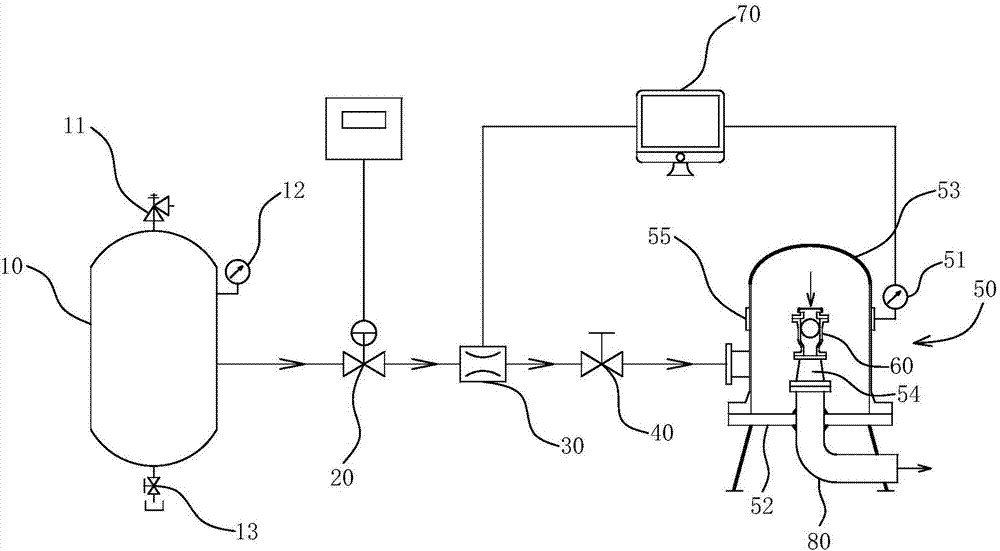

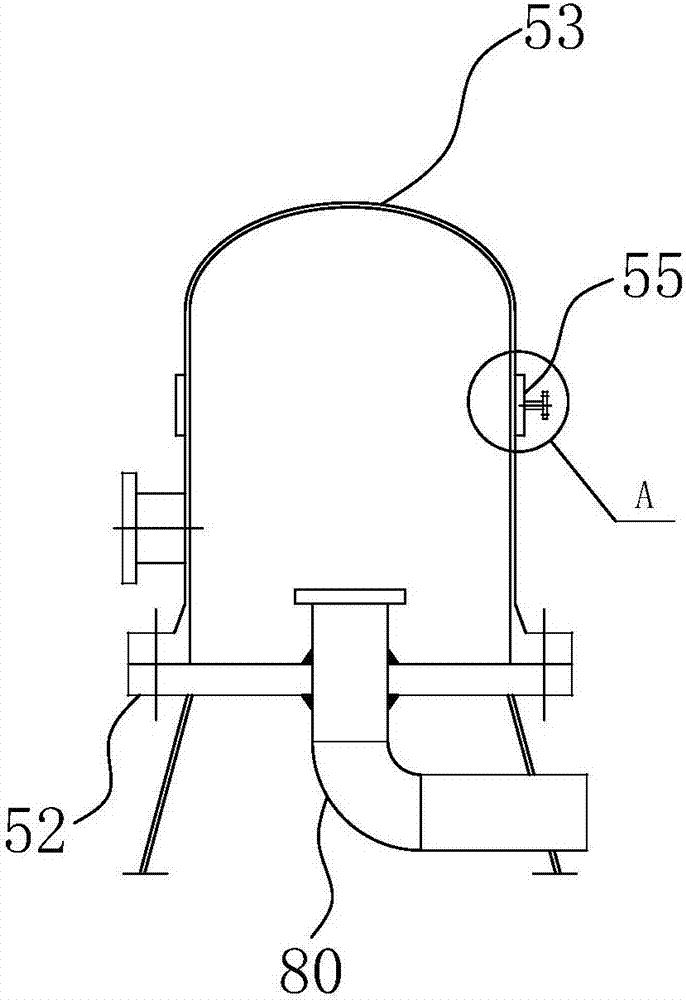

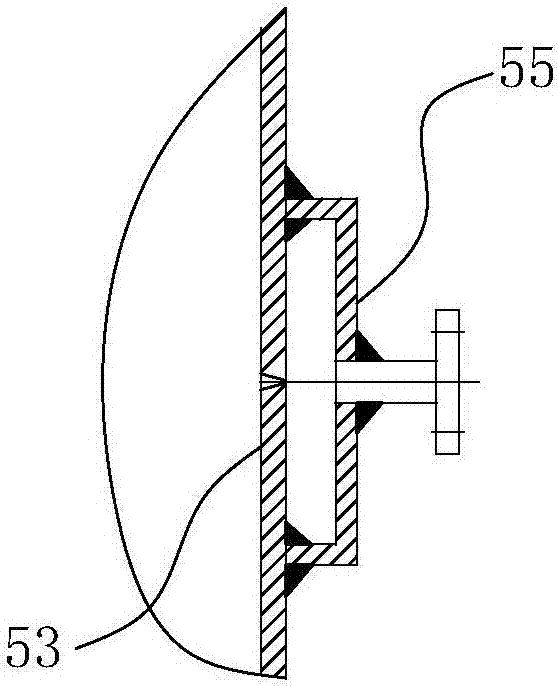

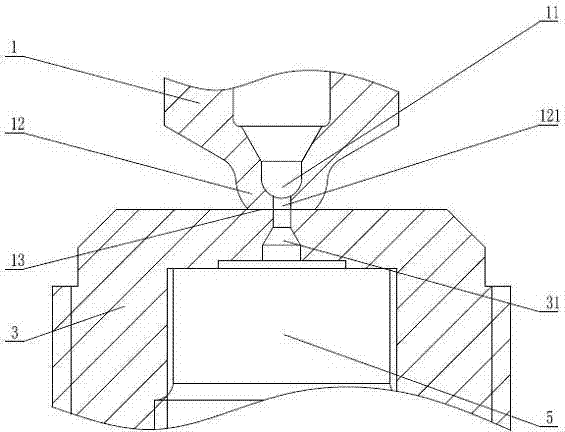

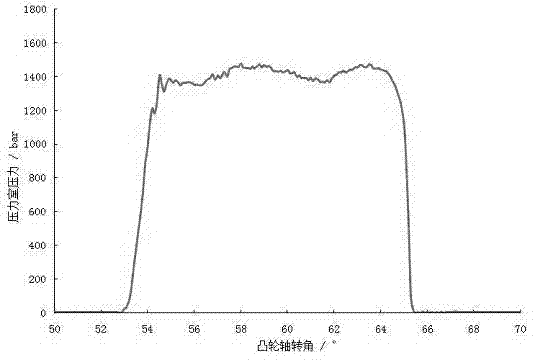

Air valve air intake performance test device and test method

The invention relates to an air valve air intake performance test device and a test method. The air valve air intake performance test device comprises a data acquisition unit, and an air storage tank, a flow control valve, a flow meter and an air collection device which are installed on a test pipe in sequence along the direction of air flow. The air collection device is internally provided with a tested air valve installed on a corresponding exhaust pipe. A pressure gauge I used for measuring the pressure inside the air collection device is installed on the air collection device. The air collection device can precisely simulate the air intake state of the air valve under actual working condition. Multiple groups of air intake pressure differences Delta P and corresponding air intake Q data can be obtained by gradually adjusting the flow control valve. The device and the method have the advantages of low cost, simple structure, and easy operation in the test process. The invention provides a simpler and novel way to test the air intake performance of an air valve.

Owner:HEFEI GENERAL MACHINERY RES INST

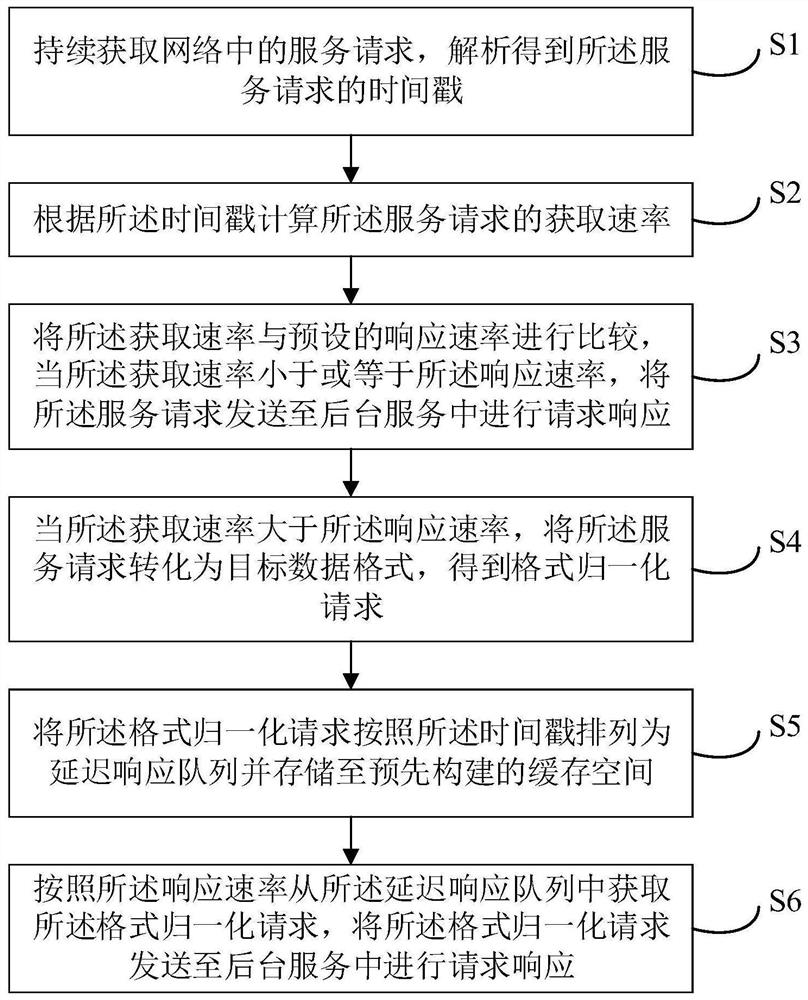

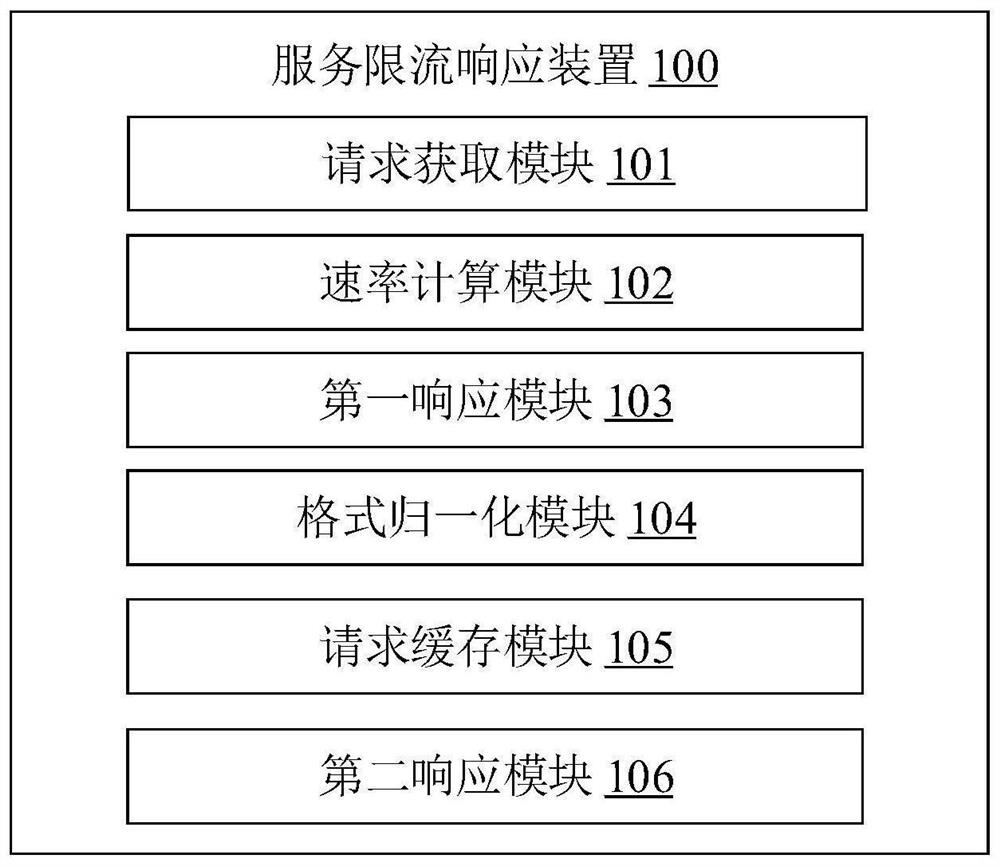

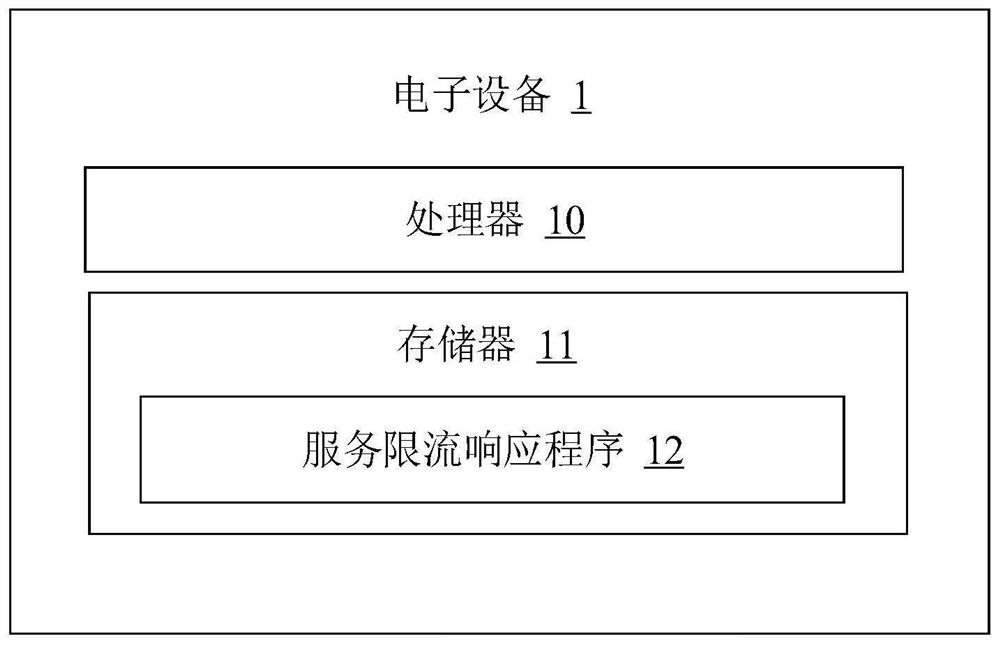

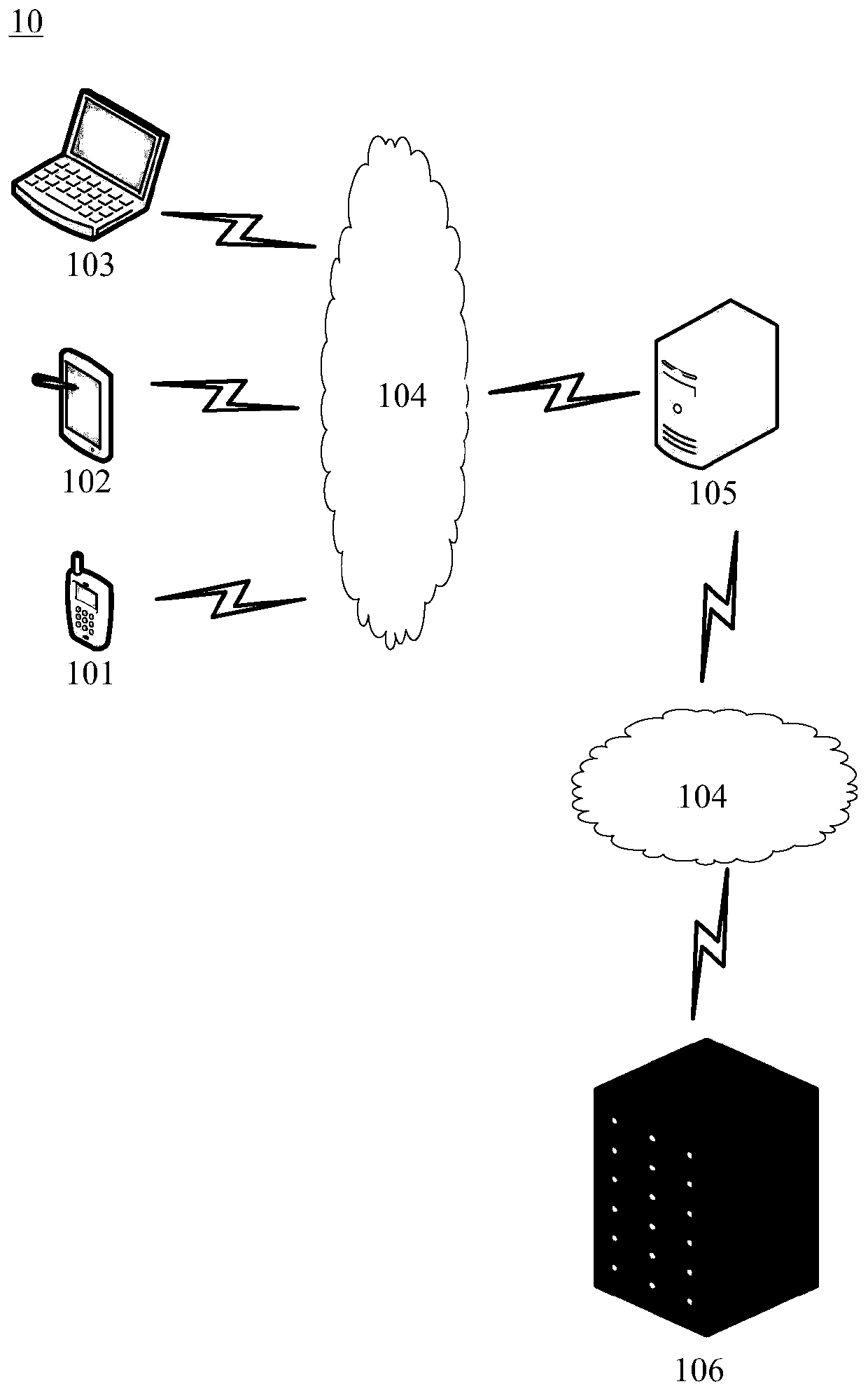

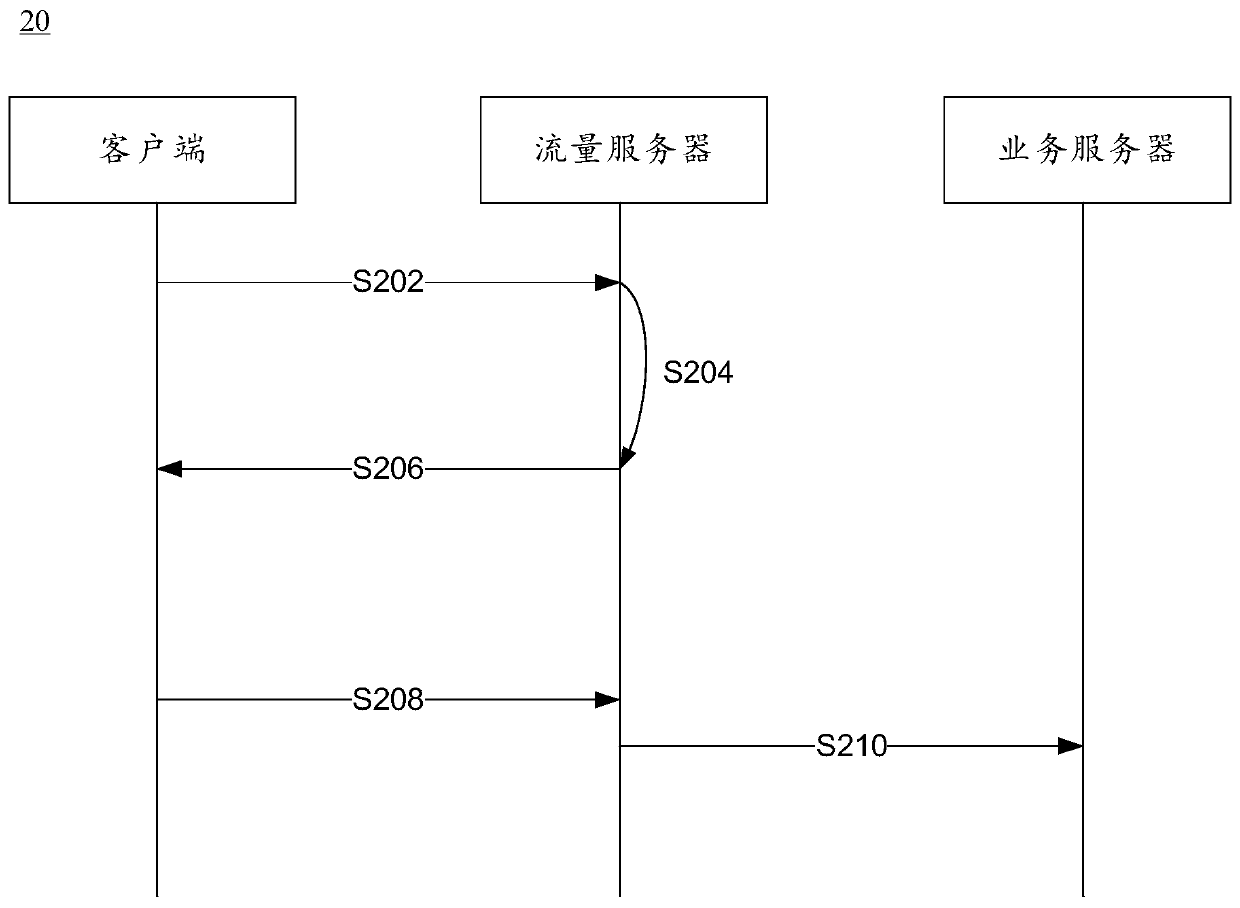

Service flow limiting response method and device, electronic equipment and readable storage medium

PendingCN112702228ARealize current limitingAvoid throttlingData switching networksService flowResponse method

The invention relates to a network protocol technology, and discloses a service flow limiting response method, which comprises the following steps of: analyzing a timestamp of an acquired service request; calculating an acquisition rate of the service request according to the timestamp; comparing the acquisition rate with a preset response rate, and when the acquisition rate is smaller than or equal to the response rate, sending the service request to a background service for request response; when the acquisition rate is greater than the response rate, converting the service request into a target data format, arranging the service request into a delay response queue according to timestamps and storing the delay response queue; and obtaining the format normalization request from the delay response queue according to the response rate, and sending the format normalization request to the background service for request response. In addition, the invention also relates to a blockchain technology, and the delay response queue can be stored in a node of the blockchain. The invention further provides a service flow limiting response device, electronic equipment and a computer readable storage medium. According to the invention, the problems of request loss and system downtime caused by overlarge service request rate can be solved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

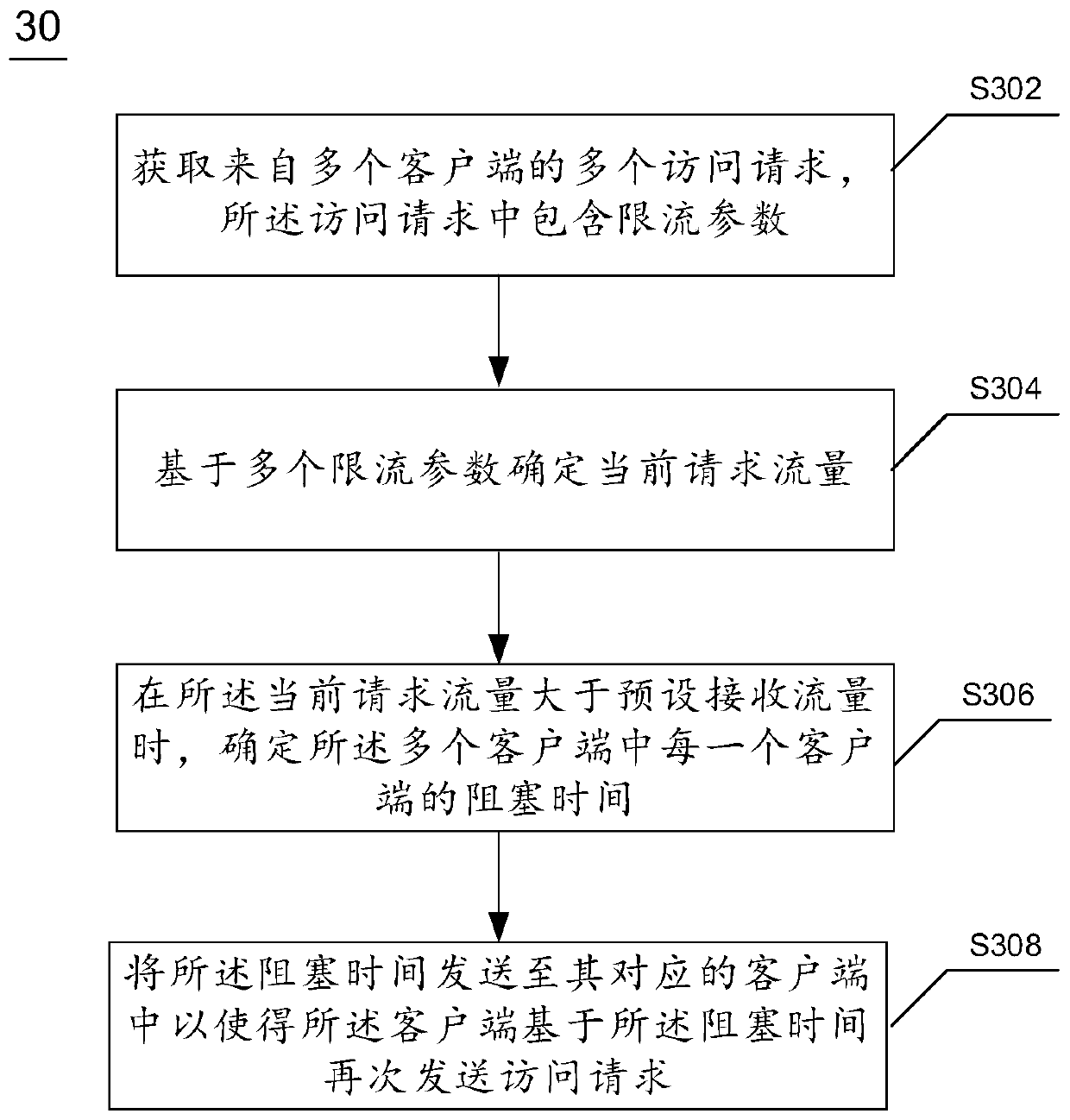

Access request processing method and device and electronic equipment

PendingCN110808914AAvoid throttlingAvoid interface call exceptionsData switching networksEngineeringReal-time computing

The invention relates to an access request processing method and device, electronic equipment and a computer readable medium. The method comprises the following steps: acquiring a plurality of accessrequests from a plurality of clients, wherein the access requests comprise flow limiting parameters; determining a current request flow based on the plurality of flow limiting parameters; when the current request flow is greater than a preset receiving flow, determining the blocking time of each client in the plurality of clients; and sending the blocking time to the client corresponding to the blocking time, so that the client sends the access request again based on the blocking time. According to the access request processing method and device, the electronic equipment and the computer readable medium, service end server flow limiting caused by the fact that the flow of the instantaneous access request is too large can be avoided, and therefore abnormal interface calling at the client side is avoided, and service losses at the client side are also avoided.

Owner:北京淇瑀信息科技有限公司

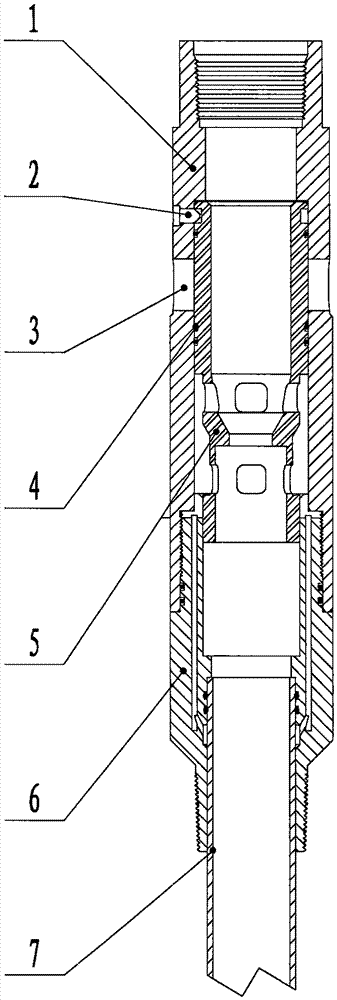

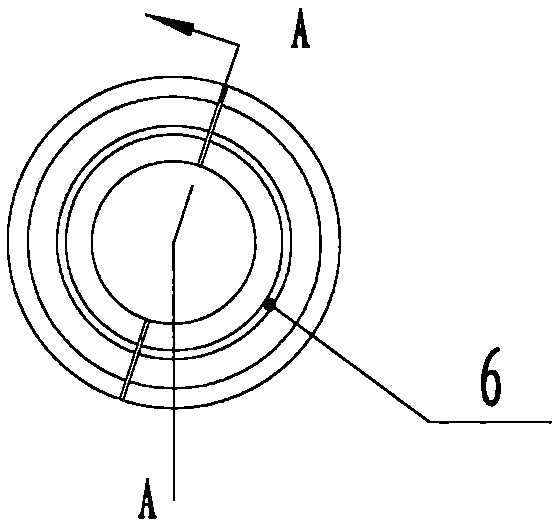

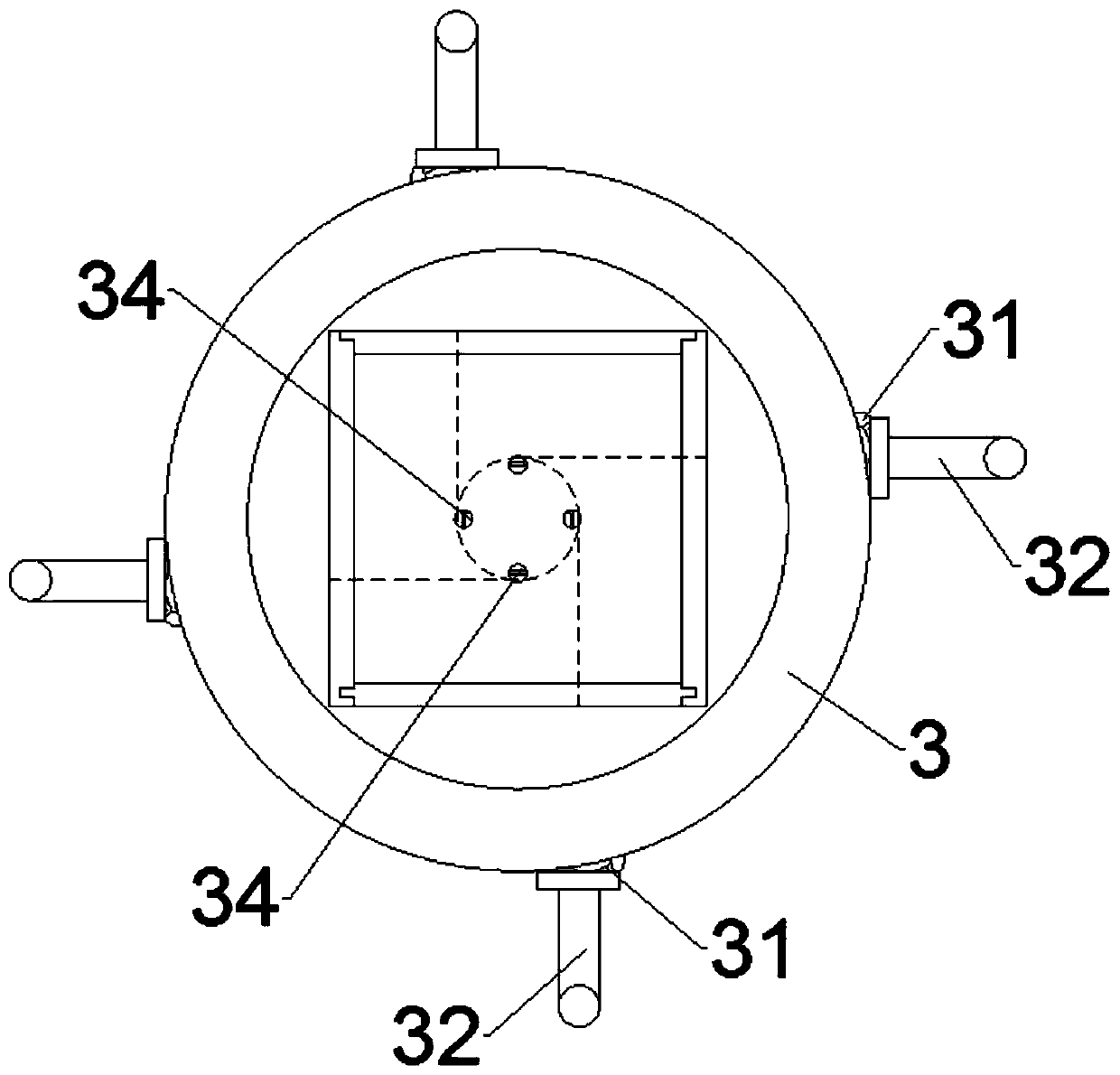

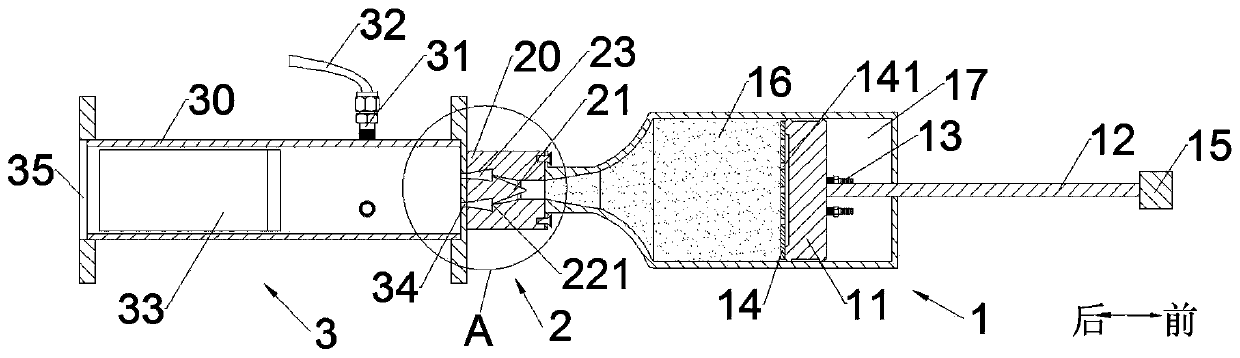

Double-layer channel flow complementary type pressure guide sand blaster

ActiveCN105443103AReduce frictional resistanceOvercoming the disadvantages of layer-by-layer throttlingFluid removalInternal pressureSand blasting

A double-layer channel flow complementary type pressure guide sand blaster comprises a sand blaster body, a pin, a sand blasting hole, a seal ring, a double-layer channel flow complementary type slide sleeve, a pressure guide lower connector, a pressure guide pipe, a water seepage kerf and an inner pressure guide channel. By means of the sand blaster, the advantage that a ball pitching sand blaster can be used in a multi-level mode is kept, and meanwhile through the unique and novel design of the double-layer channel type flow complementary type slide sleeve, the sand blaster can comprise a slide sleeve inner layer channel and a slide sleeve outer layer channel; when one of the overflow section areas of the two channels is enlarged or narrowed, the other one of the overflow section areas of the two channels is accordingly narrowed or enlarged, and complementation is achieved; a basic fixed value is achieved for the overflow area, and the disadvantage that throttling is conducted on the sand blaster layer by layer on a tubular column is overcome. By means of the pressure guide lower connector, water pressure on the upper layer passes by a low-density ball through the pressure guide lower connector and is conducted to a tool which is on the lower layer and needs water pressure, for example, a packer and a hydraulic anchor, and normal work of the construction tubular column is ensured. When the sand blaster is applied in the construction tubular column, friction force borne by high-pressure liquid in the tubular column can be reduced, the overflow amounts and the overflow speeds in the whole tubular column can be similar, flow limiting is avoided, and the sand conveying efficiency is improved.

Owner:盐城市畅海精密机械有限公司

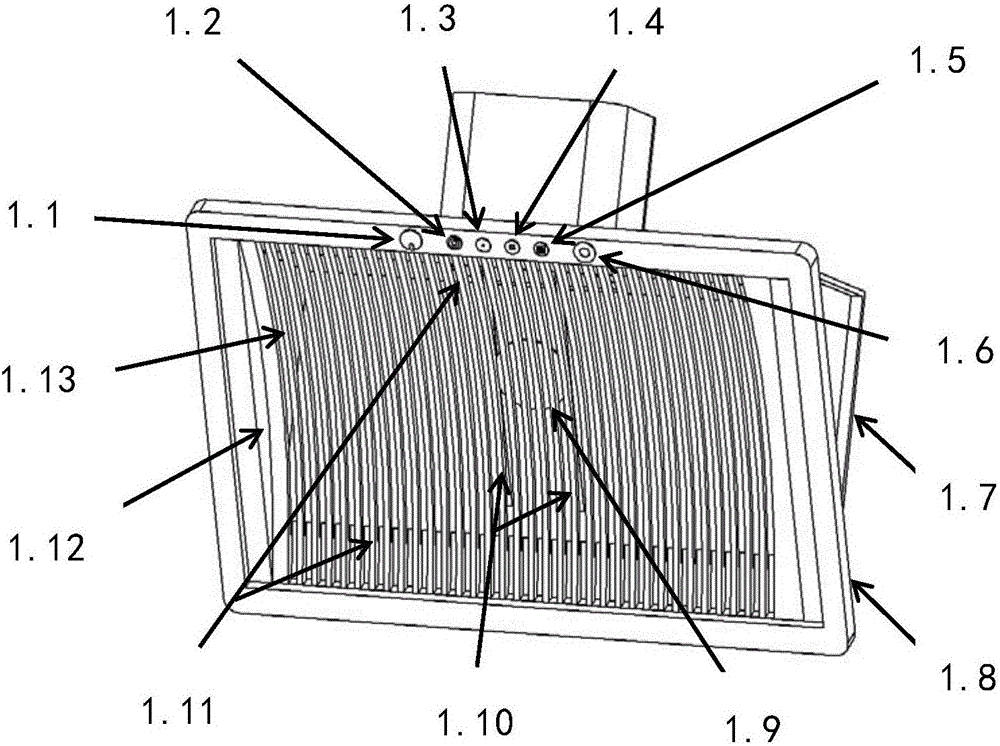

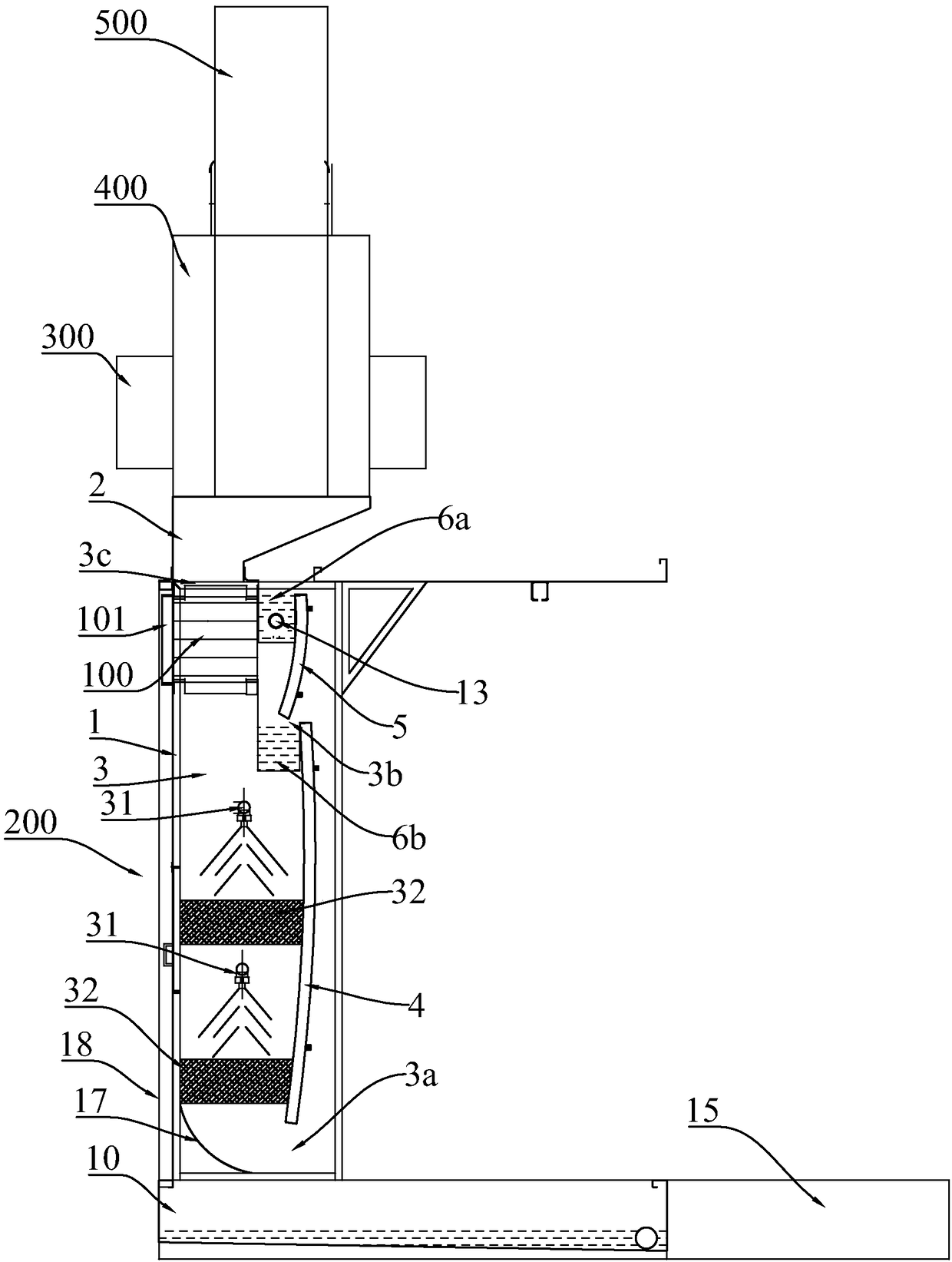

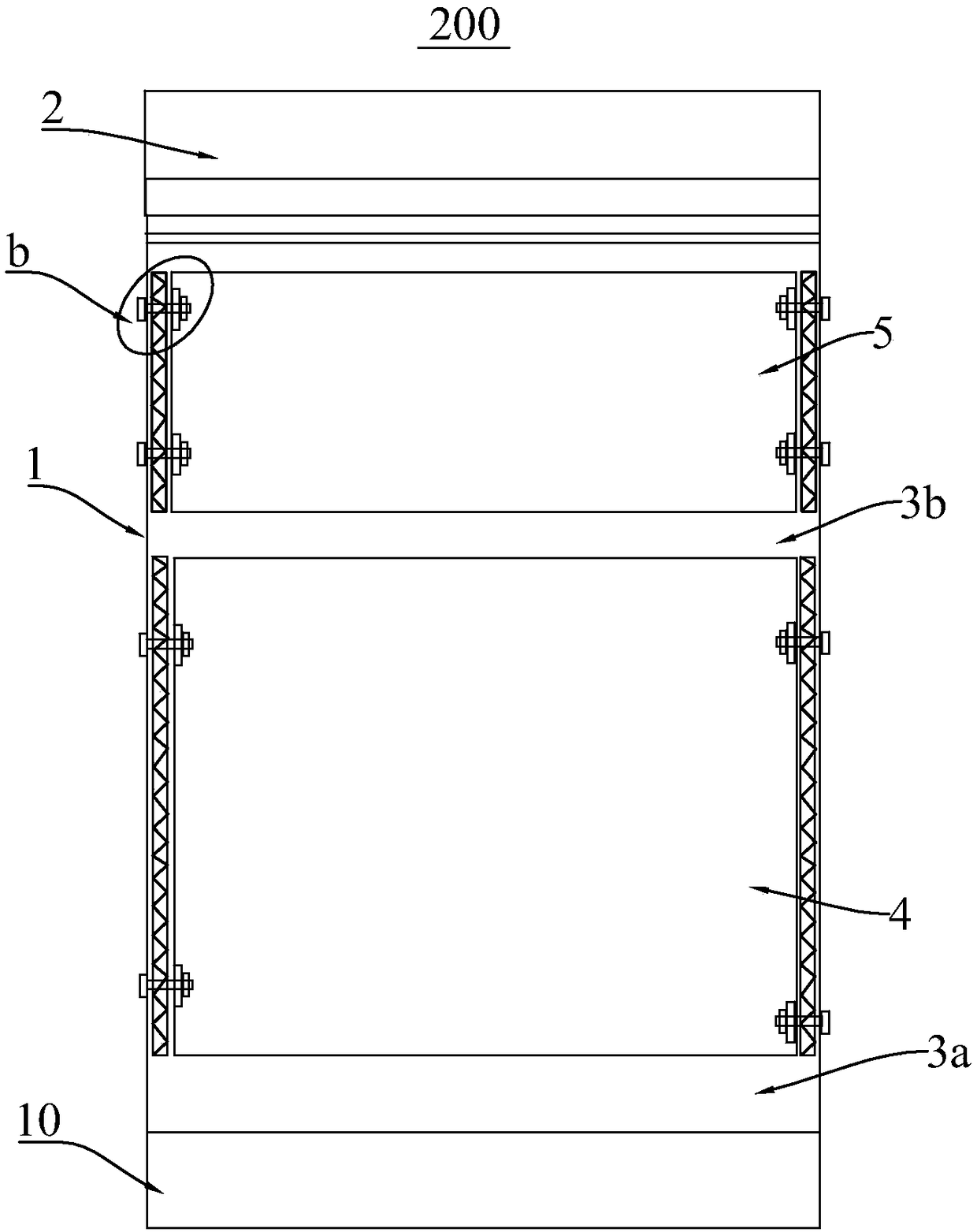

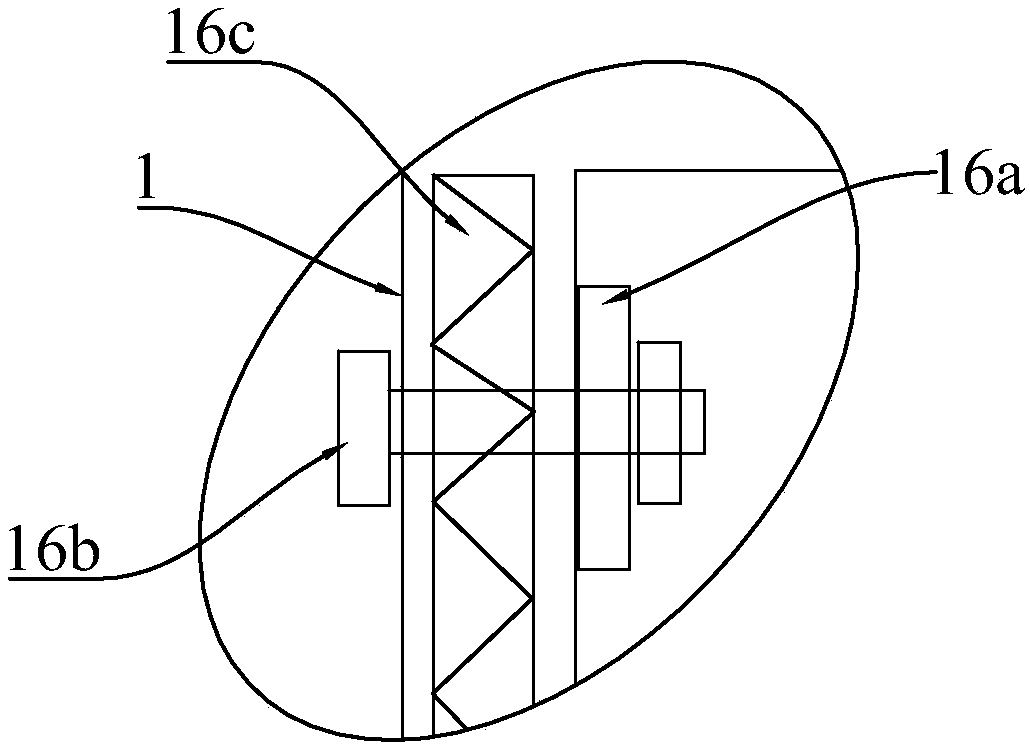

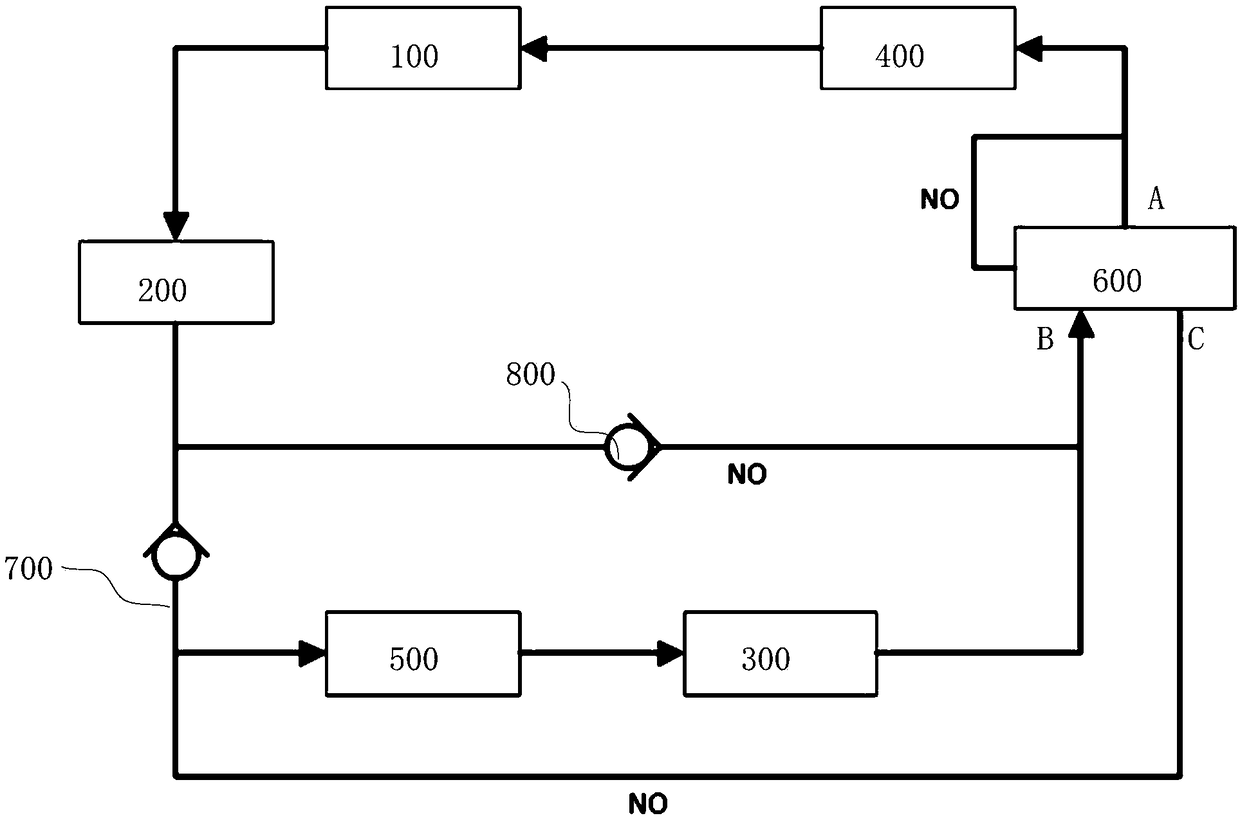

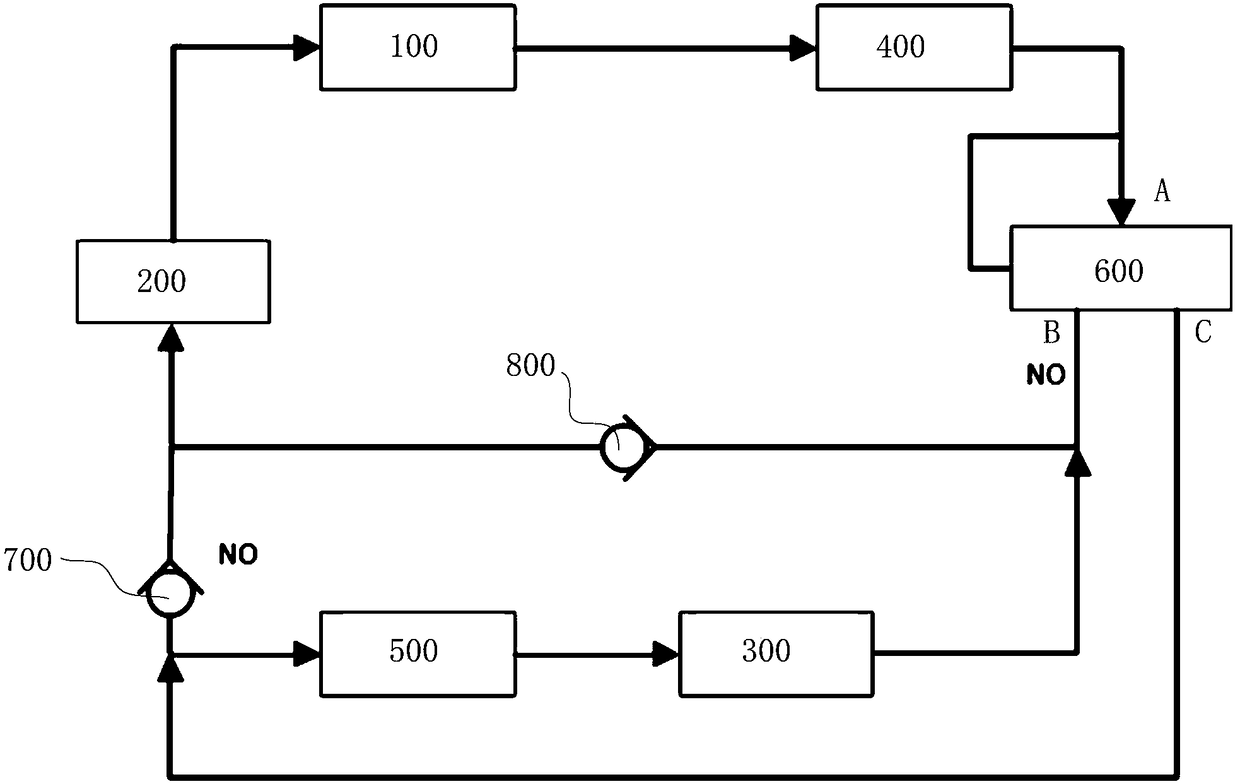

Integrated cooling pad waste gas treatment equipment

PendingCN108514788AGood indoor purification effectSmooth and quick inhalationGas treatmentUsing liquid separation agentSimple Organic CompoundsTherapeutic effect

The invention discloses integrated cooling pad waste gas treatment equipment. The integrated cooling pad waste gas treatment equipment is characterized by comprising a cooling pad paint spraying cabinet (200), UV photo-oxidation equipment (400) and a centrifugal fan (300); the centrifugal fan (300) is connected between the cooling pad paint spraying cabinet (200) and the UV photo-oxidation equipment (400) and used for feeding air to the UV photo-oxidation equipment (400) from the cooling pad paint spraying cabinet (200); an outlet of the UV light oxygenation equipment (400) leads to atmospherethrough an exhaust pipeline (500); the UV light oxygenation equipment (400) can decompose an organic compound in exhaust gas into water and carbon dioxide, and thus the waste gas of a volatile organic compound is efficiently purified. The cooling pad waste gas treatment equipment is integrally manufactured, has a good treatment effect, and is convenient to maintain and long in service life; through integrated manufacturing, the cost is reduced, moreover, unnecessary air ducts connected with the pipeline can also be reduced, the wind resistance is greatly reduced, and the amount of the exhaustair is reduced. The power of the selected fan is far smaller than that of fans of treatment equipment of other factories, and in this way, the effects of energy saving and emission reduction can be achieved.

Owner:大连美森木业有限公司

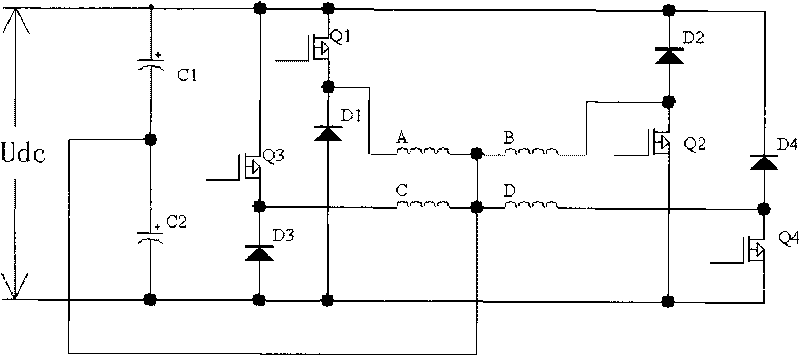

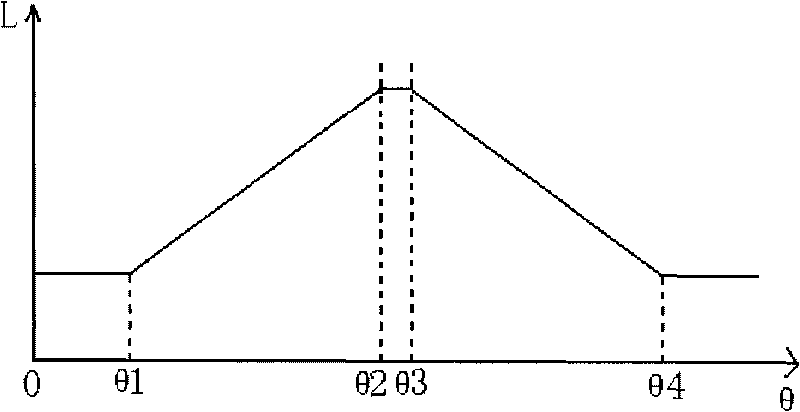

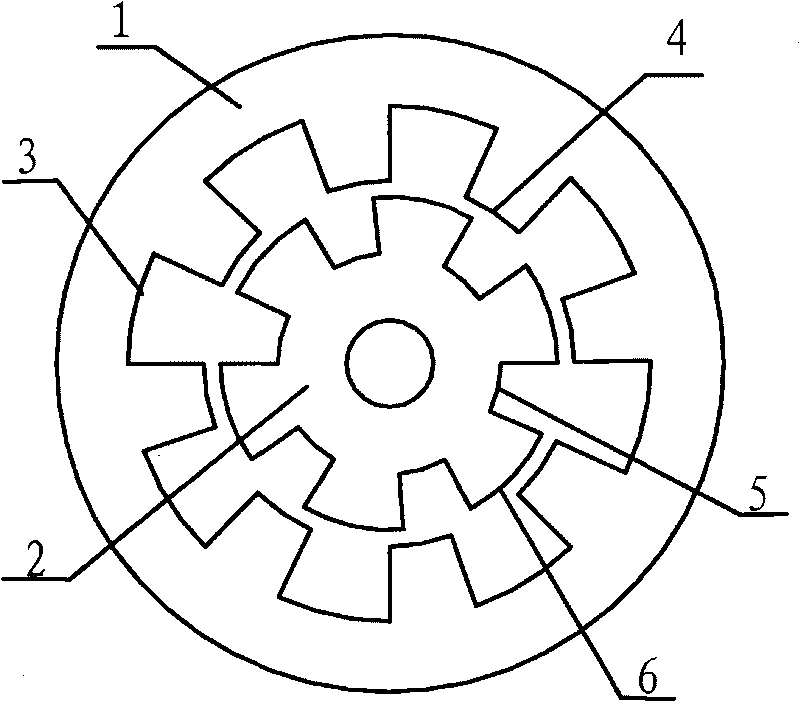

Switched reluctance motor for capacitance split circuit

InactiveCN101719709AImprove efficiencyDecrease the angle valueMagnetic circuit rotating partsMagnetic circuit stationary partsCapacitanceEngineering

The invention provides a switched reluctance motor for a capacitance split circuit, which belongs to the technical field of motors and solves the problem of low efficiency of the whole system because the operation of the traditional switched reluctance motor for a capacitance split circuit is hindered by long current endurance time of the phase A and the phase C of the switched reluctance motor. The switched reluctance motor for the capacitance split circuit comprises a stator and a rotor, wherein the external annular surface of the stator is provided with stator grooves and stator salient poles, which are uniformly distributed at intervals; the internal annular surface of the rotor is provided with rotor grooves and rotor salient poles, which are uniformly distributed at intervals; and the difference of the radian of the rotor grooves and the radian of the stator salient poles is less than the difference of the radian of the rotor salient poles and the radian of the stator grooves. The switched reluctance motor can reduce the natural current endurance time of the phase A and the phase C, improve the efficiency of the switched reluctance motor and save the energy resource.

Owner:WOLONG ELECTRIC GRP CO LTD

Backpressure Valve for Wireless Communication

InactiveUS20090301713A1Avoid throttlingControl pressureSurveyDrilling rodsPressure generationCavitation

A backpressure valve. The backpressure valve may be configured to maintain a substantially controlled pressure in coiled tubing uphole thereof while simultaneously being compatible with a pressure pulse tool downhole thereof. The backpressure valve includes pressure generating capacity below its internal valve assembly so as to avoid the tendency of the assembly to throttle open and closed. Furthermore, the pressure generation is achieved in a manner avoiding cavitation. As a result, once the backpressure valve is opened, the pressure pulse tool is able to reliably communicate with surface equipment at the oilfield.

Owner:SCHLUMBERGER TECH CORP

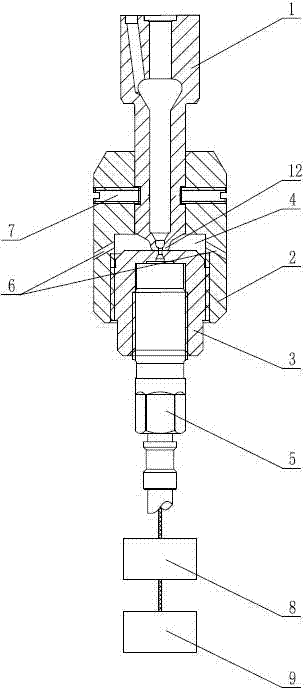

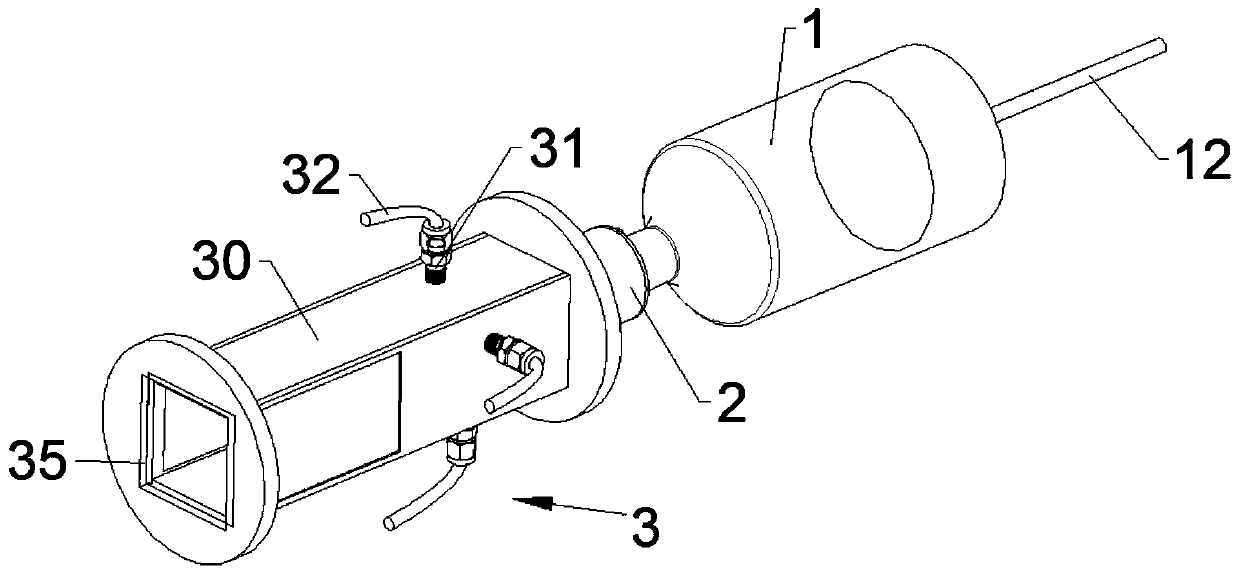

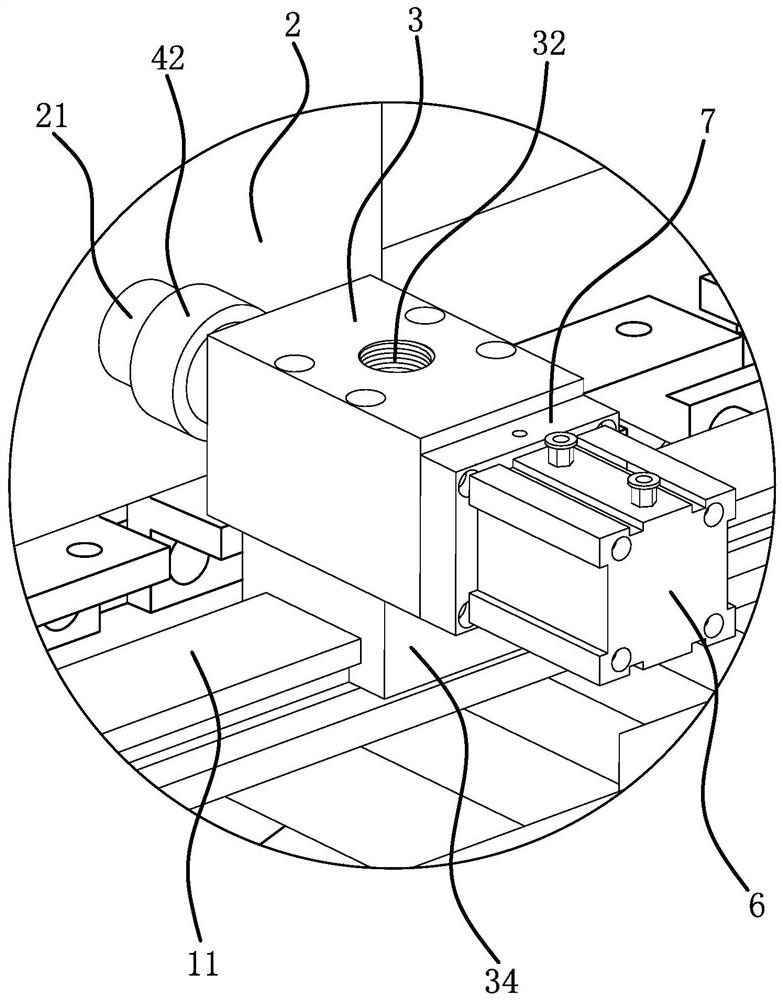

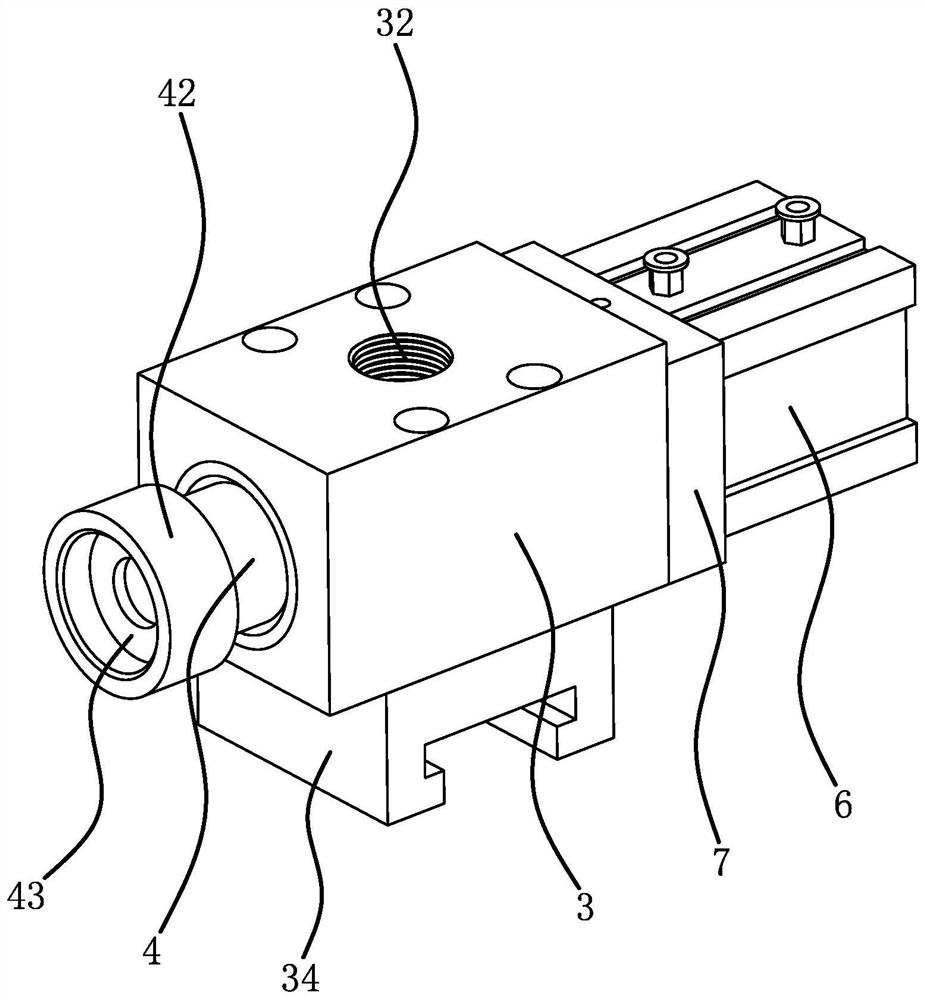

Pressure measuring device comprising oil spraying nozzle with pressure chamber

ActiveCN104728011ASolve the installationSolve the sealing problemEngine testingFuel injection apparatusSpray nozzlePressure measurement

A pressure measuring device comprising an oil spraying nozzle with a pressure chamber comprises the oil spraying nozzle with the pressure chamber, wherein the oil spraying nozzle is fixedly connected with a fixing sleeve; a groove with a downward opening is formed in the fixing sleeve; the fixing sleeve is fixedly connected to the outer periphery of a connecting pressing sleeve in a sleeving manner; oil spraying space is reserved between the upper end surface of the connecting pressing sleeve and the end surface of the top of the groove of the fixing sleeve; a ball of the oil spraying nozzle penetrates in the fixing sleeve and extends into the oil spraying space; the ball and the matched surface at the upper end of the connecting pressing sleeve are sealed in a compaction manner; the ball is provided with an axial drainage hole; the connecting pressing sleeve is provided with a pressure conduction cavity; the pressure chamber is connected with the pressure conduction cavity through the axial drainage hole; the pressure sensor is arranged on the connecting pressing sleeve and is positioned below the pressure conduction cavity; and a plurality of oil drainage holes are uniformly distributed on the periphery of the fixing sleeve and are connected with the oil spraying space. The actual pressure of the pressure chamber can be measured under the actual working state. The pressure measuring device is accurate and reliable in measurement, simple in structure and convenient to assemble and disassemble.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

Electronically controlled throttle control apparatus

ActiveUS20050155576A1Reduced sliding resistancePrevent rotationElectrical controlOperating means/releasing devices for valvesThrottle controlCoil spring

An electronically controlled throttle control apparatus prevents a throttle valve from malfunctioning due to deterioration in sliding resistance ascribable to abrasive dust at a sliding contact portion between a valve gear of a geared reduction device and a coil spring. The outer periphery of a spring inner periphery guide is provided with a plurality of groove portions as abrasive dust removing means for removing abrasive dust at least from a sliding contact portion between the outer periphery of the spring inner periphery guide and the inner periphery of a default spring, so that individual edge portions of the plurality of groove portions can rub the inner periphery of the default spring to scrape off abrasive dust from the inner periphery of the default spring and direct the abrasive dust into the plurality of groove portions.

Owner:DENSO CORP

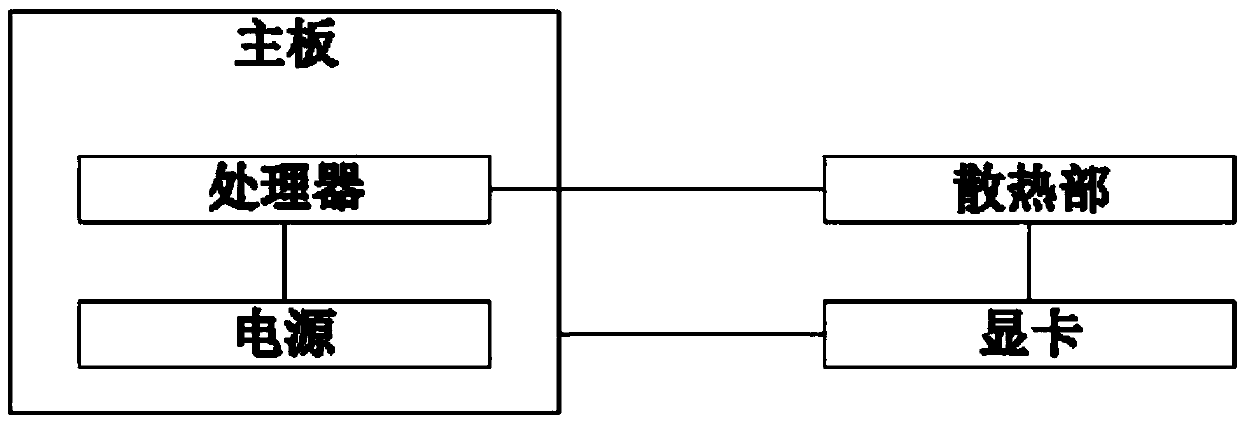

Blockchain big data virtual currency processing system and processing method

InactiveCN109634387AImprove air cooling effectReduce the temperatureFinanceDigital data processing detailsMotherboardBlockchain

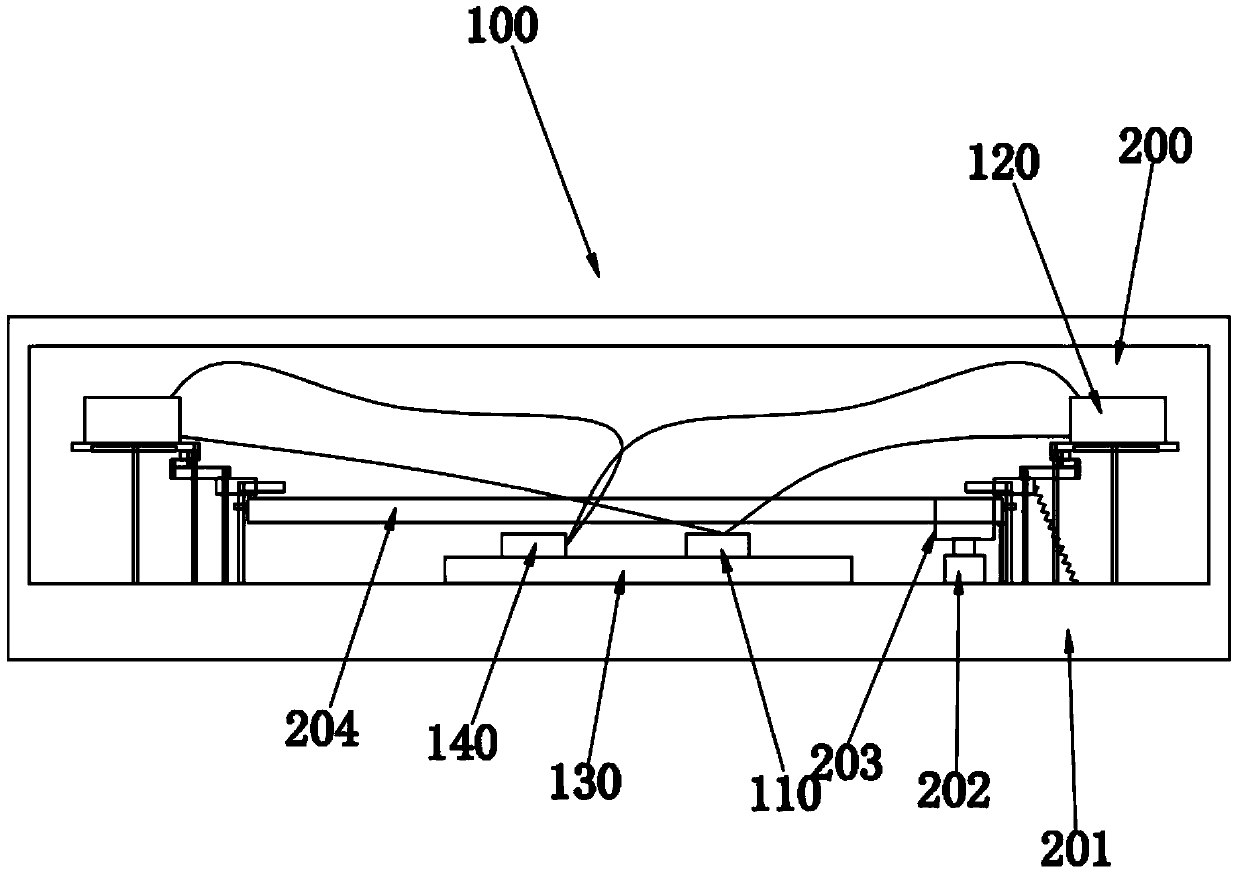

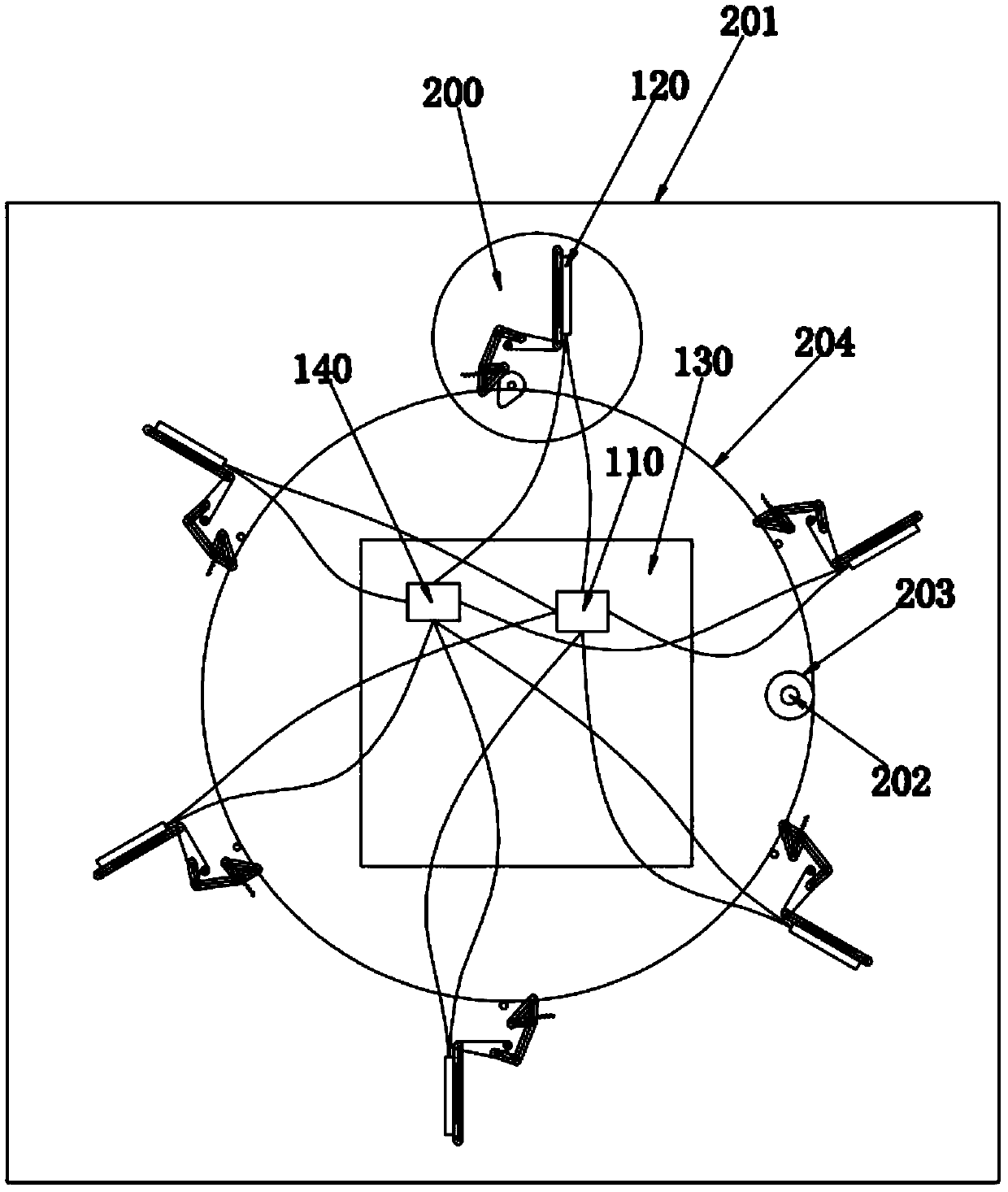

The invention discloses a blockchain big data virtual currency processing system 1. The system comprises at least five block chain nodes (100) which are connected with one another, each block chain node (100) comprises a processor (110), a display card (120), a main board (130), a heat dissipation part (200) and a power supply (140), and when the temperature of the processor (110) and the displaycard (120) exceeds a first threshold value, the display card (120) is swung. In this way, the display card (120) can be further cooled in a swinging mode, heat of the display card (120) can be evenlydistributed to the periphery of the display card (120) instead of one side of the display card (120) in a swinging mode, and therefore air flowing around the display card (120) is accelerated.

Owner:南京纸链科技发展有限公司

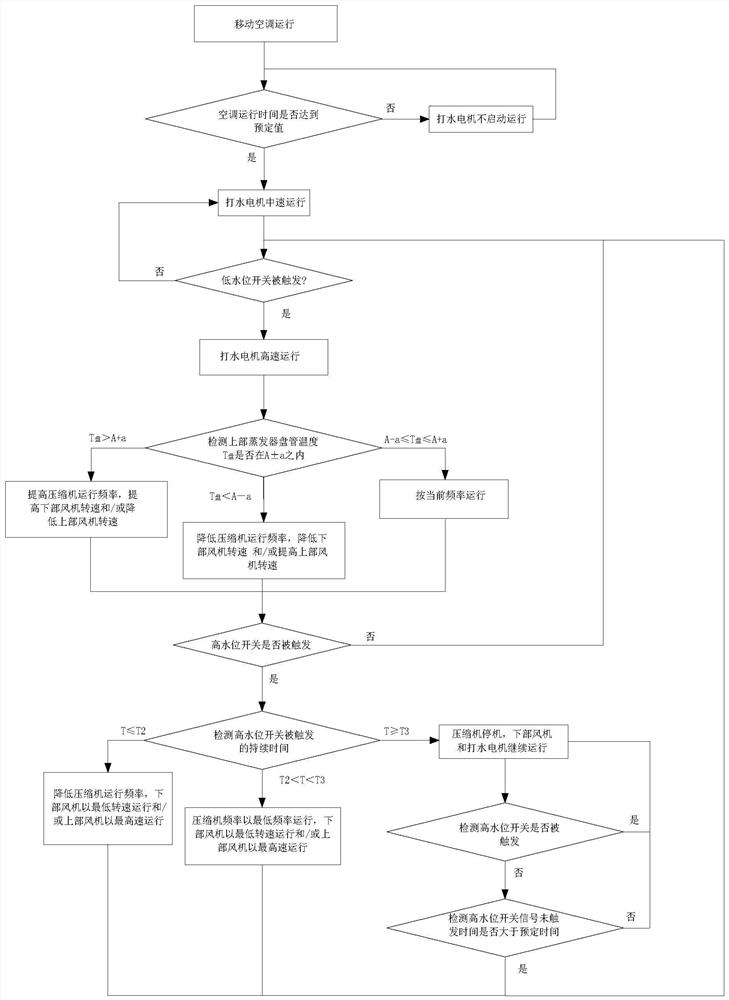

Mobile air conditioner control method and mobile air conditioner adopting same

InactiveCN112032963AIncrease the speed to the second speedImprove cooling effectMechanical apparatusSpace heating and ventilation safety systemsCondensed waterEvaporator

The invention discloses a mobile air conditioner control method and a mobile air conditioner adopting the same. The mobile air conditioner control method comprises the following steps that the mobileair conditioner operates; whether a low-water-level switch is triggered or not is detected; if the low-water-level switch is not triggered, a water fetching motor operates at a first rotating speed; if the low-water-level switch is triggered, the rotating speed of the water fetching motor is increased to a second rotating speed, and whether the temperature of an evaporator is within a preset temperature range or not is detected; if the temperature of the evaporator is within the preset temperature range, a compressor operates at the current frequency; if the temperature of the evaporator is out of the preset temperature range and is lower than the lowest temperature value of the preset temperature range, the operation frequency of the compressor is reduced; and if the temperature of the evaporator is out of the preset temperature range and is higher than the highest temperature value of the preset temperature range, the operation frequency of the compressor is increased. According to the mobile air conditioner control method, the water level of condensate water can be effectively reduced, and the user experience is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Trace powder distribution fluidization device

PendingCN111271191AWell mixedAvoid throttlingTurbine/propulsion fuel supply systemsGas turbine plantsStructural engineeringMaterials science

The embodiment of the invention provides a trace powder distribution fluidization device. The trace powder distribution fluidization device comprises a powder storage assembly, a powder distribution assembly and an observation assembly, the powder storage assembly comprises a powder storage shell, and a fuel grain is arranged in the powder storage shell, the powder distributing assembly comprisesa powder distribution shell, a conical part is arranged in the powder distribution shell, a powder channel is formed in the front end of the conical part, a powder distribution hole is formed in the rear end of the conical part, and a circular seam is formed between the powder channel and the powder distribution hole; the observation assembly comprises an observation shell, a plurality of fluidization gas connecting nozzles are arranged on the front portion of the observation shell, and observation glass is arranged on the rear portion of the observation shell. According to the embodiment of the trace powder distribution fluidization device, full mixing of the powder fuel and the fluidization gas is realized.

Owner:HUNAN AIRTOPS INTELLIGENT TECH CO LTD

Air conditioning system

PendingCN109114839AAvoid throttlingAvoid shutdownMechanical apparatusDomestic cooling apparatusEngineeringAir conditioning

The invention relates to an air regulating device, in particular to an air conditioning system. In order to solve the problem that heat dissipation efficiency of an existing air conditioner main boardis relatively low, the invention provides the air conditioning system for radiating the main board through an air conditioning refrigerant, the air conditioning system comprises a compressor, a firstheat exchanger, a throttle assembly and a second heat exchanger, which are sequentially connected to form a refrigerant circulating system, and further comprises a heat dissipation assembly, whereinthe heat dissipation assembly is in series connection with the throttle assembly for radiating the main board of the air conditioning system. An active heat dissipation way which adopts the refrigerant to absorb heat is adopted, and heat dissipation efficiency for the main board is relatively high; and moreover, excessive electric-control apparatuses do not need to additionally arrange, so that the cost is relatively low.

Owner:GREE ELECTRIC APPLIANCES INC

Spouted circulating fluidized bed and spouted circulating fluidized bed process

InactiveCN104327869AAvoid layeringAvoid throttlingDirect heating destructive distillationBiofuelsHeating systemProcess engineering

The invention relates to the field of chemical equipment, particularly relates to a spouted circulating fluidized bed and a spouted circulating fluidized bed process. A spouted circulating fluidized bed system comprises a preheating system, a feeding system, a main reactor, a gas-solid separation system, a condensation system, a gas purifying system and a monitoring system. According to the spouted circulating fluidized bed process, non-condensable gas is used as circulating fluidization carrier gas and enters the main reactor through the feeding system; biomass is introduced into the main reactor and bed materials are heated to be pyrolyzed; generated pyrolysis gas, carbon and the carrier gas enter the gas-solid separation system to be subjected to gas-solid separation to remove the solid product carbon; pyrolysis gas generated after pyrolysis is processed in the condensation system to obtain biological oil and the non-condensable gas takes part in continuous circulation; and the non-condensable gas is recycled or discharged out of the system. The spouted circulating fluidized bed and the spouted circulating fluidized bed process have the advantages that equipment facilitates industrialized production and the operation cost is relatively low.

Owner:SHAANXI YUHANG ELECTRONICS

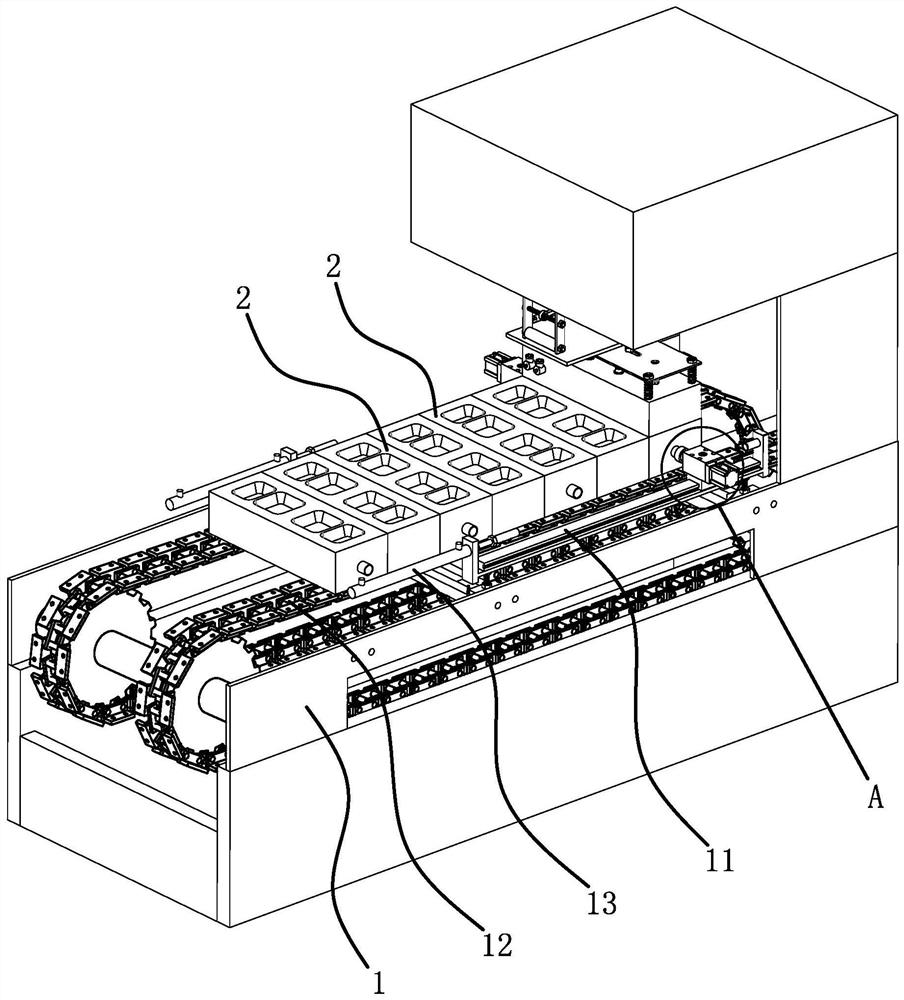

Air suction device of plastic vacuum forming machine

PendingCN112026144AAvoid rotation and excessive wear on one sideGuaranteed stabilityPhysicsEngineering

The invention provides an air suction device of a plastic vacuum forming machine, and belongs to the technical field of mechanical equipment. The problem that an air suction device of an existing plastic vacuum forming machine is poor in stability due to the fact that an air suction pipe moves in two directions is solved. According to the air suction device of the plastic vacuum forming machine, the plastic vacuum forming machine comprises a machine frame and a guide rail arranged on the machine frame; the air suction device comprises an air suction pipe and a driving piece; the air suction device further comprises a sliding base arranged on the guide rail in a sliding mode; a guide hole and an air suction hole communicating with the guide hole are formed in the sliding base; the air suction pipe is arranged in the guide hole in a sliding and penetrating mode; the driving piece is arranged on the sliding seat and can drive the air suction pipe to stretch out and draw back; an air passing hole is formed in the air suction pipe; and the air passing hole can communicate with the air suction hole when the air suction pipe stretches out, and the air passing hole and / or the air suction hole can be blocked when the air suction pipe retracts inwards. The air suction device of the plastic vacuum forming machine is good in stability.

Owner:温岭市新河食品机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com