Integrated cooling pad waste gas treatment equipment

A technology for waste gas treatment equipment and water curtain, which is applied in gas treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve problems such as environmental pollution, and achieve the effect of avoiding throttling effect, saving energy, and uniform water curtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

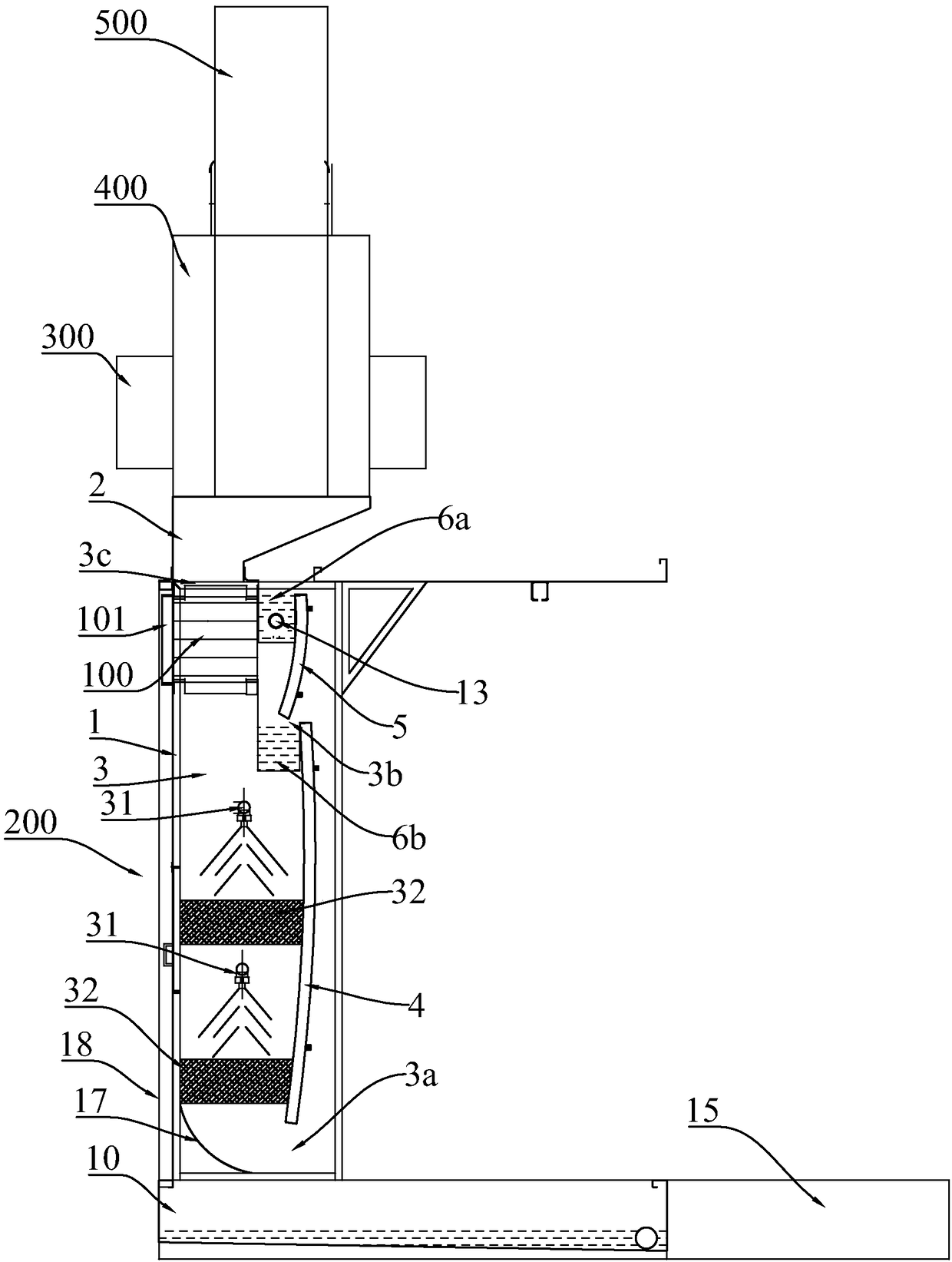

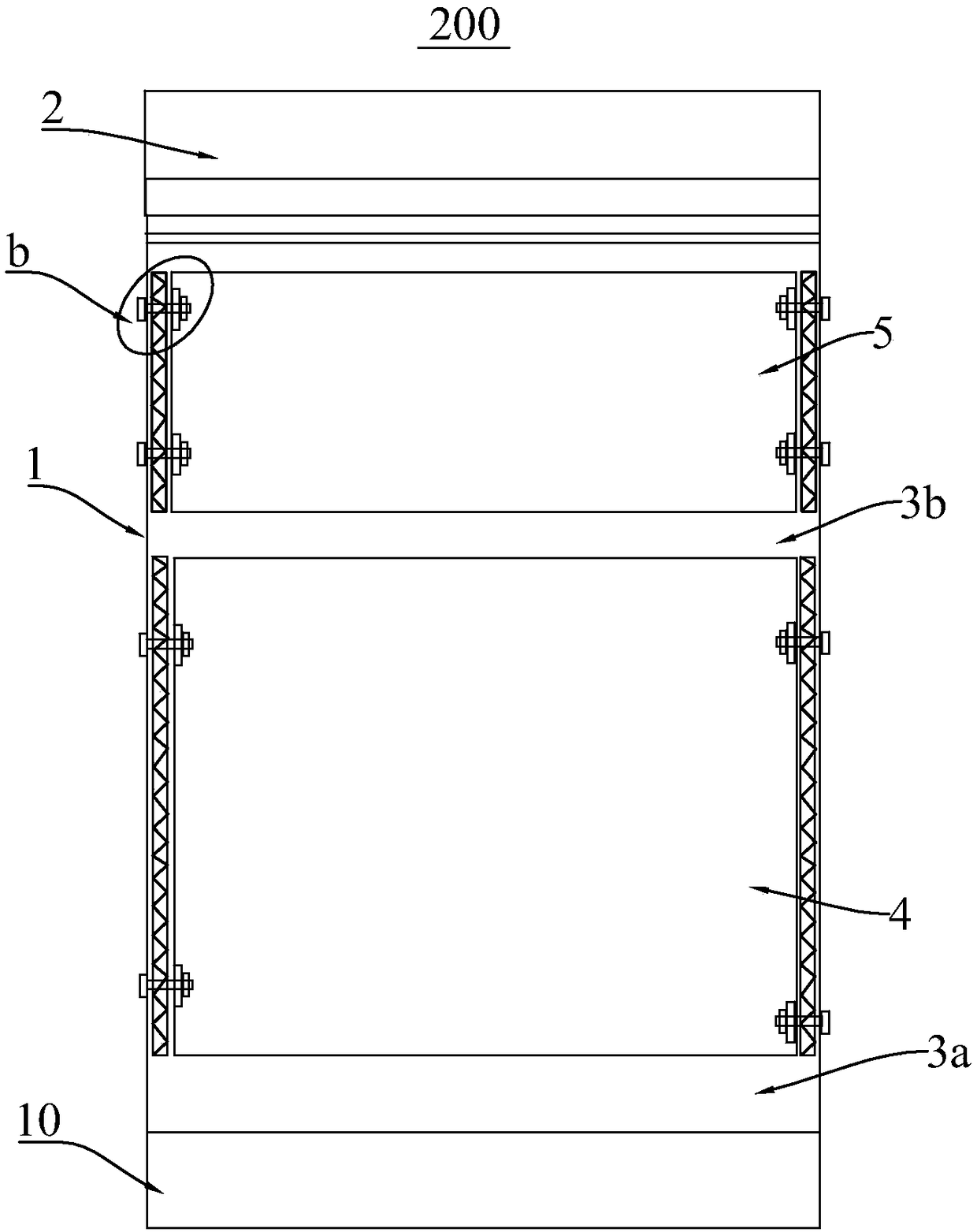

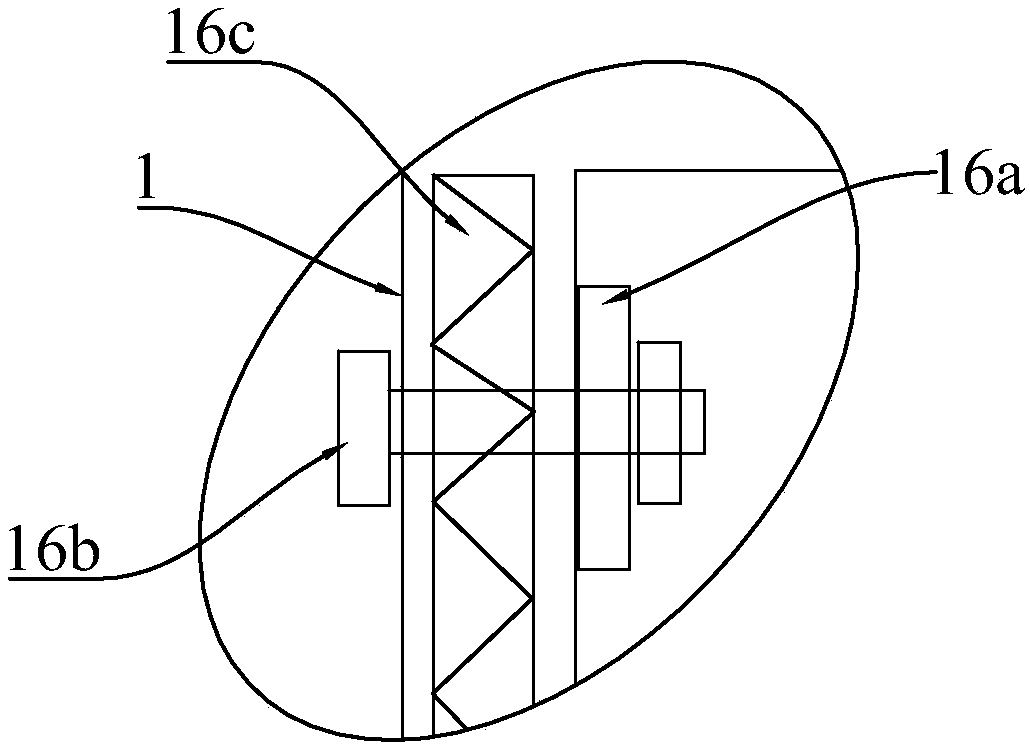

[0047] Such as Figure 1 to Figure 7 As shown, the integrated water curtain waste gas treatment equipment of the present invention includes a water curtain painting cabinet 200, a UV photooxygen equipment 400, and a water curtain spray cabinet 200 connected between the UV photooxygen equipment 400. The water curtain spray booth 200 is a centrifugal fan 300 that supplies air to the UV photooxygen equipment 400 ; the outlet of the UV photooxygen equipment 400 leads to the atmosphere through an exhaust duct 500 .

[0048] The water curtain painting cabinet 200 includes a cabinet body 1, a suction hood 2 arranged at the top of the cabinet body 1, and a water storage tank 10 provided at the bottom of the cabinet body 1, and an air flow channel 3 is provided inside the cabinet body 1 A lower water curtain 4 is arranged at the front of the air passage 3 , and an upper water curtain 5 is arranged above the lower water curtain 4 .

[0049] The air suction hood 2 is a funnel-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com