Environment-friendly type water curtain machine

A water curtain machine, an environmentally friendly technology, applied in the field of separation equipment in the field of environmental protection technology, can solve the problems of human body and environmental damage, without considering spray paint particles, etc., to avoid throttling, improve indoor purification effect, and reduce pump power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

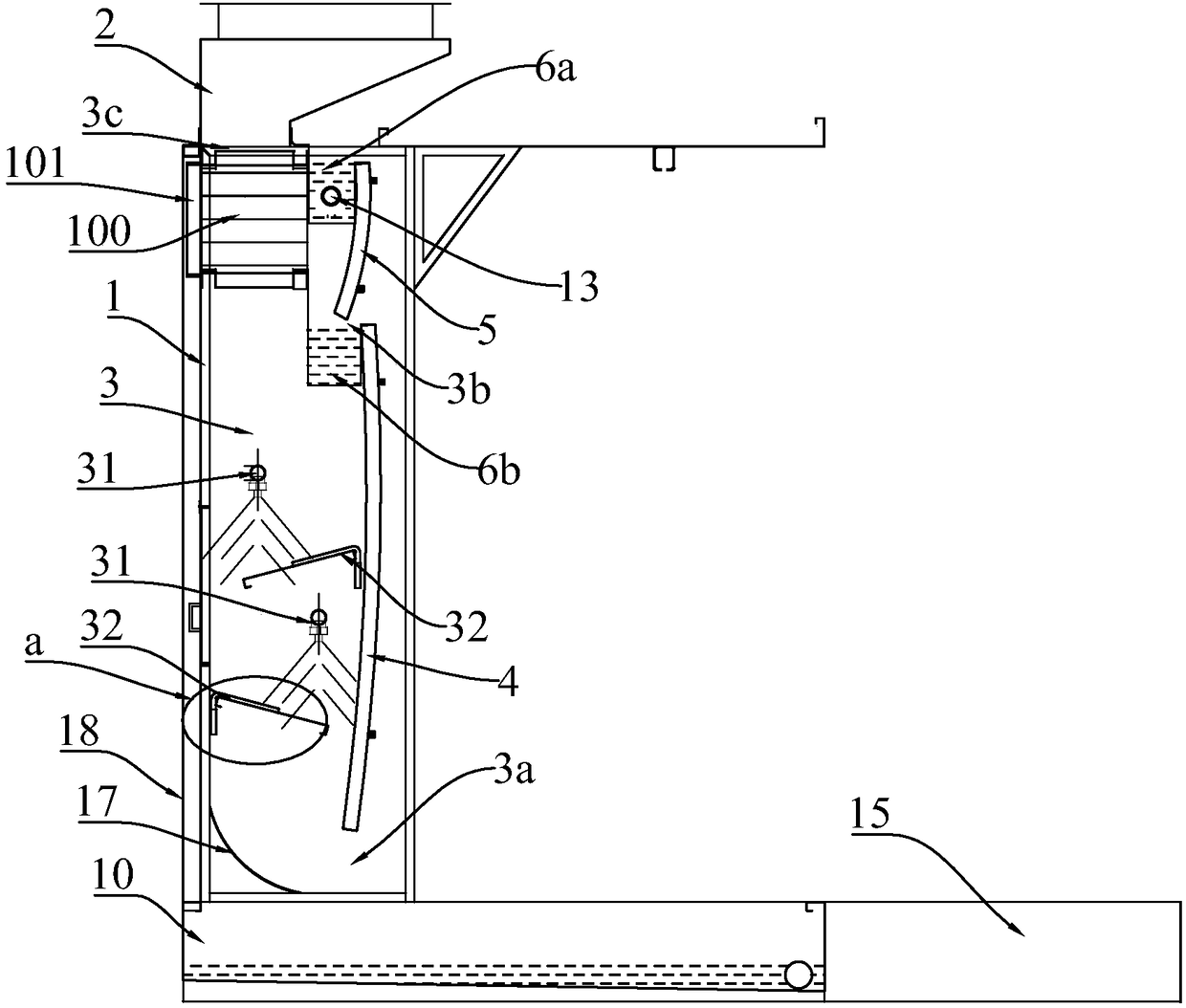

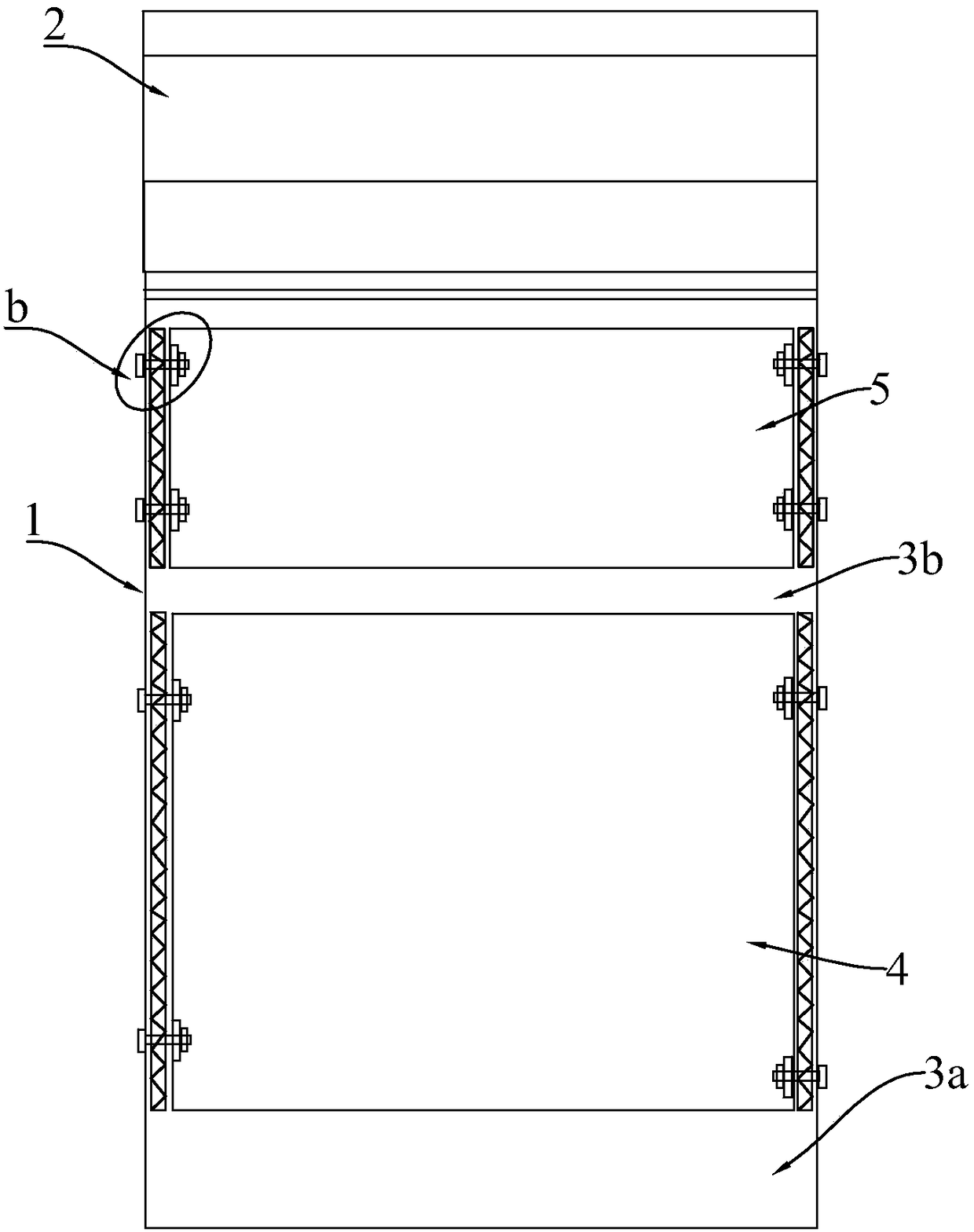

[0042] Such as figure 1 As shown, the environment-friendly water curtain machine of the present invention includes a cabinet body 1, a suction hood 2 arranged on the top of the cabinet body 1, an exhaust fan arranged on the upper inside of the suction hood 2, and the cabinet body 1 water storage tank 10 at the bottom.

[0043] The interior of the cabinet body 1 is provided with an air flow channel 3 , and an air outlet 3c at the top of the air flow channel 3 is sealed and connected with the bottom opening of the suction hood 2 .

[0044]A lower water curtain 4 and an upper water curtain 5 above the lower water curtain 4 are arranged at the front part of the air flow channel 3 . The lower part of the lower water curtain 4 is a smooth curved surface that bends toward the airflow channel 3 , and forms a first air inlet 3a leading to the airflow channel 3 between the bottom plate of the cabinet body 1 .

[0045] The lower part of the upper water curtain 5 is a smooth curved surf...

Embodiment 2

[0060] Such as Figure 1 ~ Figure 3 As shown, Embodiment 2 of the present invention is a further improvement on the basis of Embodiment 1. The specific improvement is that a spraying device is provided in the middle of the air flow passage 3, and the spraying device includes a plurality of spraying devices. Shower head 31 and a plurality of spray baffles 32; Figure 5 As shown, the water inlets of a plurality of shower heads 31 are connected to the water inlet pipe 13, and the water is supplied by the water inlet pipe 13 (only two shower heads 31 and two spray baffles are set in the accompanying drawings). In the case of the plate 32, a plurality of shower heads 31 and spray baffles 32 can be set according to actual conditions during use.

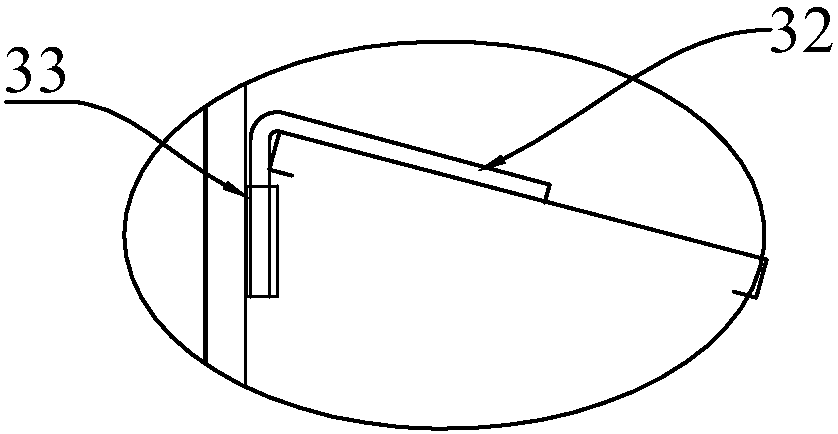

[0061] Such as figure 1 , figure 2 As shown, the cross-section of the spray baffle 32 is L-shaped, and its short side is inserted into the socket 33 on the inner wall of the air flow passage 3, and the long side is horizontally placed i...

Embodiment 3

[0066] Embodiment 3 of the present invention is a further improvement on the basis of Embodiment 2. The specific improvement is that: a group of steam-water separators 100 are horizontally spread on the top horizontal section of the air flow passage 3, such as figure 1 , Figure 7 , Figure 8 As shown, each of the steam-water separators 100 is composed of a plurality of corrugated plates 100a vertically arranged parallel to each other, and a vertical corrugated separation channel 100b is formed between the plurality of corrugated plates 100a. The gas entering the airflow channel 3 is also mixed with some water droplets carrying spray paint particles and spray paint particles not absorbed by water. Most of these water droplets or spray paint particles will adhere to the corrugated plate 100a when passing through the separation channel 100b, and after gathering into larger water droplets on the corrugated plate 100a, they will fall under the action of gravity, and finally fall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com