Pressure measuring device comprising oil spraying nozzle with pressure chamber

A technology of measuring device and fuel injection nozzle, which is applied in the direction of measuring device, fuel injection device, charging system, etc., can solve the problems of sensor installation method and installation structure, which are not mentioned in the real sense, and cannot be completely equivalent. , to avoid the throttling effect, expand the scope of application, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

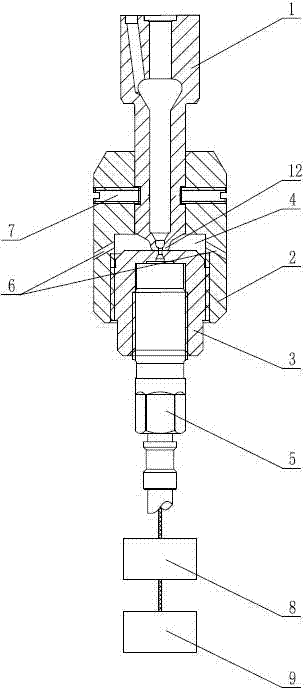

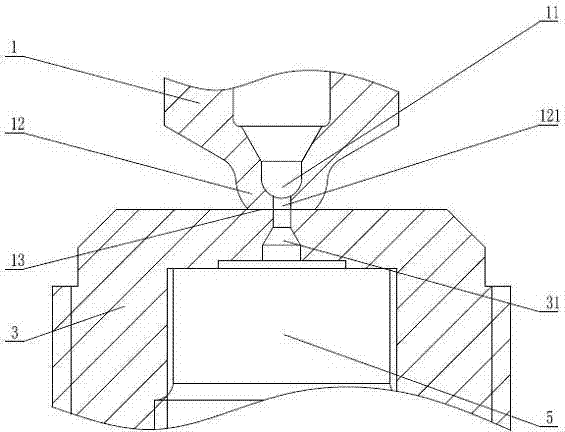

[0021] See figure 1 , figure 2 , the present invention includes a fuel injection nozzle 1 with a pressure chamber 11, the fuel injection nozzle 1 and the fixed sleeve 2 are fixedly connected by fastening screws 7, the fixed sleeve 2 is provided with a groove opening downward, and the fixed sleeve 2 passes through the groove The groove is sleeved on the outer circumference of the connecting sleeve 3, and the groove of the fixed sleeve 2 is fixedly connected with the connecting sleeve 3 through threads, and the upper end surface of the connecting sleeve 3 and the top end surface of the groove of the fixed sleeve 2 The fuel injection space 4 is left, the ball head 12 of the fuel injection nozzle 1 passes through the fixed sleeve 2 and extends into the fuel injection space 4, and the ball head 12 is pressed and sealed with the upper end mati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com