Air valve air intake performance test device and test method

A technology of testing device and air valve, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. High cost and other problems, to achieve the effect of simple structure, less floor space and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

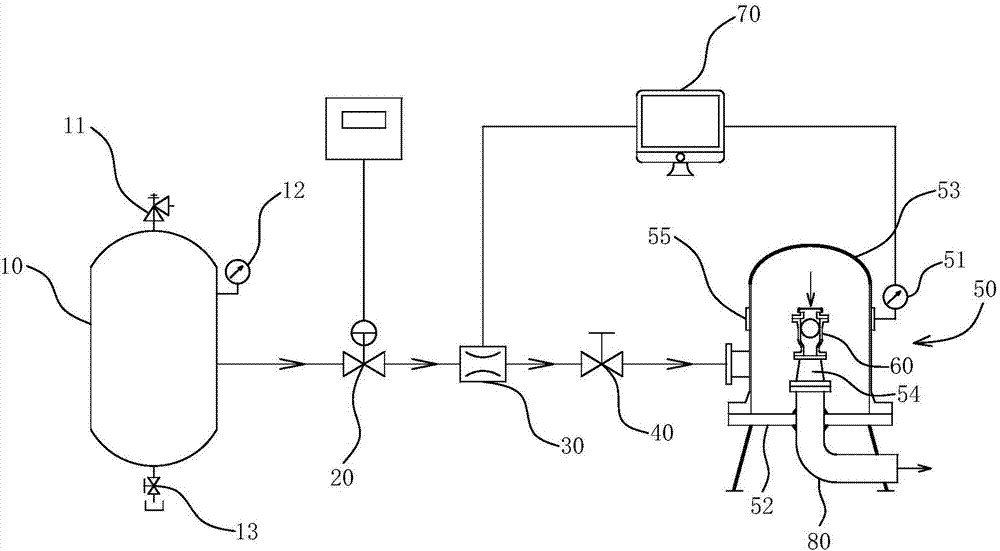

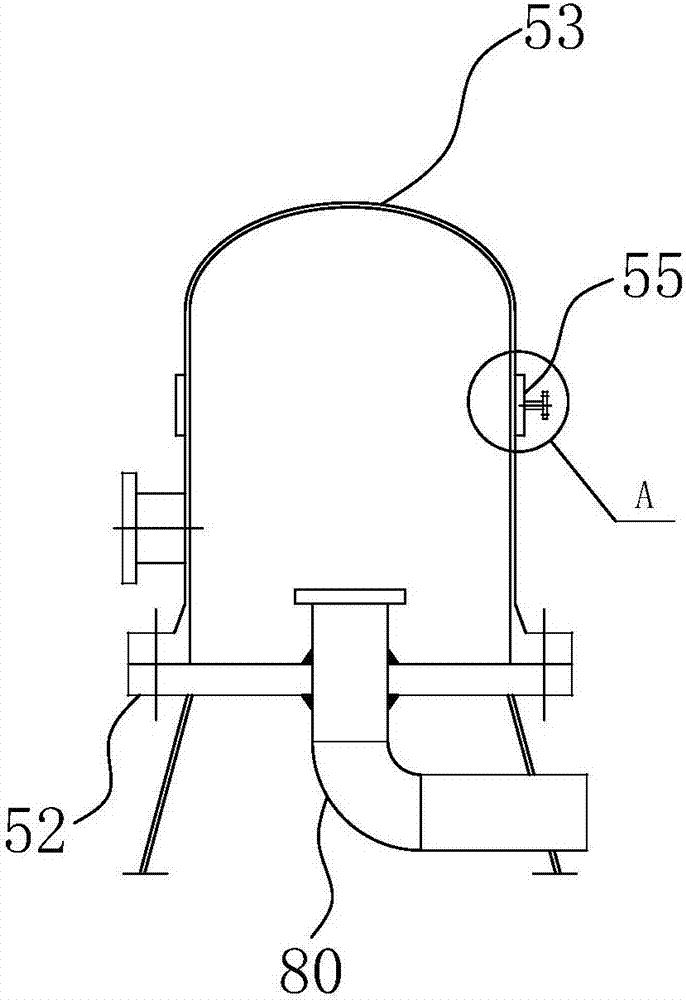

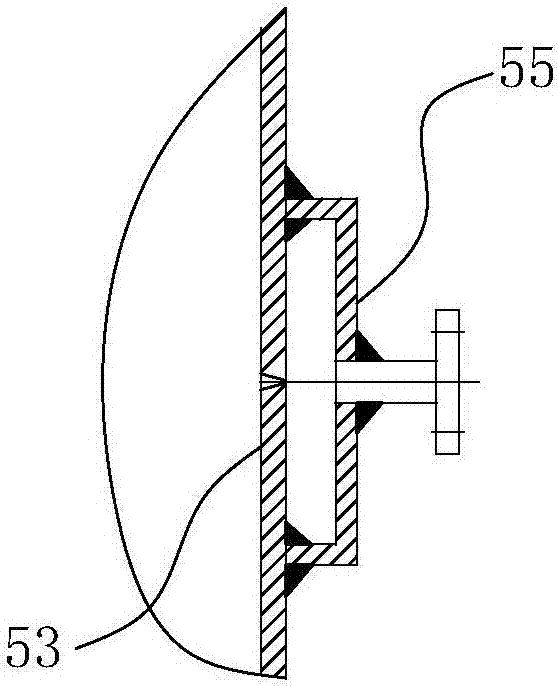

[0033] like figure 1 As shown: the air valve air intake performance testing device of the present invention includes a data acquisition unit 70 and an air storage tank 10, a flow regulating valve 20, a flow meter 30, and an air collecting device 50 installed sequentially on the test pipeline along the air flow direction , the air collecting device 50 is provided with a measured air valve 60 installed on the corresponding exhaust pipeline 80 , and a pressure gauge 1 51 for measuring the pressure inside the gas collecting device 50 is installed on the gas collecting device 50 . An on-off valve 40 is installed between the flow meter 30 and the gas collecting device 50 .

[0034] The traditional air valve intake performance test is often to use a vacuum pump to generate negative pressure in the installation pipeline of the air valve to be tested, so as to conduct the test process. However, the present invention realizes by increasing the pressure at the inlet end of the air valve...

Embodiment 2

[0042] The test method based on the air valve intake performance test device may further comprise the steps:

[0043] S1. Close the flow regulating valve 20 and the switch valve 40 located between the flow meter 30 and the gas collecting device 50, and fill the gas storage tank 10 with a sufficient amount of gas required for the test in advance;

[0044] S2. Adjust the opening of the switching valve 40 to the maximum, and then open the flow regulating valve 20. At this time, the medium flows out through the gas storage tank 10 into the test pipeline and then into the gas collection device 50, and then from small to large Gradually adjust the opening degree of the flow regulating valve 20, and at the same time, the data acquisition unit 70 acquires multiple sets of data measured by the flowmeter 30 and the pressure gauge 1 51;

[0045] During the test, when the data measured by the pressure gauge 1 reaches the pressure value of the set sampling point, keep the opening of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com