Switched reluctance motor for capacitance split circuit

A technology of switched reluctance motor and reluctance motor, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of long freewheeling time, low system efficiency, hindering the operation of switched reluctance motor, etc. Improve efficiency and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

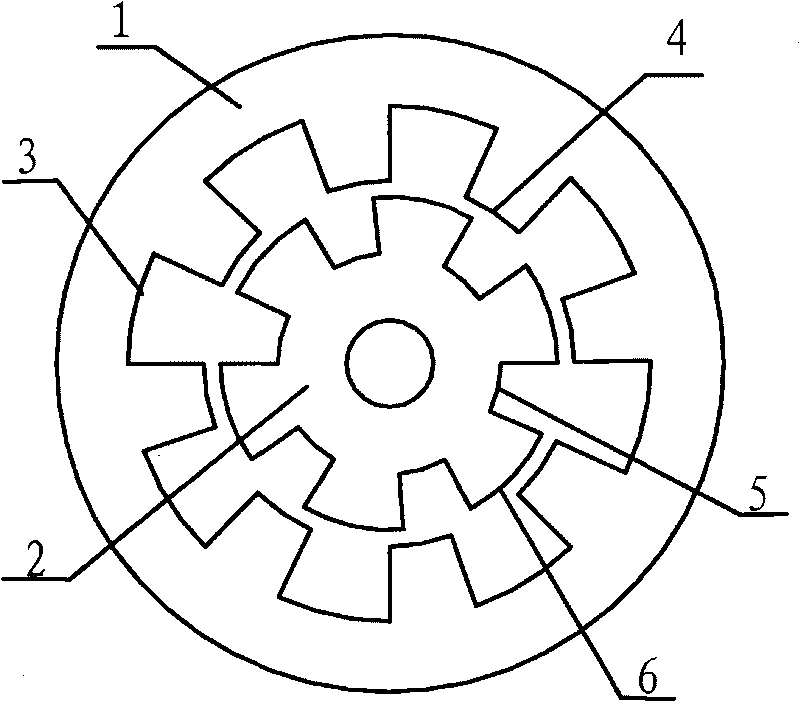

[0020] Such as image 3 As shown, the switched reluctance motor for capacitor splitting uses an 8 / 6 type four-phase switched reluctance motor, including a stator 1 and a rotor 2, and the outer ring surface of the stator 1 has stator grooves 3 and stator salient poles 4 that are evenly spaced. , the inner ring surface of the rotor 2 has rotor grooves 5 and rotor salient poles 6 that are evenly spaced. There are eight rotor salient poles 6 and six stator salient poles 4. For the convenience of description, the radian of the rotor 2 is defined as the rotor concave The sum of the 5 radians of the slot and the 6 radians of the salient pole of the rotor, and the radian of the stator 1 is defined as the sum of the 3 radians of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com