Air suction device of plastic vacuum forming machine

A technology of suction device and blister machine, which is applied in the field of mechanical equipment, can solve problems such as poor stability, achieve the effect of reducing the requirement of matching accuracy, reducing costs, and avoiding the restriction of gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

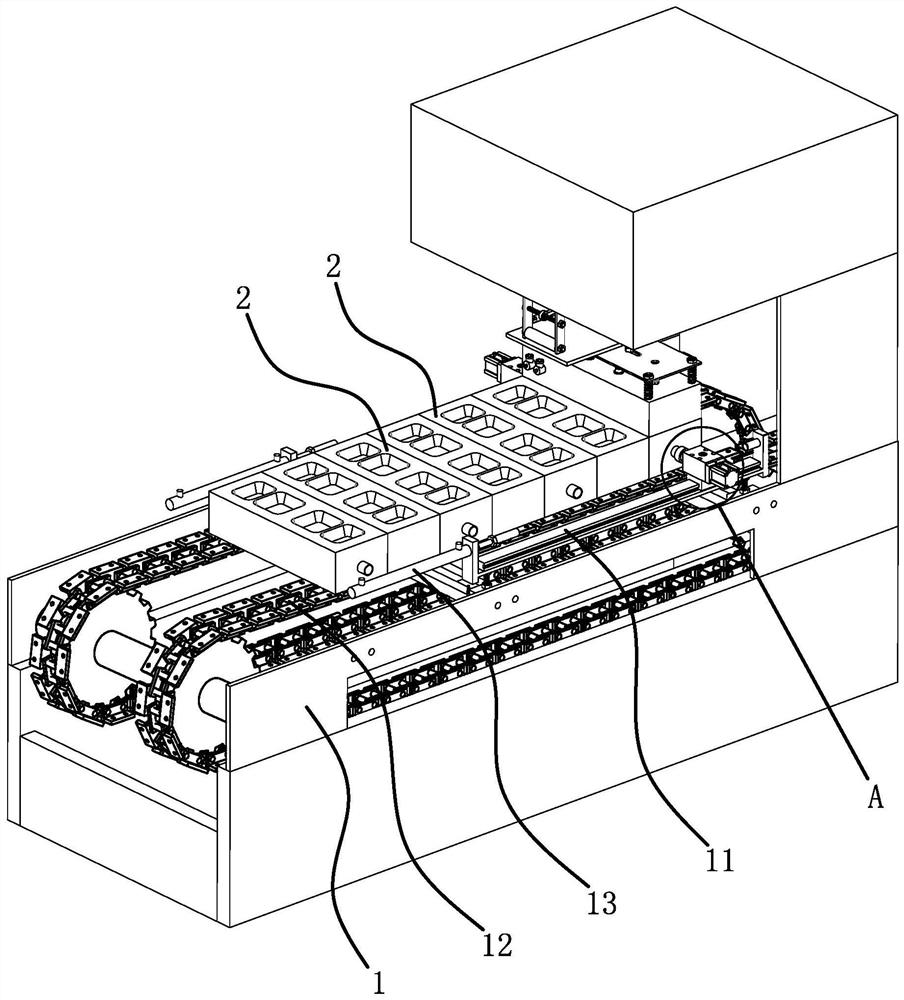

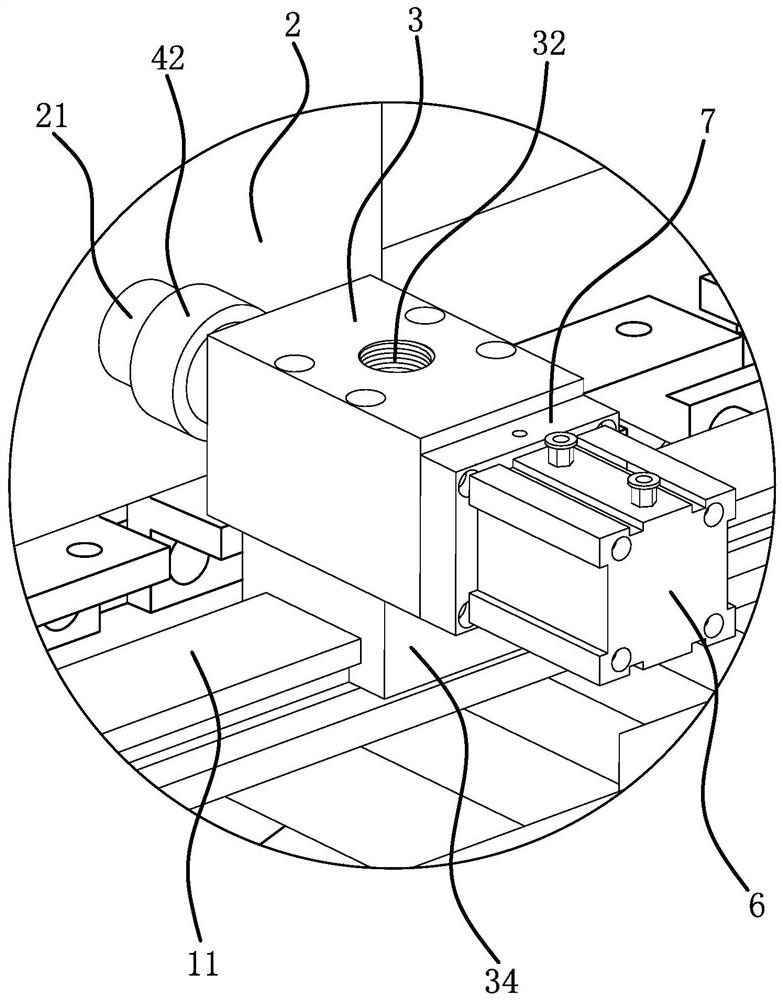

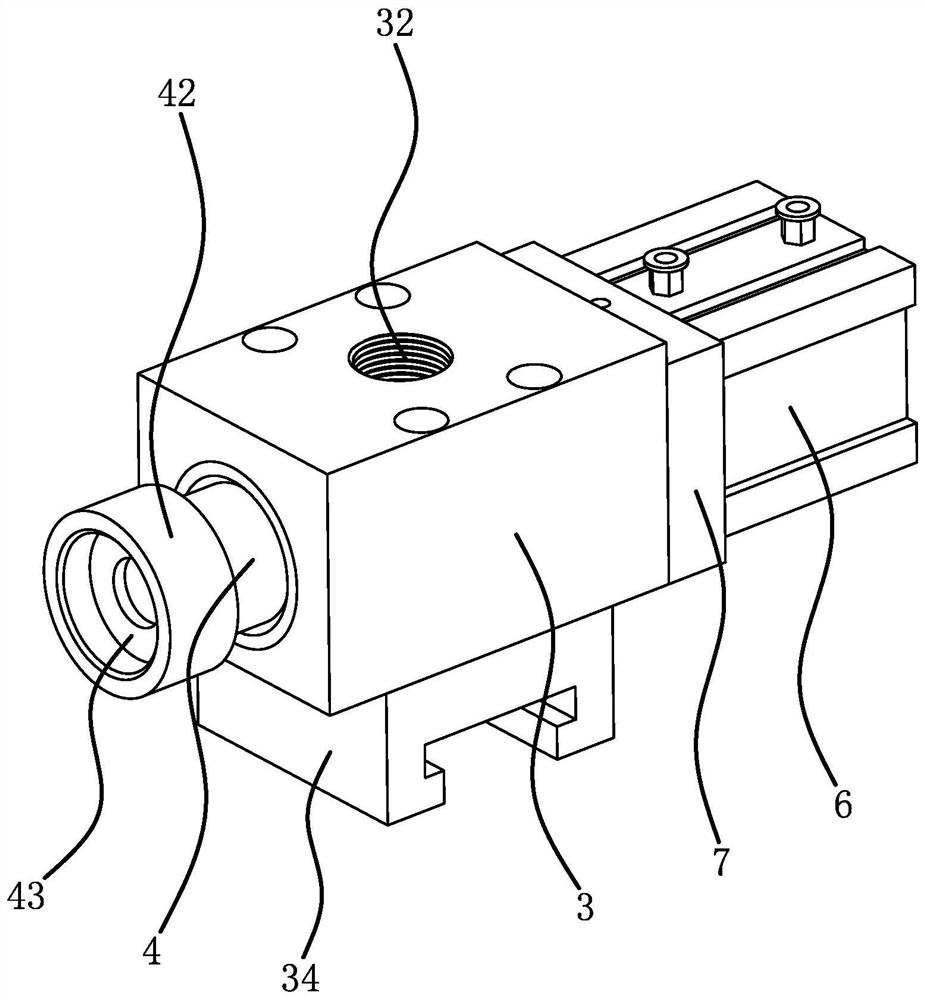

[0036] Such as figure 1 As shown, a suction device of a blister machine, the blister machine includes a frame 1, a conveyor chain 12 is provided on the frame 1, and a plurality of molds 2 are connected to the conveyor chain 12, and the multiple molds 2 are arranged in sequence And move circularly with the conveying chain 12, when the mold 2 moves to the top, the opening of the mold 2 faces upwards, and there is a connecting pipe 21 on the side of the mold 2, which is used to connect the suction device, and the suction device can suck the inner cavity of the mold 2. Gas to achieve blister. combine figure 2 , image 3 As shown, a guide rail 11 is also fixed on the frame 1. The guide rail 11 is arranged along the moving direction of the mold 2. The air suction device includes a slide seat 3, an air suction pipe 4 and a drive cylinder 6. The slide seat 3 is in the shape of a rectangular block. A slider 34 is fixed on the bottom surface of the slider 3, and the slider 34 is sli...

Embodiment 2

[0040] The suction device of this blister machine is basically the same as that of Embodiment 1, the differences are as Figure 6 , Figure 7 As shown, the two sliding sleeves 5 are fixed with the suction pipe 4, and the two sliding sleeves 5 are slidably connected in the guide hole 31, and the outer peripheral walls of the two sliding sleeves 5 form a sliding guide fit with the guide hole 31 wall. , the air hole 41 is opened on the side wall of the suction pipe 4 and communicates with the suction chamber 33 all the time. When the driving cylinder 6 drives the suction pipe 4 to stretch out, the suction chamber 33 communicates with the suction hole 32. When the driving cylinder 6 drives the suction pipe 4 to retract inwardly, the outer peripheral wall of the sliding sleeve 5 blocks the suction hole 32 .

Embodiment 3

[0042] The suction device of this blister machine is basically the same as that of Embodiment 1, the differences are as Figure 8 , Figure 9 As shown, the air suction device does not include the sliding sleeve 5, but the air suction pipe 4 is directly matched with the guide hole 31, that is, the outer peripheral wall of the air suction pipe 4 is slidingly and guidedly matched with the wall of the guide hole 31, and the outer wall of the air suction pipe 4 Grooves are opened in the upper direction to form the suction cavity 33, and the air passage 41 is directly connected to the suction cavity 33. When the driving cylinder 6 drives the suction pipe 4 to extend outward, the suction cavity 33 communicates with the suction hole 32. When the driving cylinder 6 drives the suction pipe 4 to retract inwardly, the peripheral wall of the suction pipe 4 blocks the suction hole 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com