Double-layer channel flow complementary type pressure guide sand blaster

A channel flow and sand blaster technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of reducing sand blasting holes, difficult wellhead sealing work, and reducing sand delivery efficiency, so as to avoid various The effect of reducing the level of throttling, improving safety and quality, and improving sand delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

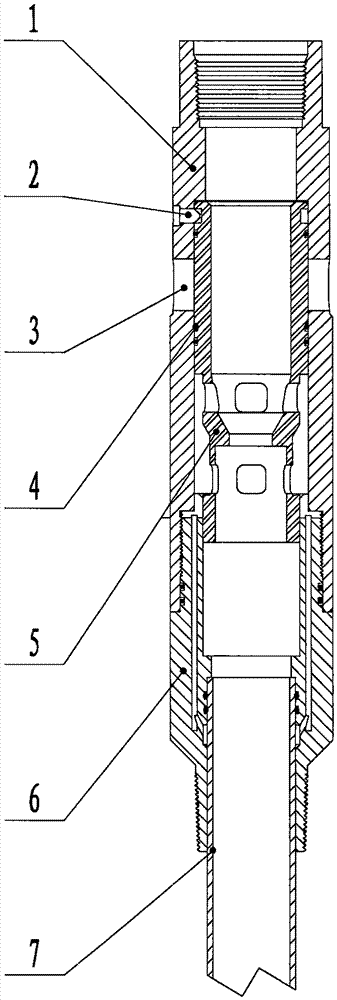

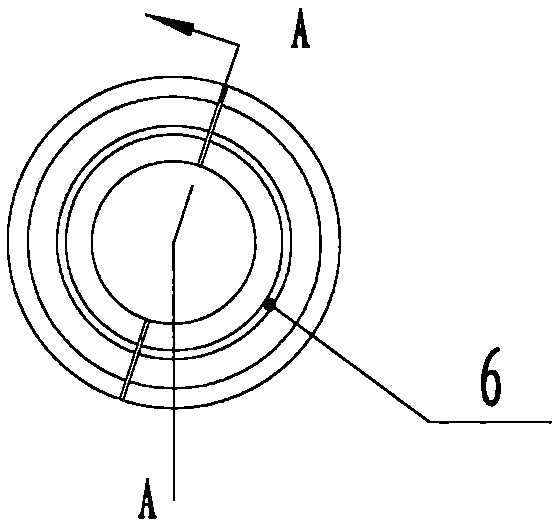

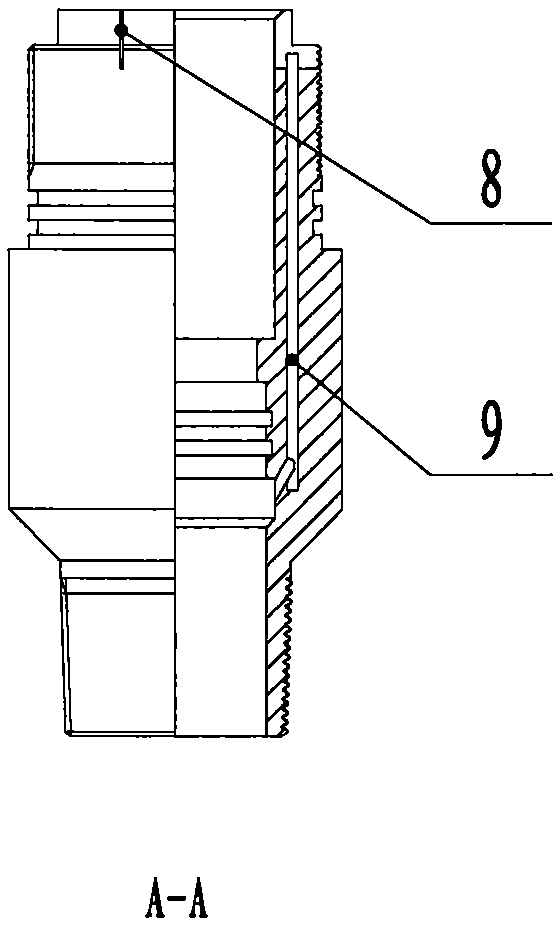

[0017] Such as figure 1 , 2 , 3, 4, and 6, the main body of the sand blaster 1 is a circular tube with pin holes and sand blast holes 3, and the double-layer channel flow complementary sliding sleeve 5 is fixed in the main body 1 of the sand blaster with pins 2. The lower part of the main body 1 of the sand blaster is connected with the pressure guide joint 6, and the pipe wall of the pressure guide joint 6 is provided with an inner pressure guide channel 9, and the inner pressure guide channel 9 passes through the water seepage slit 8 on the pressure guide joint 6 and the spray nozzle. The inside of the sander is connected, and the pressure guiding tube 7 is set under the pressure guiding lower joint 8, and the sealing ring 4 is arranged between the main body of the sand blaster 1, the pressure guiding lower joint 6, the double-layer flow complementary sliding sleeve 5, and the pressure guiding tube 7 , forming a double-layer channel flow complementary pressure-guiding sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com