Patents

Literature

76results about How to "Solve glitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

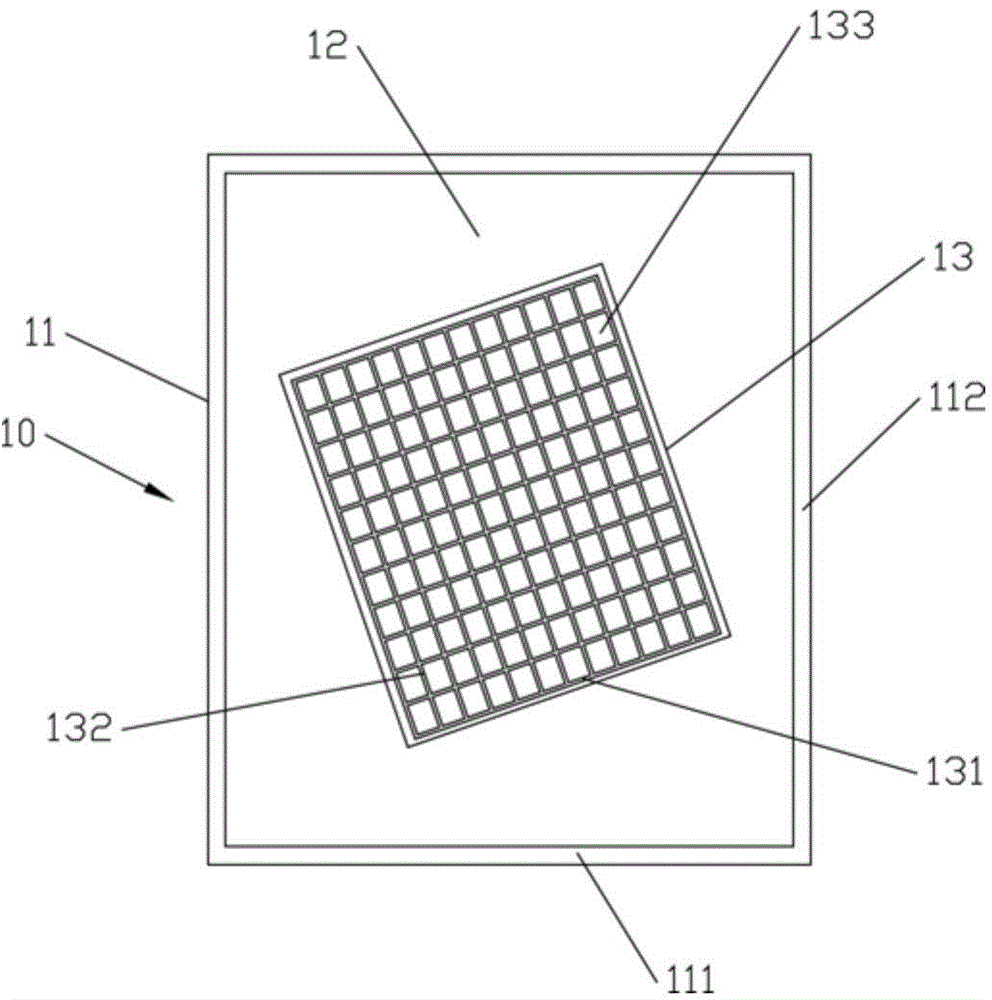

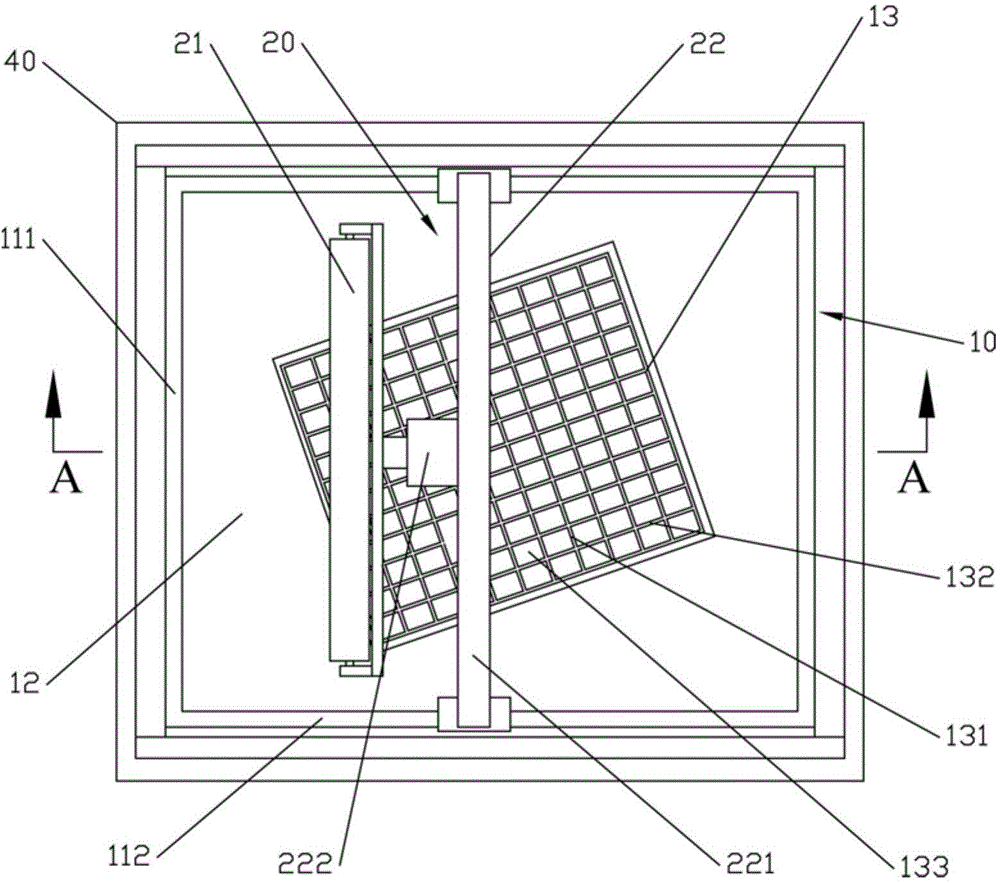

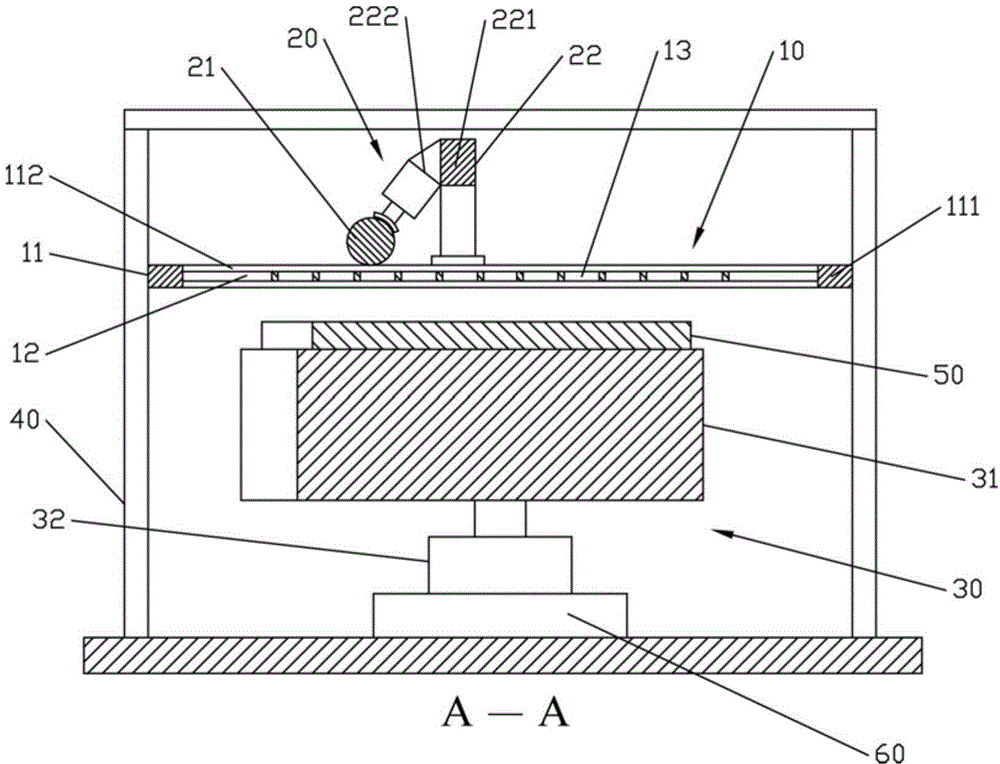

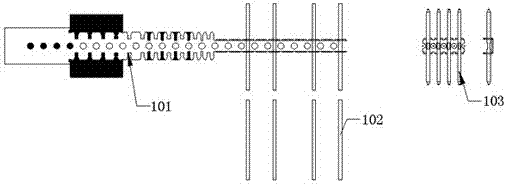

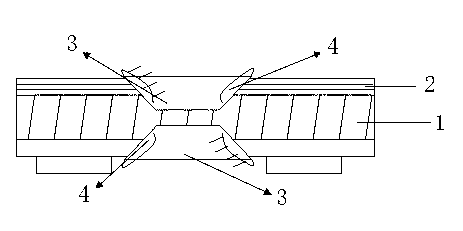

Screen printing method, screen structure and pressing marker

InactiveCN104608513AReduce defective rateAvoid different stressScreen printersOther printing apparatusScreen printingEngineering

The invention relates to the technical field of screen printing and discloses a screen printing method. The screen printing method includes: providing a screen, wherein the screen comprises a screen frame and screen cloth stretching tight on the screen frame, the screen cloth is provided with a pressing figure mold forming a plurality of grids by cross arrangement of a plurality of parallel warps and a plurality of parallel wefts, and the warps and the wefts are mutually vertical; providing a substrate, attaching the screen to the upper surface of the substrate, applying coating materials on the position corresponding to the pressing figure mold of the screen cloth, and using a scraper to press down to abut against the screen cloth prior to moving the scraper so as to enable the coating materials to be distributed according to the pressing figure mold, wherein the latitude line of the scraper and the pressing figure mold forms a first included angle, the longitude line of the scraper and the pressing figure mold forms a second included angle, and neither the first included angle or the second included angle is zero degree; removing the screen to form printing patterns on the substrate. The invention further provides a screen structure and a pressing marker, and reject ratio of screen printing can be reduced.

Owner:BOE TECH GRP CO LTD +1

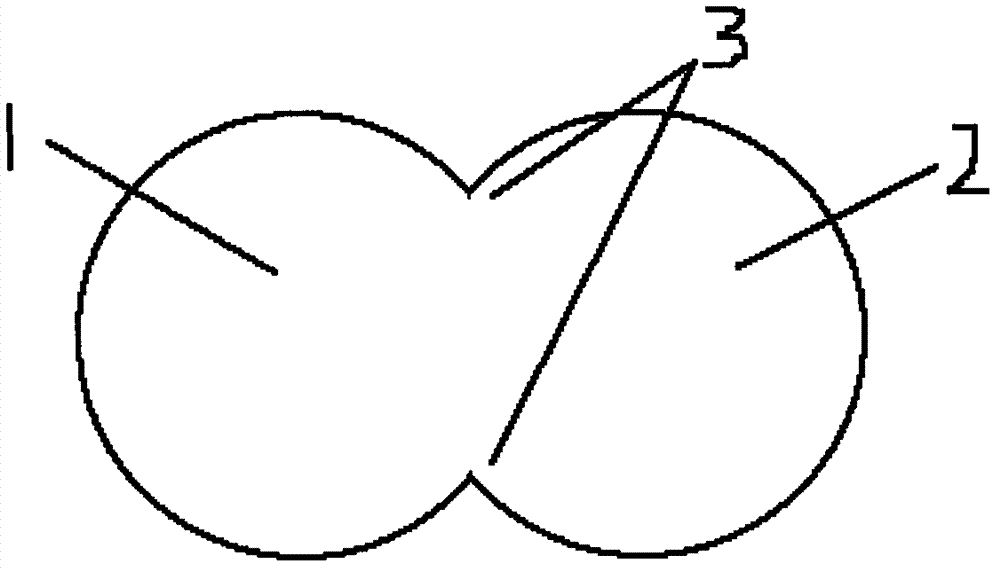

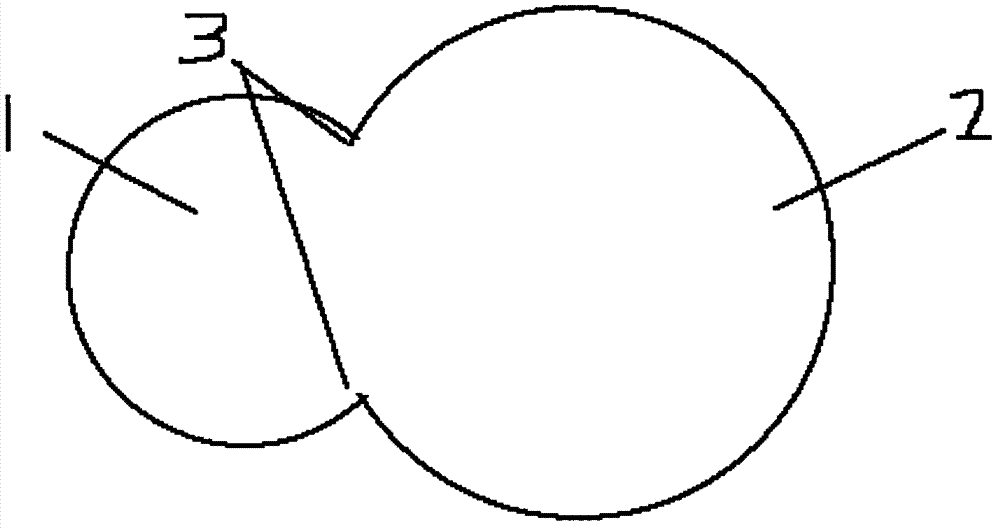

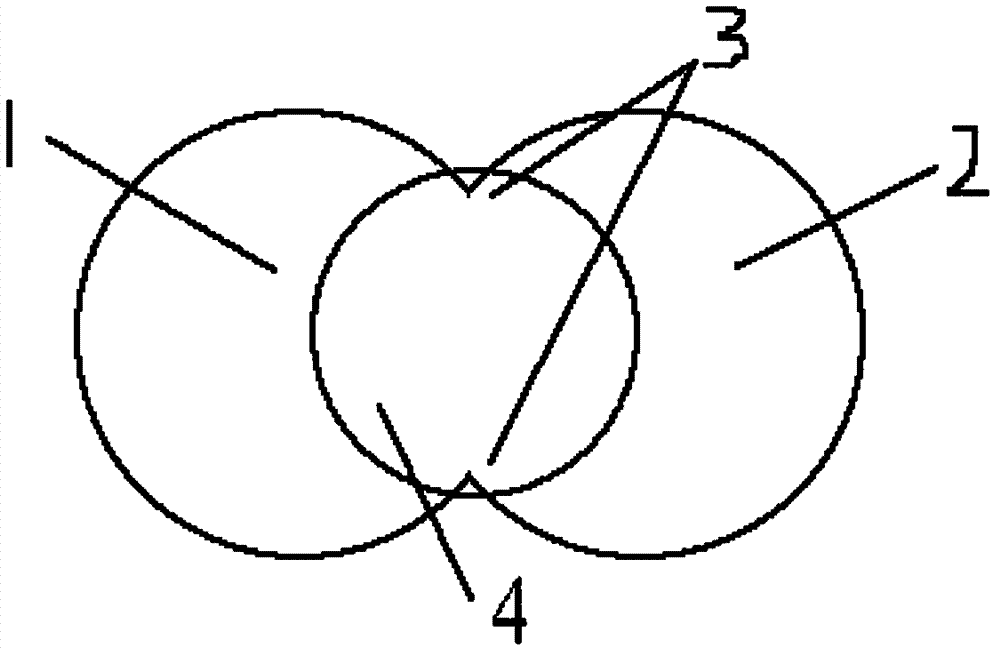

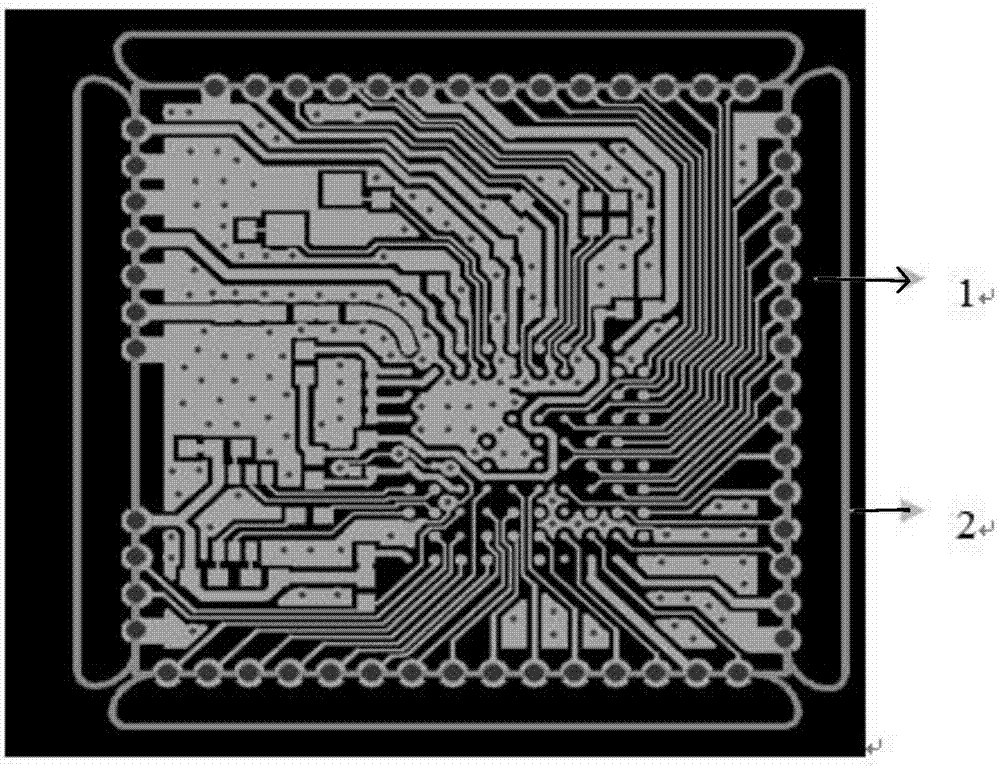

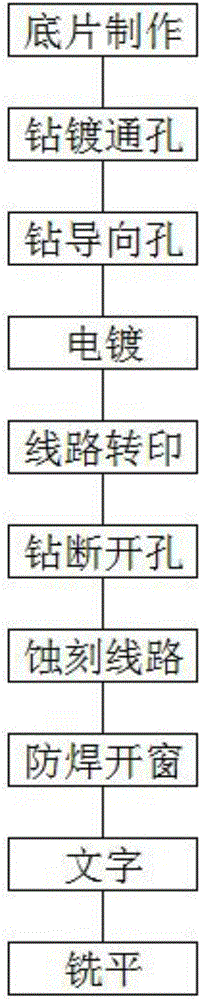

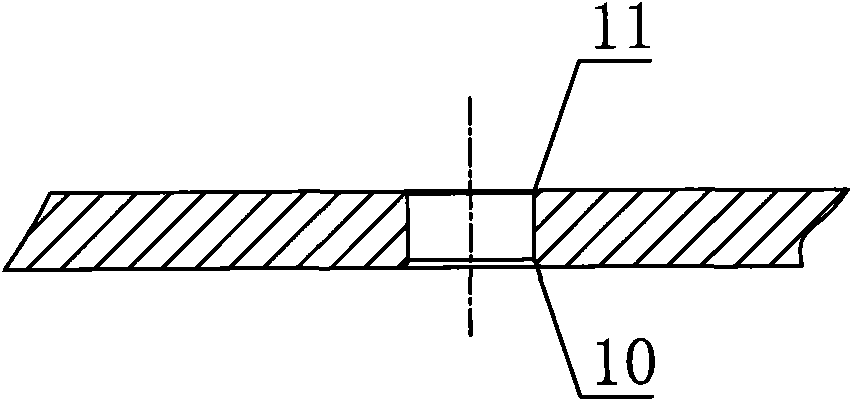

Drilling method of manufacturing printed circuit board (PCB) and PCB

InactiveCN103096622AQuality improvementSolve glitchesPrinted circuit detailsPrinted circuit manufacturePrinted circuit boardPetroleum engineering

The invention provides a drilling method of manufacturing a printed circuit board (PCB). The drilling method of manufacturing the PCB comprises the steps of manufacturing a first drilling hole on the PCB, manufacturing a second drill hole which intersects the first drilling hole on the PCB, and manufacturing a burr removing puncture hole on an intersecting part of the first drilling hole and the second drilling hole to remove burrs on the intersecting part. The invention further provides a PBC which is manufactured through the above method. The drilling method of manufacturing the PCB and the PCB solve the problem of the burrs in a relevant technology, and thus the quality of the PCB is improved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

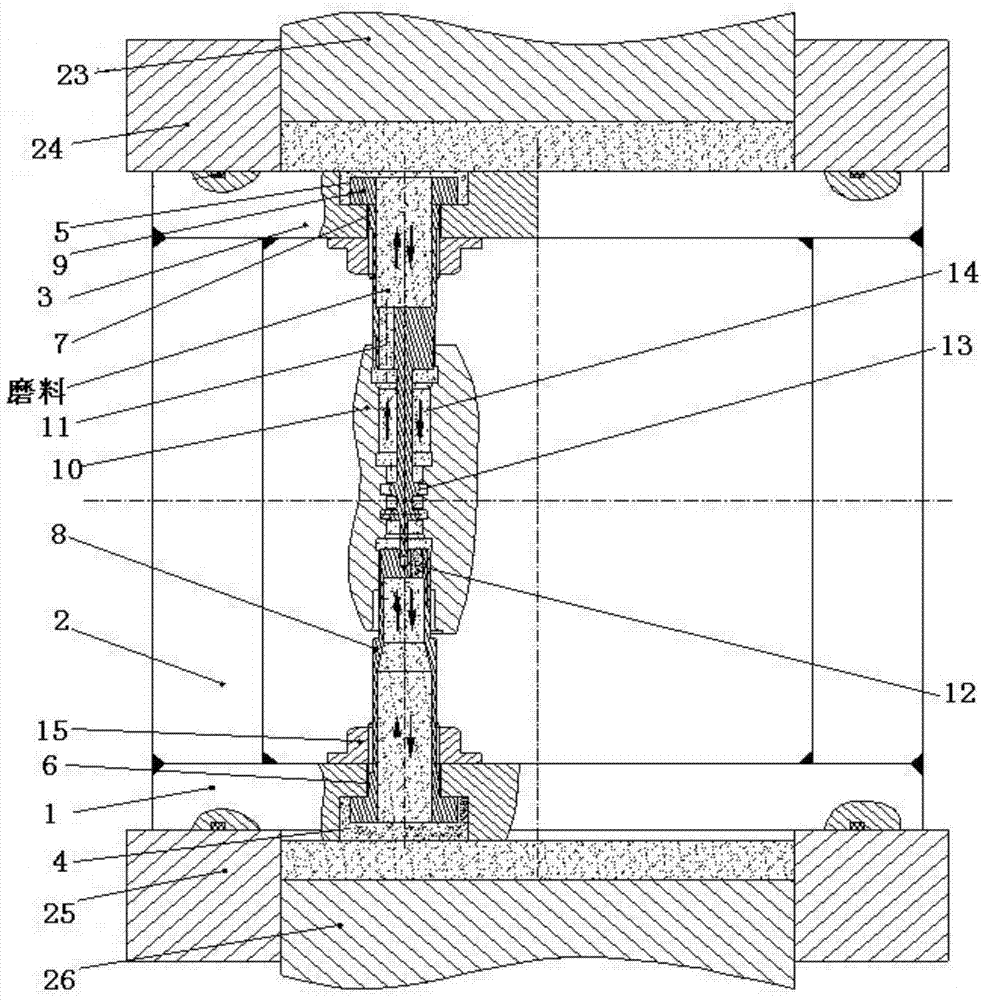

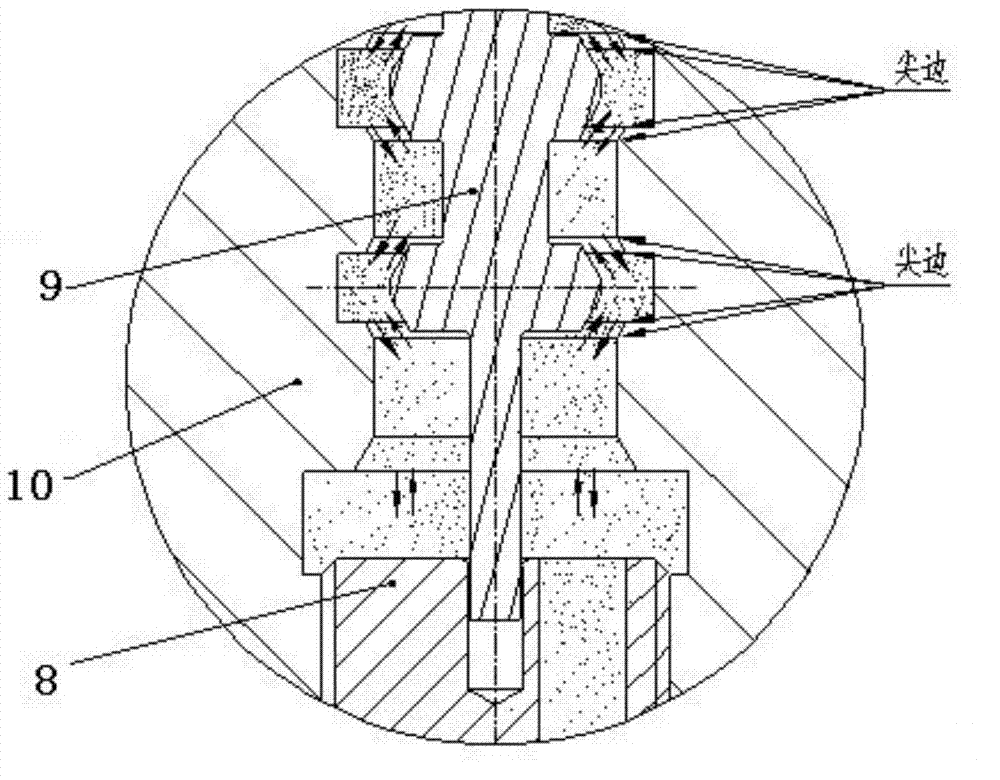

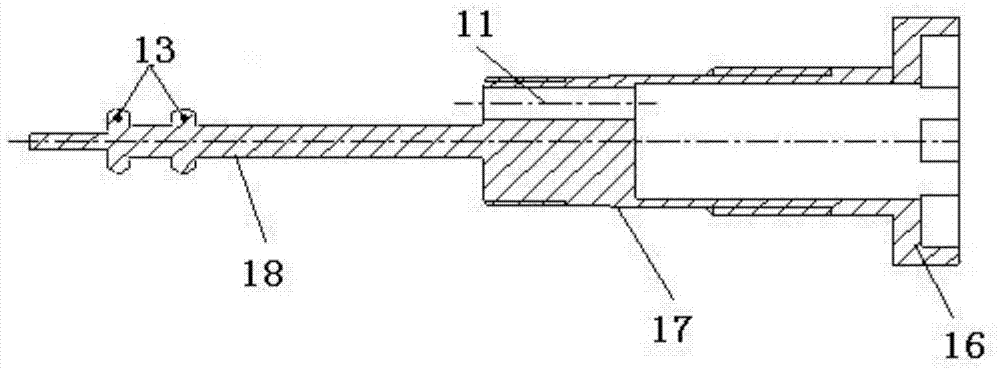

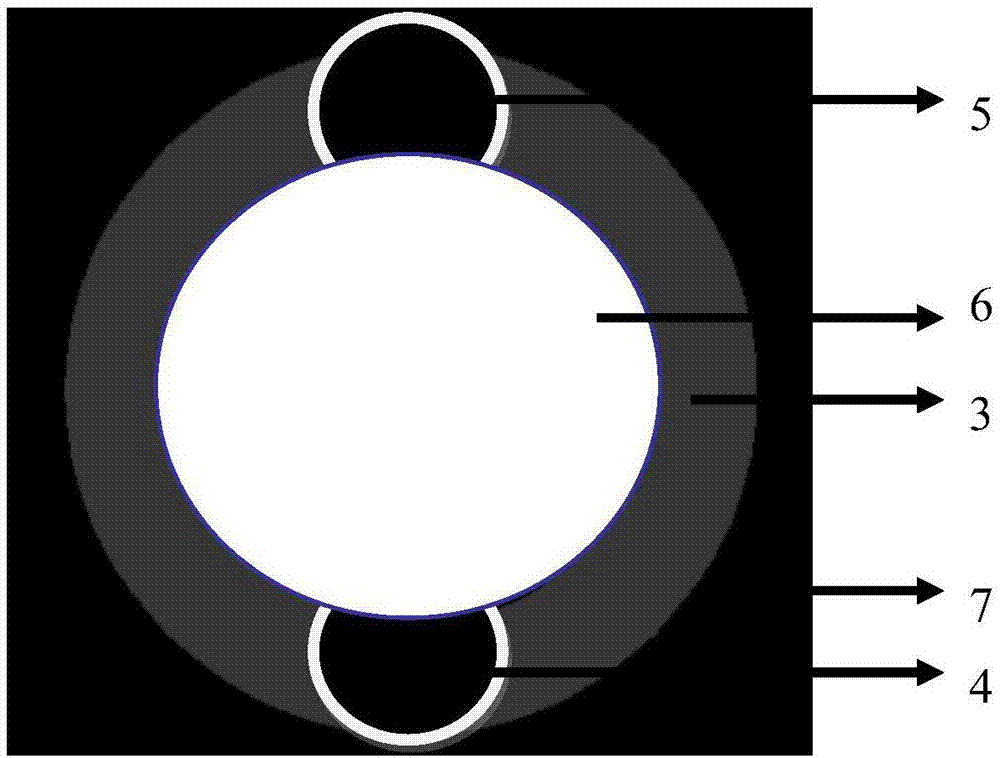

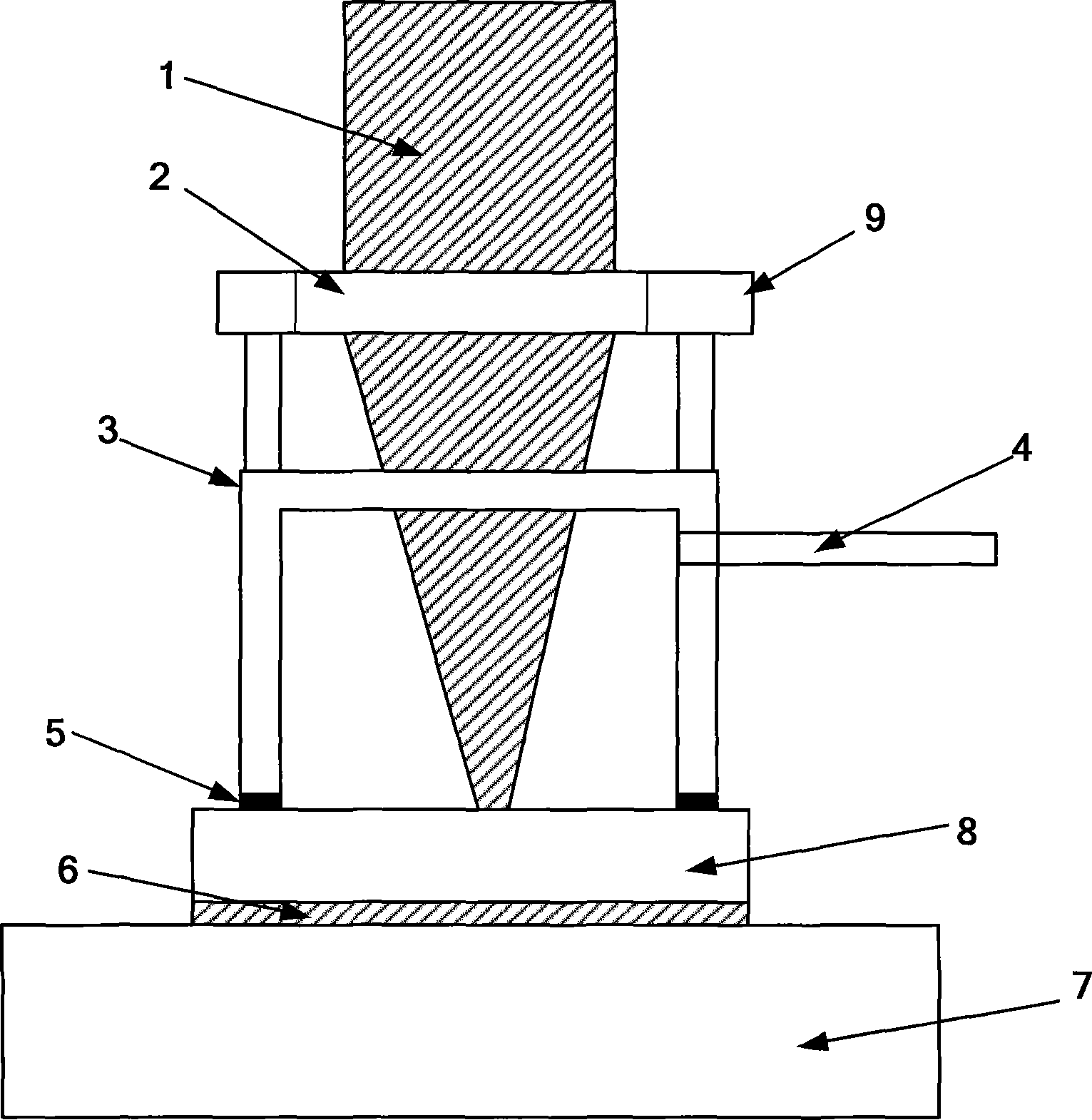

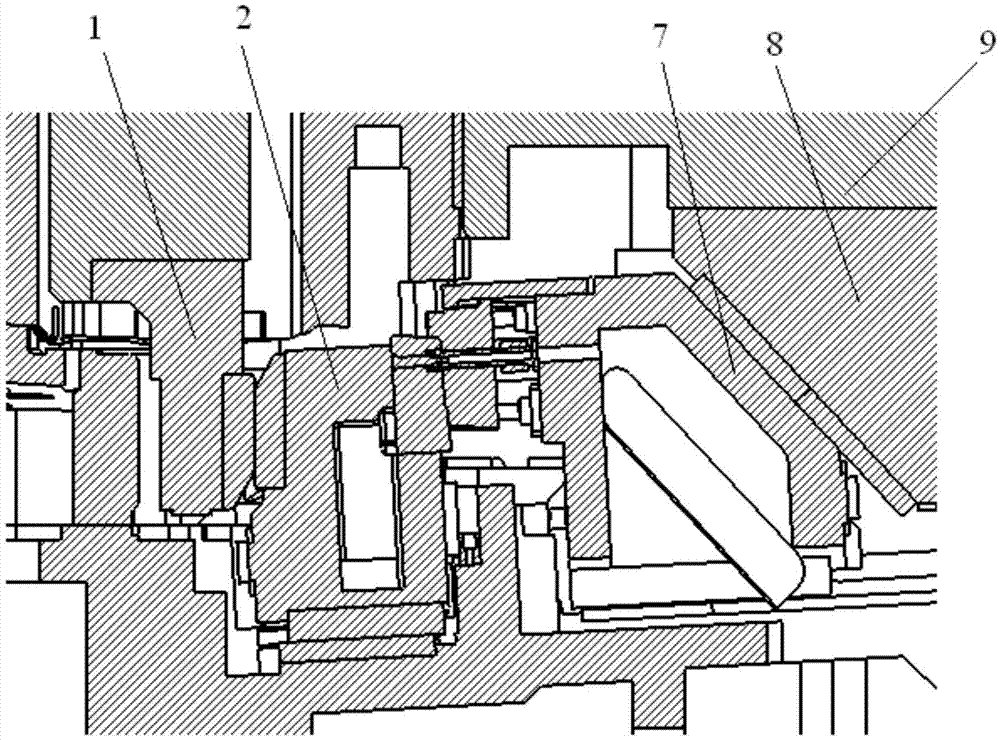

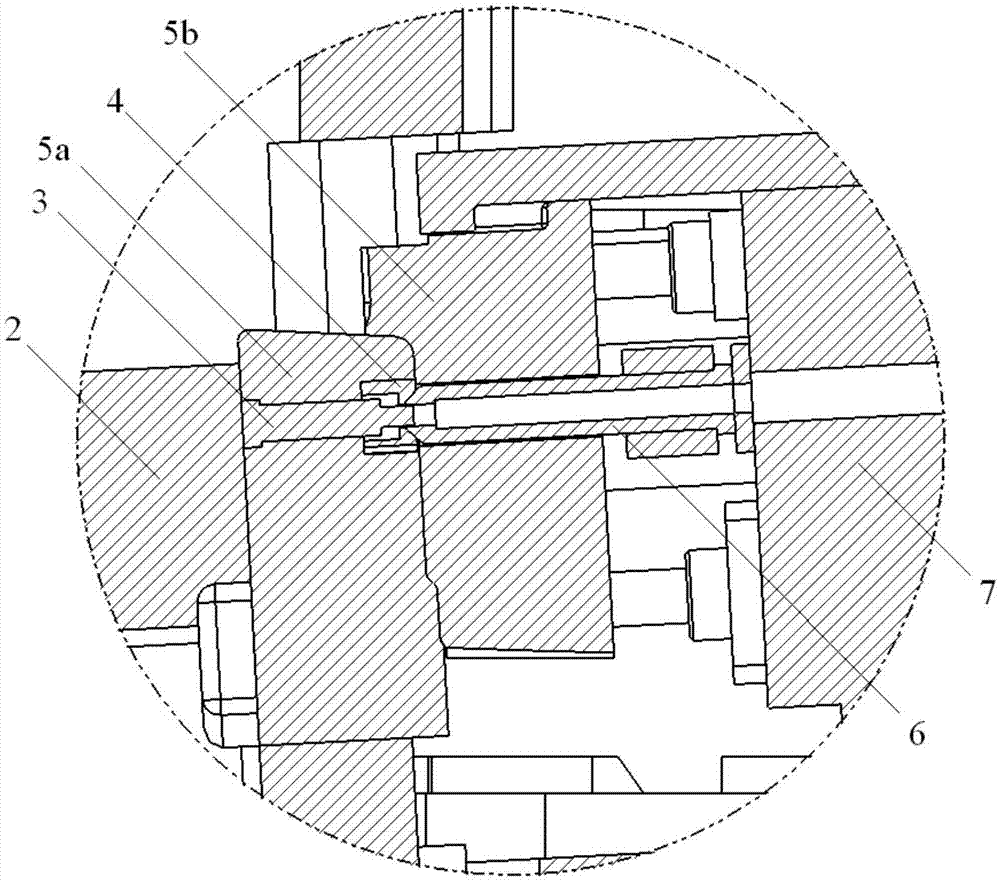

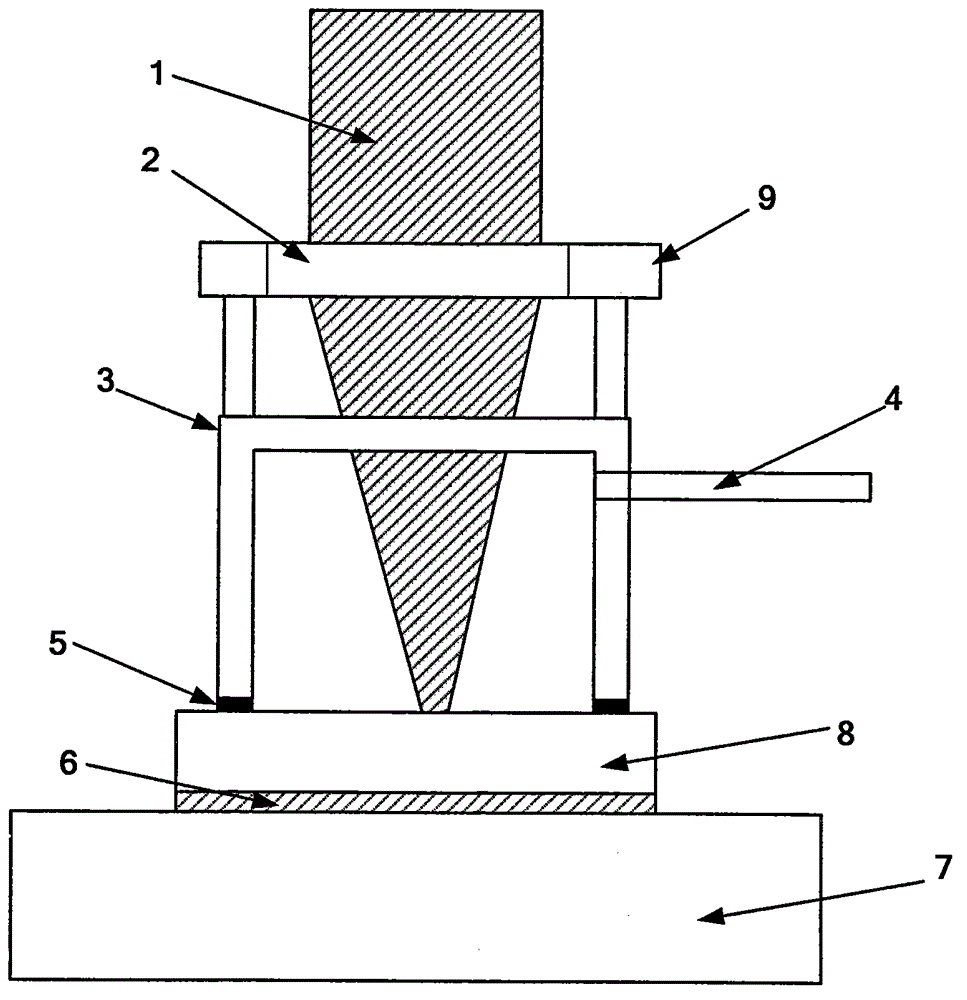

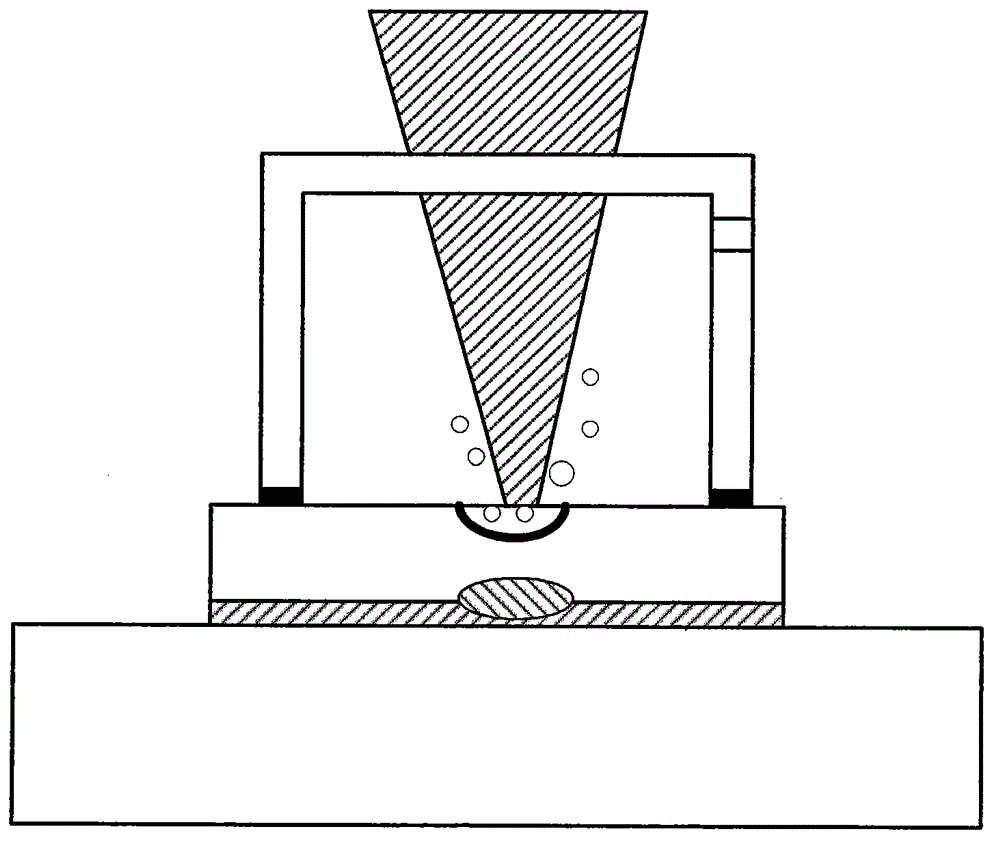

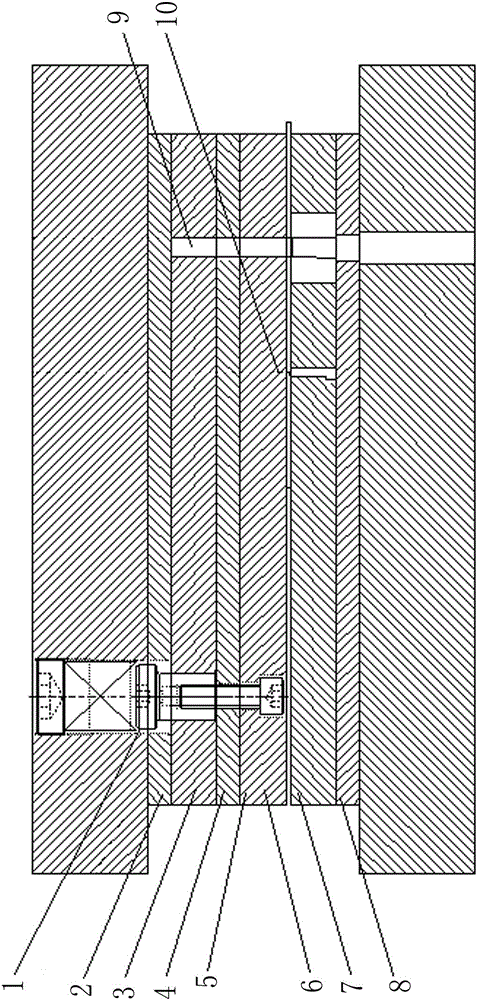

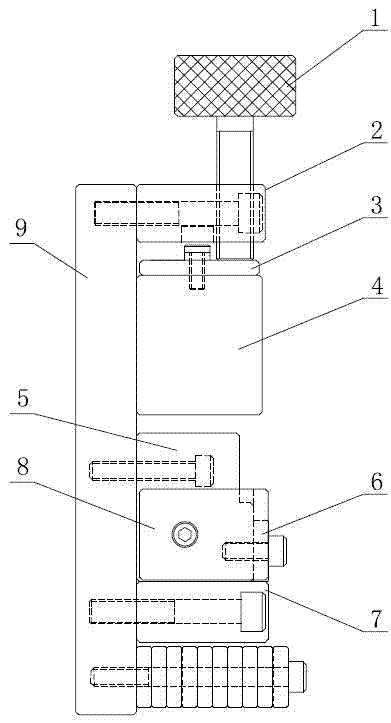

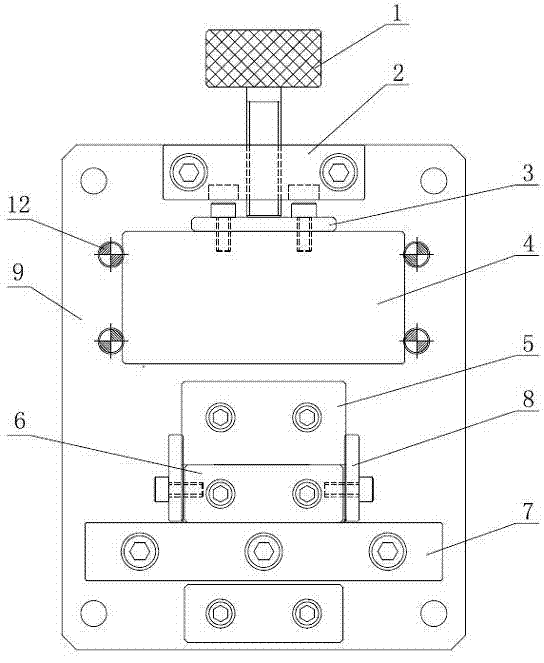

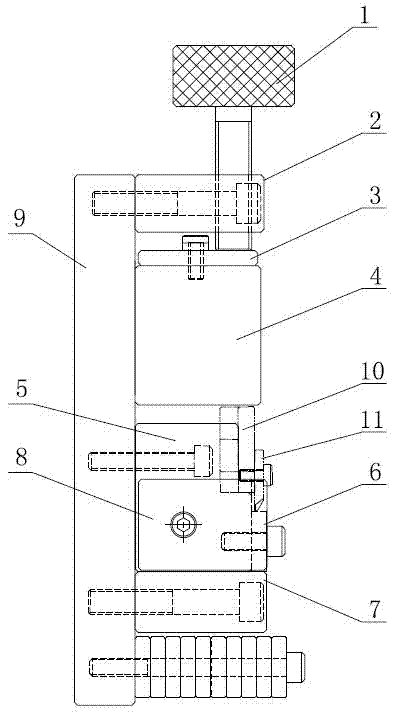

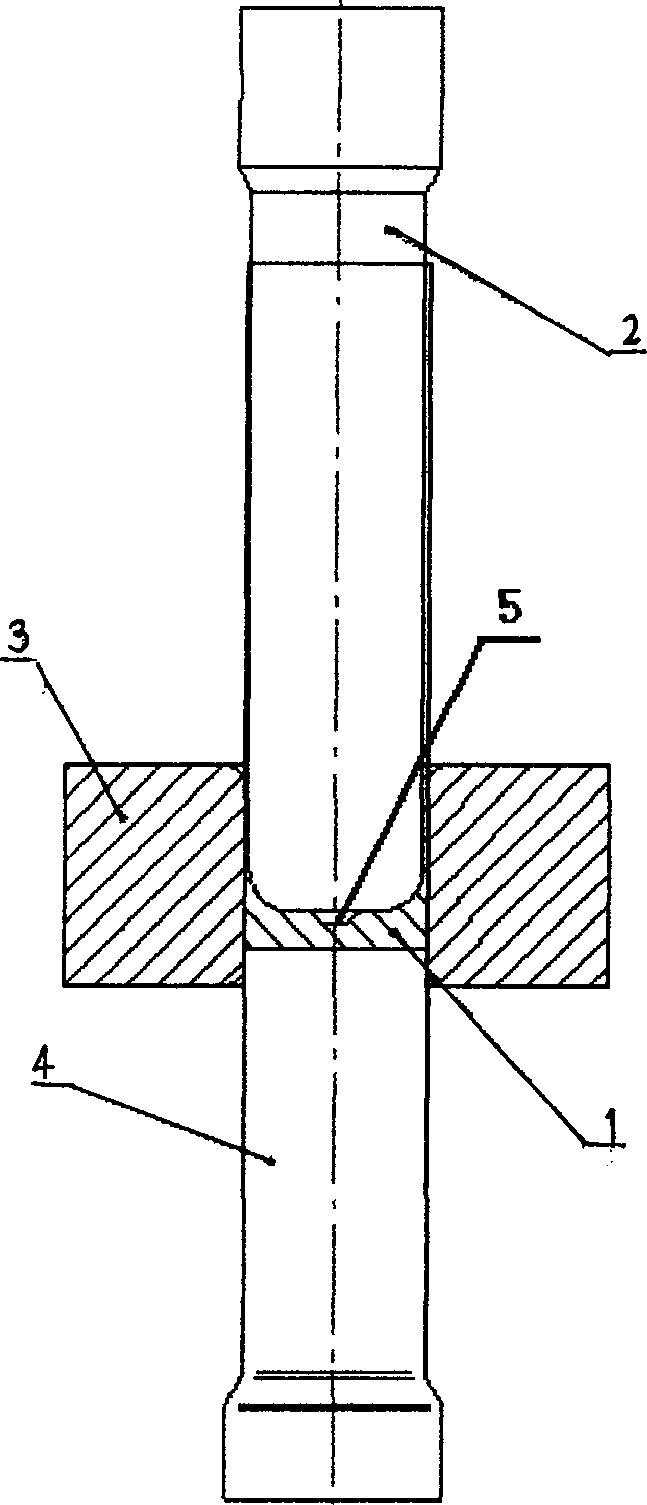

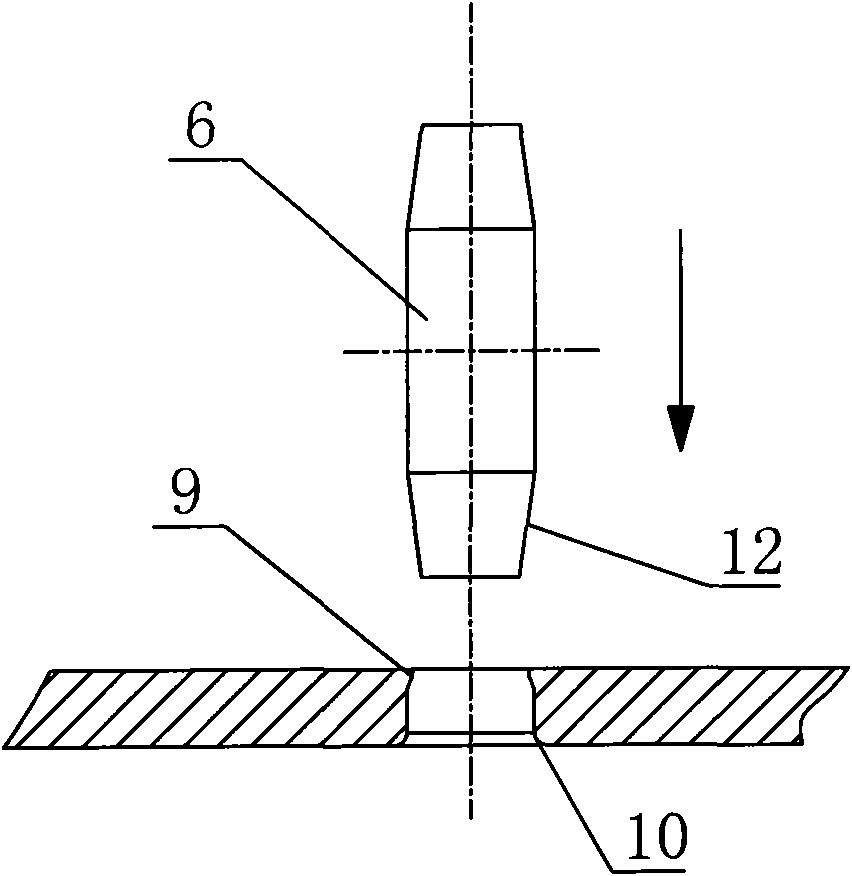

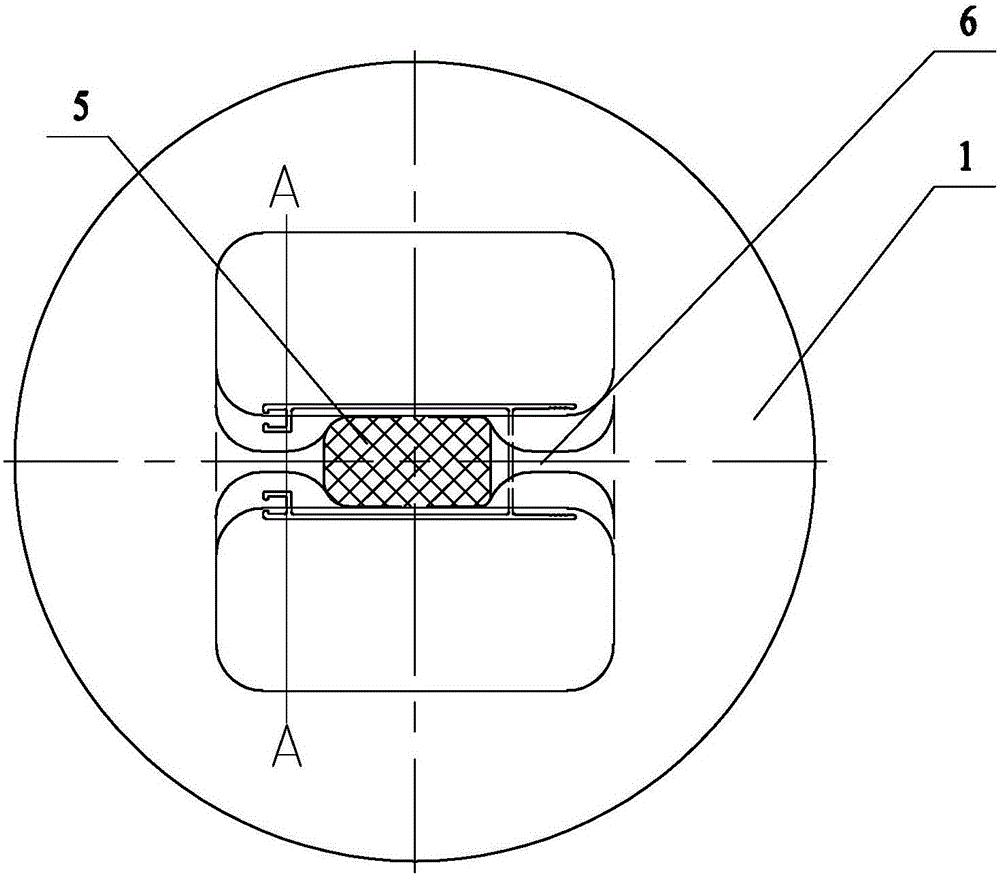

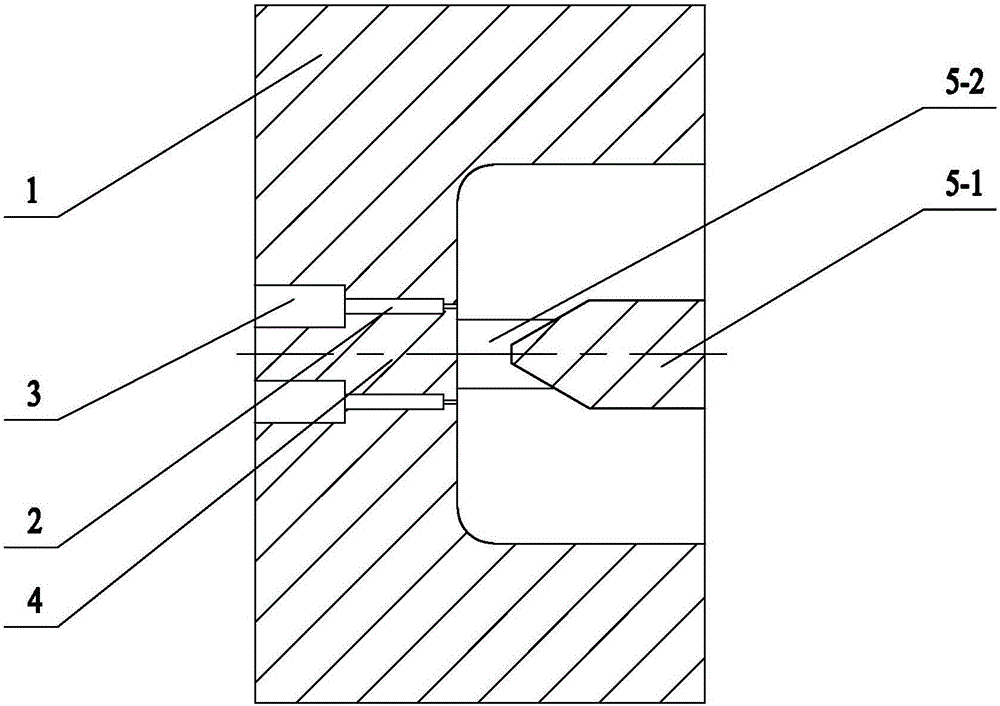

Abrasive flow machining device capable of cleaning sharp edges and burrs at annular grooves in deep holes

ActiveCN103659619AEasy to processSolve glitchesAbrasive feedersAbrasive blasting machinesAbrasive flow machiningEngineering

The invention discloses an abrasive flow machining device capable of cleaning sharp edges and burrs at annular grooves in deep holes. The device comprises a frame support structure consisting of a base plate (1), a support plate (2) and a cover plate (3), wherein a base plate counter bore (4) and a cover plate counter bore (5) which are arranged towards the outer side are formed in the base plate (1) and the cover plate (3) respectively, a base plate through hole (6) and a cover plate through hole (7) are formed in centers of the base plate counter bore (4) and the cover plate counter bore (5) respectively, a pipe joint (8) penetrating through the base plate through hole (6) is inversely buckled in the base plate counter bore (4), a flow guide rod (9) penetrating through the cover plate through hole (7) is inversely buckled in the cover plate counter bore (5), a work piece (10) is arranged between the pipe joint (8) and the flow guide rod (9), an upper passing hole (11) and a lower passing hole (12) are formed in the flow guide rod (9) and the pipe joint (8) respectively, and flow guide pieces (13) are arranged at one end of the flow guide rod (9). According to the abrasive flow machining device, the problems that the burrs at the annular grooves in the deep holes cannot be cleaned with a traditional manual deburring method and machining cannot be performed on the sharp edges of the annular grooves in the deep holes are solved.

Owner:AVIC LIYUAN HYDRAULIC

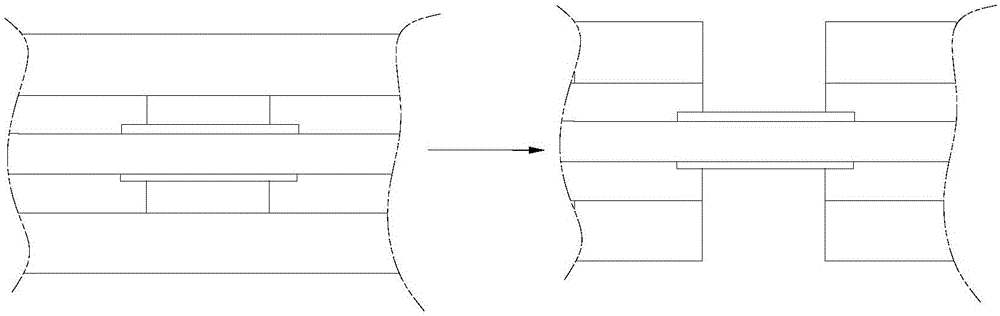

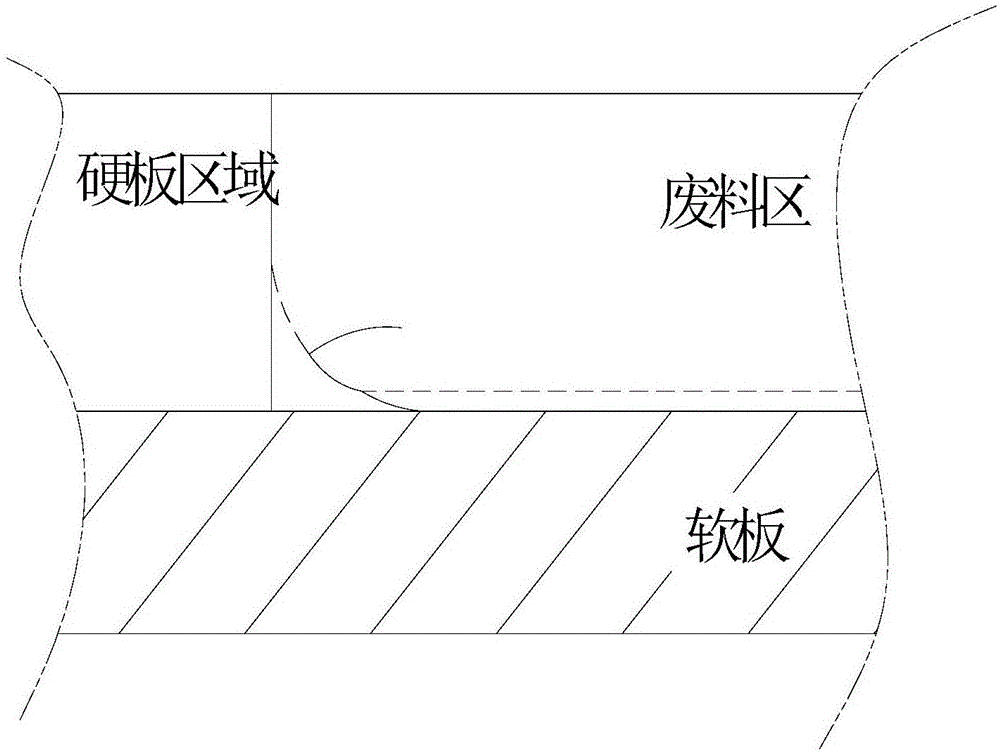

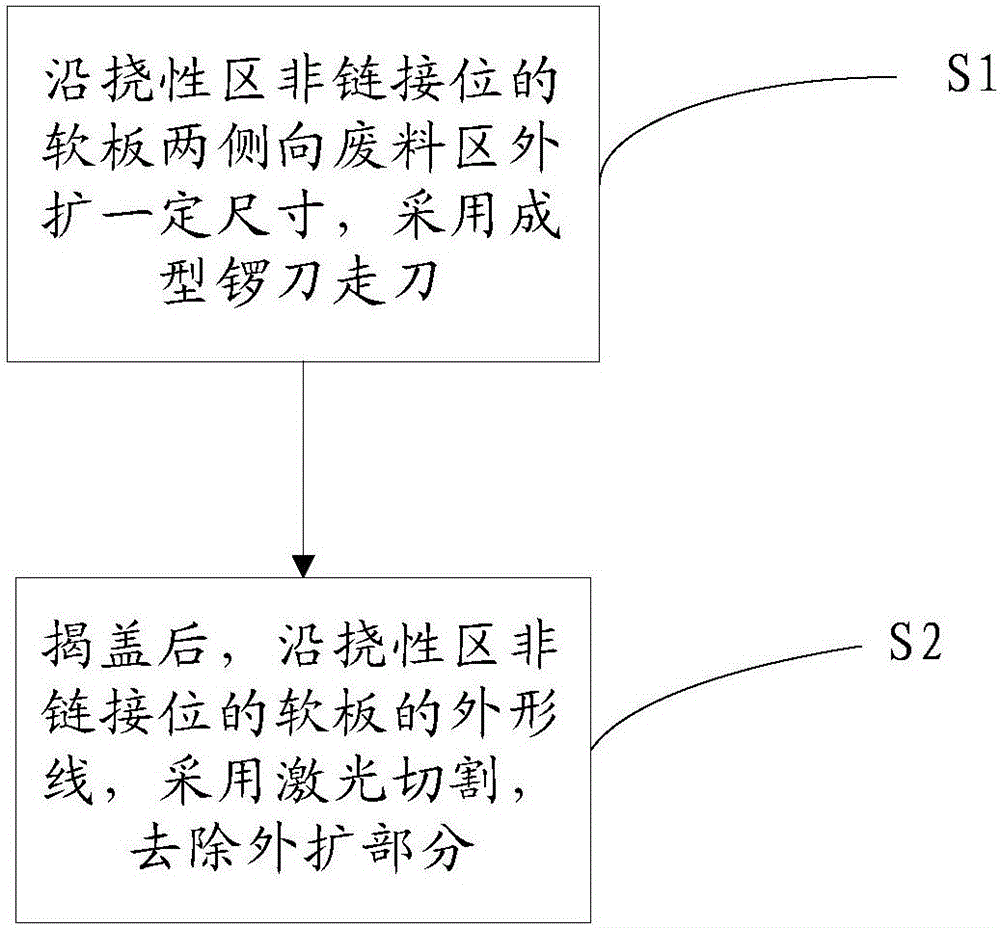

Processing method for removing burrs from flexible printed circuit board region of rigid-flexible printed circuit board

ActiveCN106658970AHigh precisionSolve glitchesFlexible printed circuitsPrinted circuit manufactureMilling cutterEngineering

The invention relates to a processing method for removing burrs from a flexible printed circuit board region of a rigid-flexible printed circuit board. The processing method comprises the following steps of expanding along the two sides of a flexible printed circuit board in a non-linking position in a flexible region to a waste material region for a certain dimension, and feeding by adopting a shaping milling cutter; and after uncovering, adopting laser cutting along the outline of the flexible printed circuit board in the non-linking position in the flexible region to remove an outward-expansion part. According to the processing method, the step of expanding along the two sides of the flexible printed circuit board in the non-linking position of the flexible region to the waste material region for a certain dimension is performed by the shaping milling cutter in advance; then uncovering is carried out, and by adopting laser cutting, the outward-expansion part is removed along the outline of the flexible printed circuit board in the non-linking position in the flexible region, so that manual repairing is not required; the high precision of the outline precision of the flexible printed circuit board is maintained; the problem of burrs on the two sides of the flexible printed circuit board in the flexible region is solved; and effects of low cost and no waste of material are achieved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Production method of metallized semi-hole of printed circuit board

InactiveCN107580419AReduce production processSolve the critique problemPrinted circuit manufactureMilling cutterEngineering

The invention provides a production method of a semi-hole of a printed circuit board. The method comprises the following steps that a, process production of the circuit board from cutting to surface treatment is completed to form a semi-hole production state board to be metallized; b, secondary drilling is conducted on the portions, on the two sides of the metallized semi-hole, of the hole wall, wherein the circuit board is fixed to a drilling machine through locating nails, a drill bit cuts in the hole wall in a rotating mode clockwise, that is to say, small holes are drilled in the portions,on the two sides of the semi-hole in the position to be milled later, of the hole wall, and hole wall copper is drilled to be broken; c, board edge milling is conducted on the metallized semi-hole, wherein a board milling program is acquired, the metallized hole edge is milled by a milling cutter clockwise to achieve a board milling movement, and the metallized semi-hole is formed; d, board milling is conducted on the unit edge, wherein the board milling program is acquired, the unit edge is milled according to normal operation parameters to achieve a board milling movement, the circuit boardis milled to small units, and a production board with the metallized semi-hole is formed. By means of the production method of the semi-hole of the printed circuit board, the burr problem is solved,the production process of the circuit board is shortened, the production cost is lowered, and the quality, the yield and the production efficiency are improved.

Owner:珠海精毅电路有限公司

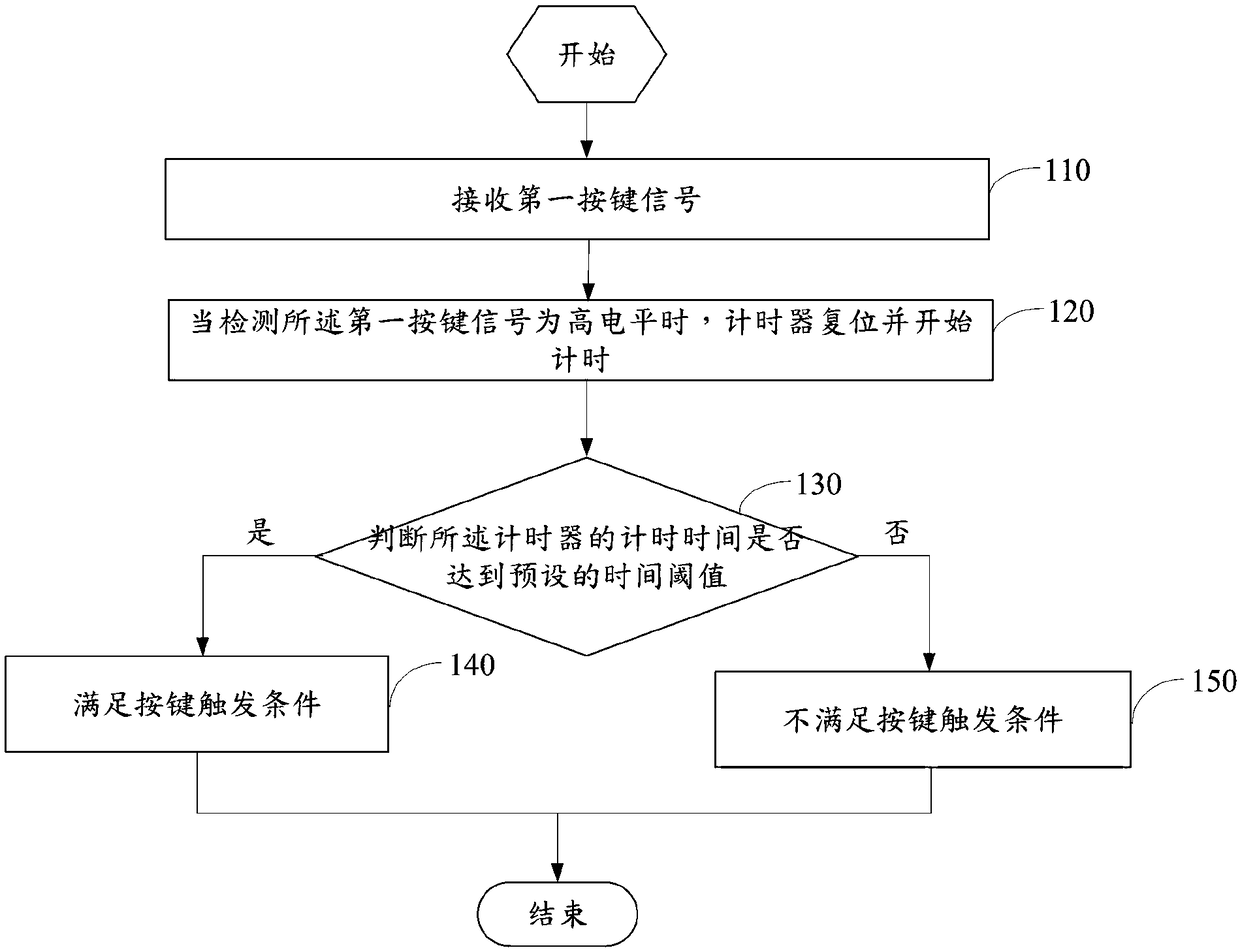

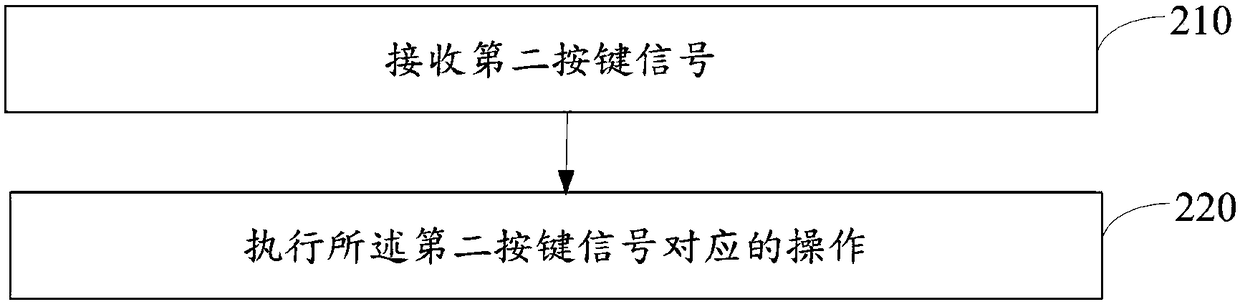

Key jitter-removing method, device and storage medium

The invention discloses a key jitter-removing method, a device and a storage medium, and belongs to the technical field of communication. The method includes the steps of receiving a first key signal;when it is detected that the first key signal is in a high level, a timer is reset and starts timekeeping; determining whether the time of the timer reaches a preset time threshold; if not, a key trigger condition is not satisfied. According to the key jitter-removing method, the device and the storage medium of the present invention, if a key signal received during a period from the start of thetimekeeping to the maximum time is determined as a glitch signal, the state of the key trigger condition is not satisfied such that an operation of the glitch signal is not triggered, thereby solvingthe glitch of the key and achieving a key jitter-removing effect.

Owner:ZTE CORP

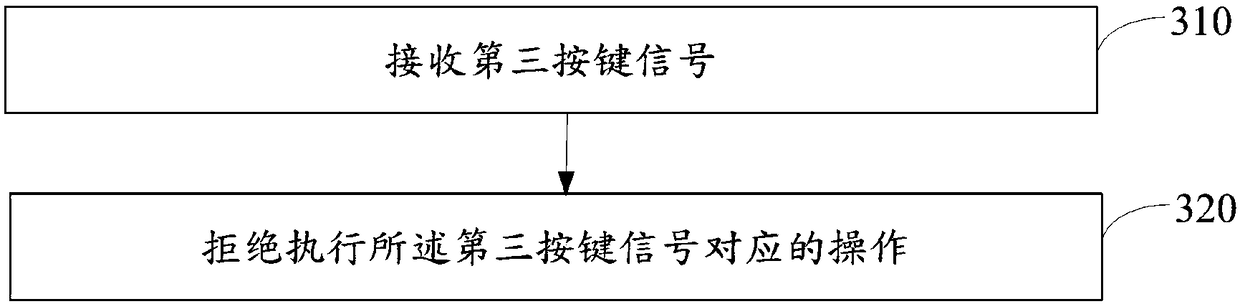

Forming process of burr-free printed circuit board (PCB)

InactiveCN105704947AImprove pass rateSolve glitchesProcessing steps orderPrinted element electric connection formationEtchingManufacturing technology

The invention belongs to the technical field of fabrication of a printed circuit board (PCB), and relates to a forming process of a burr-free PCB. The forming process sequentially comprises the following steps of substrate fabrication, plated through hole drilling, electroplating, circuit transfer-printing, hole drilling and breaking, circuit etching and milling. According to the forming process, the step of circuit etching is arranged after the step of hole drilling and breaking, burrs formed during hole drilling and breaking is corroded by a corrosion reagent, the burr problem also can be solved although the step of processing is not added, and the qualified rate of circuit board drilling is improved.

Owner:PLOTECH TECH KUNSHAN CO LTD

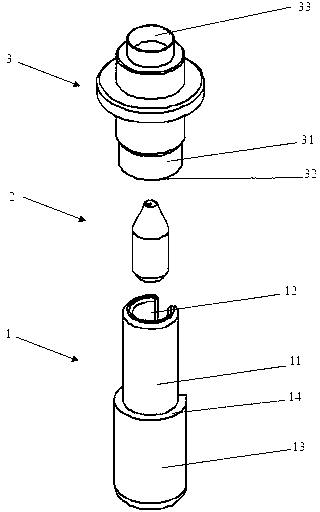

Component of ceramic ferrule and metal sleeve member and assembling method thereof

The invention discloses a component of a ceramic ferrule and a metal sleeve member. The component of the ceramic ferrule and the metal sleeve member comprises a positioning seat, the ceramic ferrule and a metal component arranged on the positioning seat. A cylindrical containing portion is arranged on the positioning seat, a containing groove used for containing the ceramic ferrule is formed in the containing portion, an installing portion for containing the containing portion is arranged on the bottom of the metal component, a cylindrical groove matched with the containing portion is formed in the installing portion, adhesive dispensing holes communicated with the cylindrical groove are formed in the top of the metal component, the component of the ceramic ferrule and the metal sleeve member is solidified through adhesive dispensing, coordinating margins can be reversed at the connecting positions of the elements, the phenomenon that burrs or iron scraps are formed on the component during the forming process of the component under the condition of interference fit is solved, and the phenomenon that the ceramic ferrule loosens during the pressing and matching process is solved at the same time.

Owner:JIANGSU ALLRAY

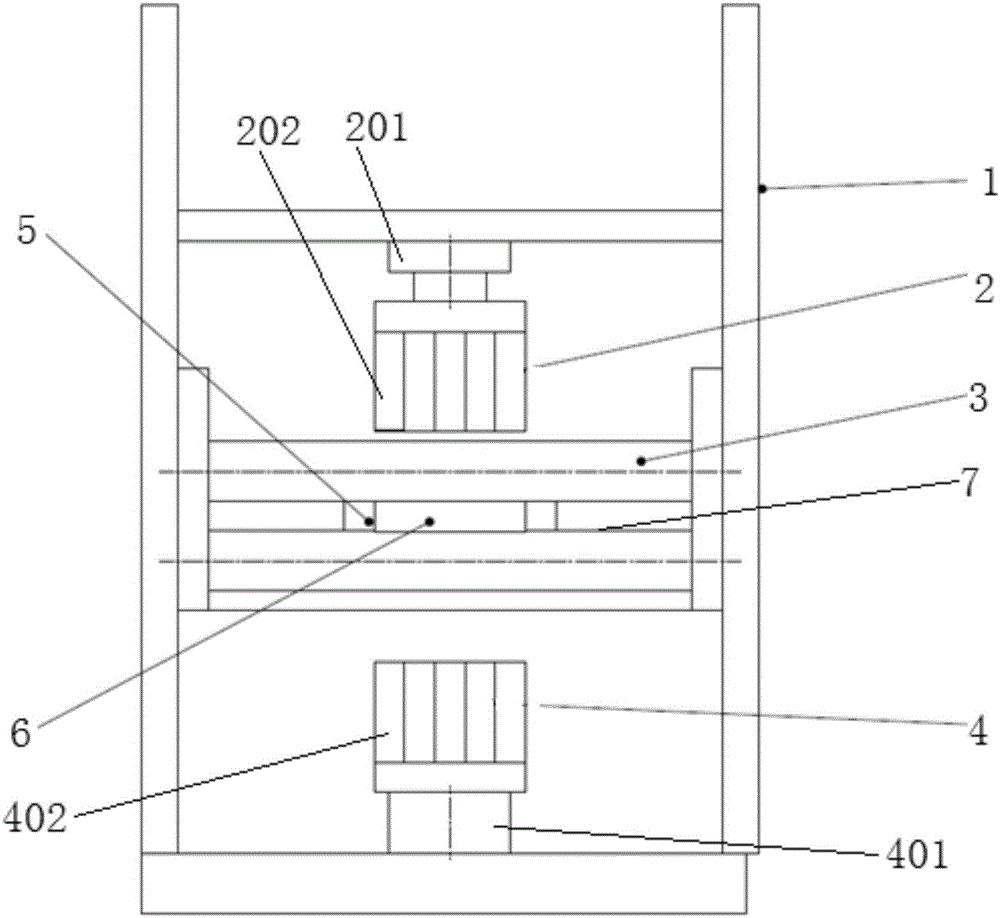

Stamping device used for manufacturing plates with unequal thicknesses

ActiveCN106583525AImprove mechanical propertiesImprove corrosion resistanceShaping toolsWorkbenchMetal flow

The invention discloses a stamping device used for manufacturing plates with unequal thicknesses. The stamping device comprises a rack, a workbench, baffle plates, an upper combined tool, a lower combined tool and a feeding mechanism, wherein one pair of baffle plates is mounted on the workbench; a distance between one pair of baffle plates is inconsistent with width of the plates with unequal thicknesses; the upper combined tool comprises an upper tool apron and a plurality of regularly arranged height-adjustable upper tool bits mounted on the upper tool apron; each upper tool bit can be independently mounted on the upper tool apron in a telescopic mode; according to shapes and depths of upper grooves in the plates with unequal thicknesses, one or more upper tool bits extend out to form envelope surfaces matched with the upper grooves; the lower combined tool is similar to the upper combined tool in structure; and when grooves are separately formed in upper surfaces and lower surfaces of the plates with unequal thicknesses, the upper combined tool is matched with the lower combined tool to work. According to the stamping device disclosed by the invention, plates with unequal thicknesses are manufactured in a stamping mode, and a metal flow direction during plastic deformation is controlled through a clamp, so that materials can be saved while different kinds of plates with different depths are produced.

Owner:WUHAN UNIV OF TECH

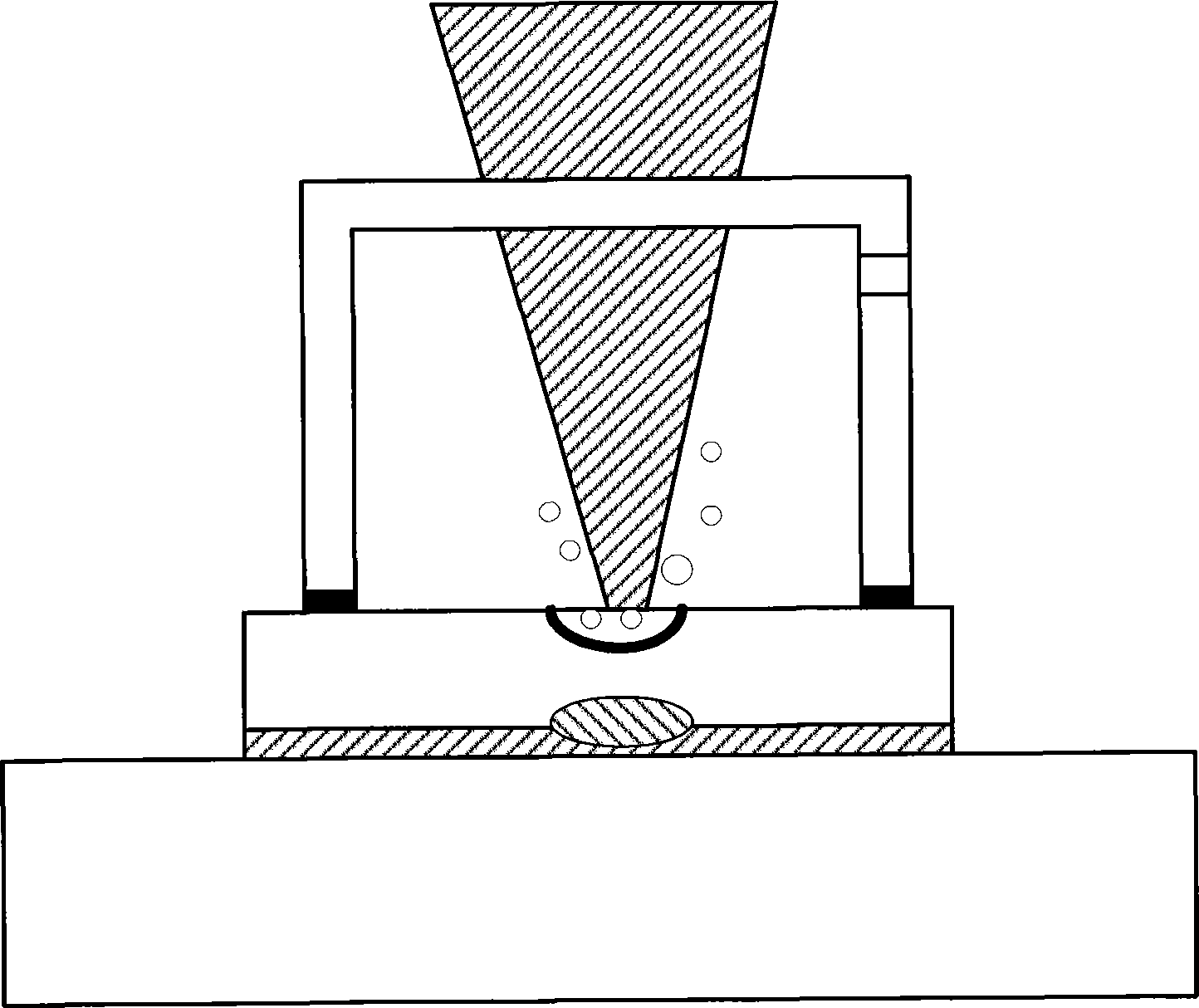

Foaming-assisted sheet metal laser precision boring method and device

ActiveCN103894743AFix glitchesImprove inner wall qualityLaser beam welding apparatusSmall holeLaser beams

The invention provides a foaming-assisted sheet metal laser precision boring method. The method includes: (1) mounting a sheet metal workpiece on a machining base plate, coating with a layer of high-temperature foaming agent between the sheet metal workpiece and the machining base plate, and covering the upper surface of the sheet metal workpiece with a sealed suction hood; (2) sucking air outwards through the suction hood to enable the sealed suction hood to be always kept in a negative-state internally; (3) outputting a laser boring pulse through a laser device; (4) keeping a laser beam to continue irradiating for 1ms-500ms, and then ending the laser boring pulse; (5) moving a focus position of the laser beam to a next position needing boring, and repeating the steps (3) and (4) till all holes are machined; (6) after all the holes are machined, taking down the workpiece. Since the method is adopted for laser boring, good hole roundness, no burr at edges of outlets and small hole diameter deviation between hole inlets and the outlets can be guaranteed. The invention further provides a foaming-assisted sheet metal laser precision boring device.

Owner:张家港市欧美轻工工具制造有限公司

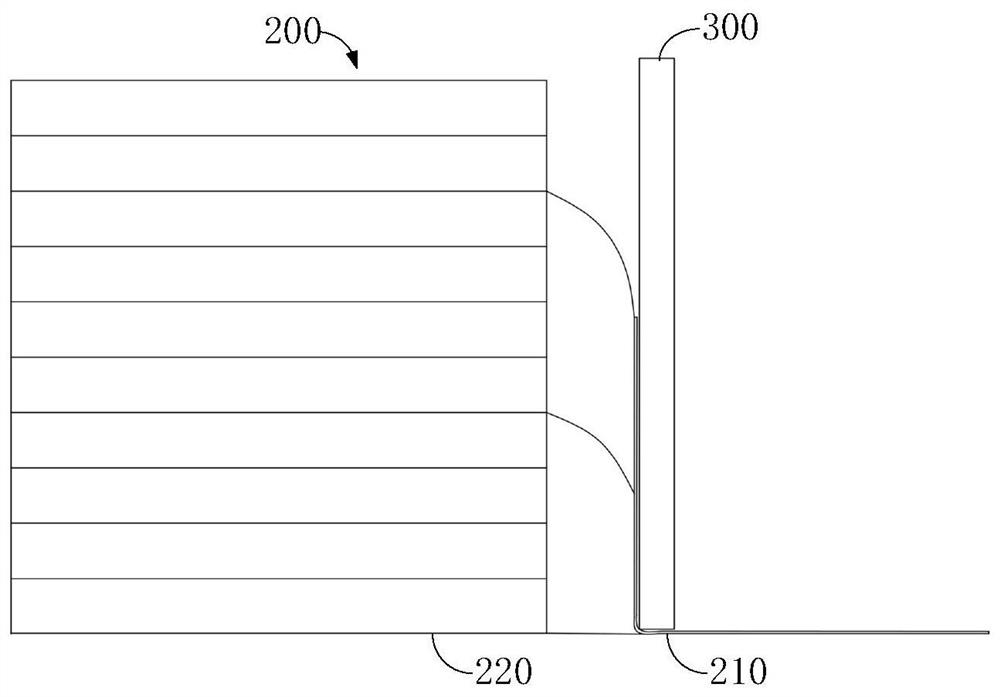

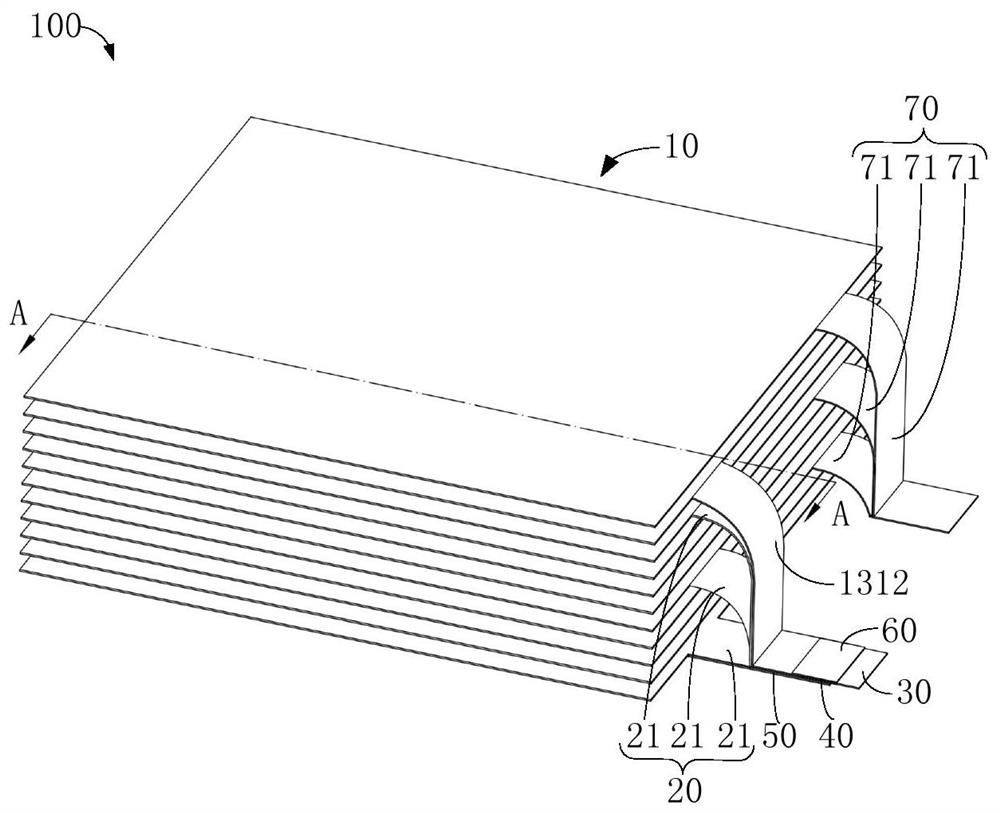

Battery cell and electronic device

PendingCN113675535AReliable connectionAvoid GlitchesCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrically conductiveEngineering

The embodiment of the invention discloses a battery cell and an electronic device. The battery cell comprises an electrode assembly and a first conductive unit, the electrode assembly comprises a plurality of first pole pieces, a plurality of second pole pieces and diaphragms, the first pole pieces and the second pole pieces are alternately stacked, the diaphragms comprise a first diaphragm and a plurality of second diaphragms, and in the thickness direction of the electrode assembly, the first pole pieces are located at one sides of the first diaphragms, and each second diaphragm is arranged between the adjacent first pole piece and second pole piece. The first diaphragm comprises a main body part and a protection part extending out of the edge of the main body part, and the protection part covers the first conductive unit and prevents the exposed part of the first conductive unit from puncturing the packaging bag.

Owner:NINGDE AMPEREX TECH

Connector pin and production process thereof

InactiveCN106981740AElimination of severe adverseSolve glitchesVehicle connectorsContact member manufacturingSheet metal stampingBiomedical engineering

The invention discloses a connector pin and a production process thereof and belongs to the automobile fitting field. The connector pin comprises a material belt and a pin, wherein the material belt comprises a sheet material and a U-shaped clip arranged on the sheet material, and the pin is embedded into the clip. The production process comprises sheet material stamping, cutting and folding to form the material belt, pin cutting, inserting the pin into the clip and molding. The connector pin is advantaged in that the connector pin can be widely utilized, square needles, circular needles and flat needles which are applied to all the connectors can be processed, production precision is high, a smooth surface and stable profile dimensions are realized, production cost is low, and efficiency is high.

Owner:深圳市天创原精密电子有限公司

Separation method for package part with cooling fins

The invention discloses a separation method for a package part with cooling fins. The package part comprises a carrier plate, a chip, a plastic package body and the cooling fins. In a separation process of the package part, the cooling fins are slotted by adopting laser or a cutter and are etched, and then a product is separated by using the cutter. According to the separation method, the problem of burrs of the cooling fins caused by direct use of the cutter for cutting in the separation process of the package part is solved.

Owner:HUATIAN TECH XIAN

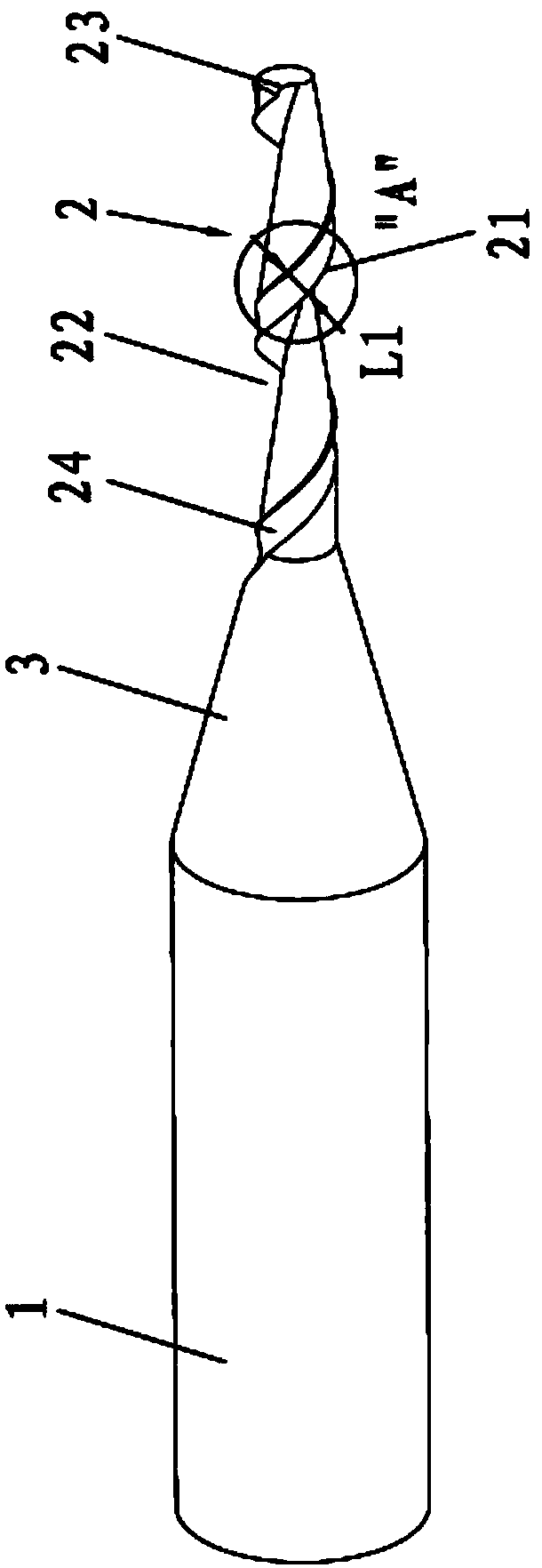

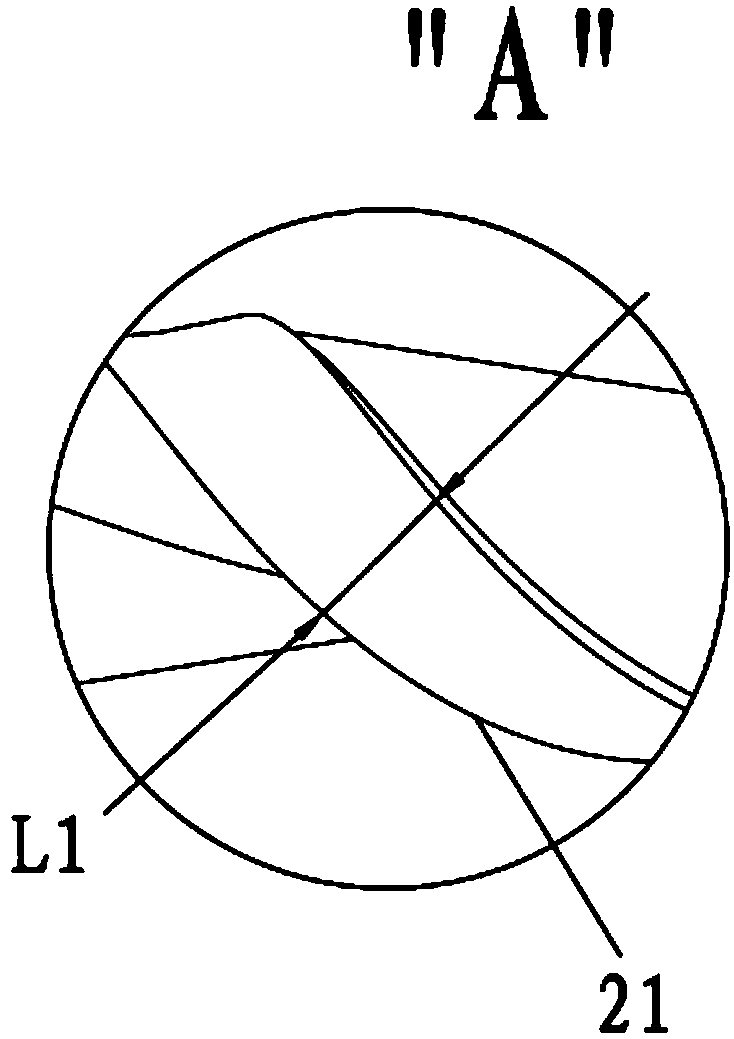

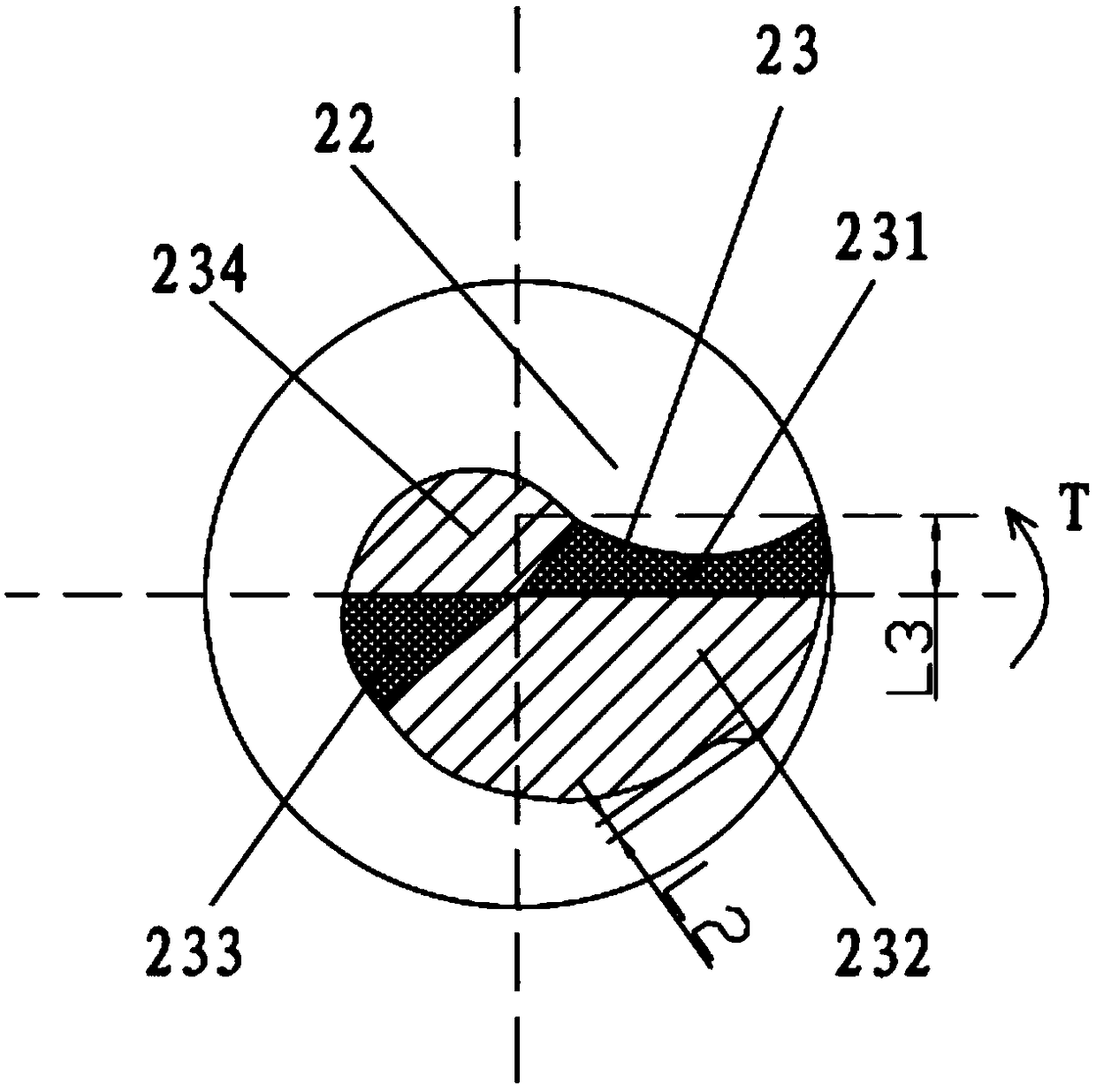

Single-blade milling cutter

PendingCN108581001AIncrease chip spaceEasy to useMilling cuttersMilling cutterAgricultural engineering

The invention discloses a single-blade milling cutter applicable to the technical field of milling cutter structures. The single-blade milling cutter comprises a cutter handle and a cutter body connected to one end of the cutter handle. The cutter body is provided with a spiral cutting blade, a chip discharging groove and a main cutting blade. The chip discharging groove and the spiral cutting blade are spirally arranged around the axis of the cutter body in the direction from the front end of the cutter body to the cutter handle. The spiral cutting blade and the chip discharging groove are same in the spiral angle. The main cutting blade is arranged at the front end of the cutter body and is adjacent to the chip discharging groove. The cutting edge of the main cutting blade is of an arc concave structure, and the main cutting edge is provided with an arc-shaped relief angle. Through the single-blade milling cutter provided by the invention, the overall stiffness strength of the milling cutter and the sharpness of the cutting edges can be improved, and meanwhile, the effect that chips are discharged smoothly is ensured.

Owner:SHENZHEN JINZHOU PRECISION TECH

Conical hole forming device, car door forming die and conical hole forming method

InactiveCN107199273AQuality improvementReduced commissioning timePerforating toolsCar doorForming processes

The invention discloses a conical hole forming device, a car door forming die and a conical hole forming method. The conical hole forming device comprises a punching male die (3), a punching female die, a hole flanging male die and a hole flanging female die (4). The punching male die (3) and the hole flanging female die (4) are connected to a first inclined wedge (2). The punching female die and the hole flanging male die are connected to a second inclined wedge (7). The punching male die (3) and the punching female die are matched so that a through hole of a car door lock catch hole can be formed. The hole flanging male die and the hole flanging female die (4) are matched with each other so that a conical counter bored hole of the car door lock catch hole can be formed. According to the conical hole forming device, the problem that burrs are produced in the conical hole forming process can be solved, the quality of the formed conical hole is improved, and the debugging time of a fitter is shortened.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

Preprocessing method of flexible substrate

ActiveCN109407372AAvoid pollutionReduce cleaningNon-linear opticsTectorial membranePretreatment method

The invention relates to a preprocessing method of a flexible substrate. The flexible substrate includes a flexible substrate body and a glass base material; one side of the flexible substrate body isprovided with a protection film. The preprocessing method of the flexible substrate includes the following steps that the flexible substrate body is adopted, the side, away from the protection film,of the flexible substrate body is attached to the glass base material, a precut position is formed on the flexible substrate body, and the protection film covers the precut position; cutting is conducted at the precut position to form a cut; the protection film is removed, and the surface of the flexible substrate body is exposed; a structure film layer is produced on the surface of the flexible substrate body. It is unnecessary to add other production processes and conduct other processing operation on the cut, and thus the problem is effectively solved that in traditional technologies, burrsexist at the cut; after precutting, the protection film is removed, contamination caused by cutting chippings on the flexible substrate body can be effectively prevented, the process of washing a cutting line is omitted, technical production processes are reduced, the production time is saved, the product yield of a whole production procedure is increased, and the production efficiency of the whole production procedure is improved.

Owner:TRULY SEMICON

Metal sheet laser precision perforating device assisting in foaming

ActiveCN104923926AAchieve removalSolve glitchesLaser beam welding apparatusFoaming agentOptoelectronics

Owner:WENZHOU UNIV

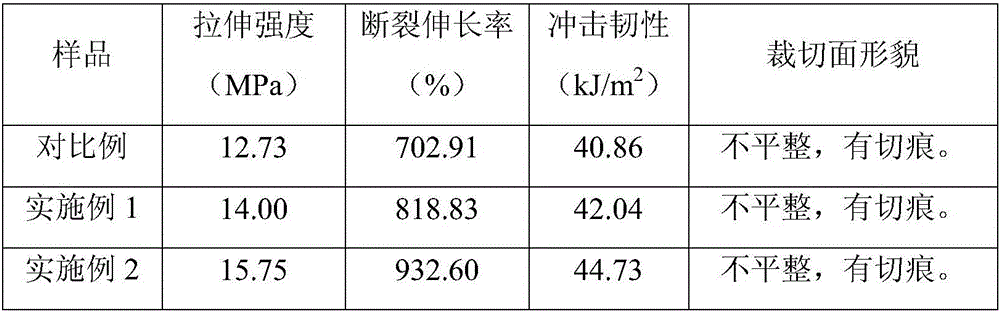

PE (poly ethylene) protection film material for automobile and preparation method thereof

The invention relates to a PE protective film material for automobiles and a preparation method thereof. According to parts by mass, the components include: 100 parts of polyethylene PE, 10-30 parts of filler, and 1-5 parts of plasticizer. The preparation method includes: (1) weighing each raw material in proportion, melt extruding and granulating; (2) putting PE pellets into a twin-screw extruder, melting and mixing at 160-170°C, and stretching to form a film , and then apply the cross-linked acrylic resin adhesive to one side of the PE protective film, then pass the protective film through the air heating channel, and finally rewind and cut it. The invention significantly improves the tensile strength, reduces the toughness to a certain extent, further eliminates the phenomenon of burrs on the edge of the film caused by the uneven cutting surface, and effectively reduces the manufacturing cost of PE protective film products for automobiles, and has good application prospects.

Owner:宁波卓胜新材料有限公司

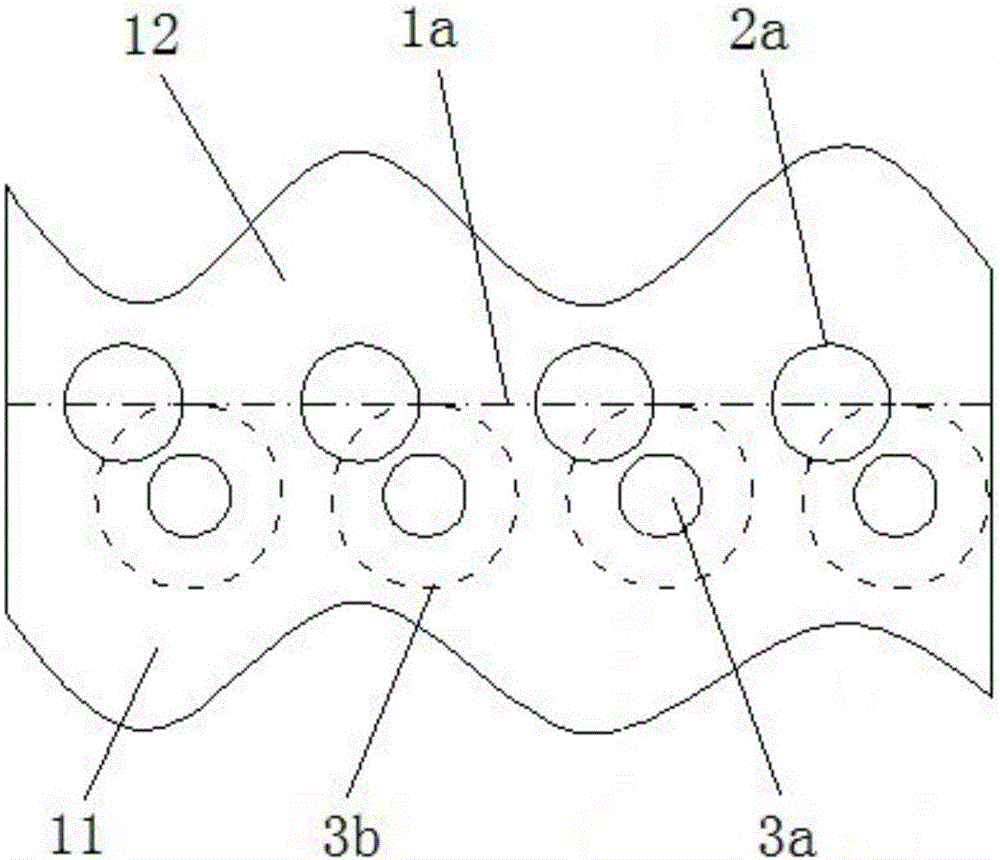

Wrapping method of warp knitting spacer fabric

ActiveCN101353845AGuaranteed breathabilityGuaranteed washabilityWarp knittingEngineeringSewing machine

The invention discloses a serging method for a warp-knitted spacer fabric, which relates to a serging technique for a fabric article and provides the serging method for the warp-knitted spacer fabric and a serging device for the warp-knitted spacer fabric. The covering device thereof is provided with two sets of sewing-machine folders. The first sewing-machine folder is provided with a fixing bracket, upper and lower ribbon slots, a zipper locating slot and upper and lower belt guides. The second sewing-machine folder is provided with a fixing bracket, a directing plate, a U-shaped pulling plate and a belt guide. The first sewing-machine folder is arranged on a sewing machine; one half of a zipper is fixed in the zipper locating slot and two ribbons are installed in the upper and lower ribbon slots; then the sewing machine sews one half of the zipper and the two ribbons together to obtain an edge-covered ribbon with one half of the zipper; the second sewing-machine folder is arranged on the sewing machine; the edge-covered ribbon with one half of the zipper is arranged into the second sewing-machine folder and pulled out through the belt guide; the core material of the warp-knitted spacer fabric is clung to the U-shaped pulling plate and the internal wall of the directing plate. The serging is finished under the traction of the sewing machine.

Owner:福建福联精编有限公司

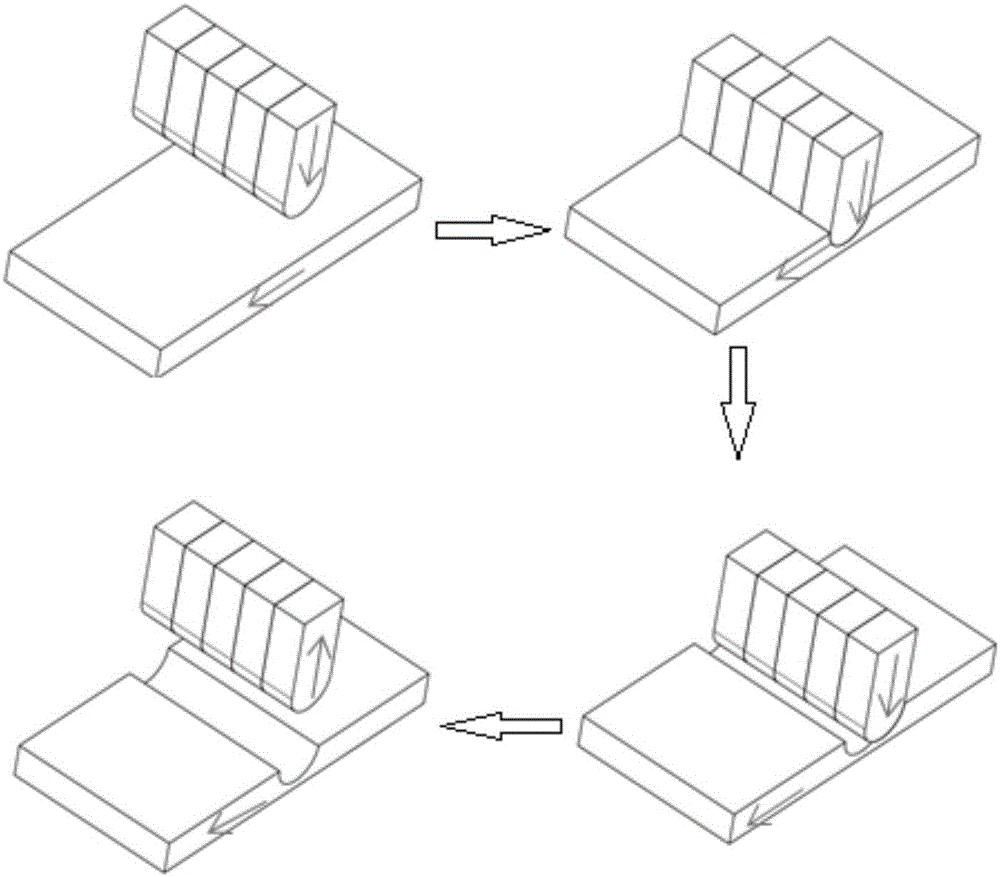

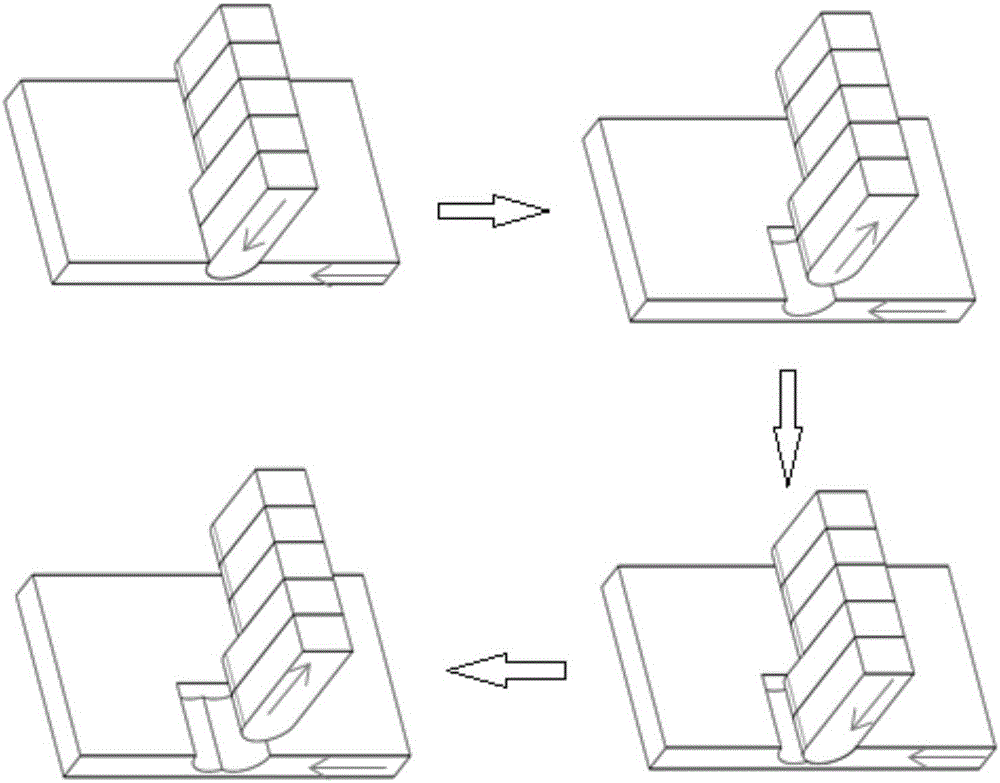

Progressive die punching process cutter joint burr processing device and process

The invention discloses a progressive die punching process cutter joint burr processing device and process. The device comprises an upper die base and a lower die base used in cooperation with the upper die base. The lower die base is provided with a concave die plate. A V shape forming punch is arranged on one side of the concave die plate, and a shearing punch is arranged on the other side of the concave die plate. The cutter joint zone of the V shape forming punch is a bevel, and the bottom of the bevel is a circular bead. The burr processing device is simple in structure and convenient to use; the cutter joint of a product is subjected to V shape forming treatment, the same position is subjected to shearing in the next procedure, and thus the problem of product burrs caused by punching in a die can be completely avoided; and the problem that cutter joint burrs cannot be processed in the die finally is solved, the subsequent deburring procedures such as vibration grinding are omitted, cost is reduced, and the quality requirement of the product is met.

Owner:FINEFORMING PRECSION ENG

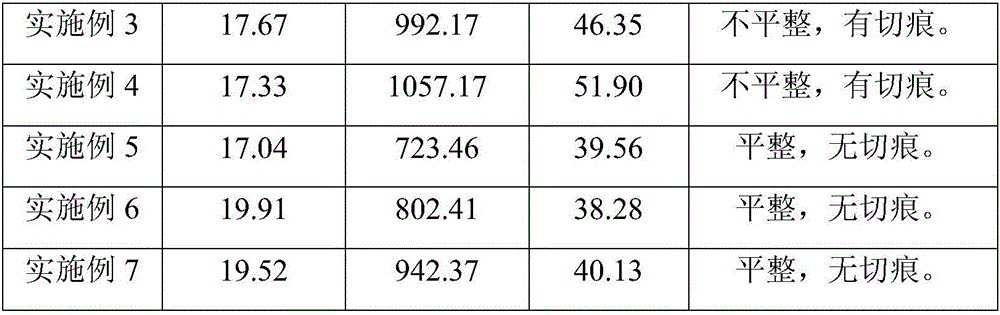

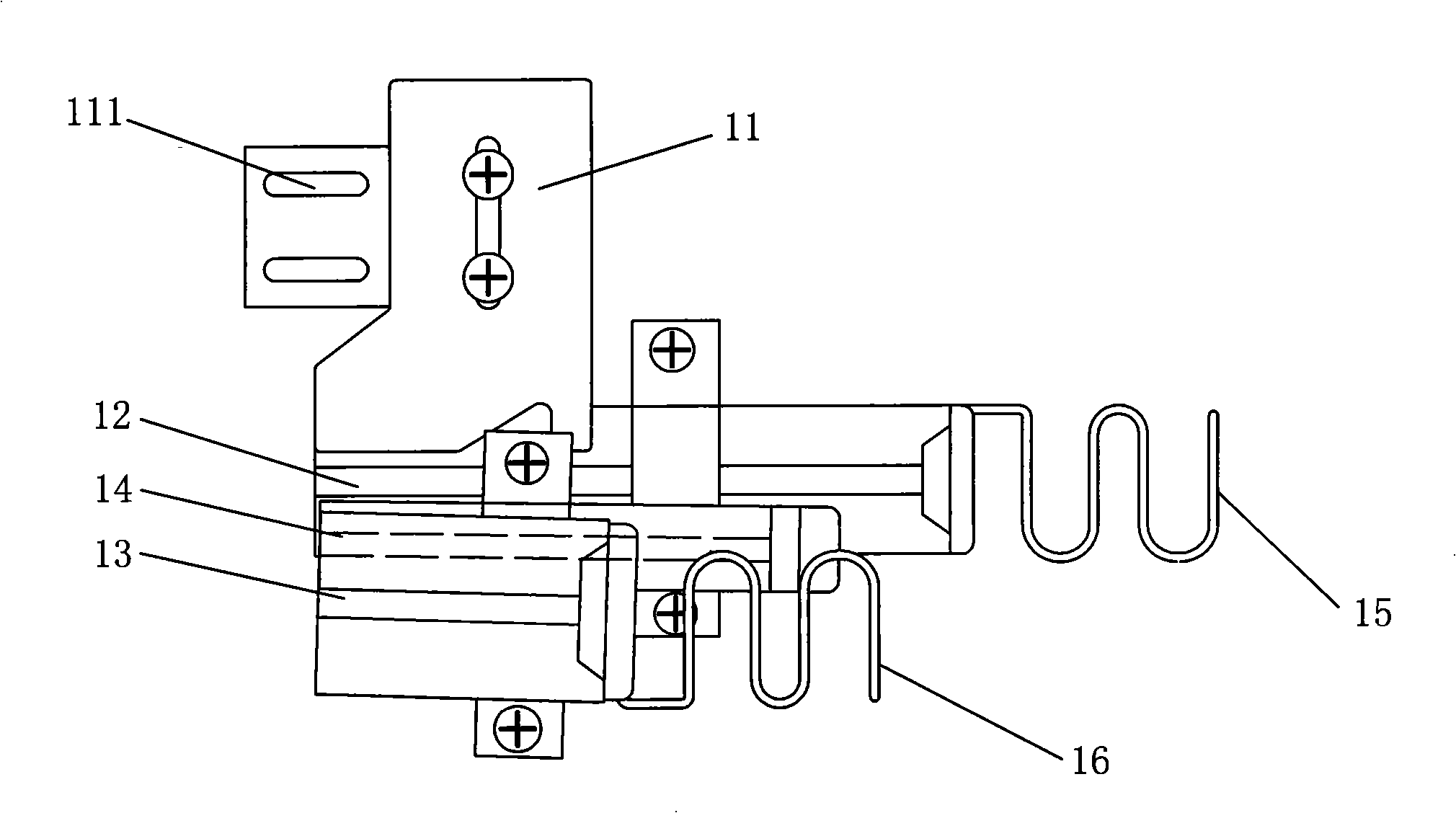

Mounting structure of longitudinal cutter in sub longitudinal cutting die for fins of air conditioners

A mounting structure of a longitudinal cutter in a sub longitudinal cutting die for fins of air conditioners comprises a die holder, a cutter rest and a screw. The screw penetrates out of a connecting block, an extending end of the screw is positioned above a pad, the connecting block is tightly connected with the die holder, the pad is tightly connected with a slider, pins are assembled on the die holder along the periphery of the slider, cap peaks of the pins are in butt joint with the slider, the cutter rest is positioned below the slider, the lower end of one side of the cutter rest for mounting a longitudinal cutting die is tightly connected with a limit block, the other side of cutter rest is tightly connected with the die holder, the front end face and the back end face of the cutter rest are respectively tightly connected with side stop blocks, a stop block is arranged right below the cutter rest, and the stop block is tightly connected with the die holder. The mounting structure is modified from a longitudinal cutter rest structure in the prior art, capable of meeting requirements of various longitudinal cutting manners of the same die, and thus, operators do not need to manufacture different cutter rests with the corresponding specifications.

Owner:WUXI MICRO RES

Manufacturing method of LED aluminum substrate V-shaped groove

InactiveCN103128348AFix glitchesGuarantee processing qualityMilling equipment detailsMetal working apparatusScrapQuality standard

The invention relates to a manufacturing method of LED aluminum substrate V-shaped groove. The method sequentially comprises the steps of aluminum substrate surface treatment; blue gum covering, aluminum substrate shaping; V-CUT cutting, blue gum removing, and the like. According to the invention, when V-CUT cutting is carried out, cutting is carried out by using common FR4 mill. When the mill operates in high speed, high temperature generated by cutting can rapidly melt the blue gum. The molten gum can wrap approximately 2 / 3 of the V-shaped groove area, and can be hardened and cooled rapidly. Irregular aluminum scraps are condensed on the blue gum, and are prevented from being condensed on aluminum surface of the V-shaped groove. When the blue gun is torn off, the aluminum craps on the blue gum is completely removed, such that the shaped V-shaped groove satisfies a quality standard. The method provided by the invention has the advantages of low cost and easy realization.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

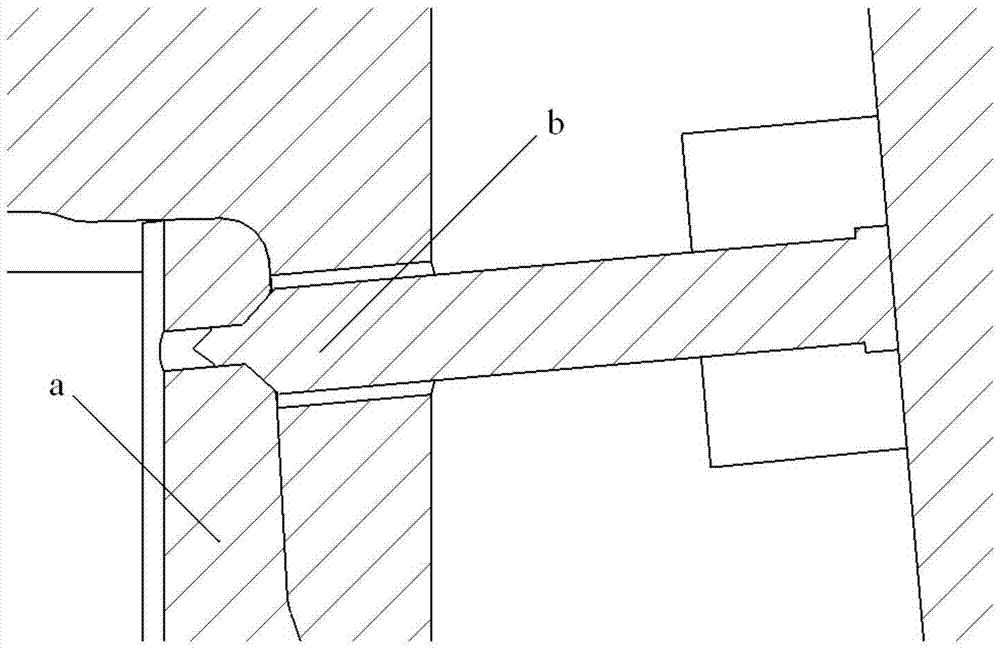

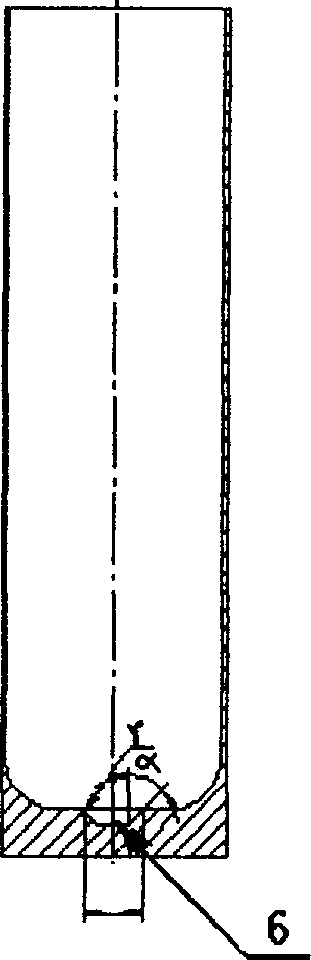

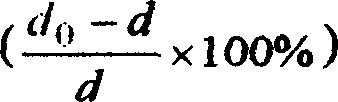

Method for eliminating bottom through-hole burr of processed deep cylindrical work pieces and dedicated male die therefor

InactiveCN1799720ASolve the problem of burrs when passing through holesSolve glitchesRams/plungersEngineeringMechanical engineering

The invention belongs to the punch processing area, which especially relates to a method and specific terrace die for eliminating the burr of through hole at the bottom of cylinder work-piece. The inventive method comprises: using the specific terrace die to extrude a round groove with certain taper at the bottom of cylinder work-piece, while the open of said groove and the bottom of said cylinder chamber are arc transition; and processing a through hole which is through with said round groove at the bottom of said cylinder work-piece, while the diameter of the open of said round groove is larger 5-25% of the diameter of the hole processed by cutting process. The invention utilizes terrace die to eliminate the burr of through hole at the bottom of cylinder work-piece, which can reduce the process of removing burr with high producing efficiency and lower cost.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

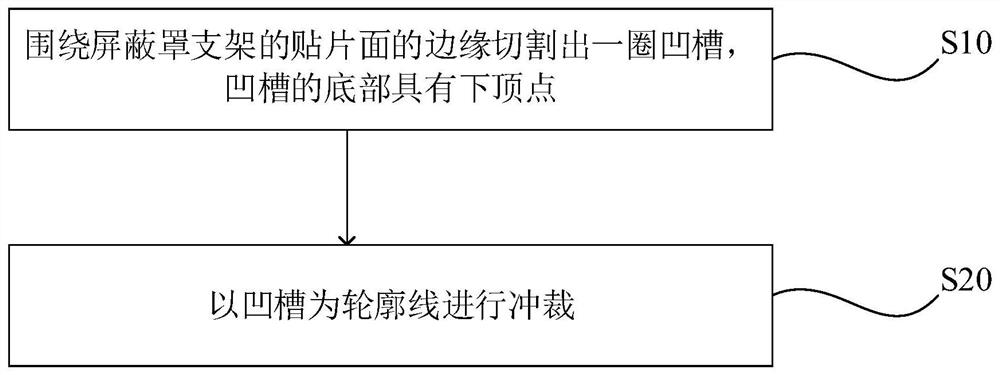

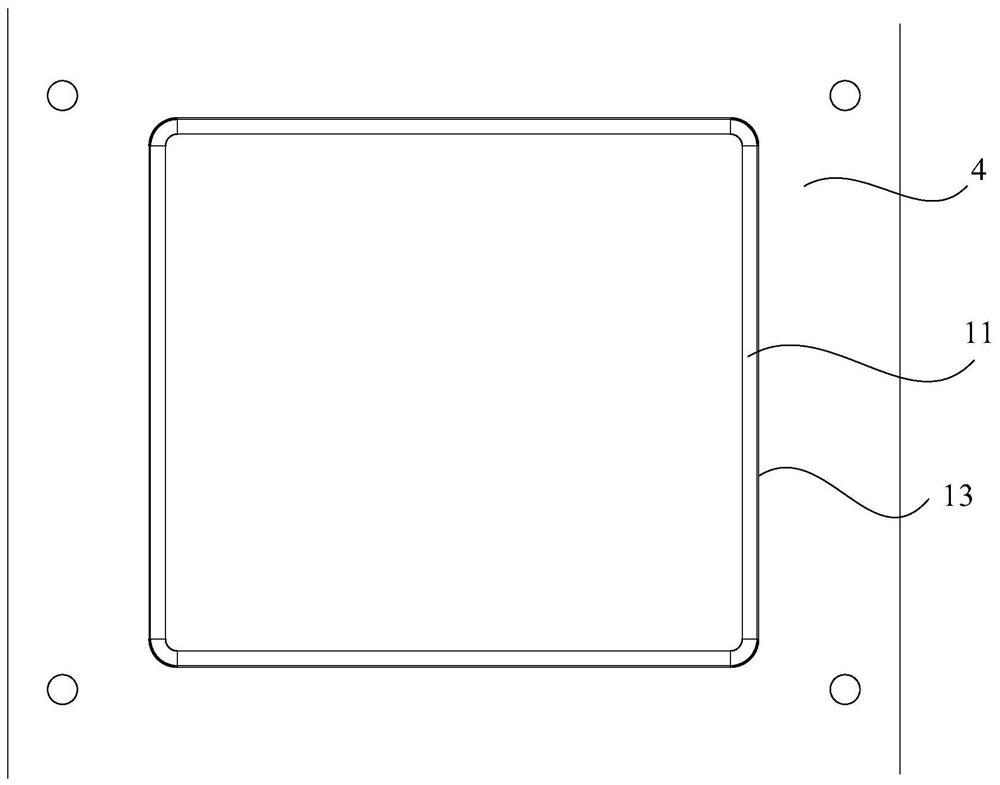

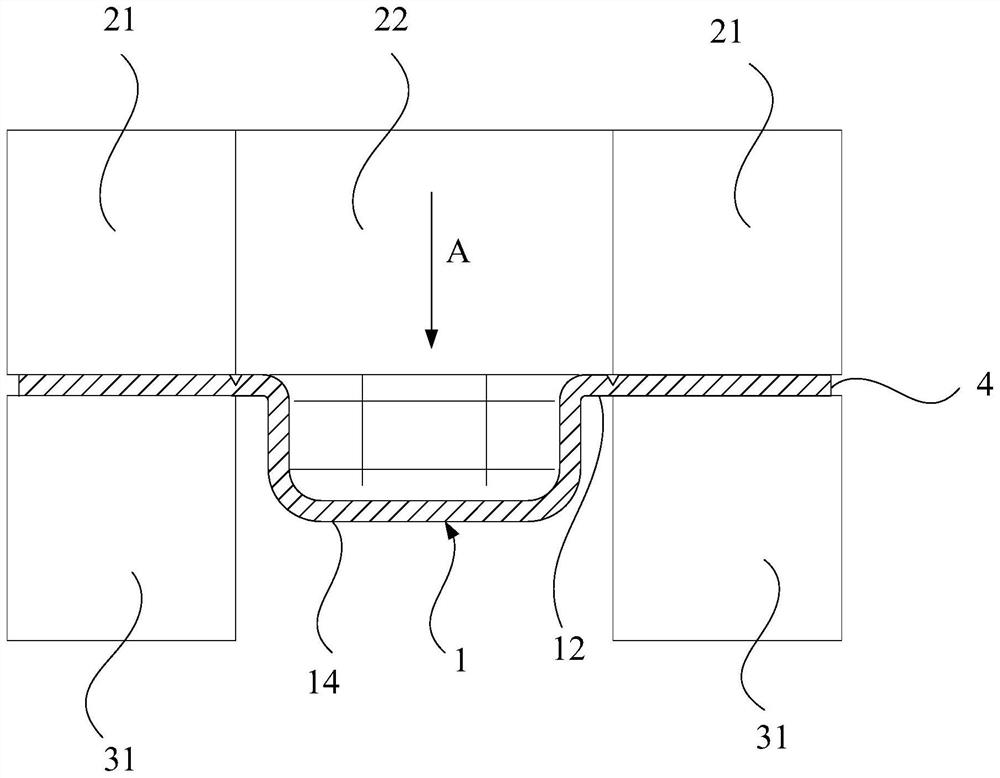

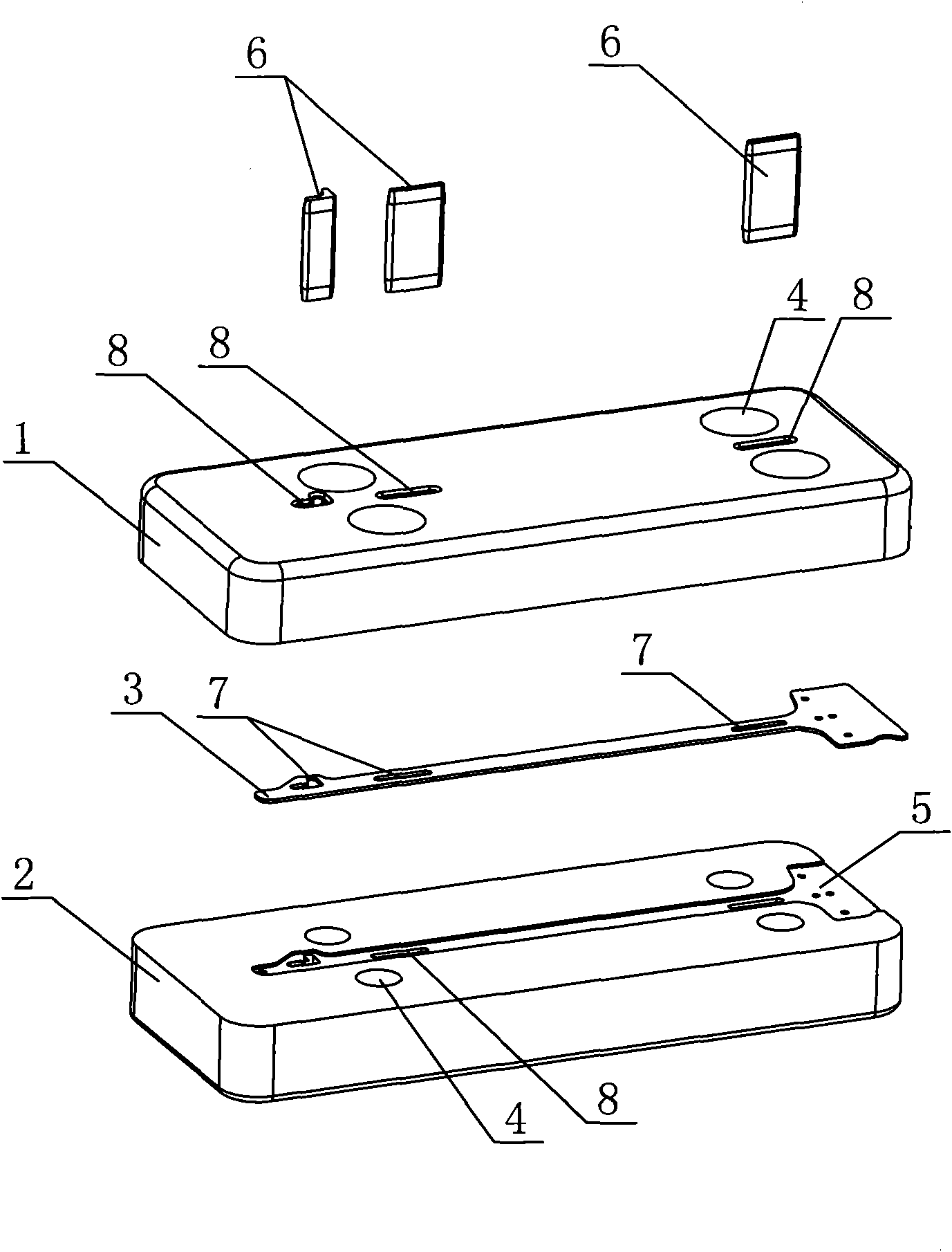

Manufacturing method of shielding case bracket

The invention discloses a manufacturing method of a shielding case bracket. The manufacturing method comprises the following steps of S10, cutting a circle of groove around the edge of a patch surfaceof the shielding case bracket, the bottom of the groove being provided with a lower vertex; and S20, blanking with the groove as the contour line. Due to the fact that the groove is additionally formed in the edge of the patch surface, when an upper die punch downwards punches raw materials of the shielding case bracket, the raw materials of the shielding case bracket are directly fractured and separated with the lower vertex as a tearing point, and therefore the burr problem caused by deformation dislocation and re-fracture is avoided. According to the manufacturing method, burrs on the surface of the flange edge patch are eliminated, and function failure caused by piercing of PCB wiring by the burrs is avoided; procedures of electrolysis or chemical treatment and the like for removing burrs in the later period of manufacturing the shielding case bracket are omitted; and in addition, burrs cannot be generated even if the die is abraded in the later period, and the service life of thedie is prolonged.

Owner:SHANGHAI CHUANGGONG COMM TECH

Burr processing jig

The invention provides a burr processing jig, which comprises an upper mold and a lower mold which are connected detachably by a fastening piece, and a punch head. The surface of the lower mold is provided with a notch which is consistent with the external contour of a workpiece to be processed, and the workpiece to be processed can be arranged in the notch. The punch head can move between the upper mold and the lower mold in a reciprocating mode. A punched hole for the punch head to pass through is respectively formed on the upper mold and the lower mold. The shape of the cross section of the punch head is consistent with a hole groove with burr of the workpiece to be processed and the contour of the punched holes of the upper mold and the lower mold. The burr processing jig has the advantages that: the structure is simple, the use is simple, and the burr problem of stamped parts can be well solved.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

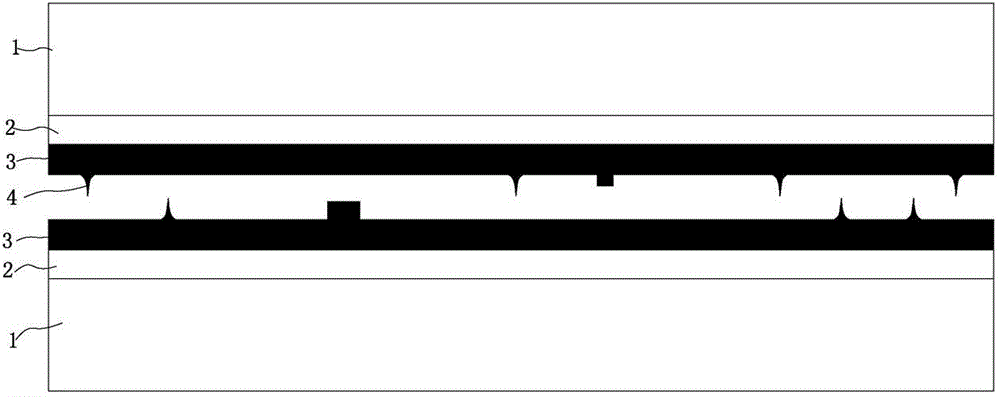

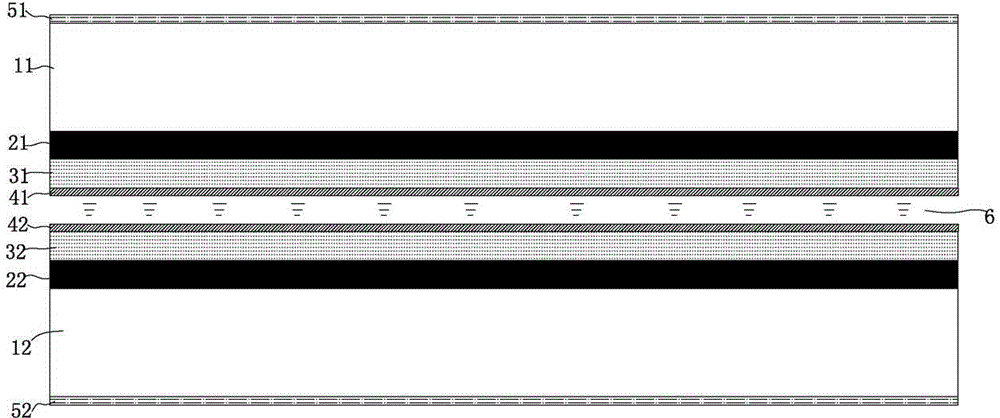

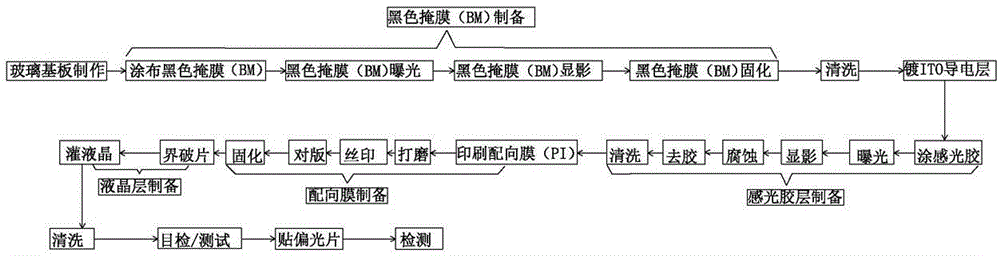

Novel liquid crystal display screen of black matrix structure and preparation method thereof

InactiveCN105353553AAvoid formingReduce defective productsNon-linear opticsLiquid-crystal displayTransmittance

The invention discloses a novel liquid crystal display screen of a black matrix structure. The novel liquid crystal display screen comprises two glass substrates. The inner surfaces of the two glass substrates are each provided with a layer of black mask. The two black masks on the two glass substrates are each provided with an ITO conductive layer. The ITO conductive layers are indium tin oxide electrodes used for displaying pixel patterns and wrap the black masks. A liquid crystal layer is arranged between the two ITO conductive layers. The upper end face and the lower end face of the liquid crystal layer are provided with matched alignment films. The upper end face of the upper glass substrate and the lower end face of the lower glass substrate are provided with an upper polaroid and a lower polaroid respectively. According to the liquid display screen, the problem that a short circuit is likely to be caused between two ITO electrodes is solved, transmission of light at the non-display pixel position, namely the gap between the ITO electrodes is blocked, the light transmittance of a non-display pixel is lowered, the contrast ratio of a display pixel to the non-display pixel is improved, the visual angle of the liquid crystal display screen is increased, the production yield is high, and the service life is long. The invention further discloses a preparation method of the liquid crystal display screen.

Owner:东莞通华液晶有限公司

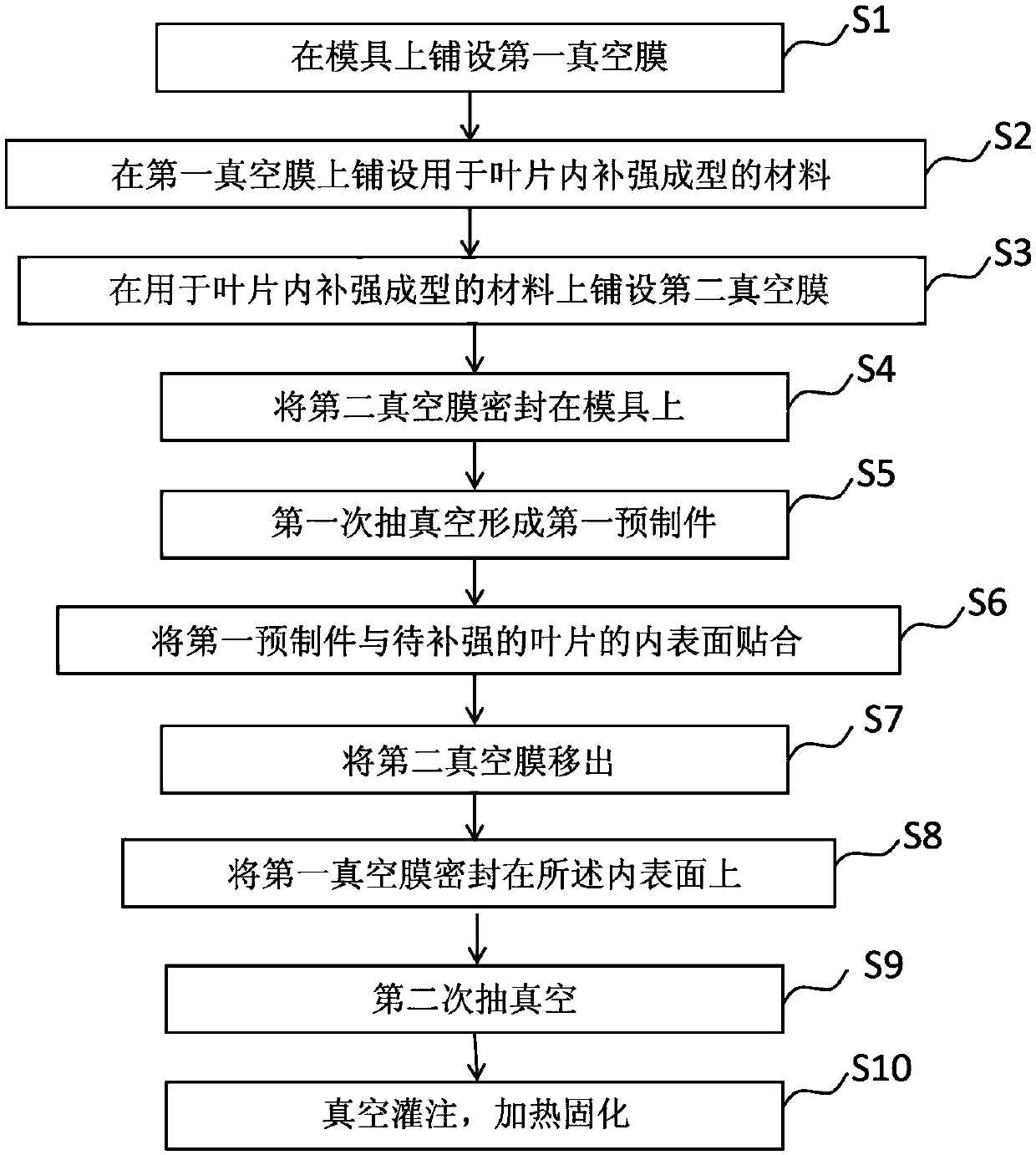

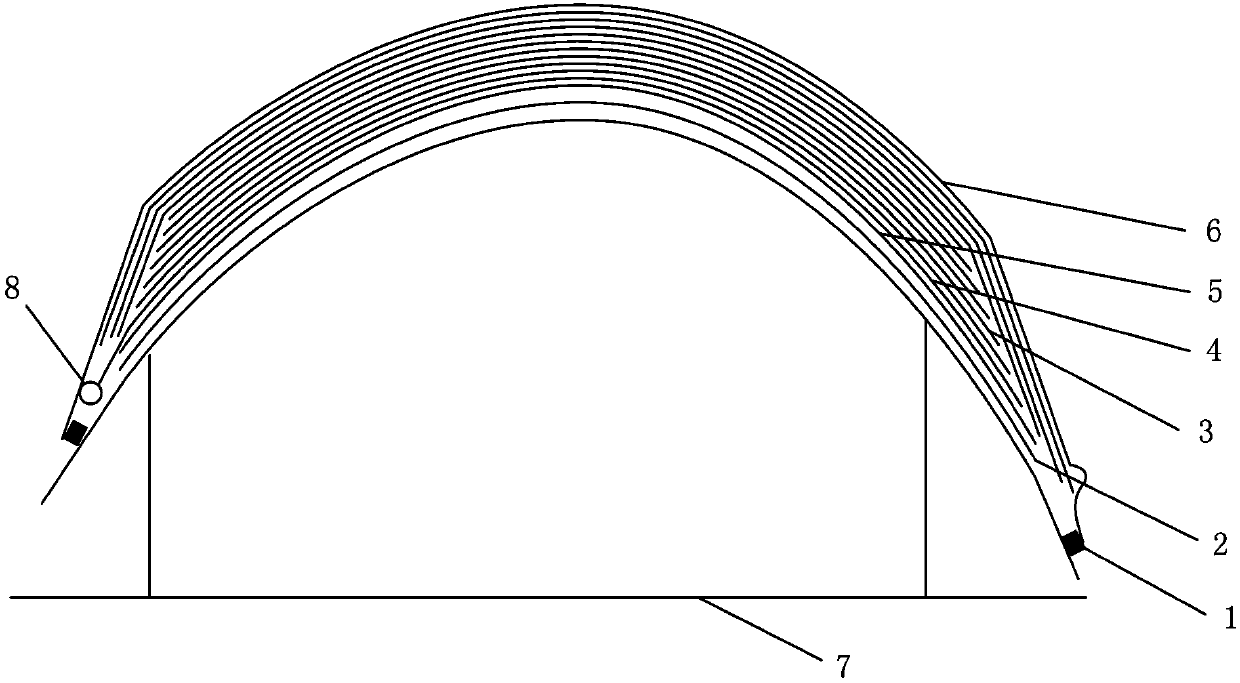

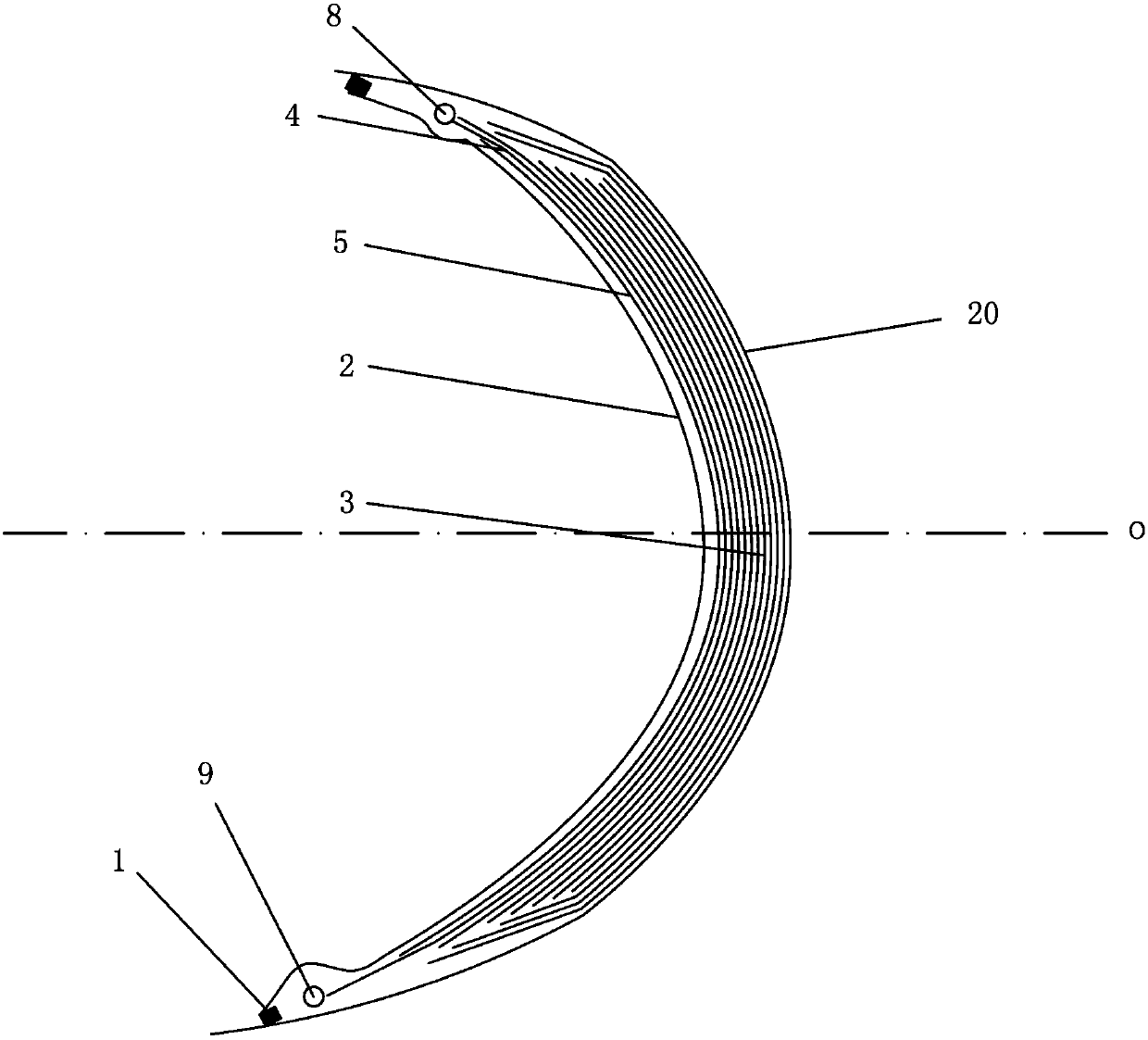

Wind generating set blade inner reinforcing preparation method and wind generating set blade

ActiveCN109986802AImprove the heating effectImprove liquidityDomestic articlesEngineeringWind power generation

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Suspension bridge type hot extrusion die for high-cantilever section bar

InactiveCN105080991ASolve the strength problemSolve glitchesExtrusion diesSuspension bridge typesEngineering

The invention relates to a suspension bridge type hot extrusion die for a high-cantilever section bar. The suspension bridge type hot extrusion die comprises a die surface. The die surface is provided with a die hole, a discharge port, a large cantilever and a small cantilever. The die hole is communicated with the discharge port. The suspension bridge type hot extrusion die is characterized in that a suspension bridge protruding out of the die surface is arranged at the feed end of the large cantilever. The suspension bridge type hot extrusion die has the following advantages that the strength problem of the cantilever positions can be directly solved after the suspension bridge is additionally arranged at the feed end, so that deformation or collapse of the cantilevers does not need to be worried; due to the fact that a traditional opening splicing mode or skin tearing mode is not used, the burr problem is completely solved.

Owner:JIANGYIN GIANSUN MOLD

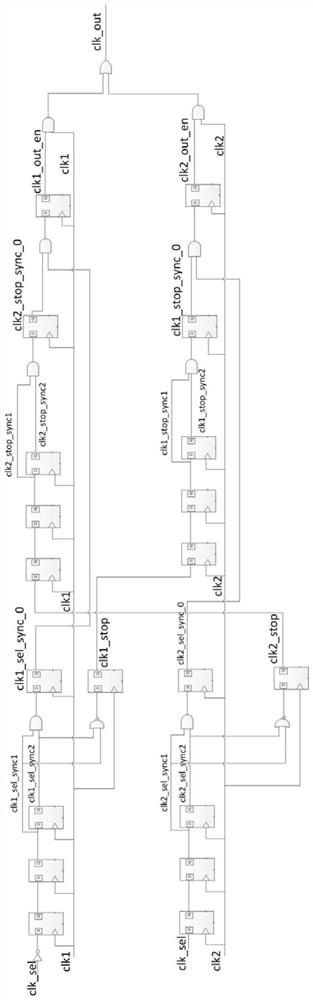

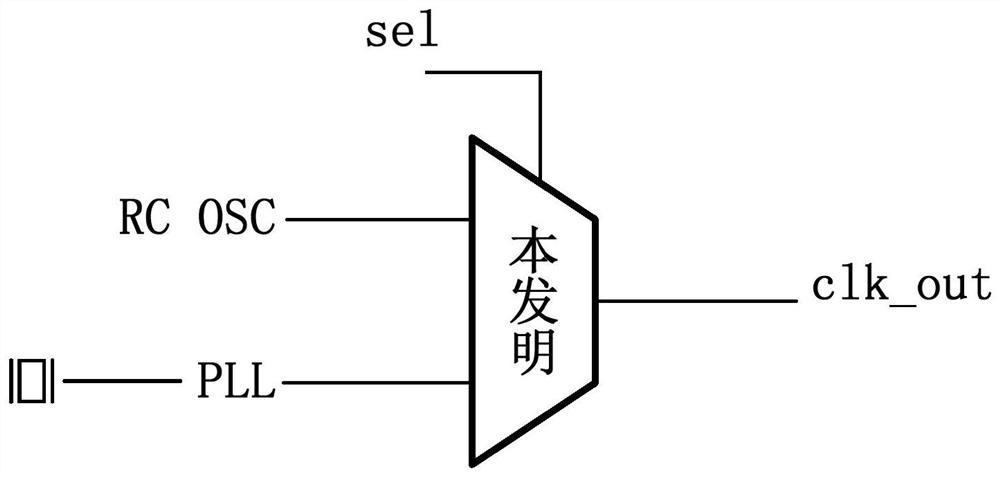

Asynchronous clock selection circuit based on cross-clock domain and switching method thereof

PendingCN112600550AIncrease clock efficiencyImprove stabilityLogic circuit coupling/interface arrangementsEnergy efficient computingEmbedded systemClock domain crossing

The invention relates to an asynchronous clock selection circuit based on a cross-clock domain and a switching method thereof, and the asynchronous clock selection circuit selects different clock signals for output according to the requirements of clock selection signals. A clock selection signal and a clock stop signal are synchronized with a target clock signal by using a cross-clock domain asynchronous clock selection circuit. The control signals are synchronized, so that asynchronous clock switching glitches can be avoided to the greatest extent while the asynchronous clock switching stability is improved. The requirement of asynchronous clock switching in an actual clock domain crossing circuit for stability is met, and meanwhile the stability of the clock domain crossing asynchronousclock selection circuit is better than that of a direct clock switching circuit.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

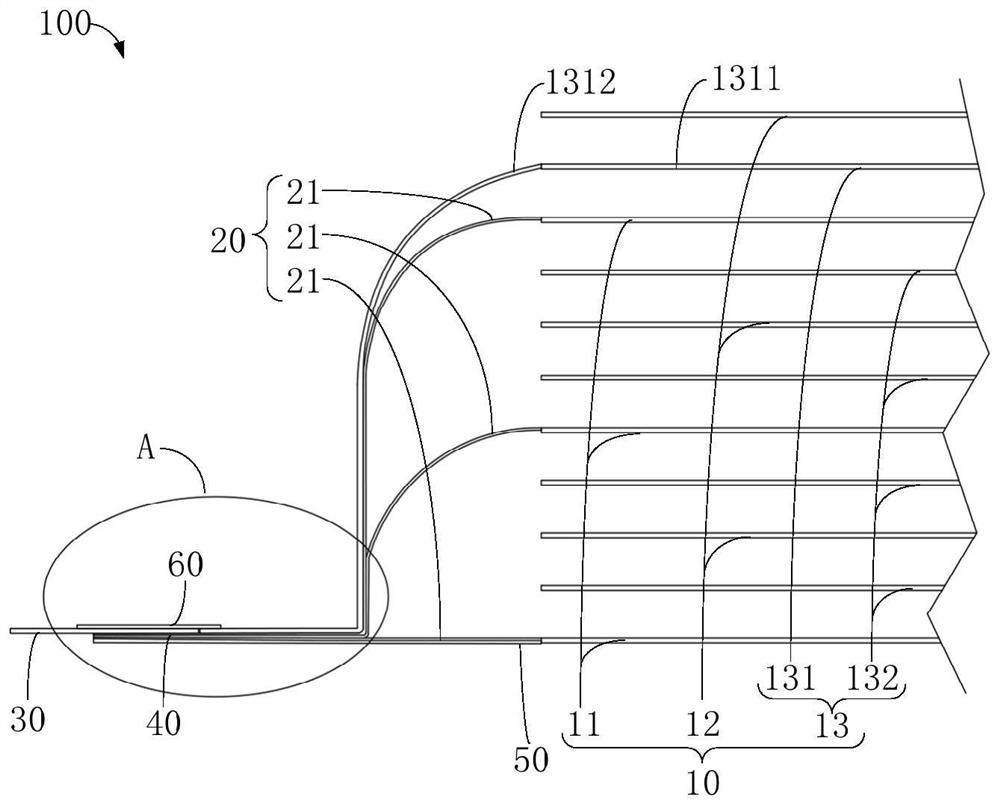

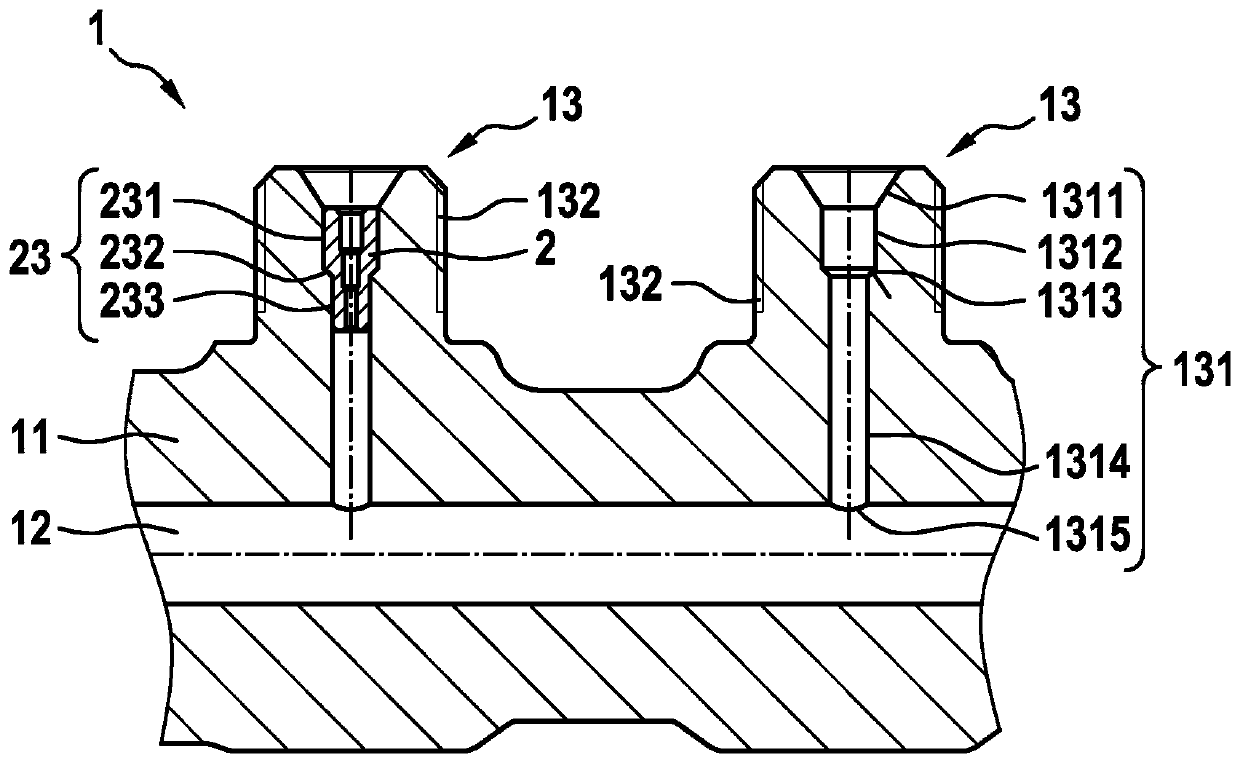

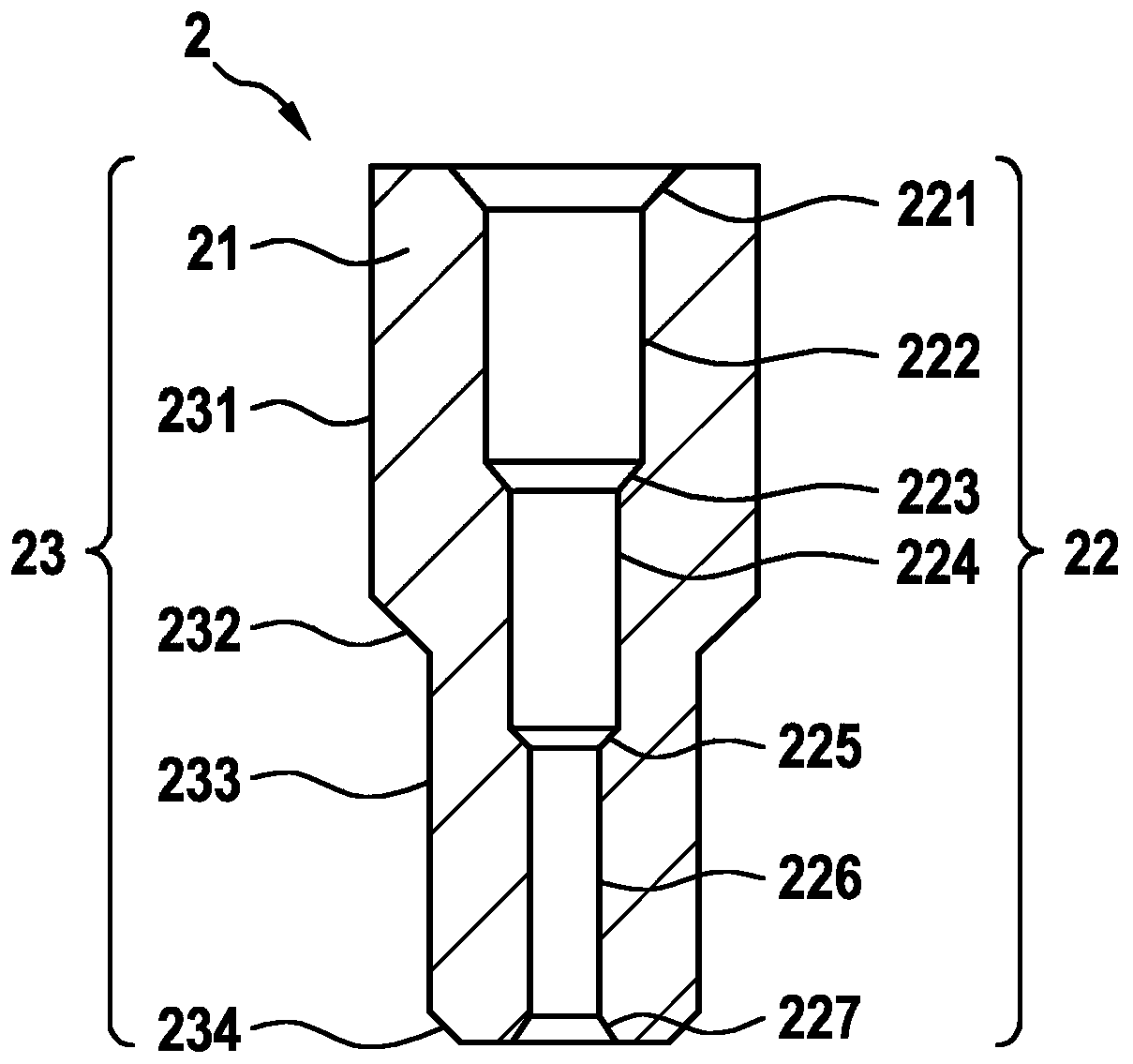

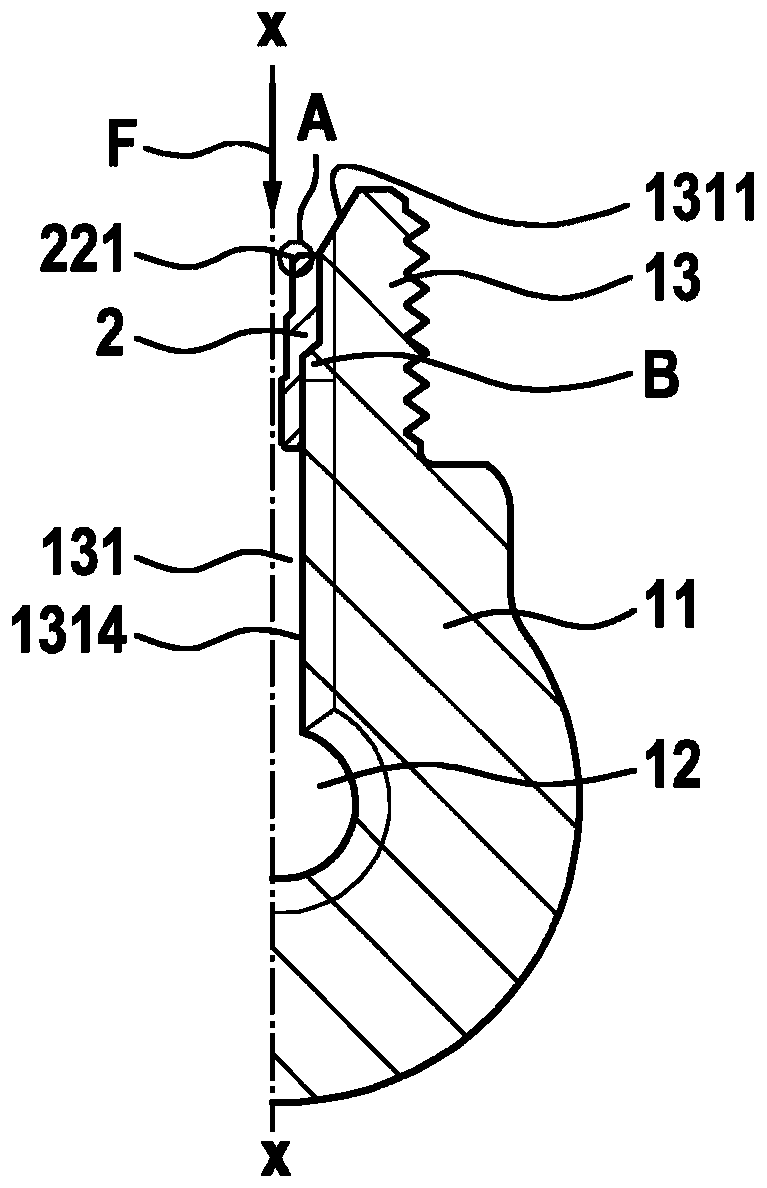

High-pressure accumulator of a high-pressure fuel injection system

ActiveCN110234865AEasy to manufactureEnsure fatigue propertiesMachines/enginesSpecial fuel injection apparatusEngineeringHigh pressure

The invention relates to a high-pressure accumulator for a high-pressure injection system made of a cylindrical body (11), which delimits a high-pressure chamber (12, 12a), and connection pieces (13,13a), which are provided with outlet passages (131, 131a) for a high-pressure liquid, said passages opening into the chamber (12, 12a), and each of which is provided with a throttle in order to weakenpressure waves generated by injectors connected downstream. Each of the connection pieces (13, 13a) has a passage (131, 131a) with a chamber (1312, 1312a) at the outlet, said chamber receiving an insert piece (2, 2a) which is provided with the throttle (22, 22a). The insert piece (2, 2a) is fixed in the chamber (1312, 1312a) in a force-fitting manner by an autofrettage process of the high-pressure accumulator.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com