Wrapping method of warp knitting spacer fabric

A warp-knitted spacer fabric and hemming technology, applied in the directions of warp knitting, knitting, textiles and papermaking, etc., can solve the problems such as affecting the air permeability and washability of the warp-knitting spacer fabric, rough and unsightly appearance, and inability to combine all around. , to achieve the effect of saving mesh, improving labor efficiency and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

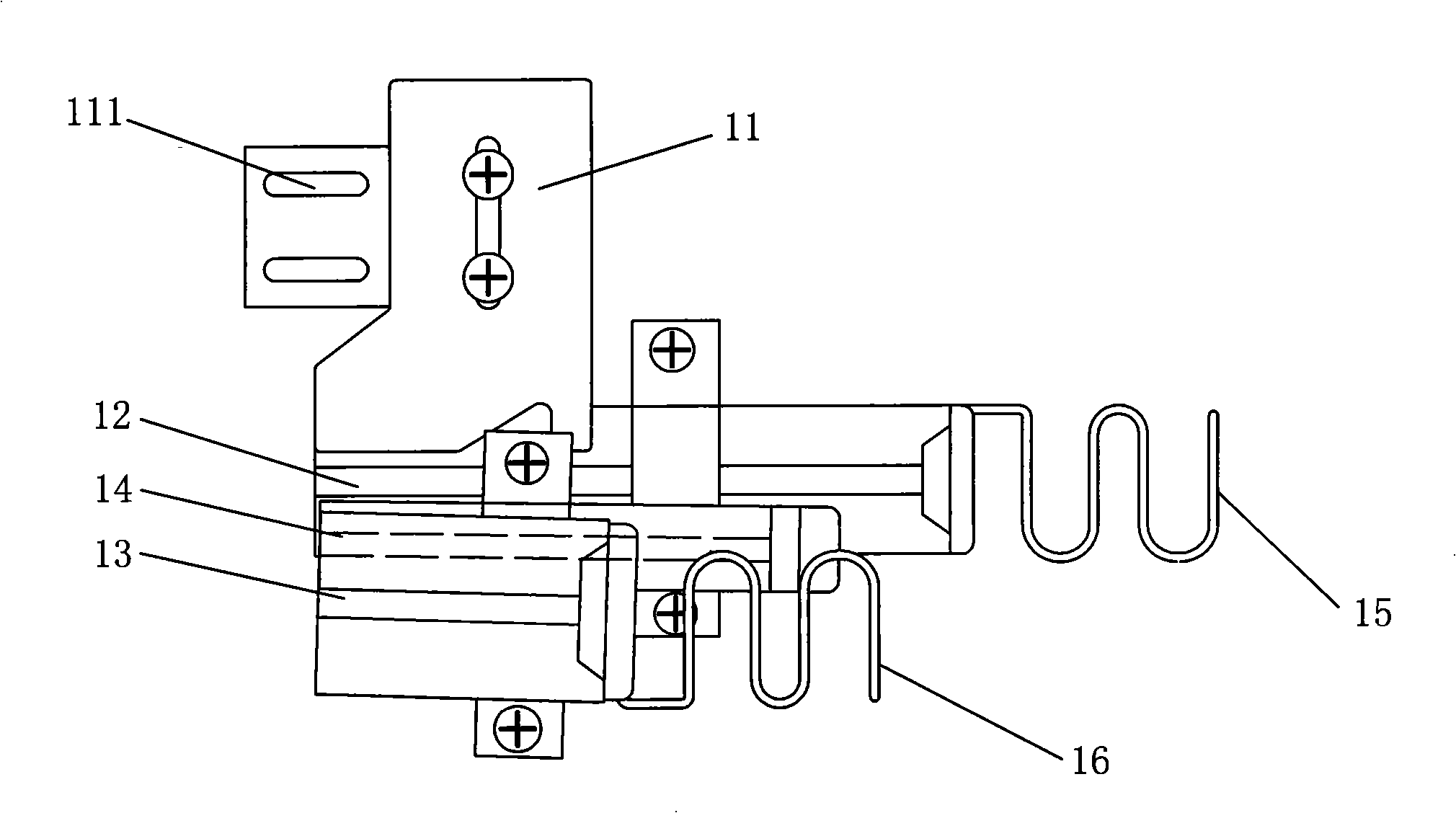

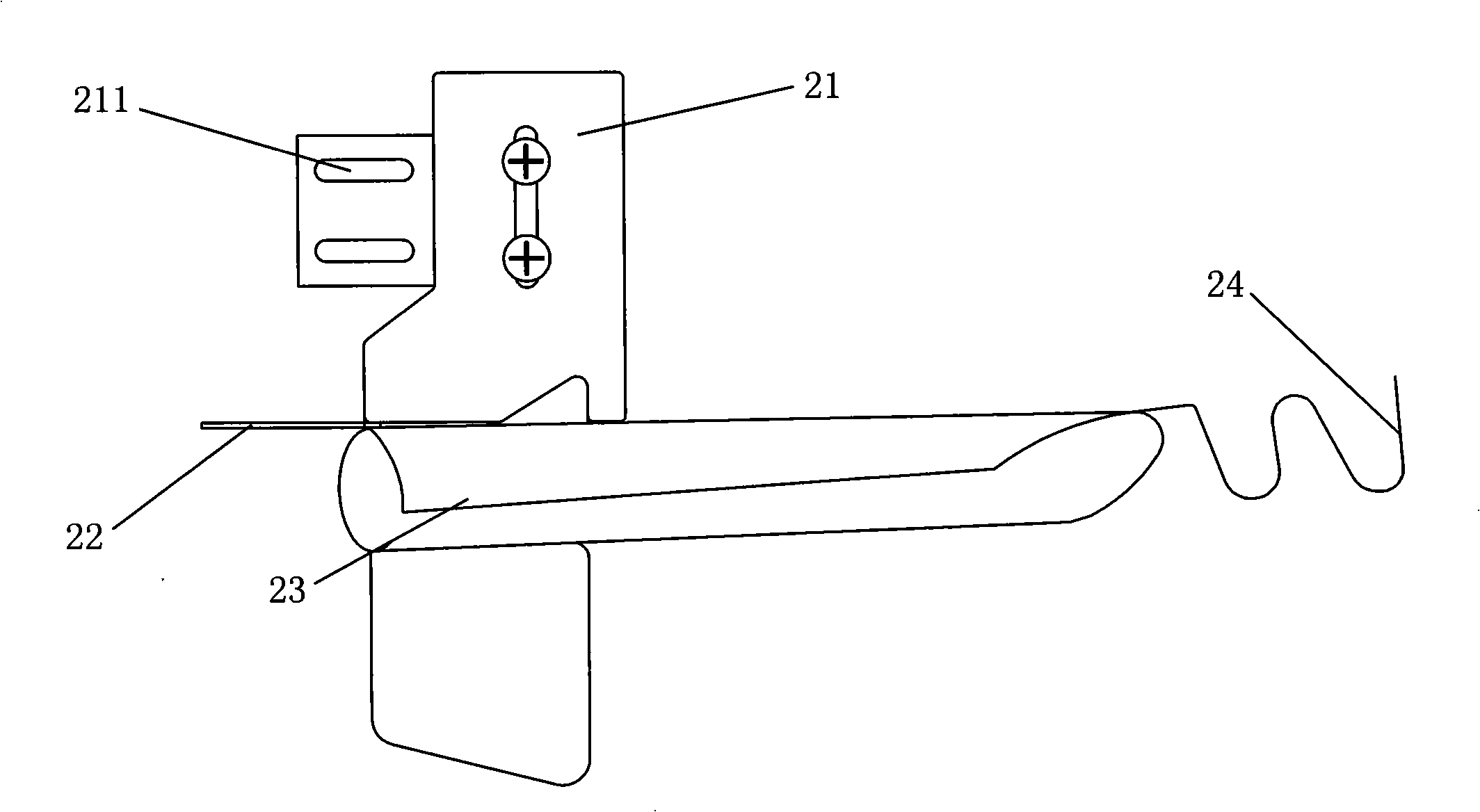

[0022] see figure 1 with 2 , the present invention adopts the needle car puller to wrap the warp knitted spacer fabric, and the needle car puller is provided with the 1st needle car puller (see figure 1 ) and the 2nd needle cylinder (see figure 2 ), the first needle puller is provided with a fixed bracket 11, an upper ribbon groove 12, a lower ribbon groove 13, a zipper positioning groove 14, an upper belt guide 15 and a lower belt guide 16, and the fixed bracket 11 is provided with a needle The adjusting screw hole 111 that the car is connected, the upper ribbon groove 12, the lower ribbon groove 13 and the zipper positioning groove 14 are located below the fixed bracket 11, the zipper positioning groove 14 is located between the upper ribbon groove 12 and the lower ribbon groove 13, and the upper guide belt One end of device 15 is fixed on an end of last ribbon groove 12. In the first sewing pulley, the upper ribbon groove 12 is located at the highest point, the zipper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com