Metal sheet laser precision perforating device assisting in foaming

A punching device and metal sheet technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems that cannot be eliminated, achieve good roundness, solve burr problems, and improve the quality of the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

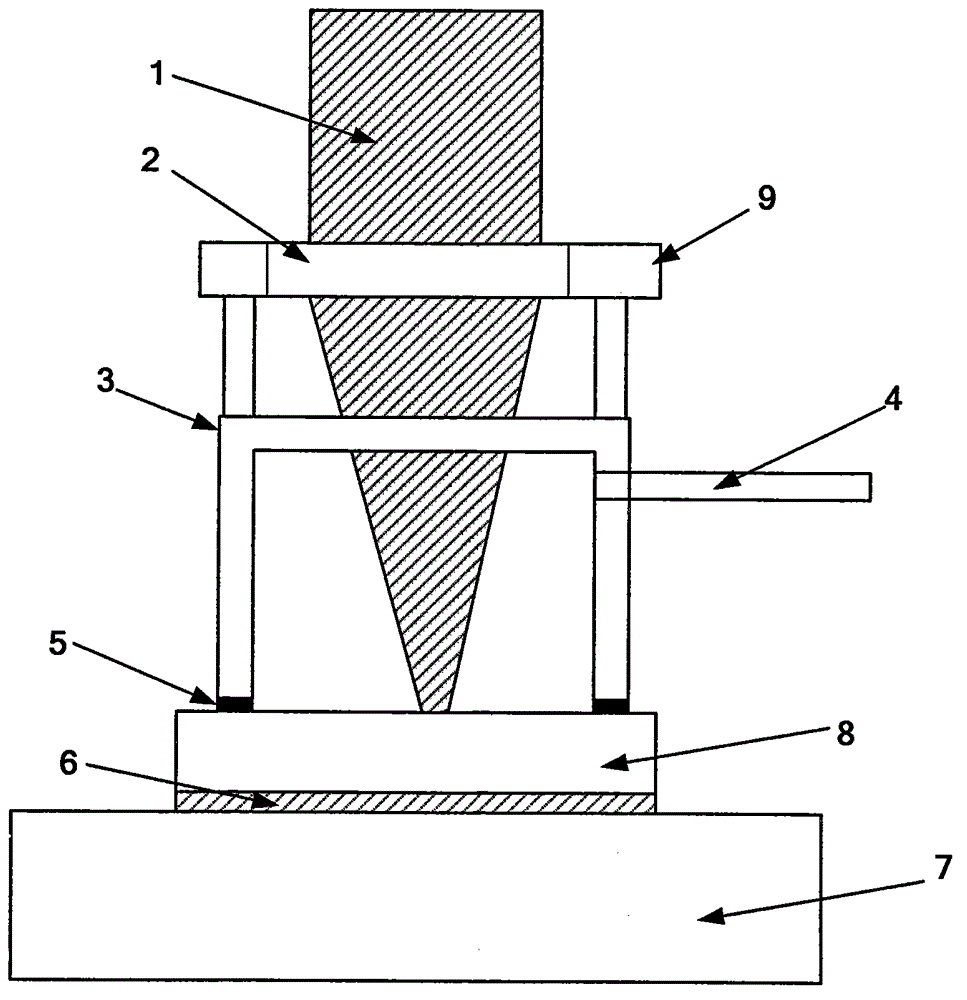

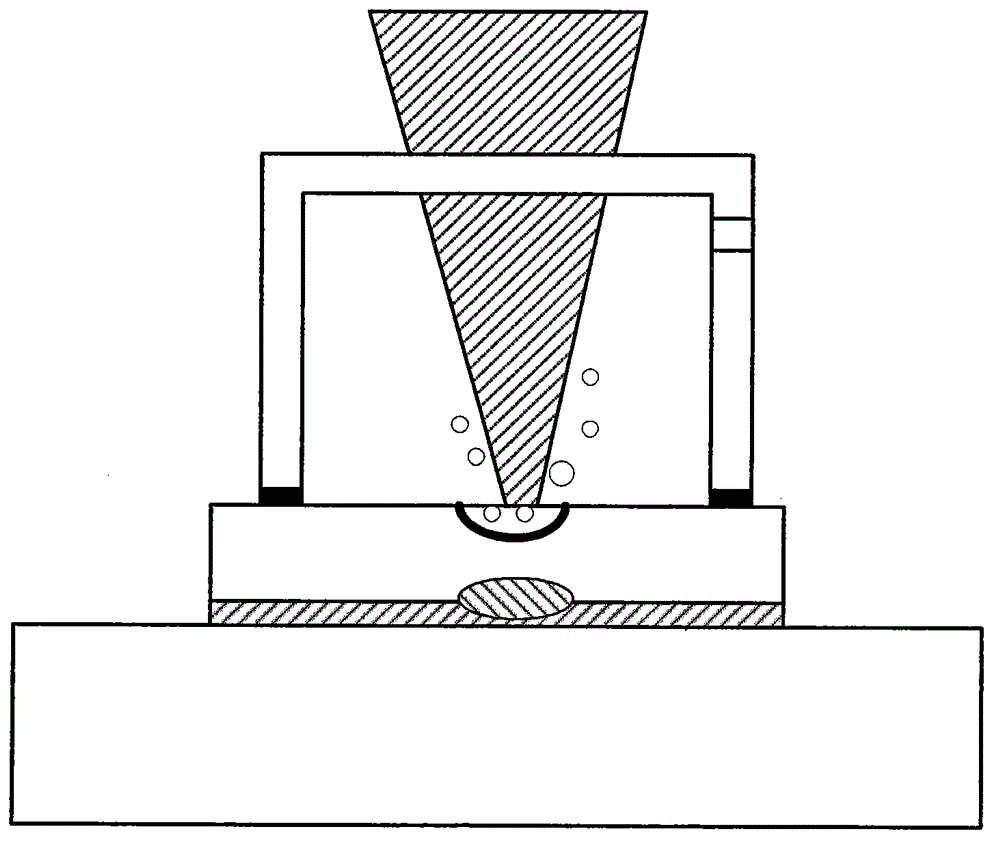

[0032] Such as figure 1 As shown, the present invention provides a foaming-assisted metal sheet laser precision drilling device, including a laser, a laser processing head, a metal sheet workpiece 8 to be processed, a substrate 7, a high-temperature foaming agent 6 and a sealed suction cover 3 .

[0033] The sheet metal workpiece 8 to be processed is installed on the substrate 7 , and the hardness of the substrate 7 to be processed is greater than that of the sheet metal workpiece 8 . The high-temperature foaming agent 6 is coated on the upper surface of the substrate 7 or the lower surface of the metal sheet workpiece 8, the thickness of the high-temperature foaming agent 6 is 0.01mm-1mm, and the foaming temperature is above 150 degrees.

[0034]The laser processing head includes a light guide path, a focusing lens 2 and a mirror b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com