Production method of metallized semi-hole of printed circuit board

A metallized half-hole, printed circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of long process and high quality risk, and achieve the goal of improving production efficiency, shortening the production process and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention and its beneficial effects will be further described in detail below in conjunction with specific embodiments, however, the specific embodiments of the present invention are not limited thereto.

[0015] This embodiment provides a method for manufacturing a metallized half-hole on a printed circuit board, which includes the following steps:

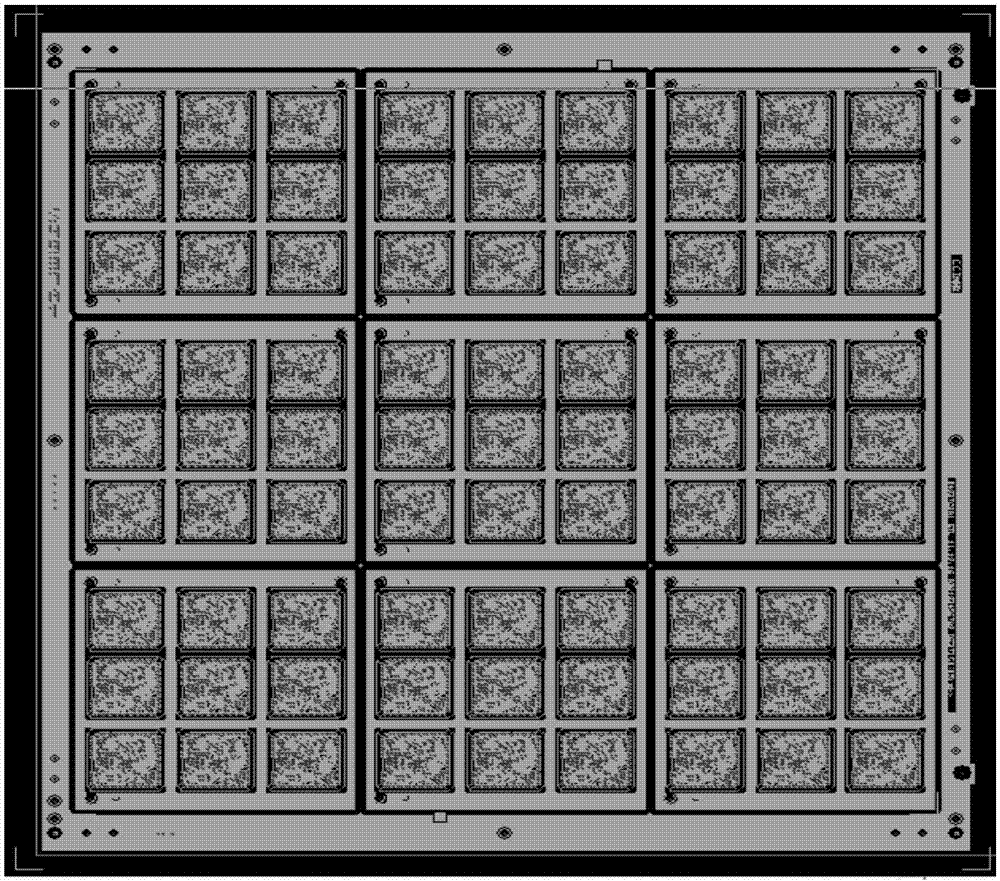

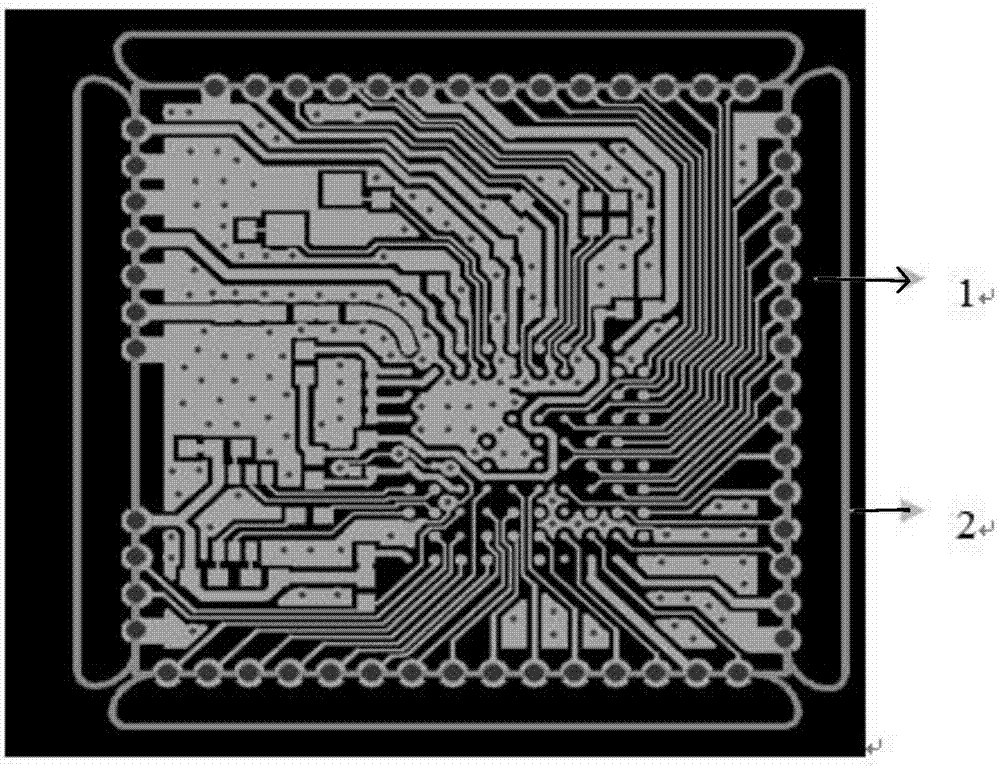

[0016] A. Complete the production process of the circuit board from material cutting to surface treatment, and form a half-hole production state board to be metallized: material cutting, baking plate, inner layer circuit, inner layer etching, inner layer AOI, pressing, edge milling, drilling Hole, electroplating, outer layer circuit, outer layer acid etching, outer layer AOI, solder mask, text, immersion nickel gold / spray tin, etc. before milling and metallizing the half hole;

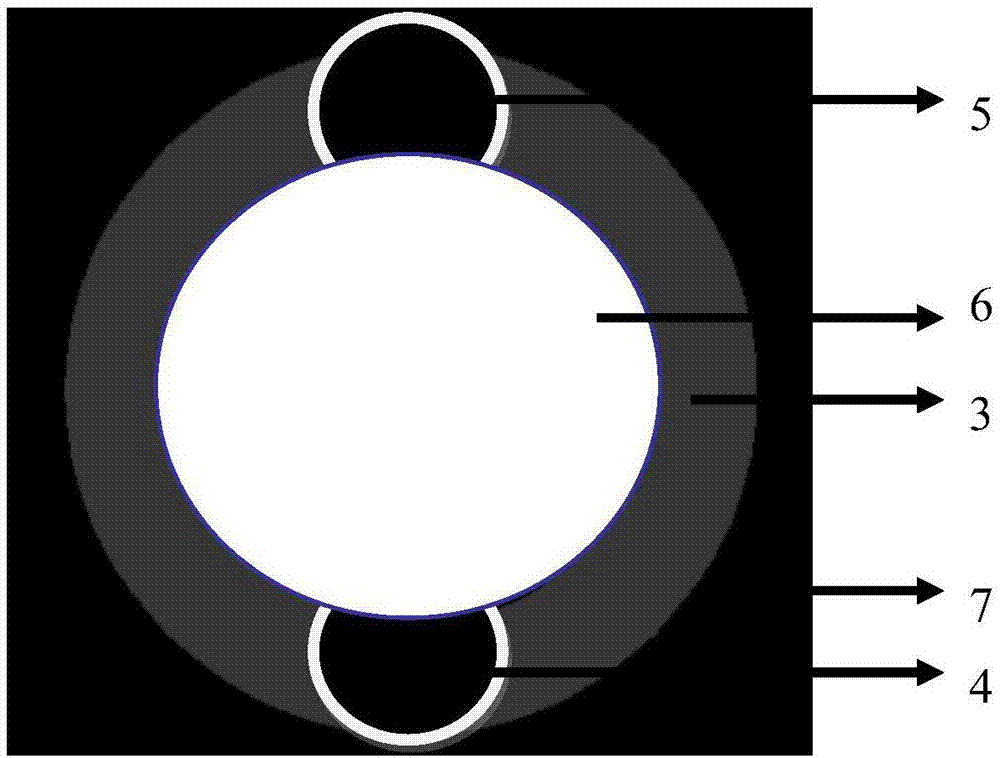

[0017] B. Design the second drill drill belt, drill a hole 4 and 5 with a diameter of 1.0mm on both sides of the hole where the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com