Stamping device used for manufacturing plates with unequal thicknesses

A stamping device and technology for thick plates, which is applied in the field of stamping devices for thick plates, can solve the problems of high cost and limited supply of poor thick plates, and achieve the effects of saving materials, solving burrs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

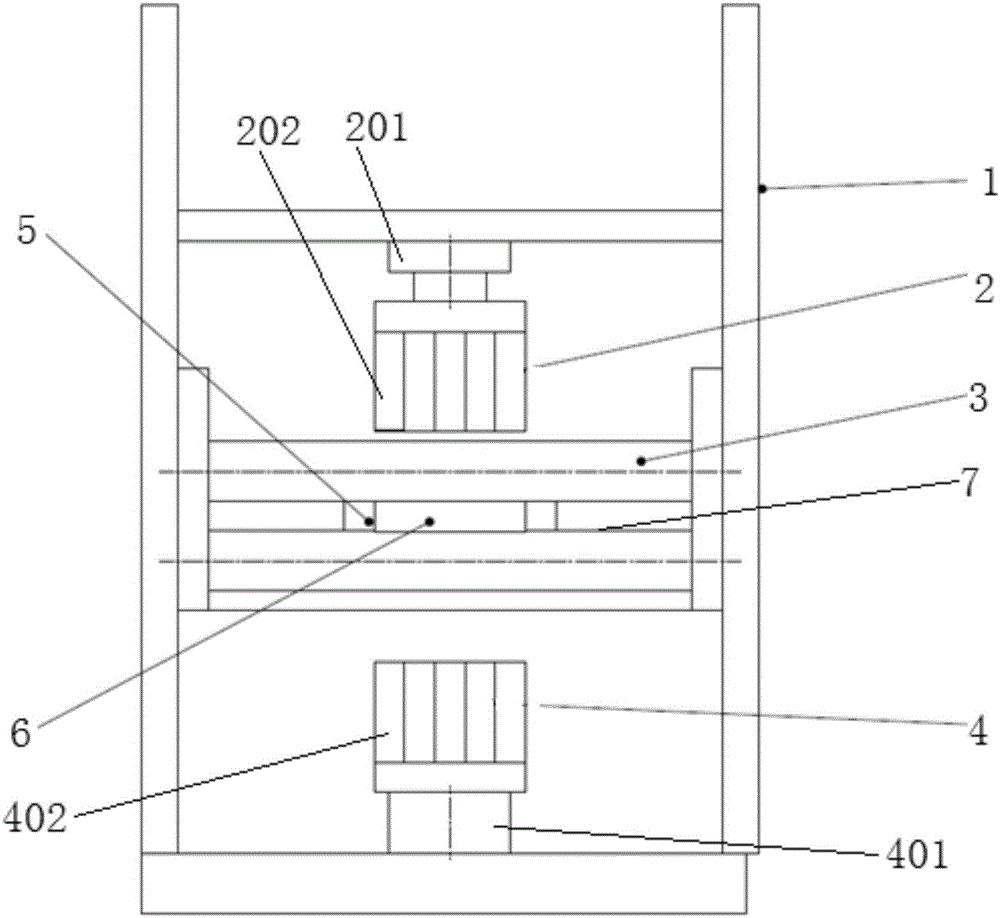

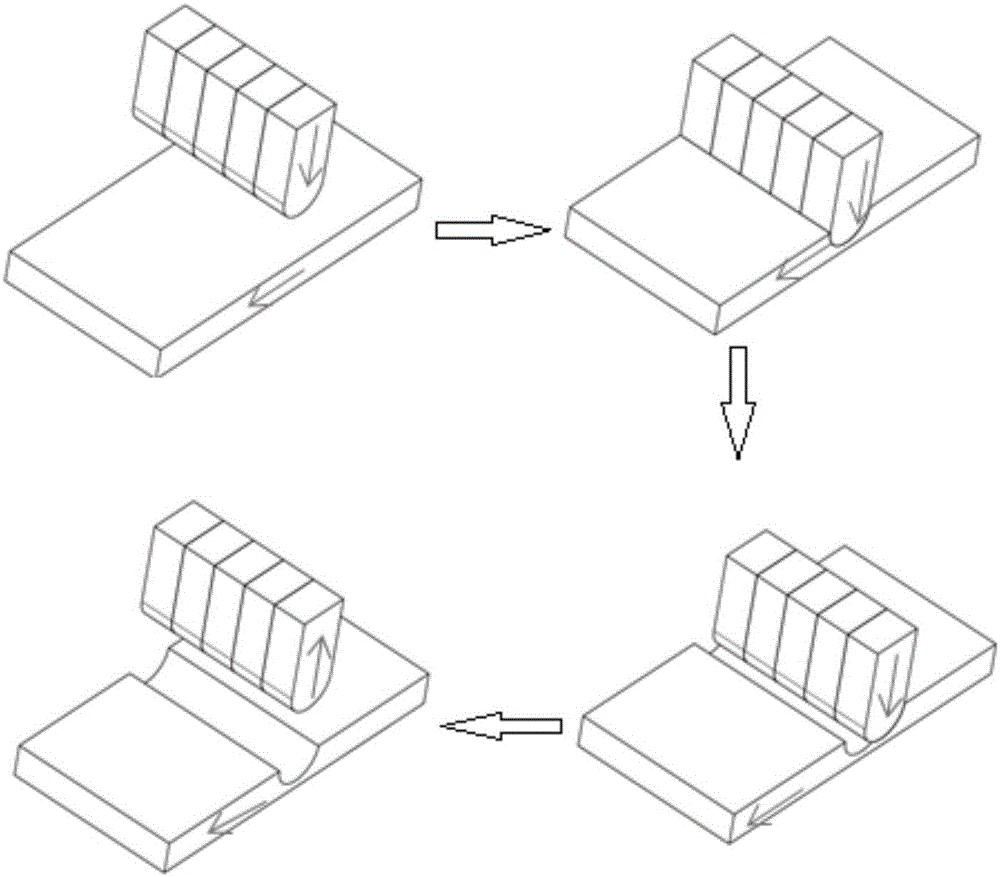

[0044] Such as figure 1 , figure 2 As shown, first fix the baffle on the workbench of the punching machine, the distance between the two baffles is the width of the sheet, and then the sheet is fed by the feeding mechanism (the feeding mechanism includes two metal cylinders up and down, when working, the upper metal cylinder reverses Rotate clockwise, the lower metal cylinder rotates clockwise) and transport it to the upper combined cutter, because the upper groove of the unequal thickness plate is deeper and wider, so a row of upper cutter heads are extended to form the upper groove , and then use a roller to flatten the indentation in the upper groove. After pressing, the unequal thick plate is continuously fed by the feeding mechanism, and the unequal thick plate can be continuously formed. In this way it is possible to form unequal thick plates with grooves of narrower width and deeper depth in one pass.

Embodiment 2

[0046] Such as figure 1 , image 3 As shown, first fix the baffle on the working table of the punching machine, the distance between the two baffles is the width of the sheet, and then the sheet is transported by the feeding mechanism to the upper combined cutter, because the upper groove of the unequal thickness plate The depth of the blade is deeper and the width is narrower, so a row of two upper grooves on the side of the upper cutter head are protruded to form the upper groove, and then the indentation in the upper groove is flattened with a roller. After the pressing, the sheet is continued by the feeding mechanism Feeding, it can continuously form unequal thick plates, so that grooves can only be formed on one side of the plate. Similarly, if the upper groove is in the middle, such as Figure 4 As shown, the middle upper cutter head of a row of upper cutter heads is pressed down to form the middle groove; if the upper groove is located on both sides, such as Figure ...

Embodiment 3

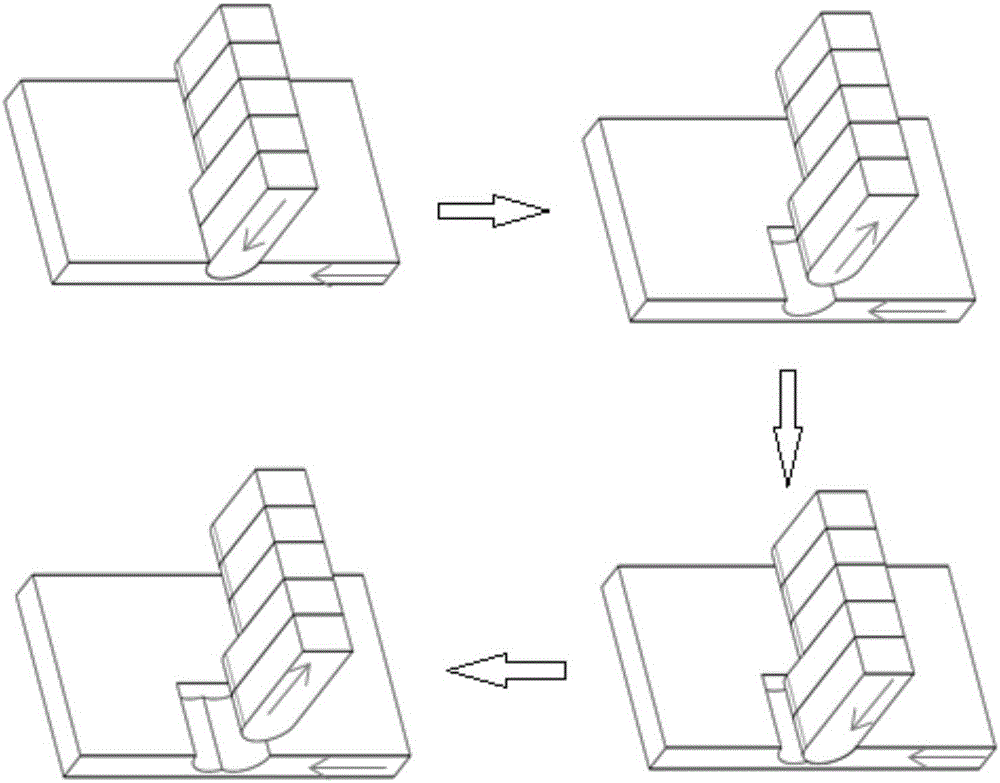

[0048] Such as figure 1 , Figure 6 As shown, first fix the baffle on the workbench of the punching machine, the distance between the two baffles is the width of the sheet, and then the sheet is transported by the feeding mechanism to the upper combined cutter, because the unequal thickness has an upper groove and The lower groove, so a row of upper cutter heads are extended to press down to form the upper groove, until the upper cutter head forms the upper groove of the sheet, the upper cutter combination presses down on the upper surface of the sheet to press the sheet on the working surface Keep still on the table, and then two upper presses on the side of a row of lower cutter heads form the lower groove, and finally use a roller to flatten the indentation. After pressing, the sheet continues to be fed by the upper and lower feeding mechanism, and continuous molding Equal thick plate, can form groove on the upper and lower surface of sheet material 6 like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com