Separation method for package part with cooling fins

A separation method and heat sink technology, which can be used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as heat sink burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for manufacturing a package with a heat sink added, specifically according to the following steps:

[0019] The first step: prepare the carrier board 5; figure 1 shown;

[0020] The second step: wafer thinning, the thinning range is 50um-250um;

[0021] The third step: dicing to form a single chip 4;

[0022] The fourth step: on the core, using the core glue 6 to connect the chip 4 on the carrier board 5; figure 2 shown;

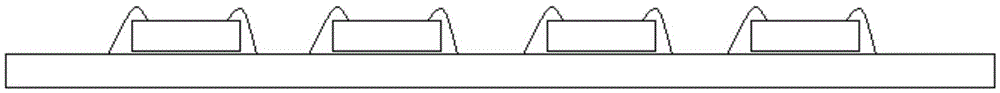

[0023] The fifth step: pressure welding, using the welding wire 3 to connect the chip 4 and the carrier board 5; image 3 shown;

[0024] The sixth step: plastic sealing, the plastic sealing body 2 surrounds the chip 4, the upper core glue 6 and the upper part of the carrier plate 5, and at the same time plastic sealing the heat sink 1, and then curing; Figure 4 shown;

[0025] Step 7: Printing, cutting, packaging.

[0026] Regarding the cutting process of the seventh step above, that is, a separation method of a package with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com