High-pressure accumulator of a high-pressure fuel injection system

A high-pressure injection and memory technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve expensive problems, achieve simple manufacturing, ensure fatigue characteristics, and optimize system efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

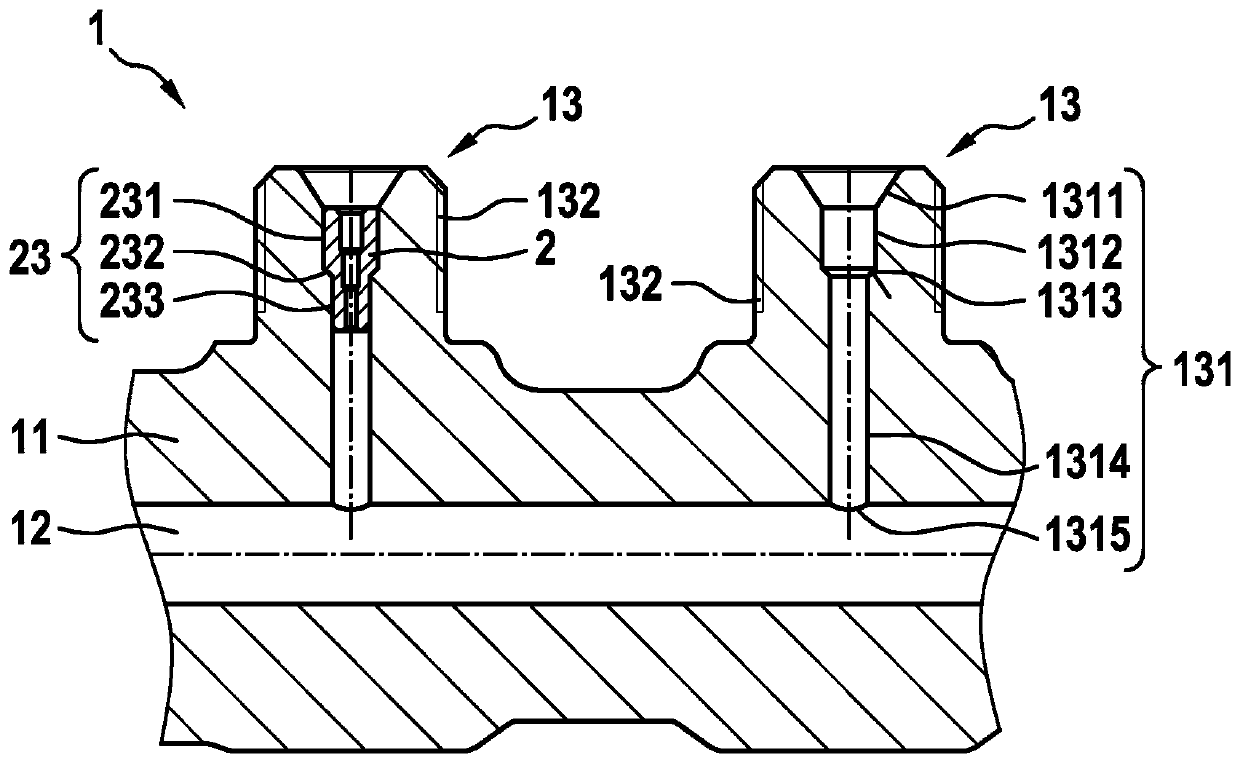

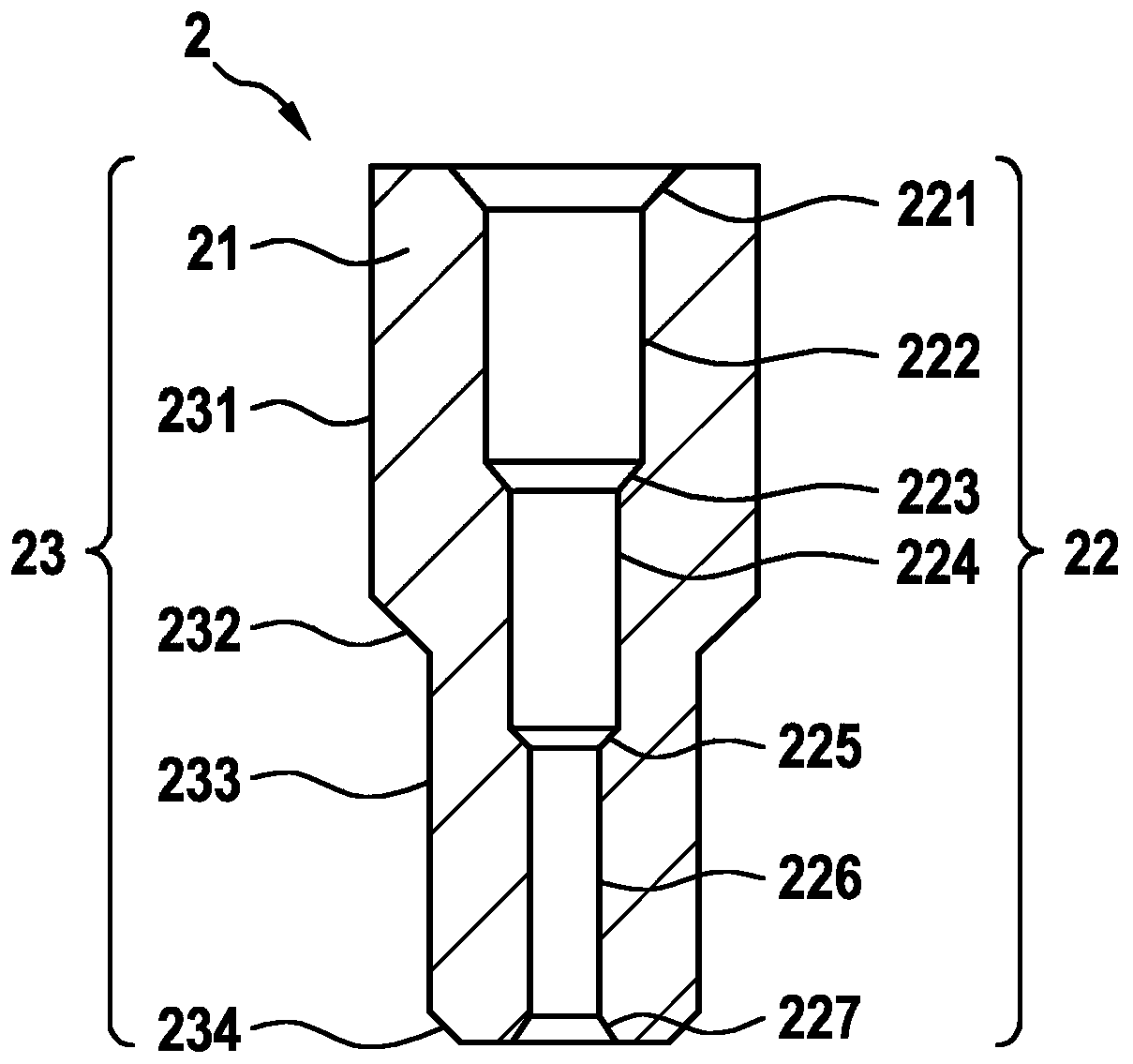

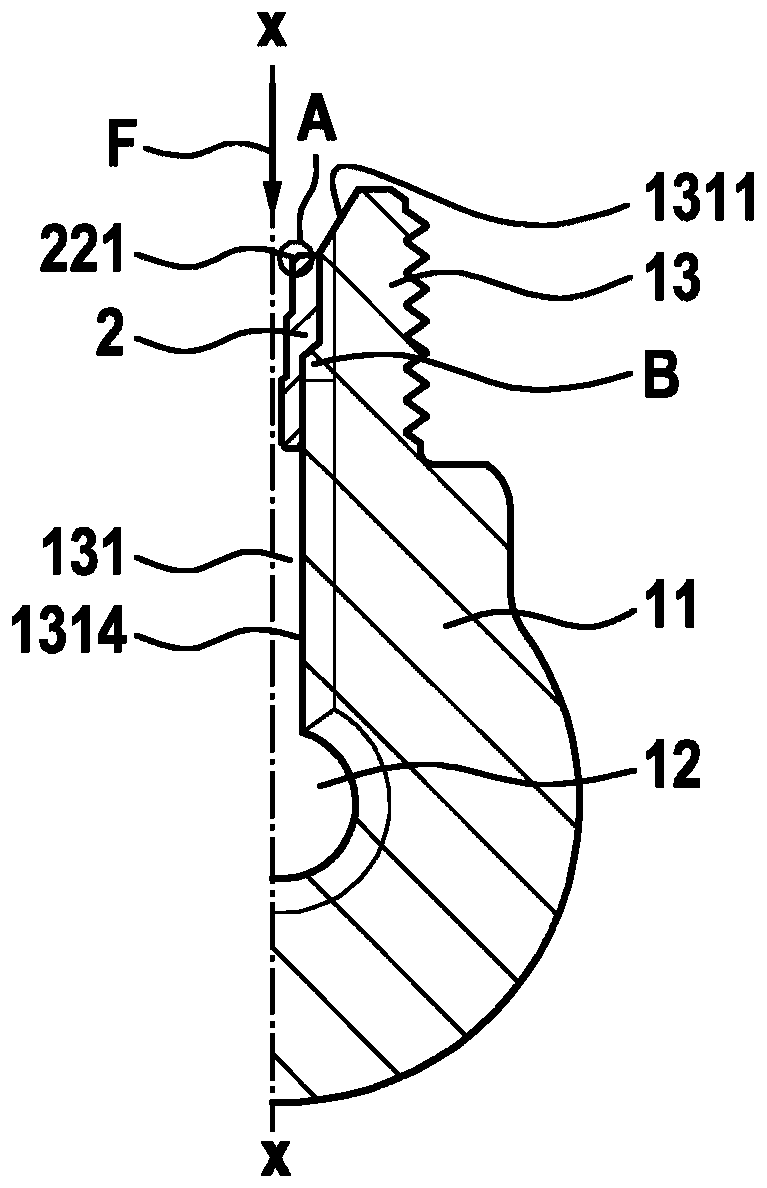

[0037] according to figure 1 , the invention relates to a rail or high-pressure accumulator 1 of a high-pressure injection system in an internal combustion engine. Common parts of the rail are shown in axial section. Other parts of the spraying device are not shown.

[0038] The high-pressure accumulator 1 is a thick-walled cylindrical body 11 made of forged steel, which encloses a high-pressure chamber 12 supplied with high-pressure fuel by a high-pressure pump in order to distribute the high-pressure fuel to injection valves (injectors) , the injection valve is controlled by the central control unit of the engine.

[0039] The closing and opening movements of the injectors generate compression and decompression waves ("pressure shocks") which are transmitted from the high pressure fluid into the piping connecting the injectors to rail 1 and thus into the rail.

[0040] The cylindrical body 11 has connection pieces 13 for connection, which are each connected via a channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com