Patents

Literature

55 results about "Autofrettage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

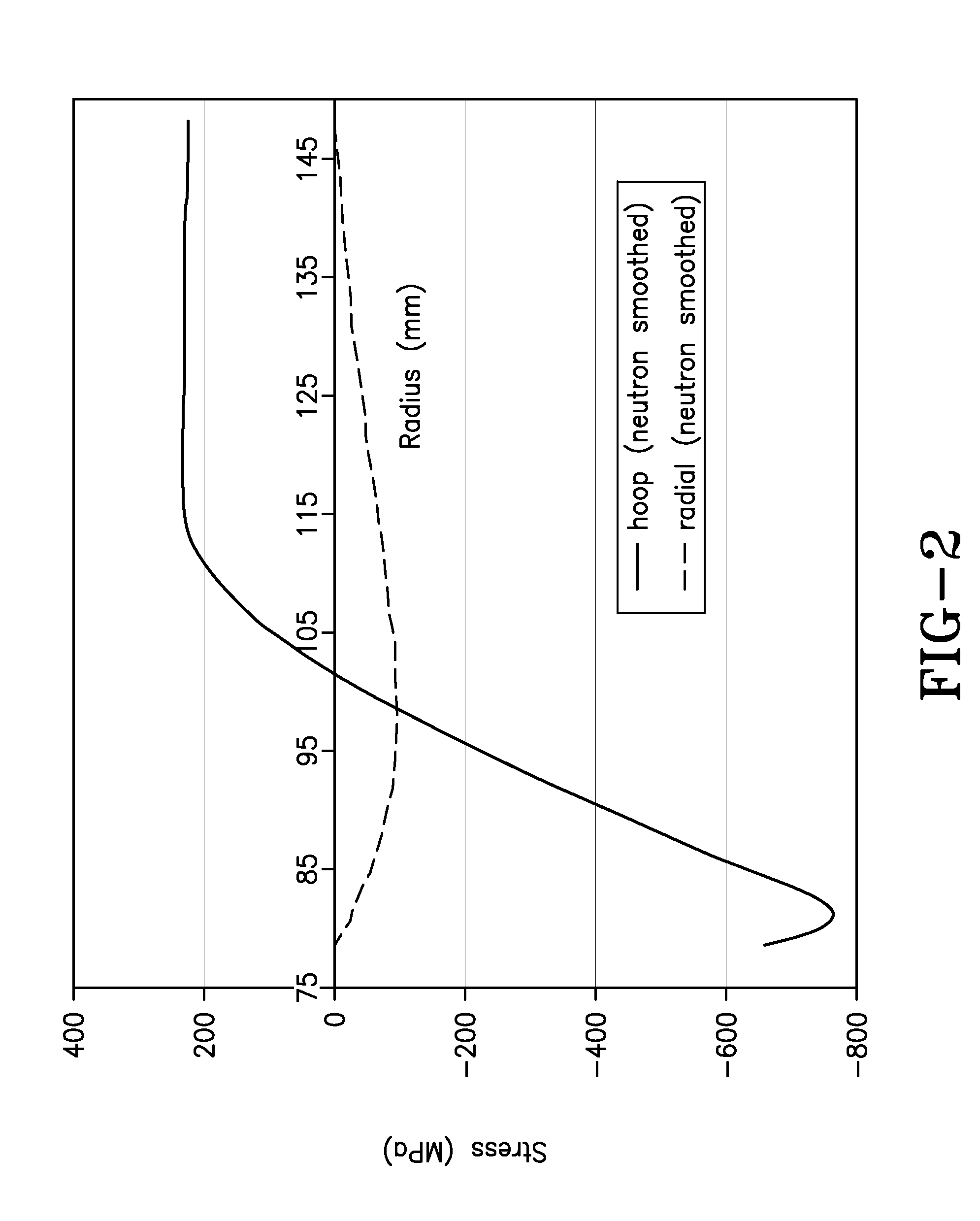

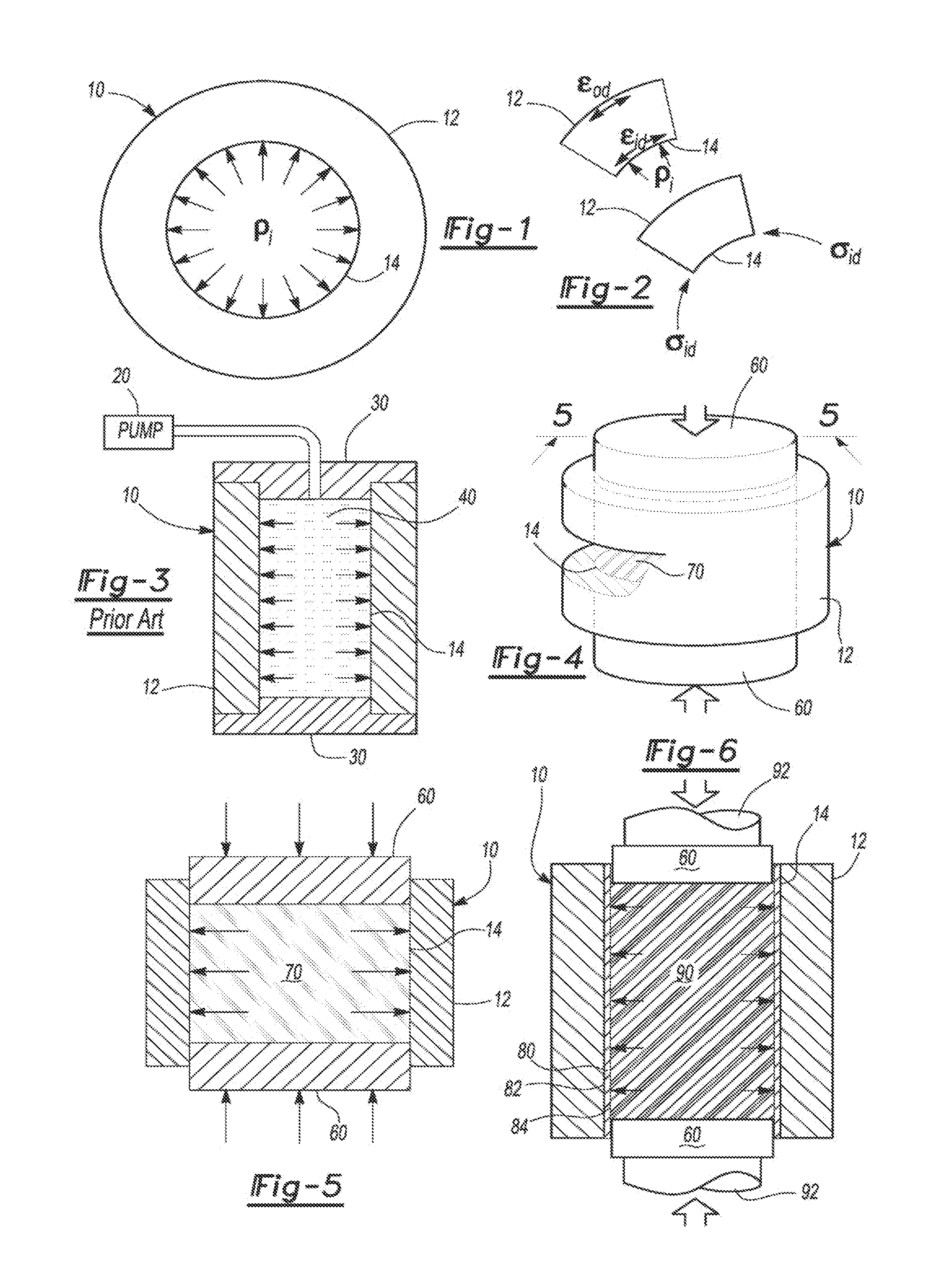

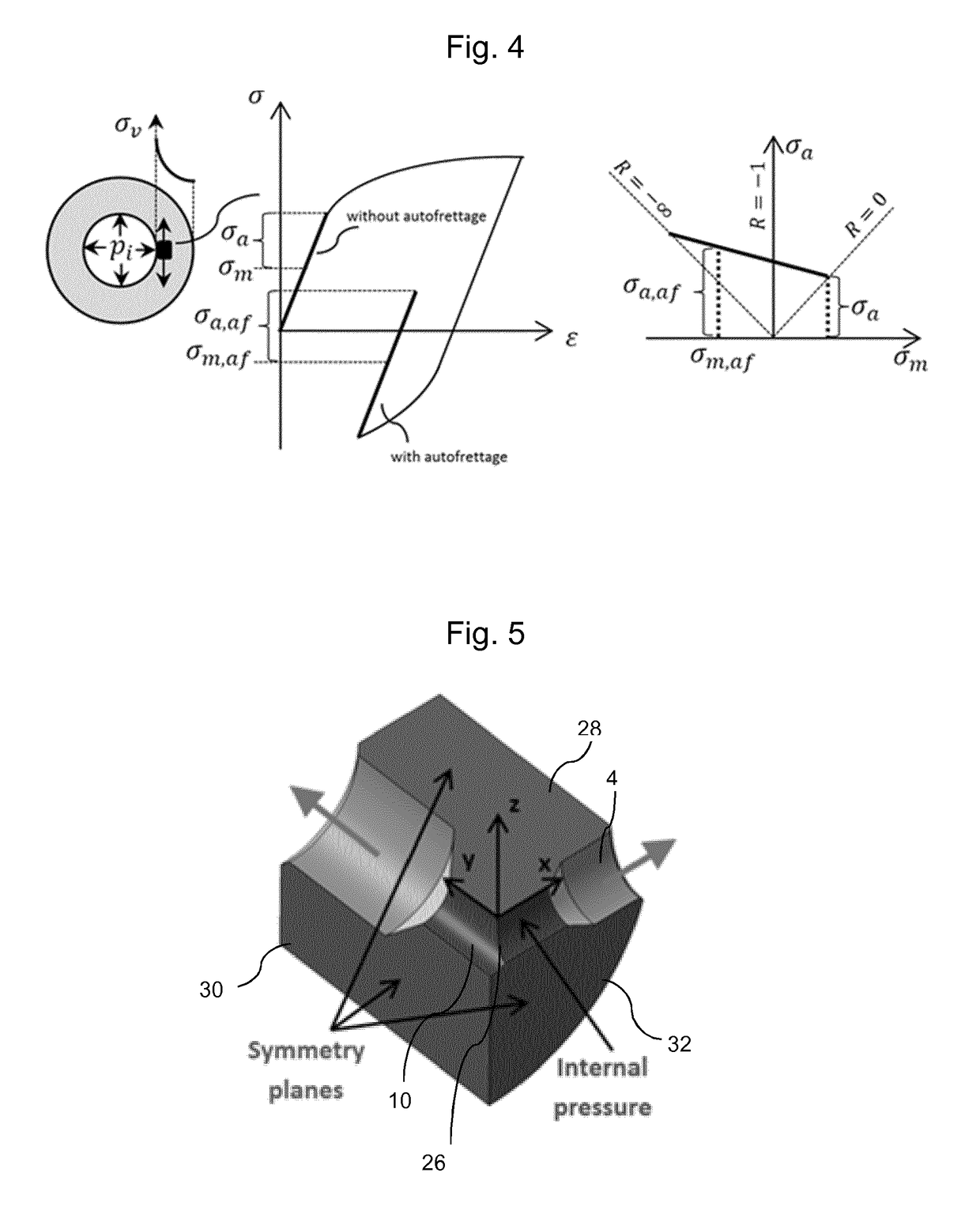

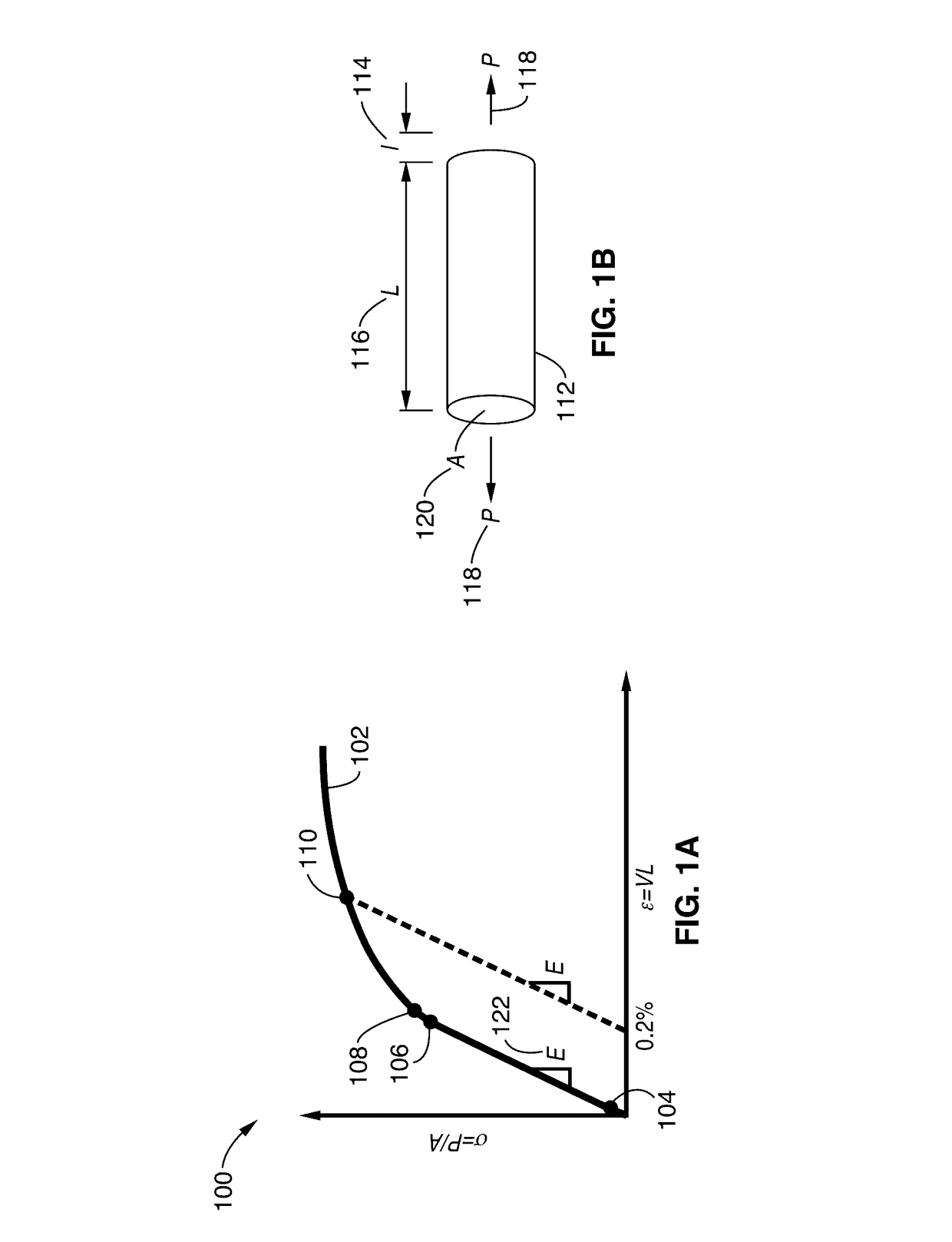

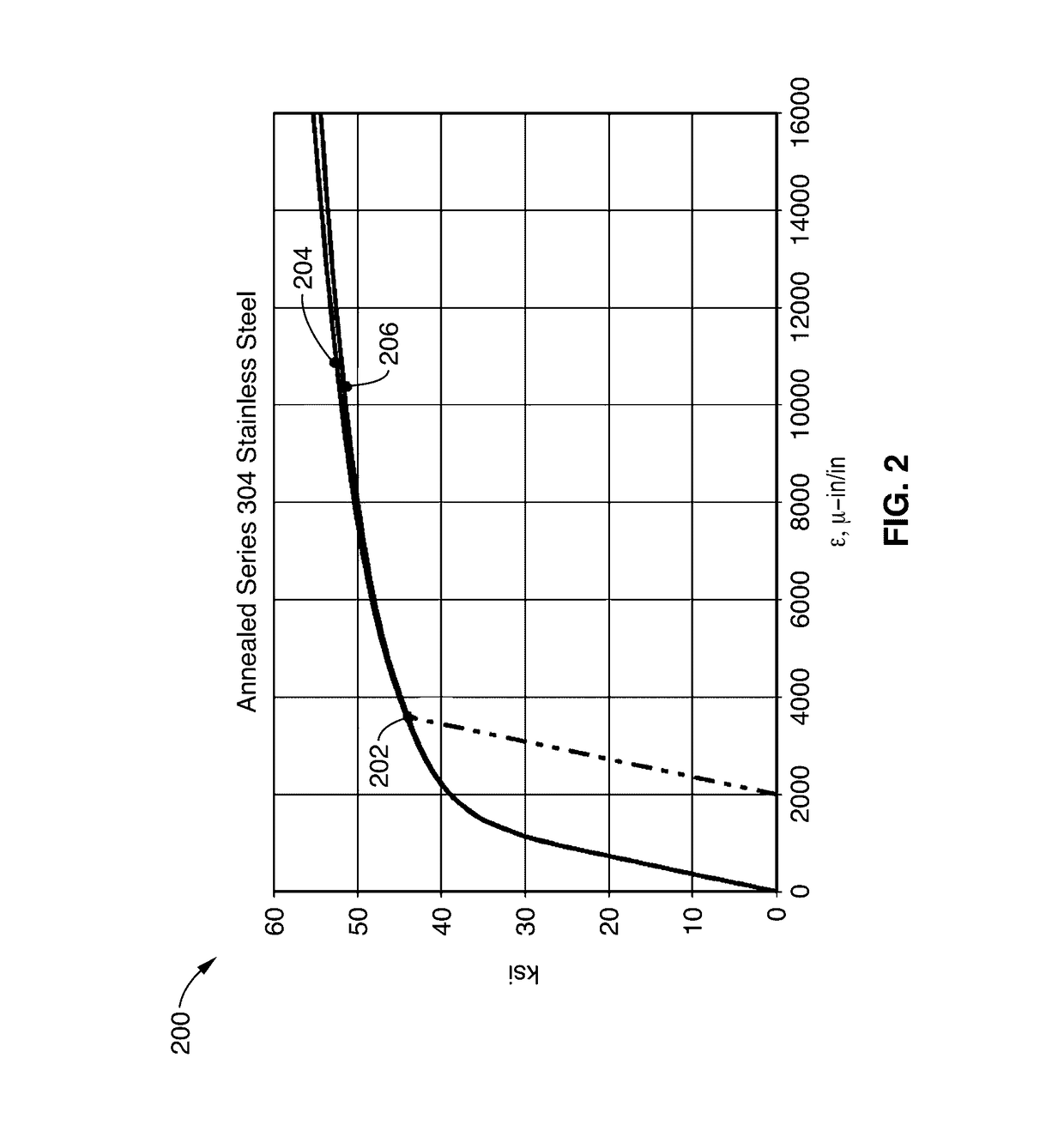

Autofrettage is a metal cold forming technique in which a pressure vessel is subjected to enormous pressure, causing internal portions of the part to yield plastically, resulting in internal compressive residual stresses once the pressure is released. The goal of autofrettage is to increase the durability of the final product. Inducing residual compressive stresses into materials can also increase their resistance to stress corrosion cracking; that is, non-mechanically-assisted cracking that occurs when a material is placed in a corrosive environment in the presence of tensile stress. The technique is commonly used in manufacture of high-pressure pump cylinders, warship and tank gun barrels, and fuel injection systems for diesel engines. While autofrettage will induce some work hardening, that is not the primary mechanism of strengthening.

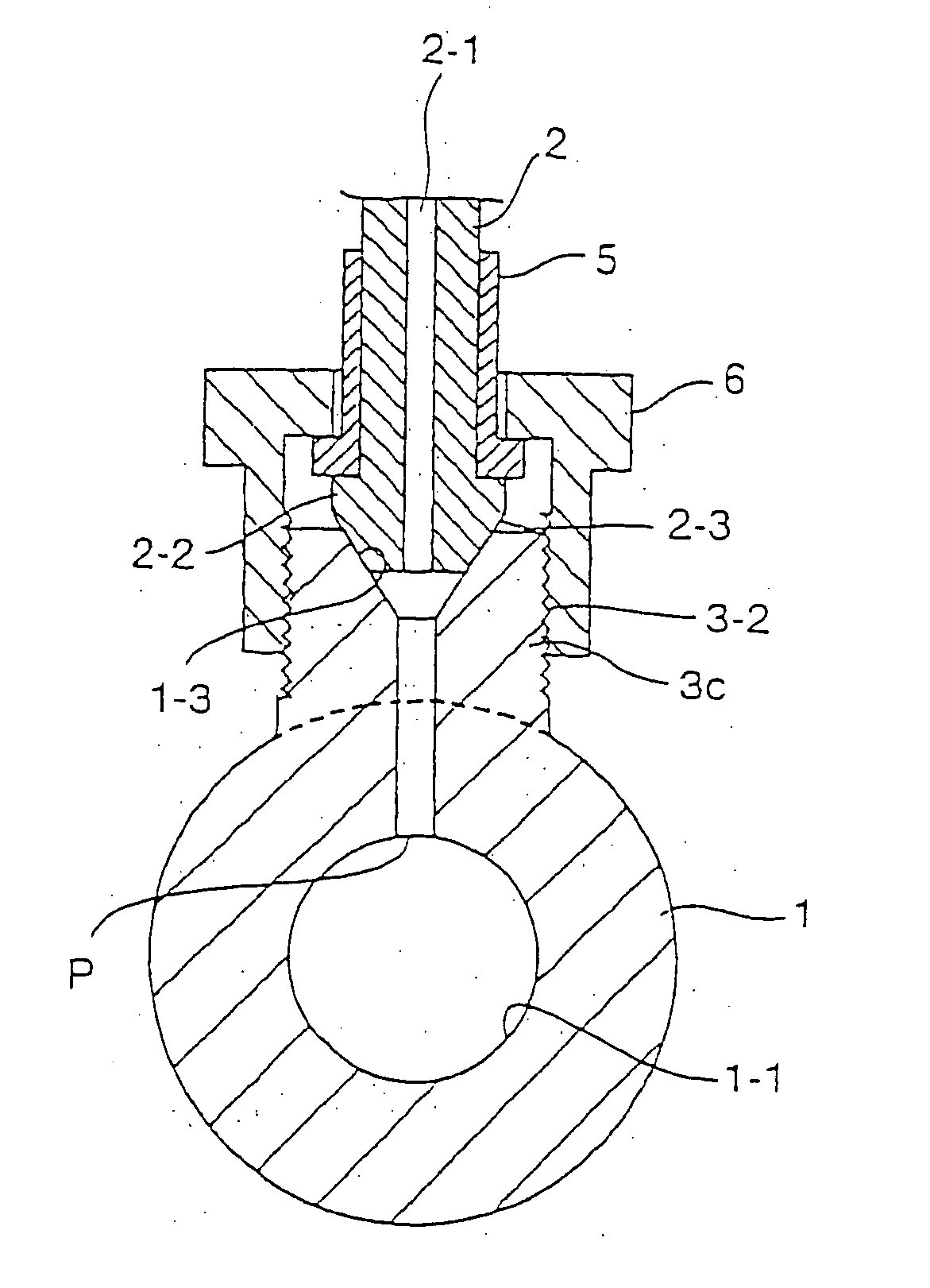

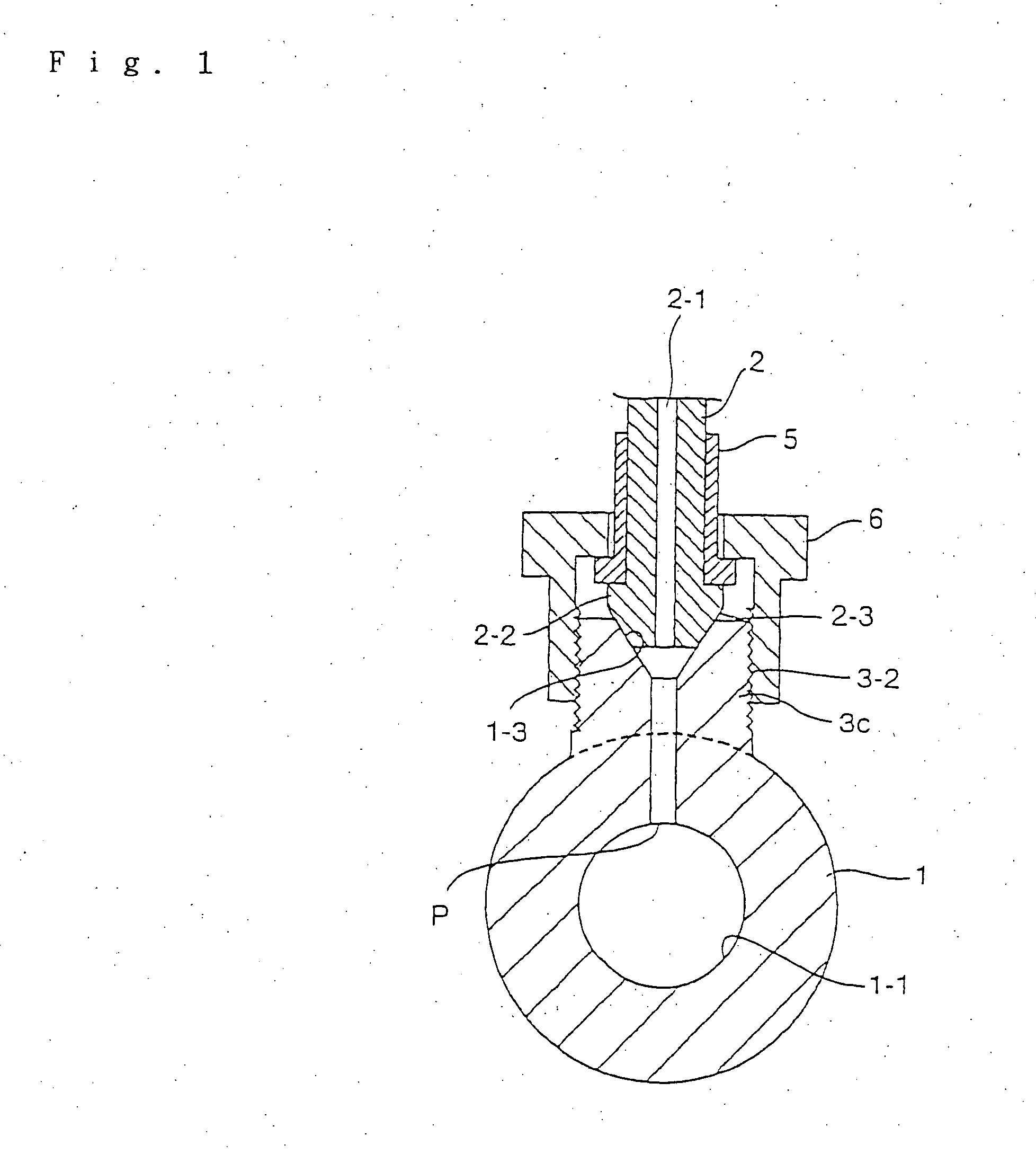

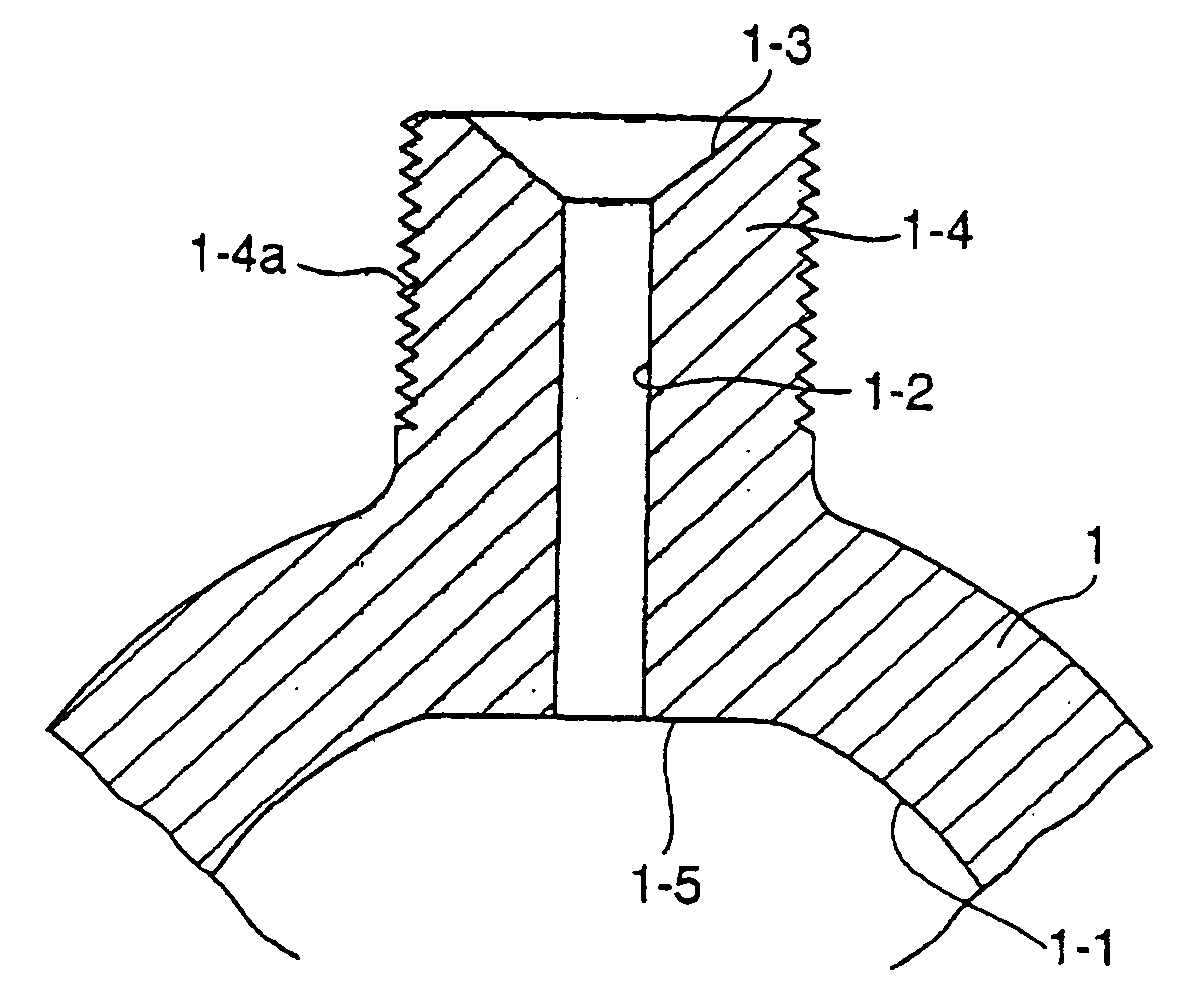

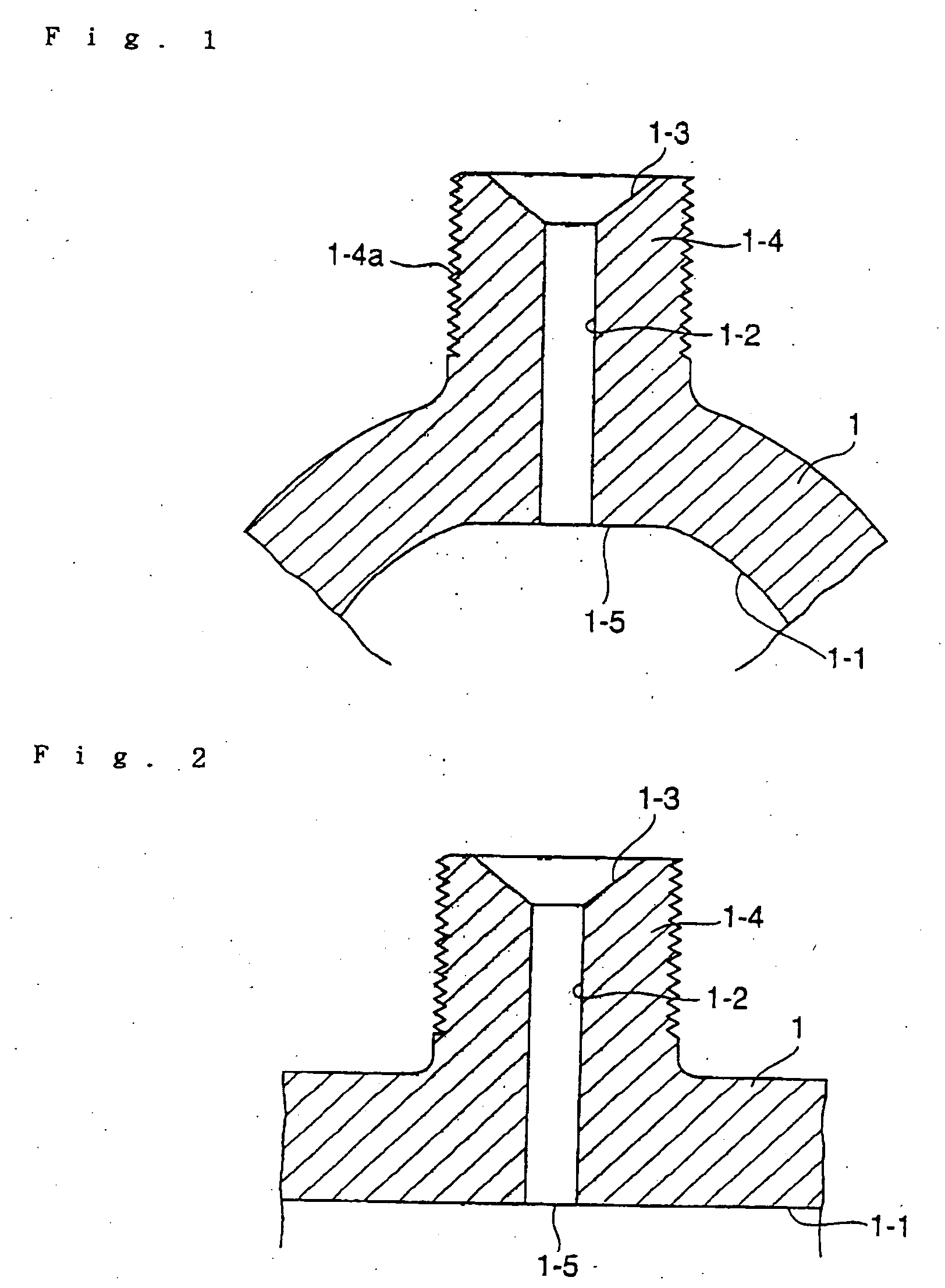

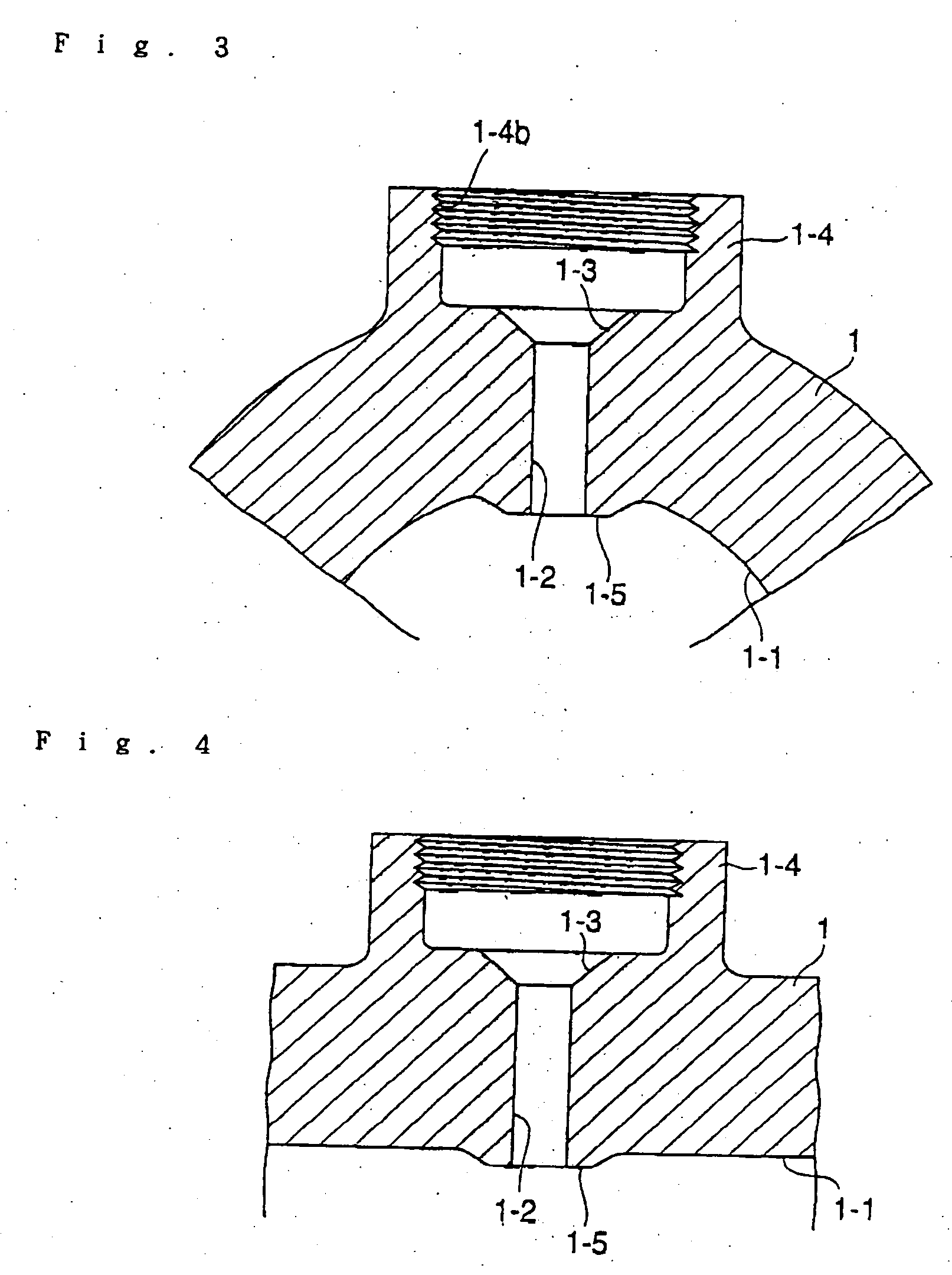

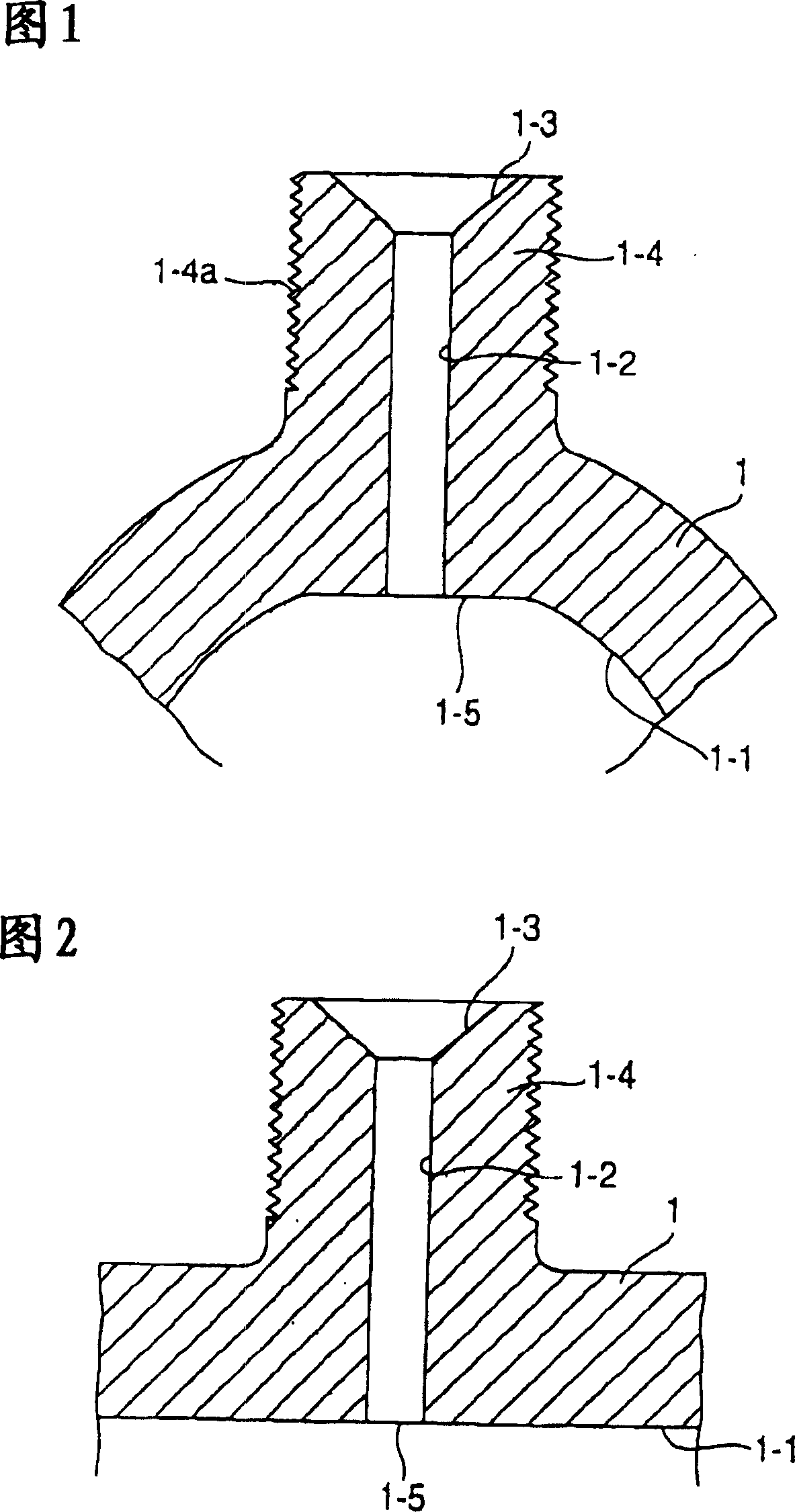

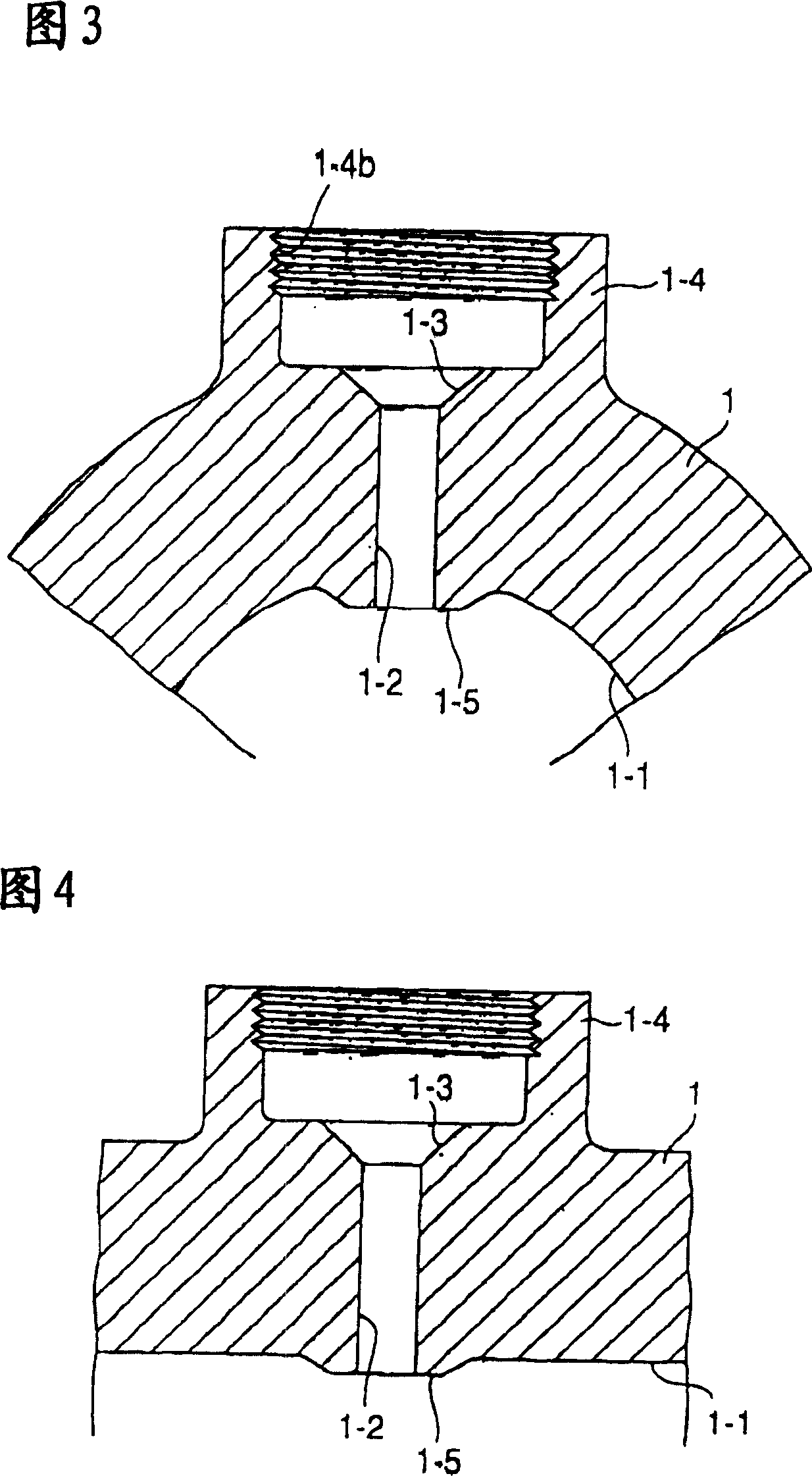

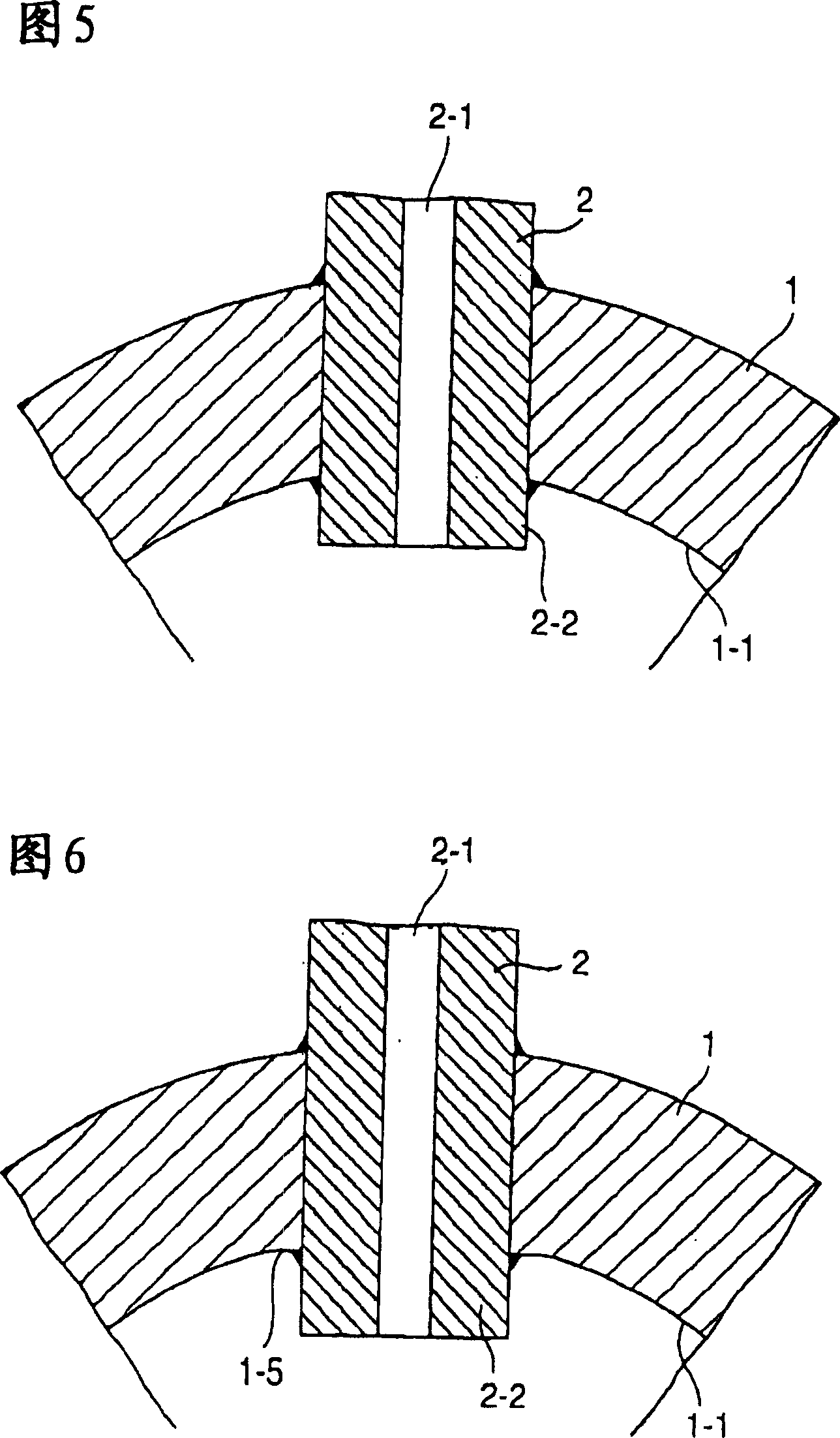

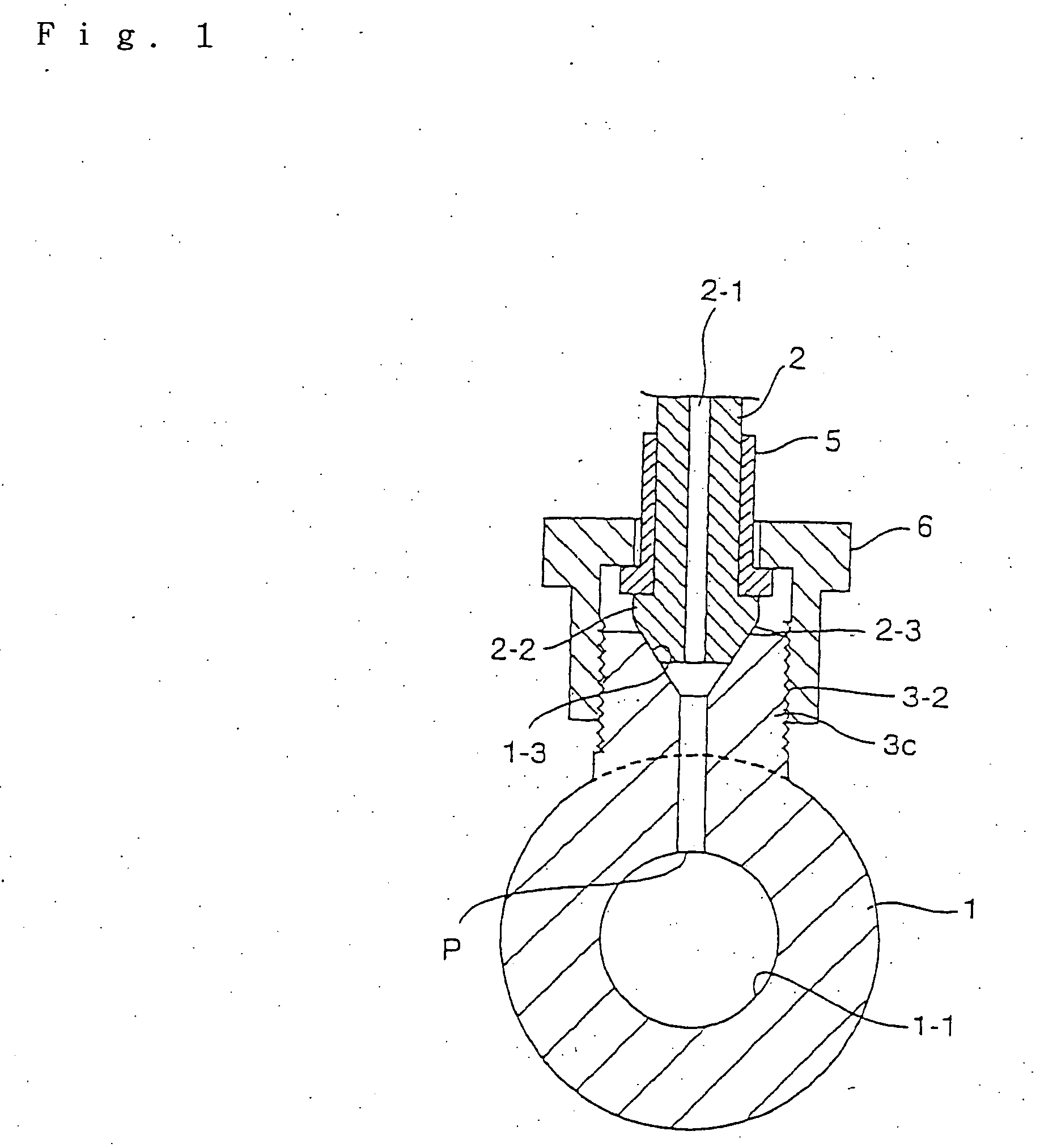

Connection head structure of high pressure fuel injection tube

ActiveUS7735473B2Improve sealingPrevent leakageJoints with sealing surfacesMachines/enginesCircular coneThick wall

Owner:USUI KOKUSAI SANGYO KAISHA LTD

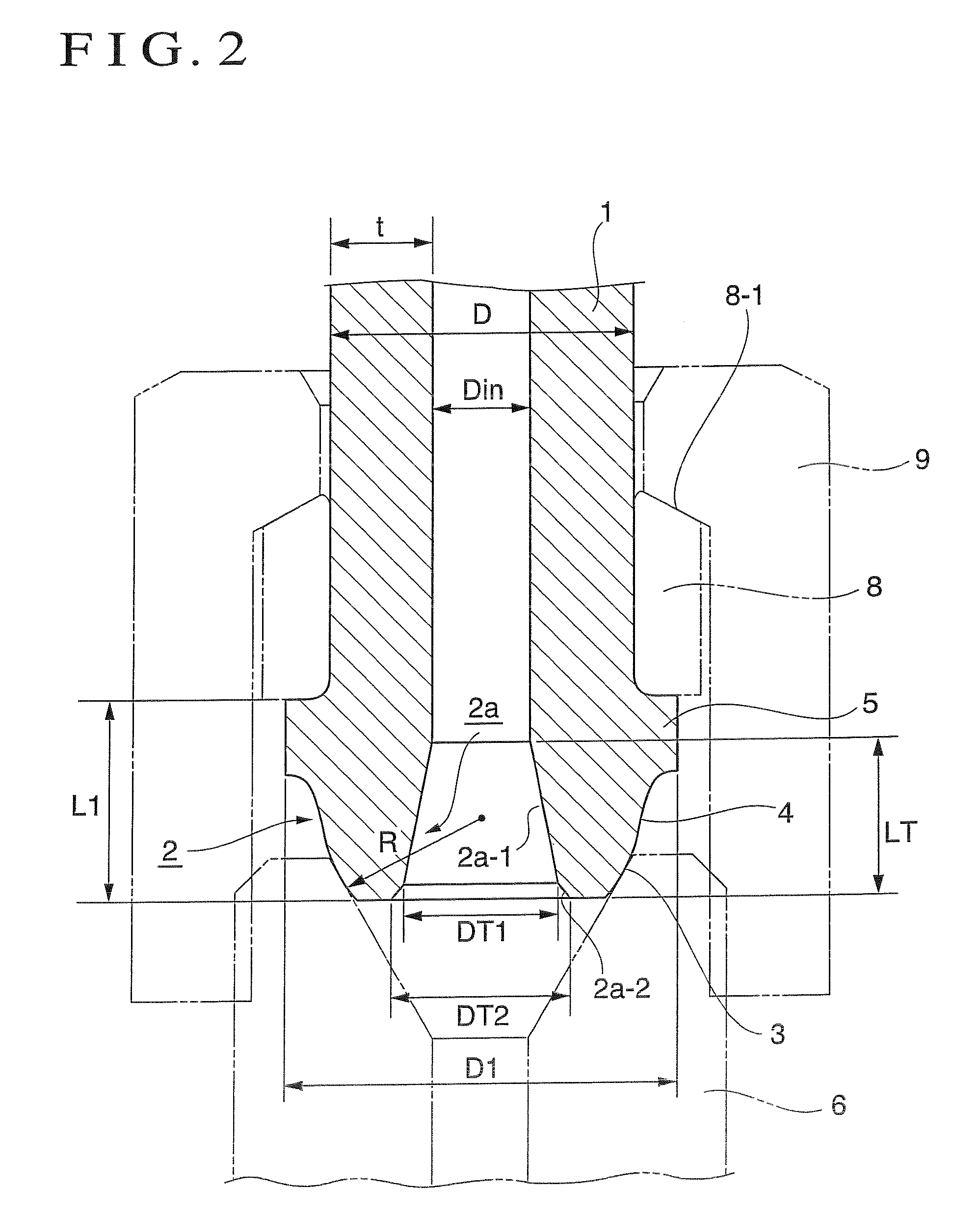

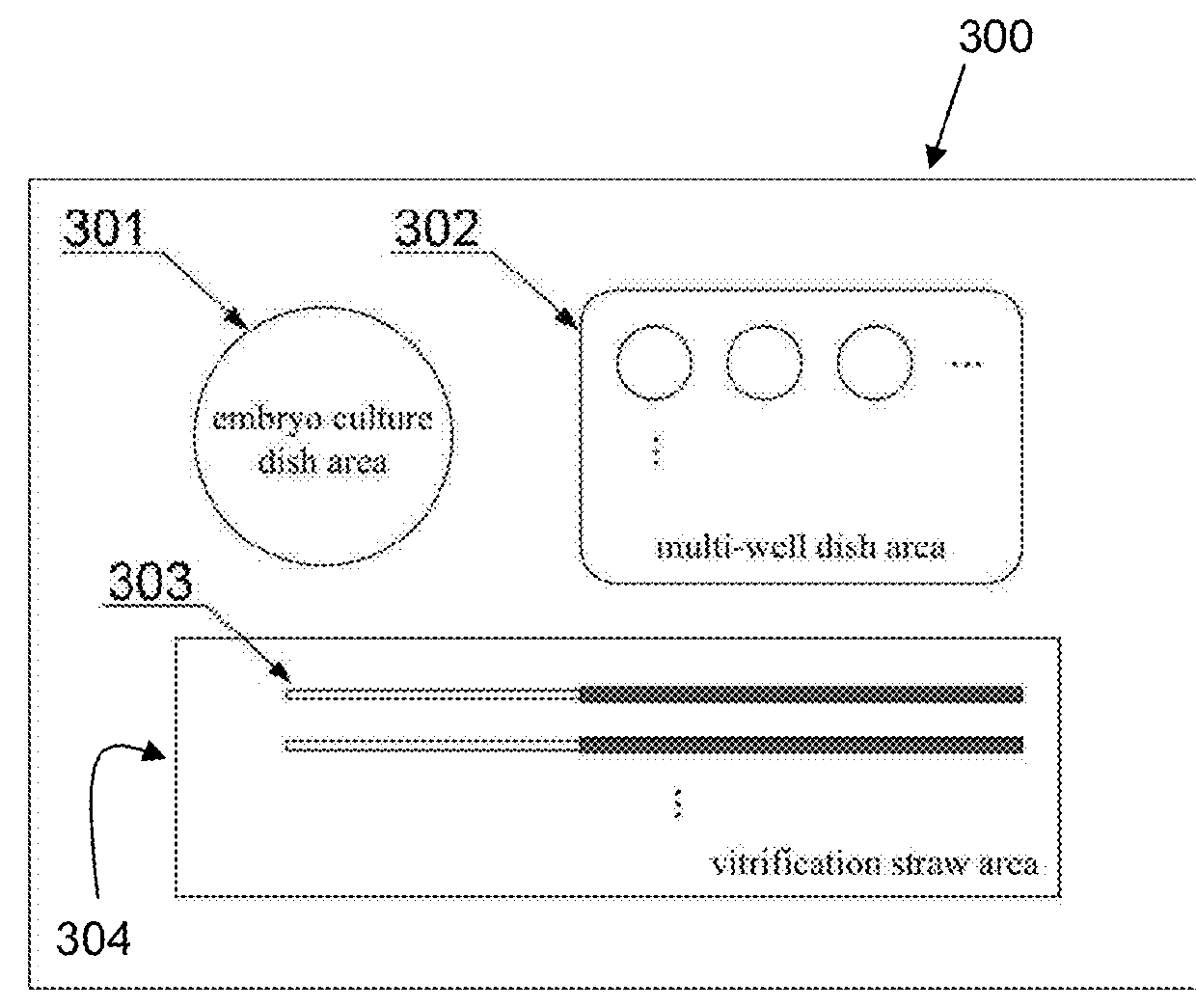

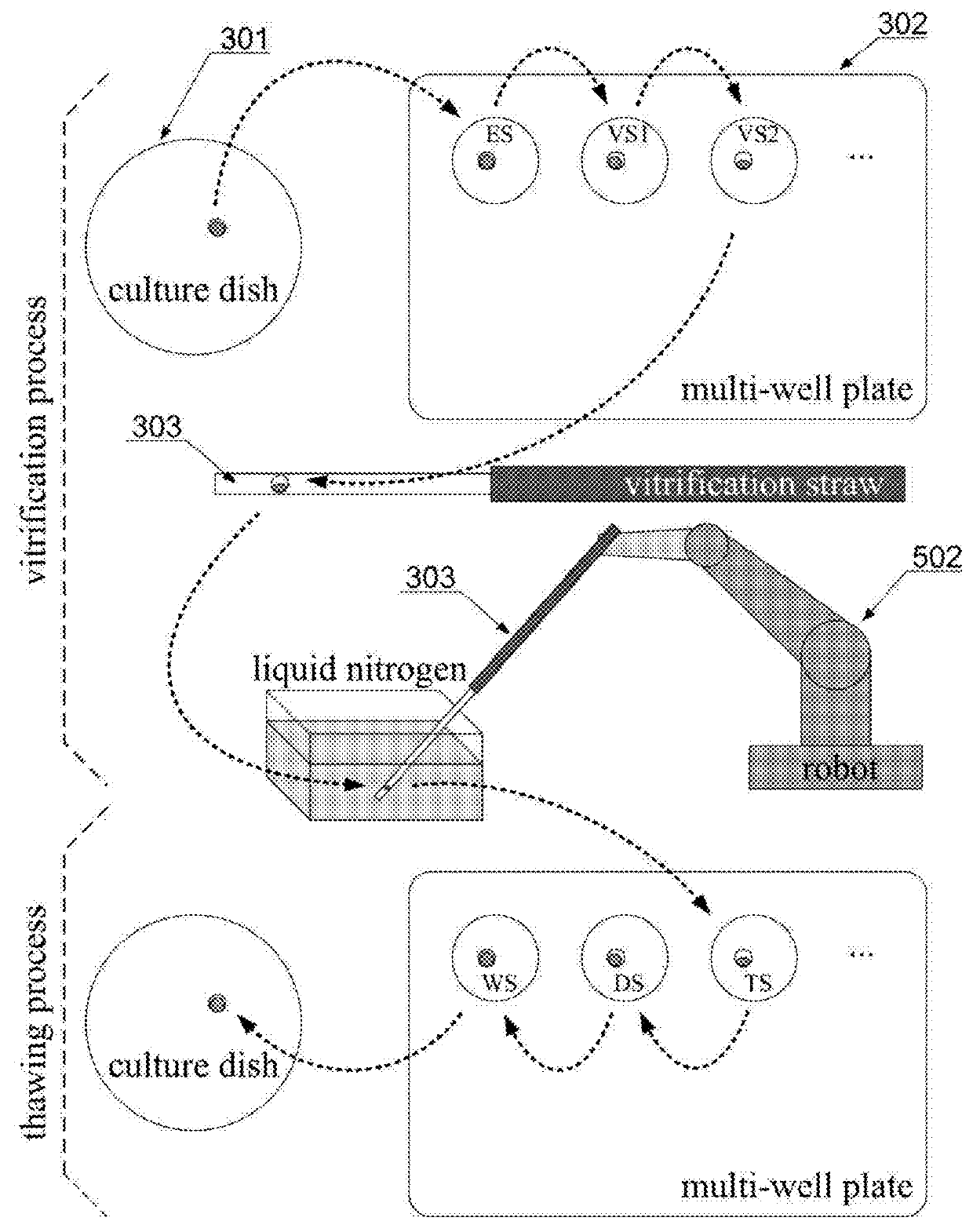

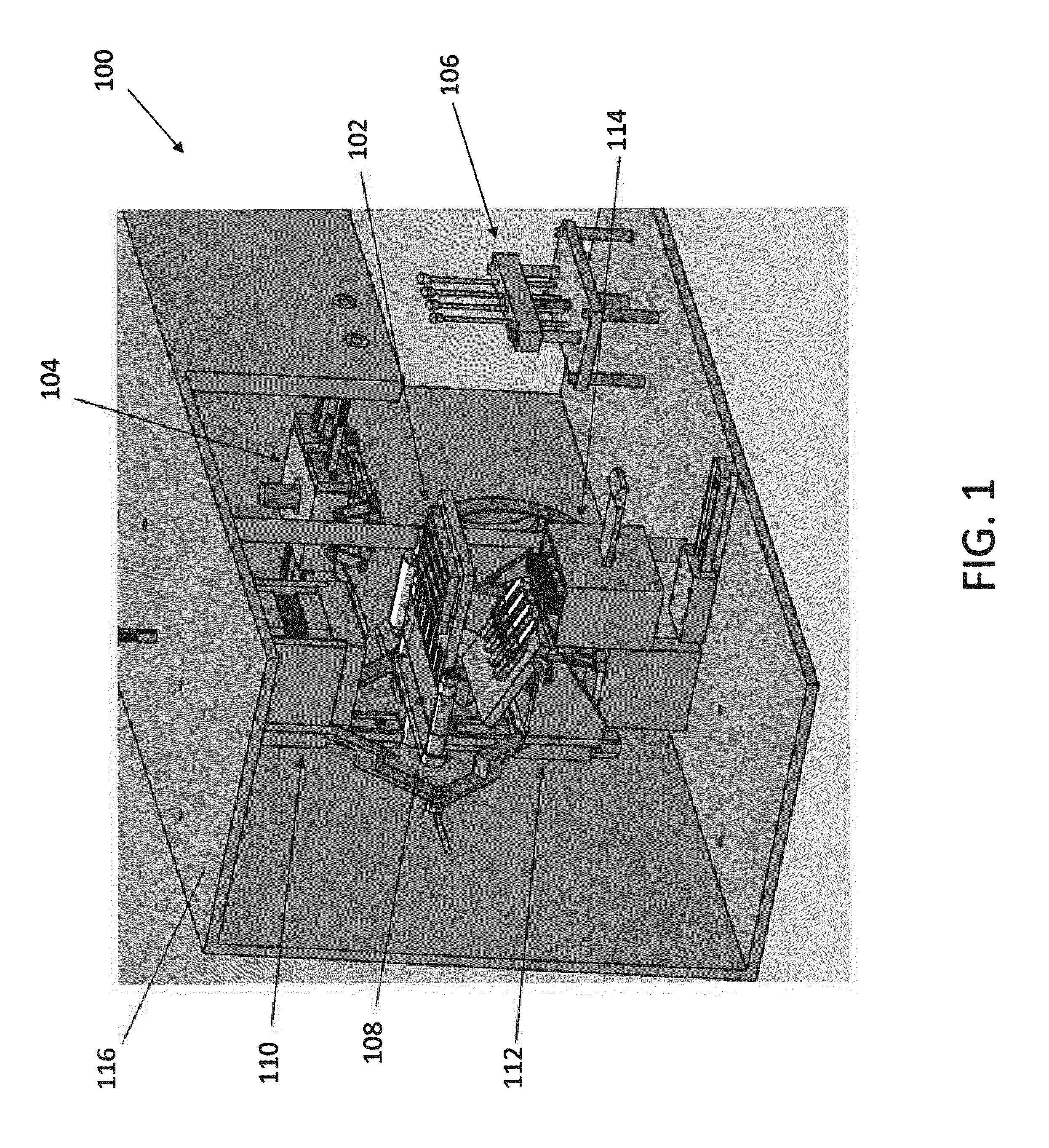

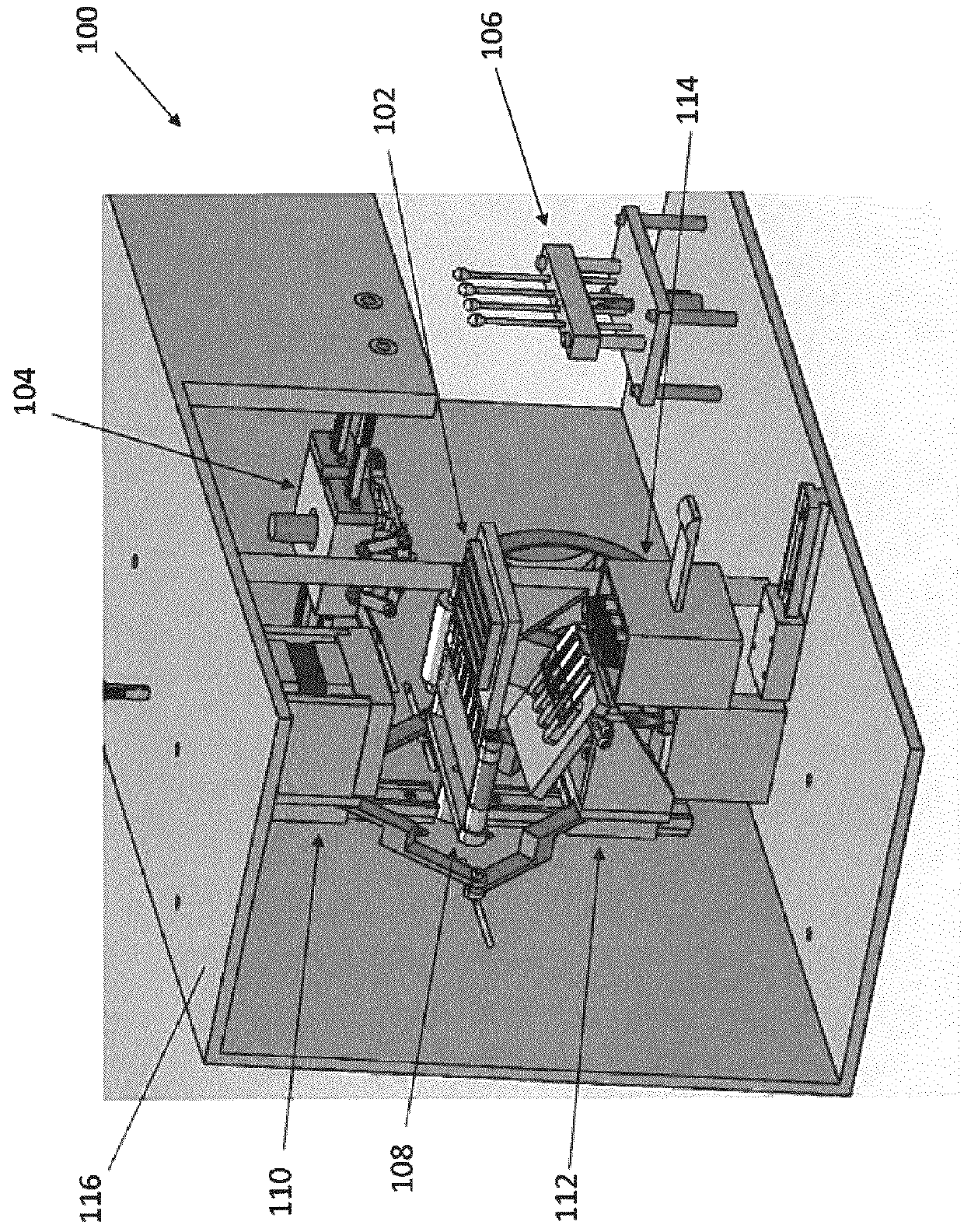

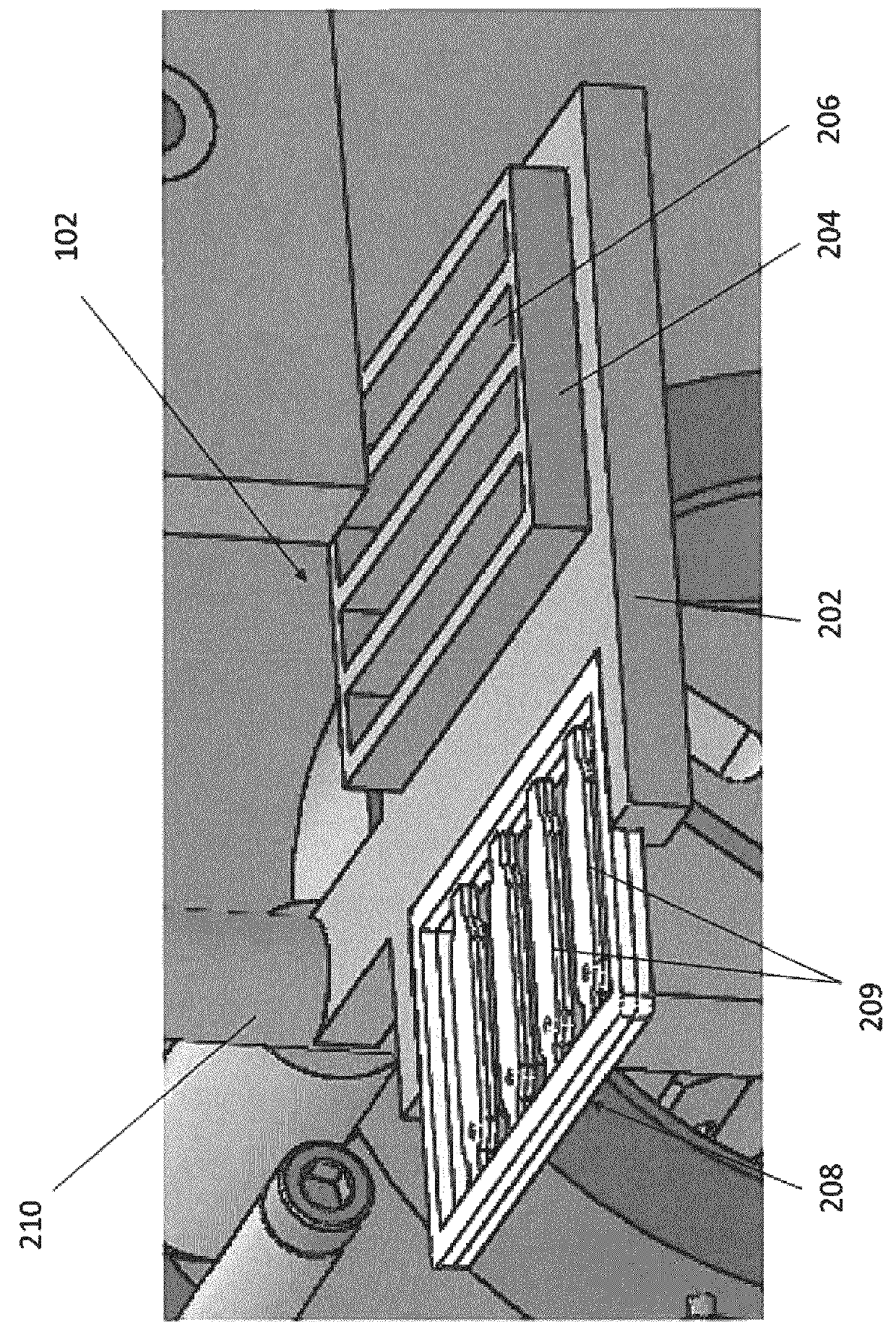

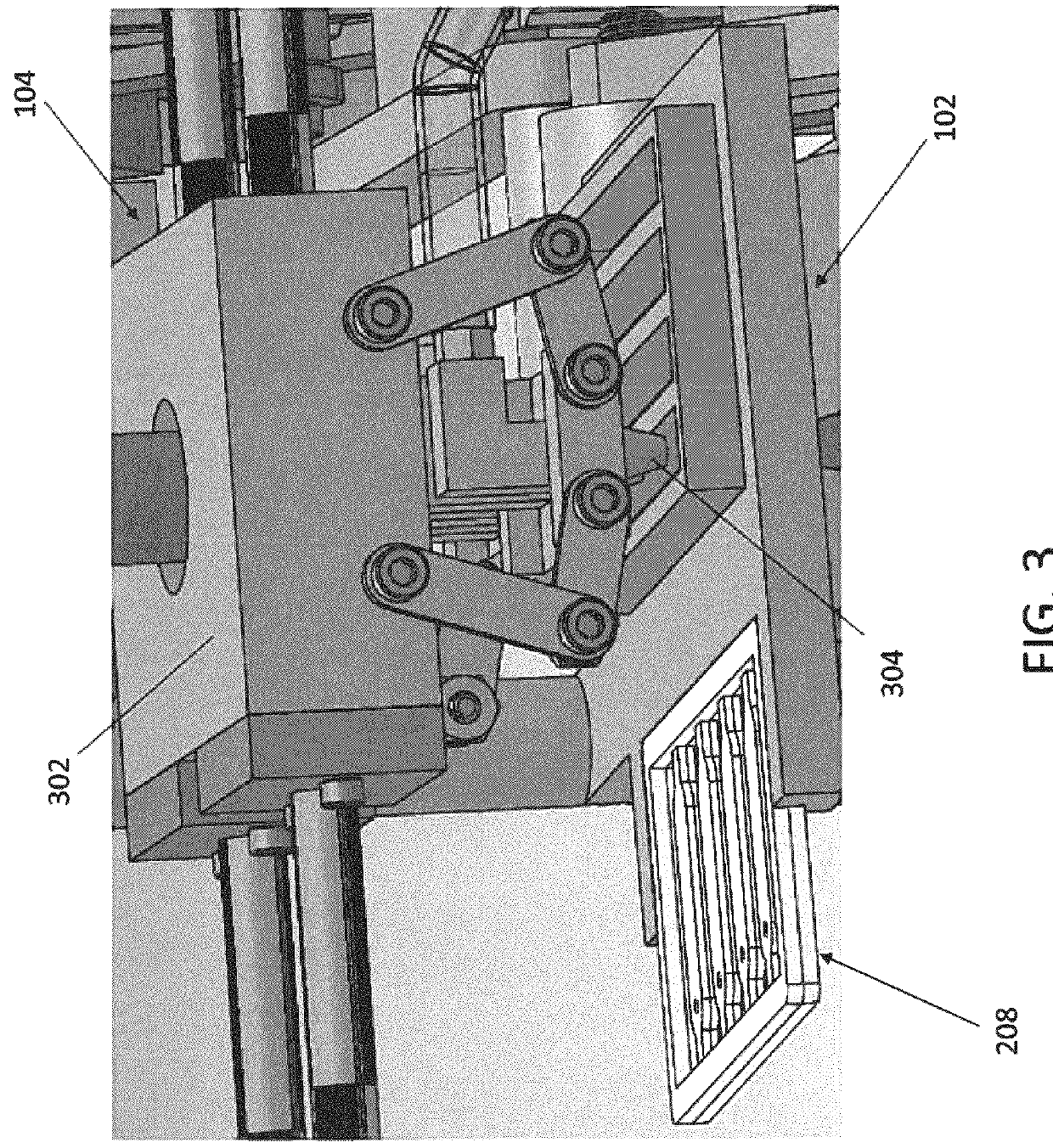

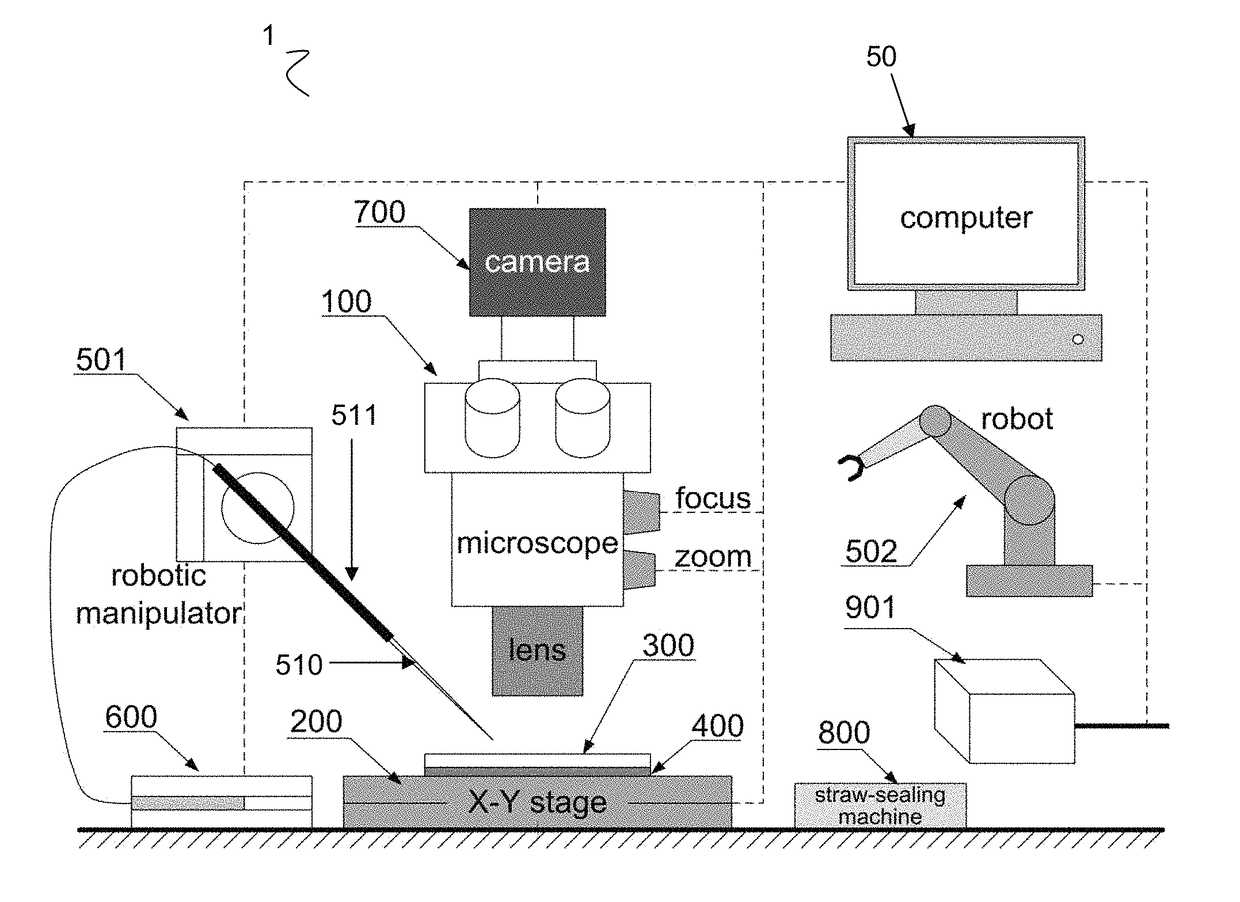

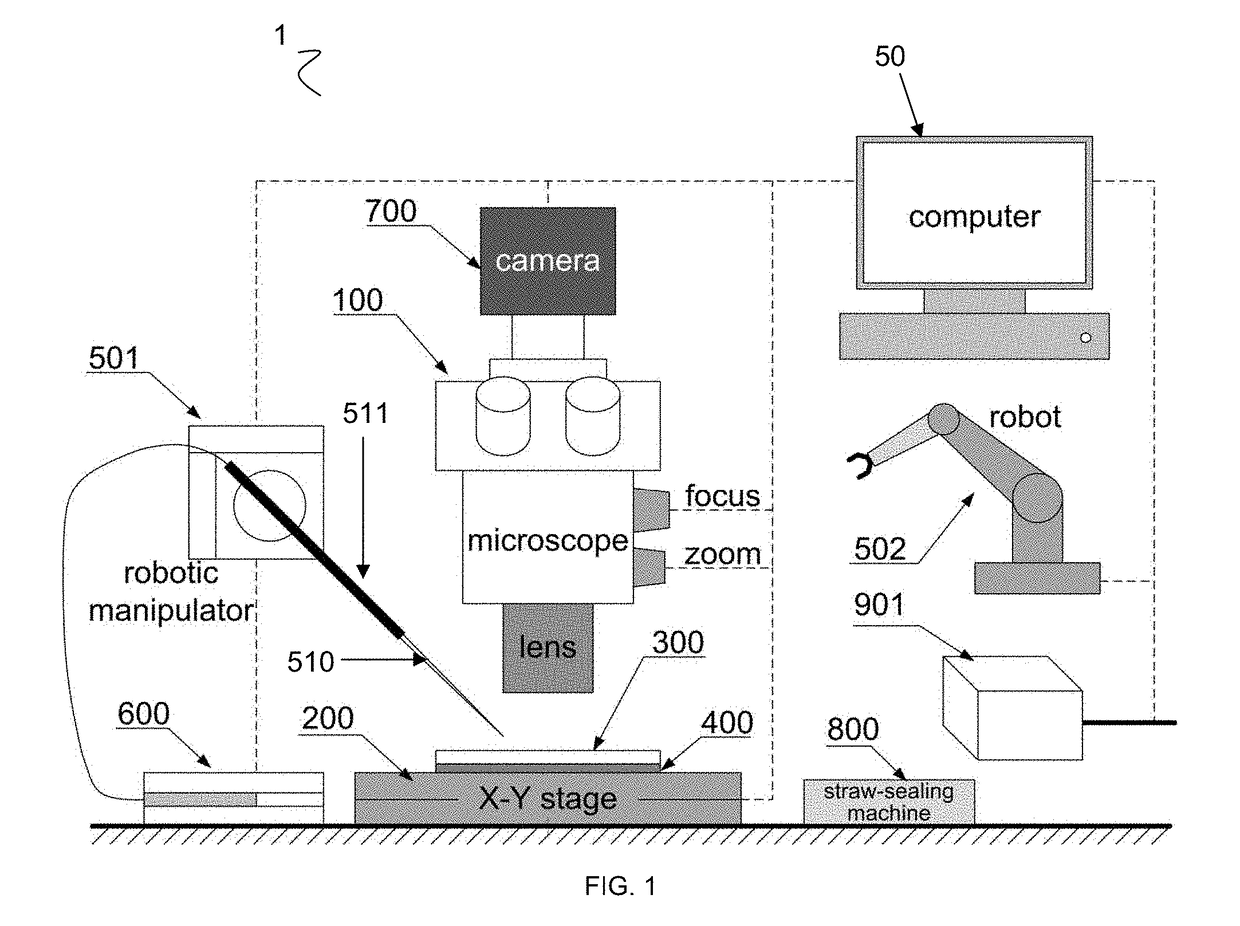

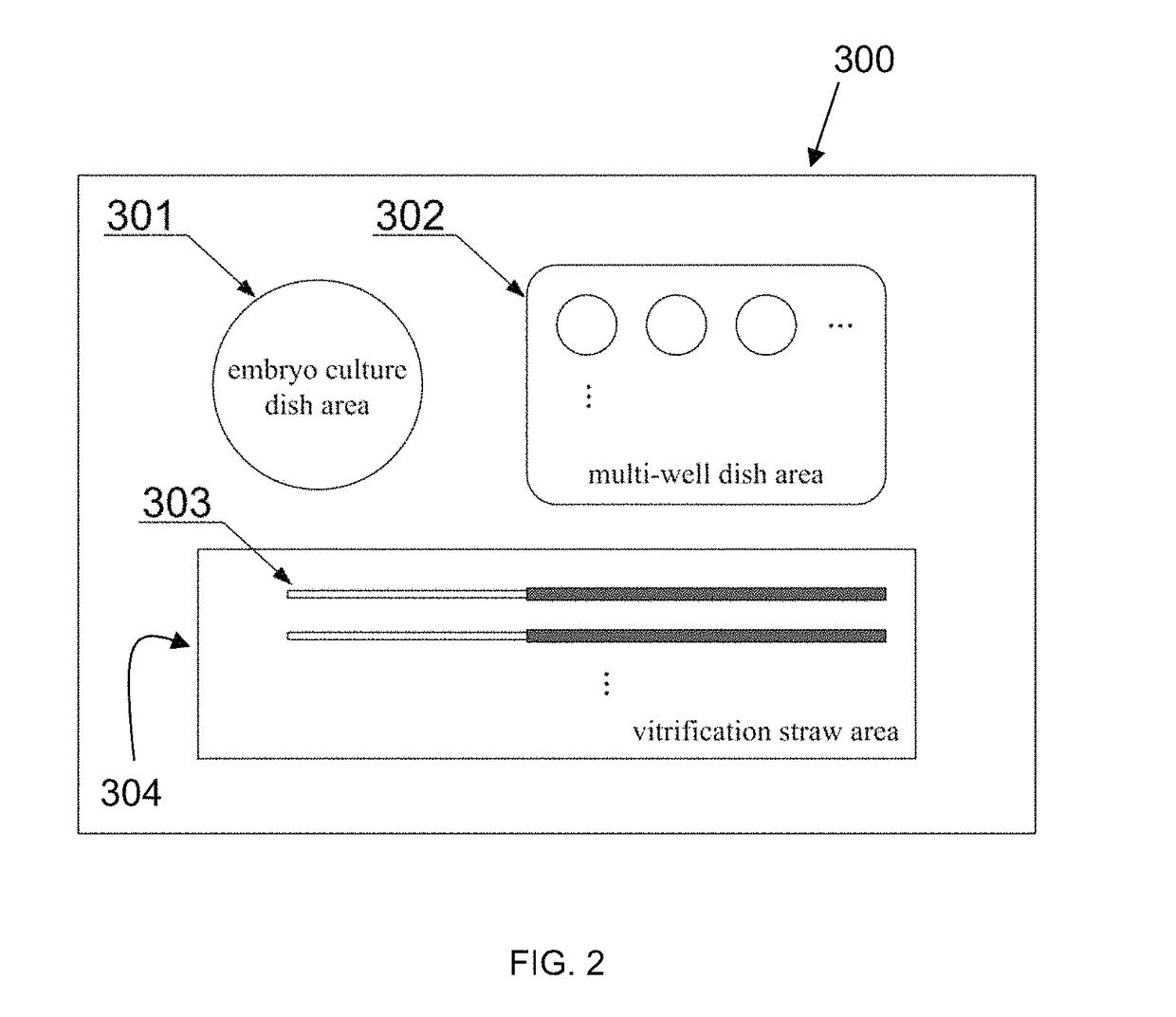

System and methods for automated vitrification of biological materials

ActiveUS20160029619A1Bioreactor/fermenter combinationsBiological substance pretreatmentsVitrificationEmbryo

The present invention relaters to a system and methods for automated vitrification of mammalian oocytes or embryos. The system and methods enable automated processing of oocytes or embryos in vitrification solutions; robotically moving vitrification devices that carry processed cells for freezing in liquid nitrogen; automated sealing of the frozen devices; and transferring the sealed devices to an automated storage system for long-term cryopreservation.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

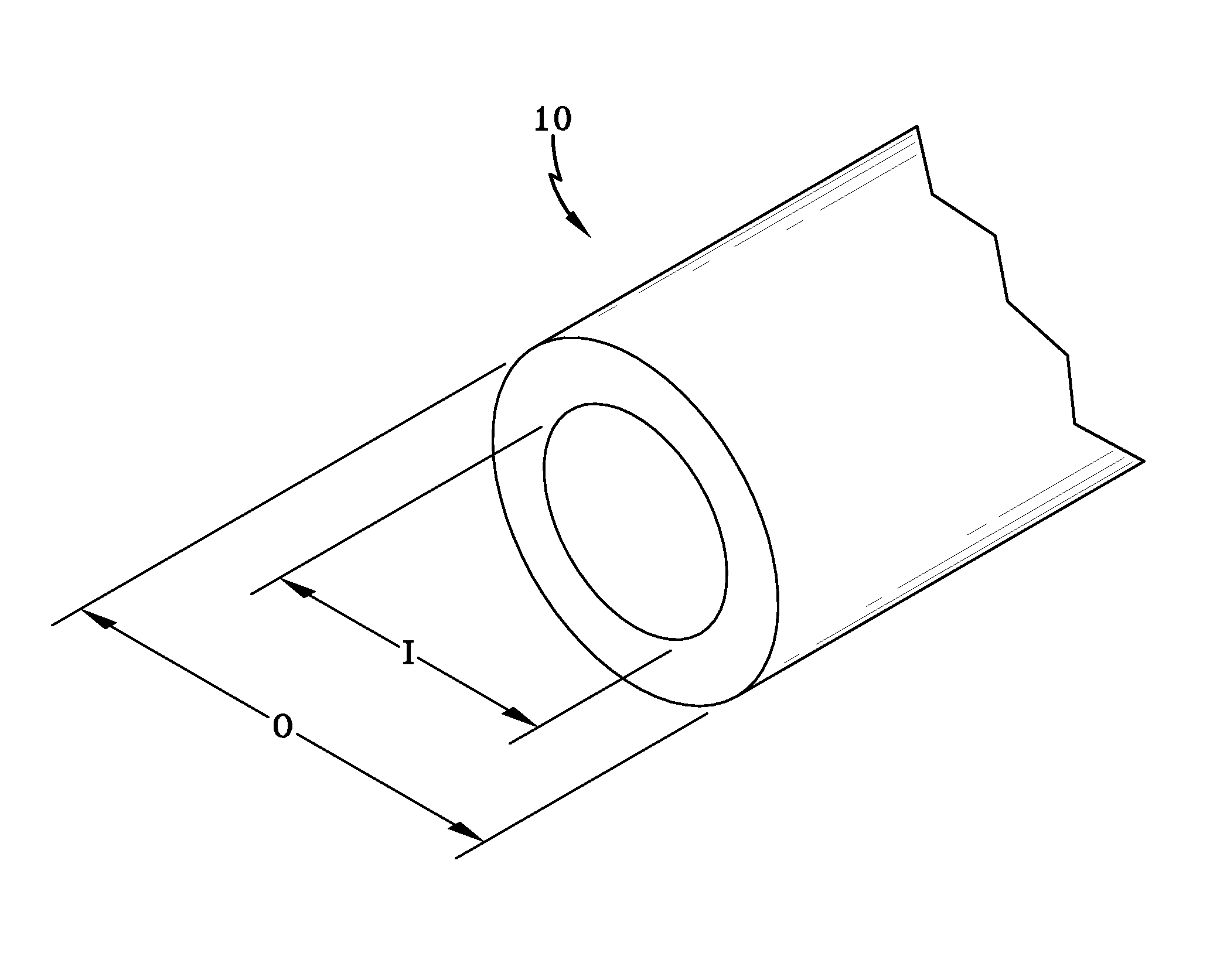

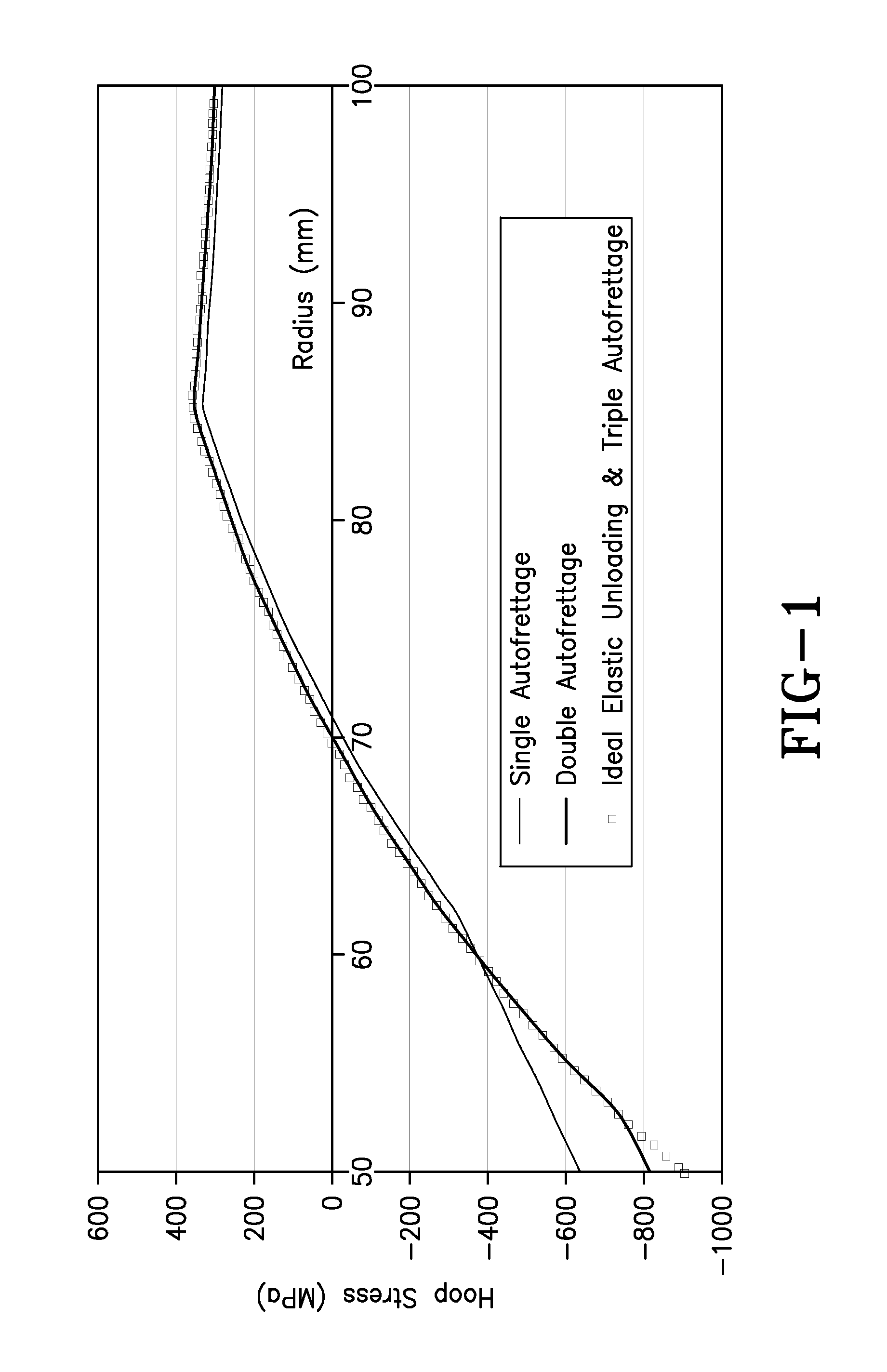

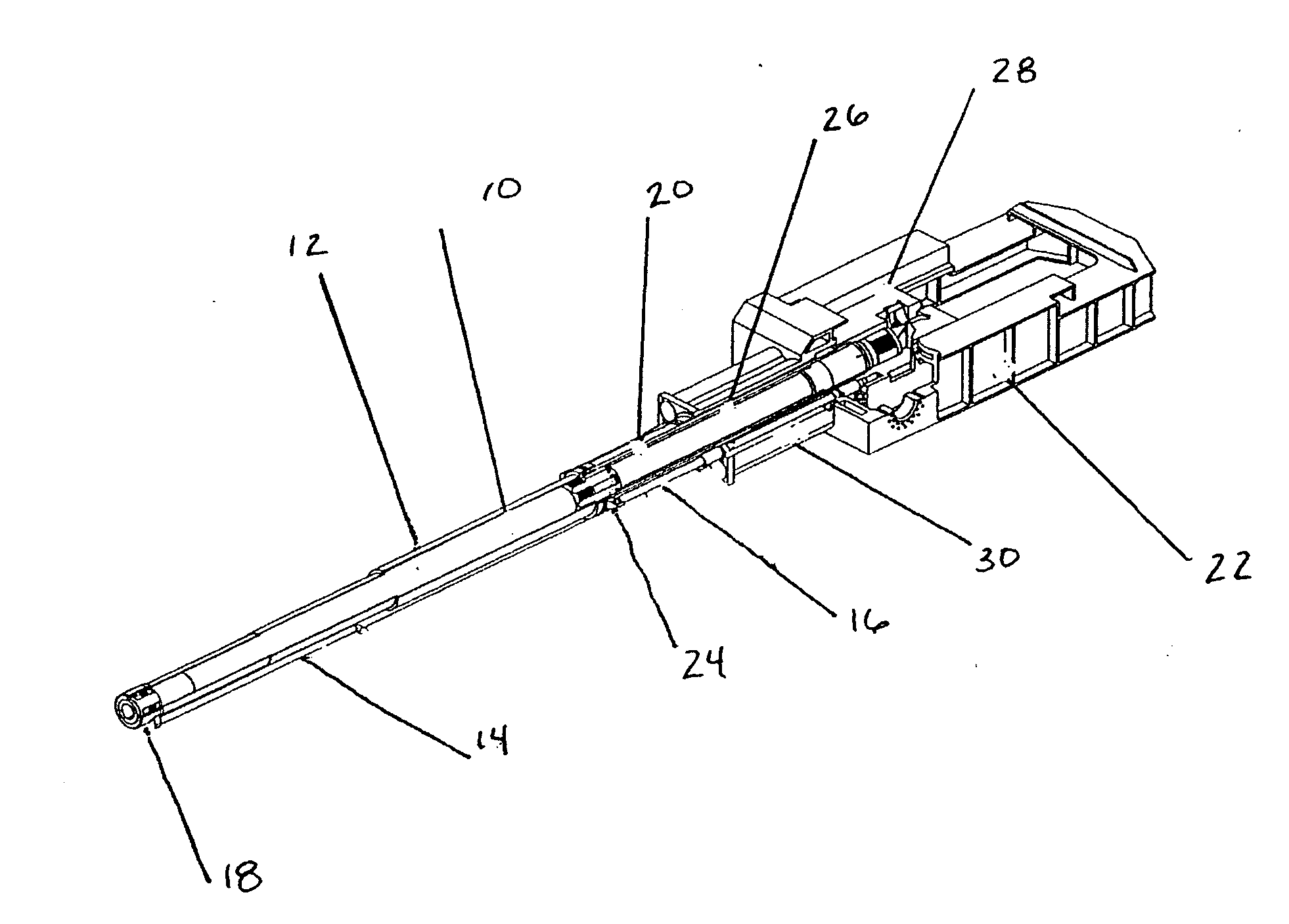

Multiple autofrettage

InactiveUS7818986B1Improve residual stressIncrease resistanceMetal working apparatusProcess engineeringGun barrel

A manufacturing method includes a first step of performing swage autofrettage on an object; a second step of heat soaking the object; and a third step of performing hydraulic autofrettage on the object. The second and third steps may be repeated one or more times. A final step may be heat soaking the object. The object may be, for example, a pressure vessel or gun barrel.

Owner:ARMY U S GOVERNMENT AS REPRESENTED BY SEC OF

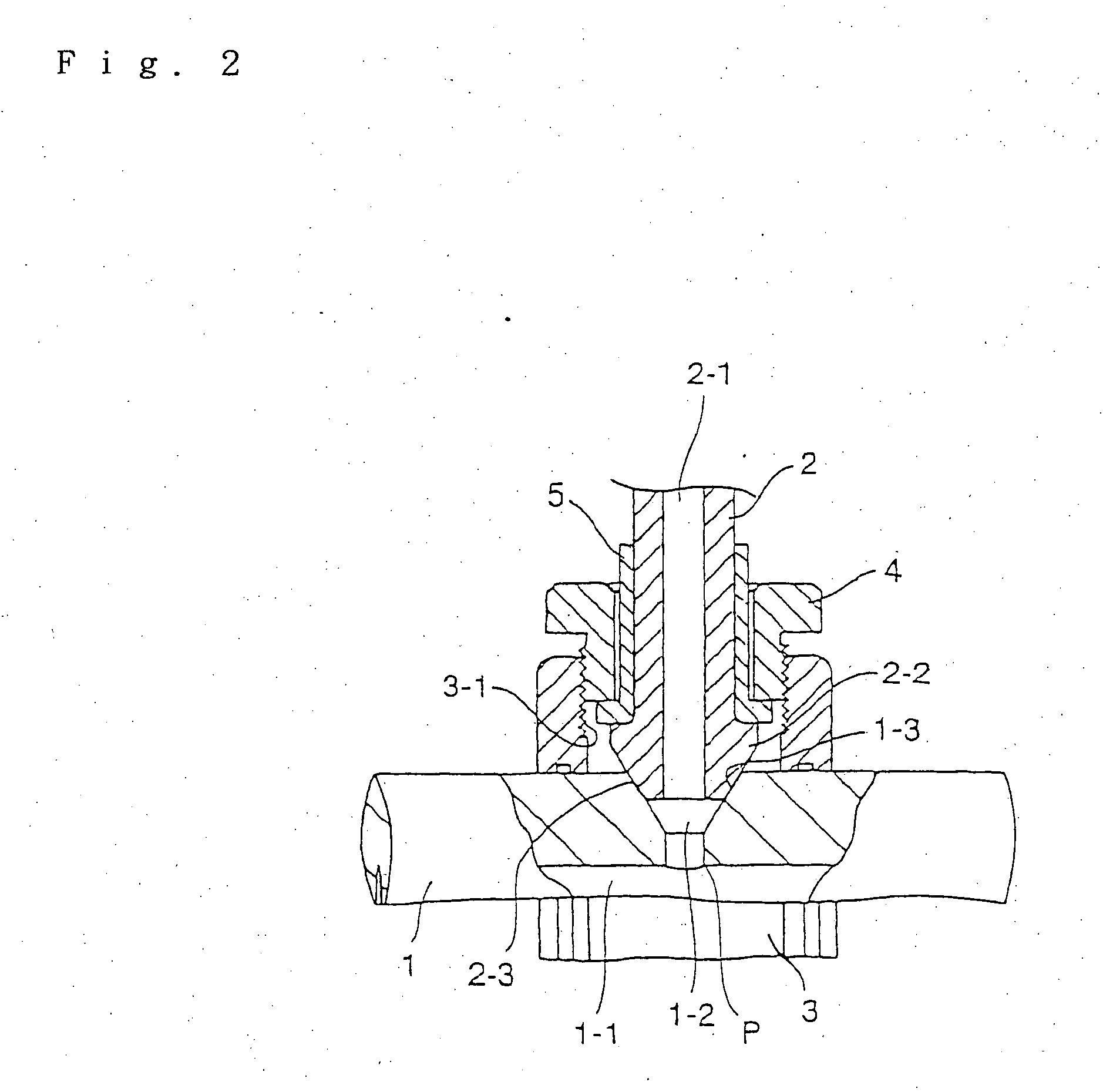

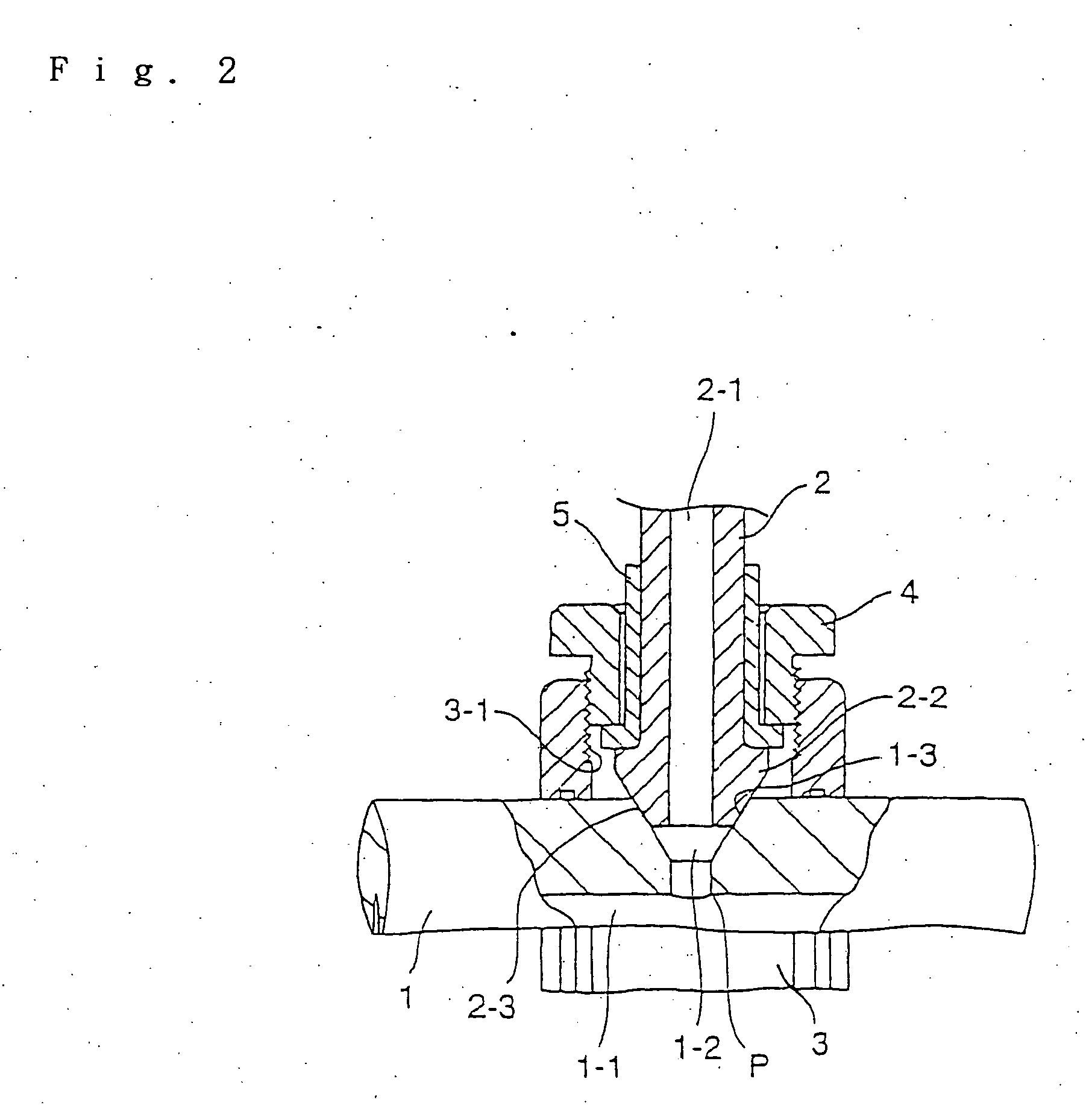

Common-rail injection system for diesel engine

InactiveUS20050005910A1Pipeline expansion-compensationLow-pressure fuel injectionStress concentrationInternal pressure

A common-rail injection system is provided for a diesel engine and has excellent internal pressure fatigue resisting characteristics, vibrational fatigue resisting characteristics and cavitation resisting property and sheet face flawing resisting property, and can be made thin and light in weight. A main pipe rail is manufactured by transformation induced plastic type strength steel. After the main pipe rail is processed, residual austenite is generated by heat treatment, and the reduction processing of stress concentration of a branch hole and a main pipe rail side flow passage crossing portion is performed. Further, it is preferable that an induced plastic transformation is generated on the inner surface of the main pipe rail by autofrettage processing, and compression residual stress is left.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

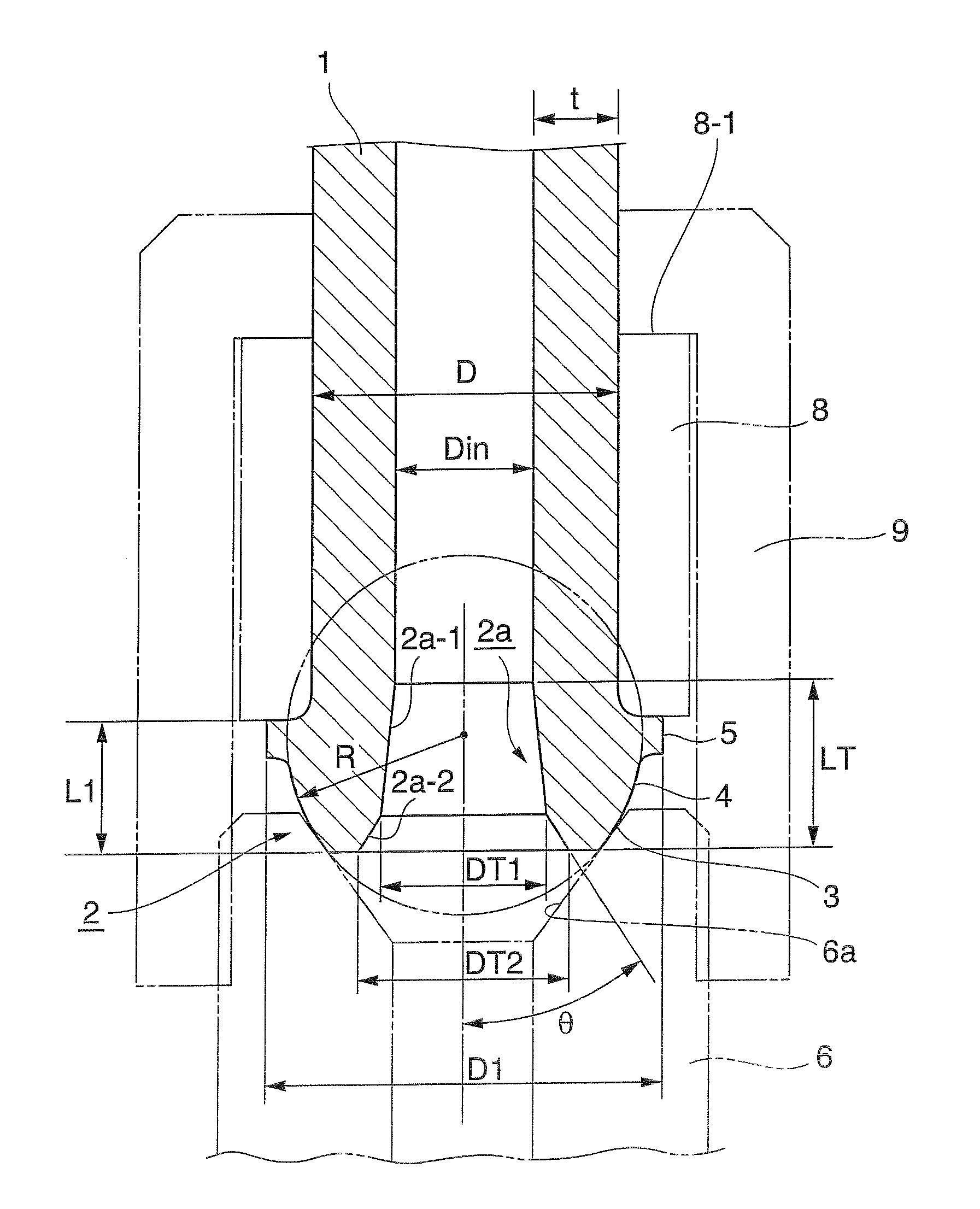

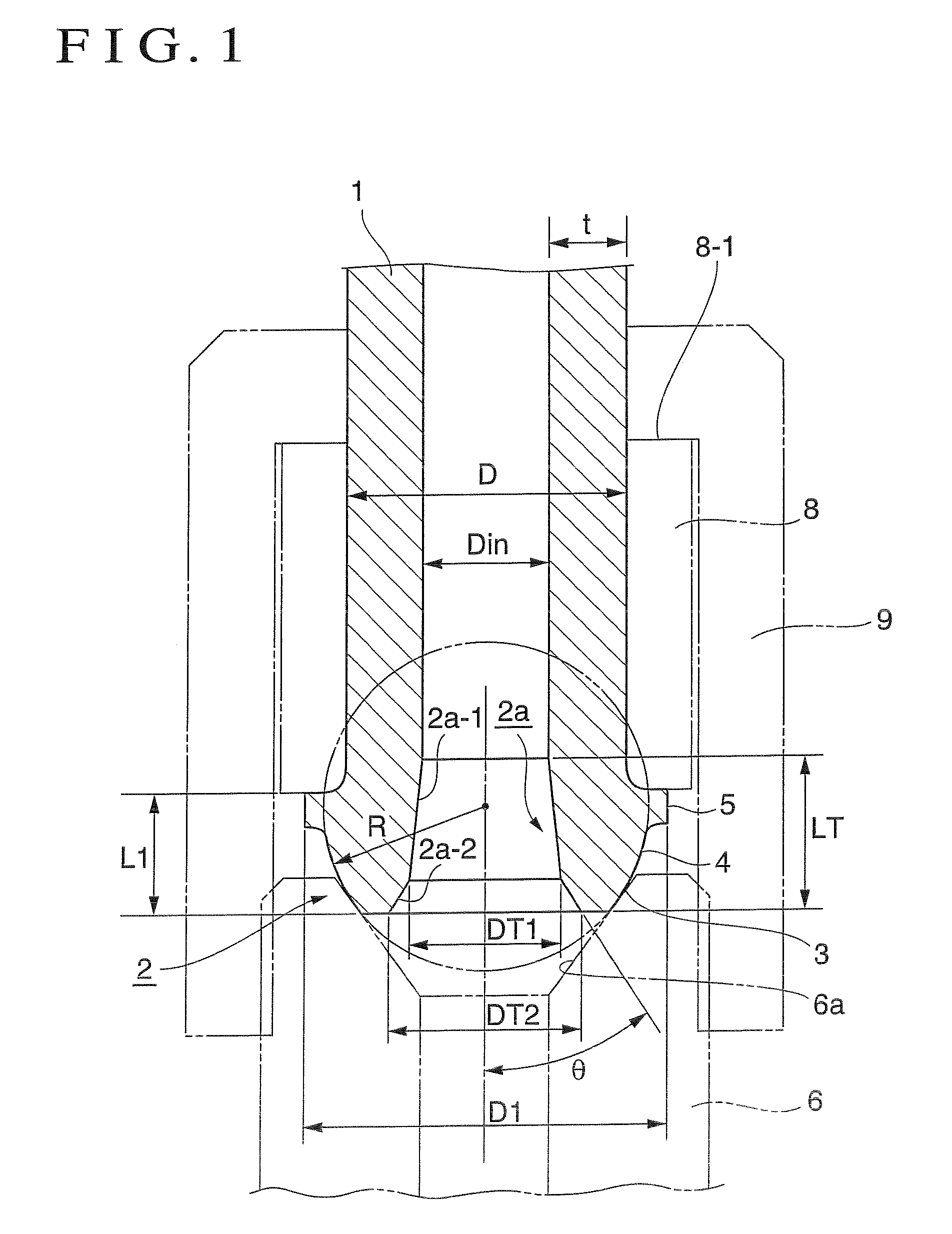

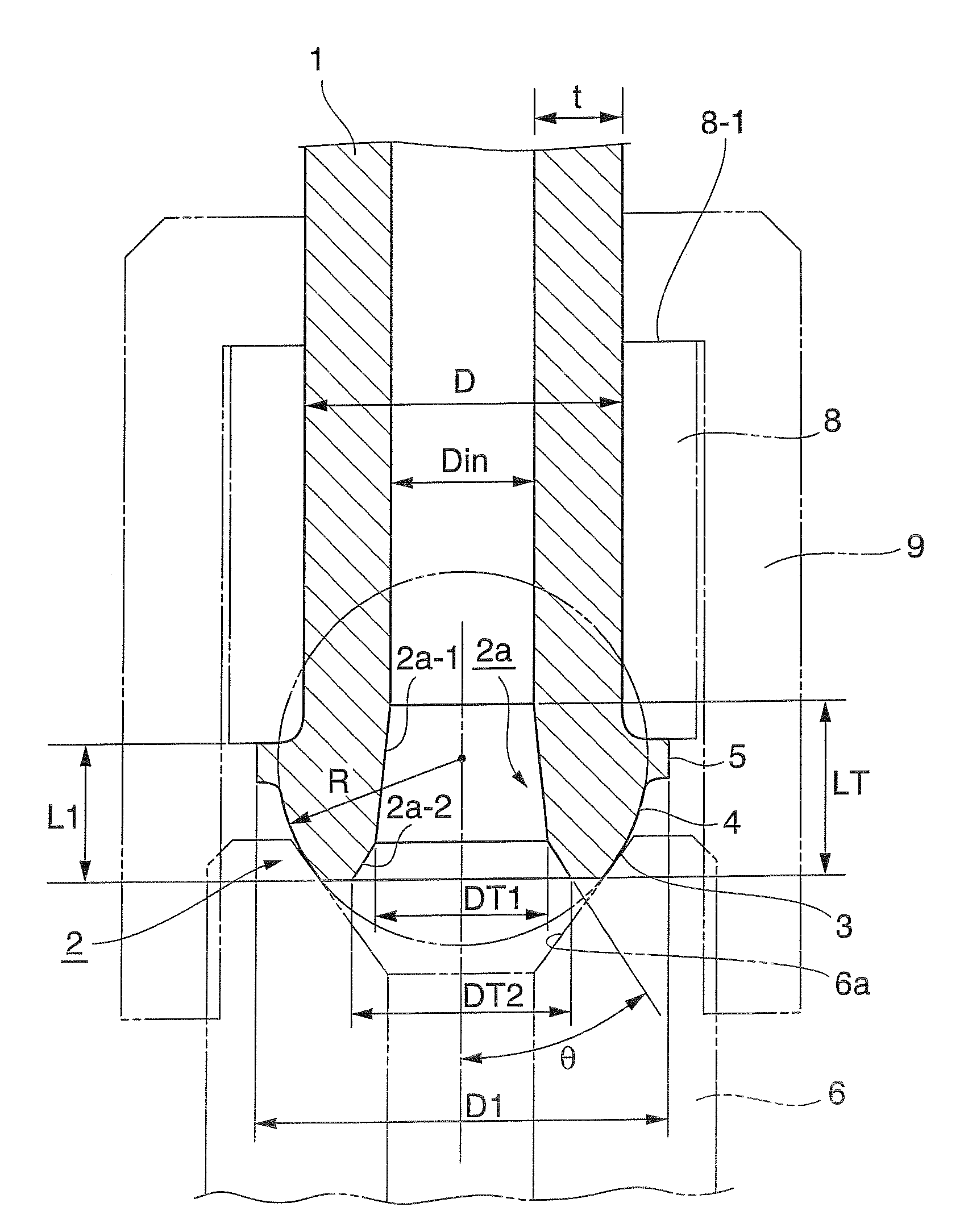

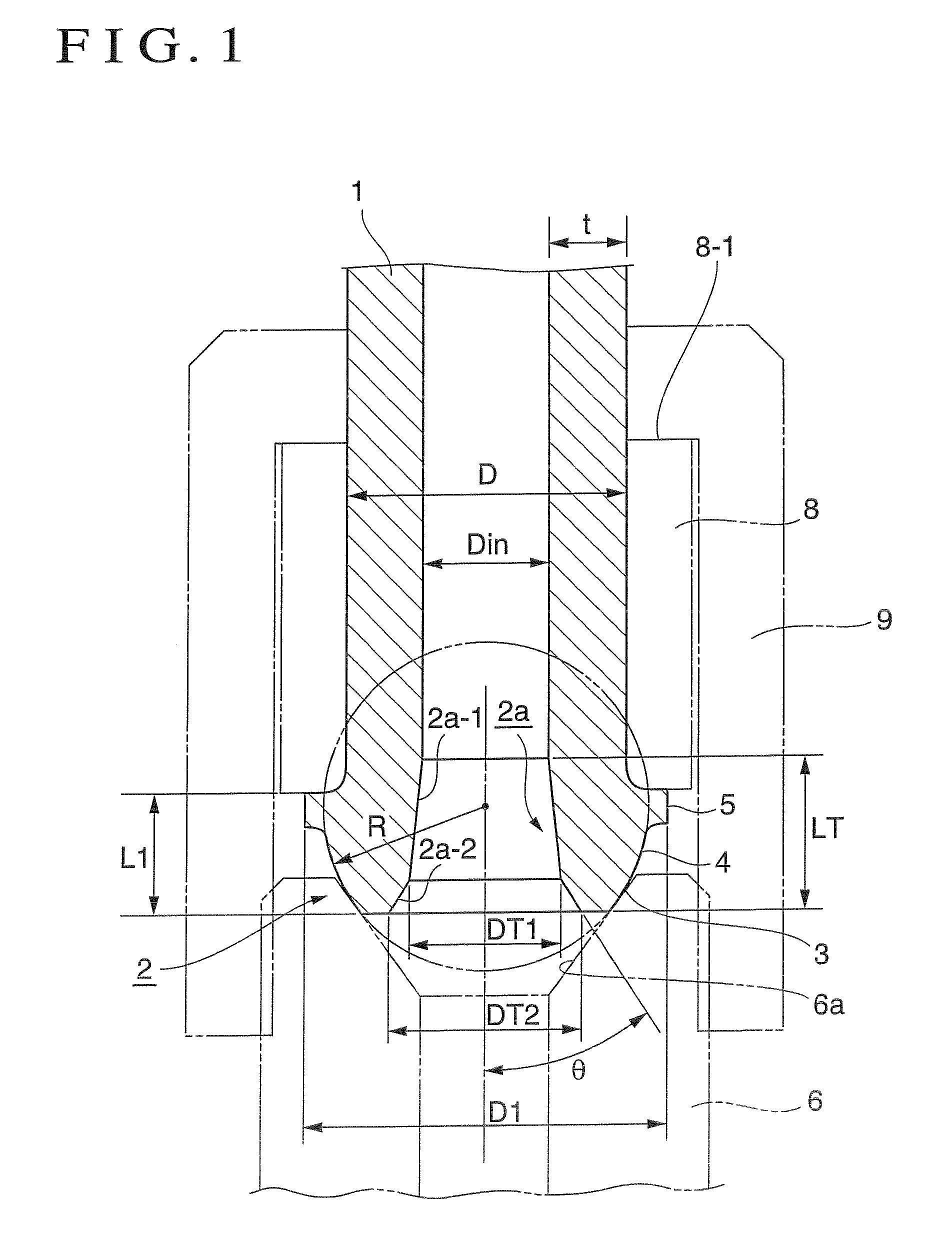

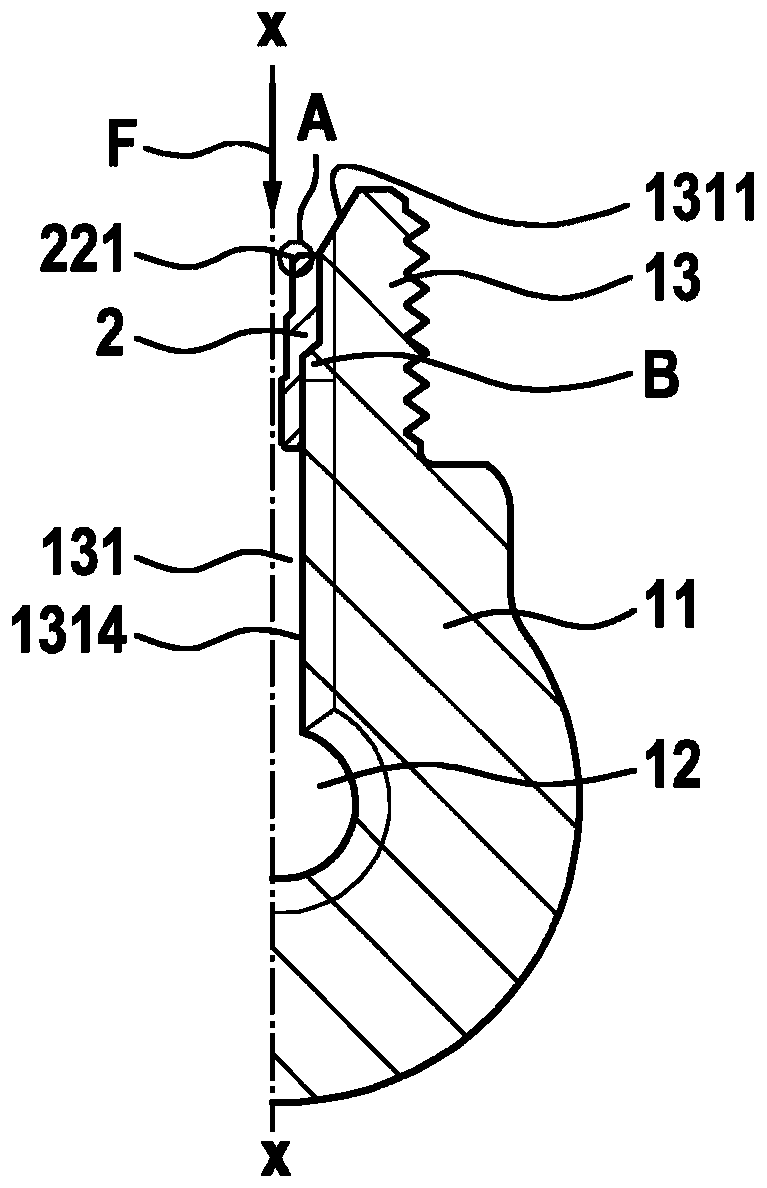

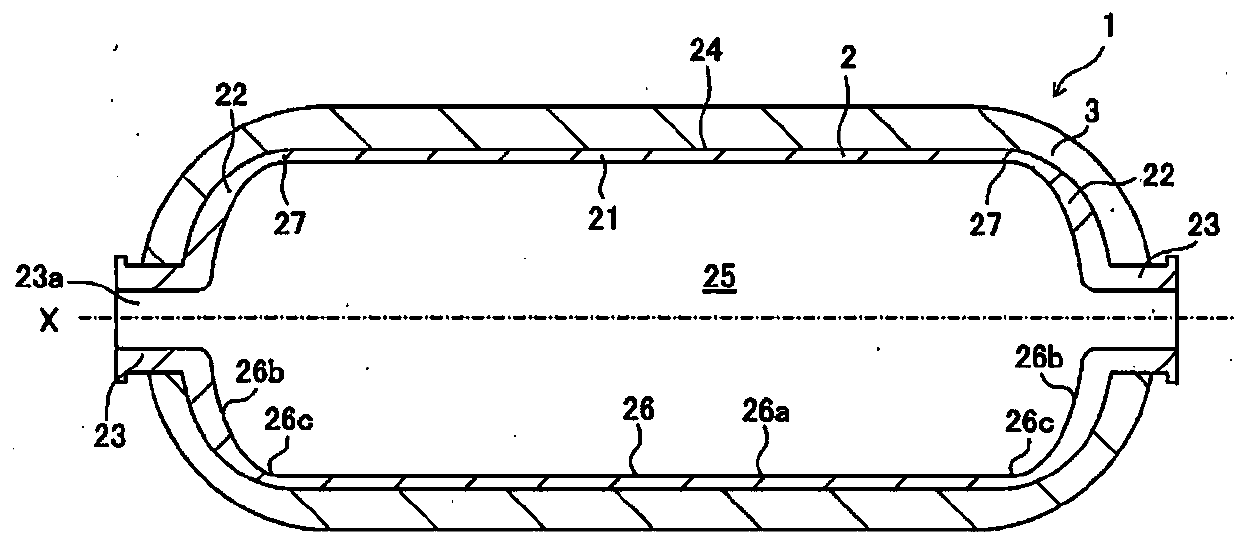

Connection Head Structure of High Pressure Fuel Injection Tube

ActiveUS20090151701A1Smoothing effect flowIncrease the tensile stressJoints with sealing surfacesMachines/enginesCircular coneThick wall

A connection head structure of a high pressure fuel injection tube is provided to avoid an interference between an annular flange and an opposing part by sufficiently maintaining an tube axial direction length of the connection head and to obtain a good sealability to prevent leaking during autofrettage processing with a high pressure of not less than 300 MPa. A connection head structure of a high pressure fuel injection tube includes, on a connection end portion of a thick walled fine steel tube, a spherical seat face, an annular flange, and a circular conic face that continuously extends from the seat face, wherein a washer and a fastening nut are assembled, characterized in that when a thick walled fine steel tube has t (wall thickness) / D (outer diameter)<0.3, an tube axial direction distance L1 from a connection head end to the back face of the annular flange is from 0.38 D to 0.7 D, a spherical body radius R of the seat face is from 0.45 D to 0.65 D, and an outer diameter D1 of the annular flange is from 1.2 D to 1.4 D, wherein an inner circumferential face of the connection head includes a two stage tapered face having a cross section outline in a tube axial direction of the steel tube that broadens toward the aperture of the tube.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

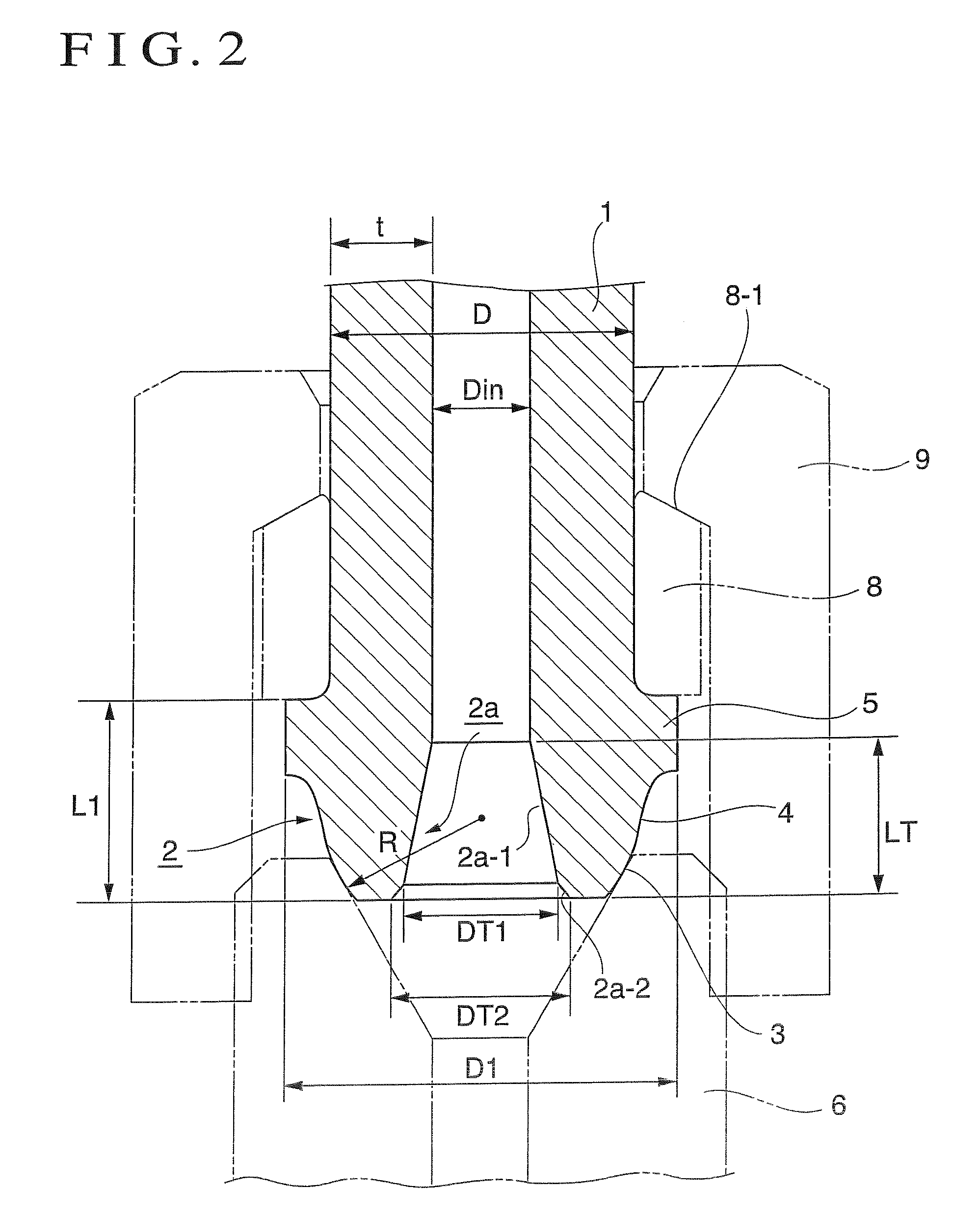

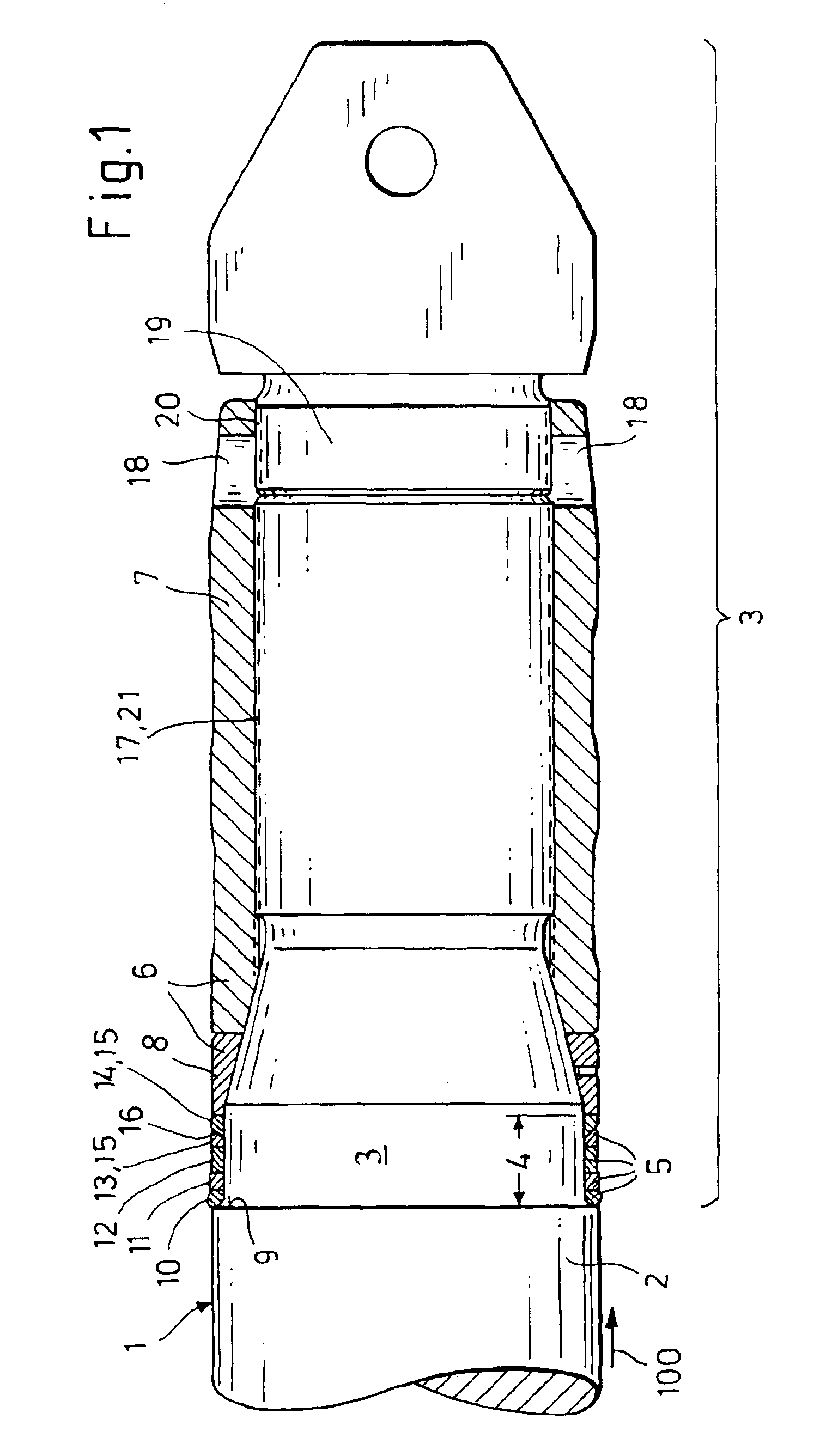

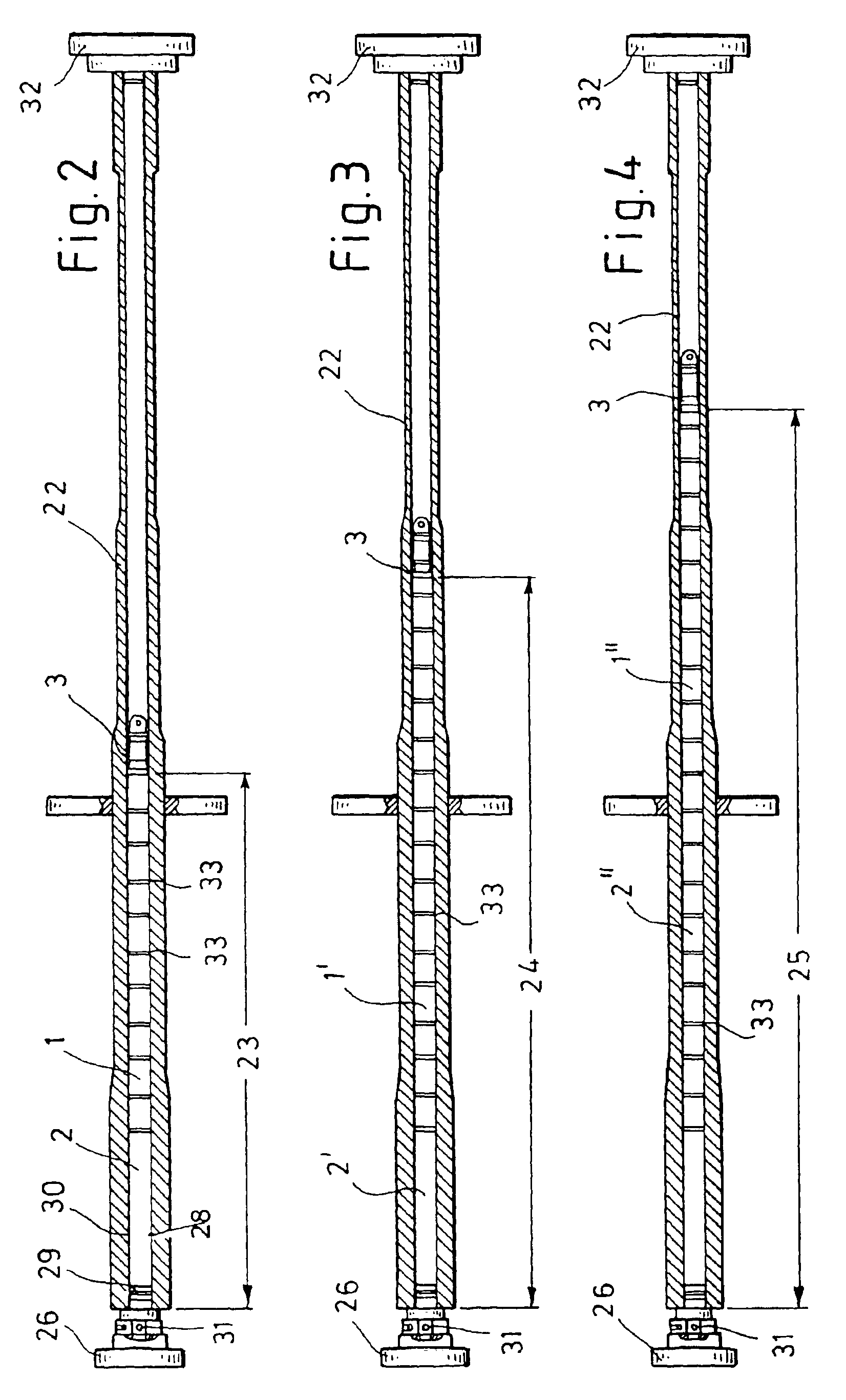

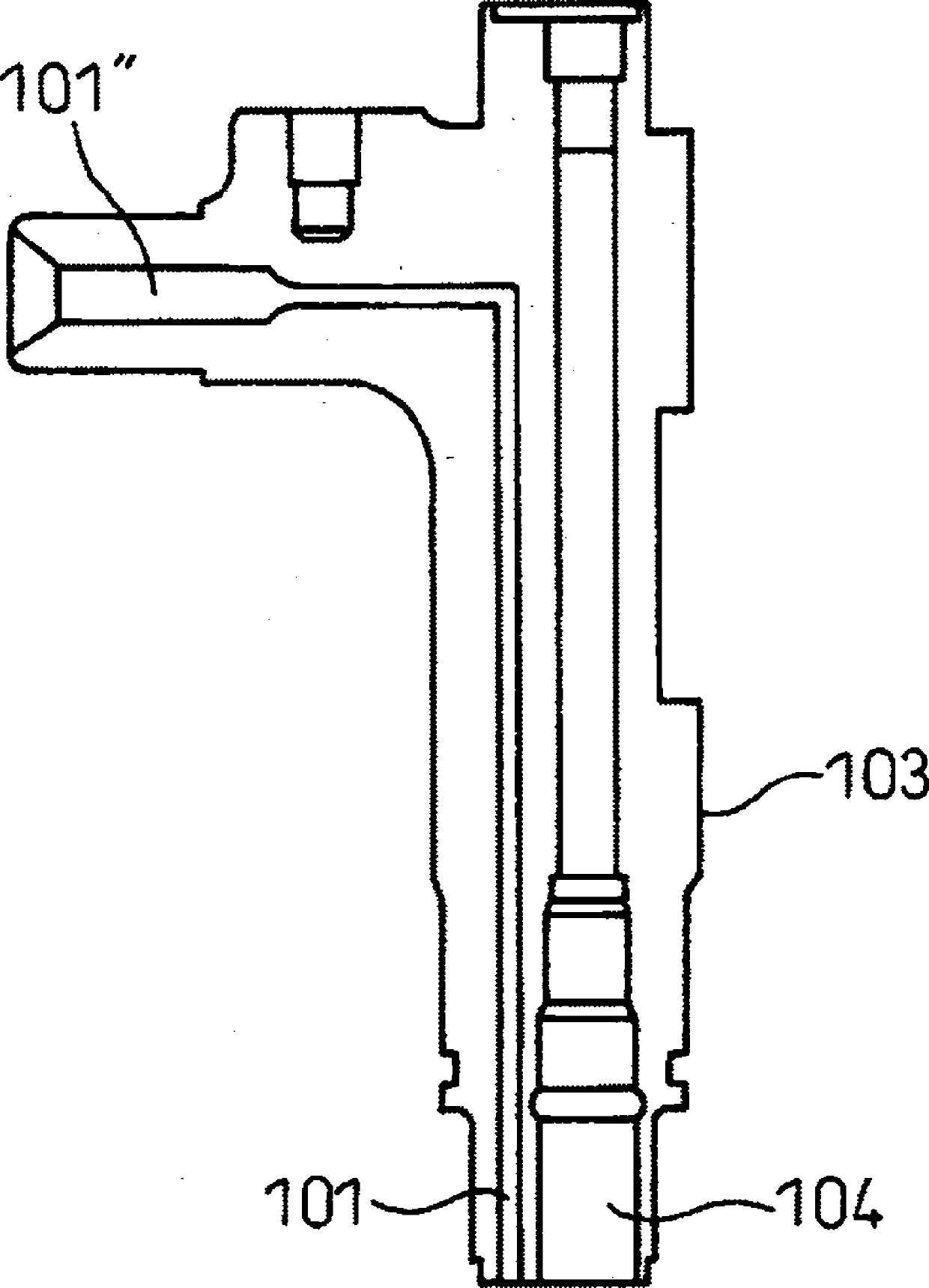

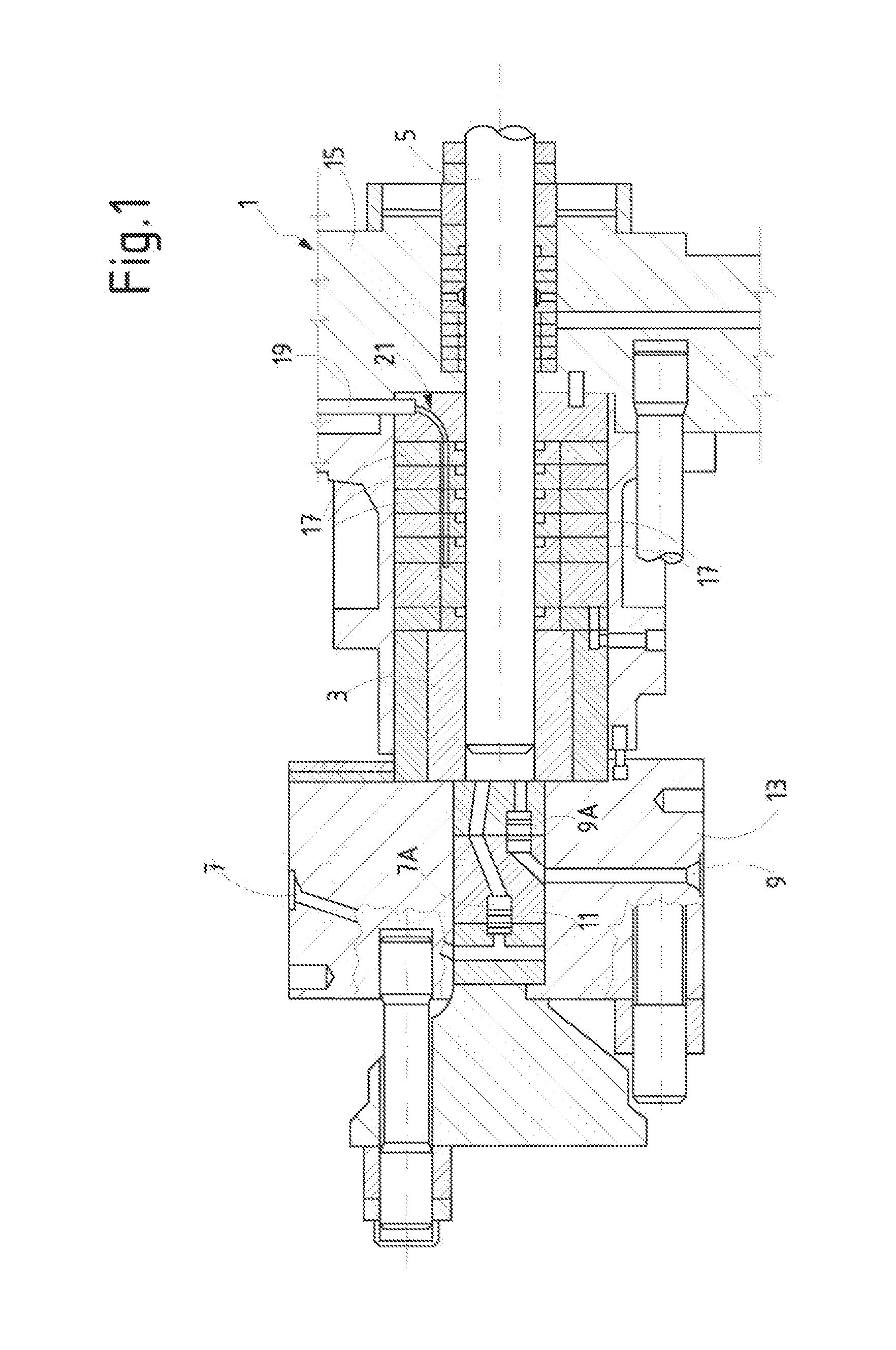

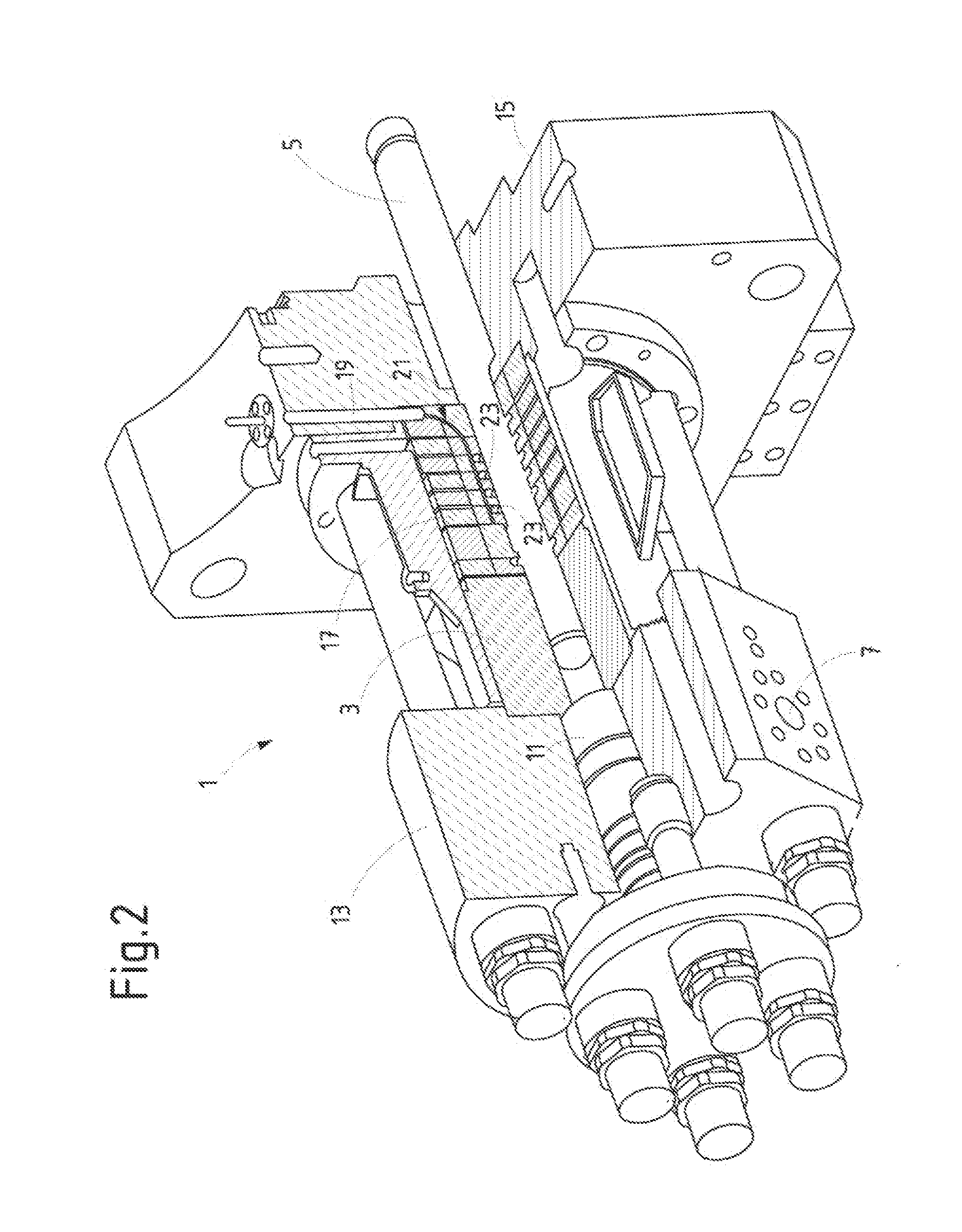

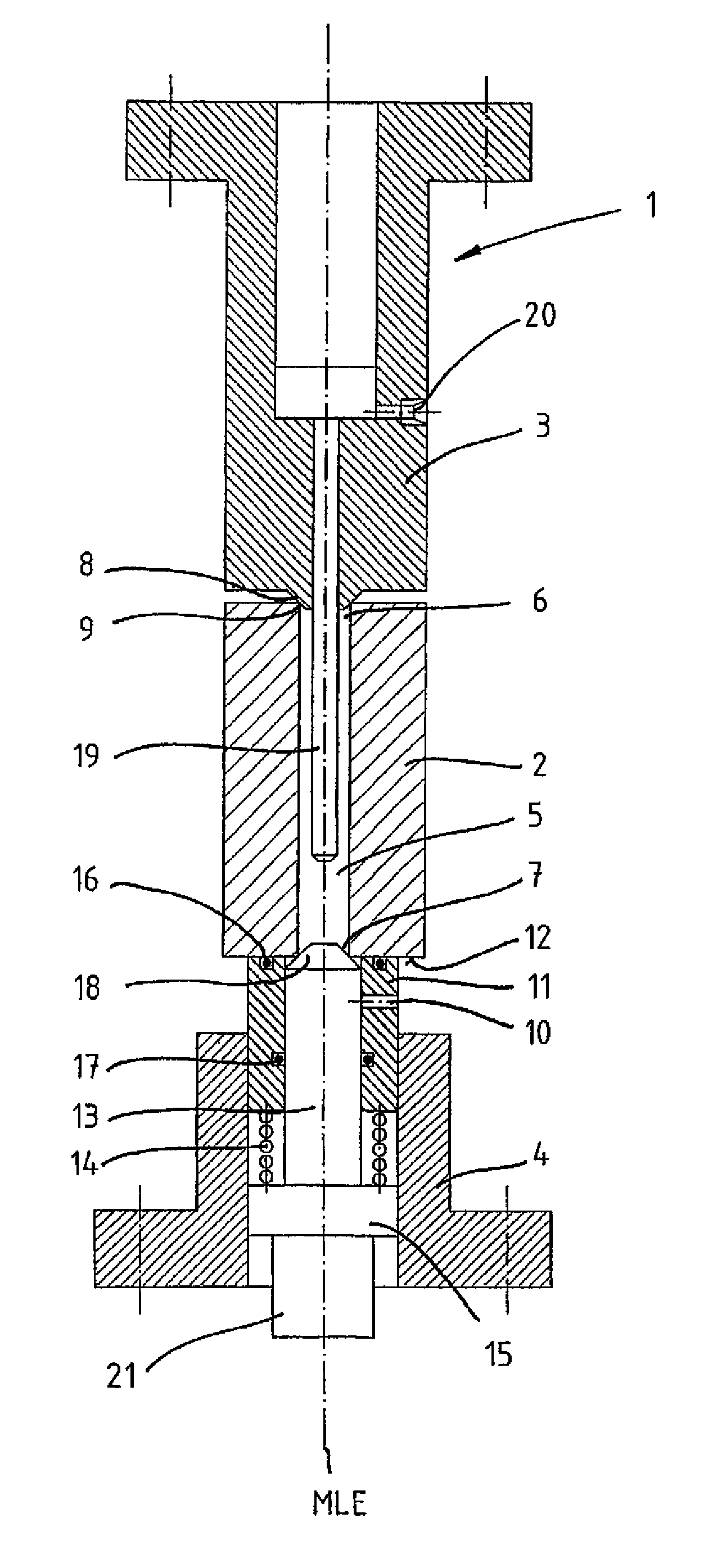

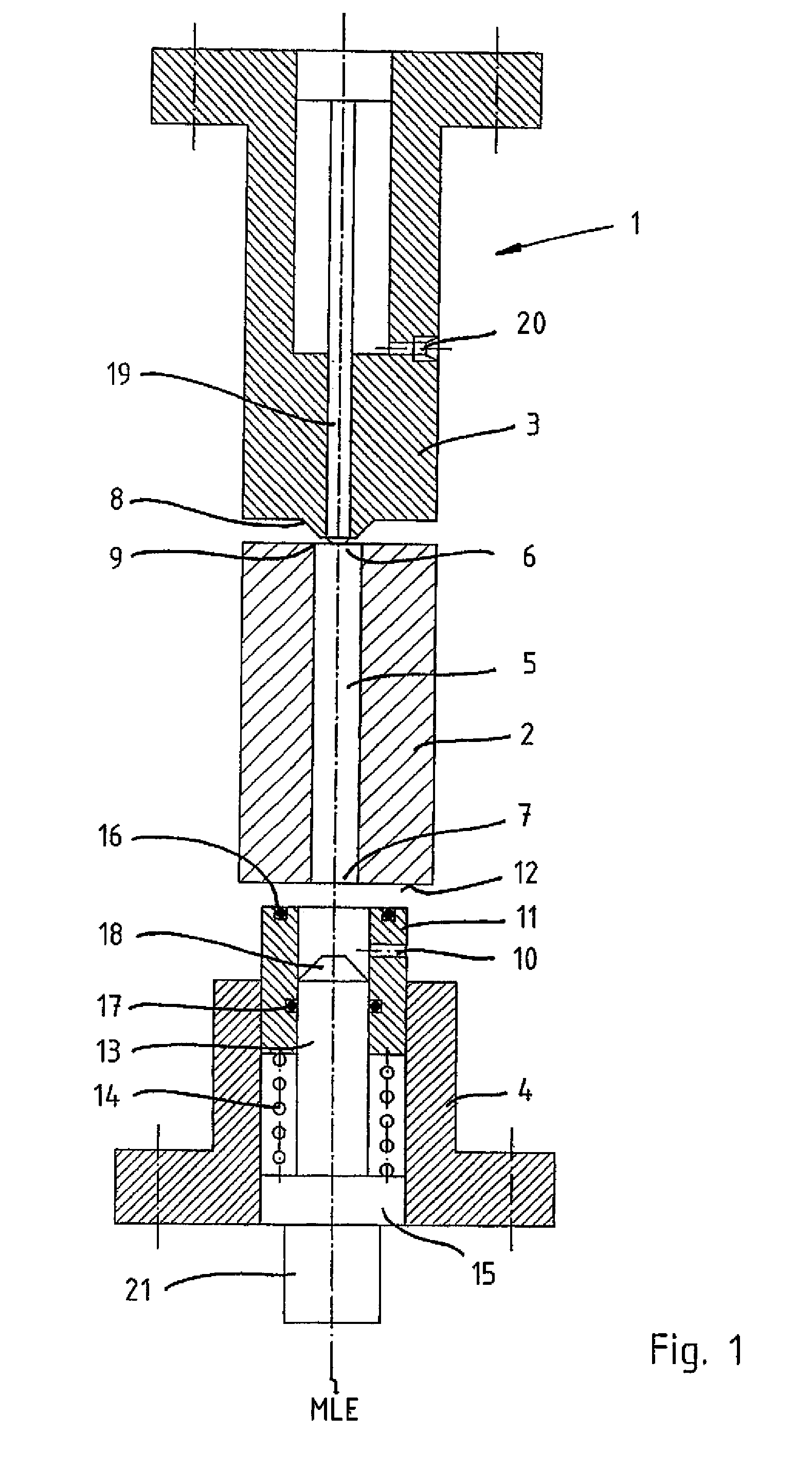

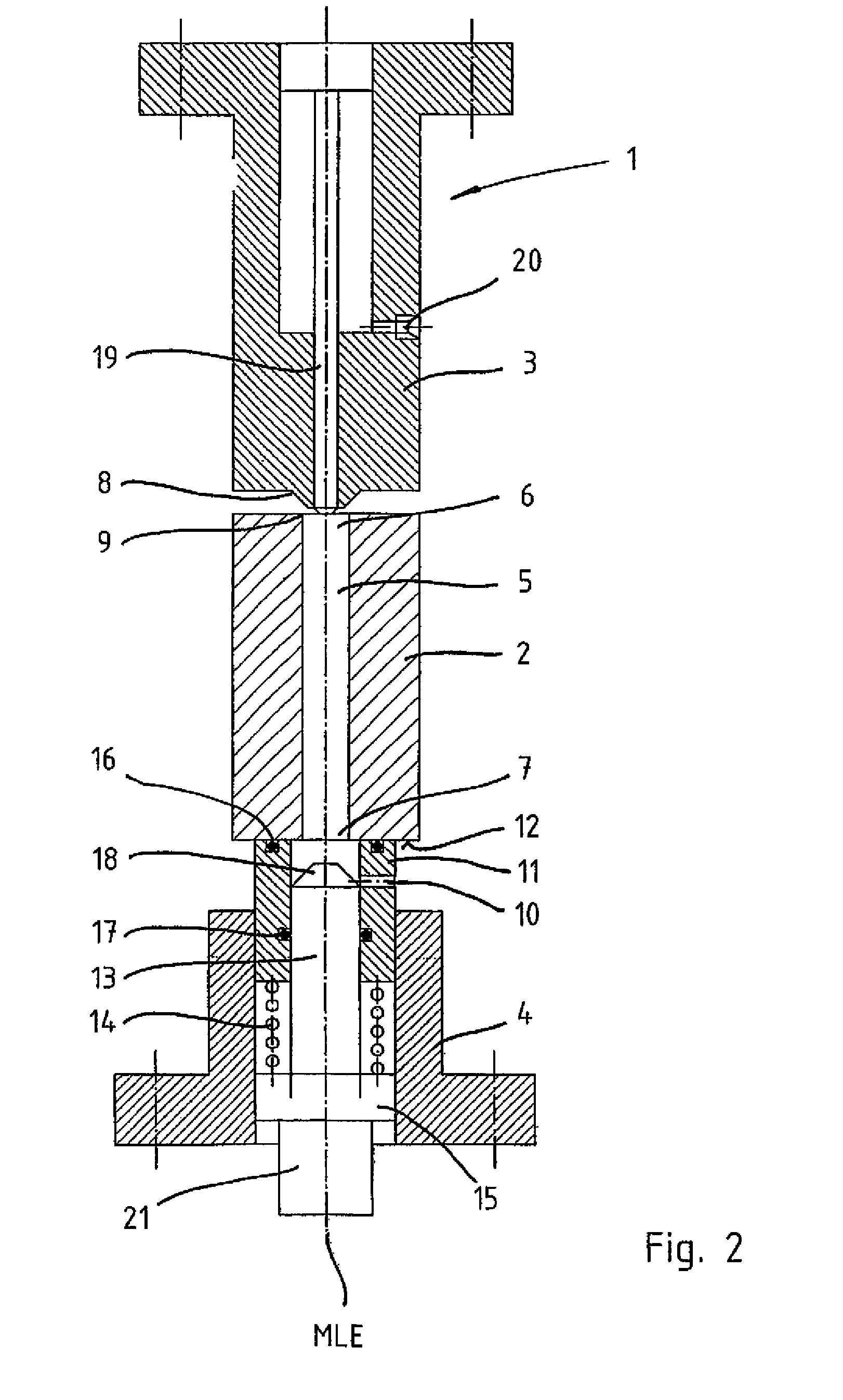

Apparatus for the section-wise autofrettage of gun barrels

InactiveUS6931776B2Sealing effectReduce the pressure rangeWeapon componentsLaunching weaponsEngineeringHigh pressure

An apparatus for the section-wise autofrettage of gun barrels (22) by a hydraulic pressure generated inside the barrel. The apparatus (1, 1′, 1″) comprises a mandrel-shaped insert (2, 2′, 2″) inserted into the barrel (22) from the breech opening. A first sealing device (3) is disposed at one end of the insert (2, 2′, 2″), and has a seal packet (5) disposed on a seal seat (4) of the insert (2, 2′, 2″). The seal seat (4) is limited at the front by a threaded sleeve (7) screwed onto the insert (2, 2′, 2″), and an annular intermediate part (8) adjoining the threaded sleeve (7) at the rear. The seal packet (5) includes at least one O-ring (10) held by a shoulder (9) of the mandrel-shaped insert (2, 2′, 2″), and a high-pressure seal (15) formed by two partial rings (13, 14) that are connected to one another by a conical contact surface (16).

Owner:RHEINMETALL W & M GMBH

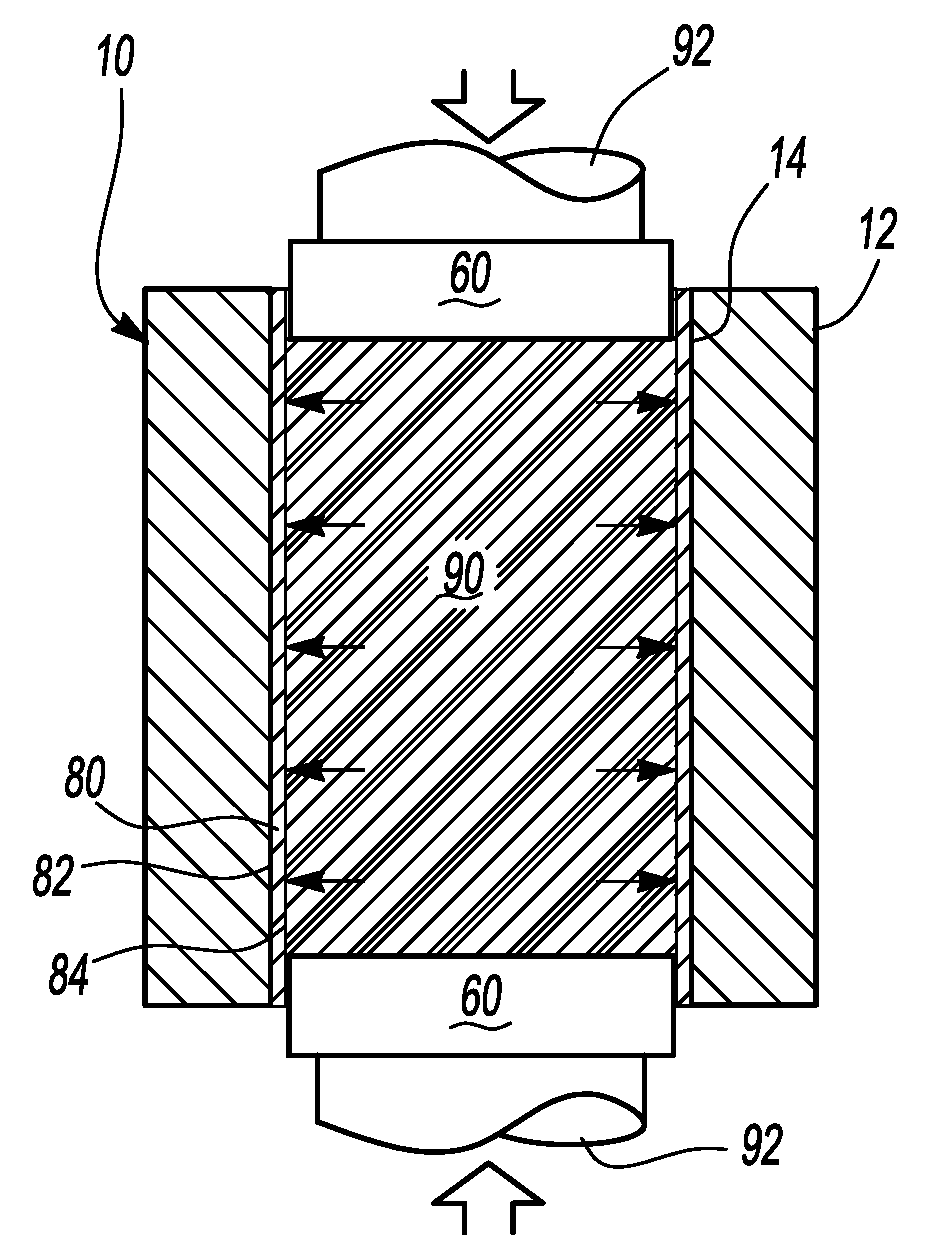

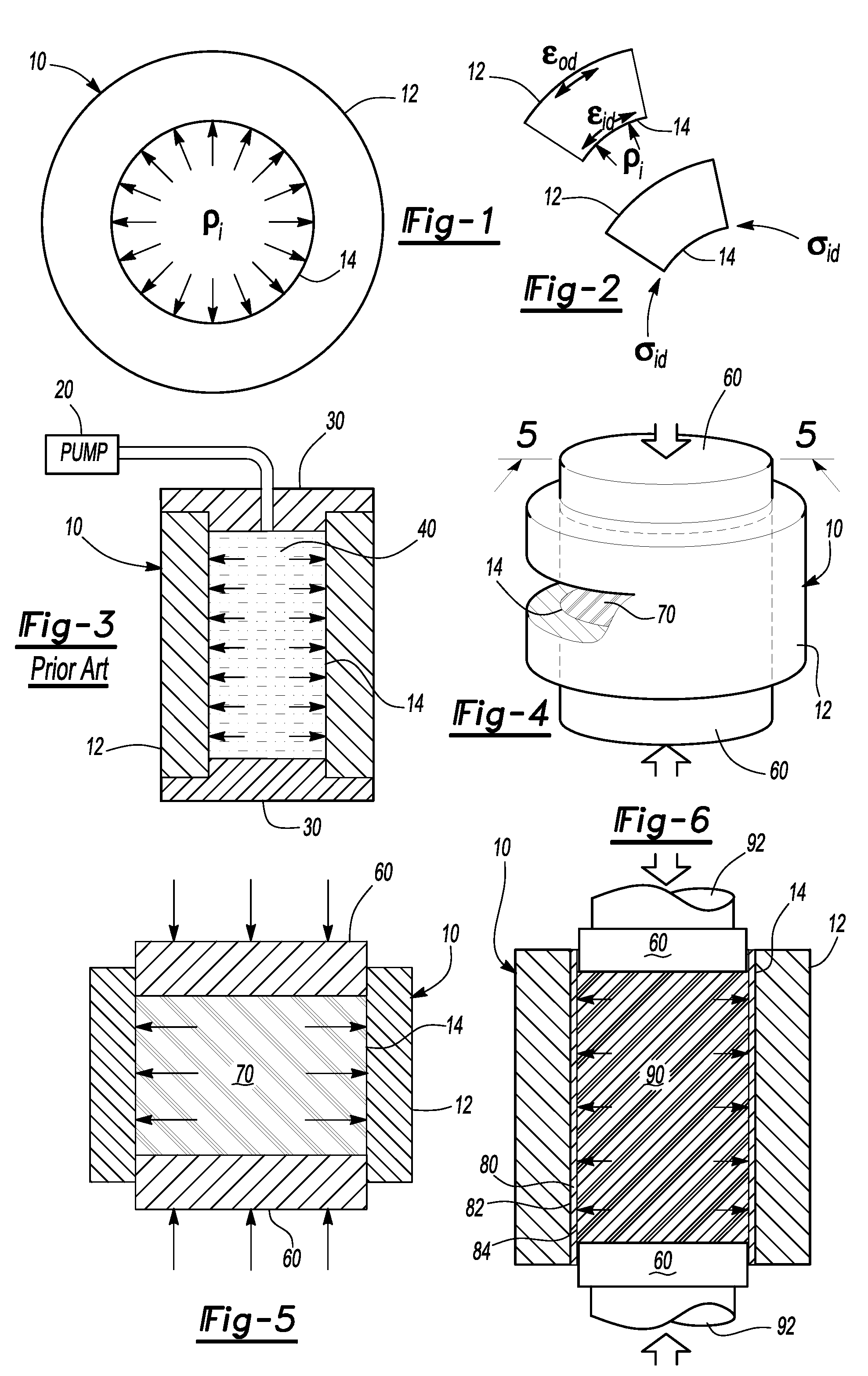

Compressed Elastomer Process for Autofrettage and Lining Tubes

An inventive process is provided for creating residual compressive stress at a surface of a structure without resort to custom mandrels and dangerous high-pressure fluids. The inventive process yields autofrettage of a structure such as a tube, gun barrel and the like, the structure having an outer surface and an inner surface.

Owner:ARMY US SEC THE THE

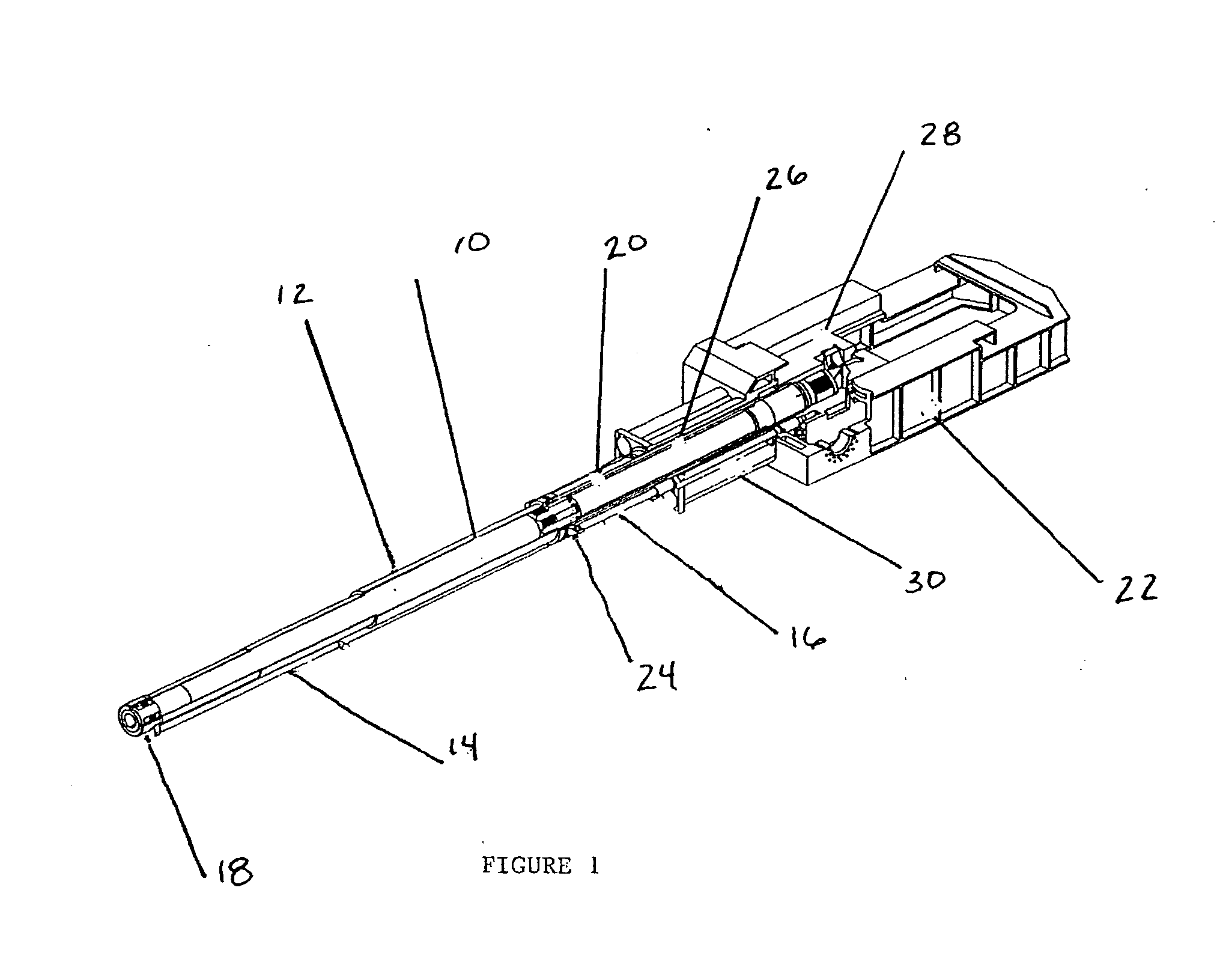

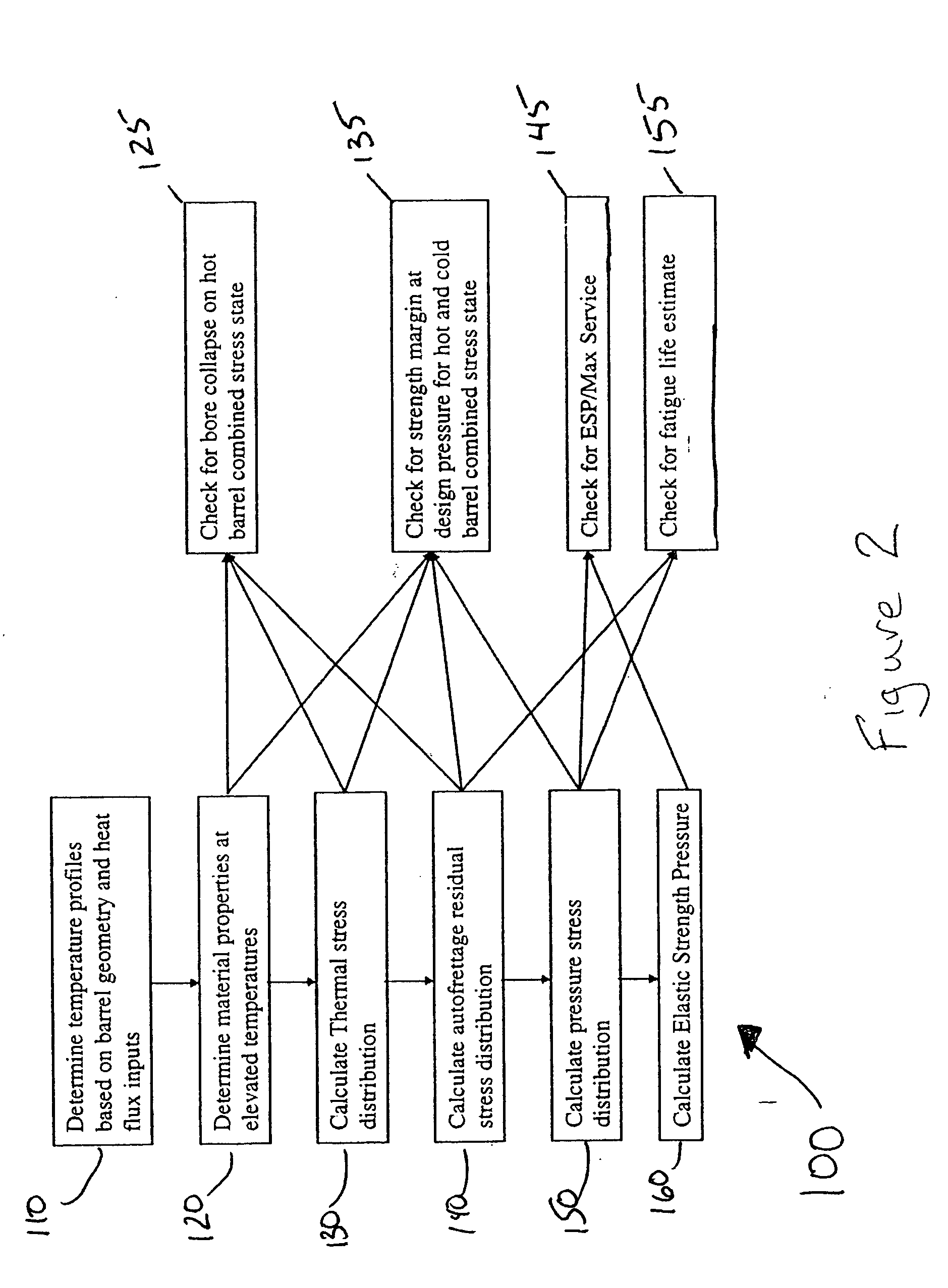

Method for gun barrel manufacture using tailored autofrettage mandrels

InactiveUS20050066801A1Acceptable stress profileVentillation systemsFurnace typesAutofrettageProcess engineering

A method of manufacturing a monobloc gun barrel by calculating an optimal residual stress profile and then applying tailored autofrettage mandrels which are mechanically pressed down the bore of a large caliber barrel, the mandrel size optimized to create a residual stress distribution on the interior of the bore within the design constraints imposed by the worst-case heat flux scenario.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

Supercritical heat-insulated oil pipe production method

ActiveCN101187292AEasy to usePrevent "hydrogen explosion"Drilling rodsMaterial analysis by electric/magnetic meansX-rayShielding gas

The invention relates to a manufacturing method in the oil pipe processing field, in particular to a process for preparation of a supercritical heat insulated oil tube. The technical proposal is that the invention comprises material selecting and preprocessing of an inner tube and an outer tube, welding wires for nesting and welding are flux-cored wires, protective gas for welding is the mixture gas of argon gas and argon gas, autofrettage is done after being welded and heat preservation for a certain time, the control thermal conductivity factor of X-ray flaw on-line detection, heating vaccum pumping, vacuum blocking welding, and magnaflux inspection are 0.01W / m DEG C to 0.04 W / m DEG C, and normal temperature anti-inner pressure test pressure of screw cutting on two ends, coating sealing grease for mounting sealing ring, an upper coupling, a path, and an integral test are more than 40MPa, a normal temperature anti-external crowded test pressure is more than 45MPa, and the invention also comprises an upper screw thread protector. Modification and tackling of the invention are from material selecting and technological condition to improve performance indicating of the insulated oil tube, the invention can satisfy steam injection pressure 26MPa, steam injection temperature 400 DEG C, the downhole depth can achieve a behavior with 2300m through process combination.

Owner:淄博孚瑞特热能科技有限公司

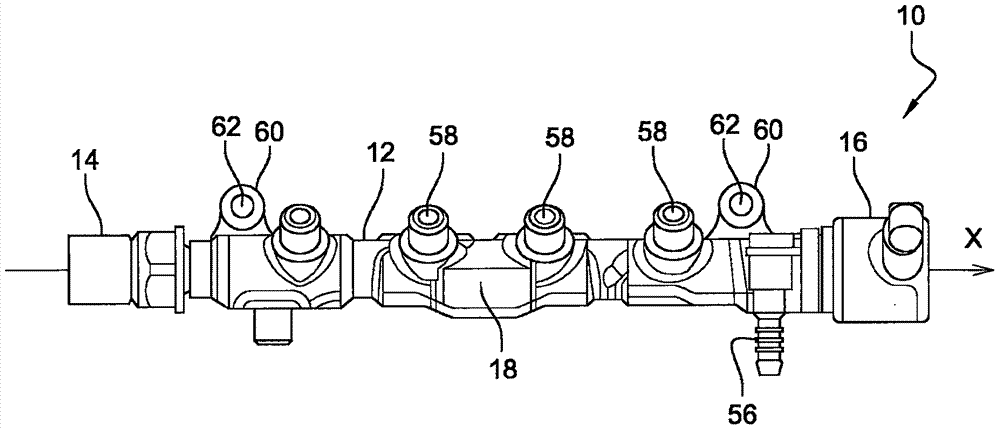

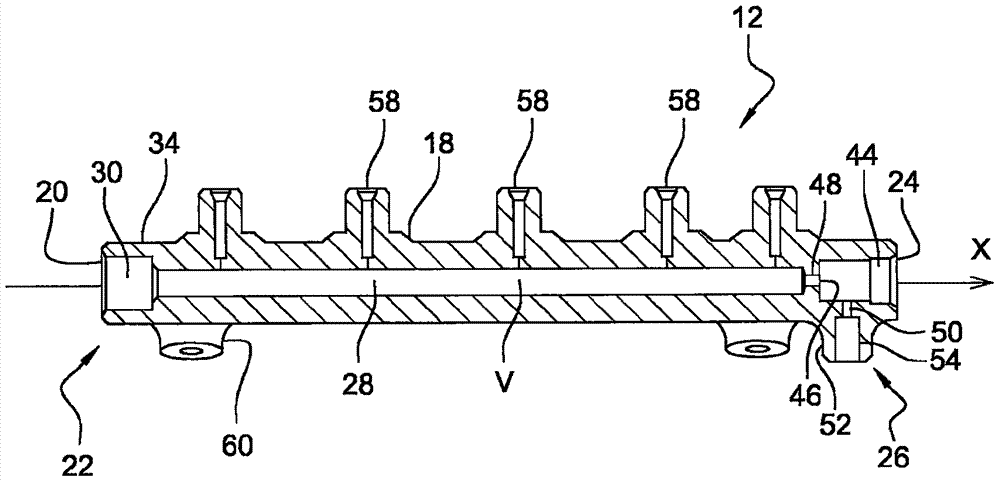

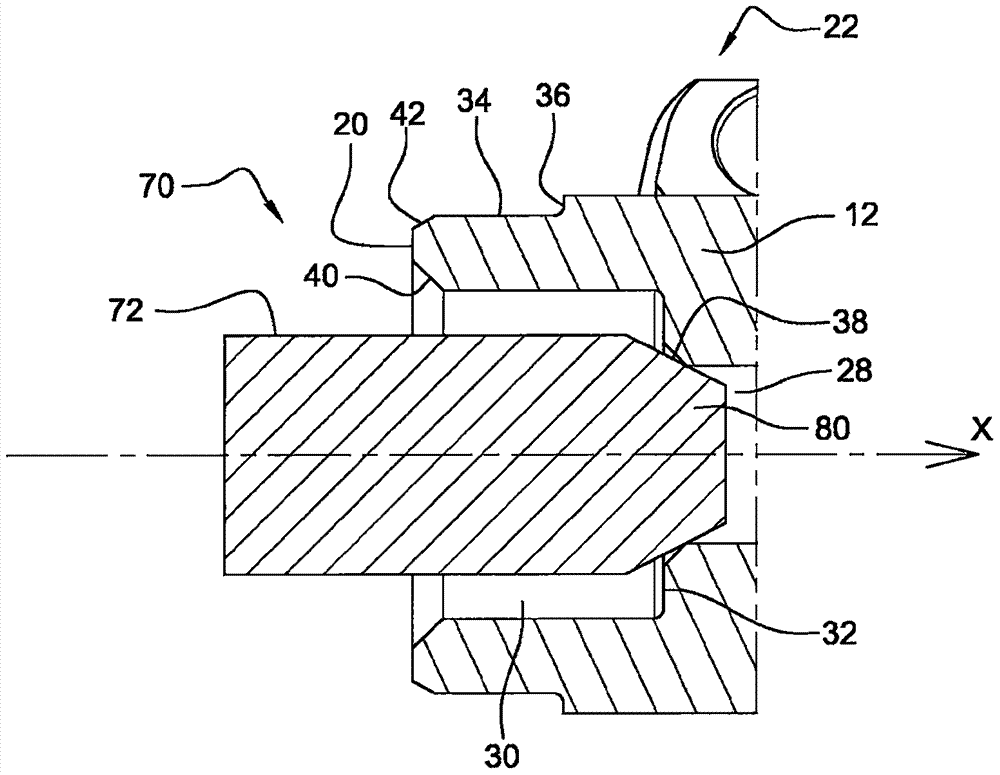

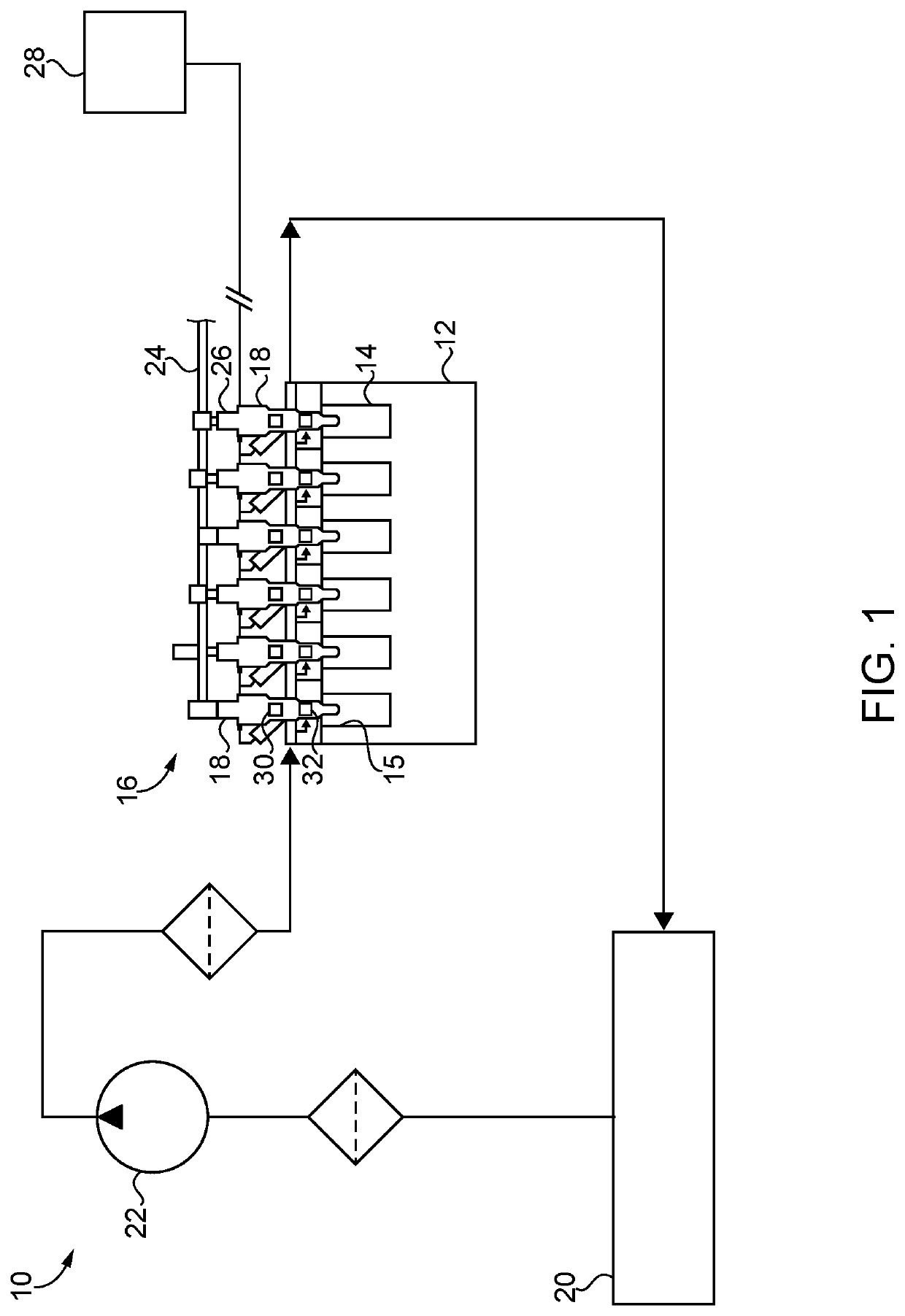

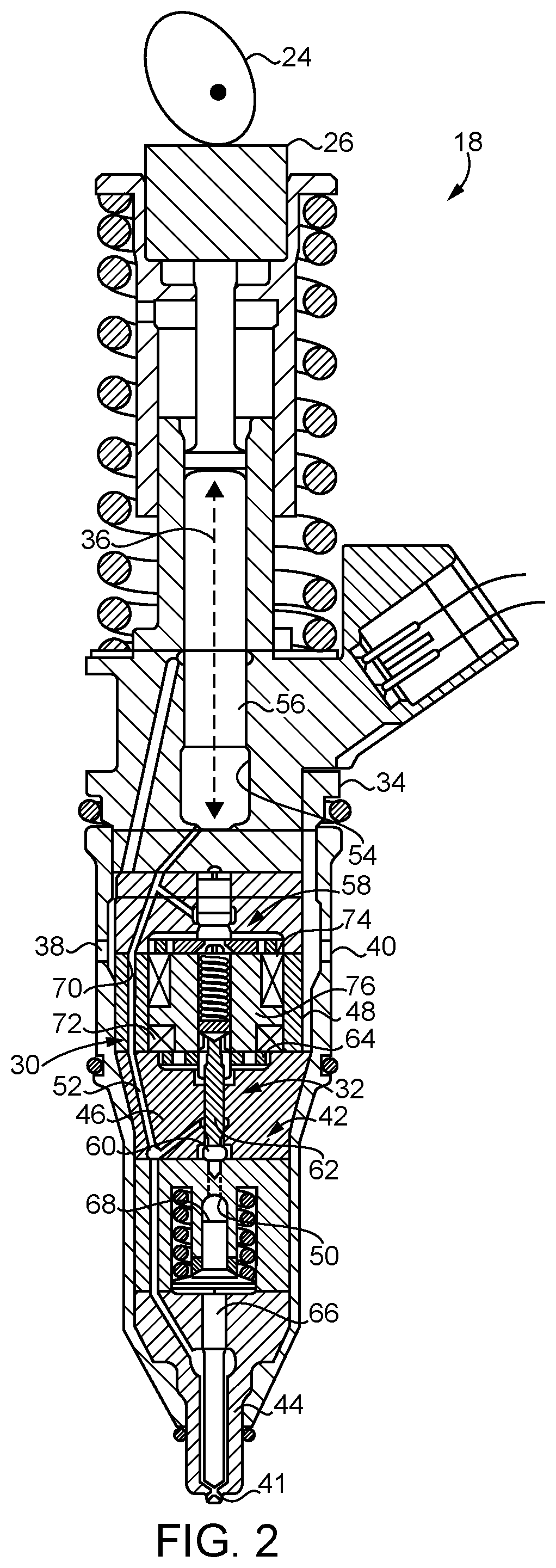

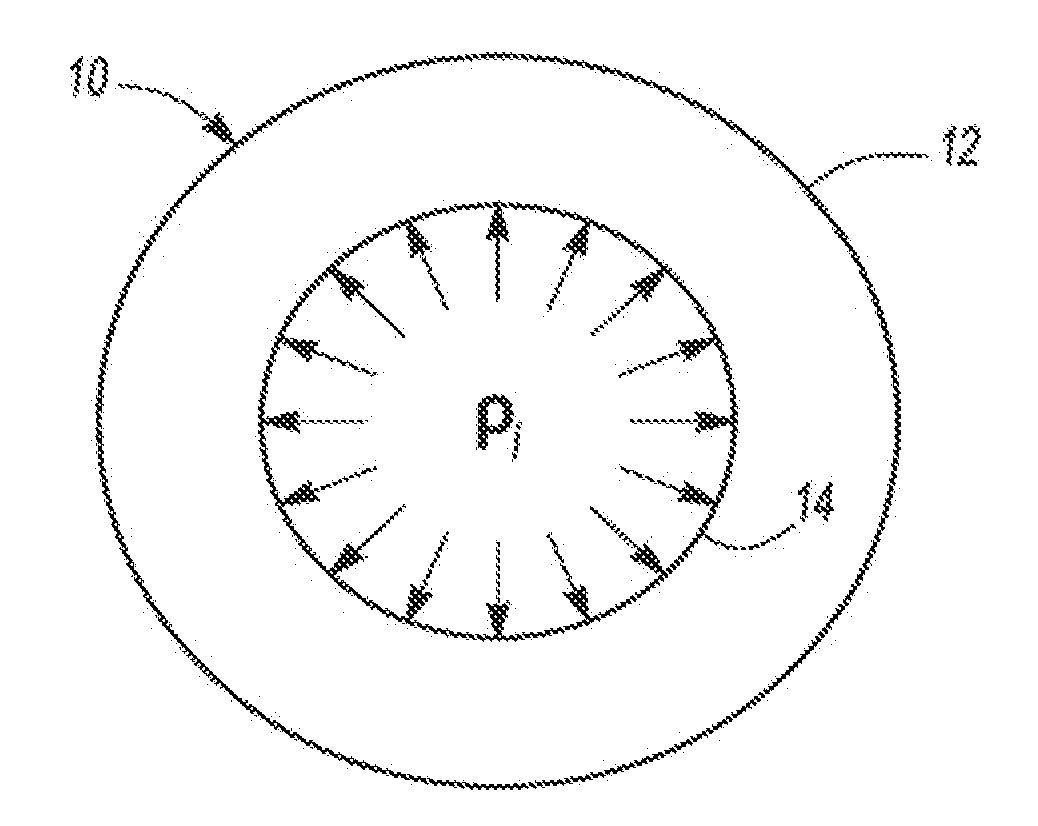

Method to manufacture a common rail

The invention discloses a method to manufacture a common rail. The method for manufacturing a common rail (12) adapted to be arranged in a fuel injection system is disclosed, the common rail (12) having a body (18) provided with a bore (28) defining an internal volume (V), said body (18) extending along a main axis (X) from a first extremity (22) having a first threaded female recess (30) to, a second extremity (26) having a second threaded female recess (44), the bore (28) opening at both ends in one of the recesses (30, 44), the method (100) comprising the steps of a first autofrettage step (130) of said bore (28), an autofrettage fluid (AF) being pressurized to a first pressure (PI) in the bore (28) during this first step (130) and, second autofrettage step (140) for treating the first female threaded recess (30), the autofrettage fluid (AF) being pressurized to a second pressure (P2) in the first recess (30) during this second step (140).

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

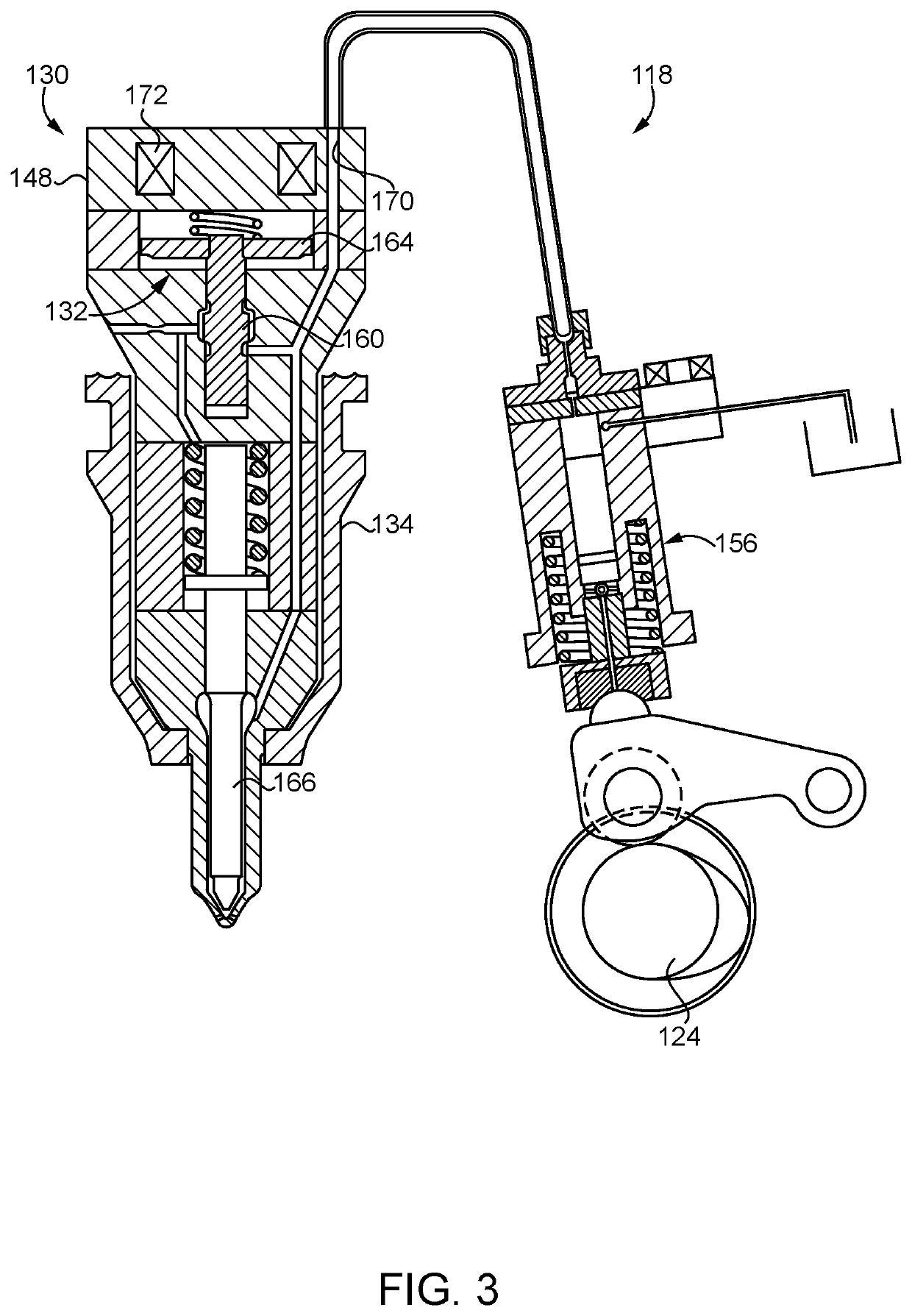

Fuel injector having residually stressed solenoid housing for improved pressure capapility

A fuel injector includes an injector body, and a stack within the injector body, and having a nozzle supply passage therein. The stack includes a solenoid assembly having a solenoid housing piece with a fuel bore formed therein that includes a segment of the nozzle supply passage. The solenoid housing piece includes a solenoid housing material in a base state, and a solenoid housing material in a residual compressive stressed state, with the fuel bore being formed by the solenoid housing material in the residual compressive stressed state. Residual stresses may be imparted by ballizing, nitriding, carburizing, autofrettage, or still another technique.

Owner:CATERPILLAR INC

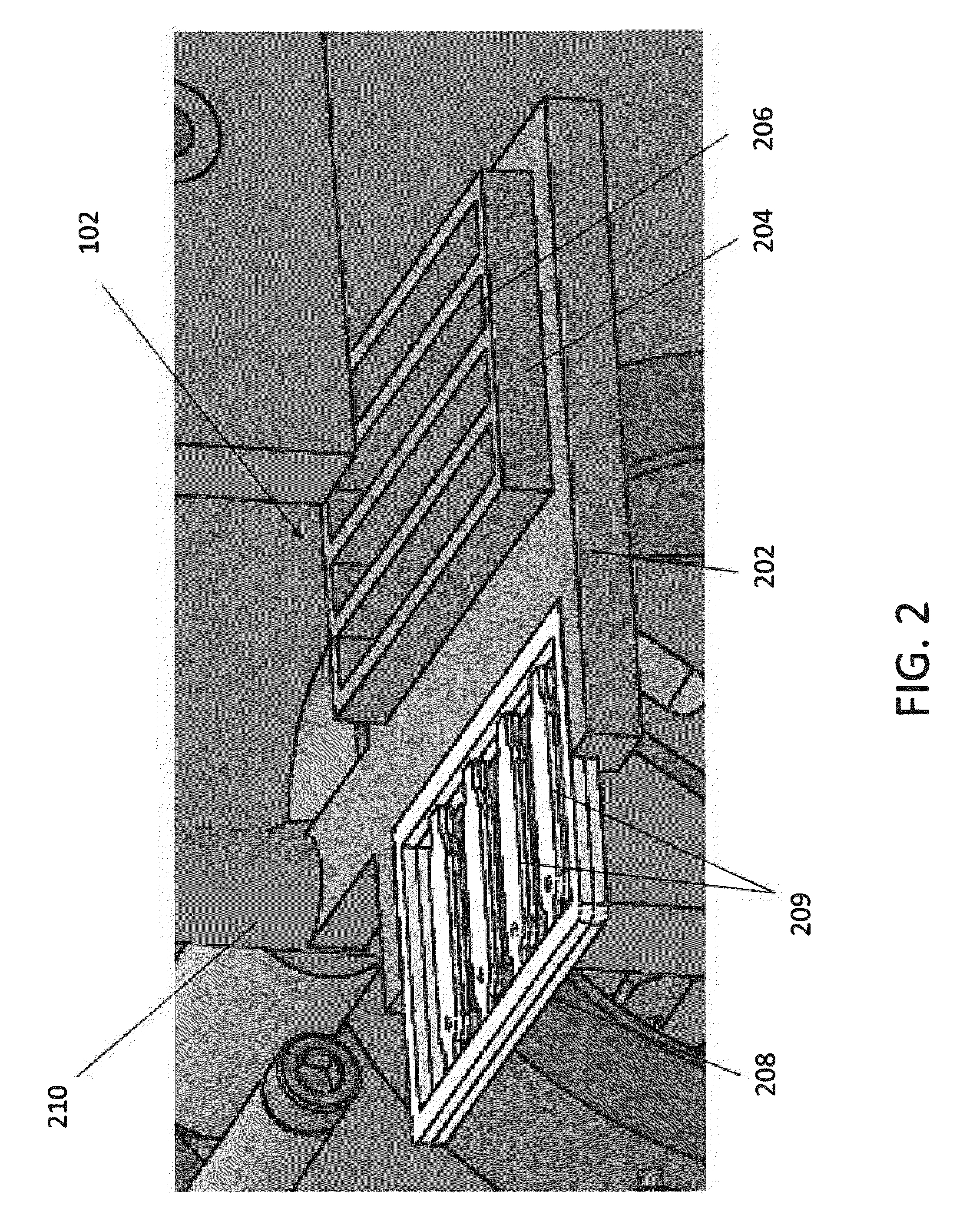

Automated vitrification device

ActiveUS20140335555A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiological pumpVitrification

The present application relates to devices for the vitrification of biological samples, including embryos, oocytes and biological tissues. Suitably, the devices are automated devices which require little if any operator intervention or sample handling, thereby reducing contamination, improving success rates and increasing efficiency. Also provided are methods of vitrifying a biological sample, suitably using the disclosed devices.

Owner:UNIVERSITY OF KANSAS

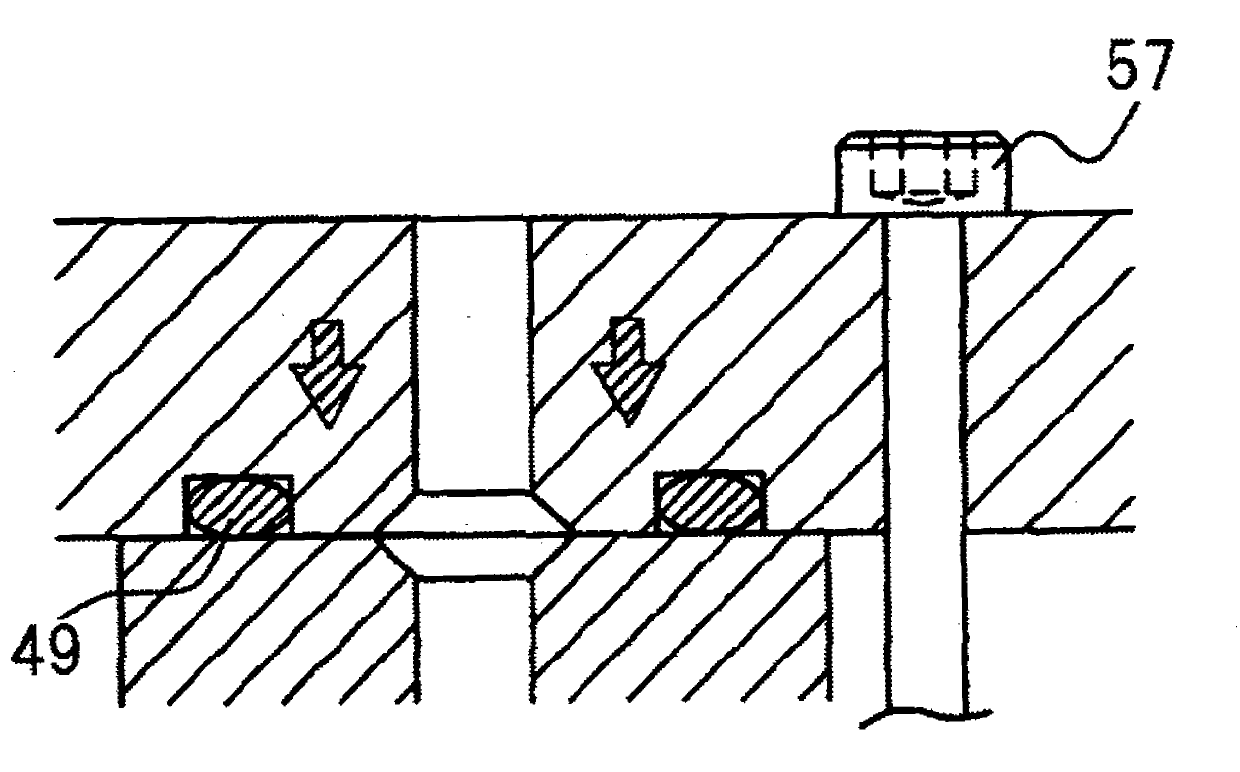

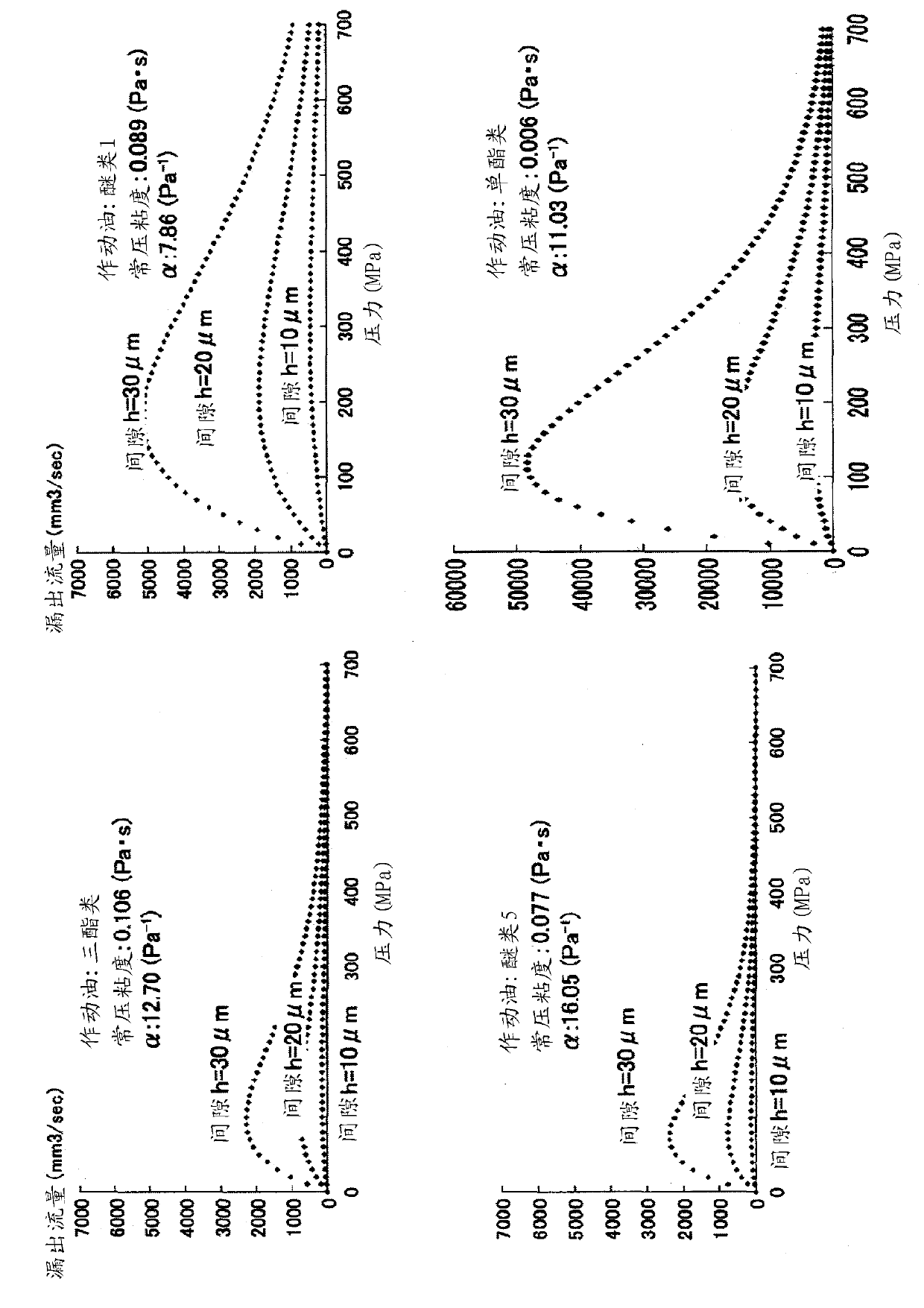

Autofrettage machining device

InactiveCN103958085AFast feedingMachines/enginesStress reducing fuel injectionCountermeasureEngineering

Provided is a solution to various limitations caused by product shape and the like. An autofrettage machining device characterized in comprising: a workpiece that is sealed off except for the workpiece end opening and in which a pressurized chamber is filled with a hydraulic oil via the workpiece end opening; a jig capable of being attached and detached from the workpiece, having an internal direct flow channel, and in which the direct flow channel is in communication without leakage with the workpiece end opening via a seal part; a piston for forming a gap having a predetermined average gap size with the inner wall of the direct flow channel provided inside the jig; and a pressurizing unit for driving the piston.

Owner:DENSO CORP

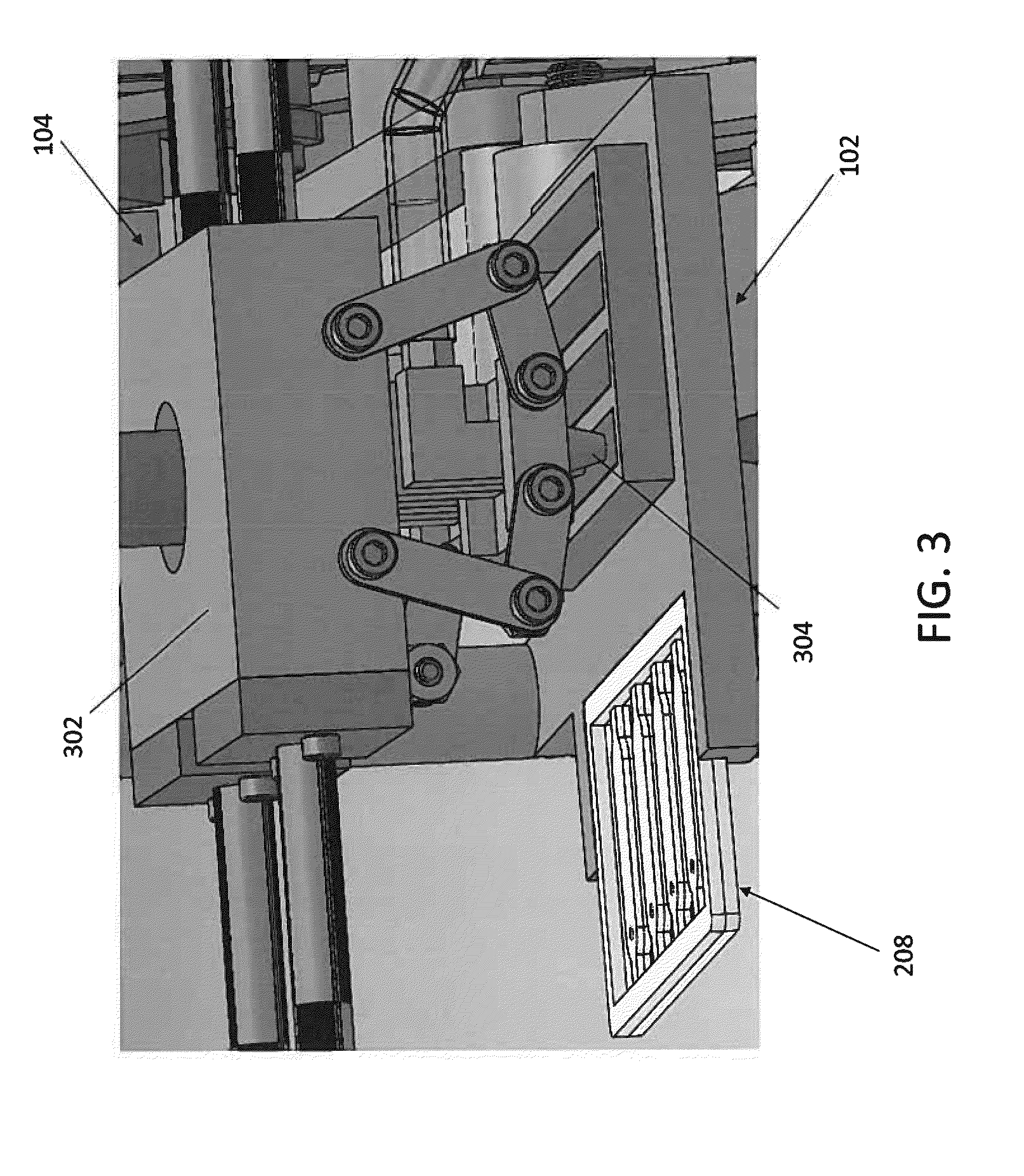

Automated vitrification device

The present application relates to devices for the vitrification of biological samples, including embryos, oocytes and biological tissues. Suitably, the devices are automated devices which require little if any operator intervention or sample handling, thereby reducing contamination, improving success rates and increasing efficiency. Also provided are methods of vitrifying a biological sample, suitably using the disclosed devices.

Owner:UNIVERSITY OF KANSAS

System and methods for automated vitrification of biological materials

ActiveUS9723831B2Maximizing measureSave processing timeBioreactor/fermenter combinationsBiological substance pretreatmentsVitrificationCryopreservation

Owner:THE GOVERNING COUNCIL OF THE UNIV OF TORONTO

Common rail for diesel engines

InactiveUS20060260124A1High compressive residual stressIncreased durabilityMetal-working apparatusFuel injection apparatusStress concentrationCommon rail

A common rail for a diesel engine has a main pipe rail with an axial flow passage. Branch holes are made in the main pipe rail and communicate with the axial flow passage. The main pipe rail is worked to decrease stress concentration near the branch holes. The whole inner peripheral surface of the main pipe rail and the branch holes then is subjected to autofrettage processing to generate a compressive residual stress on the entire inner peripheral surface of the main pipe rail and the branch holes for increasing fatigue strength.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Common rail for diesel engine

InactiveCN1316159CExpected residual stressIncreased durabilityFuel injection apparatusMachines/enginesInternal pressureStress concentration

A common rail, in which a flow passage in a main pipe rail and portions of branch holes are improved in durability while the portions of branch holes are enhanced in fatigue strength for inner pressures, is provided. A common rail for diesel engines, comprising branch holes made in a main pipe rail having therein a flow passage in an axial direction, to be communicated to the flow passage, wherein stress concentration in the vicinity of the branch holes is relaxed, and then a whole inner peripheral surface of the main pipe rail and the branch holes are subjected to autofrettage processing.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Common-rail injection system for diesel engine

A common-rail injection system is provided for a diesel engine and has excellent internal pressure fatigue resisting characteristics, vibrational fatigue resisting characteristics and cavitation resisting property and sheet face flawing resisting property, and can be made thin and light in weight. A main pipe rail is manufactured by transformation induced plastic type strength steel. After the main pipe rail is processed, residual austenite is generated by heat treatment, and the reduction processing of stress concentration of a branch hole and a main pipe rail side flow passage crossing portion is performed. Further, it is preferable that an induced plastic transformation is generated on the inner surface of the main pipe rail by autofrettage processing, and compression residual stress is left.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

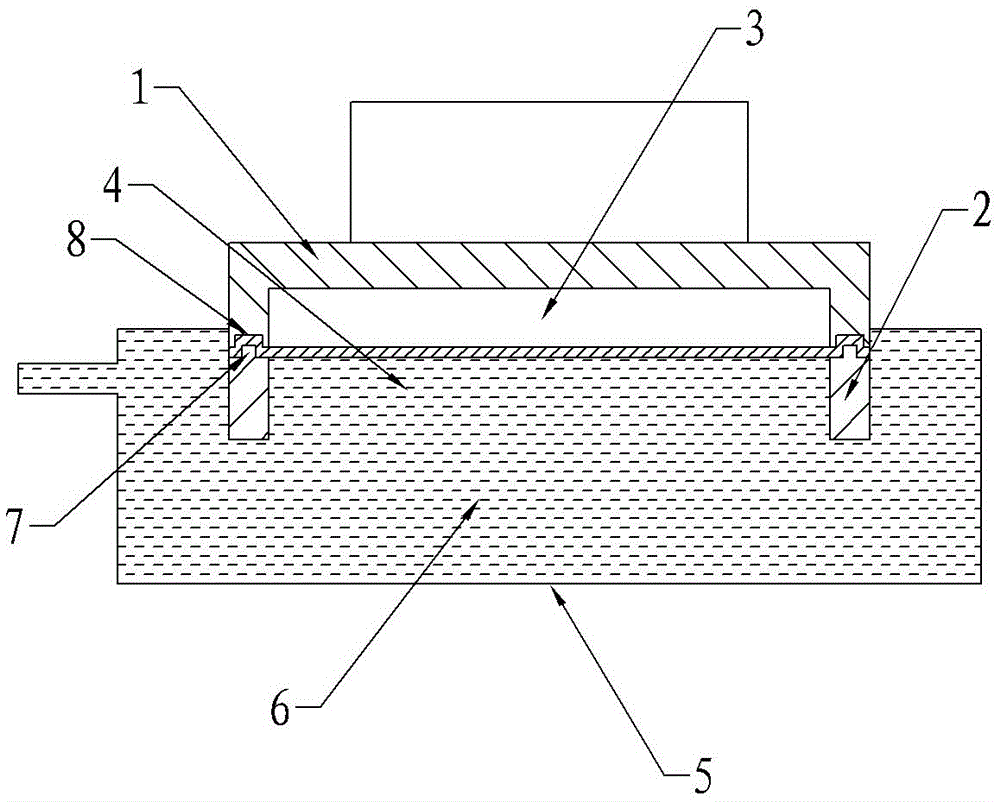

Novel liquid-expansion molding device and liquid-expansion molding process

The invention discloses a novel liquid-expansion molding device and a liquid-expansion molding process. The novel liquid-expansion molding device comprises an autofrettage pressure mould and a floating pressure mould. The autofrettage pressure mould is provided with a molding cavity; a through hole matched with the molding cavity is formed in the middle of the floating pressure mould which is mounted in a liquid-expansion pressure cavity; the edges of a plate to be molded are pressed by the adjoining plane of the floating pressure mould and the autofrettage pressure mould which is connected with a press machine; the liquid-expansion pressure cavity is connected with high-pressure liquid; in the molding process, the press machine is used for pressing and sealing the edges of the plate to be molded, and the high-pressure liquid is input into the liquid-expansion pressure cavity and acts on the plate to be molded, so that the plate to be molded deforms toward the molding cavity of the autofrettage pressure mould and is molded. The structures of the liquid-expansion molding moulds can achieve liquid-expansion molding of the plate, and the structure of the novel liquid-expansion molding device can also be conveniently used for liquid-expansion molding of the plate. The process is simple, requirements for the moulds are low, and the precision of molding can also be improved. Further, the structure can reduce the work load of the press machine, the work pressure of the press machine is reduced at the same time, and use requirements are lowered.

Owner:HONY MACHINERY CO LTD

Compressed Elastomer Process for Autofrettage and Lining Tubes

An inventive process is provided for creating residual compressive stress at a surface of a structure without resort to custom mandrels and dangerous high-pressure fluids. The inventive process yields autofrettage of a structure such as a tube, gun barrel and the like, the structure having an outer surface and an inner surface.

Owner:US SEC THE ARMY THE

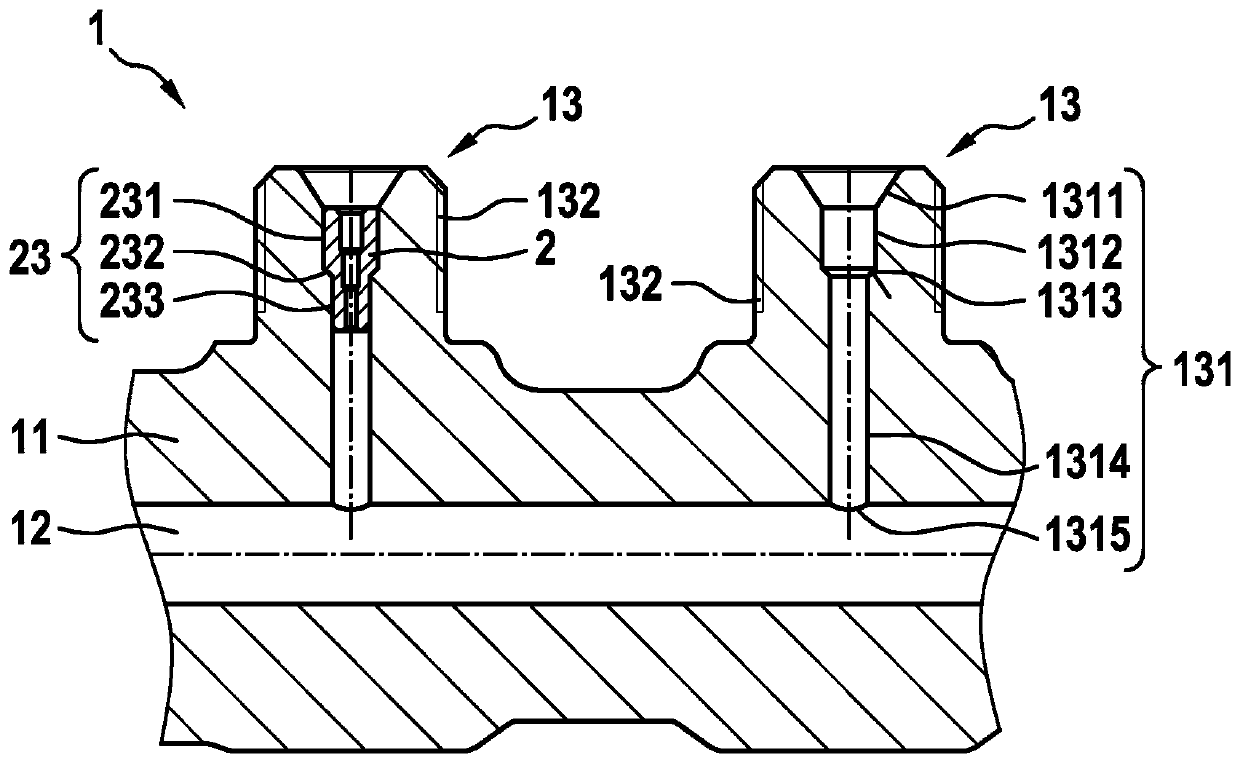

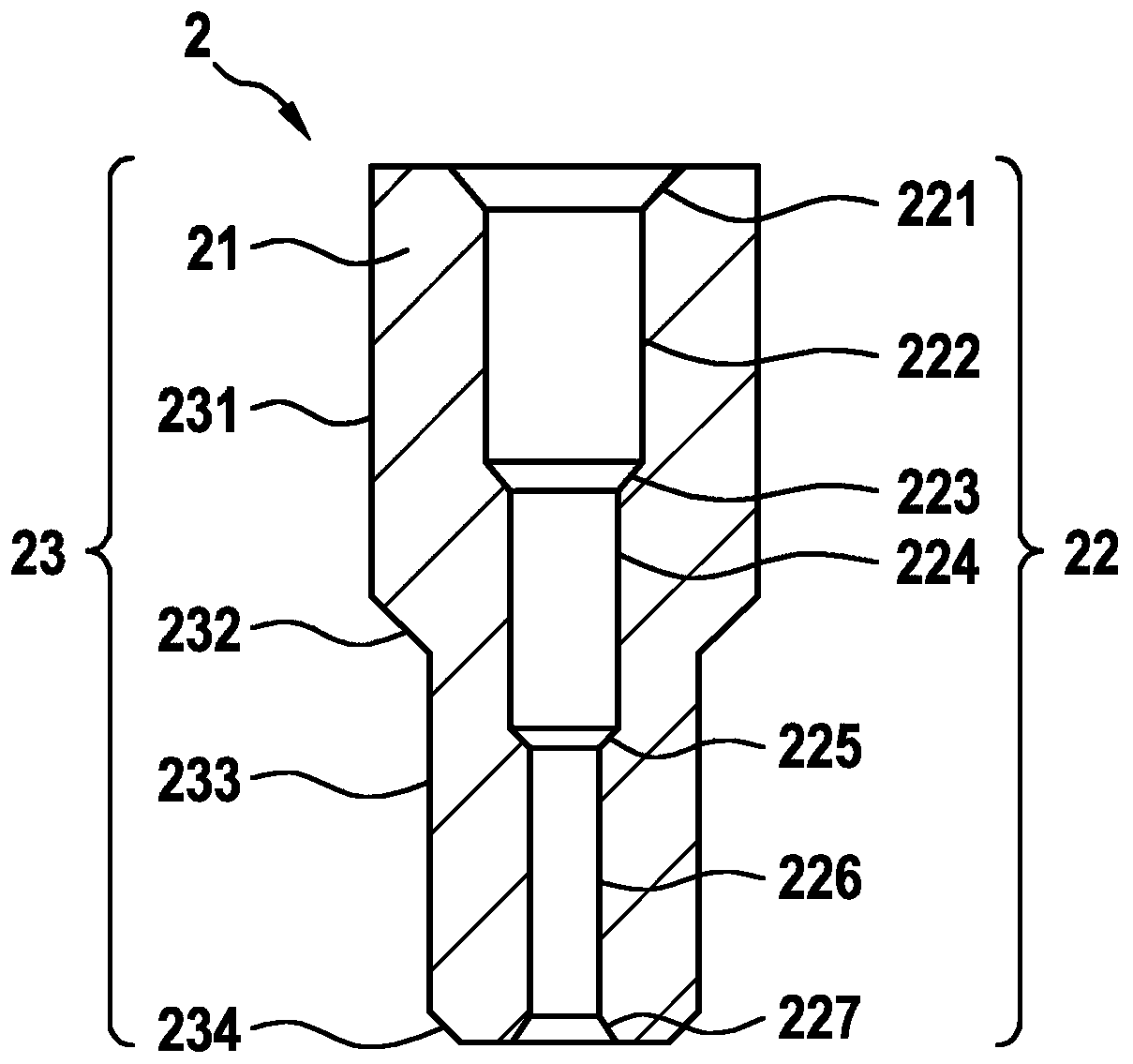

High-pressure accumulator of a high-pressure fuel injection system

ActiveCN110234865AEasy to manufactureEnsure fatigue propertiesMachines/enginesSpecial fuel injection apparatusEngineeringHigh pressure

The invention relates to a high-pressure accumulator for a high-pressure injection system made of a cylindrical body (11), which delimits a high-pressure chamber (12, 12a), and connection pieces (13,13a), which are provided with outlet passages (131, 131a) for a high-pressure liquid, said passages opening into the chamber (12, 12a), and each of which is provided with a throttle in order to weakenpressure waves generated by injectors connected downstream. Each of the connection pieces (13, 13a) has a passage (131, 131a) with a chamber (1312, 1312a) at the outlet, said chamber receiving an insert piece (2, 2a) which is provided with the throttle (22, 22a). The insert piece (2, 2a) is fixed in the chamber (1312, 1312a) in a force-fitting manner by an autofrettage process of the high-pressure accumulator.

Owner:ROBERT BOSCH GMBH

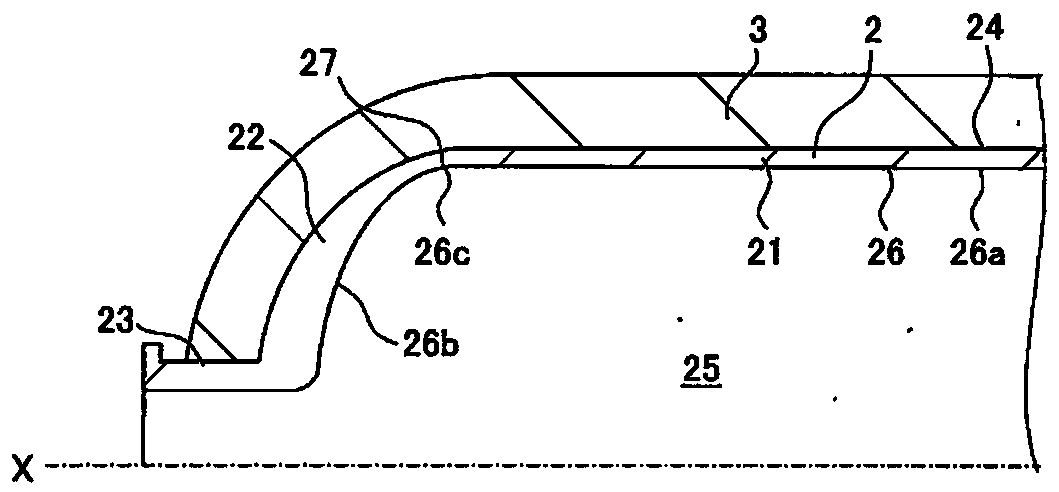

Manufacturing method for high pressure tank

InactiveCN110159912AReduce fatigue strengthVessel manufacturingVessel geometry/arrangement/sizeInternal pressureFiber

A manufacturing method for a high pressure tank includes preparing a liner including a cylindrical body portion and a pair of side end portions, forming a reinforcing layer by winding fiber-reinforcedresin around an outer peripheral surface of the liner, carrying out shot peening by shooting a shot material towards an inner periphery region of a boundary between the body portion and each of the side end portions, and carrying out autofrettage after the reinforcing layer is formed and the shot peening is carried out. The autofrettage is carried out by applying internal pressure to the liner such that the liner is plastically deformed and then eliminating the internal pressure such that compression stress is applied to the liner.

Owner:TOYOTA JIDOSHA KK

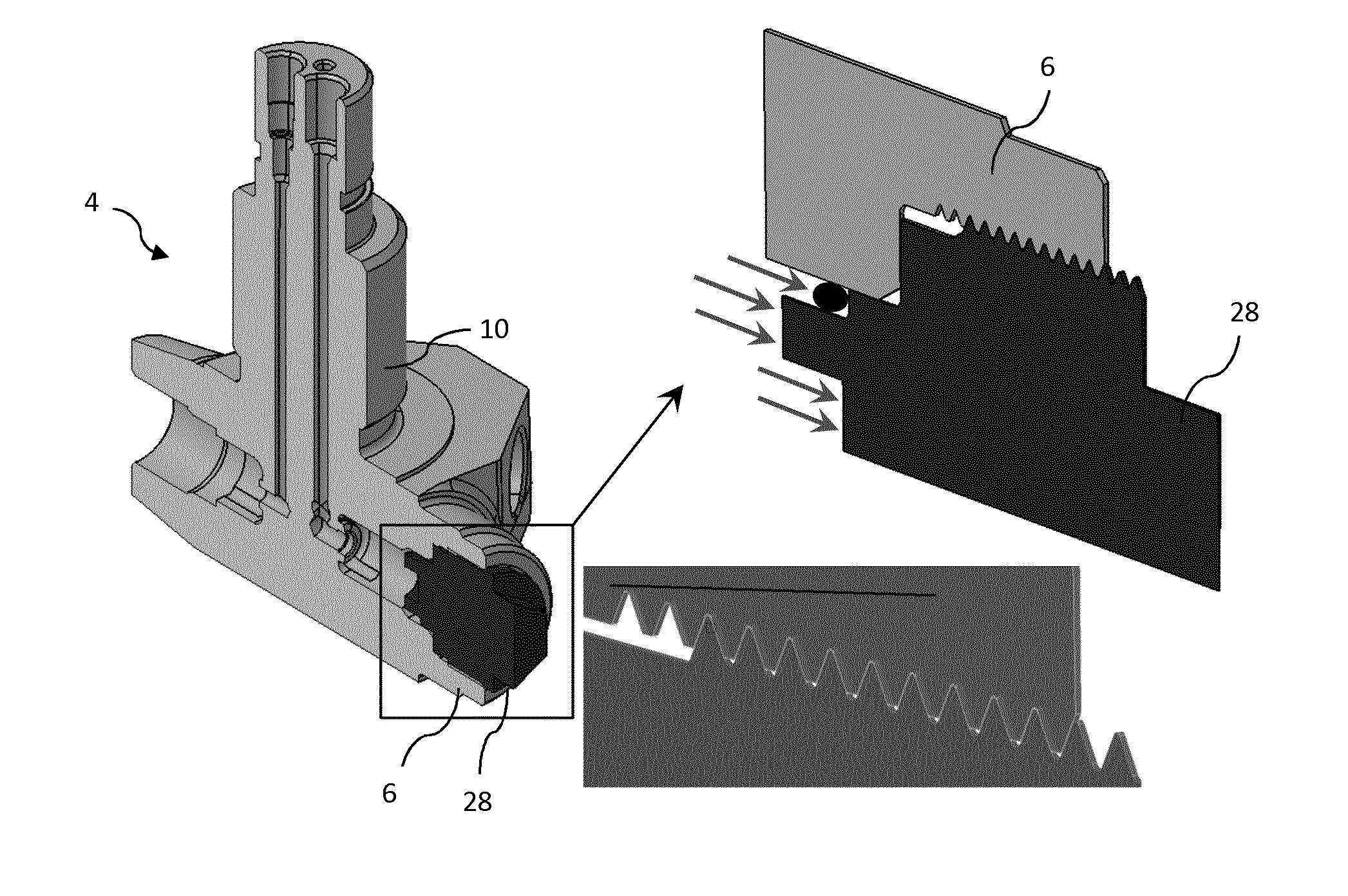

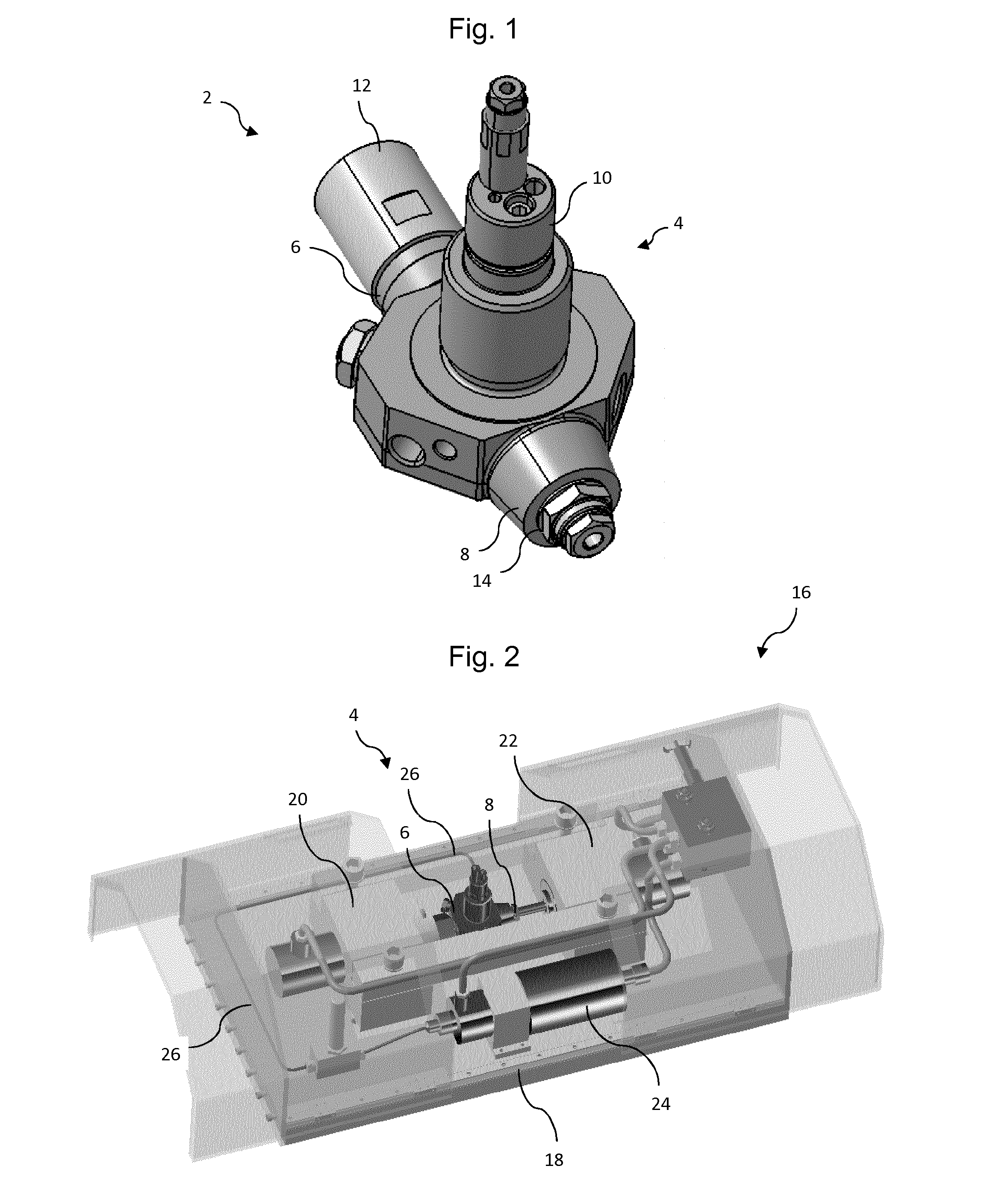

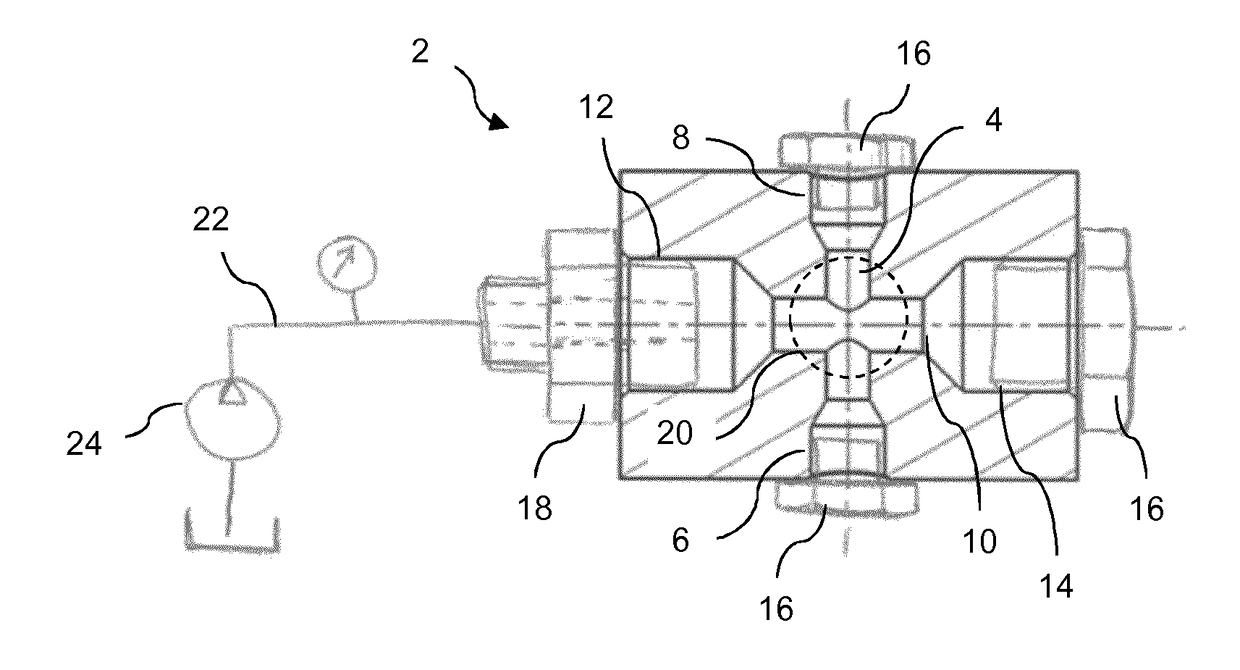

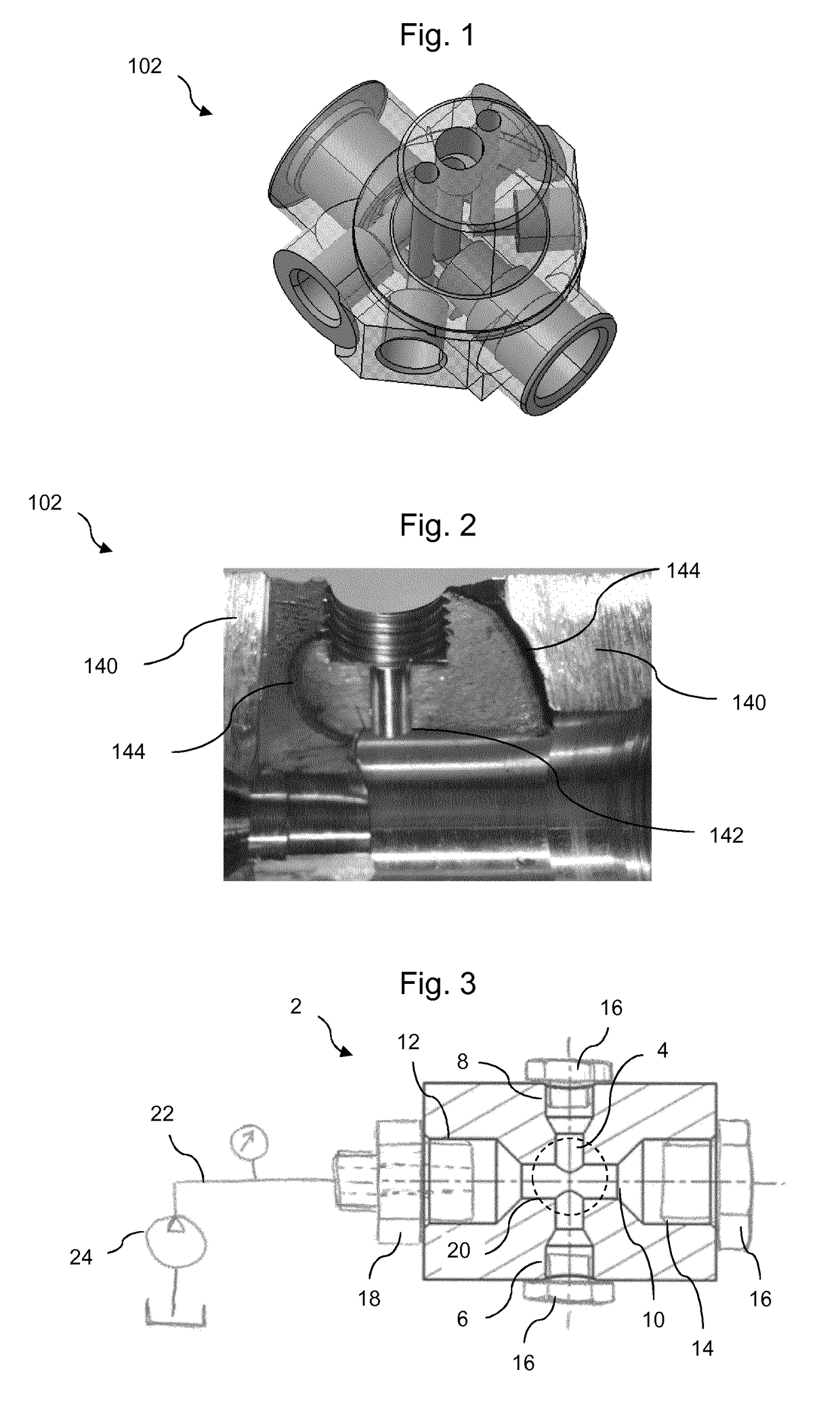

Metallic Body with Threaded Port Subject to Autofrettage

The invention is directed to a method for improving the mechanical behavior of a metallic body (4) comprising an internal volume for a fluid and at least one threaded connecting port (6, 8) to said internal volume, the method comprising a step of treatment by autofrettage of the internal volume by applying a pressure to a liquid inside said volume. The autofrettage step comprises closing the internal volume by screwing a plug (28) to each the at least one threaded connecting port (8), so that the thread(s) of said port(s) is / are also subject to the autofrettage treatment. The invention is also directed to a body (4) resulting from such a treatment, with compressive stresses at the root of one of the most carrying turns of the thread of each of the connecting ports. The compressive stresses improve the fatigue behavior of the body.

Owner:ROTAREX SA

Valve Body Treated by Autofrettage

ActiveUS20170240984A1Improves fatigue mechanical behaviorIncrease pressureMachines/enginesSpecial fuel injection apparatusEngineeringAutofrettage

The invention is directed to a method for improving the fatigue behavior of the body (2) of a gas valve, the body comprising at least two bores (4, 10) and at least one bore intersection (20) defining an internal volume; wherein the method comprises the following step: subjecting the internal volume to an autofrettage by applying a pressure of comprised between 100 MPa and 500 MPa by means of a liquid. 10. The invention is also directed to a gas valve body (2) comprising at least two bores (4, 10) and at least one bore intersection (20) defining an internal volume with an internal wall; wherein the internal wall is treated by autofrettage resulting in compressive stresses at the intersection or at least one of the intersections.

Owner:ROTAREX SA

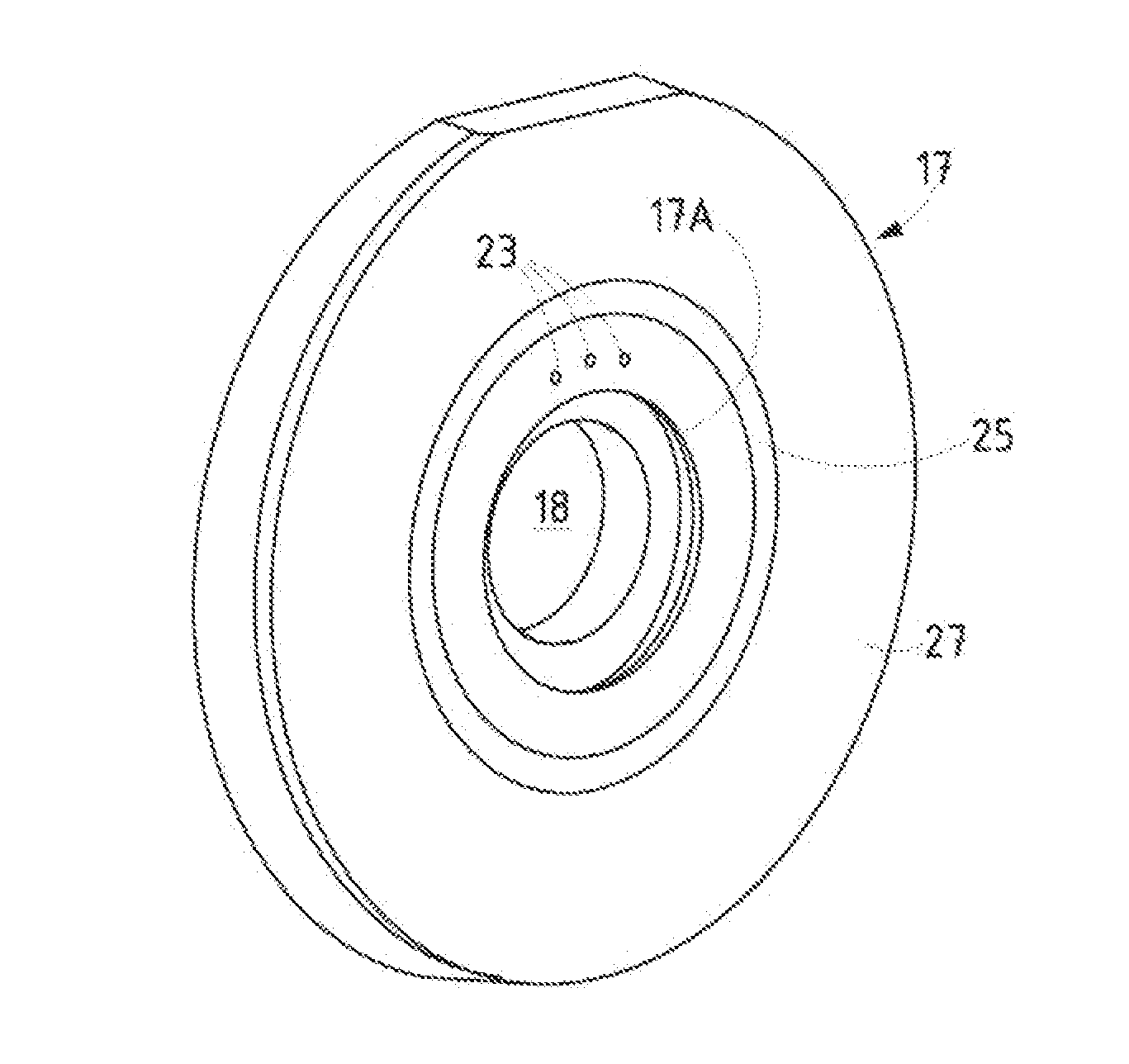

Packing cups manufacturing

A method of manufacturing a packing cup for a hyper-compressor is described. The method comprises the following steps:providing an inner disc (25), having opposed first front face (25X) and second front face (25Y), a central axial hole (18) and at least one lubrication-oil duct (23);autofrettaging the lubrication-oil duct (23);after autofrettaging, removing a thickness (D) of the inner disc on both faces thereof.

Owner:NUOVO PIGNONE TECH SRL

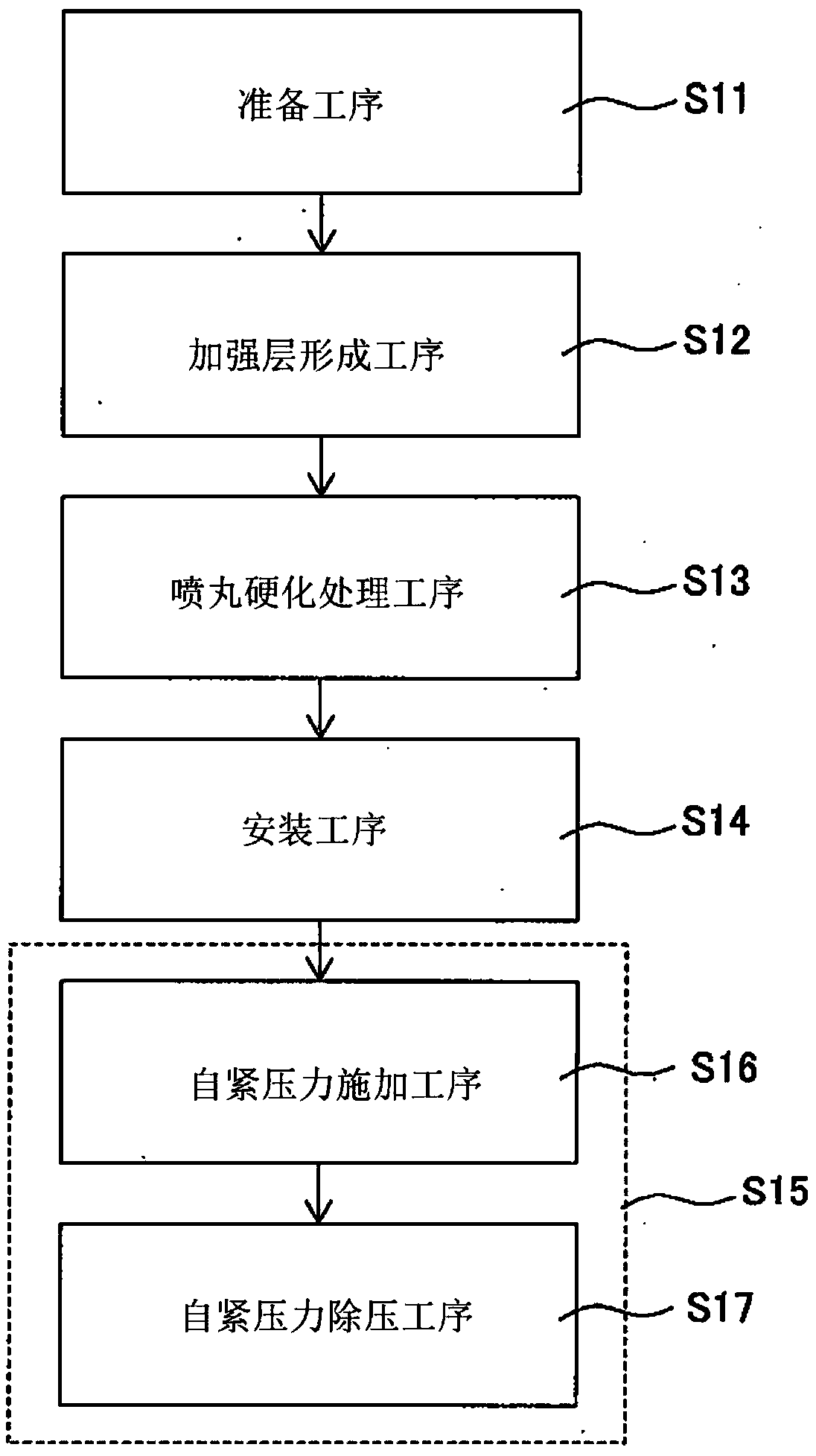

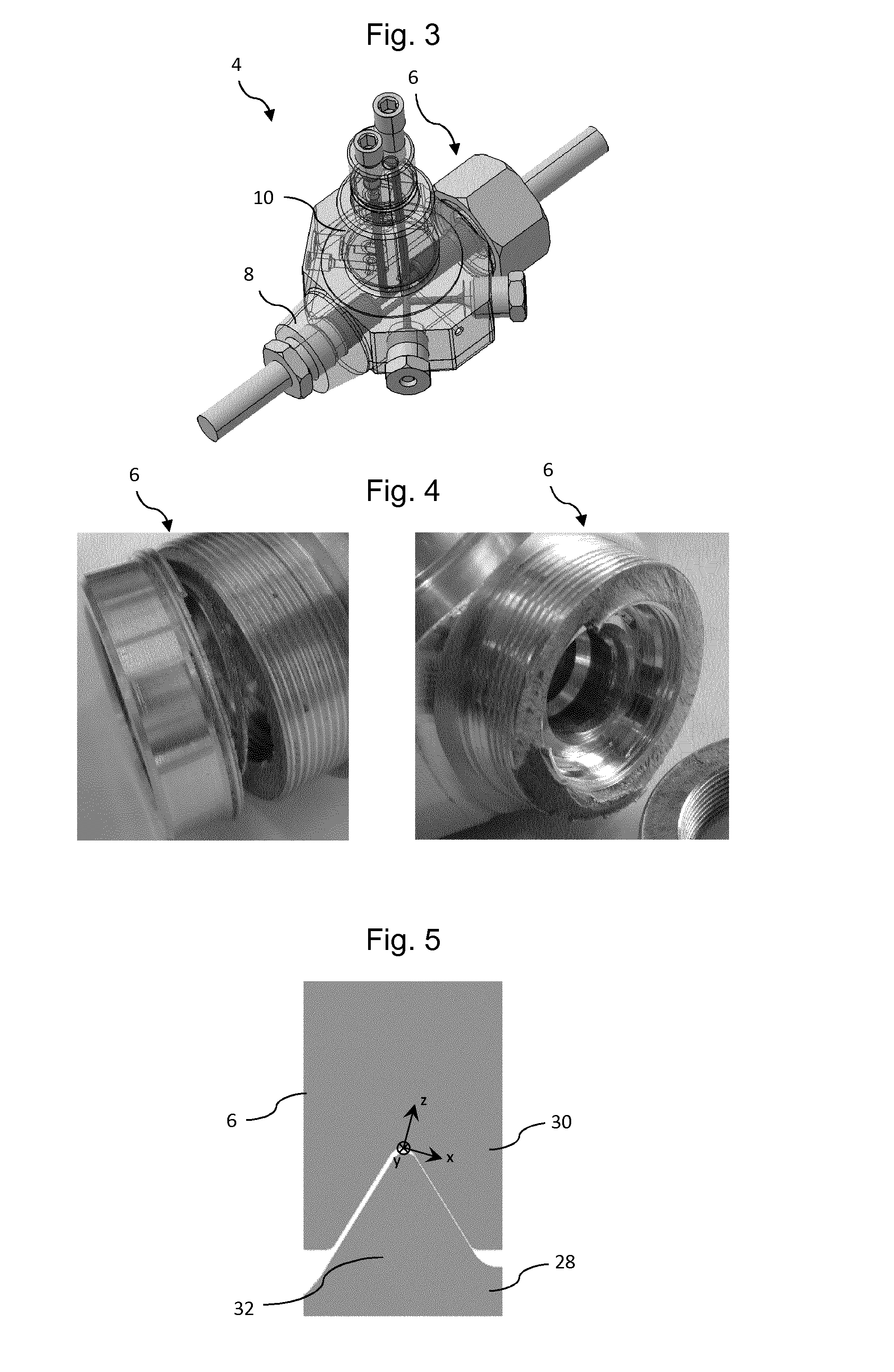

Autofrettage process and autofrettage apparatus

InactiveUS8408033B2Lower the volumeLow costMetal-working apparatusFurnace typesInterior spaceEngineering

In the autofrettage process, a thick-walled workpiece (2) to undergo autofrettage is positioned in an autofrettage apparatus (1). The interior space (5) of the workpiece (2) is filled with a fluid and closed so as to be pressure-tight. The volume available to the fluid in the interior space (5) of the workpiece (2) is reduced by a displacement piston (19) which is moved into the interior space (5) of the workpiece (2) through a displacement piston opening (6) of the workpiece (2). The pressure is therefore generated in the interior space (5) of the workpiece (2).

Owner:MAXIMATOR

Supercritical heat-insulated oil pipe production method

ActiveCN101187292BEasy to usePrevent "hydrogen explosion"Drilling rodsMaterial analysis by electric/magnetic meansX-rayShielding gas

The invention relates to a manufacturing method in the oil pipe processing field, in particular to a process for preparation of a supercritical heat insulated oil tube. The technical proposal is that the invention comprises material selecting and preprocessing of an inner tube and an outer tube, welding wires for nesting and welding are flux-cored wires, protective gas for welding is the mixture gas of argon gas and argon gas, autofrettage is done after being welded and heat preservation for a certain time, the control thermal conductivity factor of X-ray flaw on-line detection, heating vaccum pumping, vacuum blocking welding, and magnaflux inspection are 0.01W / m DEG C to 0.04 W / m DEG C, and normal temperature anti-inner pressure test pressure of screw cutting on two ends, coating sealinggrease for mounting sealing ring, an upper coupling, a path, and an integral test are more than 40MPa, a normal temperature anti-external crowded test pressure is more than 45MPa, and the invention also comprises an upper screw thread protector. Modification and tackling of the invention are from material selecting and technological condition to improve performance indicating of the insulated oiltube, the invention can satisfy steam injection pressure 26MPa, steam injection temperature 400 DEG C, the downhole depth can achieve a behavior with 2300m through process combination.

Owner:淄博孚瑞特热能科技有限公司

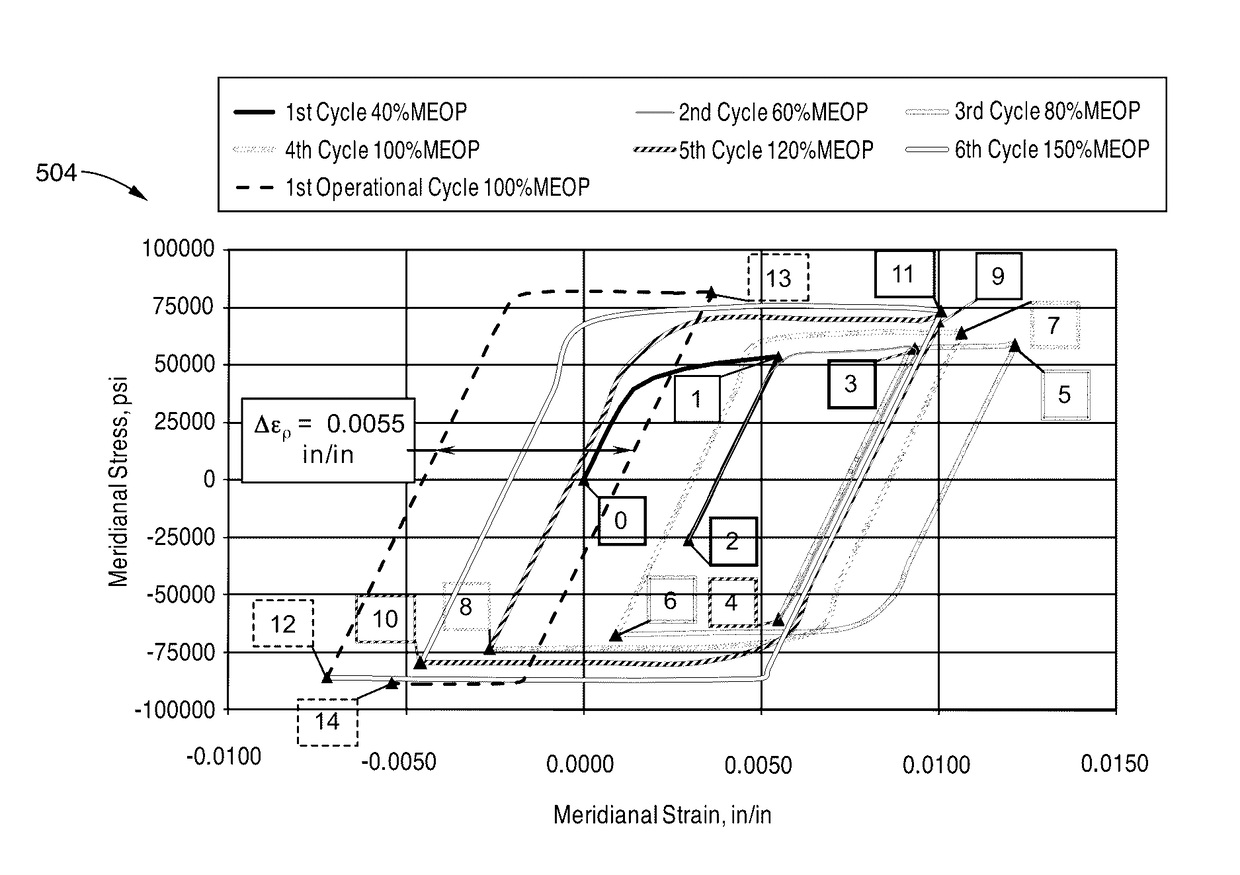

Methods for increasing cycle life of metal liners and products manufactured therefrom

ActiveUS9687902B1Increasing metal yield strengthHigh yield strengthFurnace typesPressure vesselsInternal pressureAutofrettage

A method of incremental autofrettage is taught herein, whereby the cycle life of a metal liner in a pressure vessel is increased. This method serves to increase the yield strength of the metal liner through sequential work hardening due to repeated autofrettage at increasing pressures. By incrementally increasing the internal pressure used in the autofrettage process, the compressive stresses at an inner surface of the metal liner may be controlled so that post-pressurization buckling does not occur, yet the yield strength of the metal liner is substantially increased. The higher compressive stresses in the metal liner mean that higher Maximum Expected Operating Pressures (MEOPs) may be used without detracting from the cycle life of the metal liner, or alternatively, for lower pressures, a longer metal liner cycle life may be obtained. Either internal or external pressures may be used, generated by a pressure source, or a suitable die.

Owner:SPENCER COMPOSITES CORP

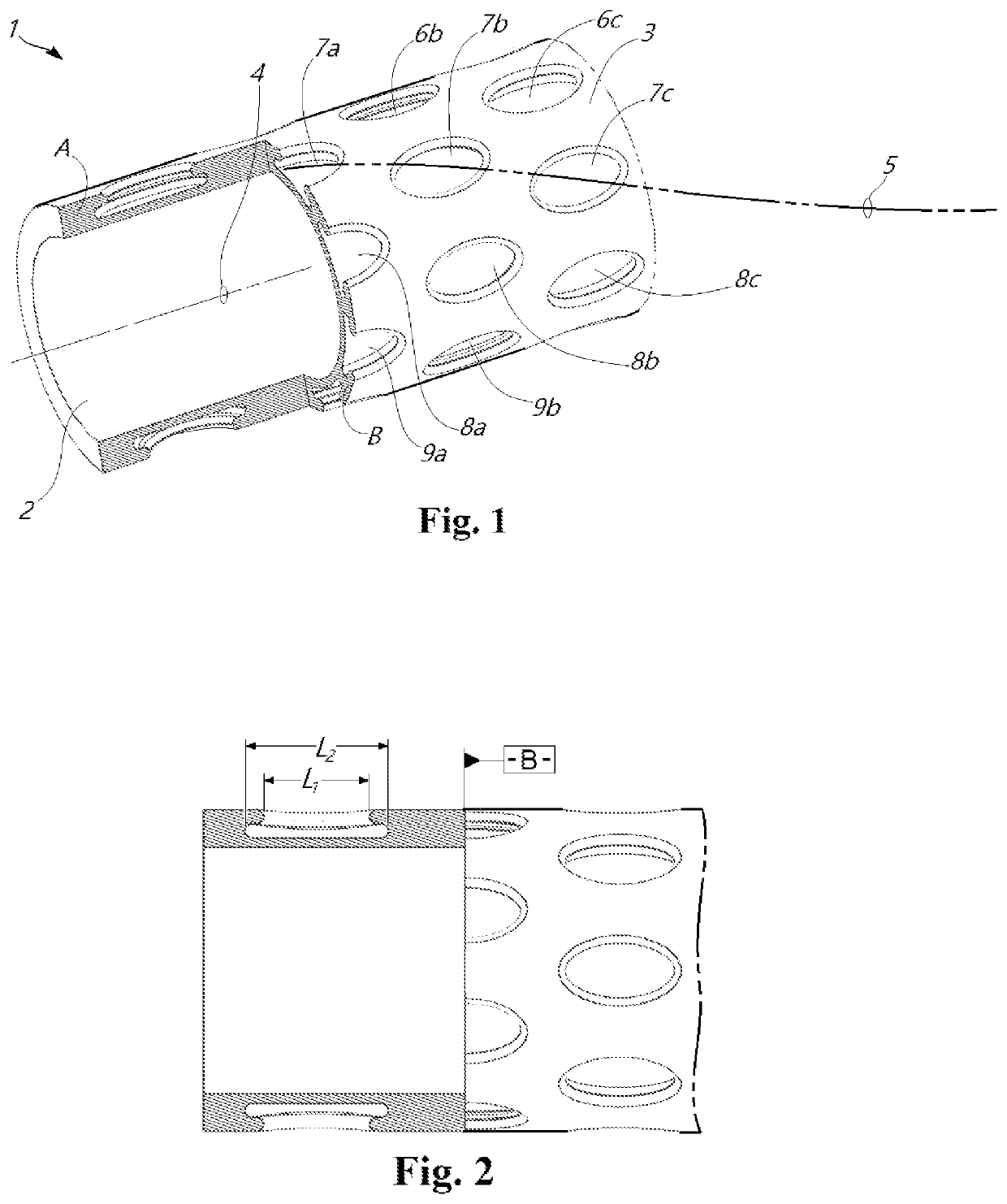

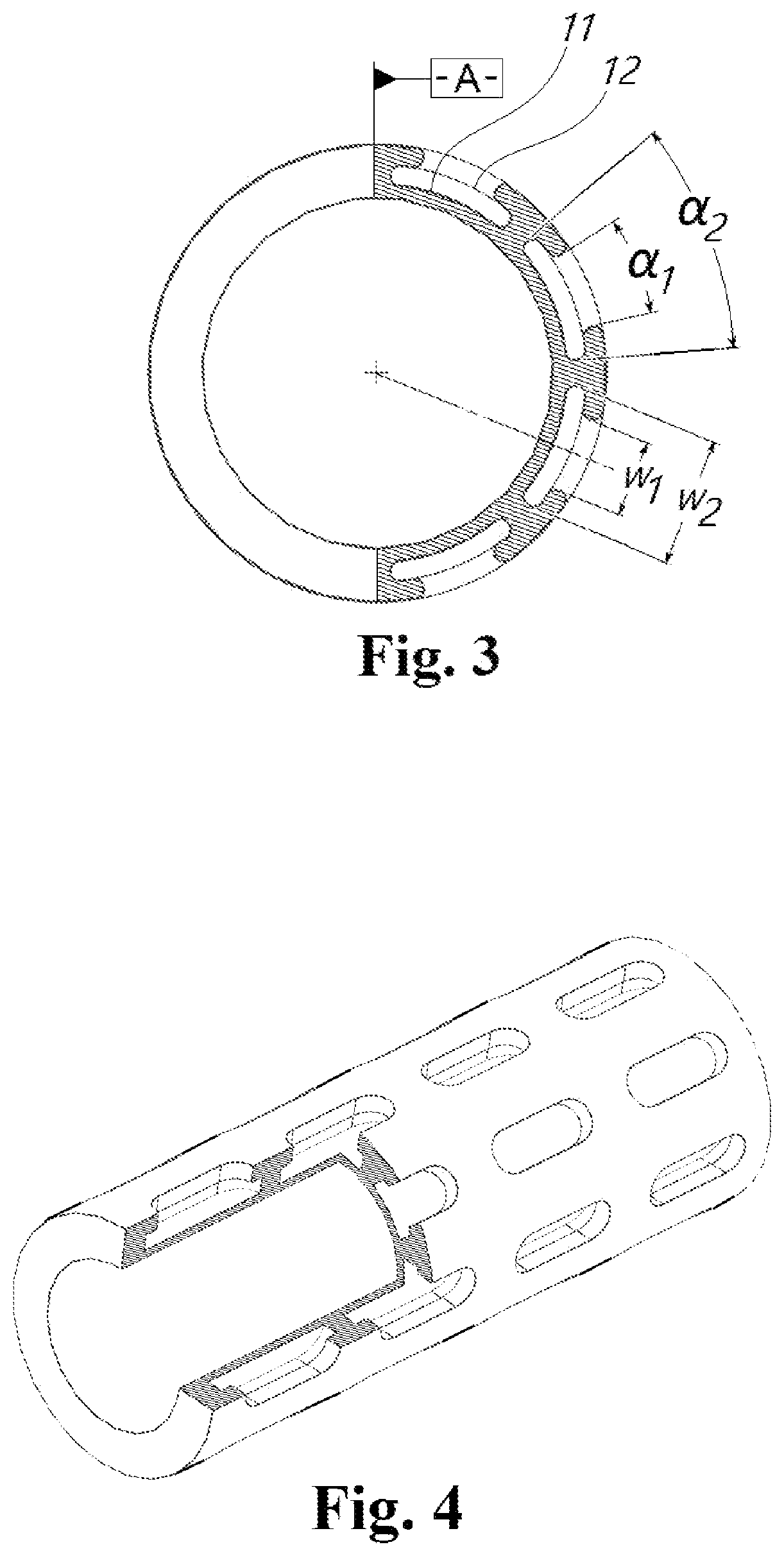

Gun Barrel or Sleeve Therefor

InactiveUS20220282948A1Heat dissipation fastSufficient rigidity for accurateBarrelsEngineeringGun barrel

A gun barrel or sleeve for a gun barrel is provided. The invention includes staggered helical arrays of elliptical or oval blind cavities along the length of the gun barrel or sleeve. As a sleeve, the invention may be press-fit or force-fitted over a regular barrel or a barrel of reduced wall thickness. The cavities have radially extending orifices by which an angular width of an interior portion of a cavity is greater than an angular width of the orifice of that cavity, and a longitudinal dimension of the interior portion of that cavity is greater than a longitudinal dimension of the orifice of that cavity. The product may be produced by additive manufacturing, autofrettage, casting, forging or traditional CNC machining.

Owner:REMO MICHAEL

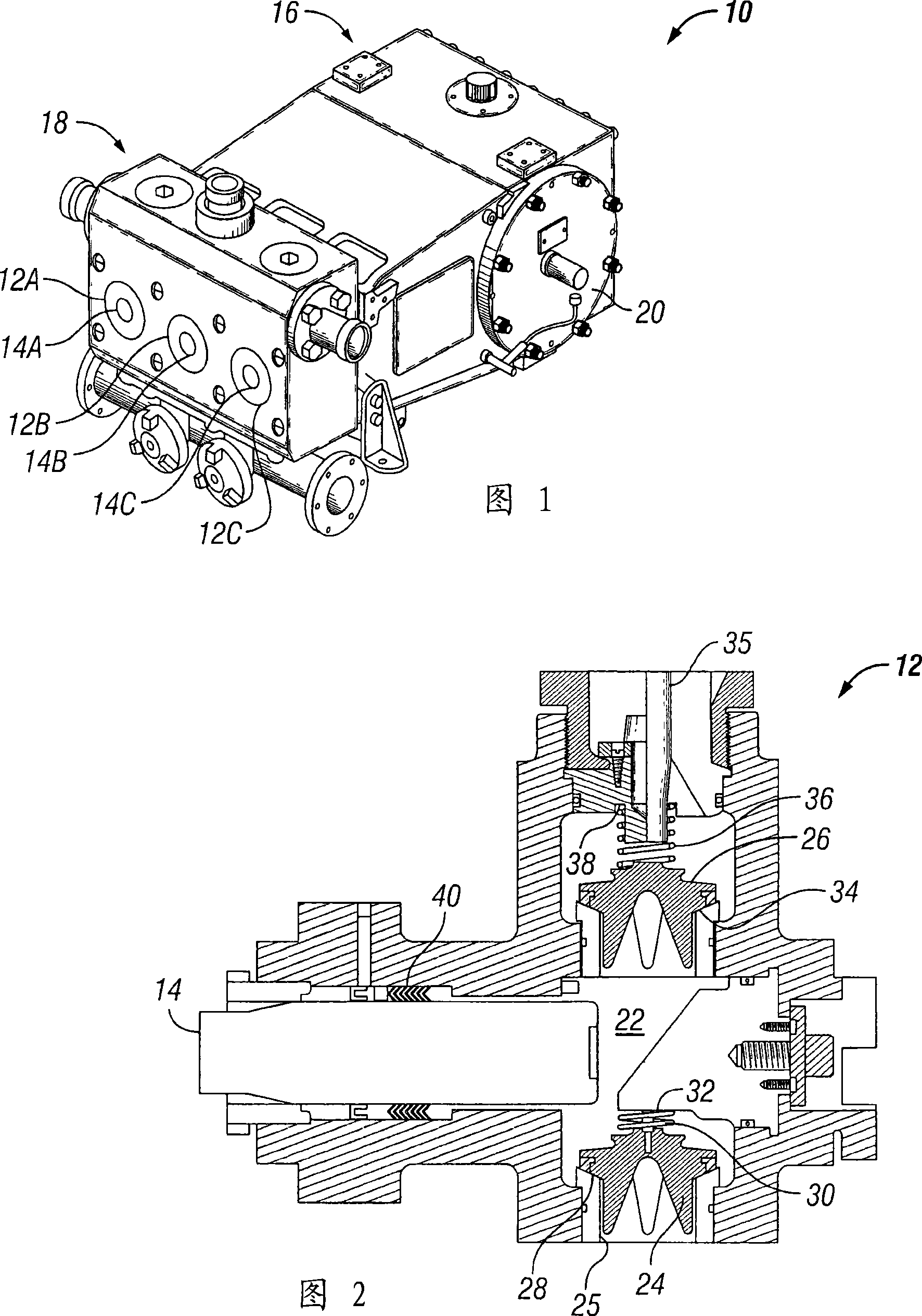

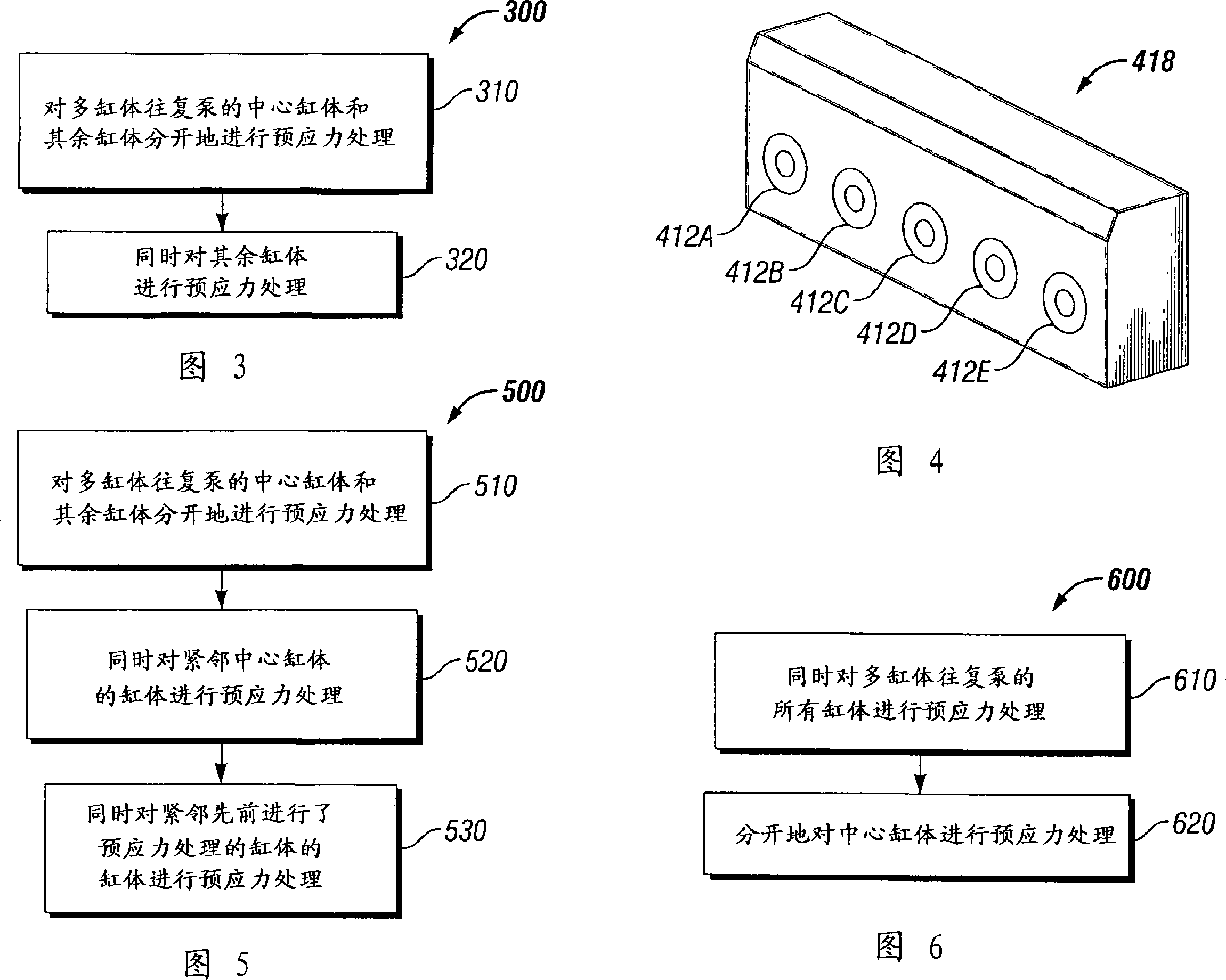

Autofrettage process for a pump fluid end

A multi-step autofrettage process for pre-treating a multi-cylinder reciprocating pump fluid end that has a central cylinder and at least two side cylinders is provided that includes autofrettaging the central cylinder; and autofrettaging the at least two side cylinders, wherein the autofrettaging of the central cylinder is performed independently of the autofettaging of the at least two side cylinders.

Owner:普拉德研究及发展公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com