Common rail for diesel engine

A diesel engine and common rail technology, applied in the field of common rail, can solve the problems of poor strength, failure to function, and deterioration of internal pressure fatigue strength, and achieve the effect of good durability and improved fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

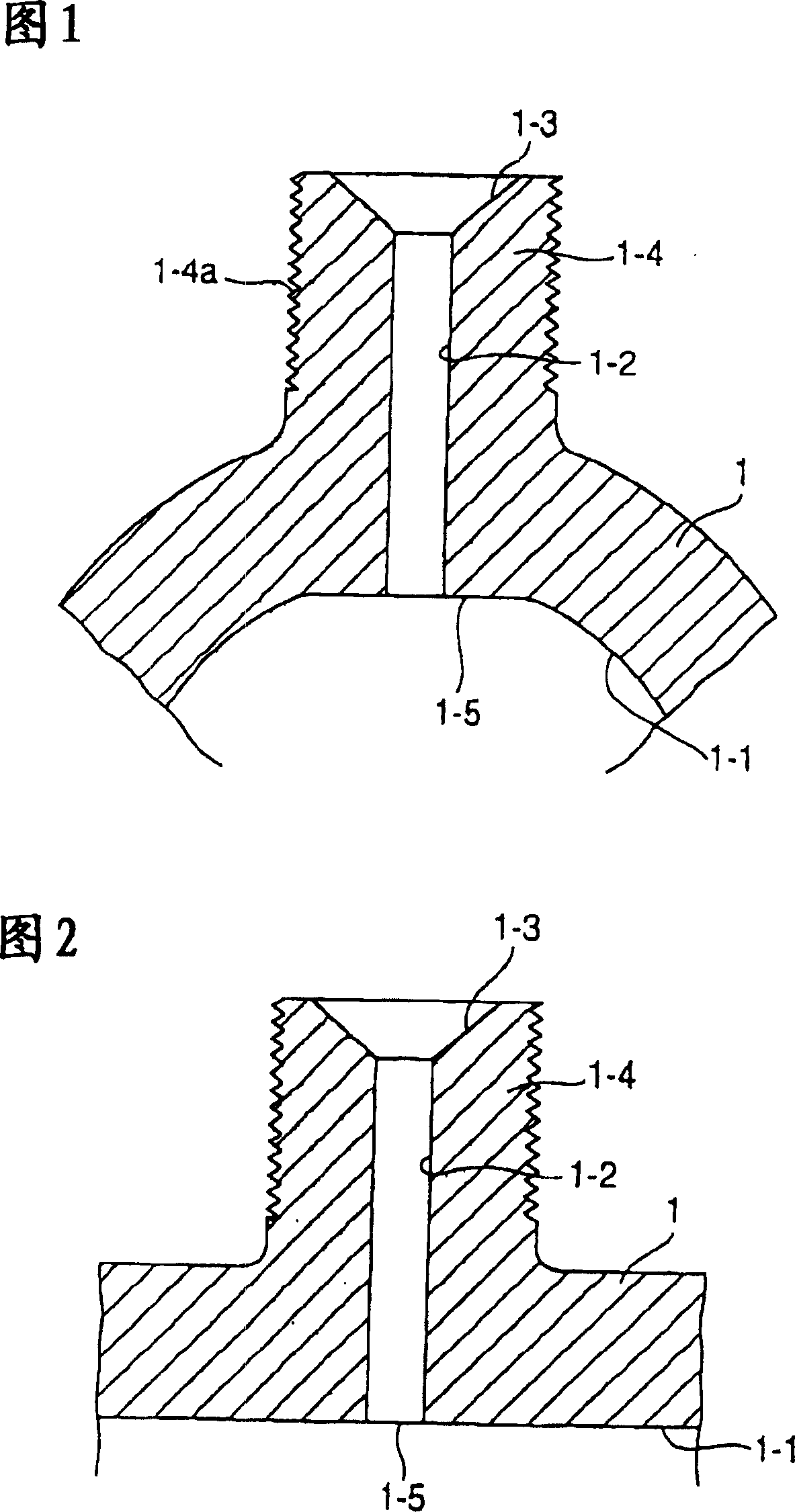

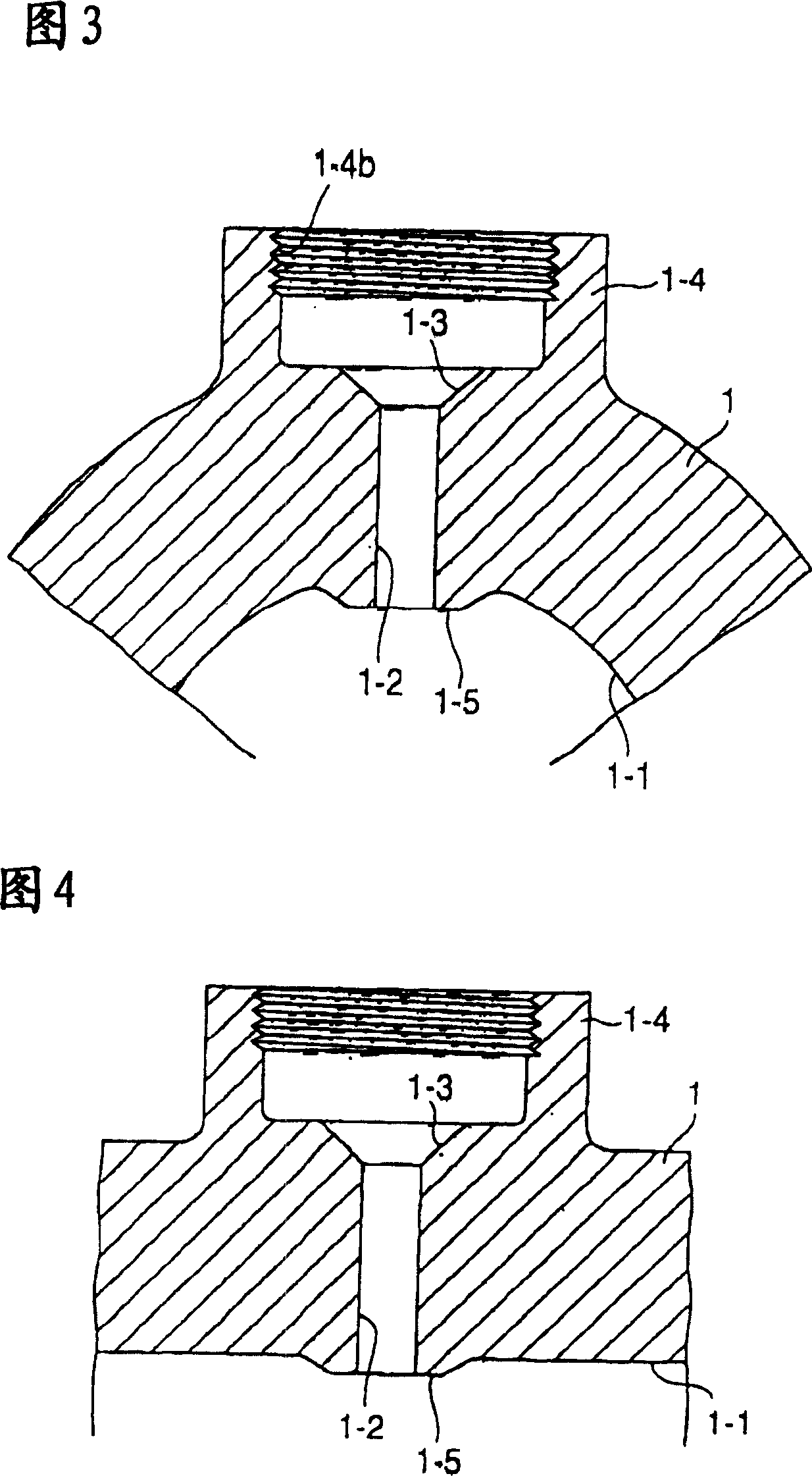

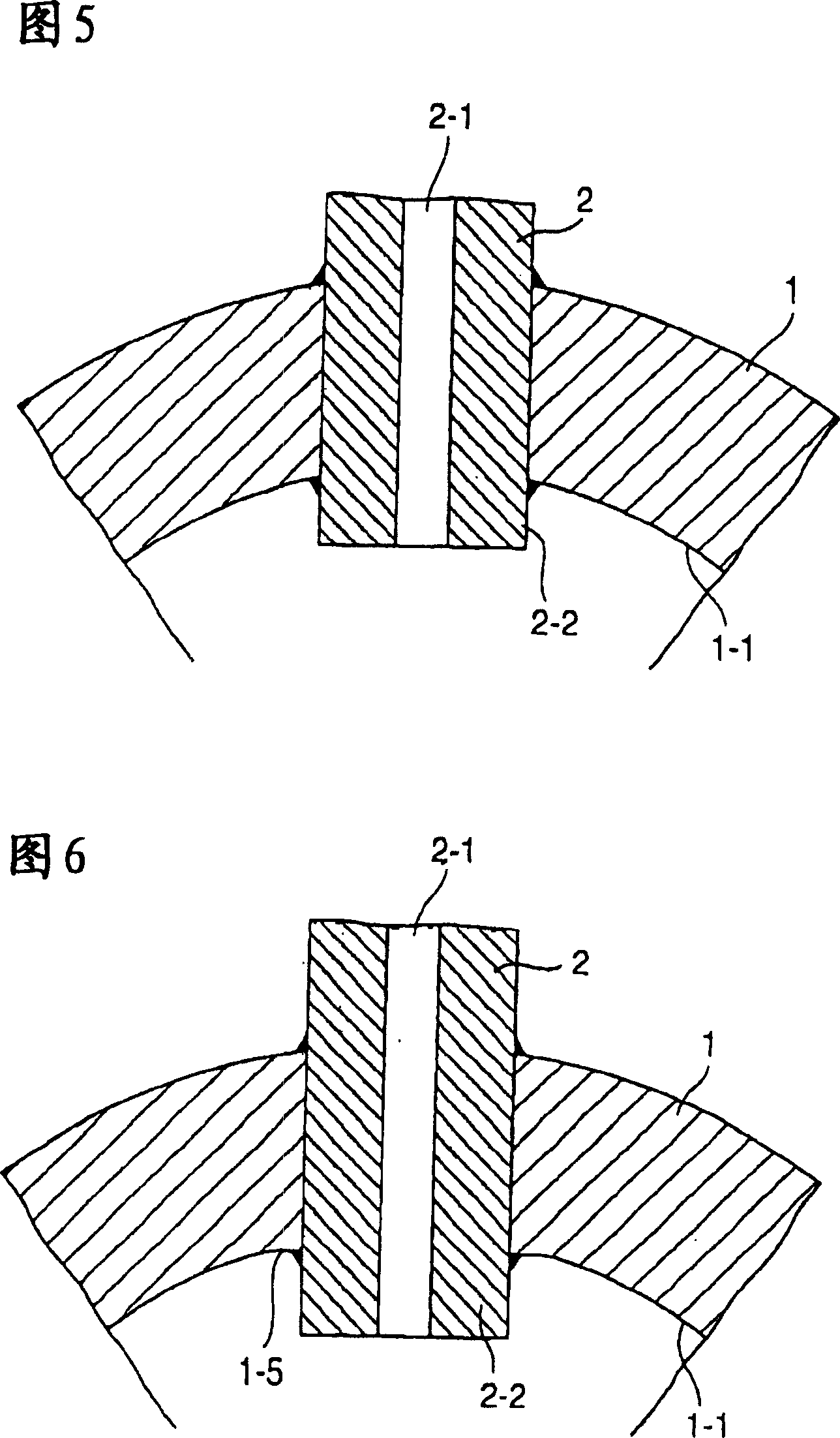

[0029] In the present invention, reference numeral 1 represents the main rail, reference numeral 1-1 represents the flow channel, reference numeral 1-2 represents the side hole, reference numeral 1-3 represents the surface of the pressure seat, and reference numeral 1- 4 represents a boss portion, reference numeral 1-4a represents a male thread, reference numeral 1-5 represents a flattened surface, reference numeral 2 represents a branch pipe, reference numeral 2-1 represents a flow channel, and reference numeral 2-2 Indicates a raised portion.

[0030]The main pipe rail 1 shown in Figures 1-4 as a common rail is a forging of S45C or similar material, having a tubular portion with a relatively thick wall, for example, a diameter of 28 mm and a wall thickness of 9 mm. The inside of the central axis is machined such as boring, deep hole drilling, etc. to form a flow channel 1-1, and a plurality of bosses are arranged on the peripheral wall, and are axially spaced apart from each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com