Patents

Literature

52 results about "Increased fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

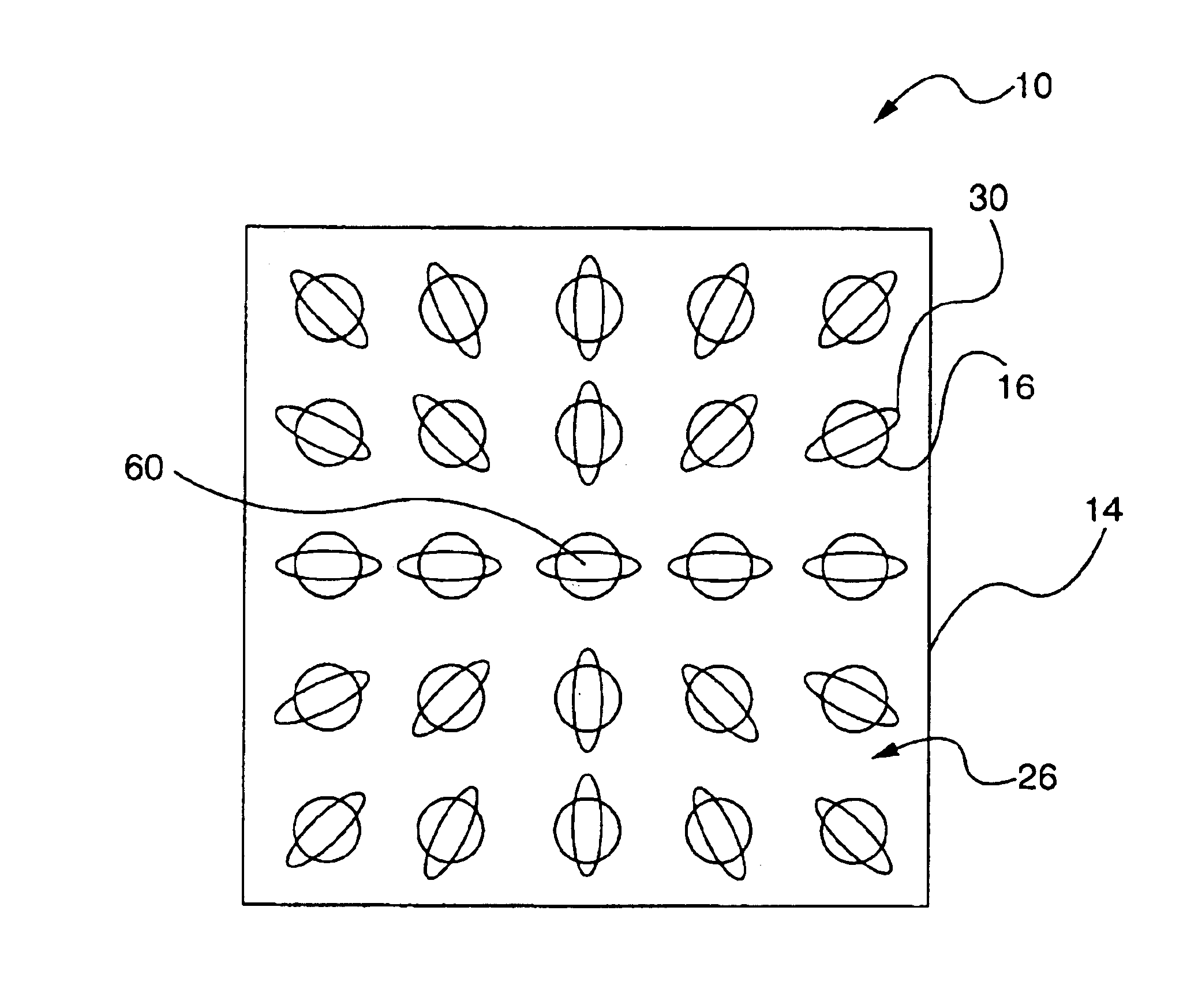

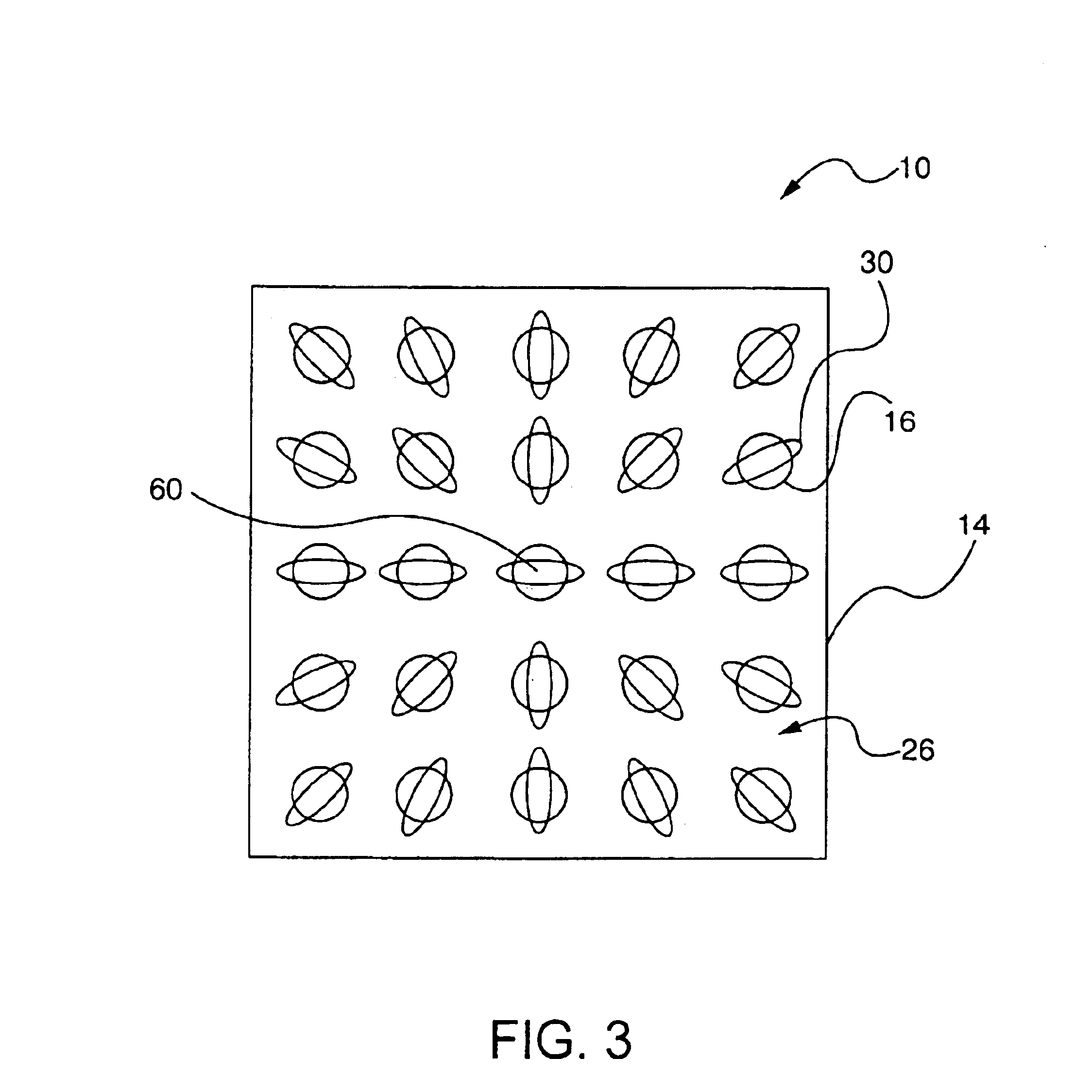

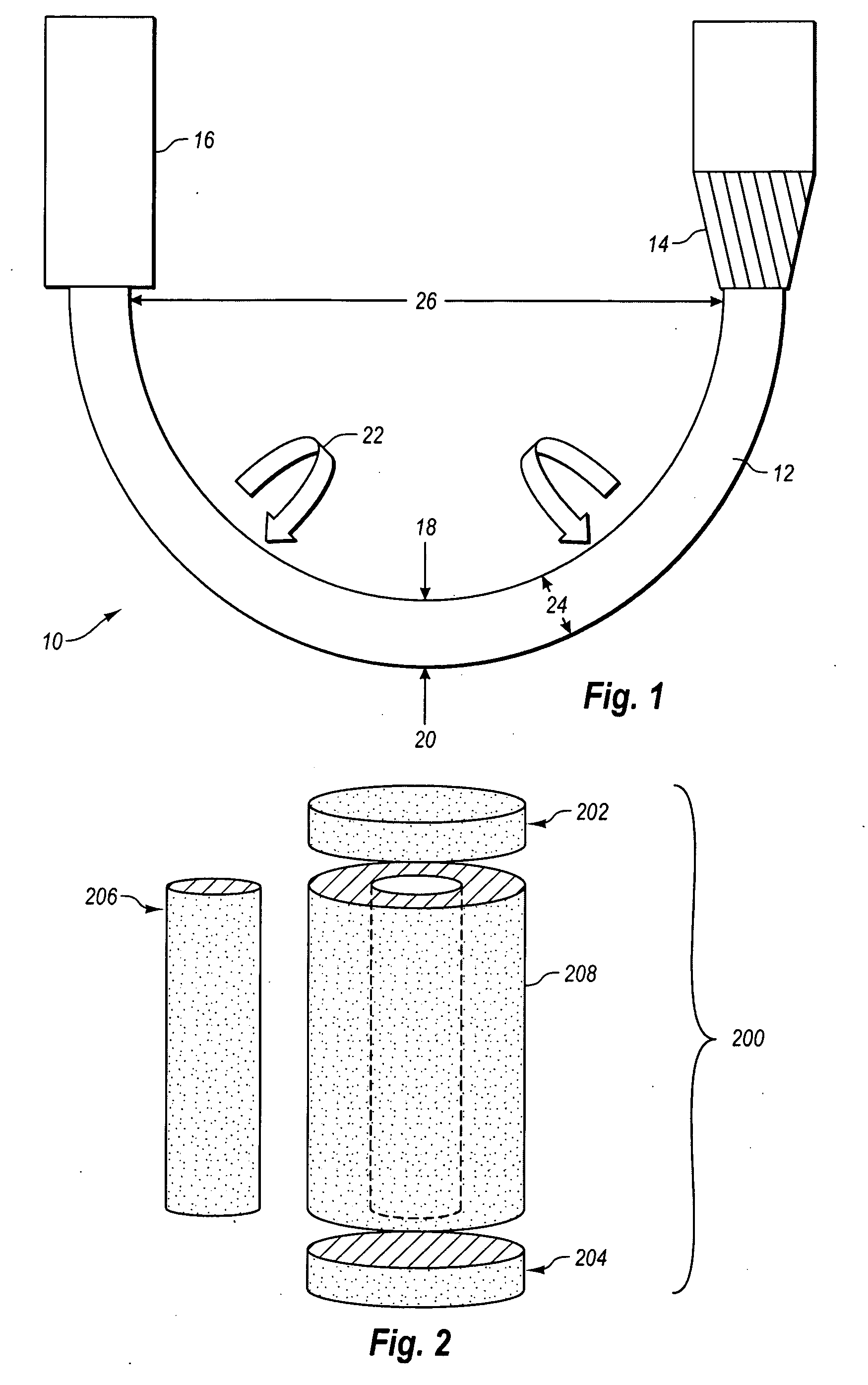

Partially captured oriented interconnections for BGA packages and a method of forming the interconnections

InactiveUS6913948B2Improve fatigue lifeEnhanced pad adhesionPrinted circuit assemblingSemiconductor/solid-state device detailsIncreased fatigueEngineering

A Ball Grid Array package having an increased fatigue life and improved conductive pad adhesion strength, as well as providing sufficient wiring space within the package, is disclosed. In particular, solder joints having a combination of mask-defined and pad-defined solder joint profiles are formed using a mask having non-circular elongated openings. The non-circular elongated openings of the mask have a major axis and a minor axis, such that the dimension of the openings along the major axis is greater than the diameter of the conductive pads, and the dimension of the openings along the minor axis is less than the diameter of the conductive pads. In addition, the major axis of the openings within the mask are selectively oriented in the direction of highest stress for each solder joint within the package, while providing ample wiring space therein.

Owner:IBM CORP

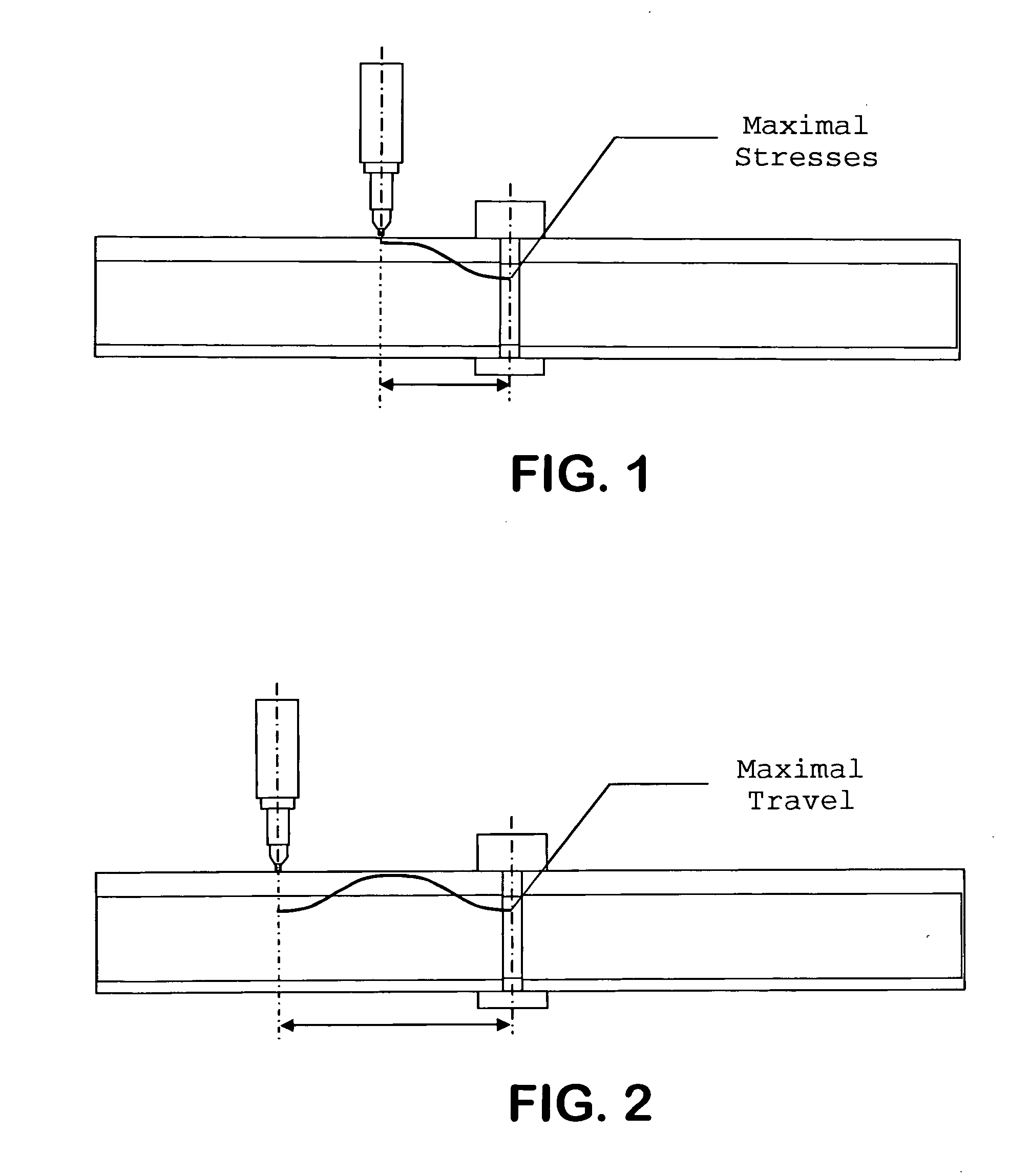

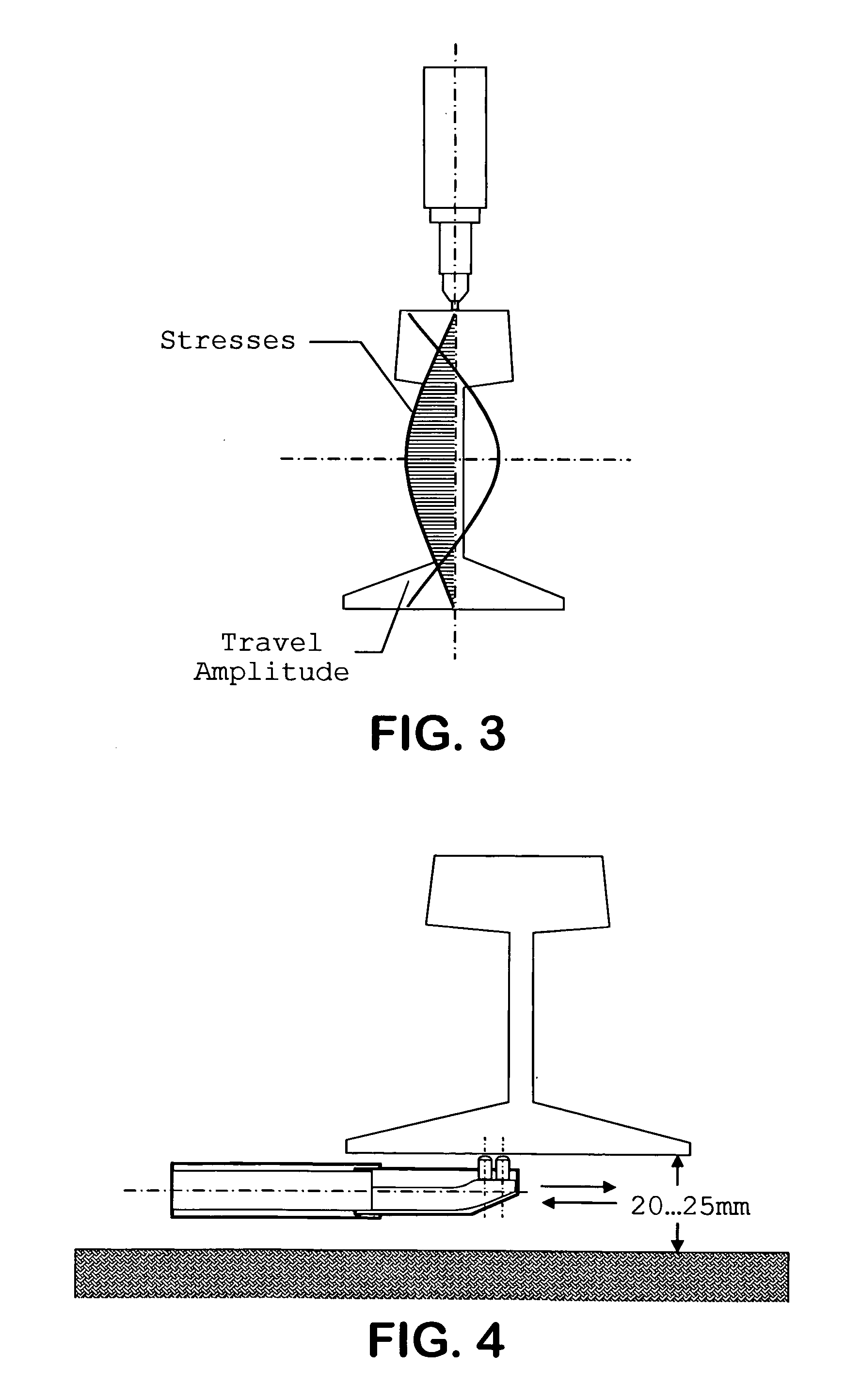

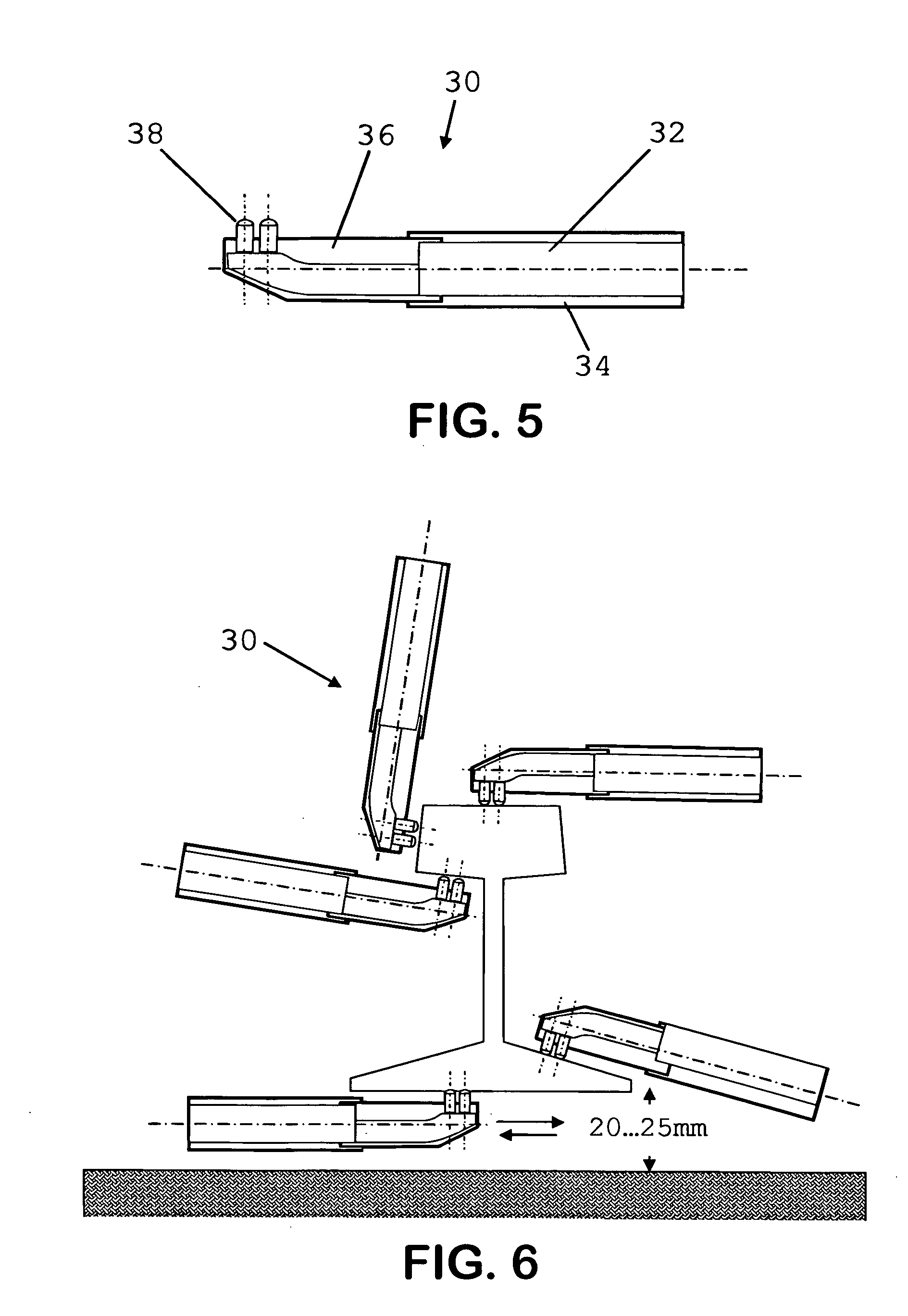

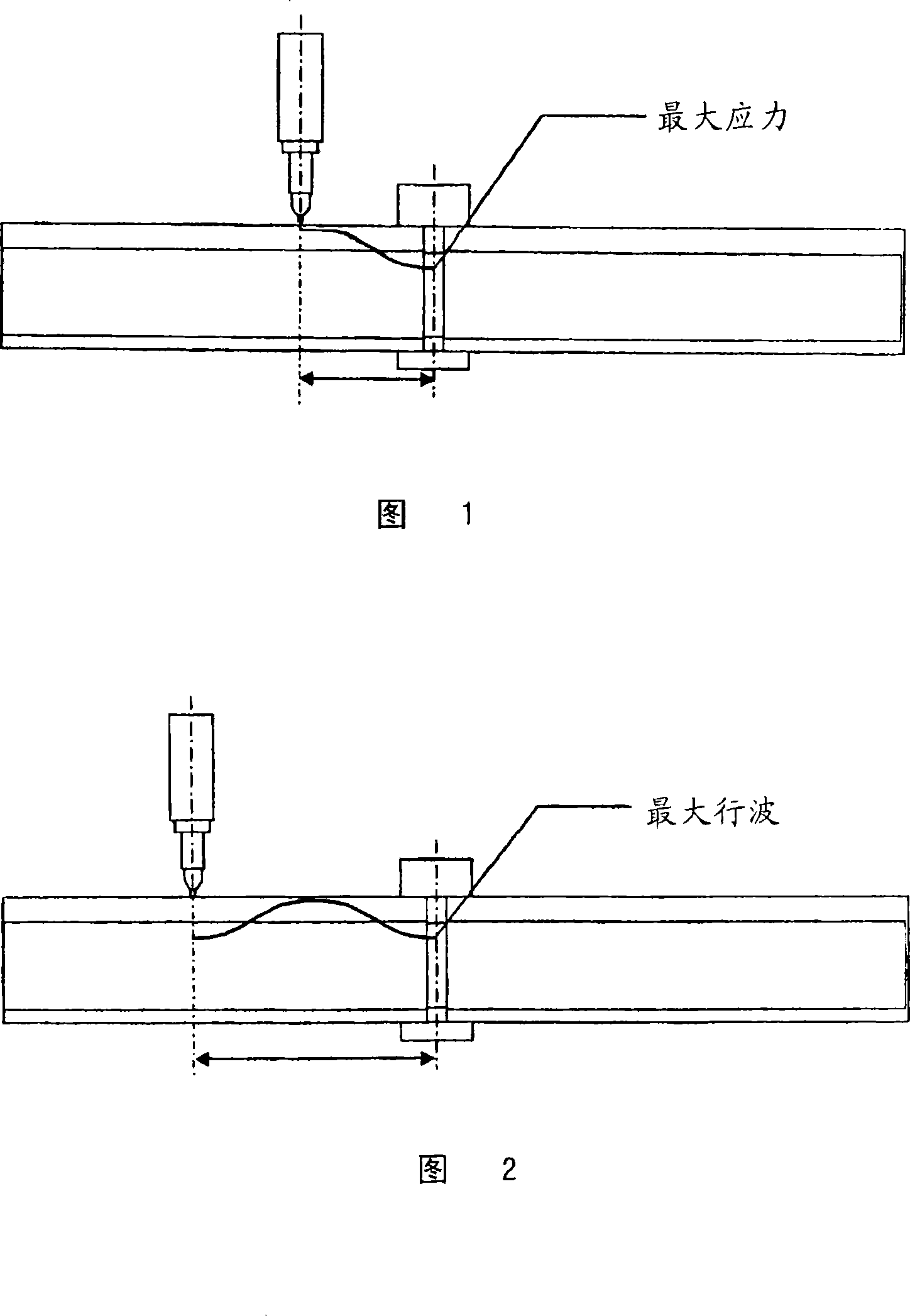

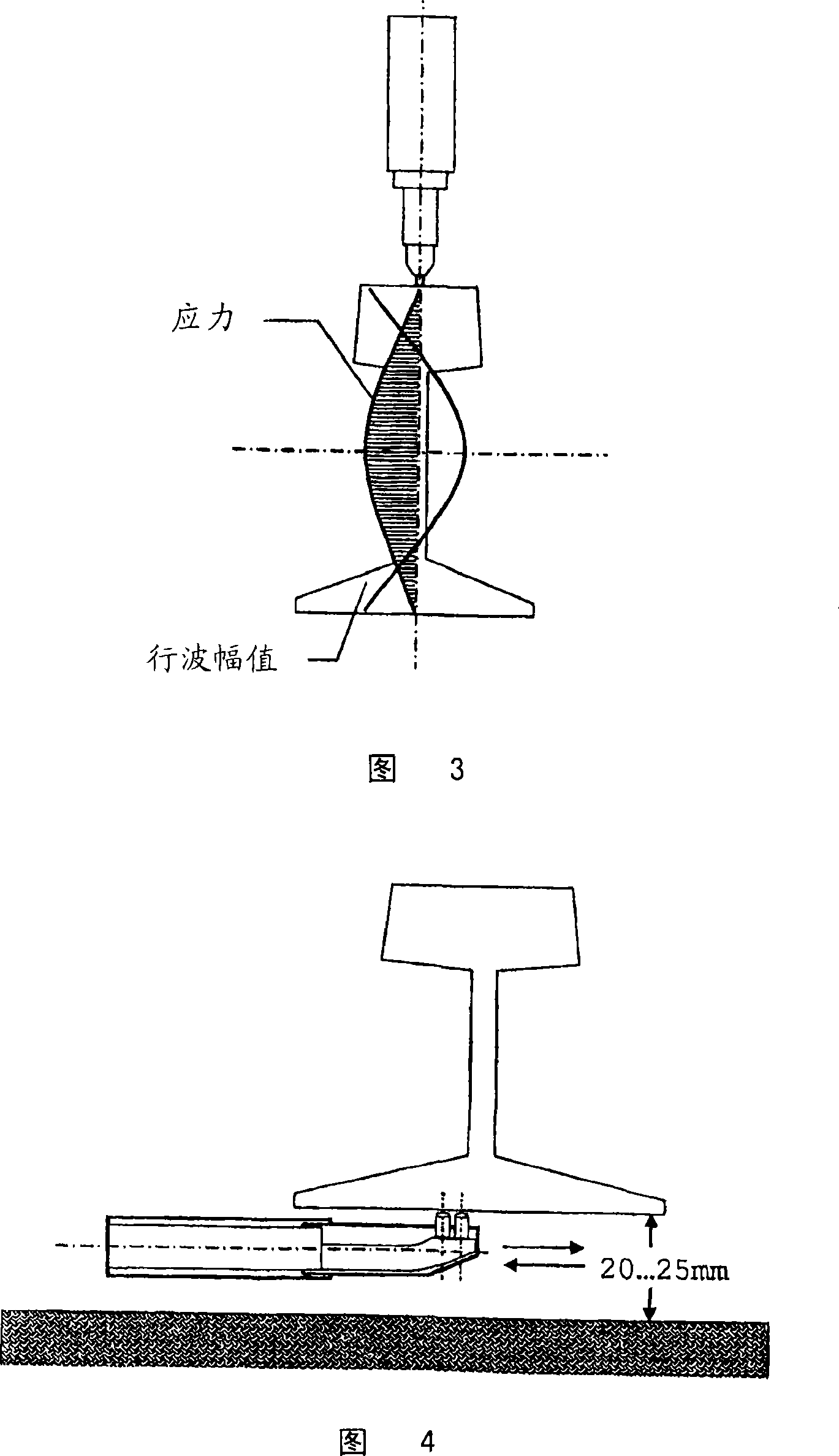

Method of improving quality and reliability of welded rail joint properties by ultrasonic impact treatment

InactiveUS20060016858A1Improving statistical reliabilitySolution to short lifeRailsCooking-vessel materialsIncreased fatiguePulse energy

A method for improving the performance of sections of rails joined together by welding by reworking welded joints utilizing an ultrasonic impact treatment (UIT) process either before welding, during welding, after welding or during repairs of used rails, including treatment of a joint, around a joint and / or length of a rail, in order to increasing fatigue life and / or other properties of welded rail sections is disclosed. The method provides reduction of stress defects and redistribution of internal stress patterns in the vicinity of weld seams of rails. The UIT provides periodic pulse energy impact treatment with surfaces in welded rails to induce internal compression waves inducing a metal plasticity state in the vicinity of the weld seam of the rail or in the rail itself.

Owner:UIT LLC

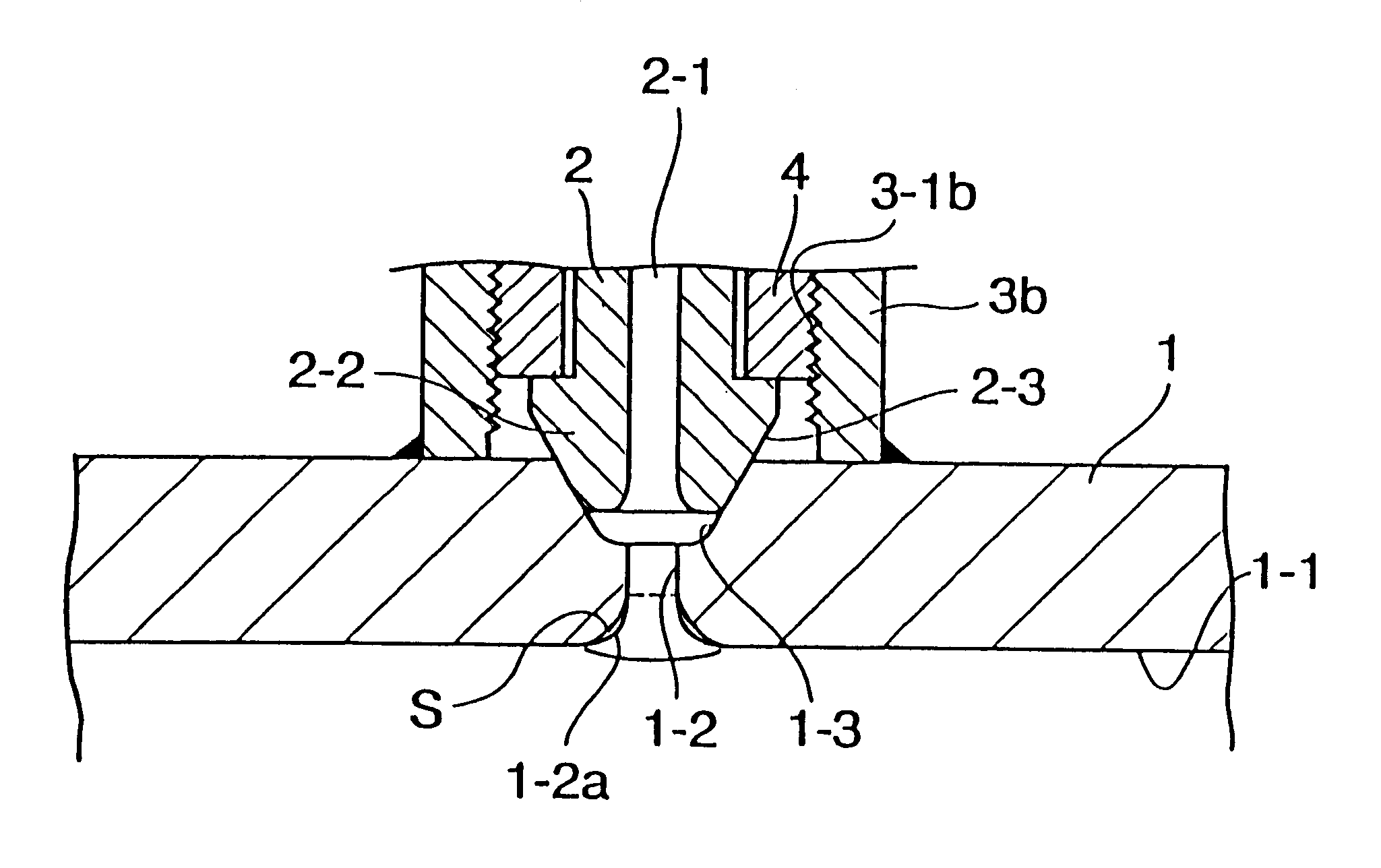

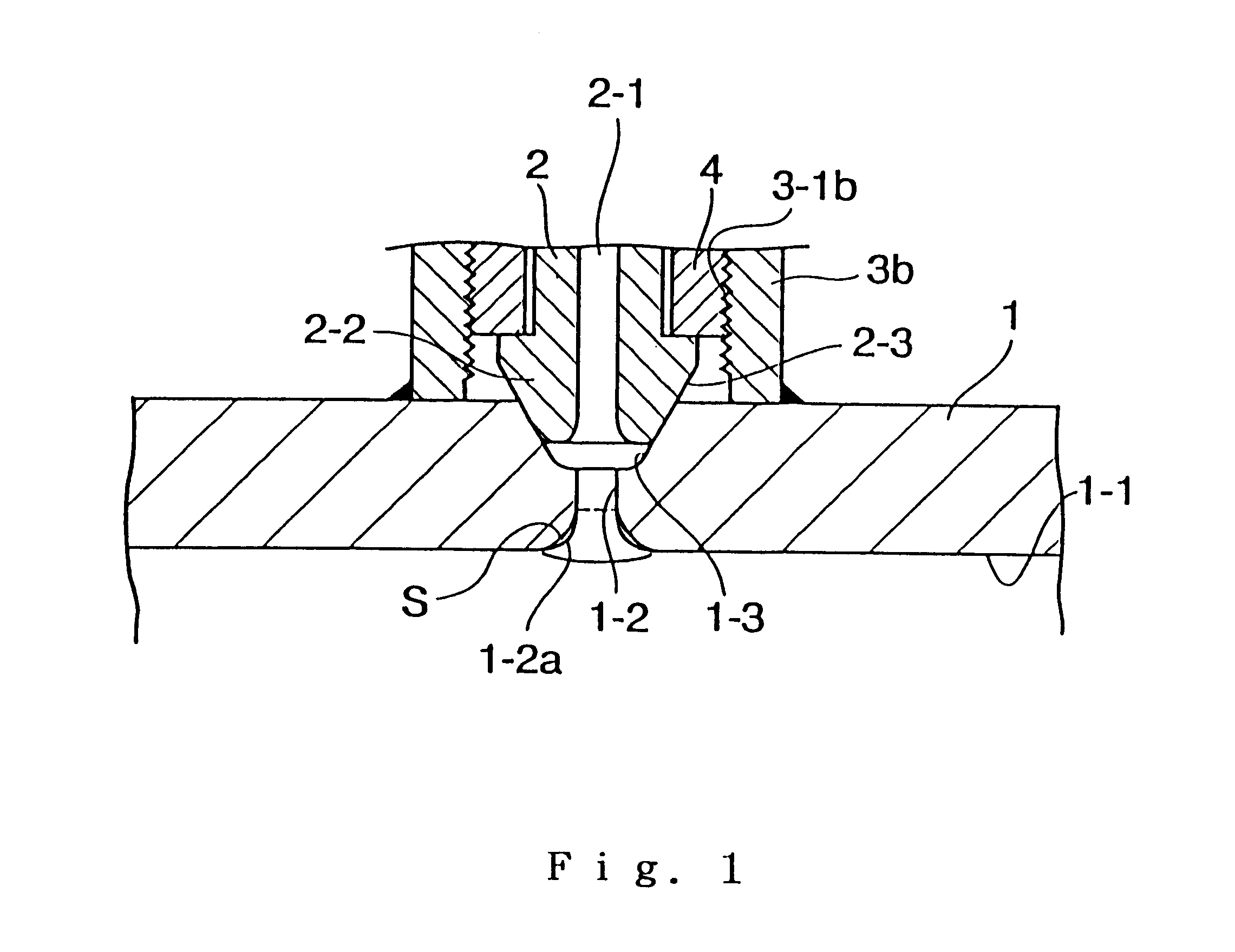

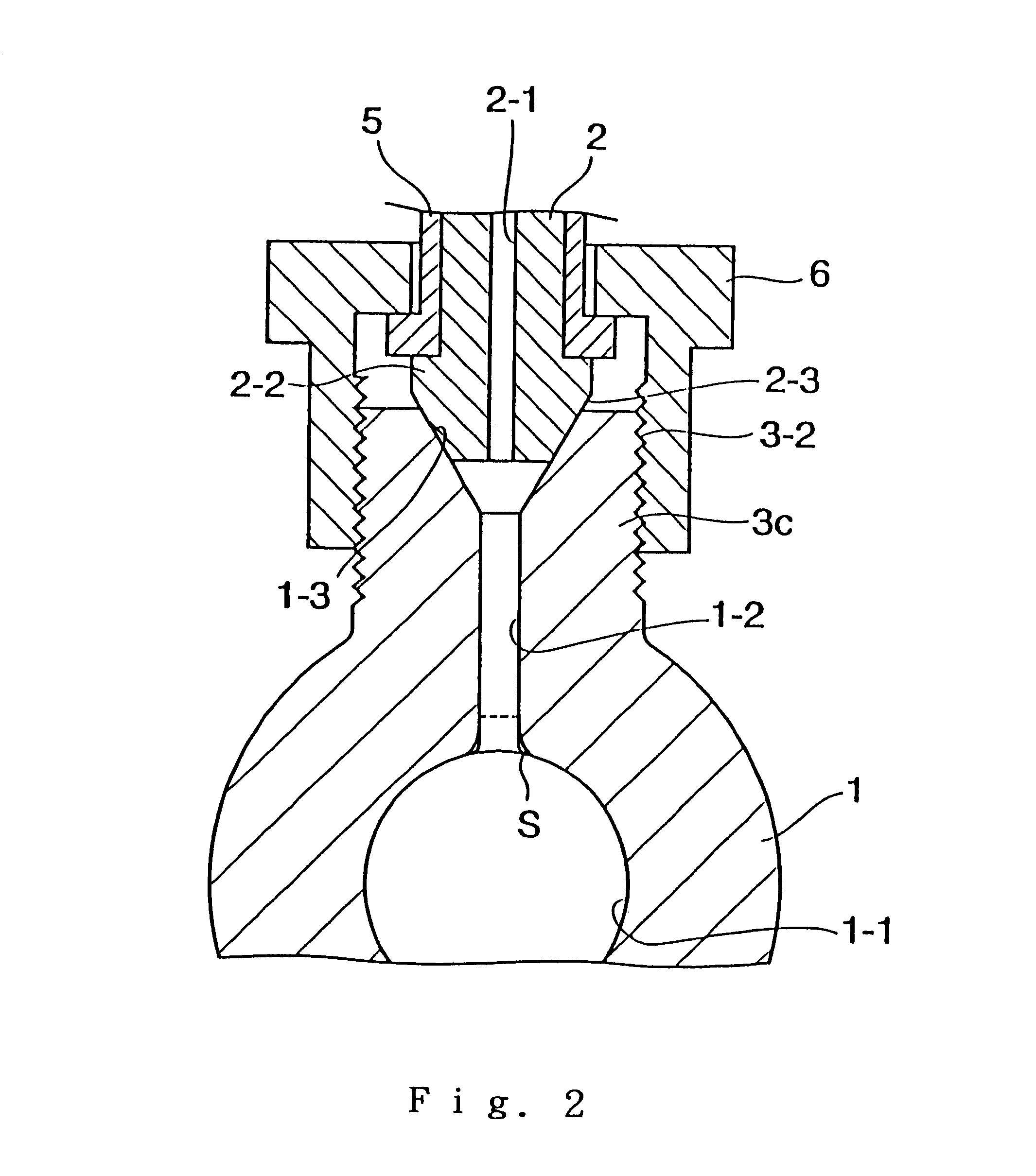

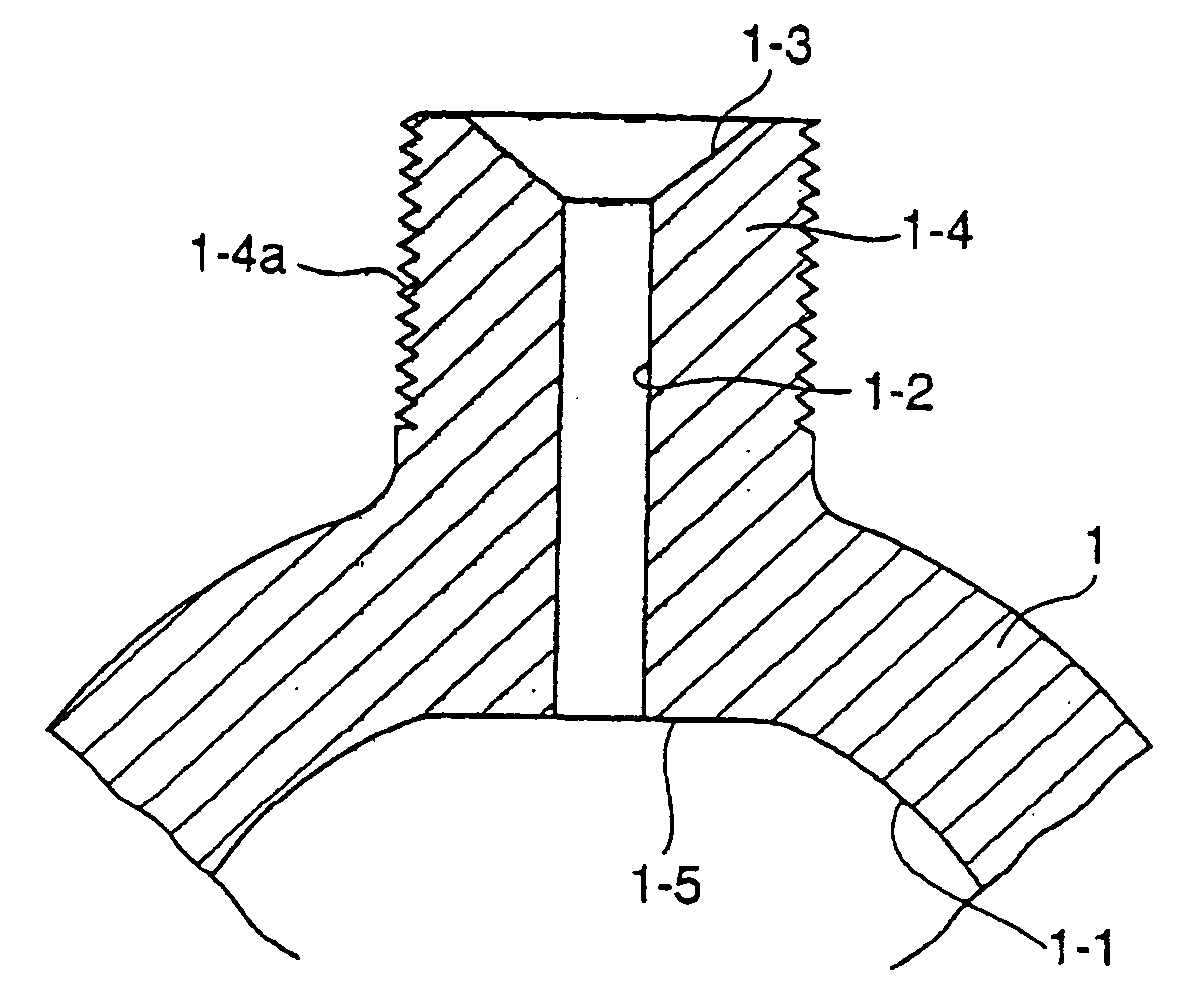

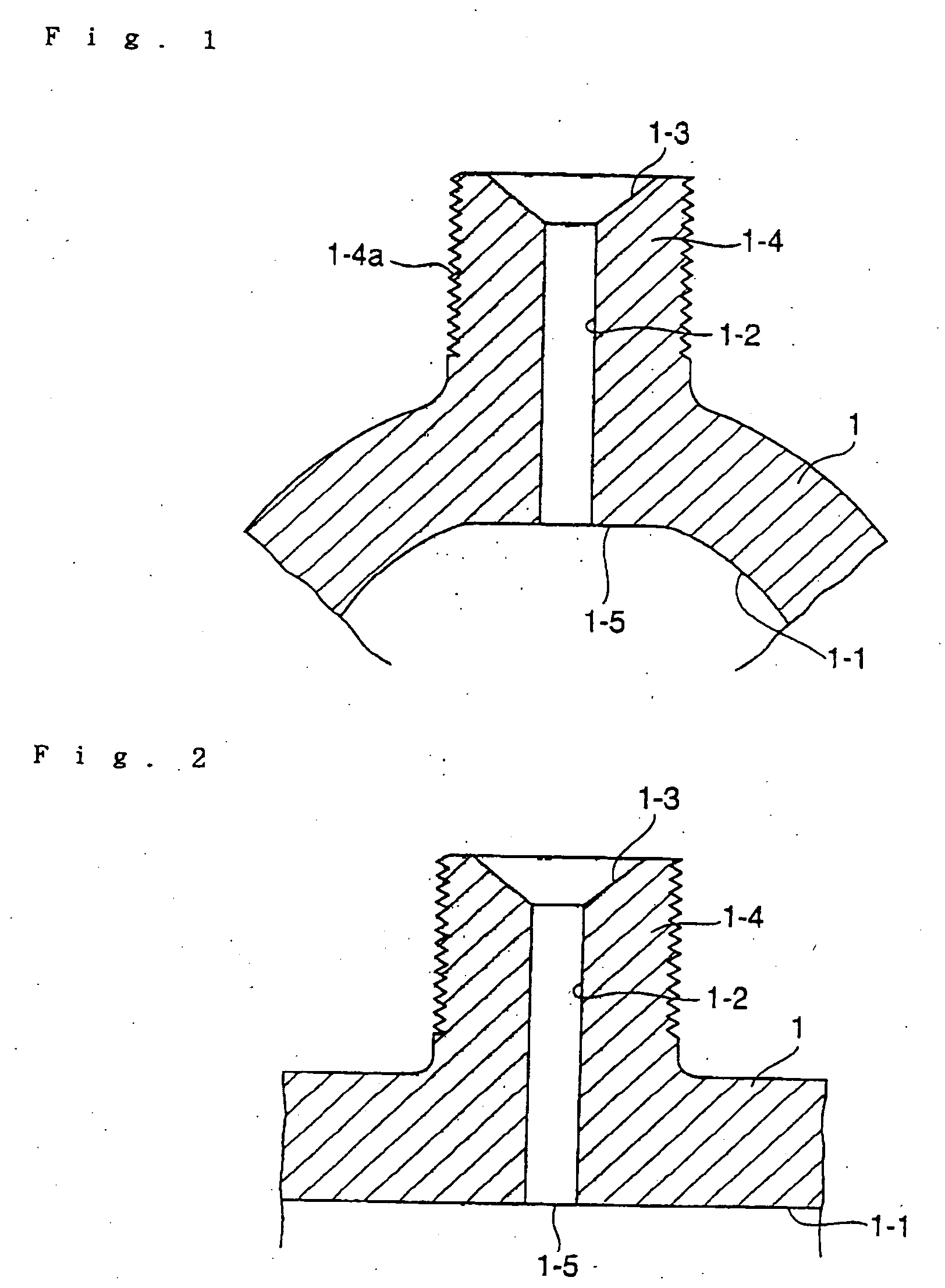

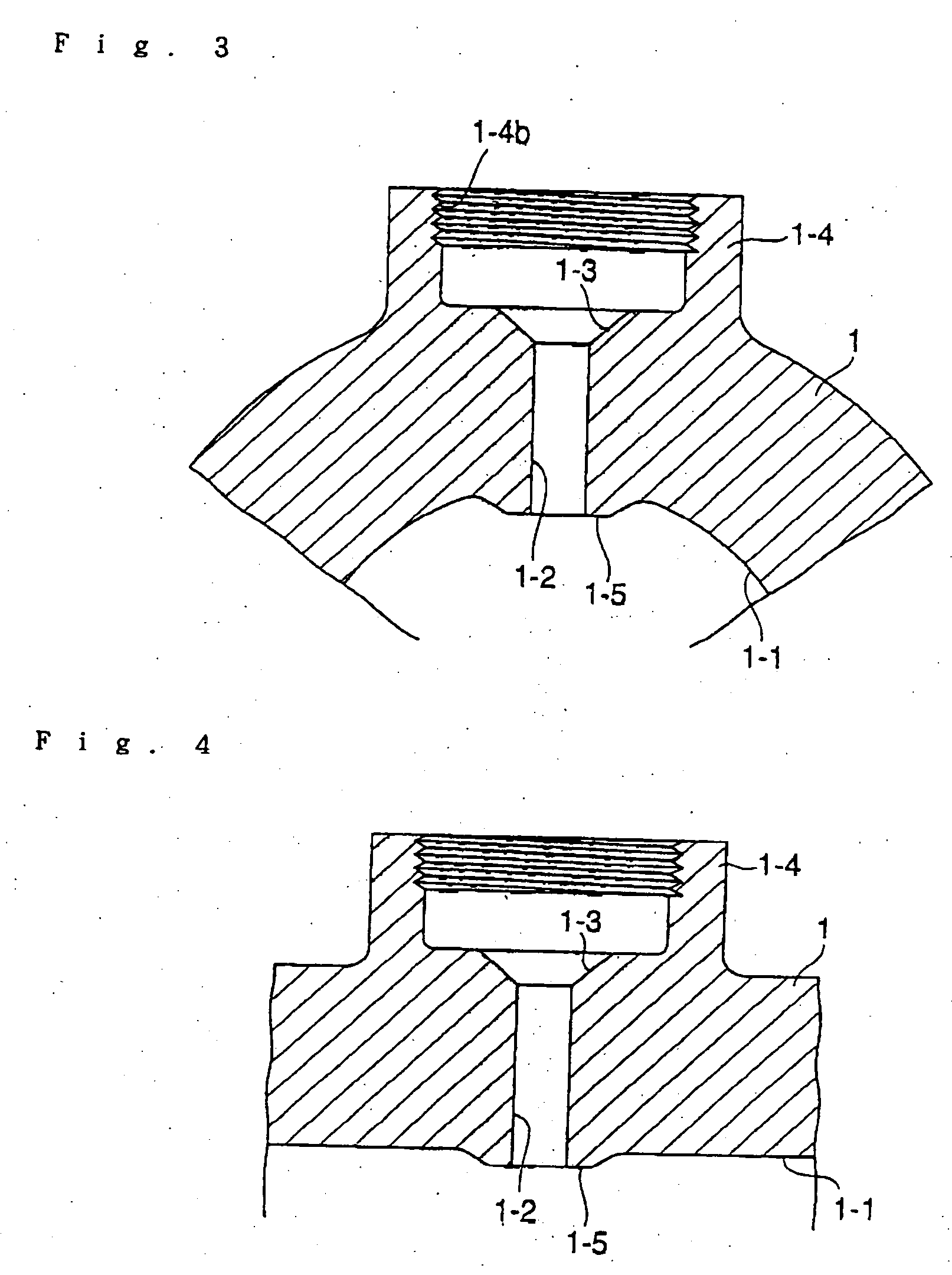

Common rail for diesel engine

InactiveUS6494183B2High strengthReduce stress concentrationLow pressure fuel injectionMachines/enginesInternal pressureCommon rail

A common rail includes a main pipe rail having a circulating passage extending in its inside in the axial direction thereof, branch holes formed in an axial peripheral wall portion of the main pipe rail, and branch connectors connected to the respective branch holes integrally or via separate connecting members. A Ni-diffused fatigue strength reinforcing layer is formed by heating a Ni layer plated in advance on at least a portion of an inner circumferential surface of the common rail. The increased strength and the action of the fatigue strength reinforcing layer lowers the degree of fatigue concentration to increase fatigue strength against inner pressure.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

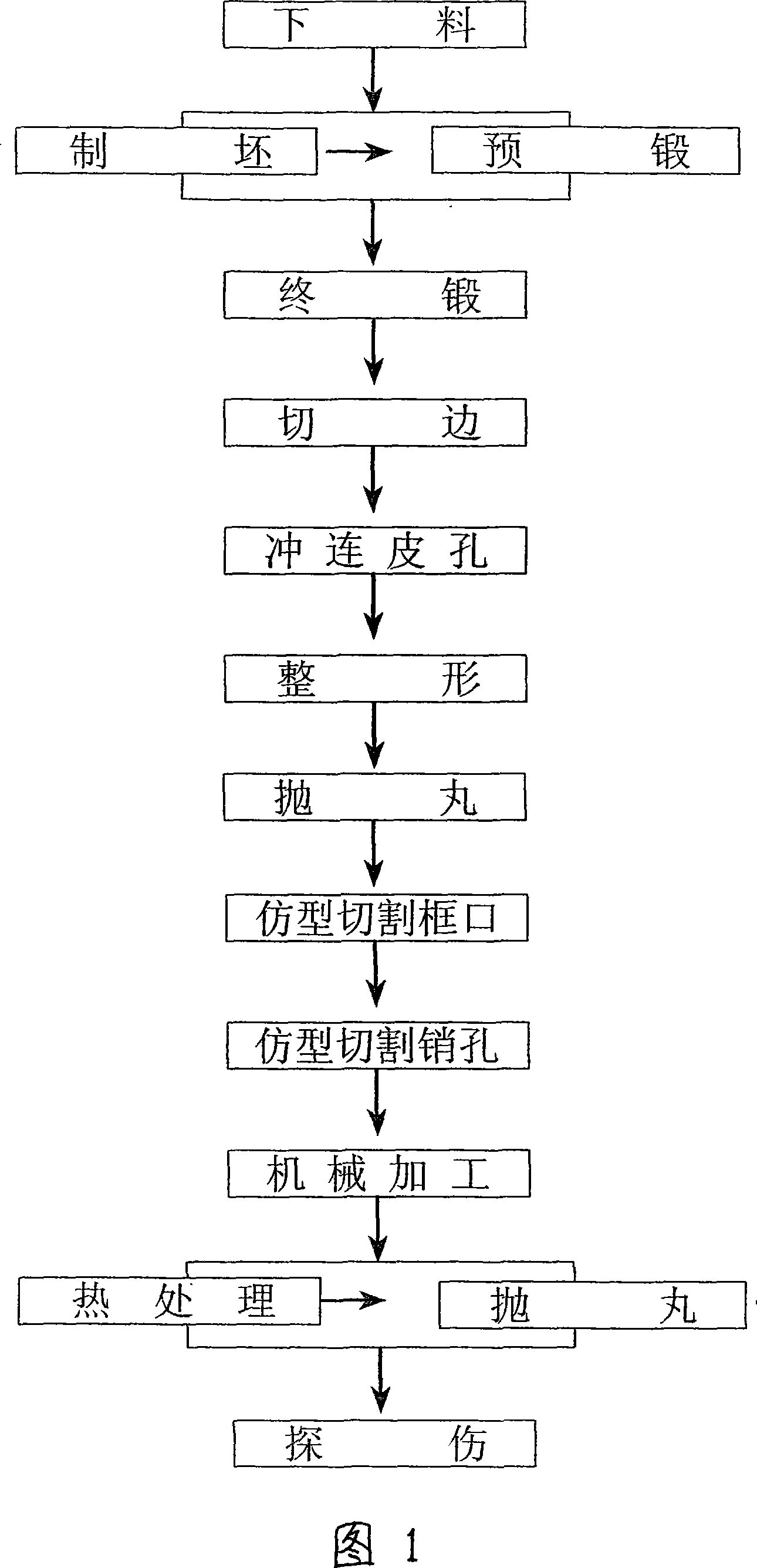

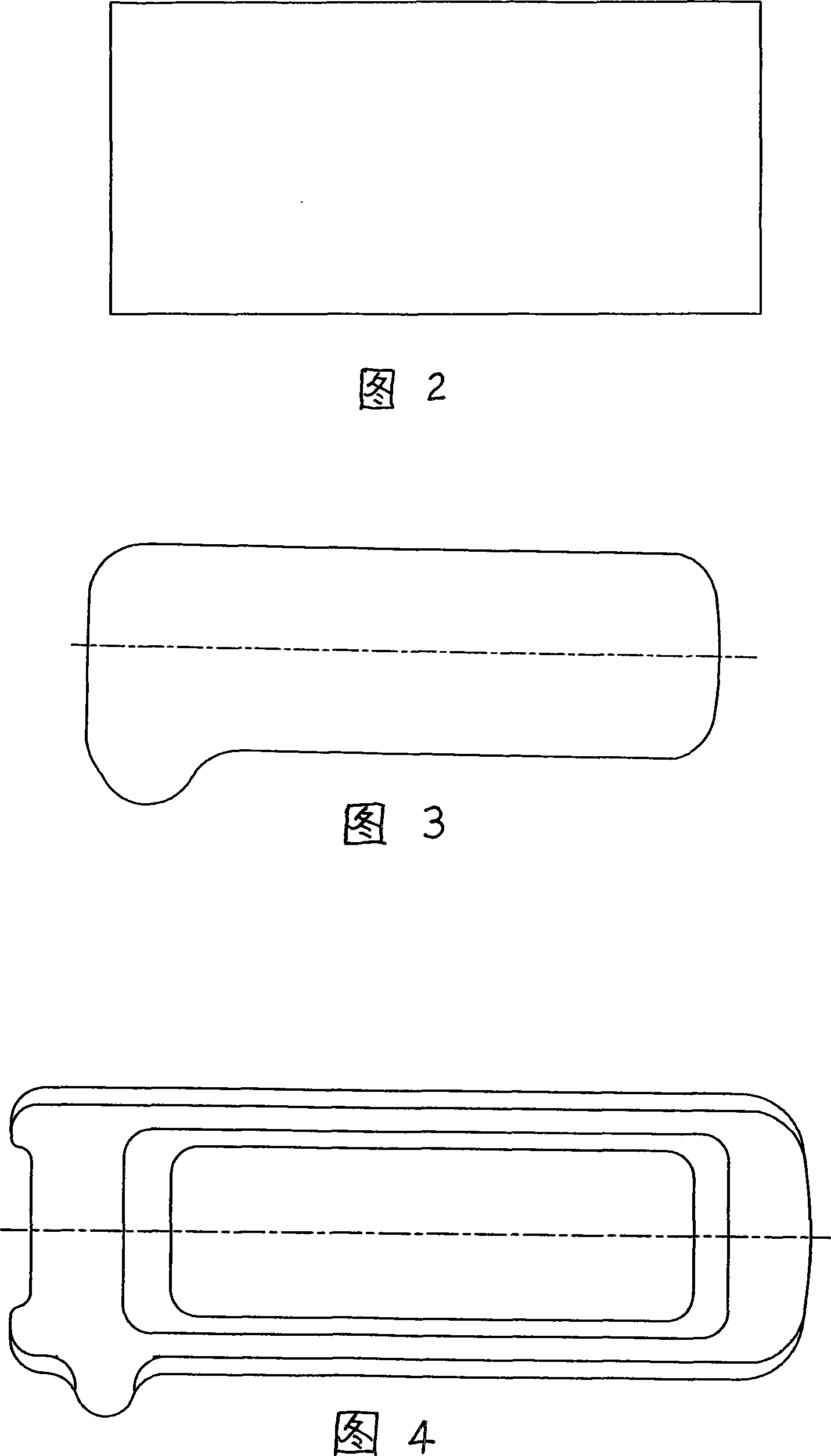

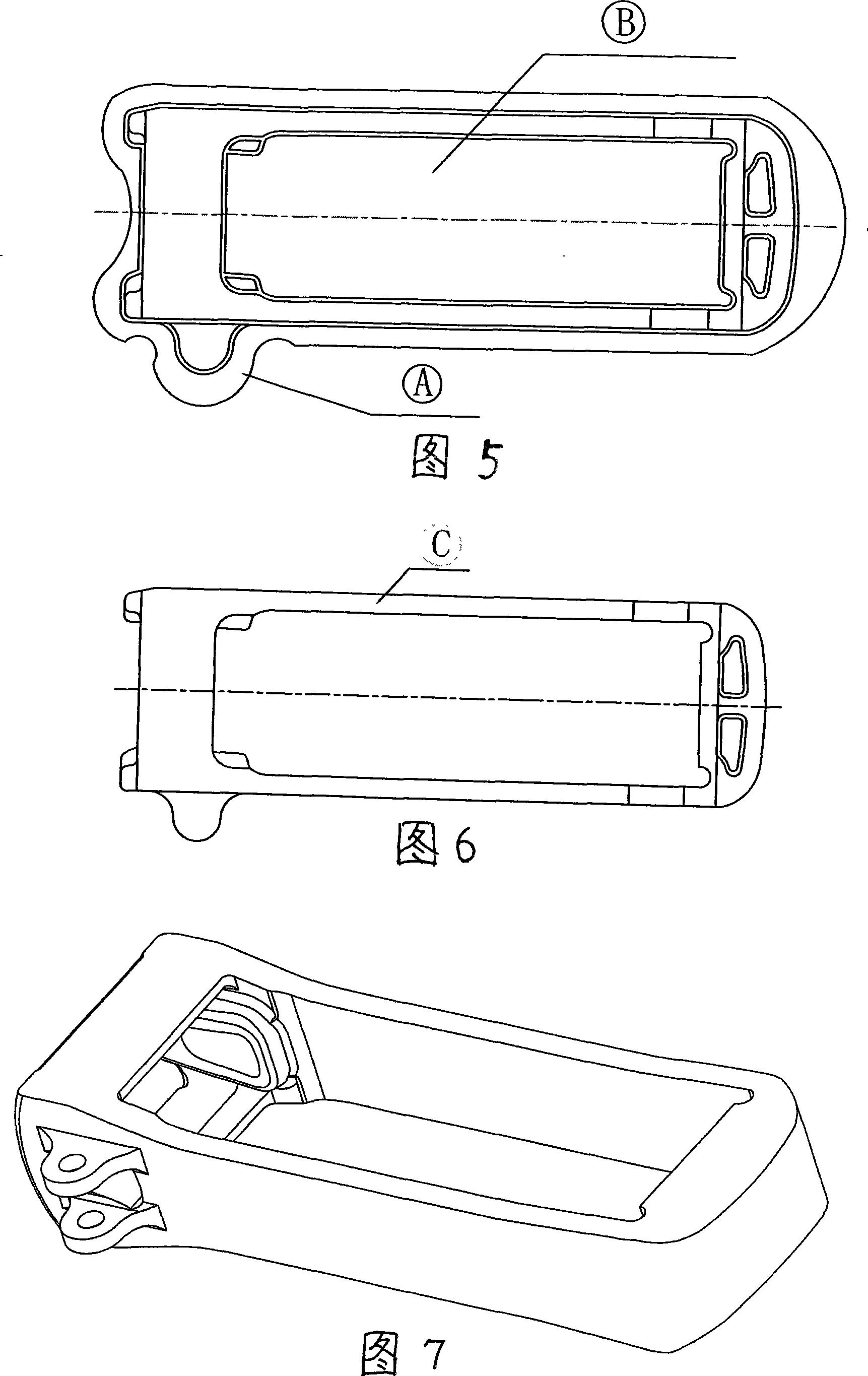

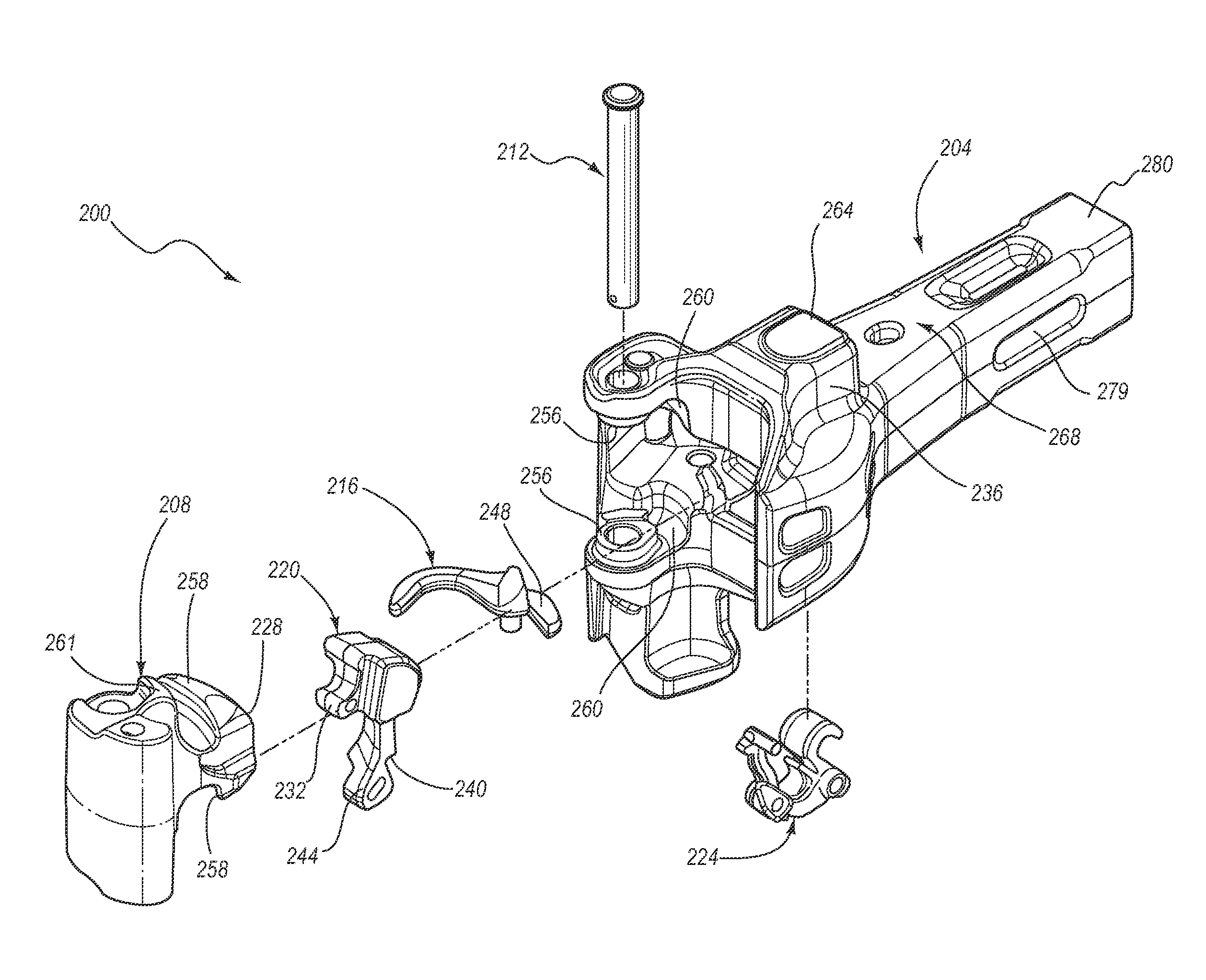

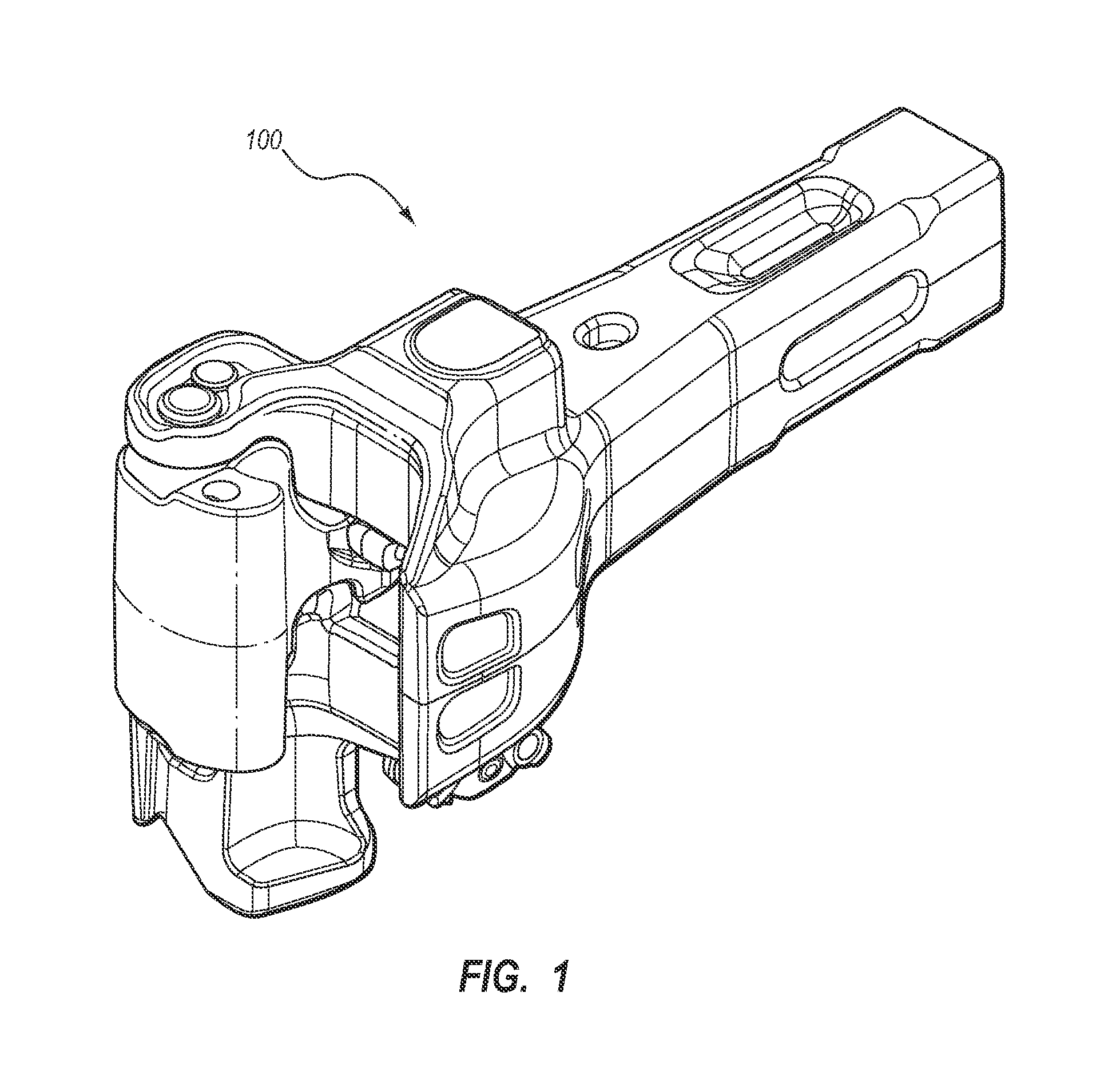

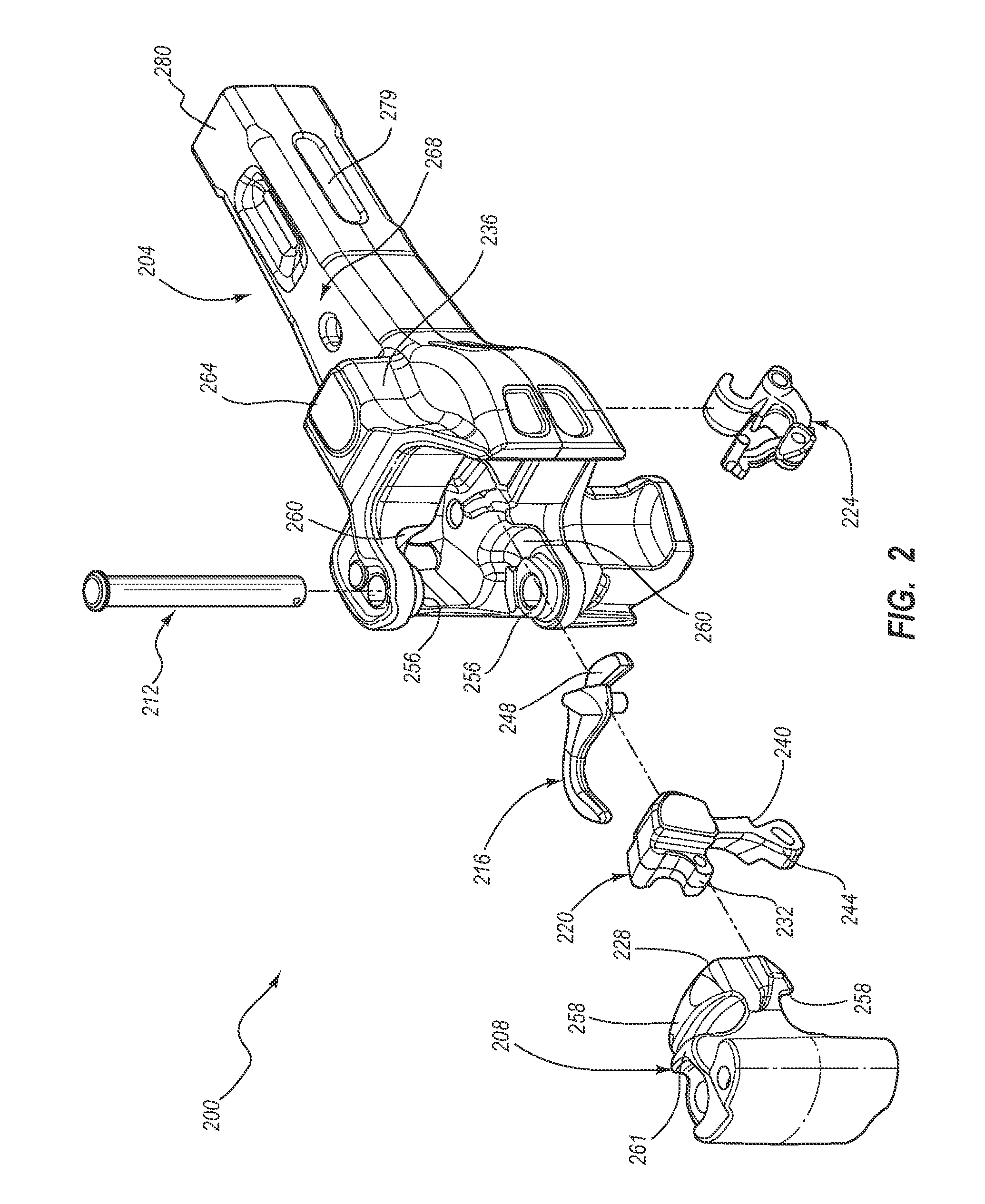

Preparation method for railway freight car coupler tail frame integral forging

The high strength alloy steel blank is made through blank making, casting, rectifying, cutting, machining, heat treatment, pill thrusting, and it excels with greatly reduced defects rate, improved in comprehensive feature, doubly increased in part strength and durability. The anti stretch strength reaches 850N / mm2. The impact power Akvj reaches over 27. Through static charge testing, stresses for all the parts are within the allowable scope, increasing fatigue 80%, and durability two times.

Owner:南京中盛铁路车辆配件有限公司

Continuous application of paint, via a traditional paint brush

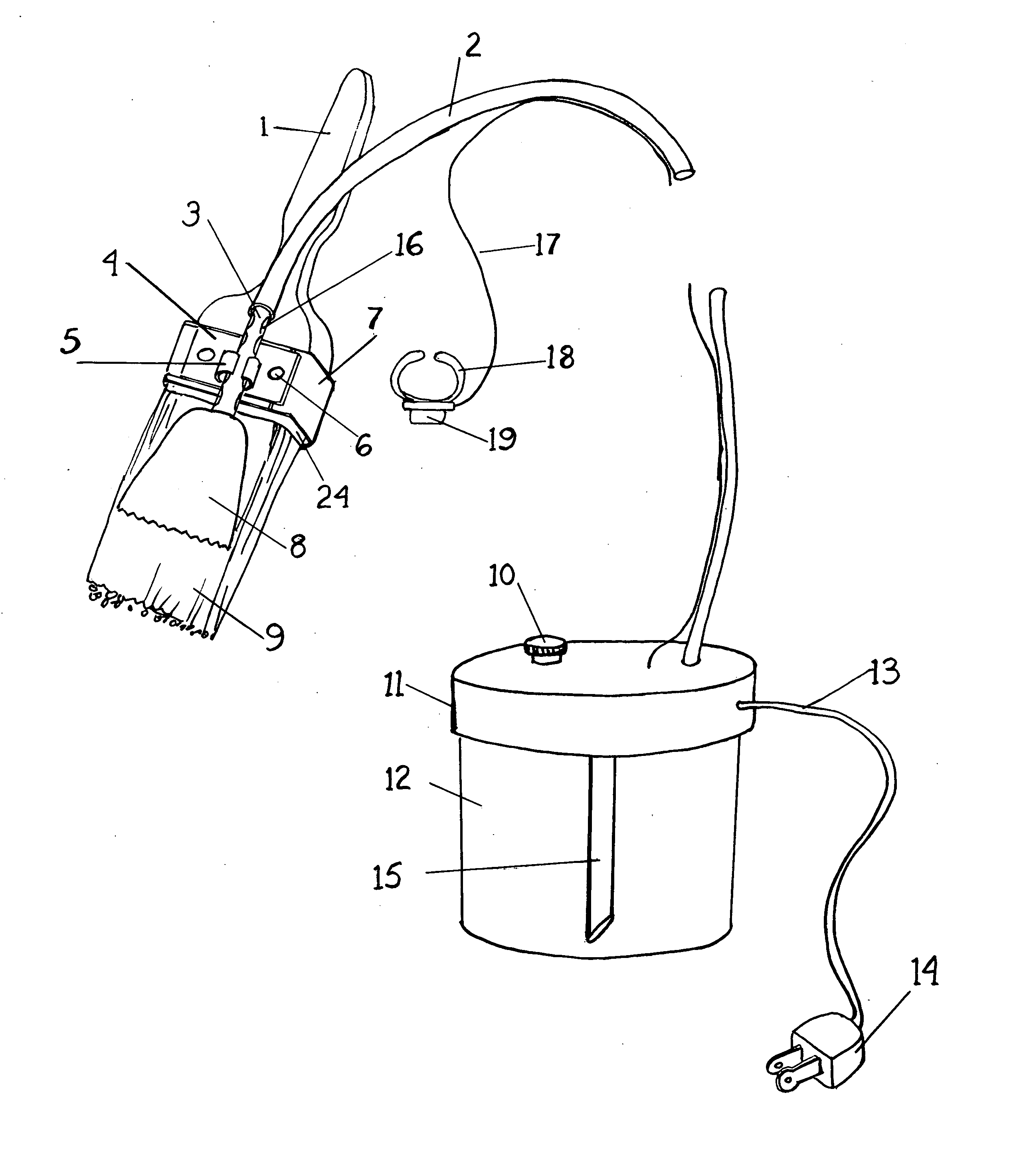

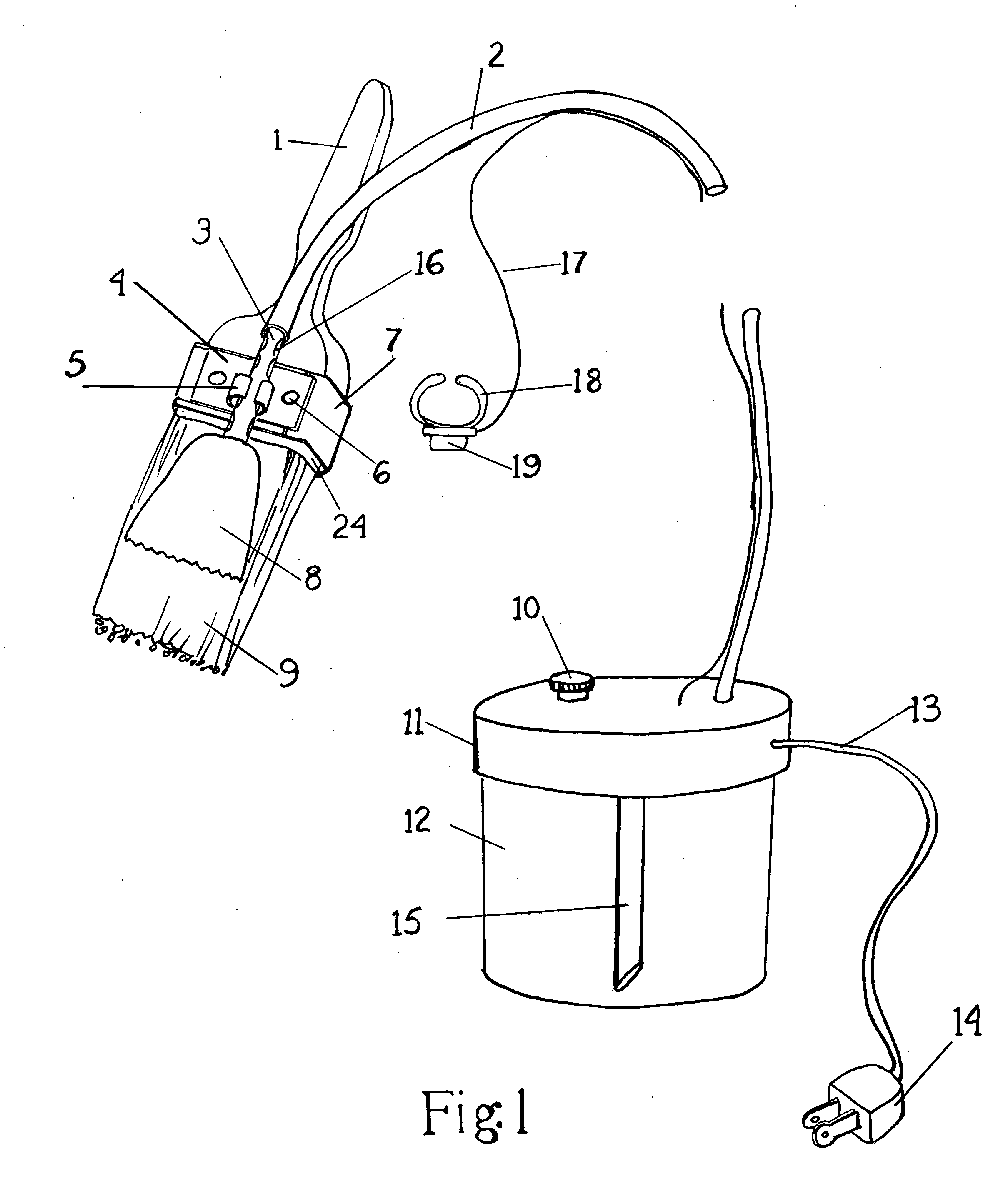

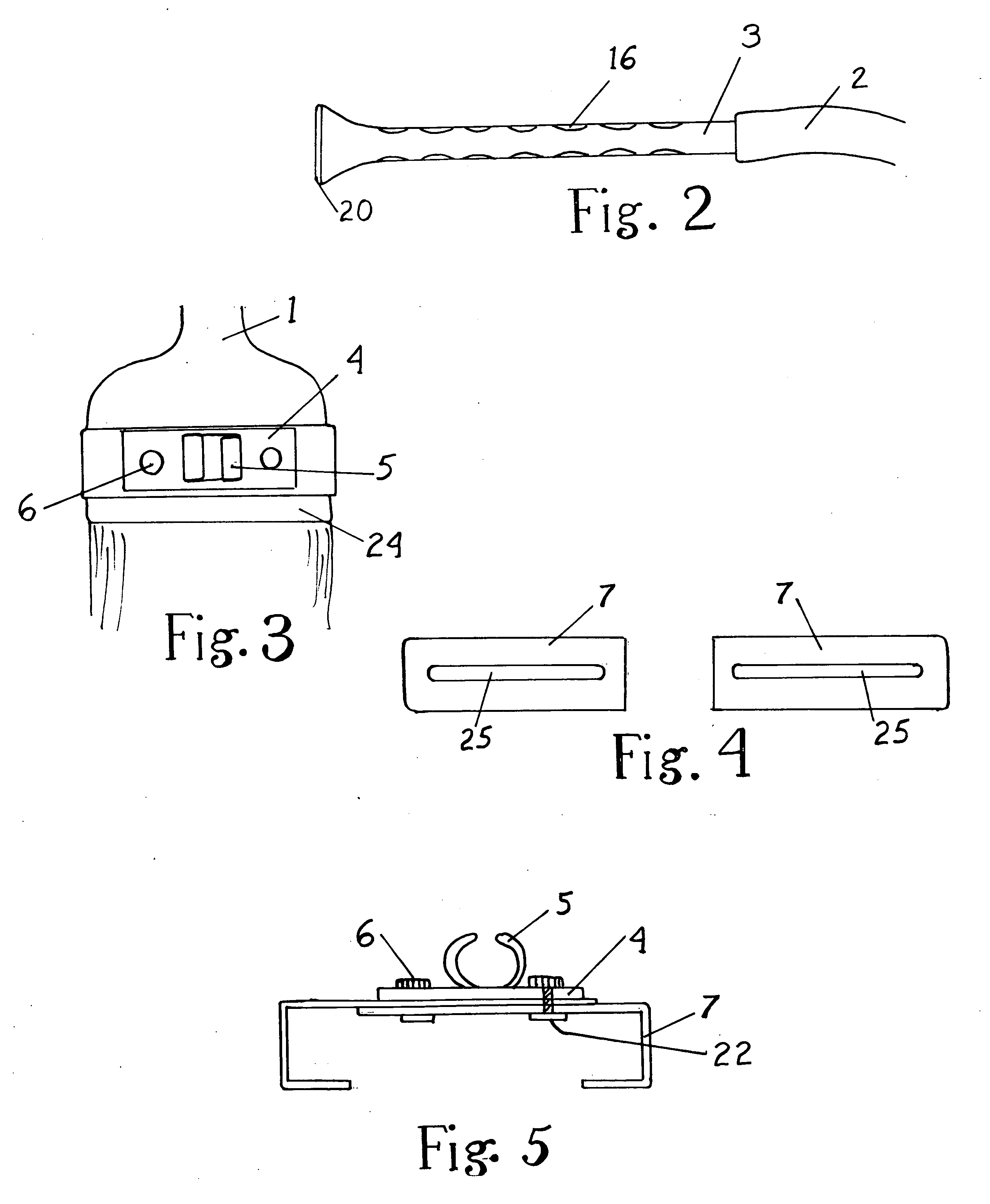

InactiveUS20050226680A1Precise positioningControl flowLiquid surface applicatorsCarpet cleanersOff the shelfBristle

A device capable of delivering a continuous or intermittent amount of common paint or paint-like material to a surface to be painted utilizing a standard, off the shelf paint brush, the novel use of which allows the operator the ability to continuously paint with the brush and not having to break the work sequence of painting by continuous interruption of having to reload the brush by dipping it into a paint can, the component parts of which consists of a stationary platform which is centrally mounted on the brush in between the area of the brush handle and bristles, this being securely held in place by a pair of lateral brush clamps, these designed to accommodate a variety of brush sizes and widths, and or as an alternative, a broad band of flexible material having a series of central perforations, longitudinally and also having at its ends, reusable, self-adhesive material, and a rigid tube that is mounted on the top of the stationary platform or, alternately, held in place centrally by the perforations in the flexible banding, the tube acting as a conduit for paint, which is delivered from a remote source to the rigid tube via another flexible connecting tube, the paint being pumped or otherwise delivered to the rigid tube terminus and thus flowing onto the bristle portion of the brush, the paint flow being properly distributed on the bristles by an attached apron, which also aids in reducing paint drippings, all of which allows the painter to continuously apply paint to a surface without interruption or increased fatigue.

Owner:LAWRENCE JOHN S

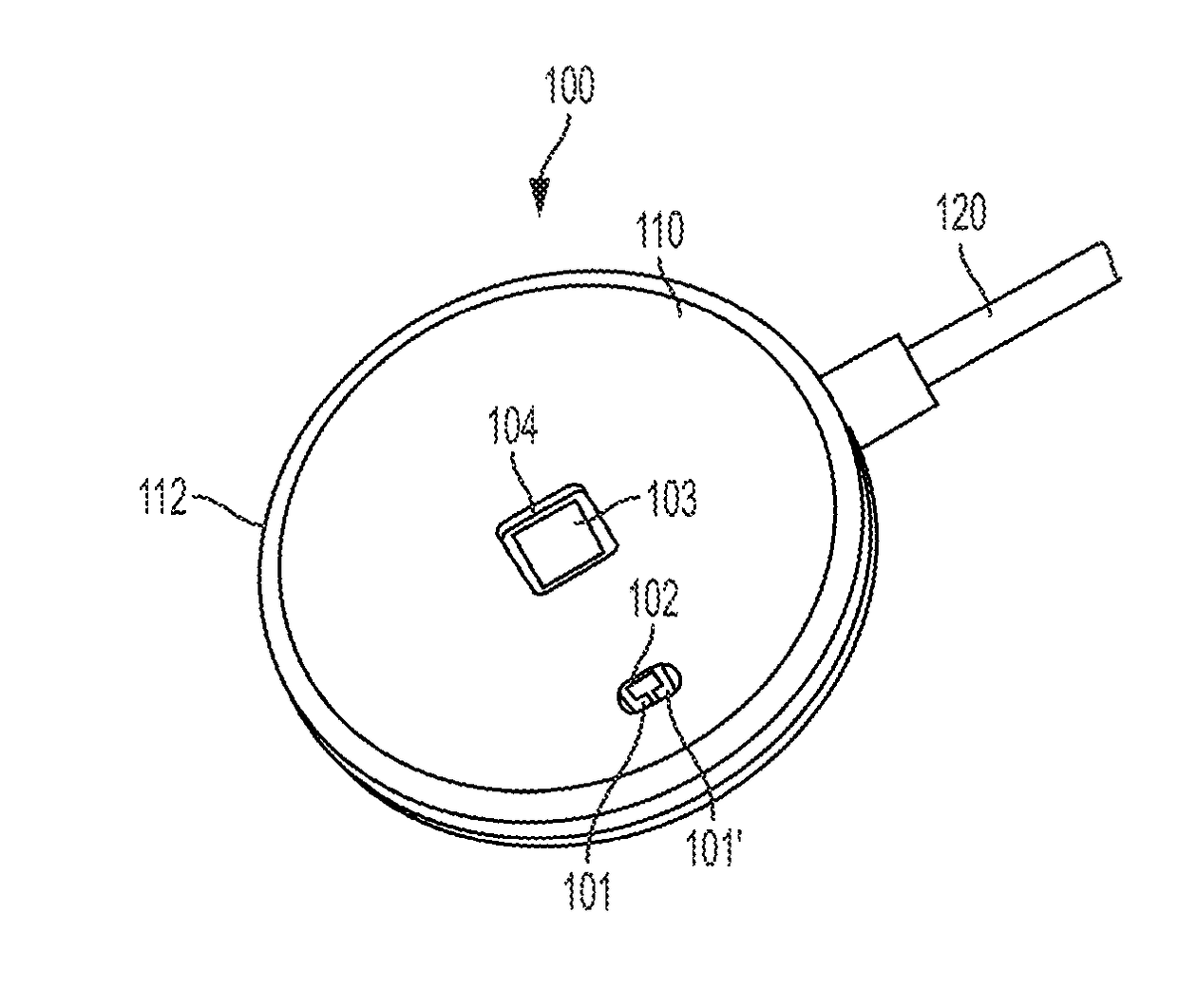

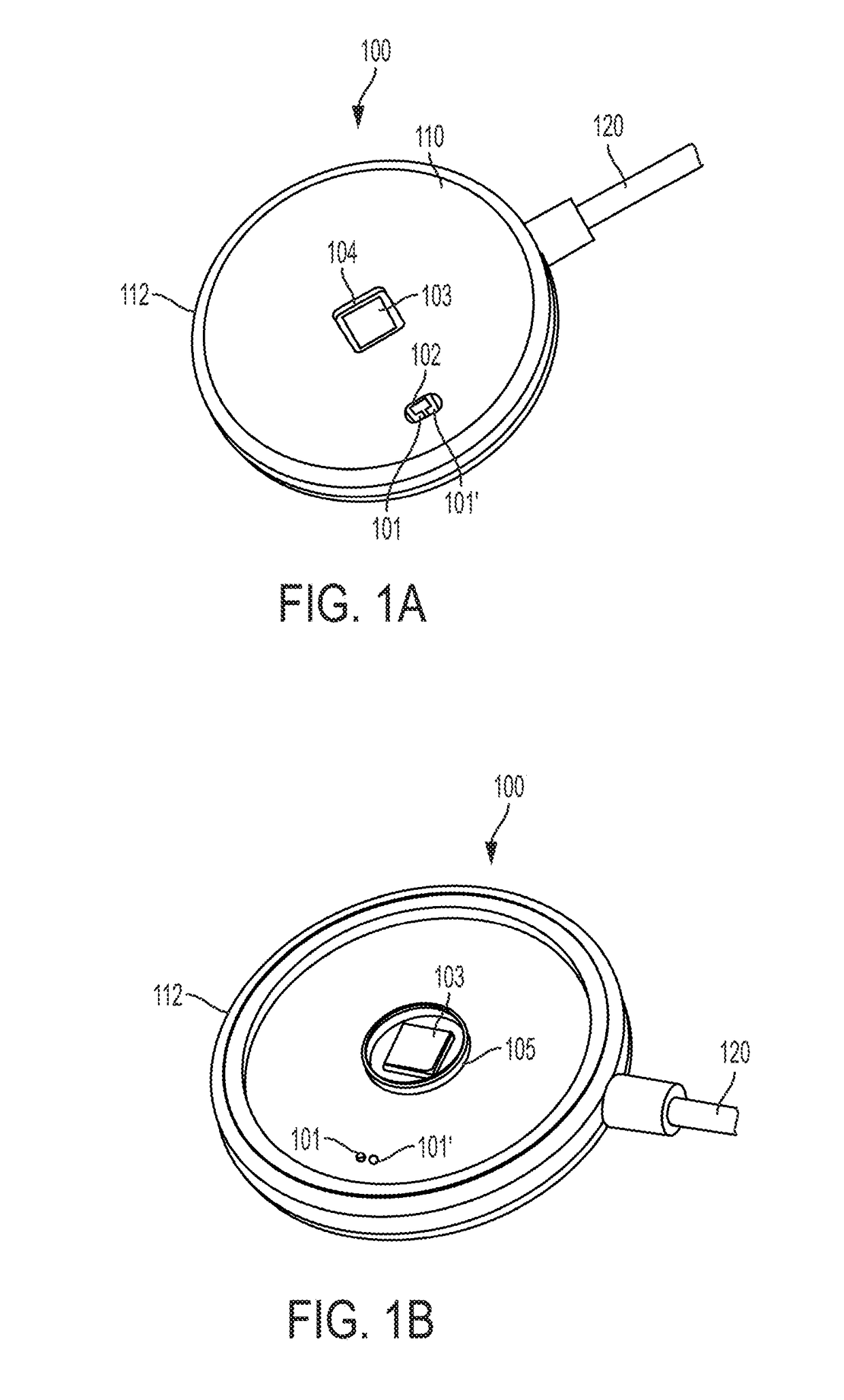

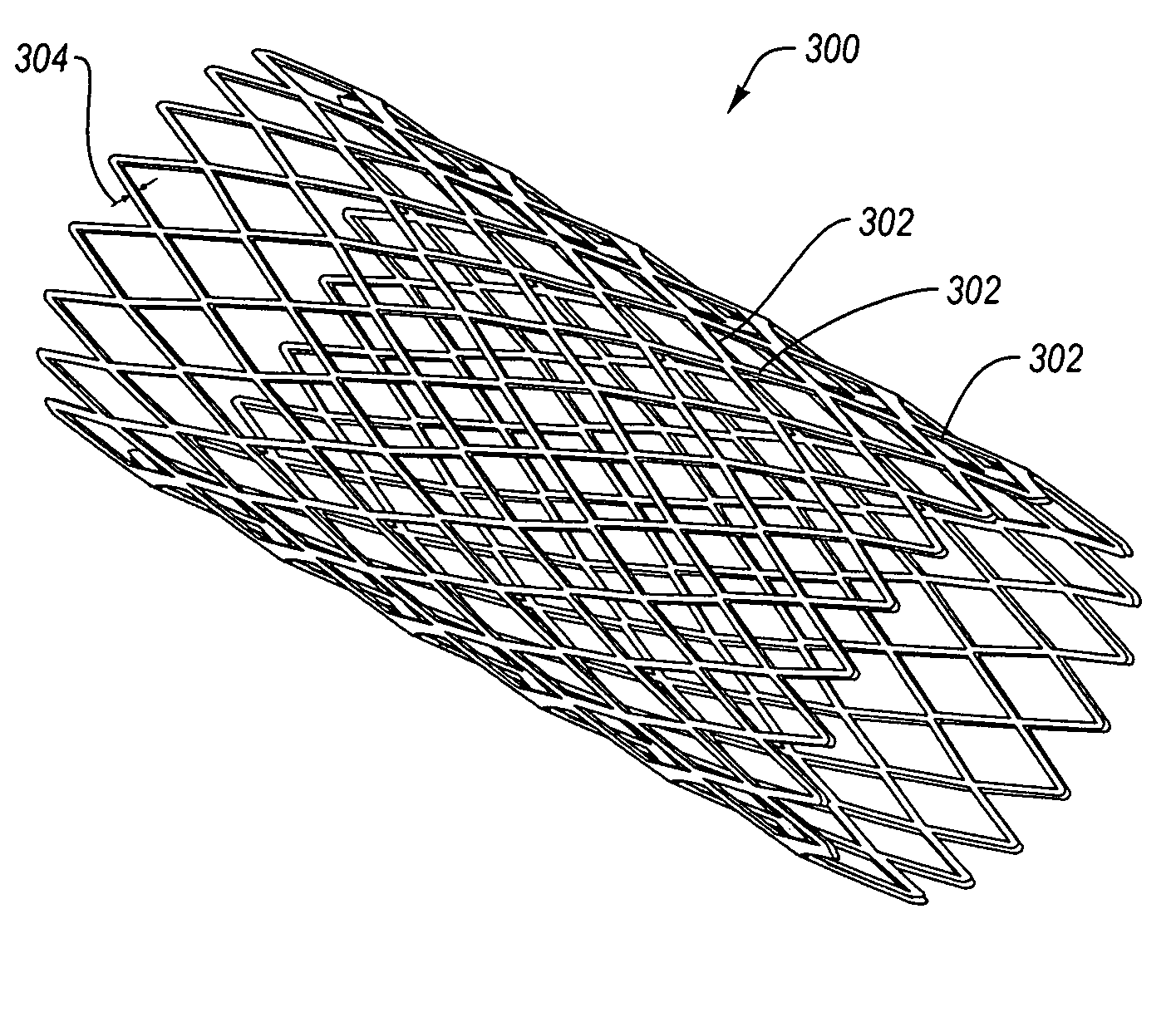

Optical physiologic sensors and methods

ActiveUS20170112422A1High strengthIntensity continuous body motionDiagnostics using spectroscopySensorsPhysical exhaustionBlood gas analysis

Physiologic sensors and methods of application are described. These sensors function by detecting recently discovered variations in the spectral optical density at two or more wavelengths of light diffused through the skin. These variations in spectral optical density have been found to consistently and uniquely relate to changes in the availability of oxygen in the skin tissue, relative to the skin tissue's current need for oxygen, which we have termed Physiology Index (PI). Current use of blood gas analysis and pulse oximetry provides physiologic insight only to blood oxygen content and cannot detect the status of energy conversion metabolism at the tissue level. By contrast, the PI signal uniquely portrays when the skin tissue is receiving ‘less than enough oxygen,’‘just the right amount of oxygen,’ or ‘more than enough oxygen’ to enable aerobic energy conversion metabolism. The PI sensor detects one pattern of photonic response to insufficient skin tissue oxygen, or tissue hypoxia, (producing negative PI values) and a directly opposite photonic response to excess tissue oxygen, or tissue hyperoxia, (producing positive PI values), with a neutral zone in between (centered at PI zero). Additionally, unique patterns of PI signal response have been observed relative to the level of physical exertion, typically with a secondary positive-going response trend in the PI values that appears to correspond with increasing fatigue. The PI sensor illuminates the skin with alternating pulses of selected wavelengths of red and infrared LED light, then detects the respective amount of light that has diffused through the skin to an aperture located a lateral distance from the light source aperture. Additional structural features include means of internally excluding light from directly traveling from the light emitters to the photodetector within the sensor. This physiology sensor and methods of use offer continuous, previously unavailable information relating to tissue-level energy conversion metabolism. Several alternative embodiments are described, including those that would be useful in medical care, athletics, and personal health maintenance applications.

Owner:REVEAL BIOSENSORS INC

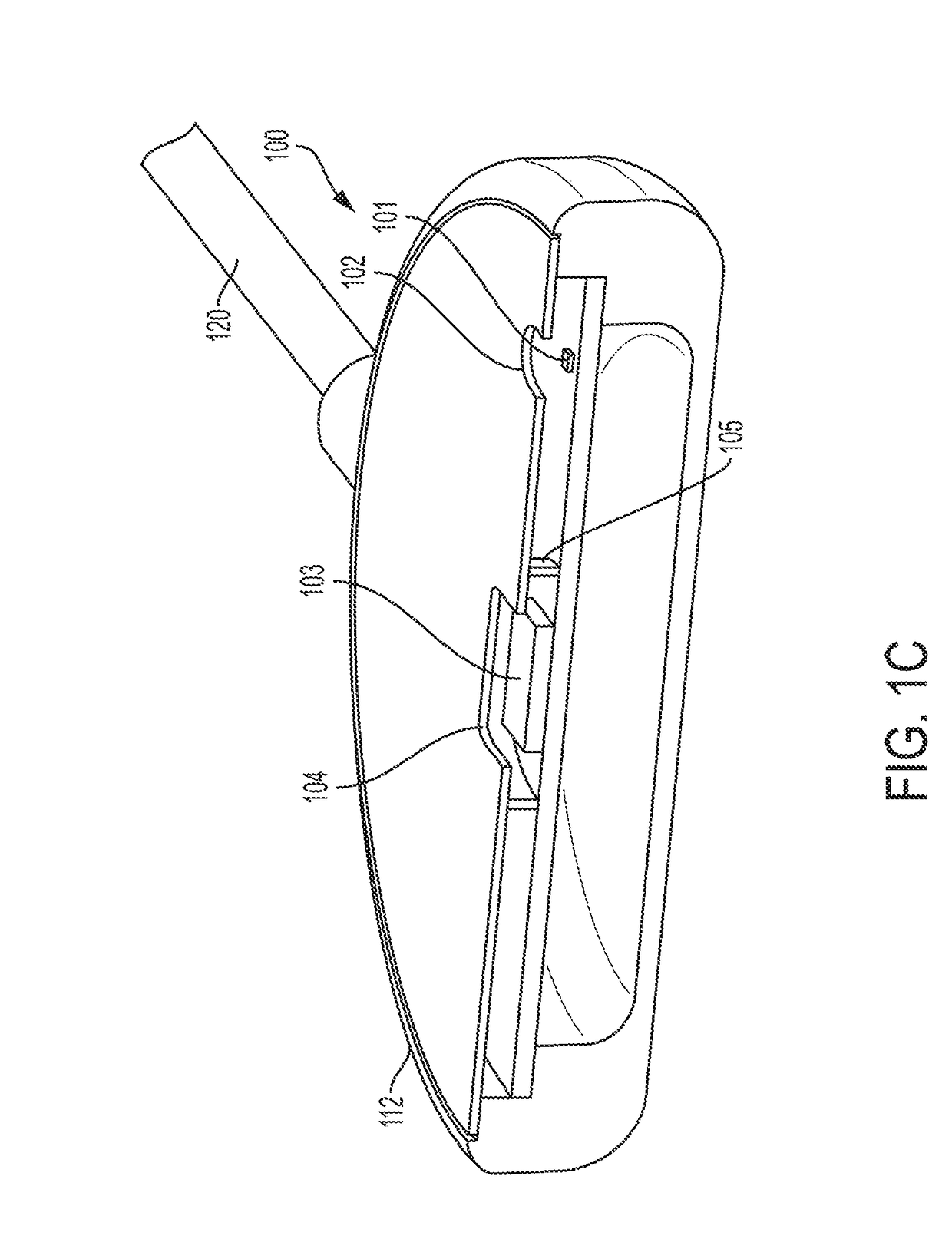

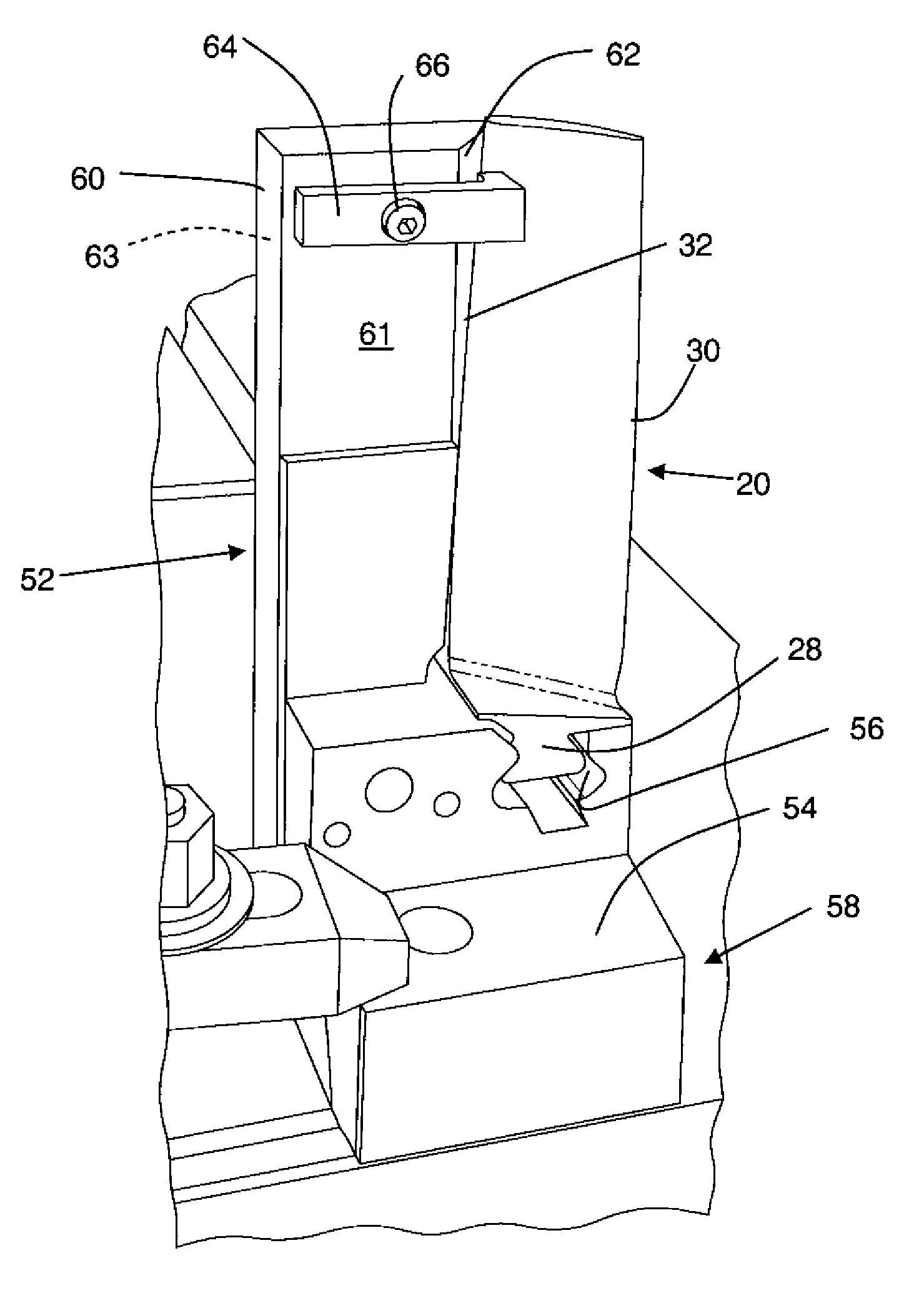

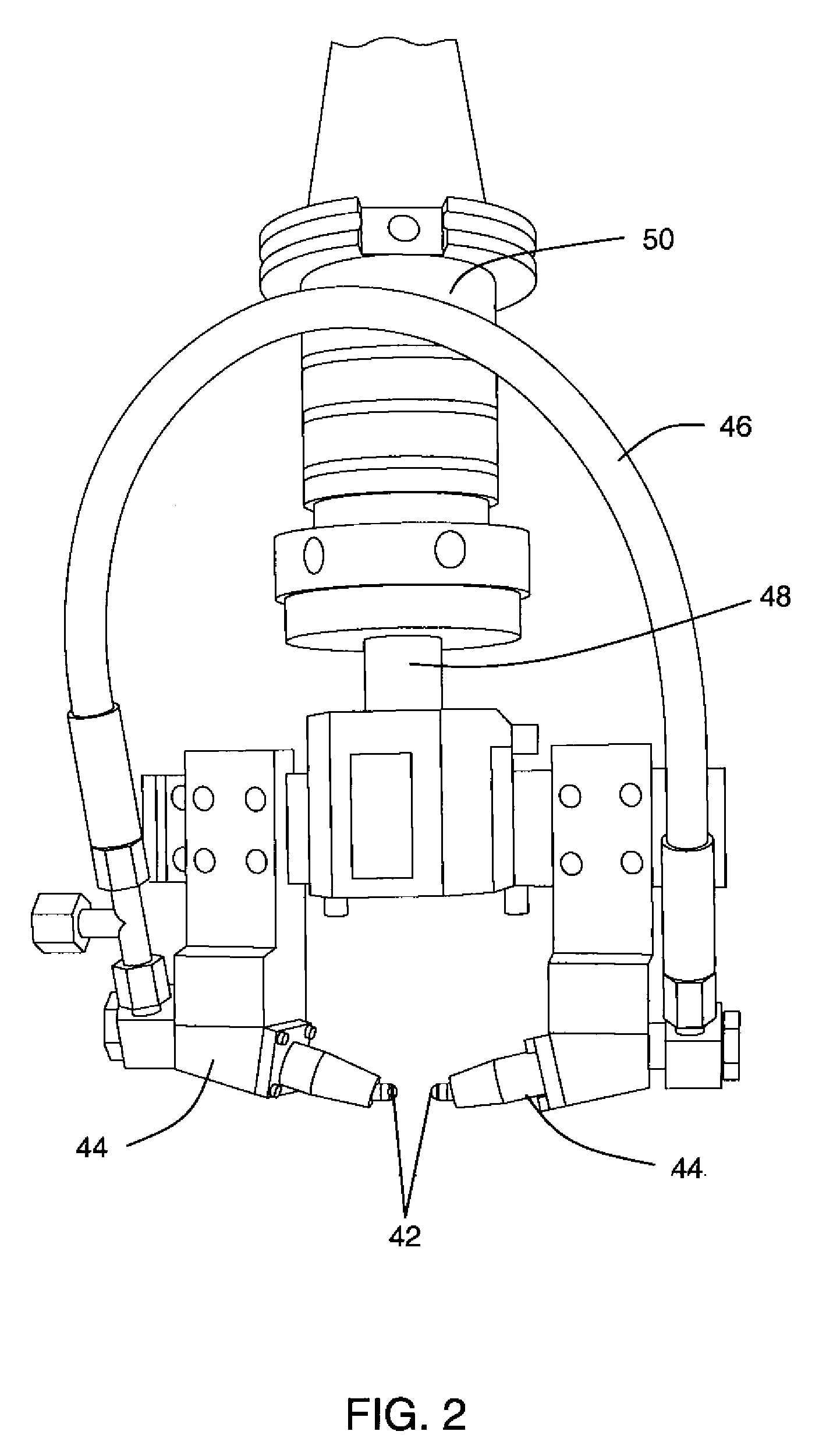

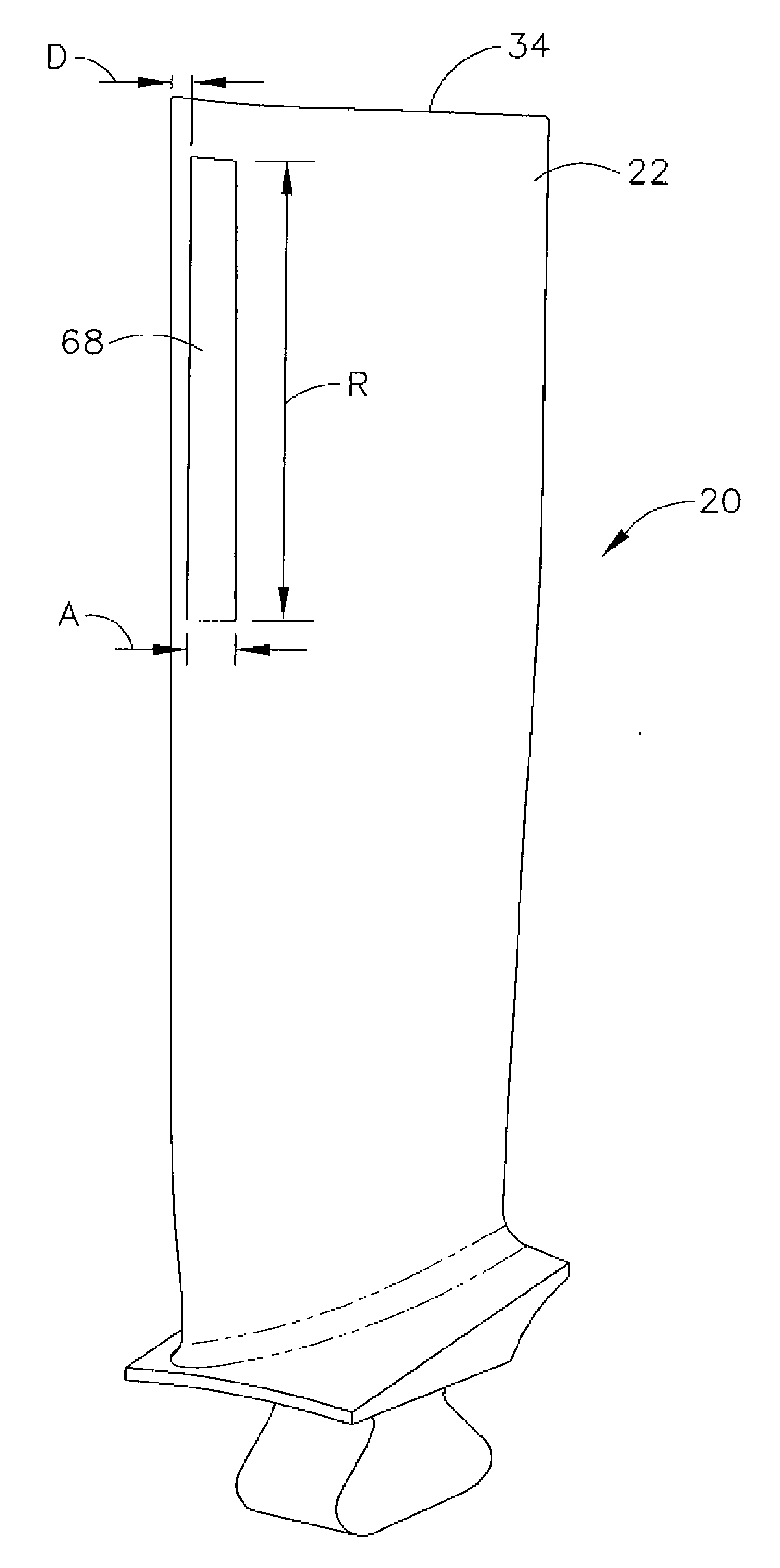

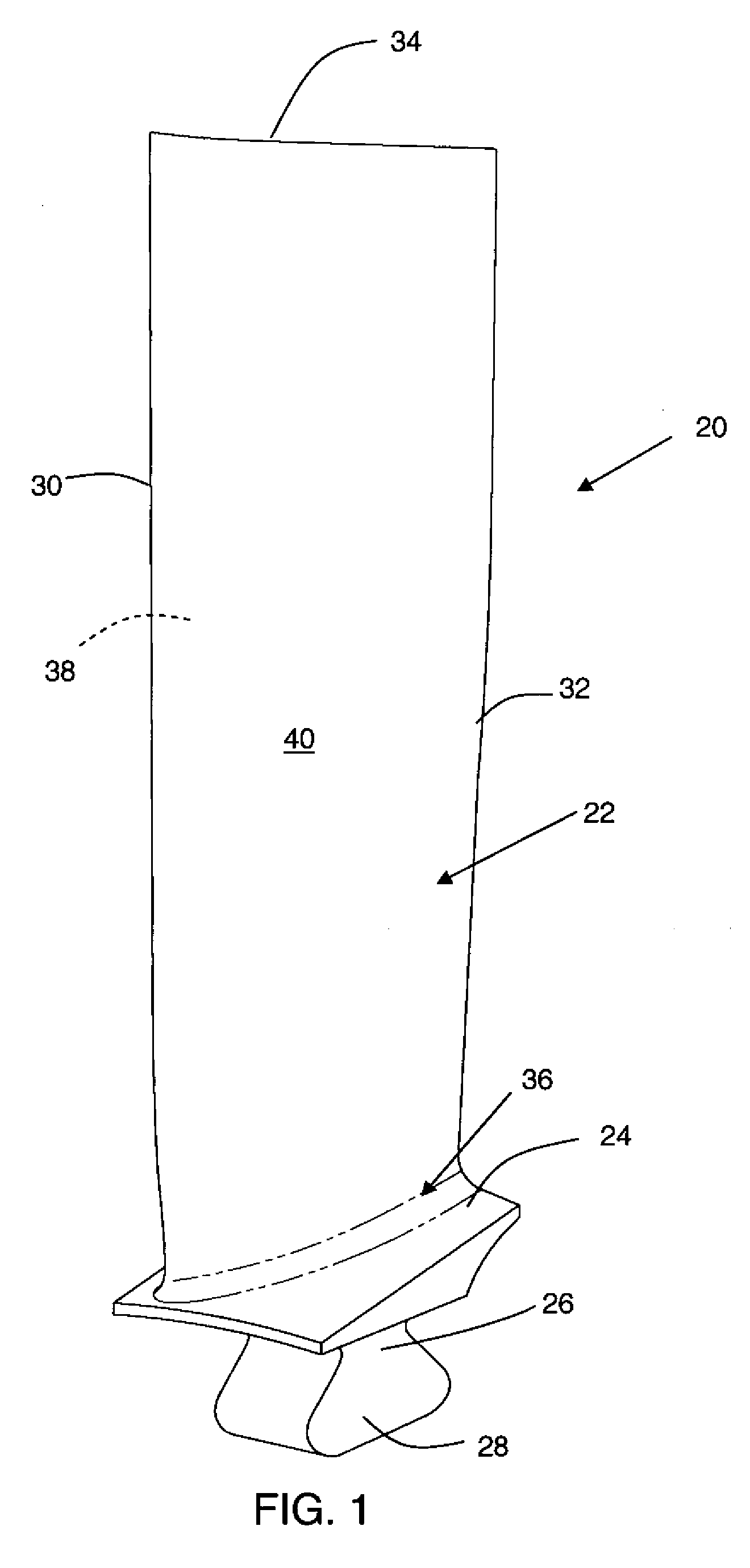

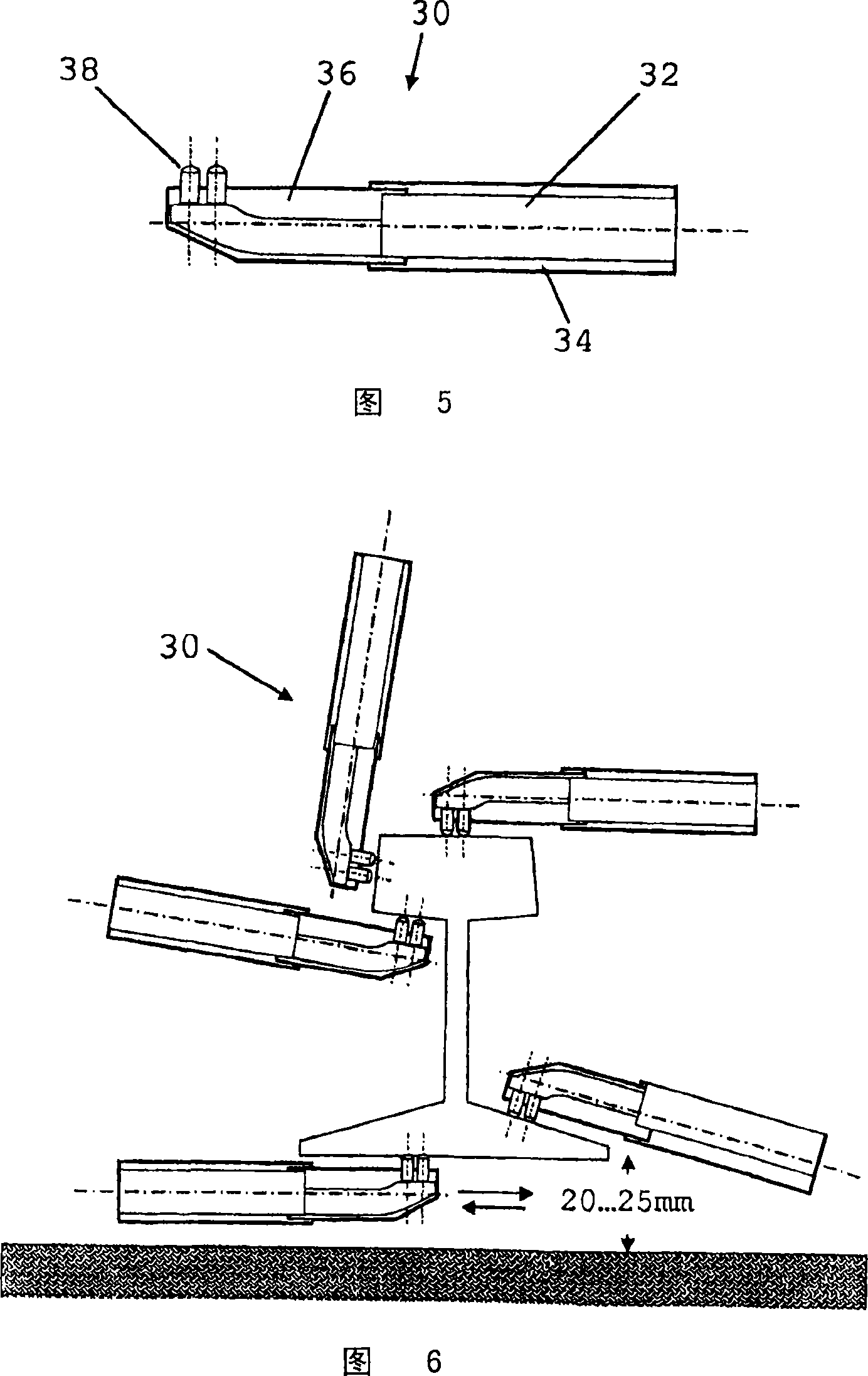

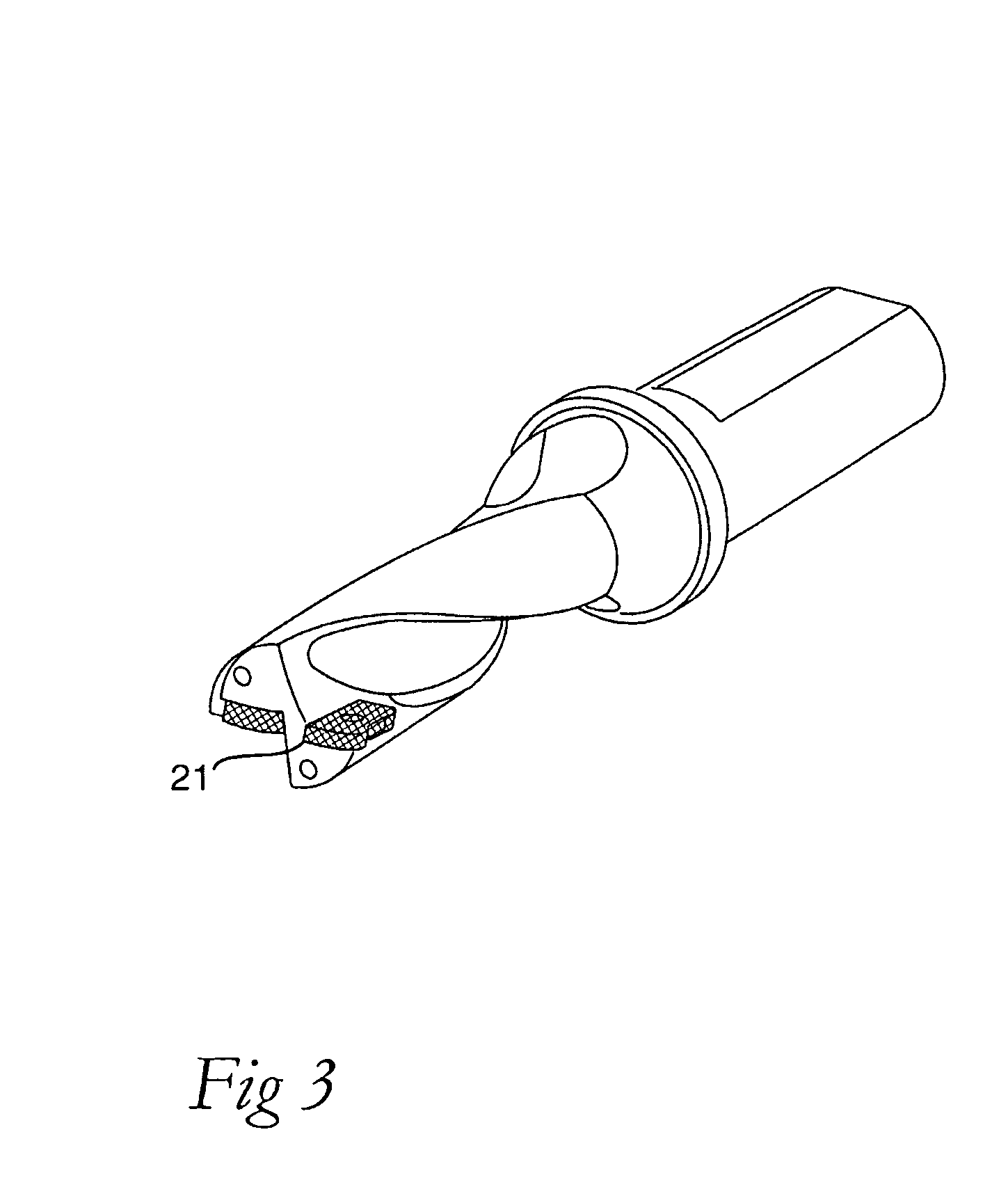

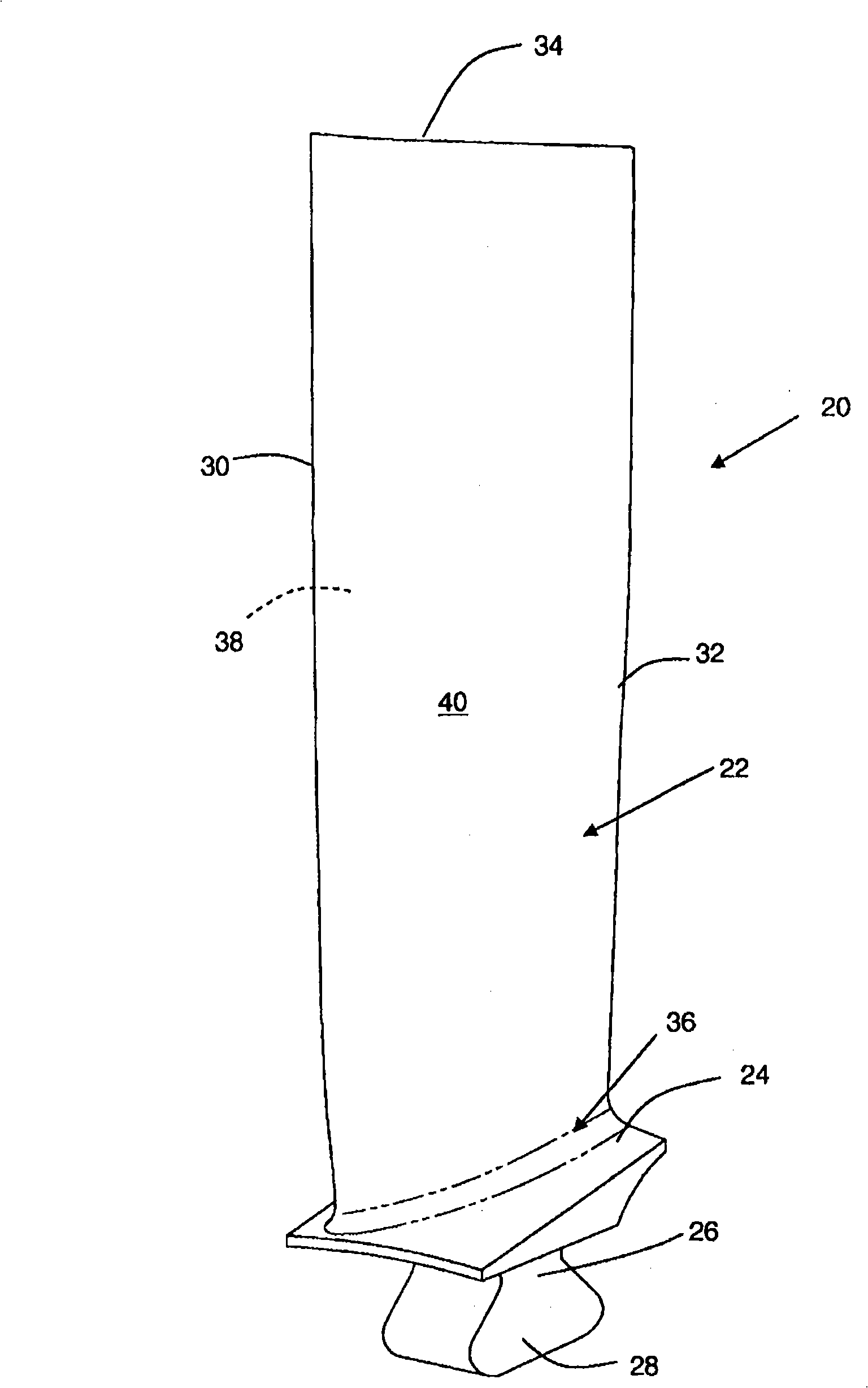

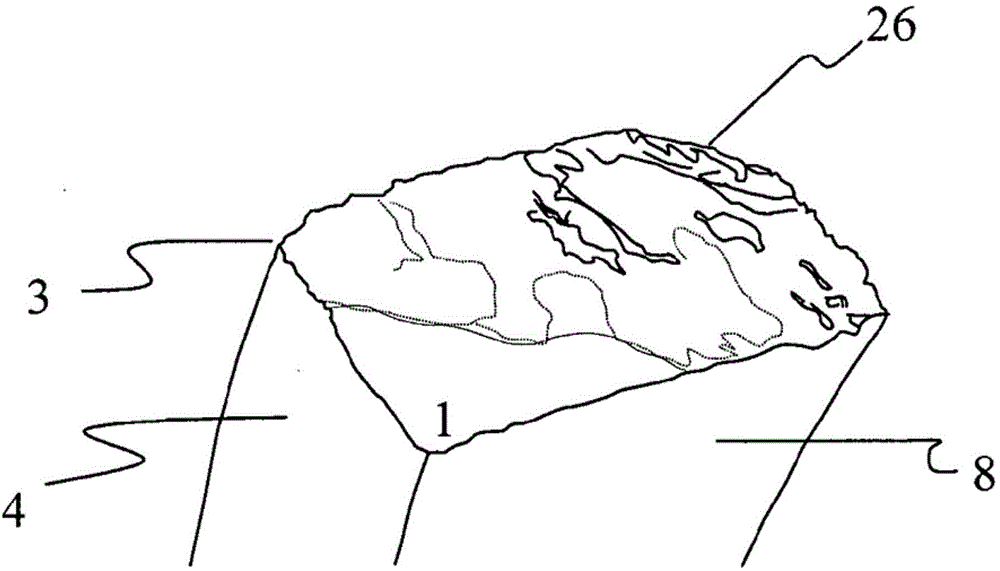

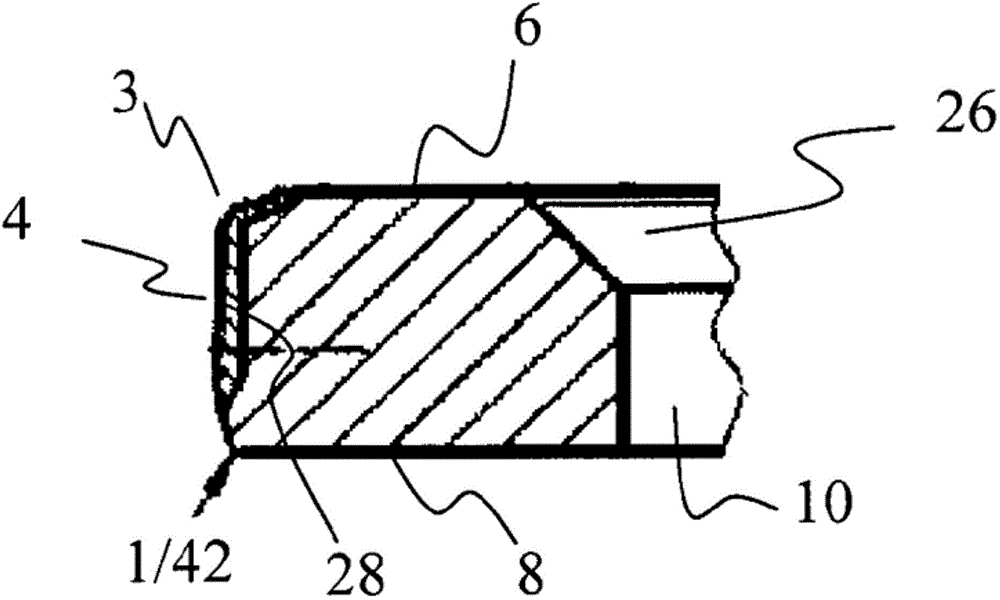

Method for increasing fatigue notch capability of airfoils

InactiveUS8051565B2Reduce crack propagationAvoid deformationBurnishing machinesEngine componentsLeading edgeOffset distance

A method of reducing crack propagation in an airfoil includes: providing an airfoil having a root spaced apart from a tip, spaced-apart leading and trailing edges, a suction side extending from the leading edge to the trailing edge, and an opposed pressure side extending from the leading edge and the trailing edge, supporting the airfoil against bending loads; and burnishing the airfoil using a burnishing element, so as to create at least one burnished section of residual compressive stress, the at least one burnished section being located adjacent the leading edge and spaced from the leading edge by an offset distance selected so as to avoid deformation of the leading edge.

Owner:GENERAL ELECTRIC CO

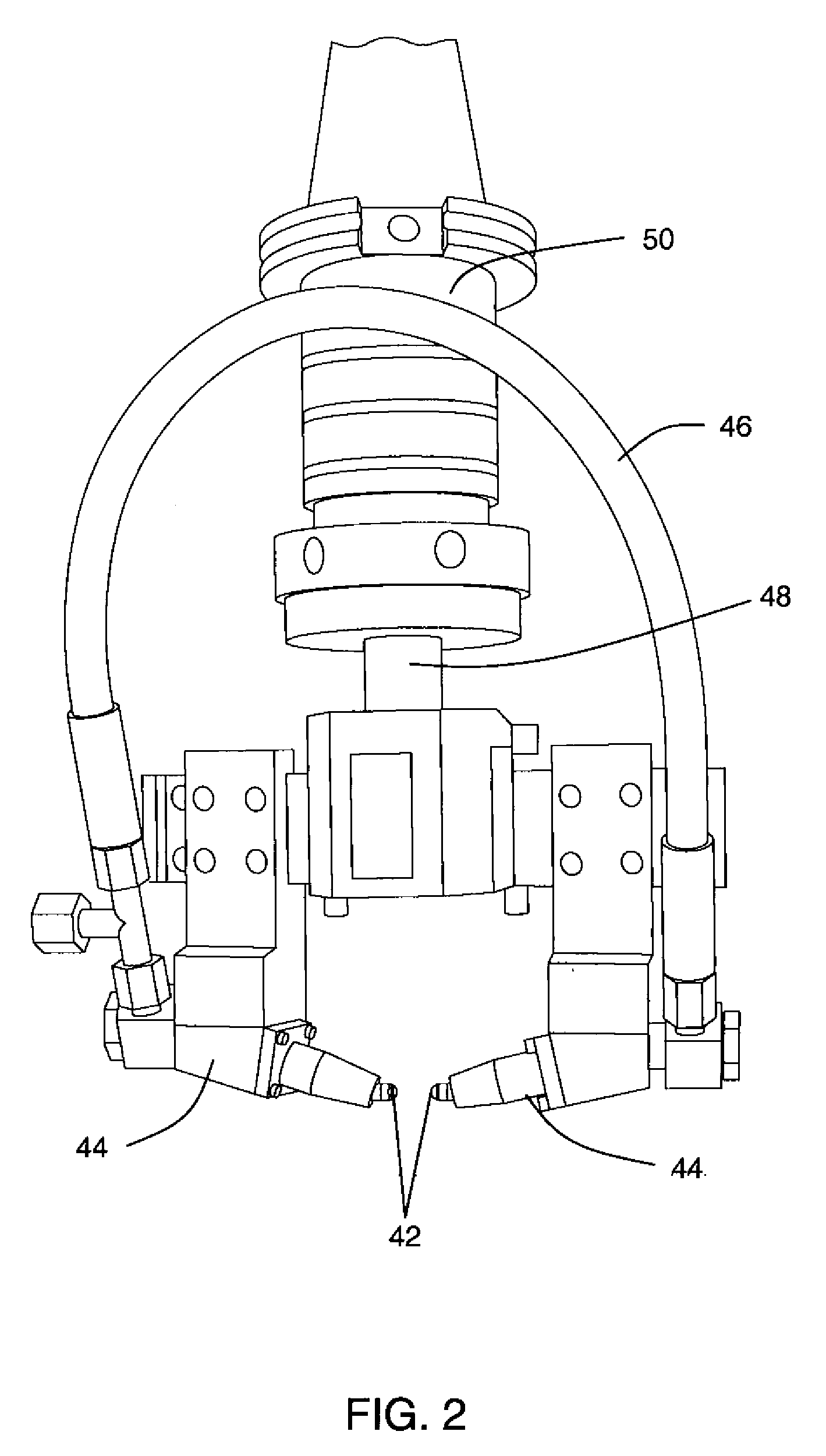

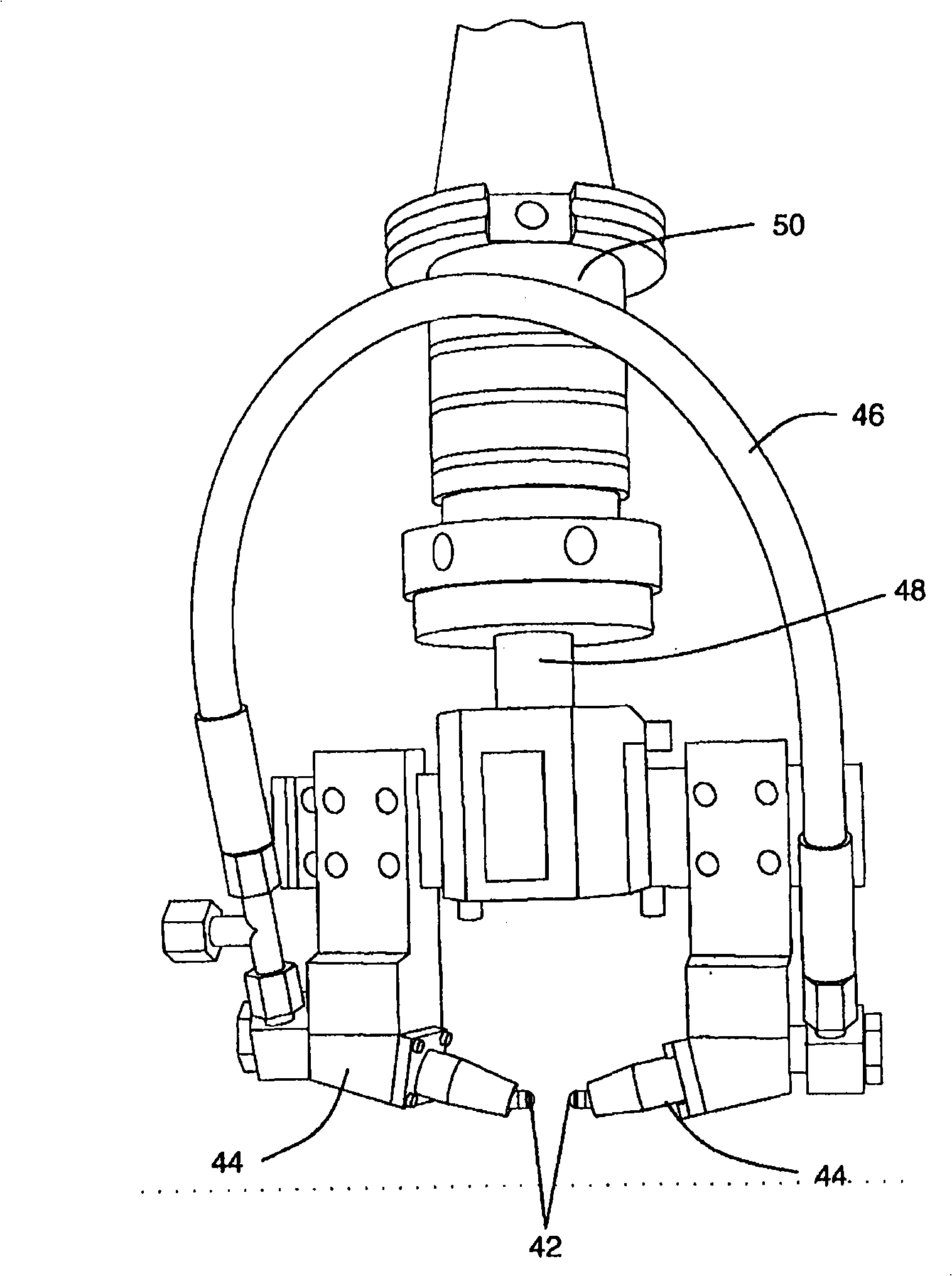

Method and apparatus for increasing fatigue notch capability of airfoils

InactiveUS20080155802A1Reduce crack propagationAvoid deformationBurnishing machinesEngine componentsLeading edgeSuction stress

A method of reducing crack propagation in an airfoil includes: providing an airfoil having a root spaced apart from a tip, spaced-apart leading and trailing edges, a suction side extending from the leading edge to the trailing edge, and an opposed pressure side extending from the leading edge and the trailing edge, supporting the airfoil against bending loads; and burnishing the airfoil using a burnishing element, so as to create at least one burnished section of residual compressive stress, the at least one burnished section being located adjacent the leading edge and spaced from the leading edge by an offset distance selected so as to avoid deformation of the leading edge.

Owner:GENERAL ELECTRIC CO

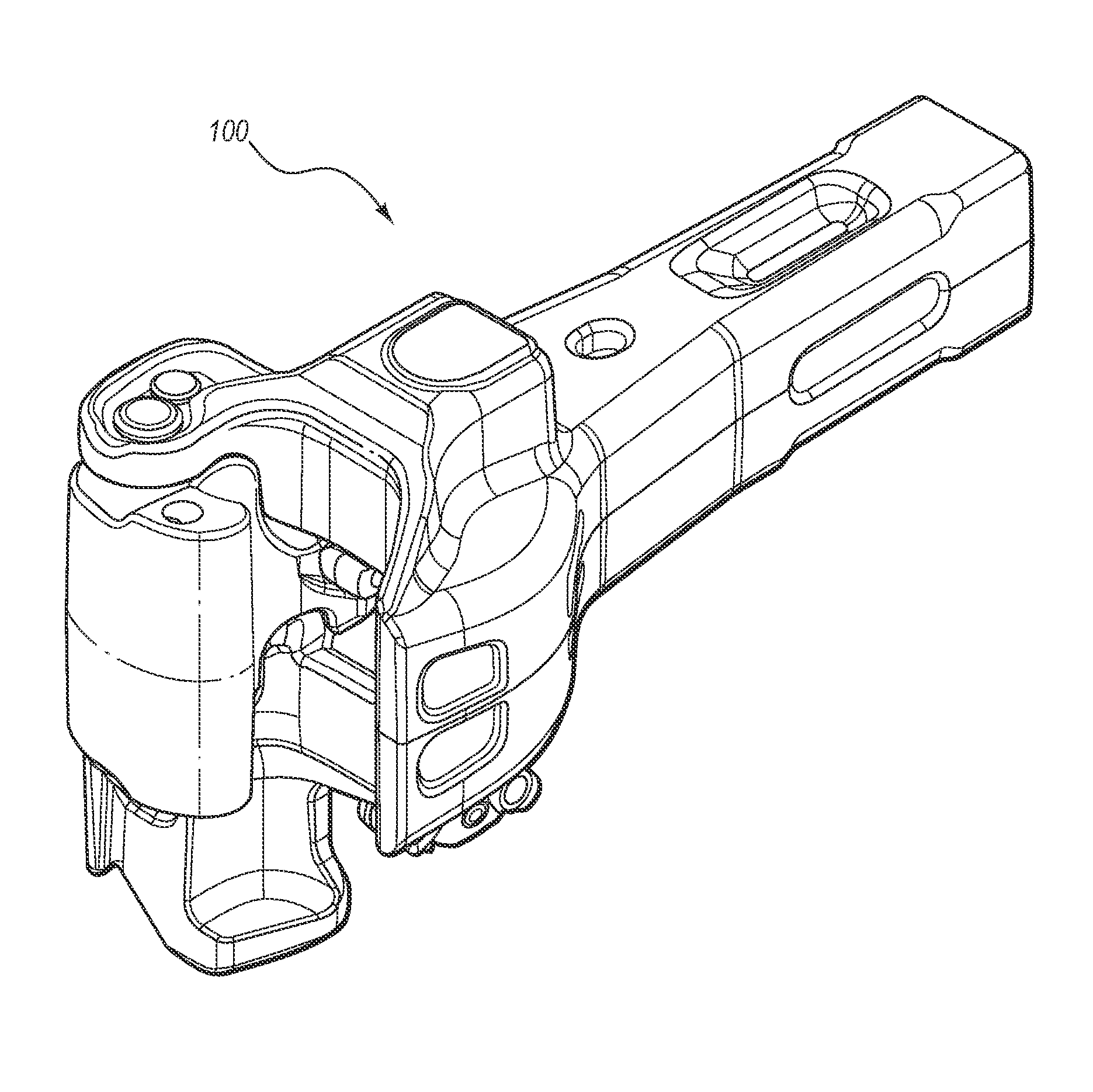

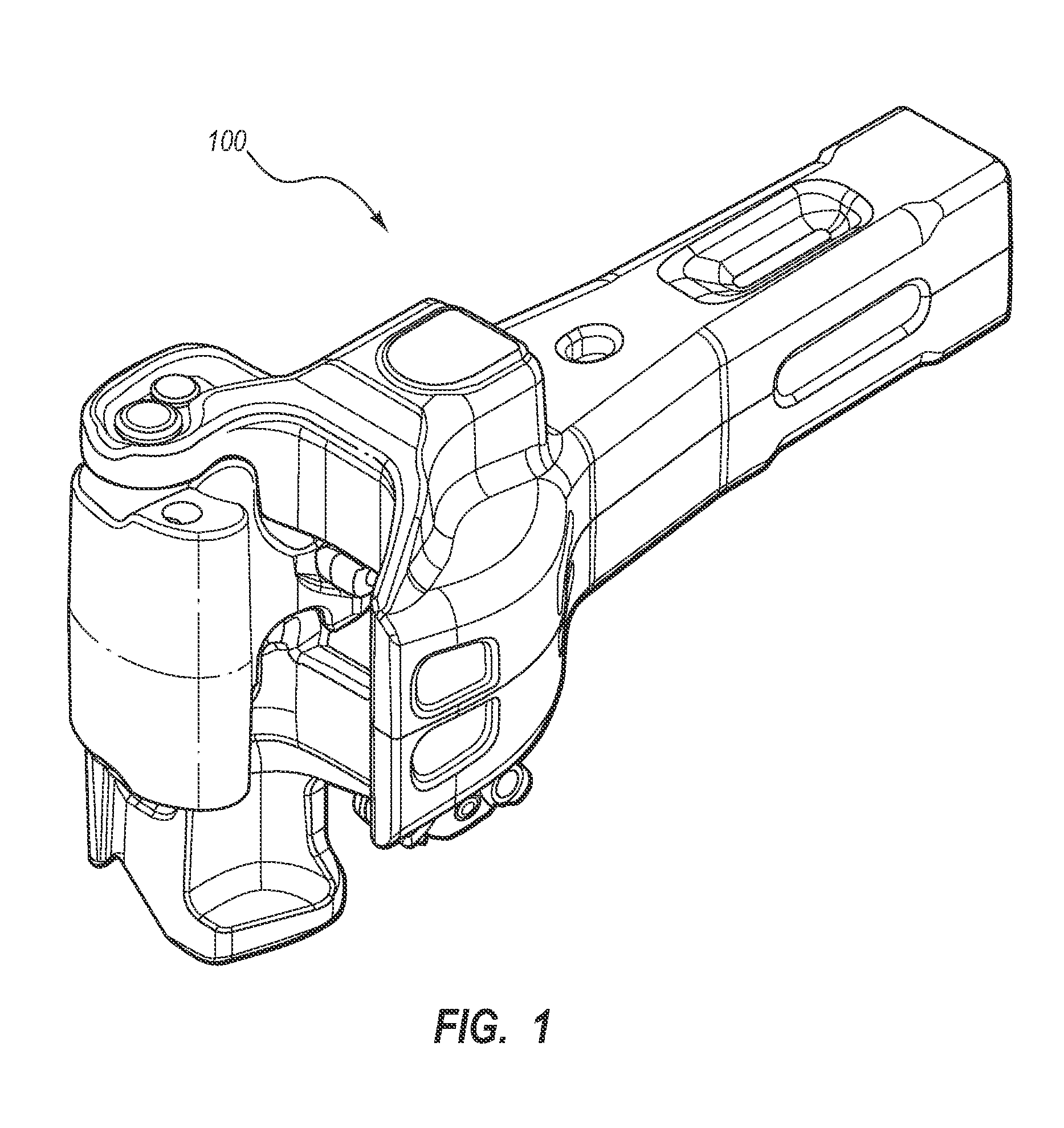

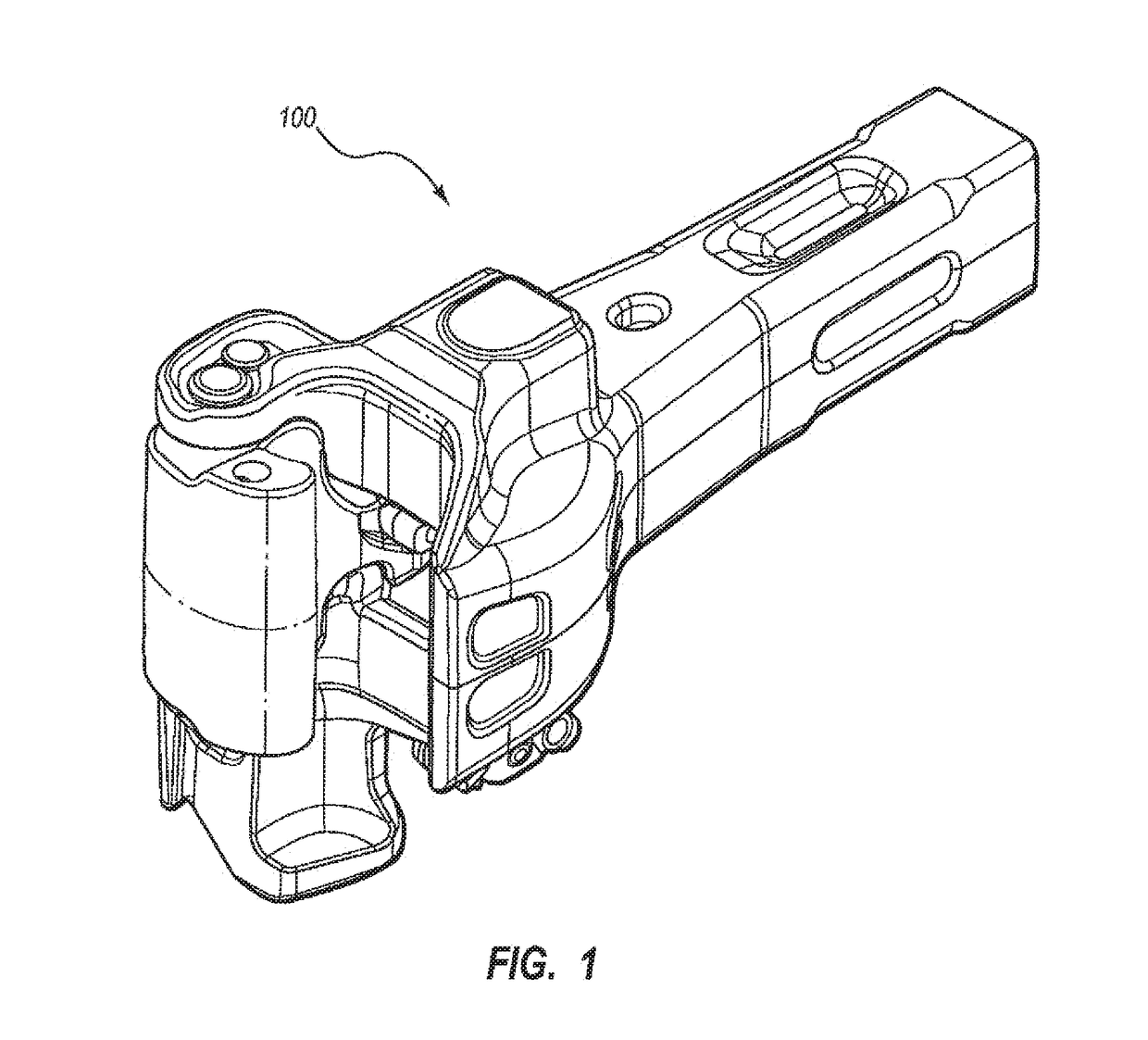

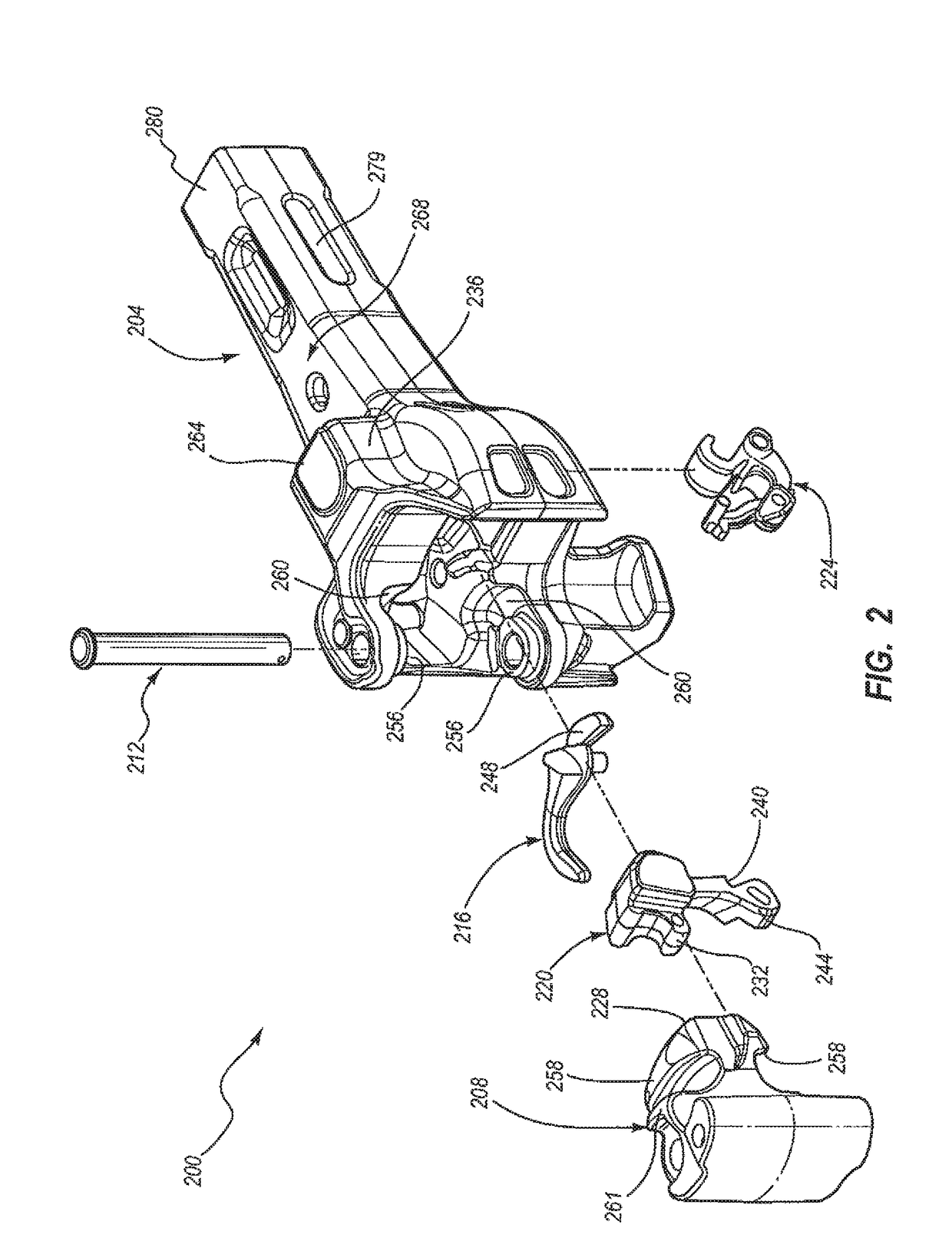

Use of no-bake mold process to manufacture railroad couplers

A railroad coupler assembly having at least a body and a knuckle both formed in a no-bake manufacturing process, the body and the knuckle having dimensional tolerances of distances between features that wear during operation that are about half those obtained from a body and a knuckle manufactured by a green sand process, resulting in increased fatigue life compared to the body and the knuckle manufactured by a green sand process.

Owner:BEDLOE IND LLC

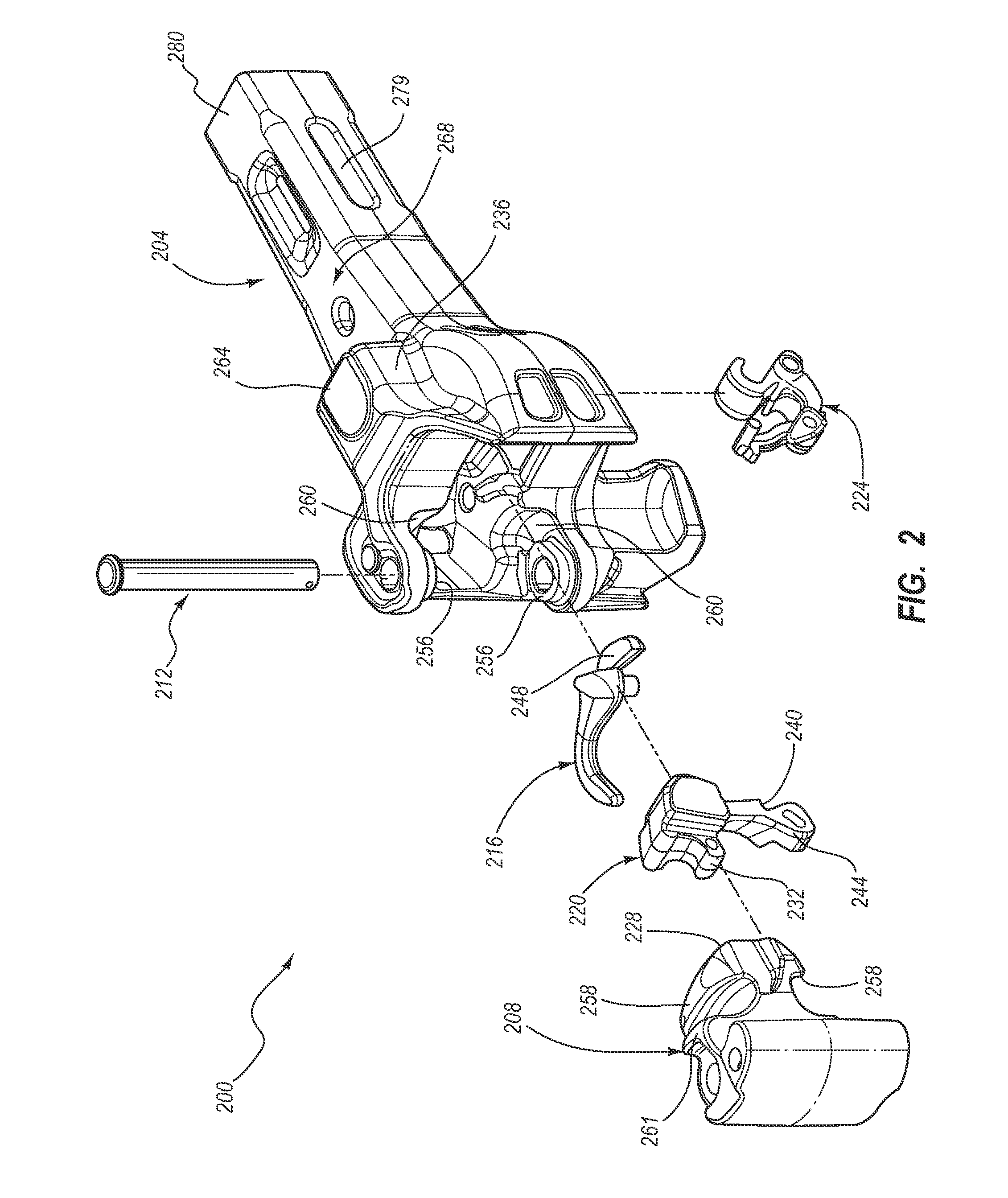

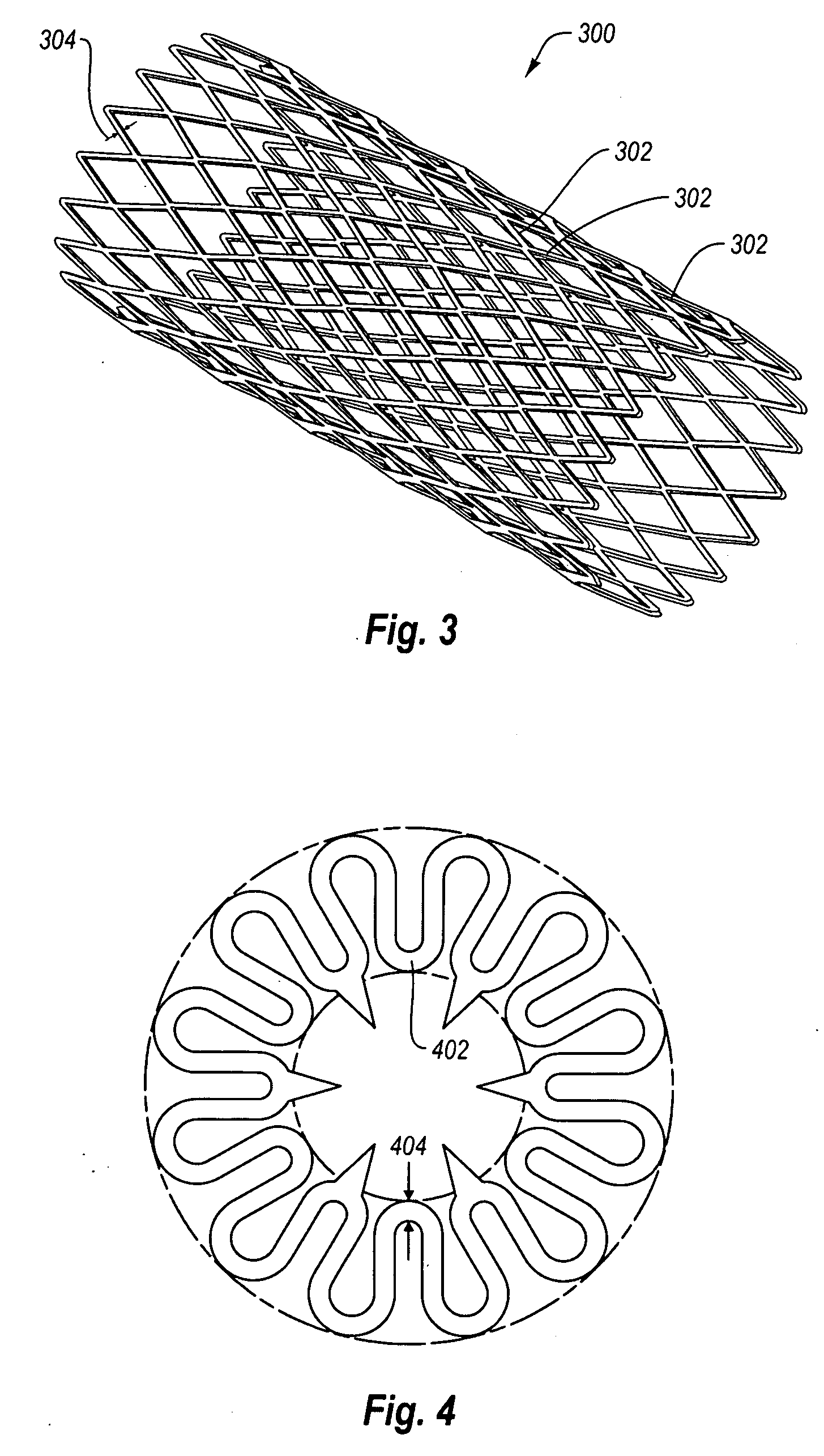

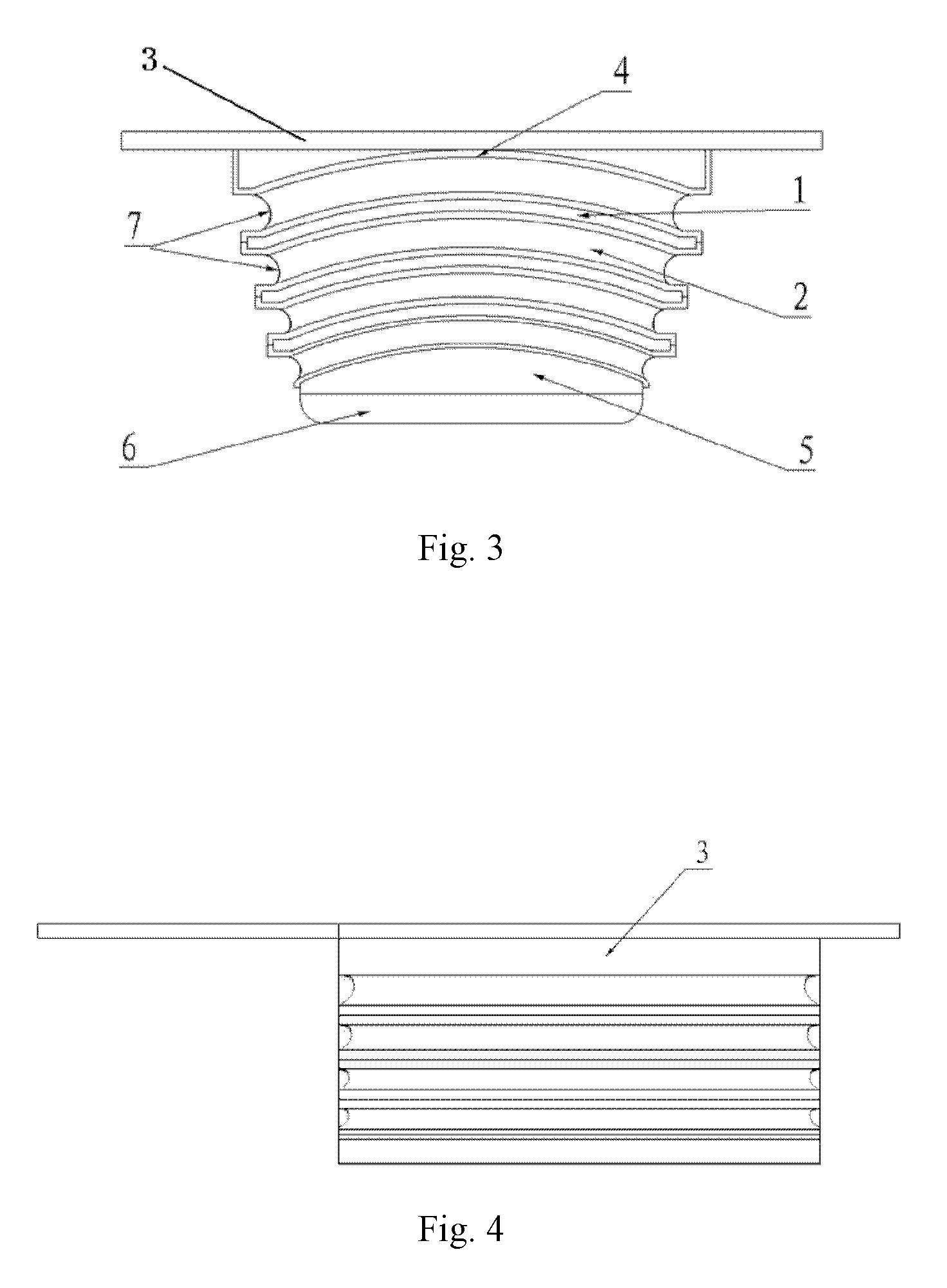

Fatigue-resistant nickel-titanium alloys and medical devices using same

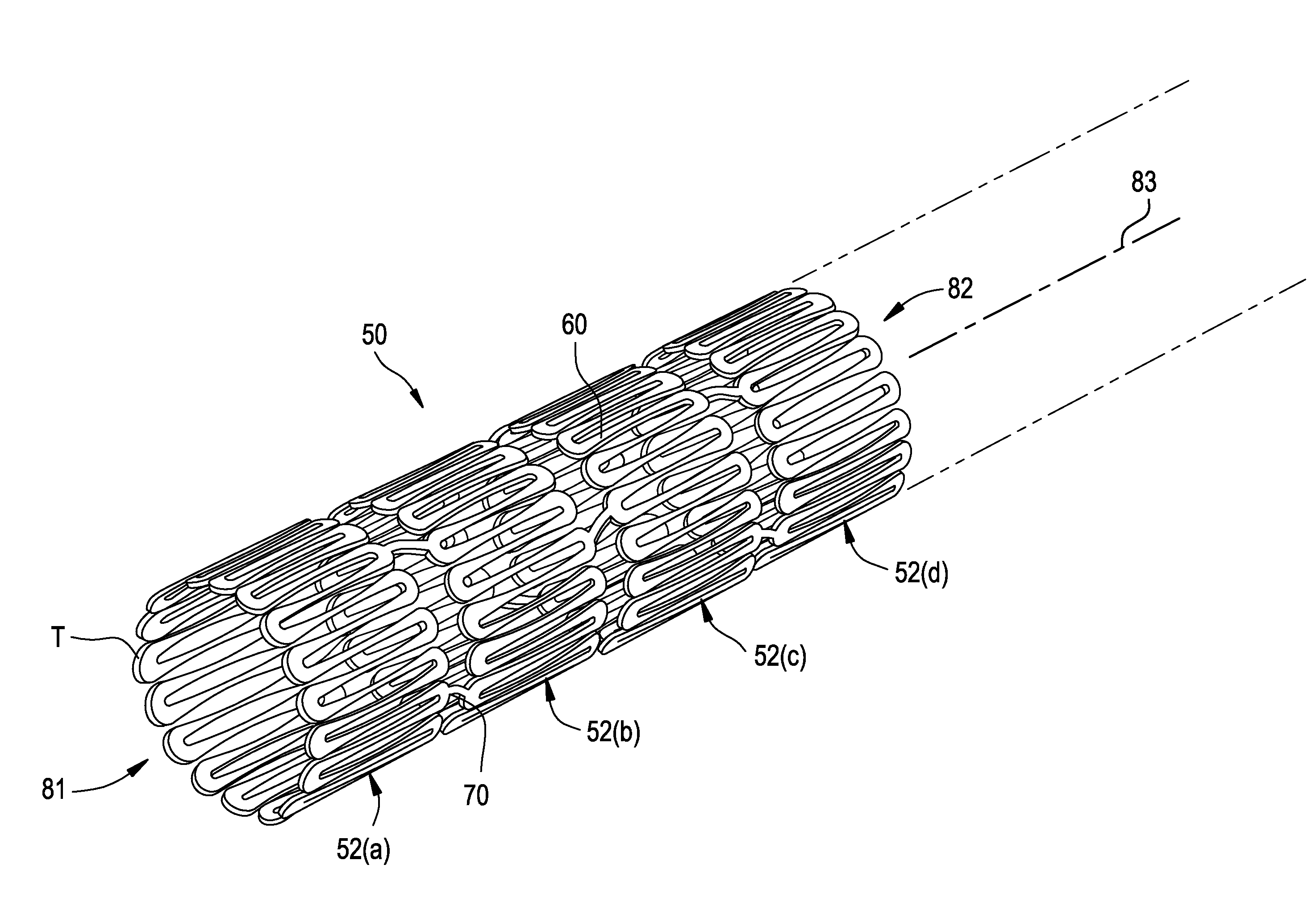

Superelastic and / or shape memory nickel-titanium alloys having an increased fatigue life that is superior to known nickel-titanium alloys are disclosed. The nickel-titanium alloys have a minimum fatigue life that may be at least about 10 million strain cycles at a strain of at least about 0.75. The minimum fatigue life may be due, at least in part, to the nickel-titanium alloy having at least one of an oxygen concentration of less than about 200 ppm, a carbon concentration of less than about 200 ppm, the absence of oxide-based and / or carbide-based inclusions having a size greater than about 5 microns (μm), the presence of an R-phase, or combinations of the foregoing. Articles manufactured from such fatigue-resistant nickel-titanium alloys can be more durable because they are more resistant to repetitive strain and crack propagation.

Owner:ABBOTT LAB INC

Method of improving quality and reliability of welded rail joint properties by ultrasonic impact treatment

A method for improving the performance of sections of rails joined together by welding by reworking welded joints utilizing an ultrasonic impact treatment (UIT) process either before welding, during welding, after welding or during repairs of used rails, including treatment of a joint, around a joint and / or length of a rail, in order to increasing fatigue life and / or other properties of welded rail sections is disclosed. The method provides reduction of stress defects and redistribution of internal stress patterns in the vicinity of weld seams of rails. The UIT provides periodic pulse energy impact treatment with surfaces in welded rails to induce internal compression waves inducing a metal plasticity state in the vicinity of the weld seam of the rail or in the rail itself .

Owner:UIT LLC

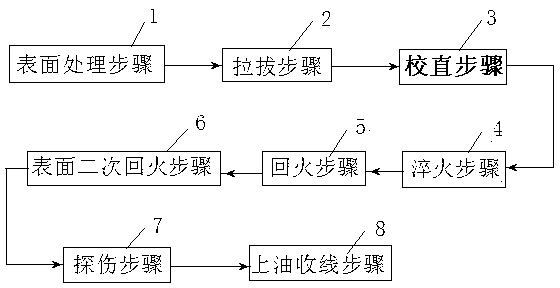

Spring steel wire processing process for increasing fatigue performance of high strength spring steel wire

The invention discloses a spring steel wire processing process for increasing a fatigue performance of a high strength spring steel wire. The process comprises the following steps: a surface treatment step, wherein the surface treatment step is carrying out surface oxide skin removing on a spring steel wire raw material; a drawing step; a straightening step; a quenching step; a tempering step; a secondary surface tempering step; a surface eddy current defectoscopy step; and an oil taking step. According to the process, the secondary tempering step on the surface of the material is added after quenching and tempering are performed, and a hardness (strength) of a high strength spring material surface layer is slightly reduced so as to improve material surface toughness, reduce affection caused by material defects, and increase a spring fatigue life effect.

Owner:SHANGHAI SPRING CORP

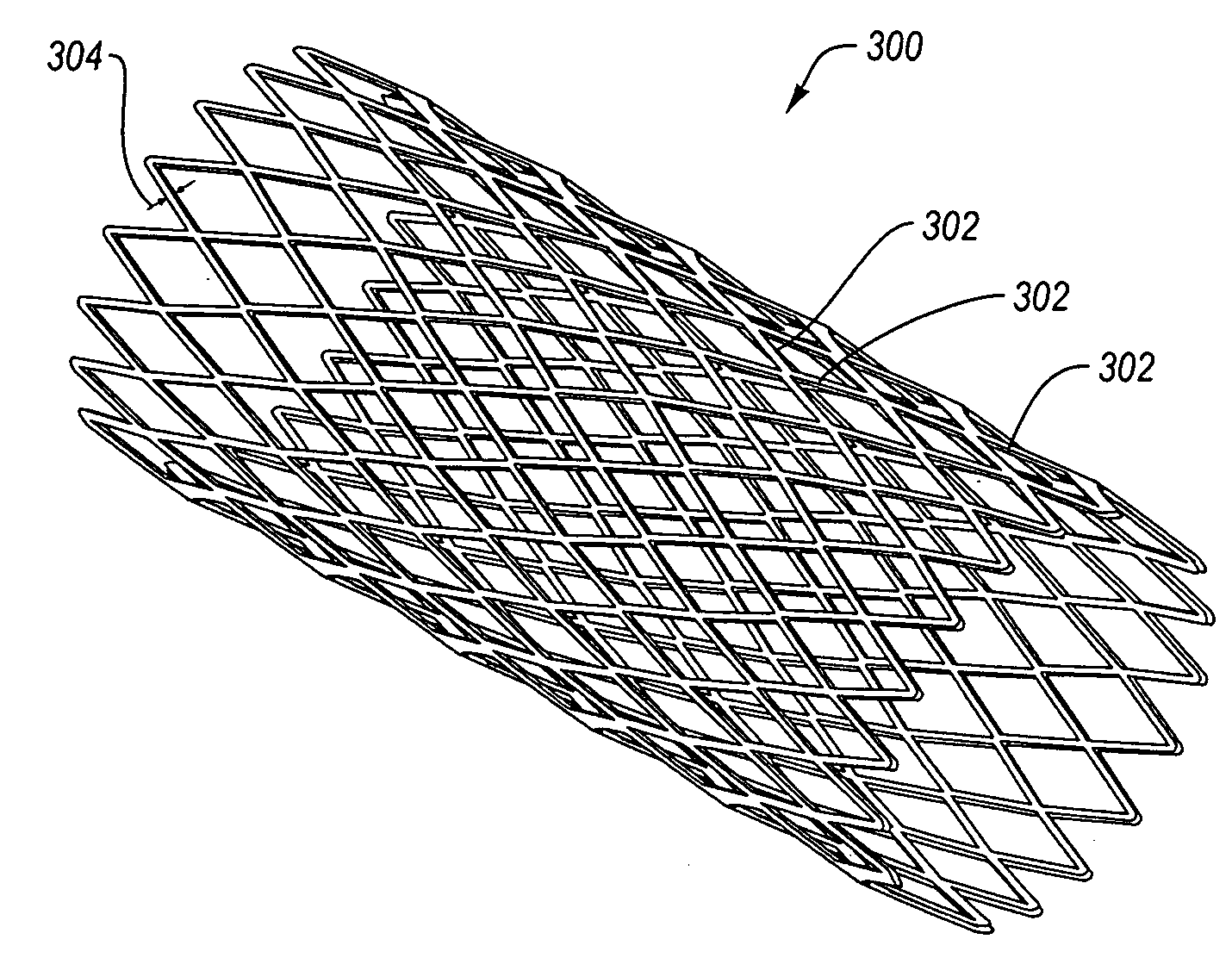

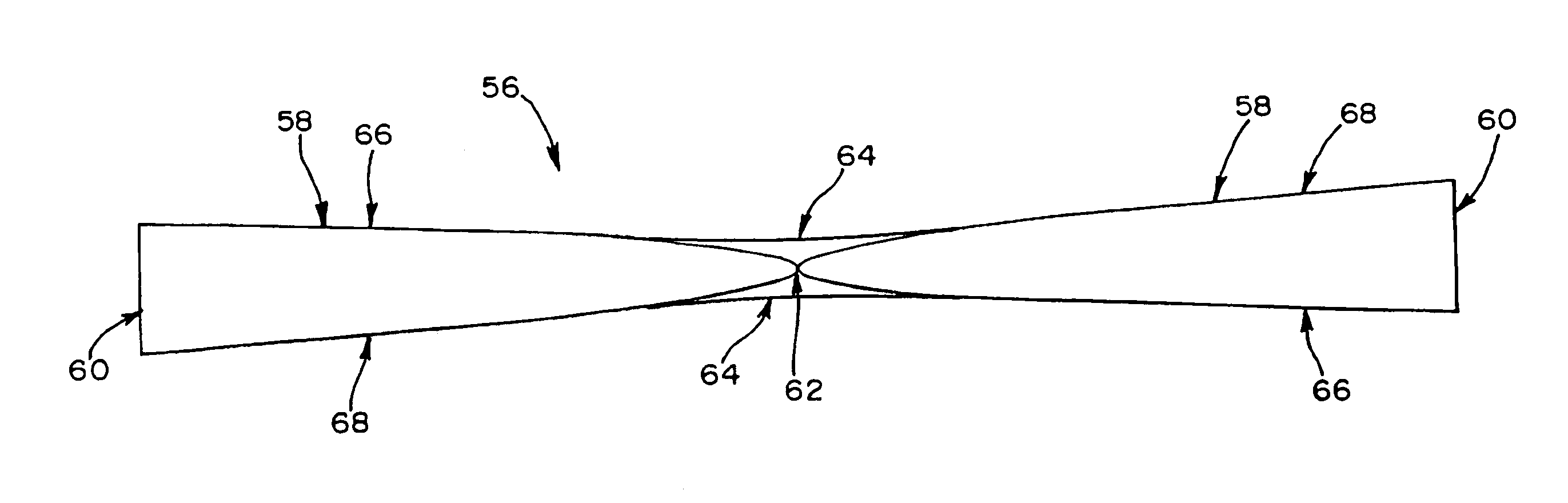

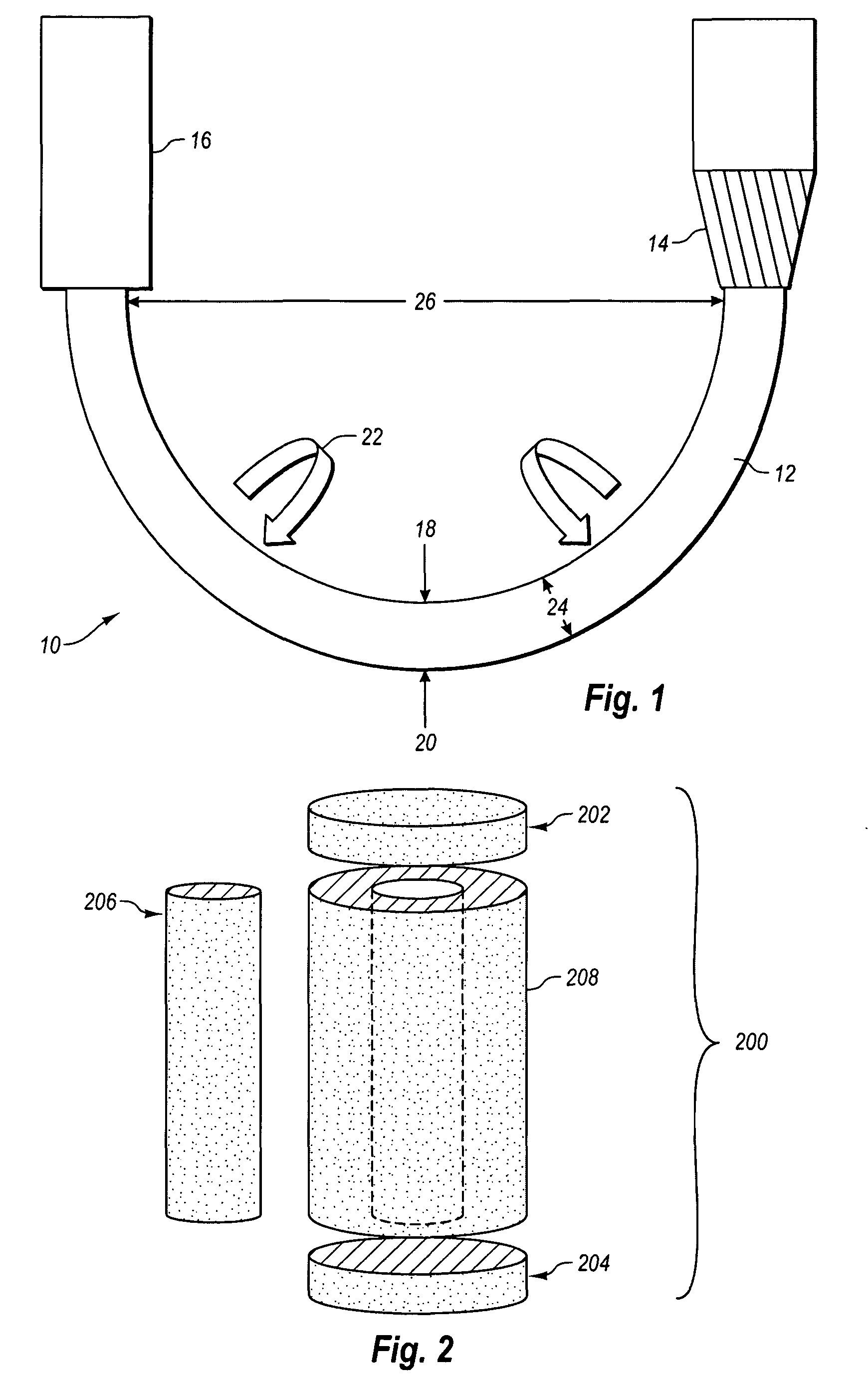

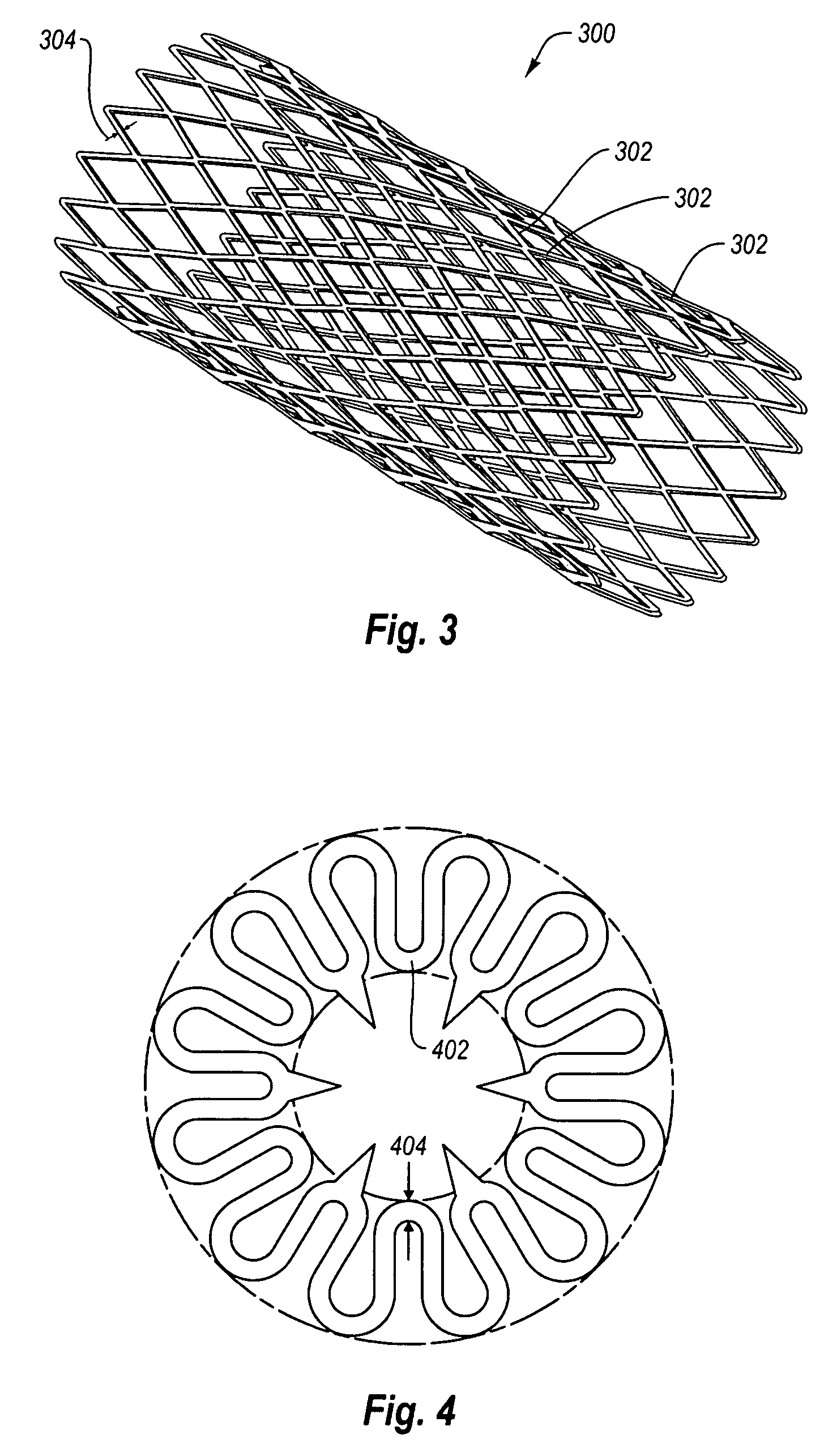

Intraluminal device with improved tapered beams

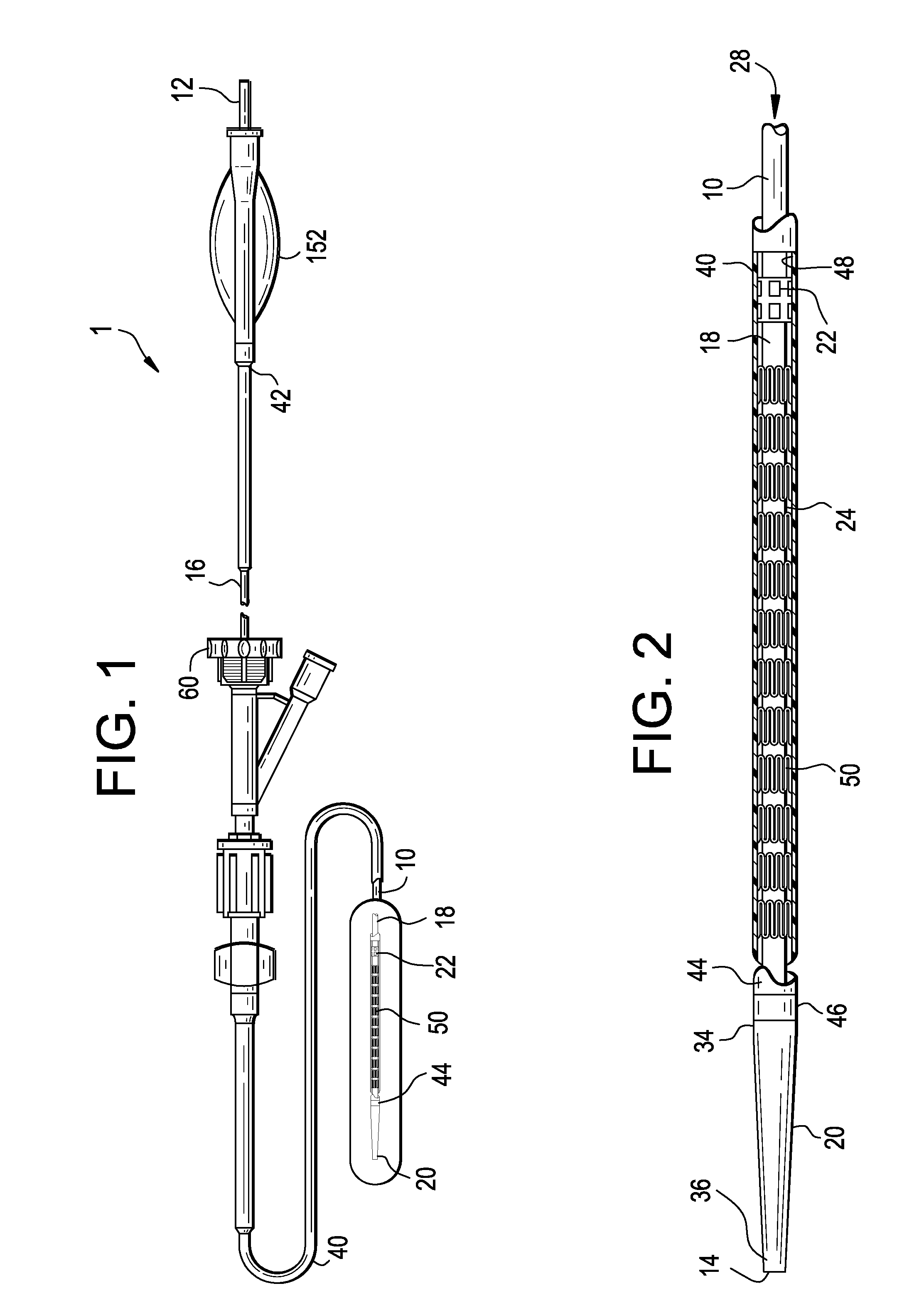

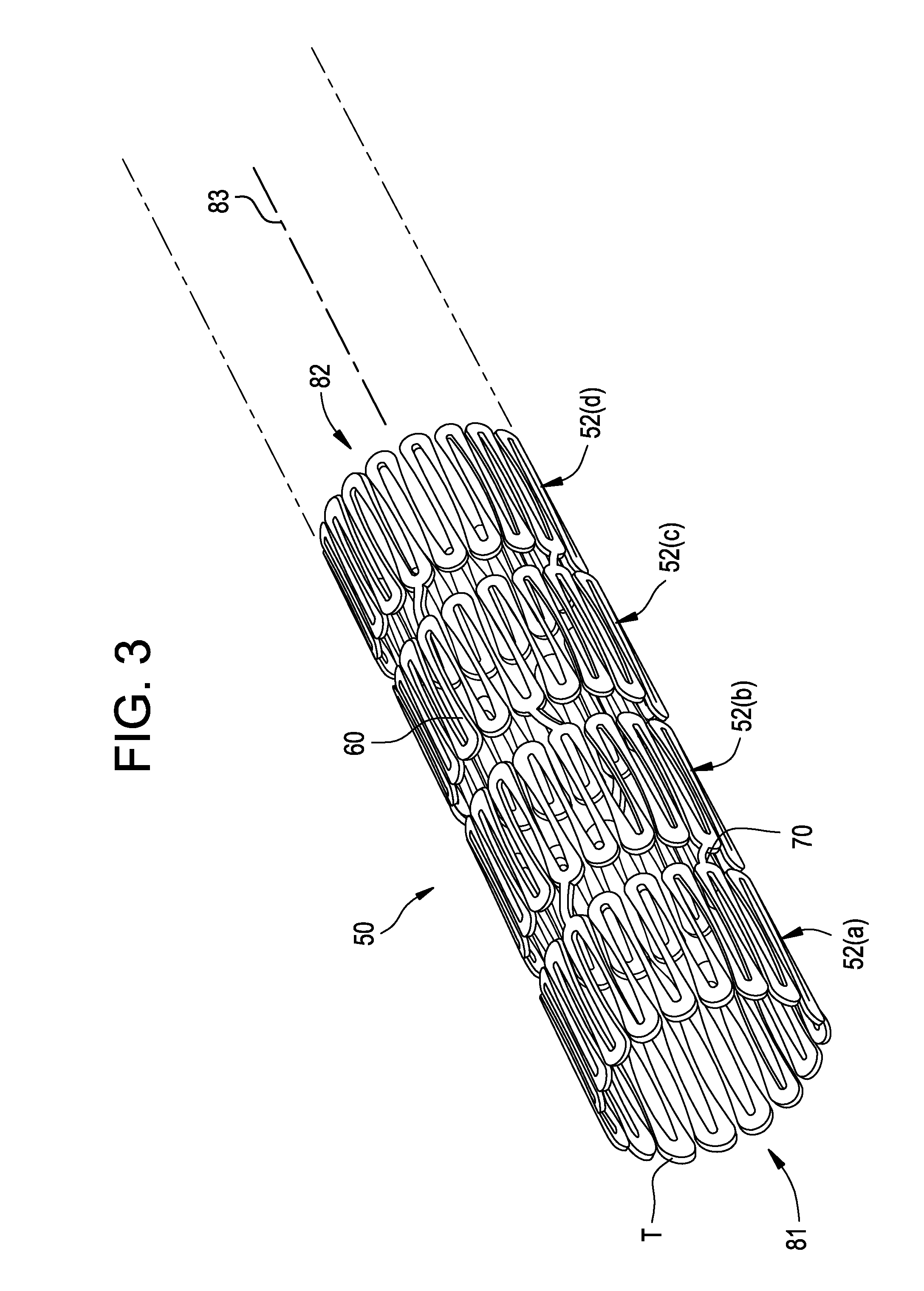

ActiveUS20070021824A1High levelImproved strain distributionStentsBlood vesselsIncreased fatigueTapered beam

A strut, or beam, is provided for intraluminal devices. Strain which is introduced into a stent or other intraluminal device is distributed more evenly along the length of the improved strut by maintaining a substantially constant strain level along the length of an end portion. This may increase fatigue life or improve the performance of devices using the improved strut. The strain along the length of the end portion may be maintained substantially constant by varying a section property of the strut, including the width, thickness, cross-sectional area, material property or other characteristic of the end portion.

Owner:COOK MEDICAL TECH LLC

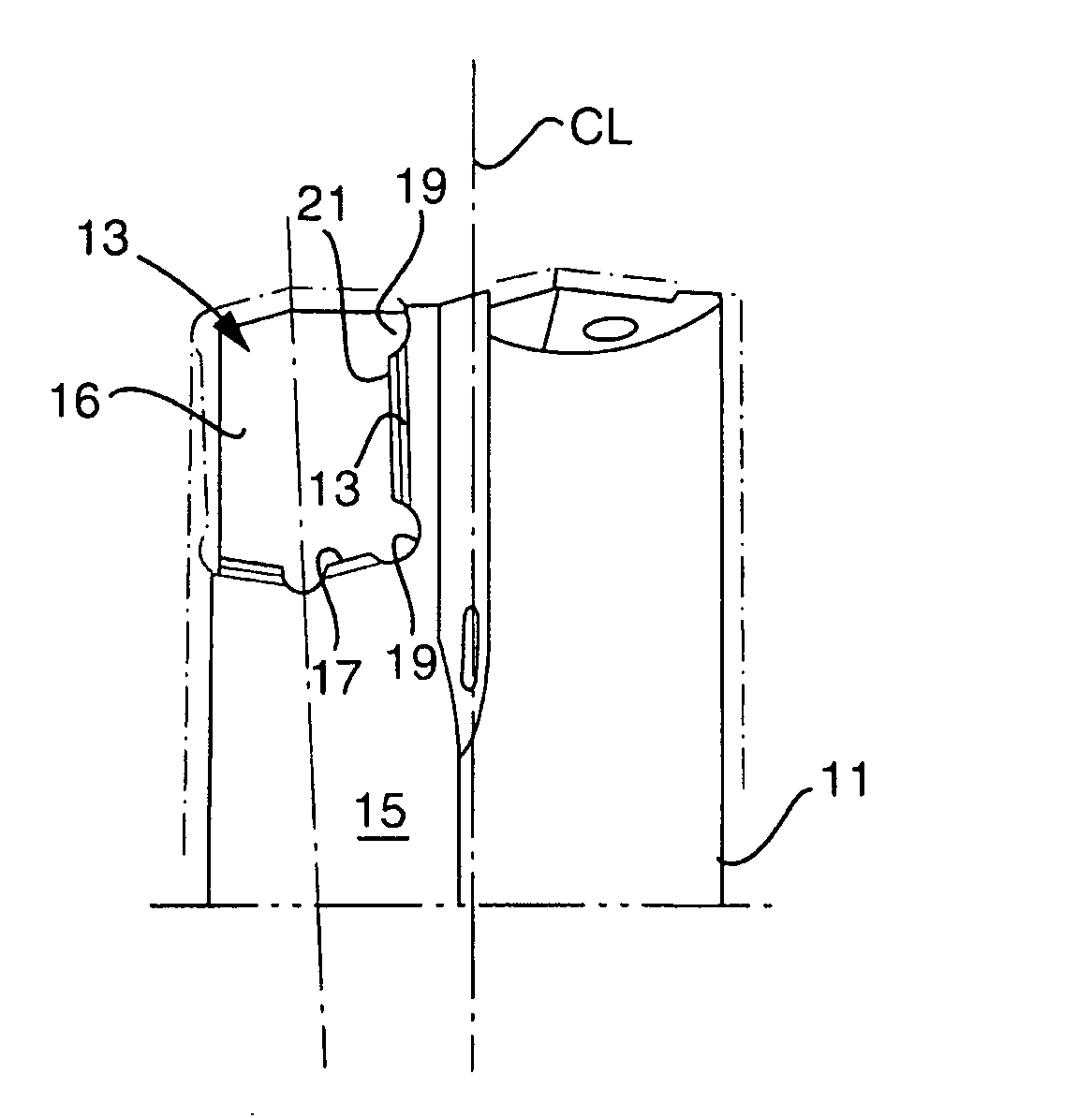

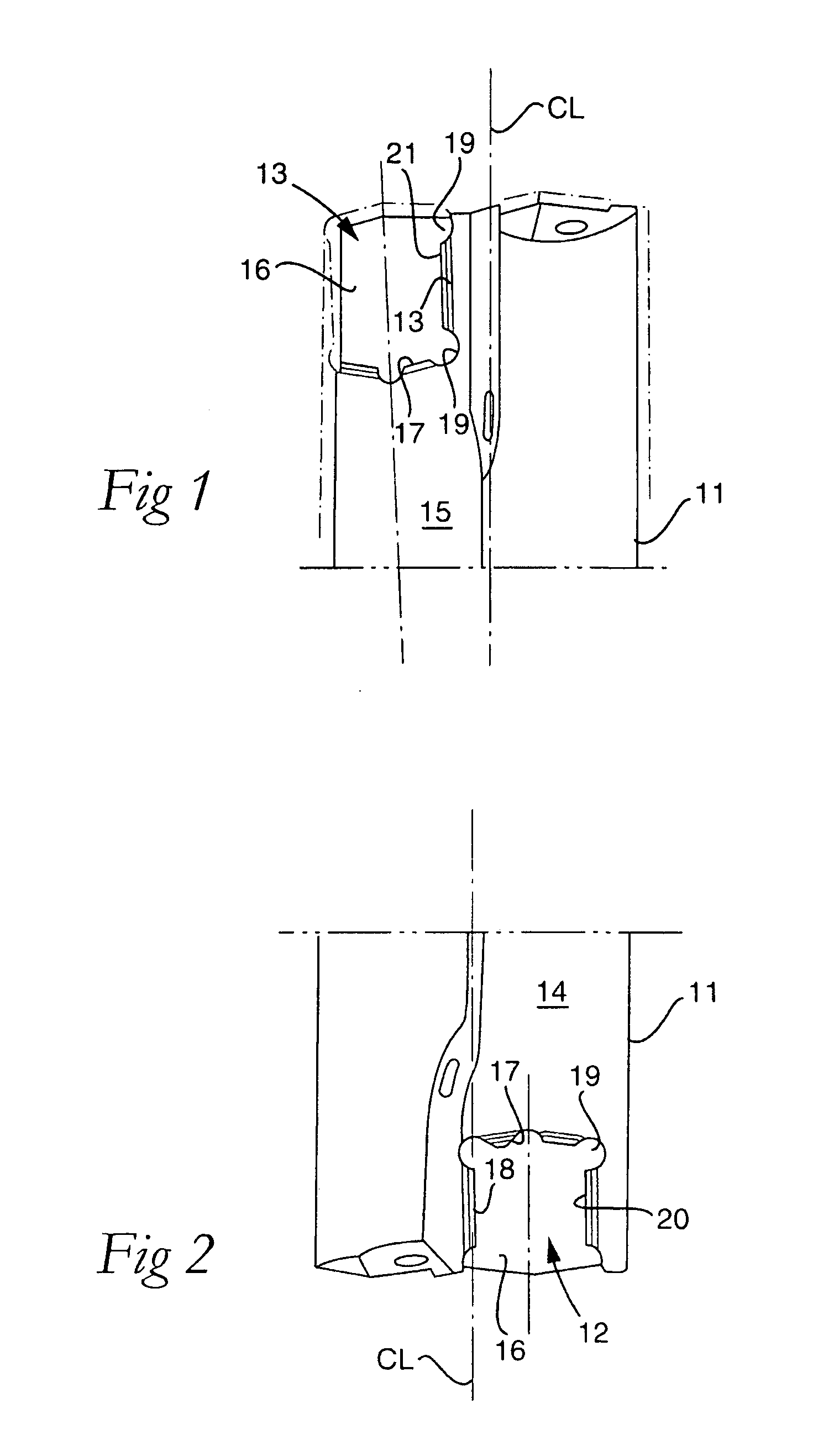

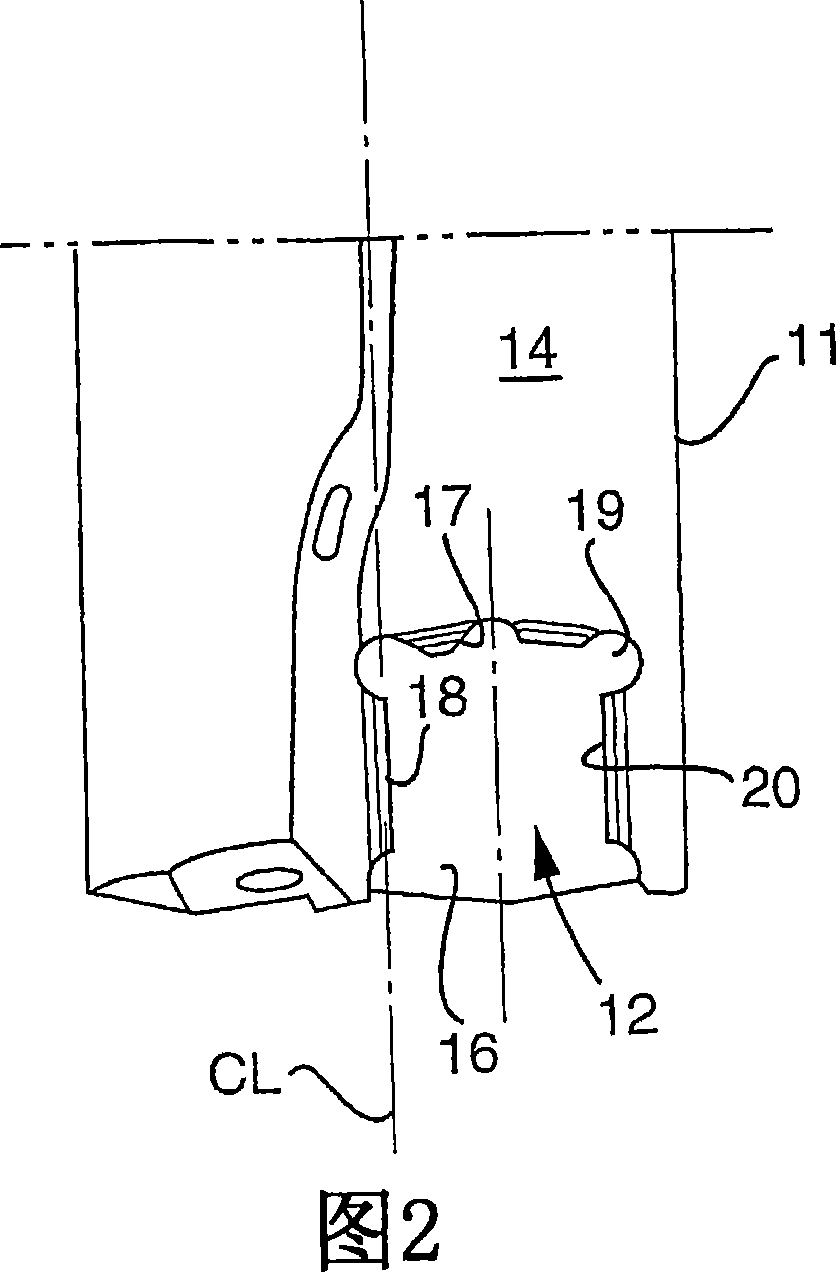

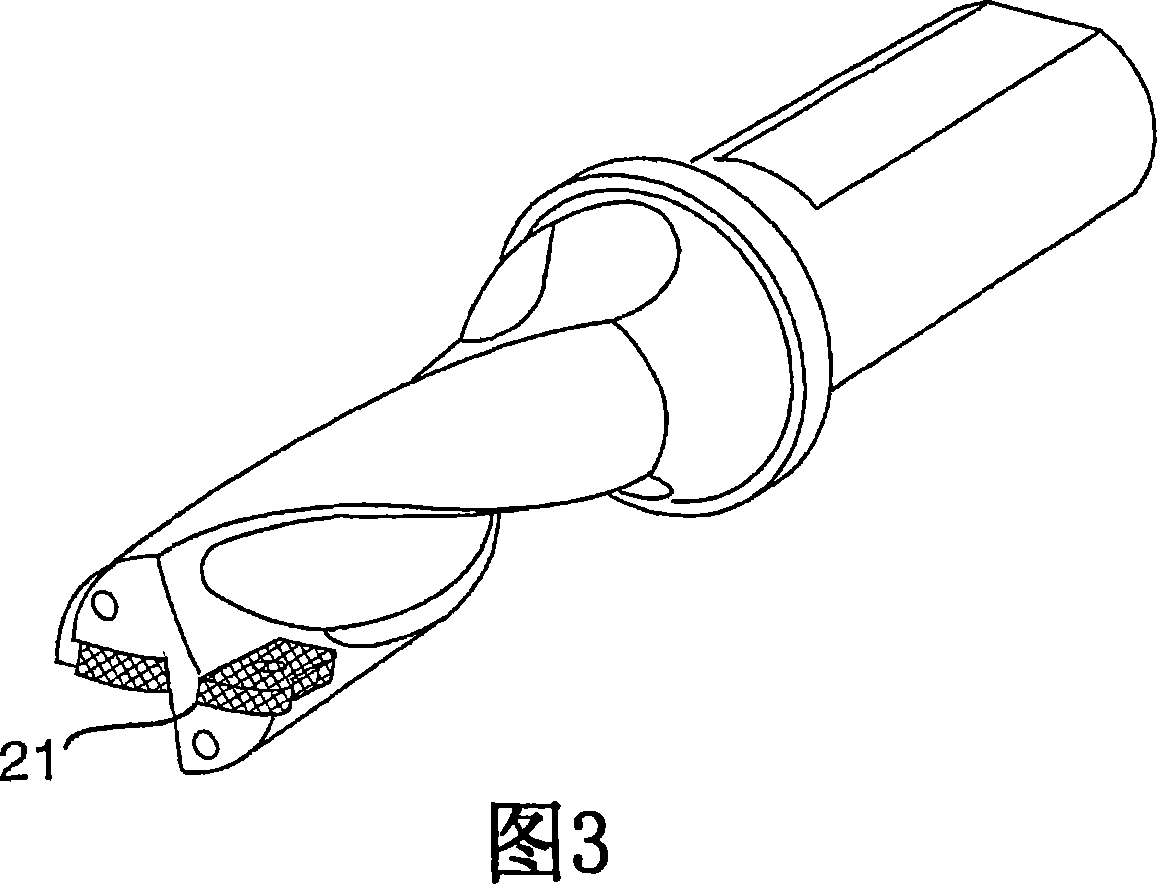

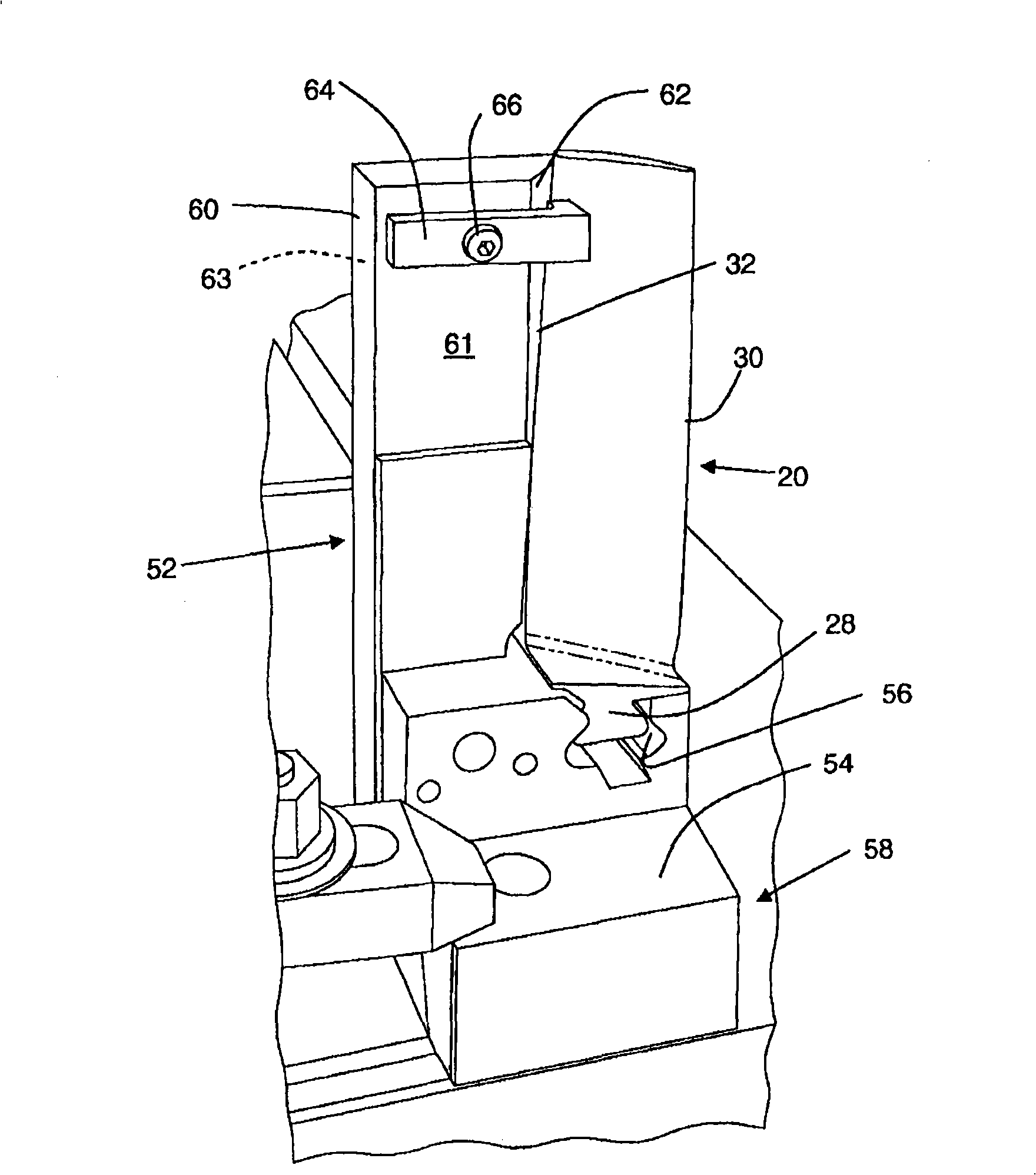

Holder for a cutting tool for metalworking and a method for the production of a holder for a cutting tool

InactiveUS20060260439A1Improve fatigue strengthReduce riskMetal-working drilling toolsTransportation and packagingMetalworkingIncreased fatigue

There is disclosed a holder for a cutting tool and a method for the production of a cutting tool for metalworking that results in a holder body having increased fatigue strength at loads over 60% of the yield point in tension. The method and the tool are characterized in that the holder body of the tool is subjected to a hardening process resulting in deep hardening, and that the holder body then is subjected to a surface treatment resulting in a strain hardening of the surface in order to introduce compressive stresses in the surface zone of the holder body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

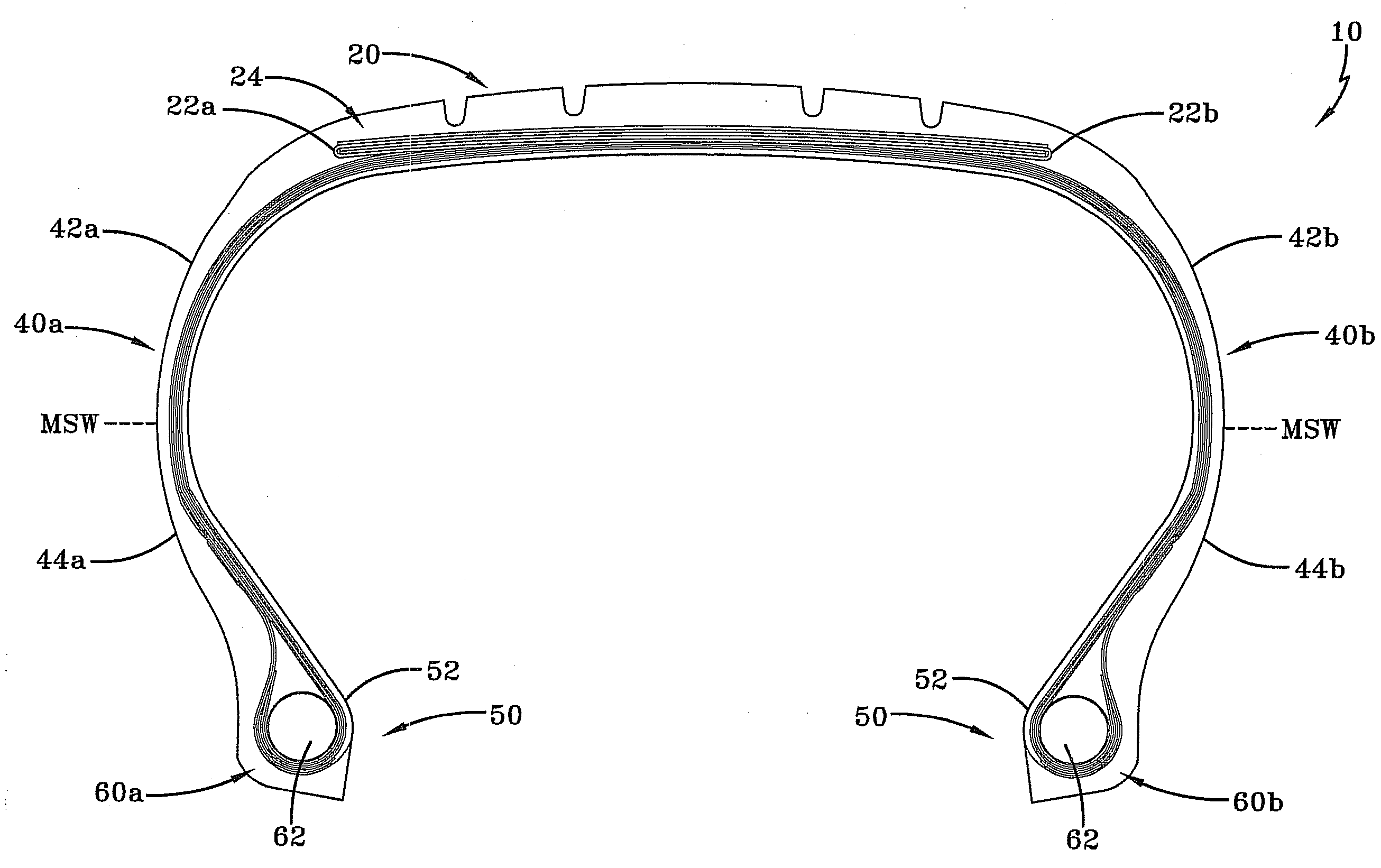

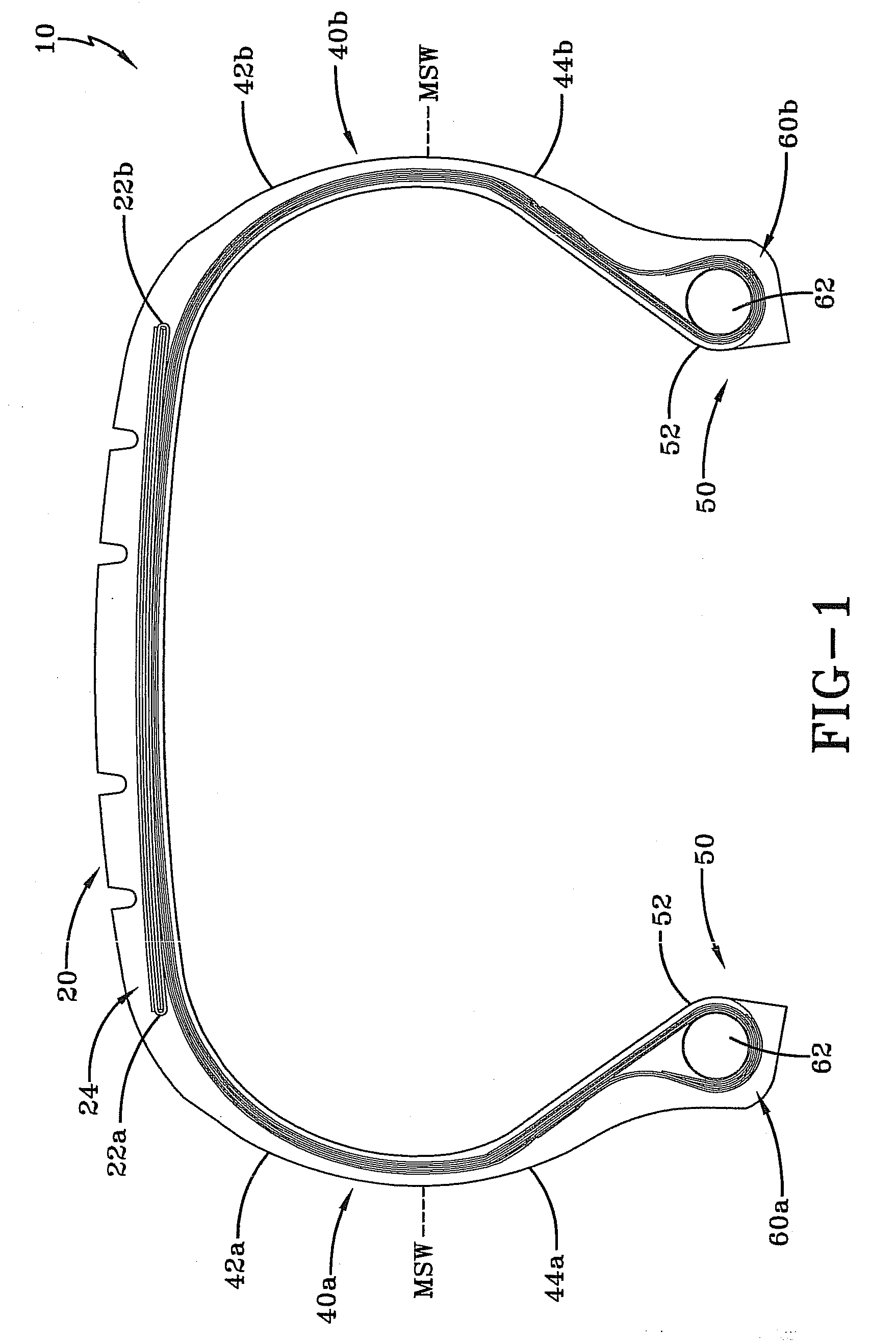

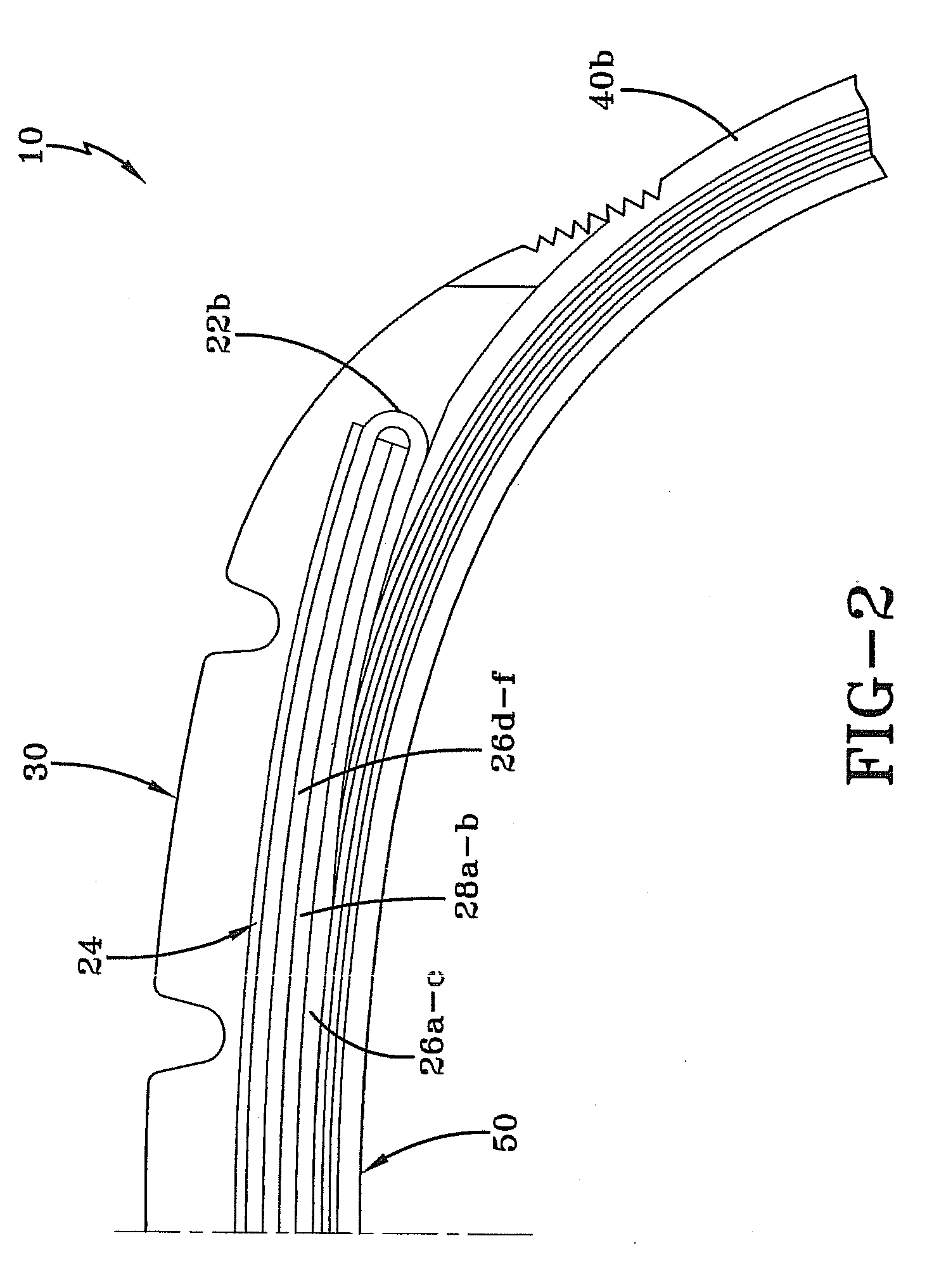

Pneumatic tire with increased lower sidewall durability

InactiveUS20090151843A1High fatigue compression durabilityWeight increaseTyresPneumatic tyre reinforcementsIncreased fatigueLow modulus

A pneumatic tire may use a combination of high modulus and low modulus plies to provide increased fatigue compression durability without significantly increasing the weight of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

Cutting tool for metal working and method for producing it

InactiveCN101056996AImprove fatigue strengthReduced risk of crack formationTransportation and packagingMilling cuttersMetalworkingTreatment results

According to the invention, there is provided a cutting tool and a method in the production of a cutting tool for metalworking that results in a holder body having increased fatigue strength at loads over 60 % of the yield point in tension. The method and the tool are characterized in that the holder body of the tool is subjected to a hardening process resulting in deep hardening, and that the holder body then is subjected to a surface treatment resulting in a strain hardening of the surface in order to introduce compressive stresses in the surface zone of the holder body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

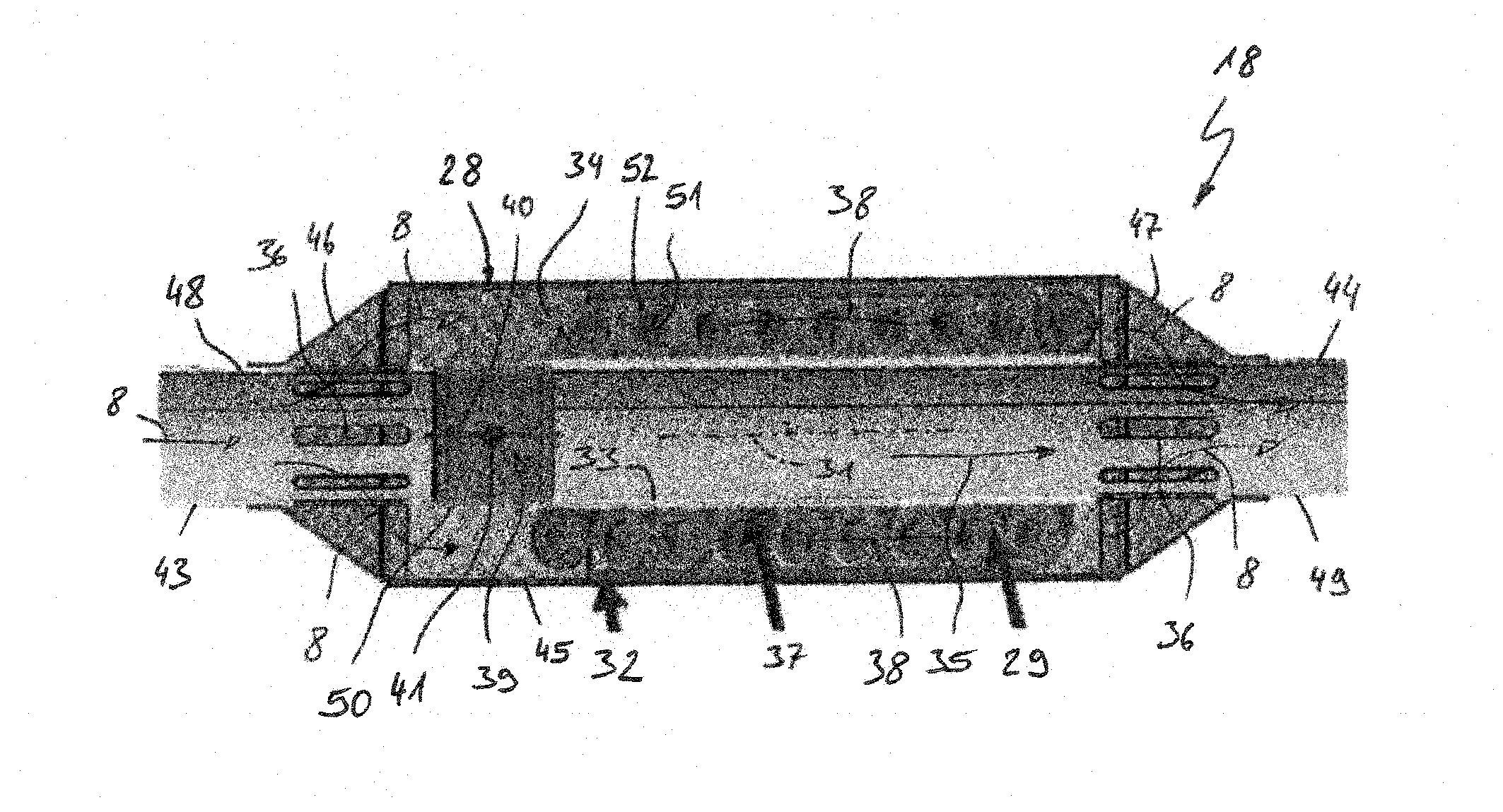

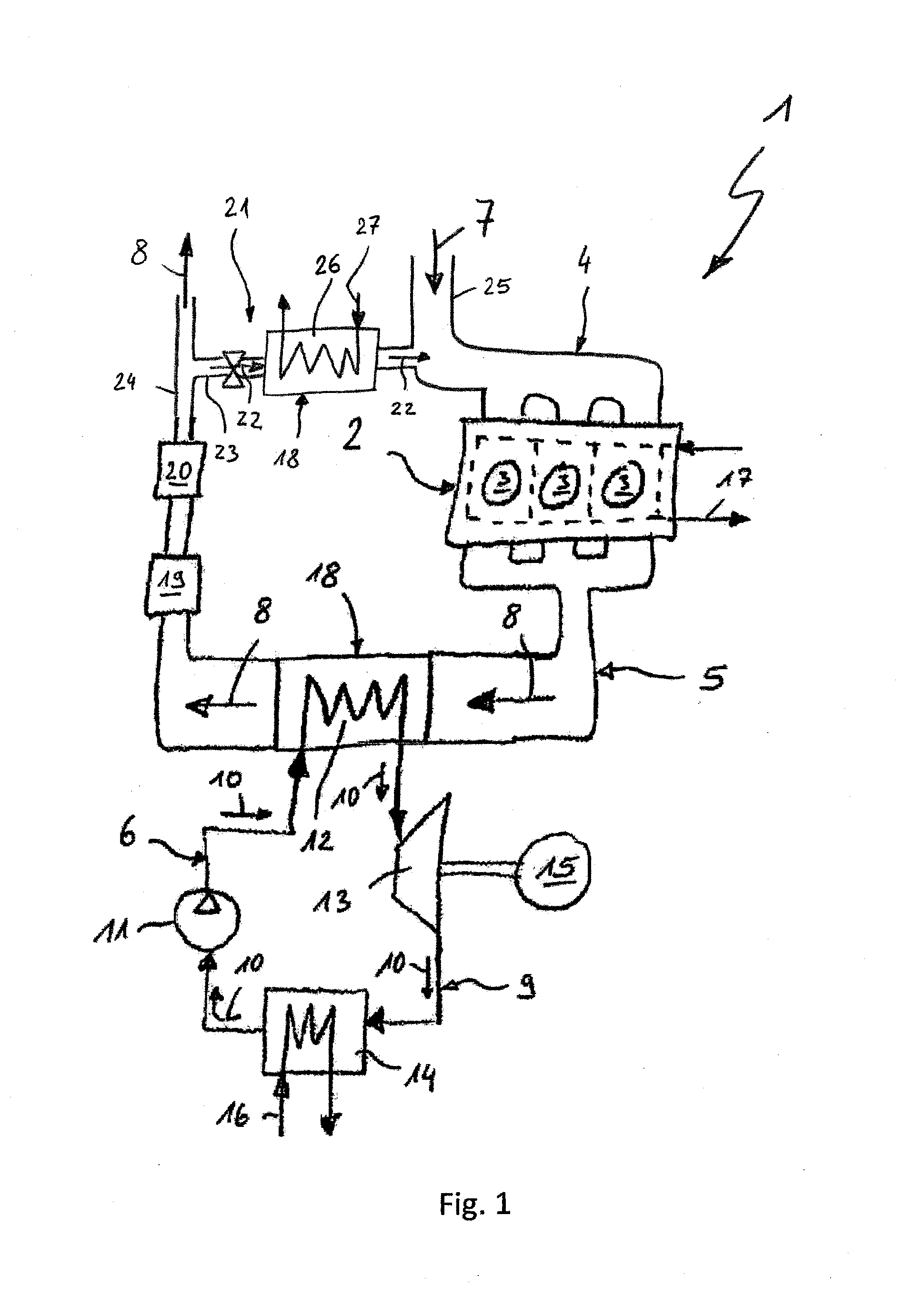

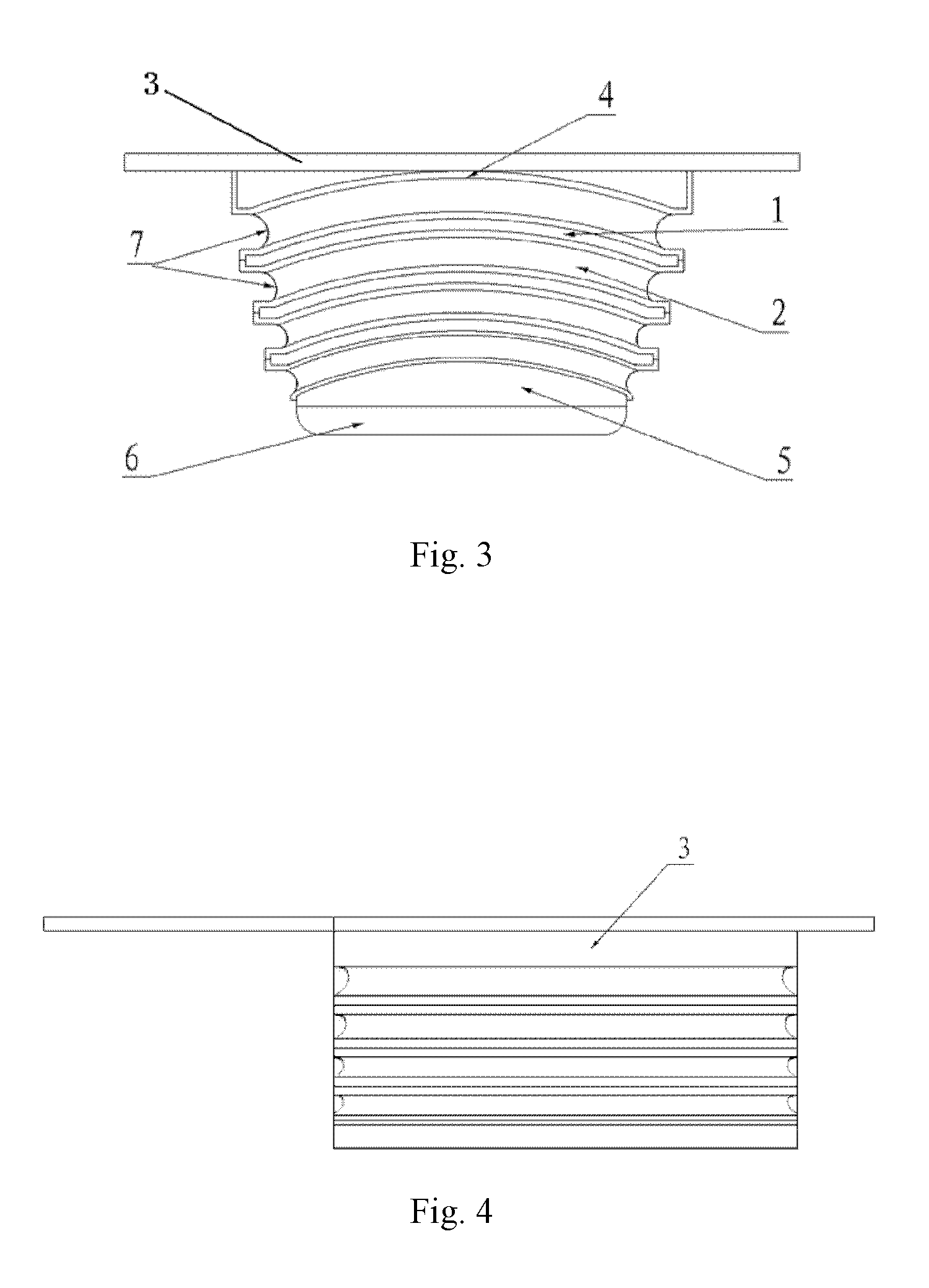

Heat exchanger of an internal combustion engine

InactiveUS20140208725A1Improve fatigue strengthReduce heat dissipationInternal combustion piston enginesRecuperative heat exchangersIncreased fatigueEngineering

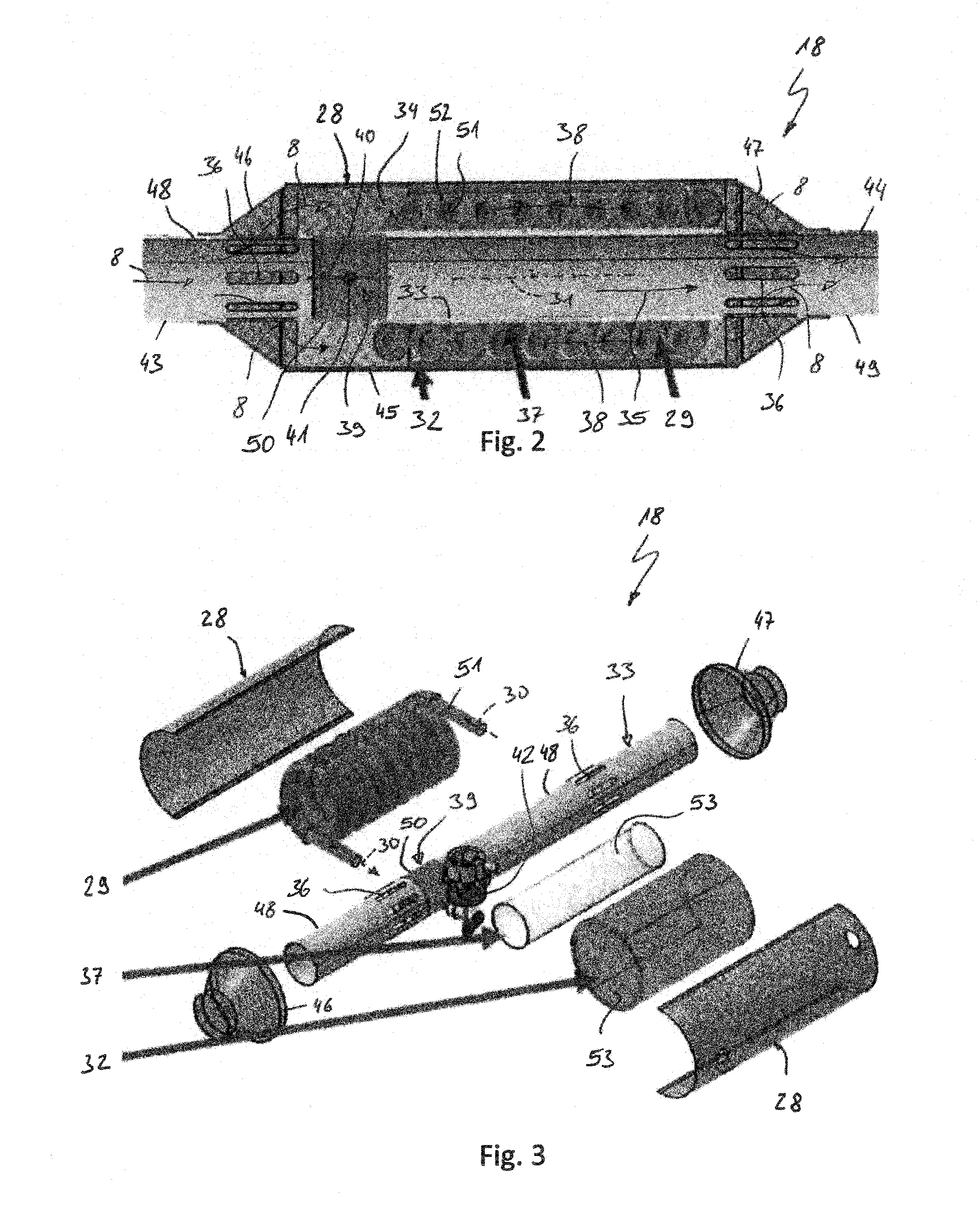

A heat exchanger (18) is provided for an internal combustion engine (1) for heat transfer between a gas stream (8) and a working medium stream (10). The heat exchanger (18) comprises a housing (28), which encloses a gas path (38), and with at least one spiral tube (29), which carries a working medium path (30) and which is arranged in the gas path (38) and which extends helically in relation to the central longitudinal axis (31) of the housing (28). Increased fatigue strength is achieved with an elastic outer mounting layer (32). The elastic outer mounting layer (32) is arranged between the housing (28) and the at least one spiral tube (29).

Owner:EBERSPACHER EXHAUST TECH GMBH & CO

Bumpy cement concrete road surface mending agent

The invention relates to road construction field, in particular to a bumpy cement concrete road surface mending agent, aiming at solving such problems of mending materials adopted in current cement concrete road surface mending as slow strength development, poor combination with original cement concrete layer, easy contraction and cracking and the like. The invention comprises 15-25% of acrylic ester elastic latex, 5-20% of 108 adhesive, 5-10% of AKD latex, 8-15% of polyvinyl alcohol fiber, 0.5-2% of common silicate cement, 1-3% of sand and balance water. The mending agent has good tenacity and anti-deformation capability, reduces drying shrinkage, has higher cementing strength with the old concrete interface, good compatibility, enhanced rupture strength and antifatigue property, increased fatigue life and good mechanical property, satisfies the requirement of fast mending the cement concrete road surface, improves use property of the road surface, prolongs service life of the road surface, saves project cost, shortens construction period and is beneficial for enhancing mending quality and speed of cement road surface.

Owner:亢吉田

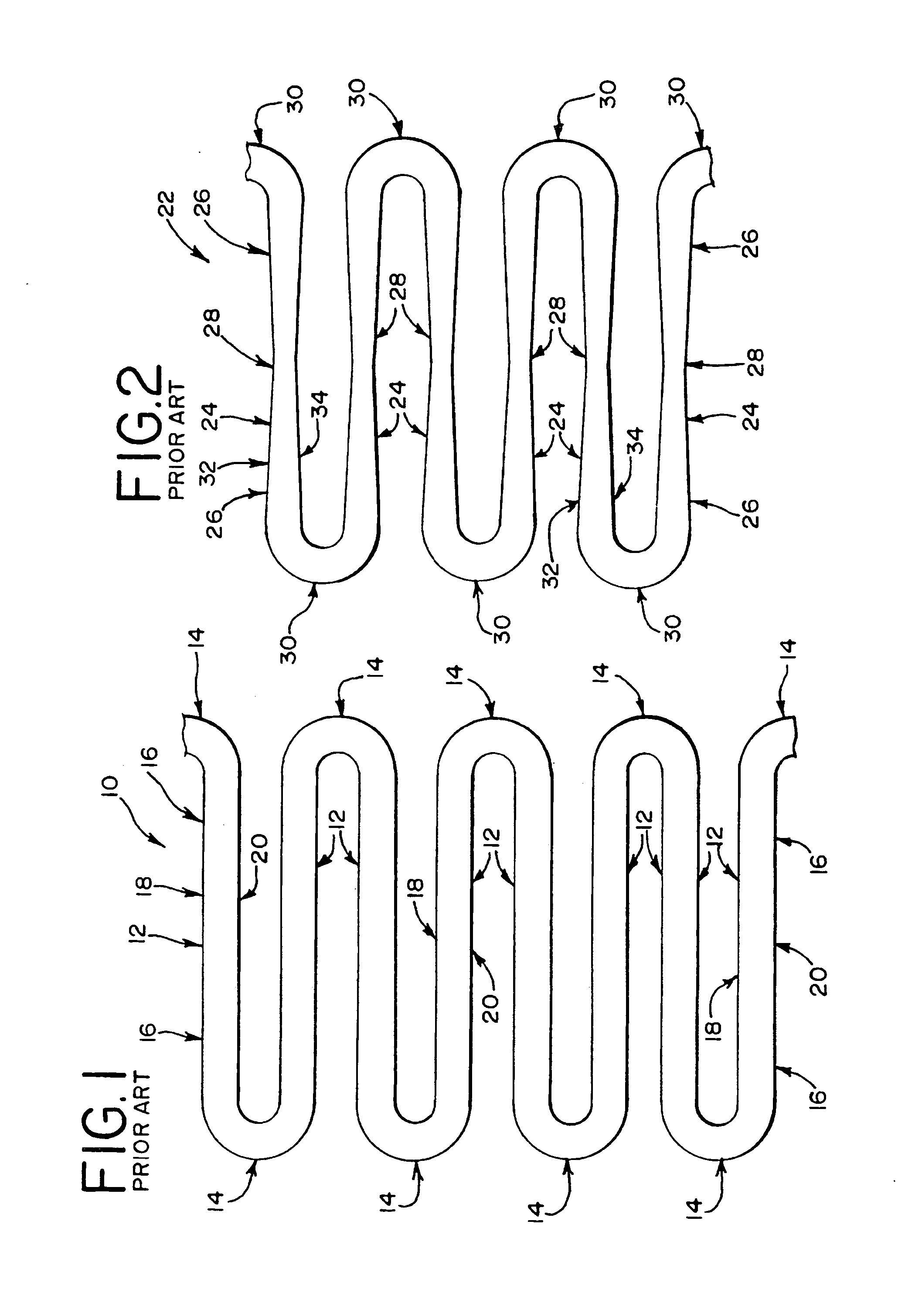

Intravascular stent having imrproved design for loading and deploying

InactiveUS20100057187A1Increase thrustWithout complicating delivery system featureStentsBlood vesselsIncreased fatigueIntravascular stent

A stent may be inserted into a vessel in order to open and then maintain the patency of the vessel. The stent has a strut design that increases the overall fatigue resistance of the stent. Each strut is tapered to better distribute strain and thus increase fatigue resistance. In addition, some of the struts may comprise protrusions to increase the pushability of the stent during loading into a delivery device.

Owner:CORDIS CORP

Use of no-bake mold process to manufacture side frame and bolster for a railway truck

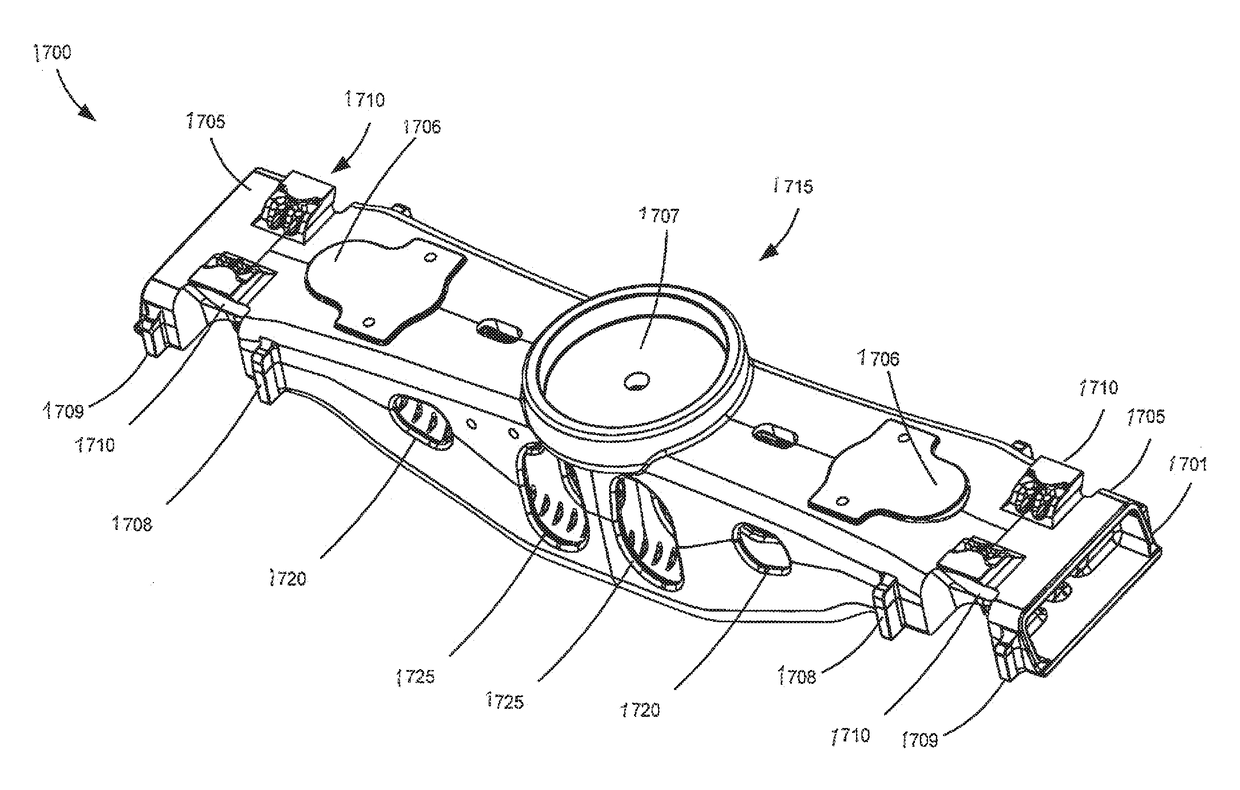

InactiveUS20170232503A1Improve fatigue lifeFoundry mouldsFoundry coresSurface finishManufacturing technology

A method for casting a railroad component such as a component of a railway car truck. The component of the railway car truck may be, e.g., a side frame or a bolster of the railway car truck. The method includes manufacturing the railroad component made of steel in a no-bake manufacturing process including use of a chemically-bonded sand system that results in a sand mold from which the railroad component is cast. The railroad component resulting from the no-bake manufacturing process has a surface finish less than 750 micro-inches RMS, resulting in increased fatigue life compared to a railroad component manufactured by a green sand process.

Owner:NEVIS IND

Method and apparatus for increasing fatigue notch capability of airfoils

The present invention provides a method and apparatus for increasing fatigue notch capability of airfoils. The method of reducing crack propagation in an airfoil includes: providing an airfoil having a root spaced apart from a tip, spaced-apart leading and trailing edges, a suction side extending from the leading edge to the trailing edge, and an opposed pressure side extending from the leading edge and the trailing edge, supporting the airfoil against bending loads; and burnishing the airfoil using a burnishing element, so as to create at least one burnished section of residual compressive stress, the at least one burnished section being located adjacent the leading edge and spaced from the leading edge by an offset distance selected so as to avoid deformation of the leading edge.

Owner:GENERAL ELECTRIC CO

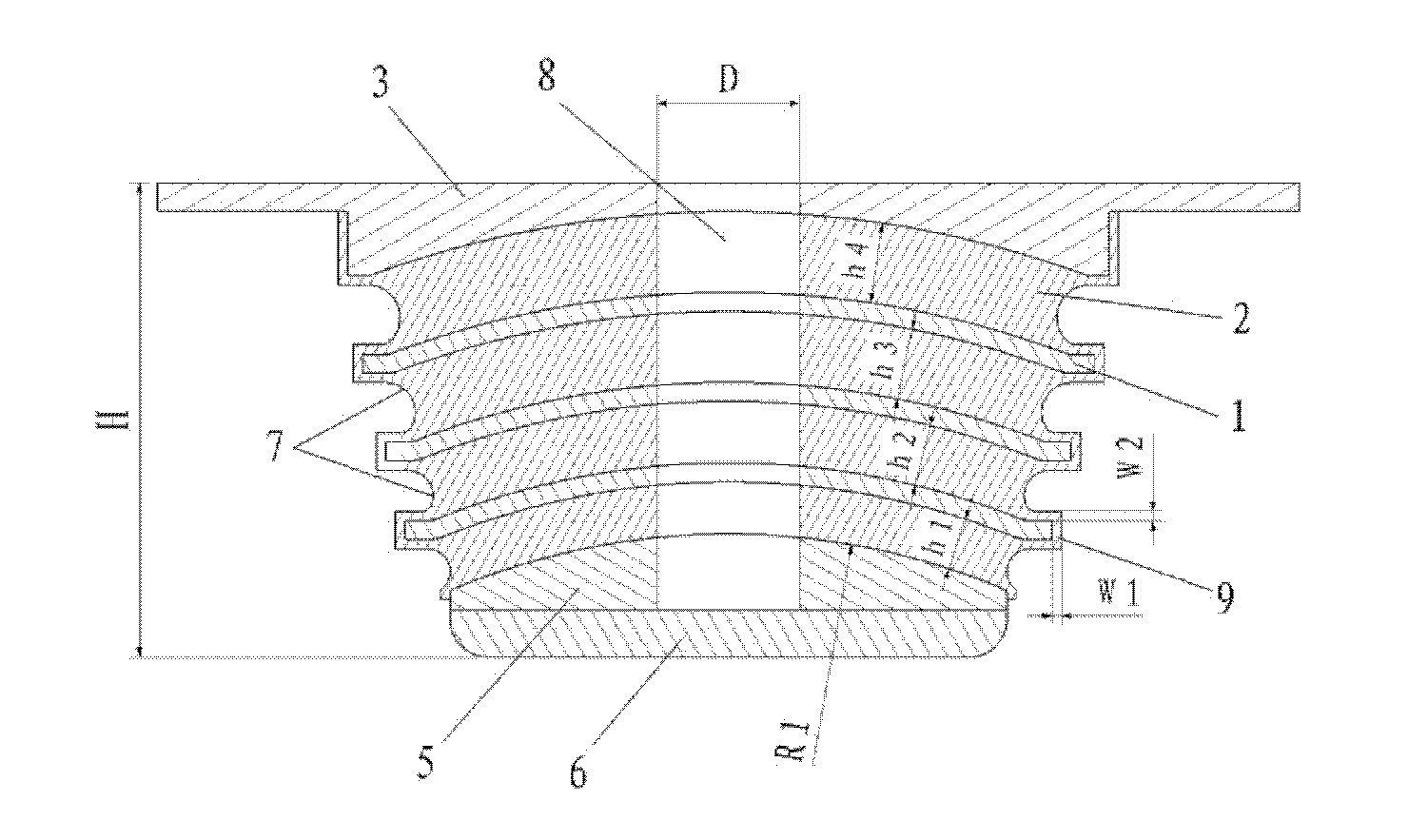

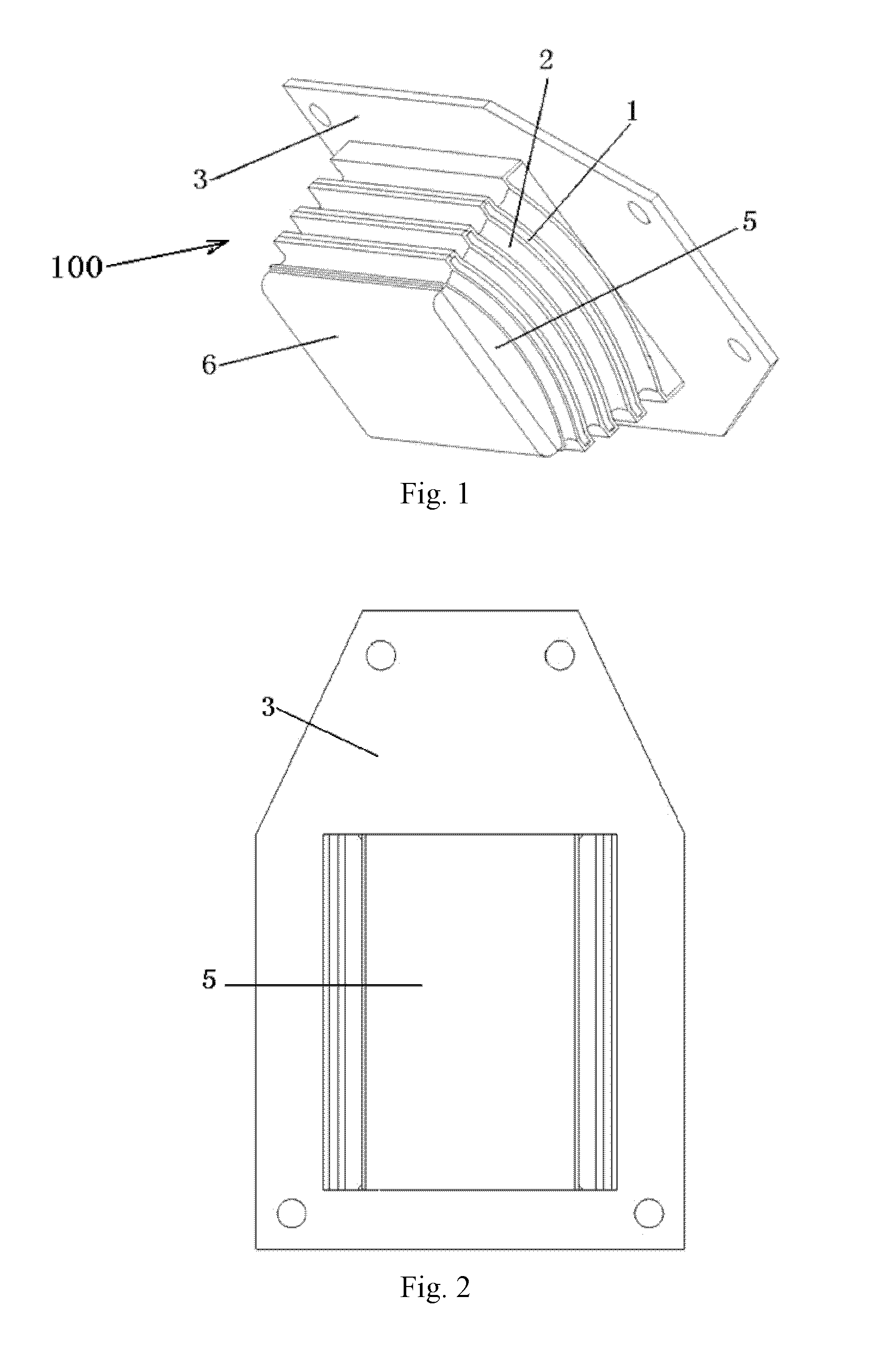

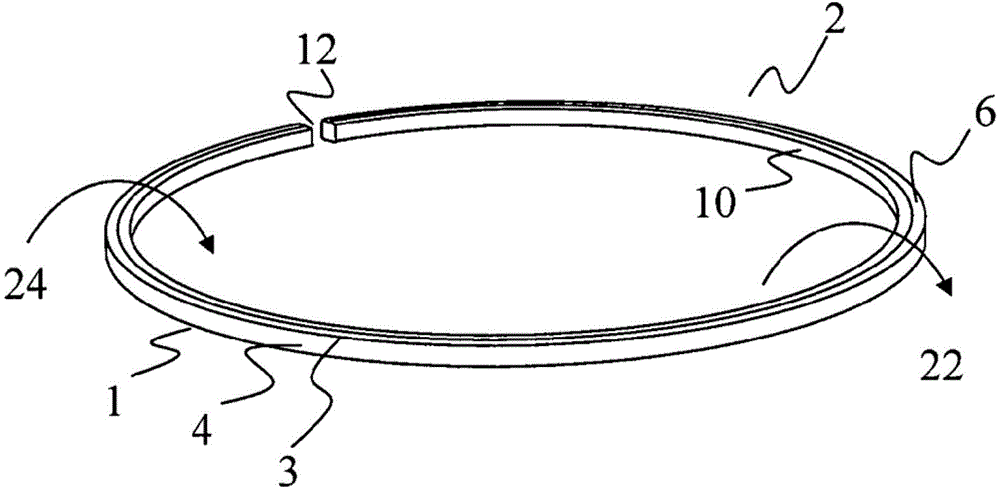

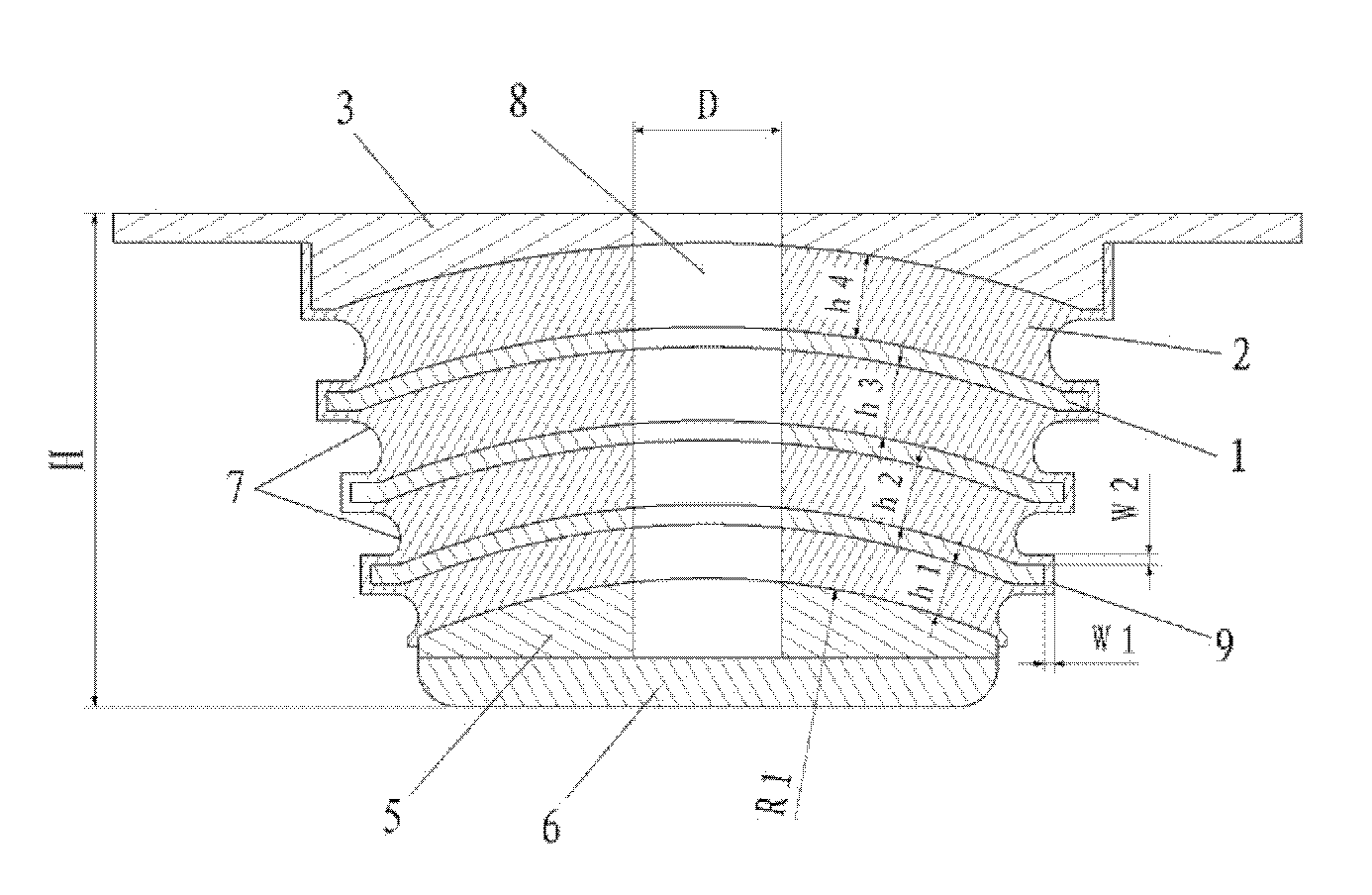

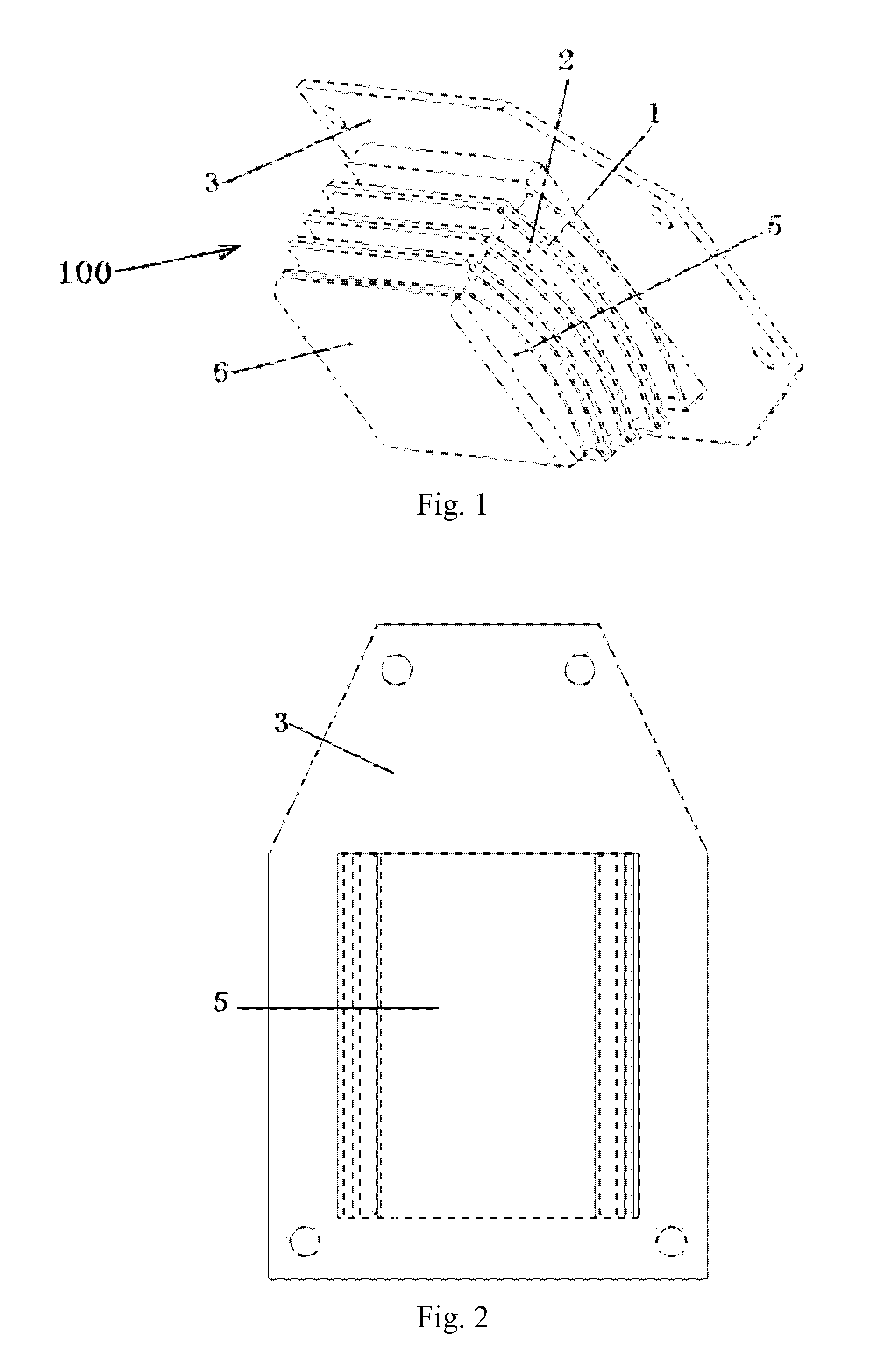

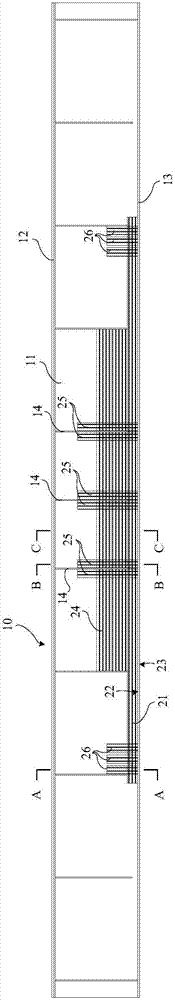

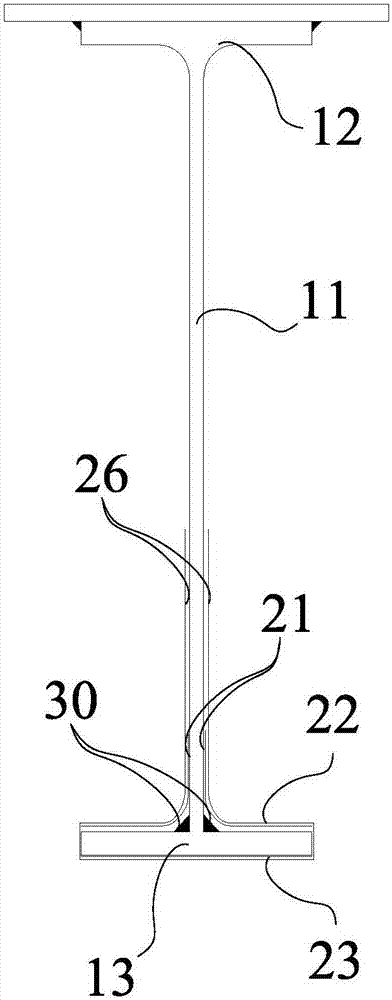

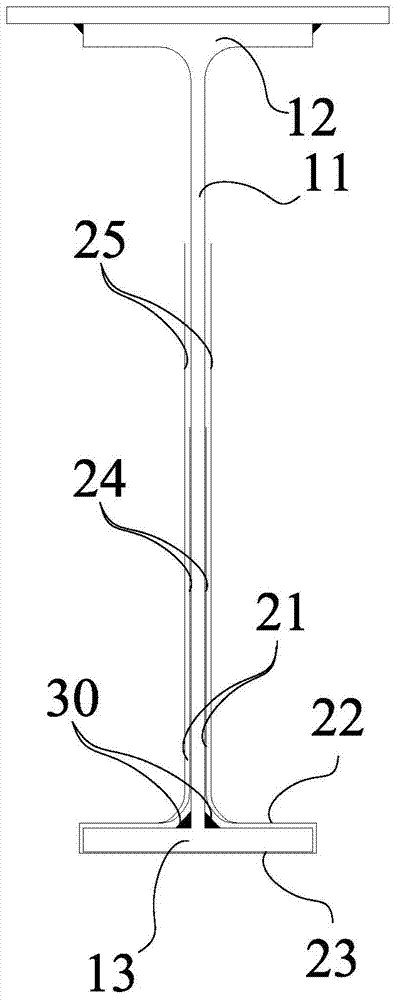

Auxiliary rubber spring for automobile suspension

ActiveUS20150217616A1Reduce stress concentrationImprove fatigue resistanceResilient suspensionsVehicle springsIncreased fatigueEngineering

An auxiliary rubber spring for an automobile suspension, comprising: N layers of metal partitions, N being an integer greater than or equal to 1, and a transverse section of each metal partition being arc-shaped; N+1 rubber layers, the rubber layers being alternately lapped with the metal partitions, and a transversal section of each rubber layer being arc-shaped; a supporting plate provided with a first convex arc surface on one side thereof, the first convex arc surface being bonded to a first concave arc surface of an outermost rubber layer; and a connecting plate provided with a second concave arc surface on one thereof, the second concave arc surface being bonded to a second convex arc surface of another outermost rubber layer. The auxiliary rubber spring for an automobile suspension according to the present invention may increase fatigue resistance of the rubber spring and effectively extend service life thereof.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Piston ring for internal combustion engines with increased fatigue strength, and method for producing same

Owner:FEDERAL MOGUL BURSCHEID

Use of no-bake mold process to manufacture railroad couplers

A railroad coupler assembly having at least a body and a knuckle both formed in a no-bake manufacturing process, the body and the knuckle having dimensional tolerances of distances between features that wear during operation that are about half those obtained from a body and a knuckle manufactured by a green sand process, resulting in increased fatigue life compared to the body and the knuckle manufactured by a green sand process. The body and the knuckle resulting from the no-bake manufacturing process have no observable laps, scabs, chaplets or welding in critical areas of the body and knuckle, which are reflected in surface conditions matching SCRATA (Steel Castings Research and Trade Association) values of: D1 (laps); E1 (scabs); F1 (chaplets); and J1 (welds).

Owner:BEDLOE IND LLC

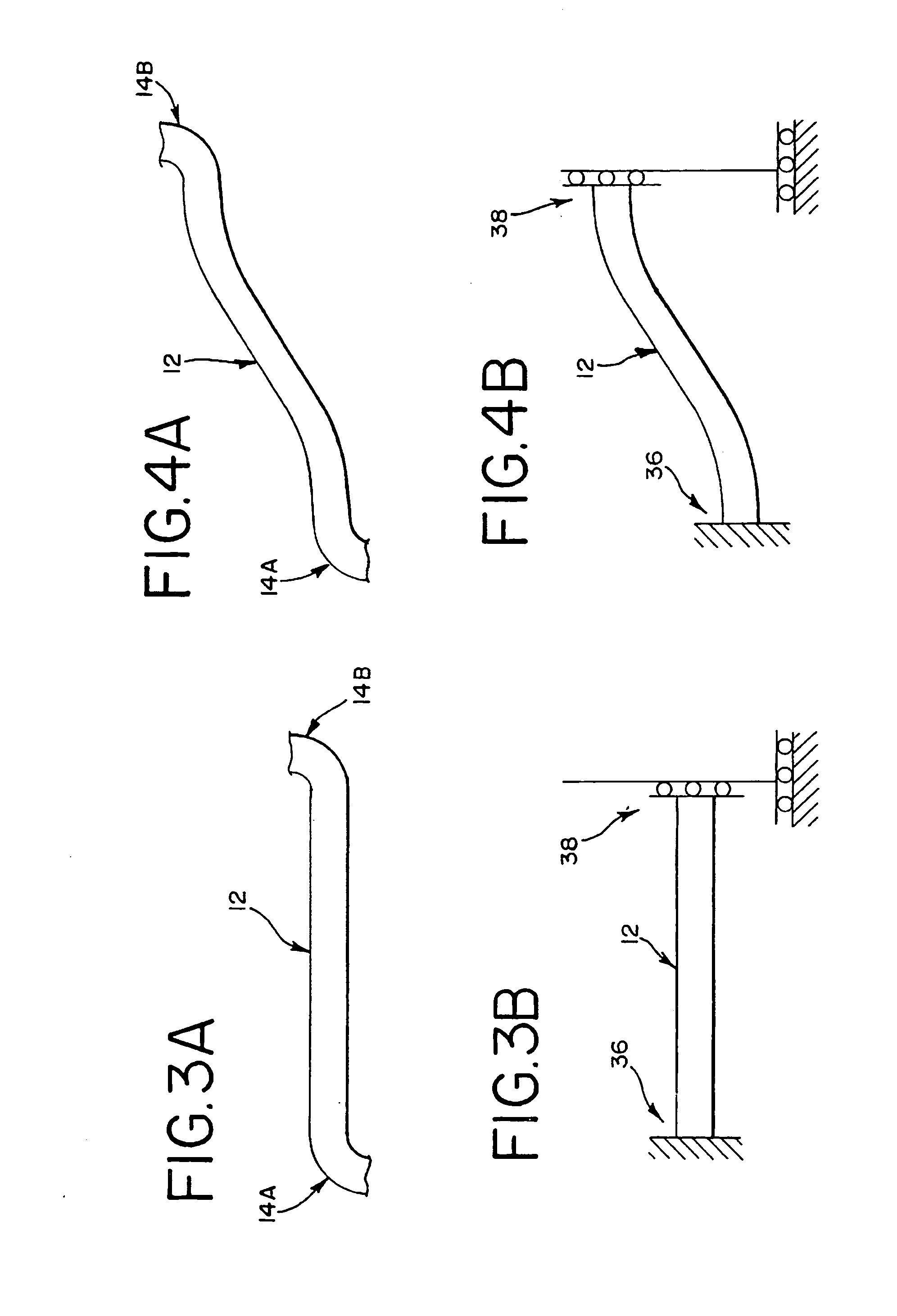

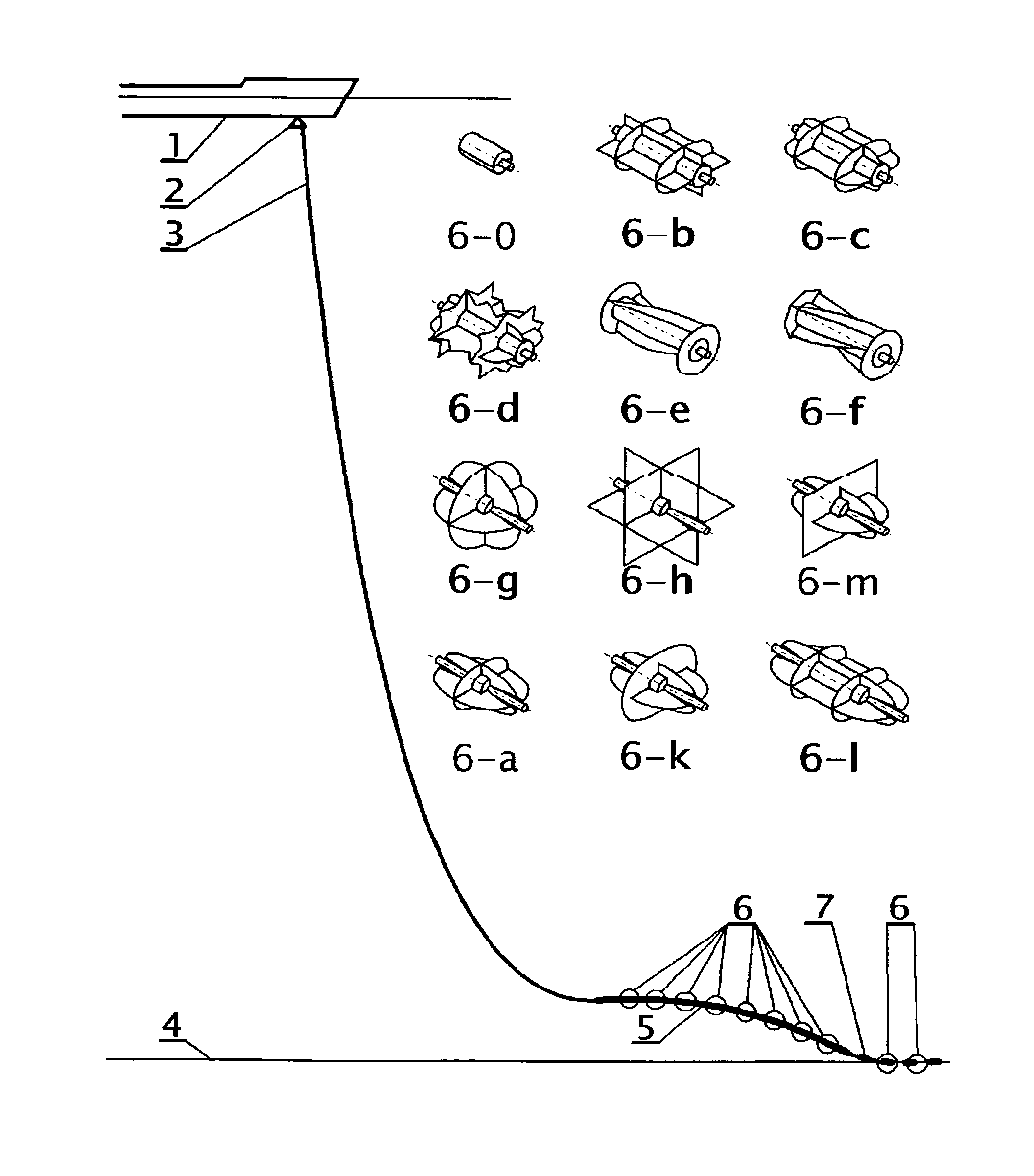

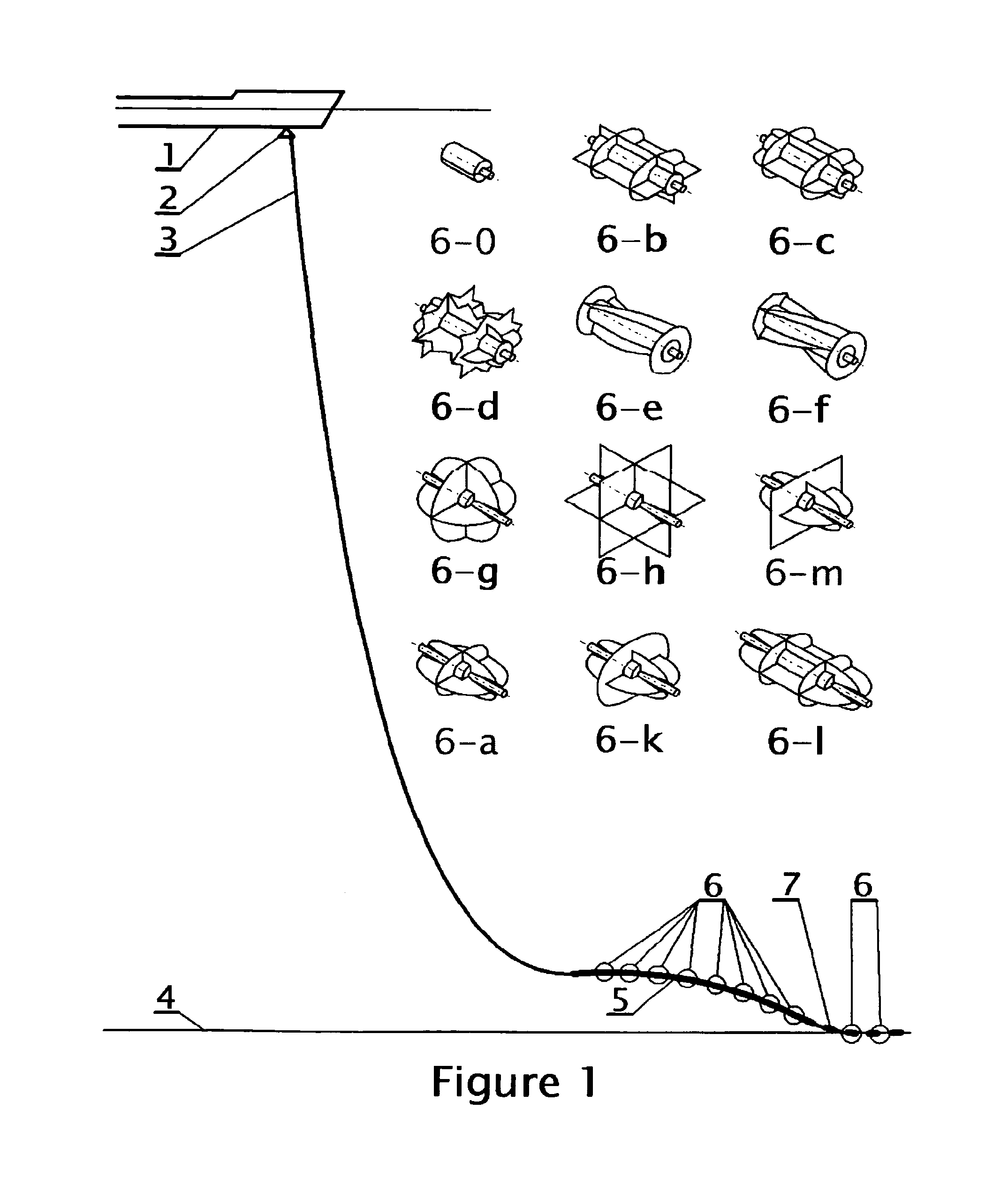

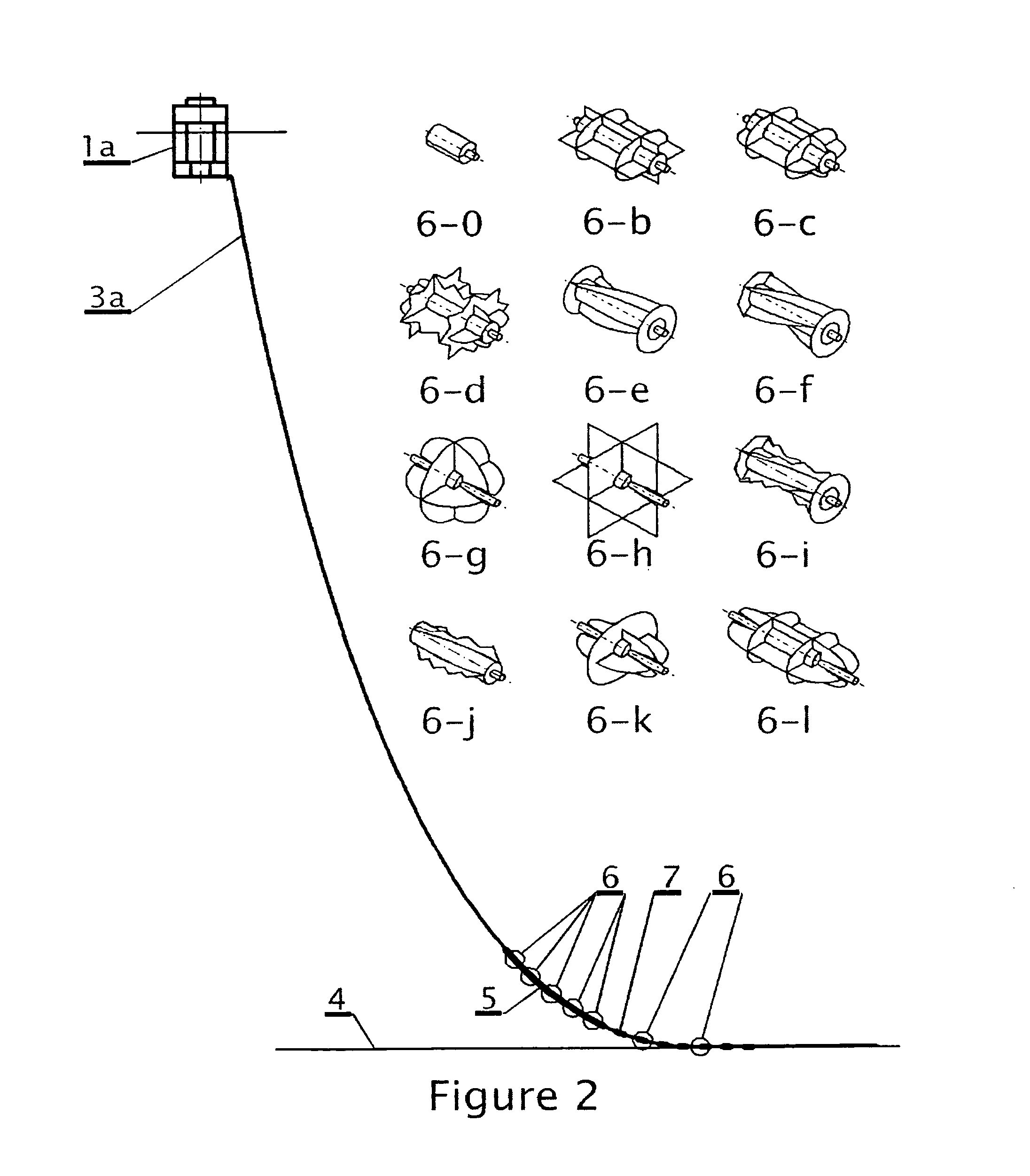

Catenary line dynamic motion suppression

Owner:WAJNIKONIS KRZYSZTOF JAN

Common rail for diesel engines

InactiveUS20060260124A1High compressive residual stressIncreased durabilityMetal-working apparatusFuel injection apparatusStress concentrationCommon rail

A common rail for a diesel engine has a main pipe rail with an axial flow passage. Branch holes are made in the main pipe rail and communicate with the axial flow passage. The main pipe rail is worked to decrease stress concentration near the branch holes. The whole inner peripheral surface of the main pipe rail and the branch holes then is subjected to autofrettage processing to generate a compressive residual stress on the entire inner peripheral surface of the main pipe rail and the branch holes for increasing fatigue strength.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

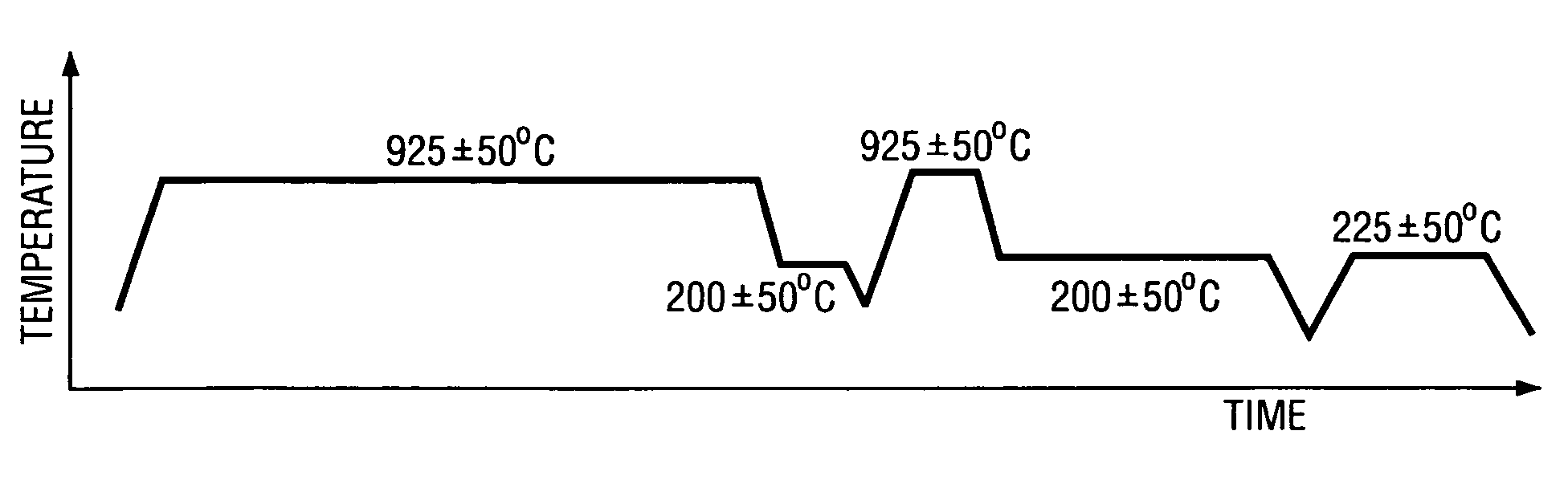

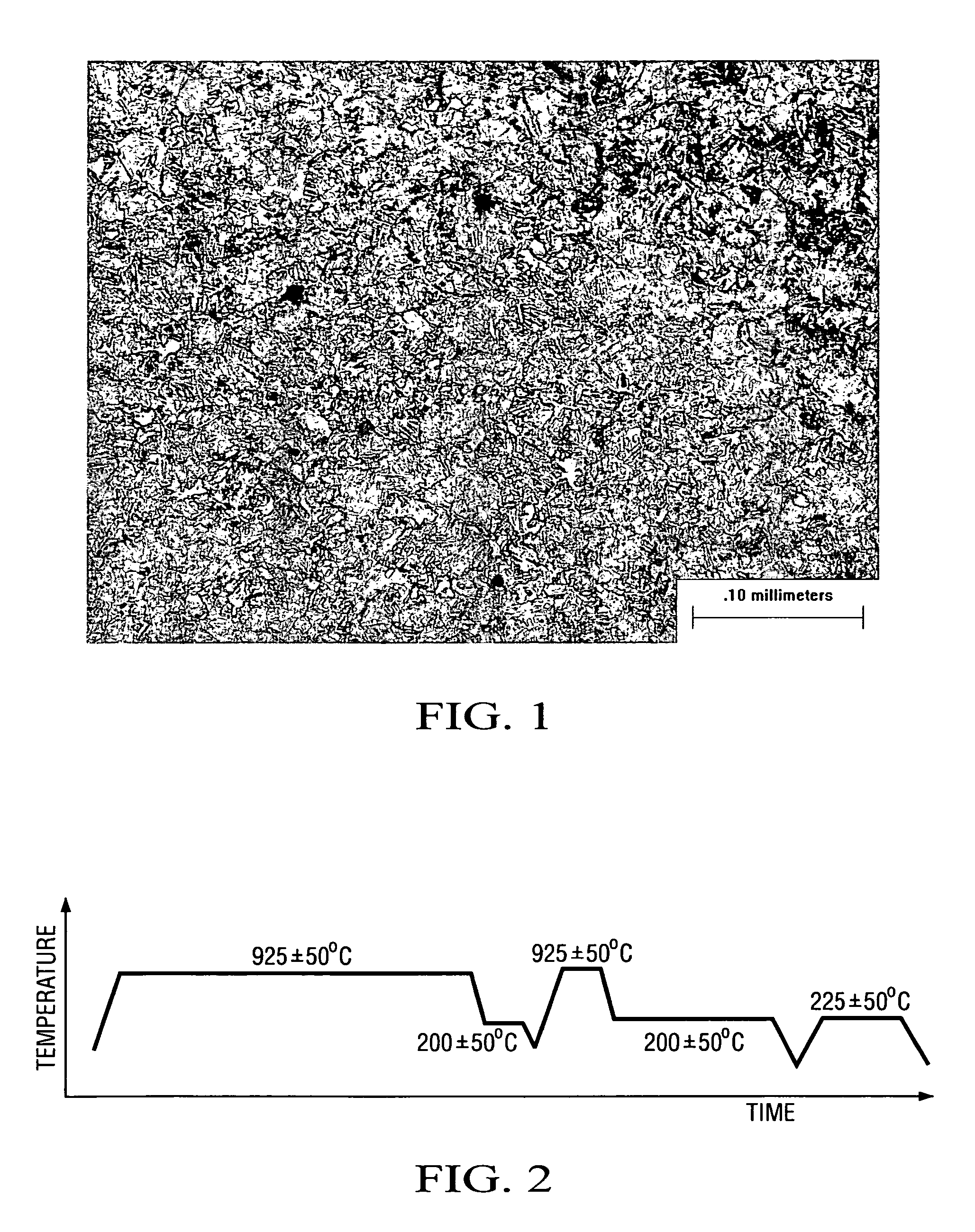

Torque transferring low carbon steel shafts with refined grain size

A double carboaustempering combined with a martensite-producing quench provides plain-carbon and low alloy steel power transmission shafts with a carbon-rich exterior having a martensite and bainite microstructure and a substantially bainite interior. The shafts offer increased fatigue resistance.

Owner:GM GLOBAL TECH OPERATIONS LLC

Auxiliary rubber spring for automobile suspension

ActiveUS9499022B2Improve fatigue resistanceExtended service lifeResilient suspensionsVehicle springsIncreased fatigueEngineering

An auxiliary rubber spring for an automobile suspension, comprising: N layers of metal partitions, N being an integer greater than or equal to 1, and a transverse section of each metal partition being arc-shaped; N+1 rubber layers, the rubber layers being alternately lapped with the metal partitions, and a transversal section of each rubber layer being arc-shaped; a supporting plate provided with a first convex arc surface on one side thereof, the first convex arc surface being bonded to a first concave arc surface of an outermost rubber layer; and a connecting plate provided with a second concave arc surface on one thereof, the second concave arc surface being bonded to a second convex arc surface of another outermost rubber layer. The auxiliary rubber spring for an automobile suspension according to the present invention may increase fatigue resistance of the rubber spring and effectively extend service life thereof.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Fatigue-resistant nickel-titanium alloys and medical devices using same

Superelastic and / or shape memory nickel-titanium alloys having an increased fatigue life that is superior to known nickel-titanium alloys are disclosed. The nickel-titanium alloys have a minimum fatigue life that may be at least about 10 million strain cycles at a strain of at least about 0.75. The minimum fatigue life may be due, at least in part, to the nickel-titanium alloy having at least one of an oxygen concentration of less than about 200 ppm, a carbon concentration of less than about 200 ppm, the absence of oxide-based and / or carbide-based inclusions having a size greater than about 5 microns (μm), the presence of an R-phase, or combinations of the foregoing. Articles manufactured from such fatigue-resistant nickel-titanium alloys can be more durable because they are more resistant to repetitive strain and crack propagation.

Owner:ABBOTT LAB INC

Anti-fatigue Strengthening Method of Steel Structure Beam

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com