Piston ring for internal combustion engines with increased fatigue strength, and method for producing same

A technology of fatigue resistance and piston ring, applied in the field of piston ring, can solve the problems of piston ring breakage and enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The same reference numerals in the drawings and description indicate the same or similar elements.

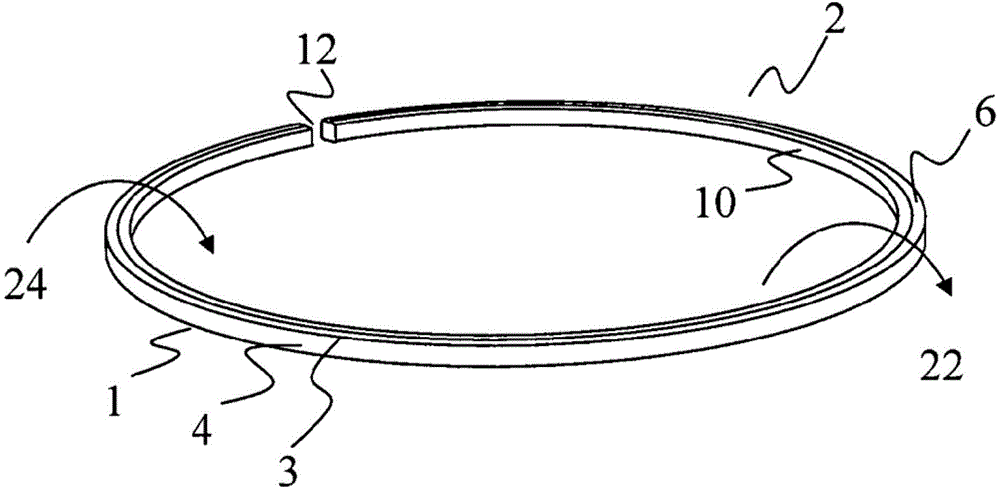

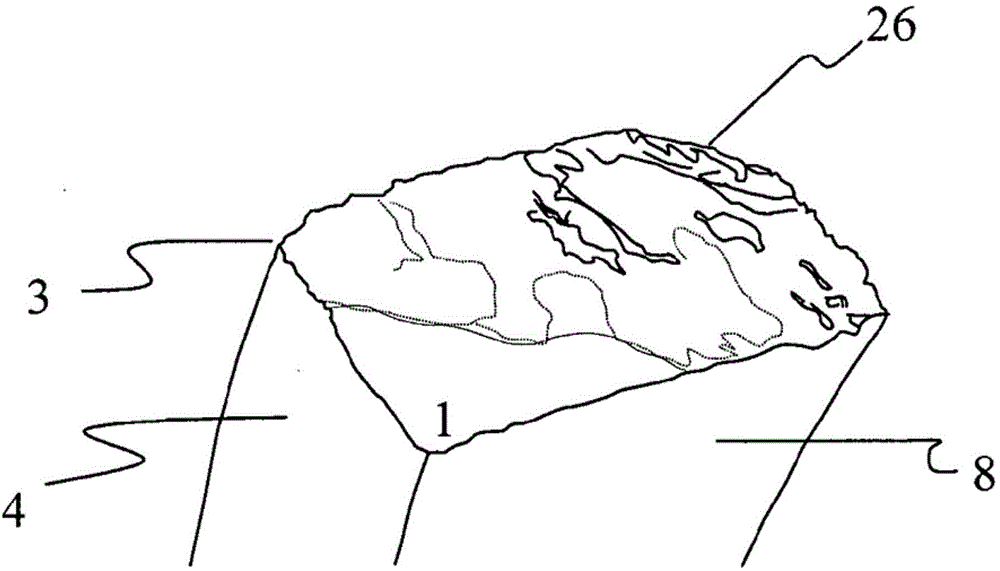

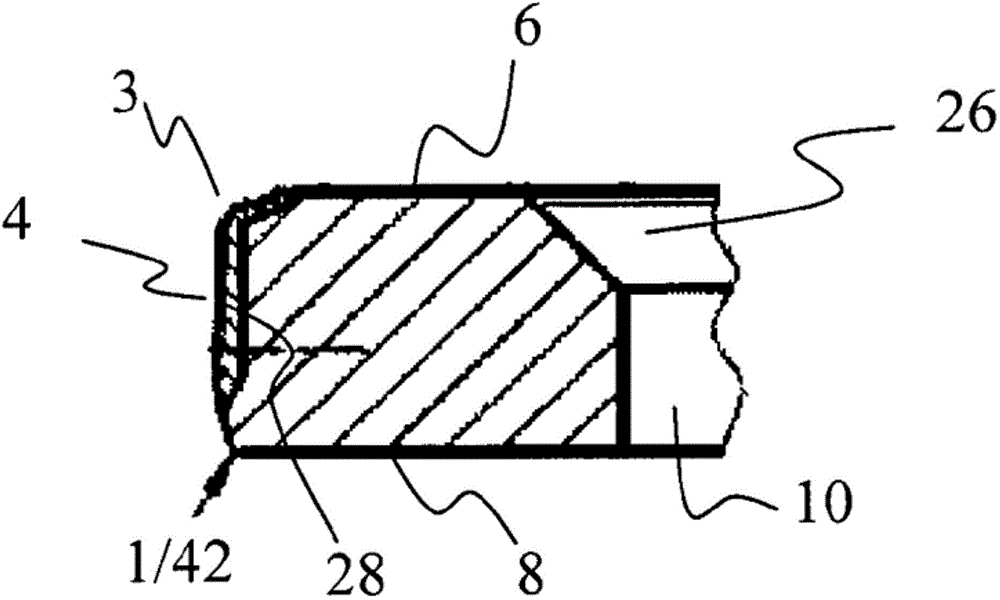

[0037] figure 1 A perspective view of the piston ring 2 is shown. The piston ring 2 has a working surface 4 located on the outside. The underside of the piston ring, which cannot be seen in this figure, forms the underside of the piston ring 2, whose reference number is 8 in other figures. The upper side of the piston ring is formed by the upper side 6 of the piston ring. The working surface 4 is in contact with the upper side 6 of the piston ring at the upper edge 3 of the working surface 4. The working surface 4 is in contact with the lower side of the piston ring at the lower edge 1 of the working surface 4, and the reference number of the lower side of the piston ring is 8, which is not shown in the figure. The piston ring is bounded on the inside by the inner surface 10 of the piston ring. The piston ring 2 opens at the piston ring gap 12.

[0038] Under load, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com